A method and device for treating and reusing waste water from on-line printing, dyeing and washing

A waste water treatment and waste water technology, applied in the direction of energy waste water treatment, adsorption water/sewage treatment, light water/sewage treatment, etc., can solve the high investment cost and operation cost of printing and dyeing waste water reuse technology, lack of printing and dyeing waste water regeneration and reuse Commercial planning, increased COD of washing wastewater and other issues, to achieve the effect of improving washing fastness, reducing water consumption and operating costs, and saving detergent

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

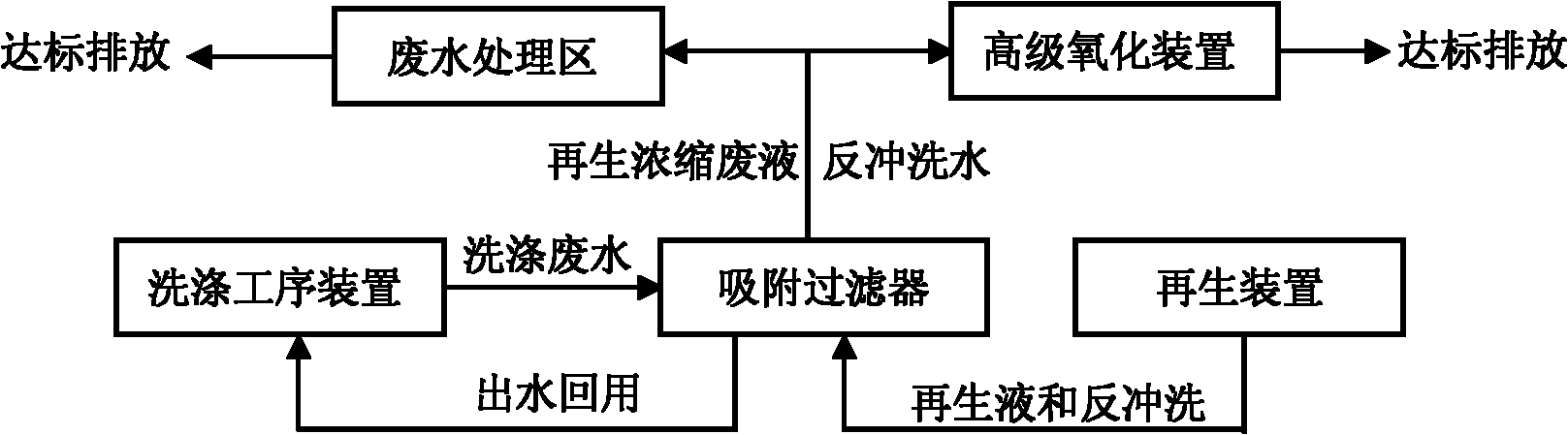

Method used

Image

Examples

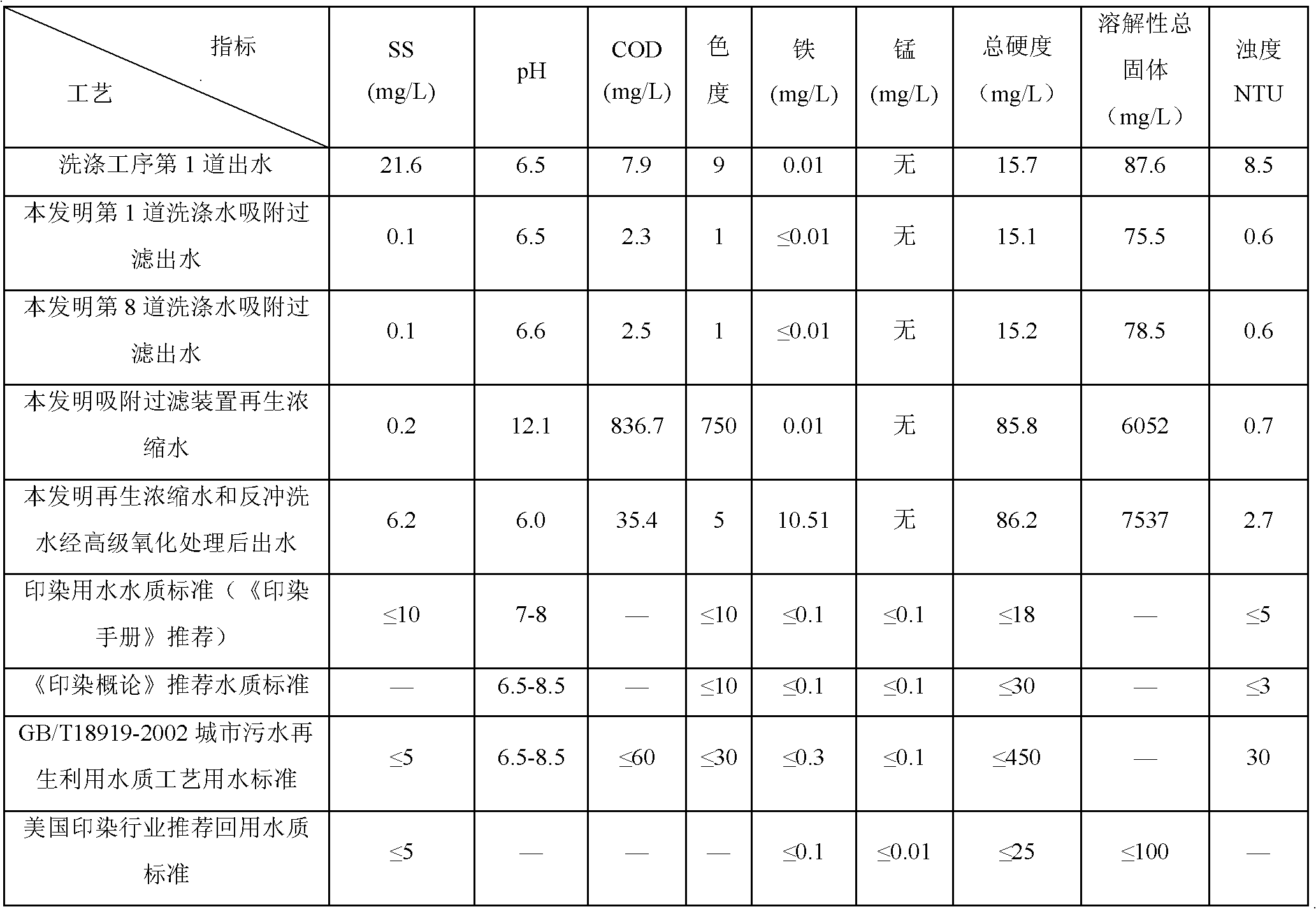

Embodiment 1

[0064] Taking the effluent of the nylon fabric washing process as the treatment object (the pollutants are mainly weak acid dyes), the fabrics in each cylinder were washed 8 times after dyeing, each 10L, and each washing time was 10min, requiring a total of 80L of fresh tap water. See Table 1 for the effluent water quality indicators of Channel 1. Using the treatment process and device of the present invention, 10L of washing water in the first channel and 1L of pre-inflow water in the adsorption filtration device are used for online treatment and recycling, that is, the subsequent washing 7 channels are all carried out with the outlet water after adsorption and filtration. (That is, equivalent to the 8th washing water) See Table 1 for the water quality of the effluent after adsorption filtration. After continuous washing of 20 cylinders of fabrics, the adsorption and filtration device reaches the breakthrough point, and then the regenerated adsorption medium is eluted with th...

Embodiment 2

[0072] Taking the effluent of the acrylic fabric washing process as the treatment object (the pollutants are mainly basic dyes and cationic surfactants), the fabrics in each cylinder are washed 4 times after dyeing, each 10L, and each washing time is 10min, requiring fresh tap water The water volume is 40L in total, and the water quality indicators of the first channel are shown in Table 1. Using the treatment process and device of the present invention, 10L of washing water in the first channel and 1L of pre-inflow water in the adsorption and filtration device are used for online processing and recycling, that is, the subsequent washings are all carried out with the outlet water after adsorption and filtration. (That is, equivalent to the fourth washing water) The quality of the effluent after adsorption filtration is shown in Table 1. After continuous washing of 22 cylinders of fabrics, the adsorption and filtration device reaches the breakthrough point, and then the regener...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com