Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

37results about How to "Increase the percentage of dyeing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Textile and non-woven cloth plasma surface treating device

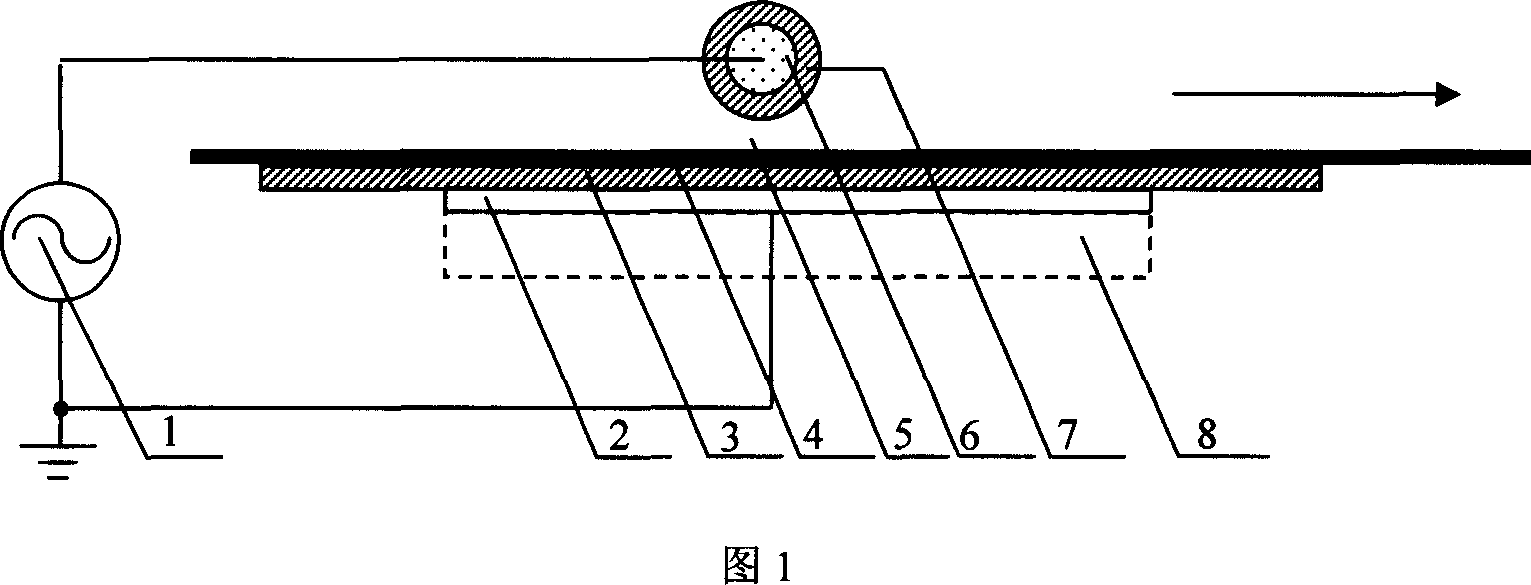

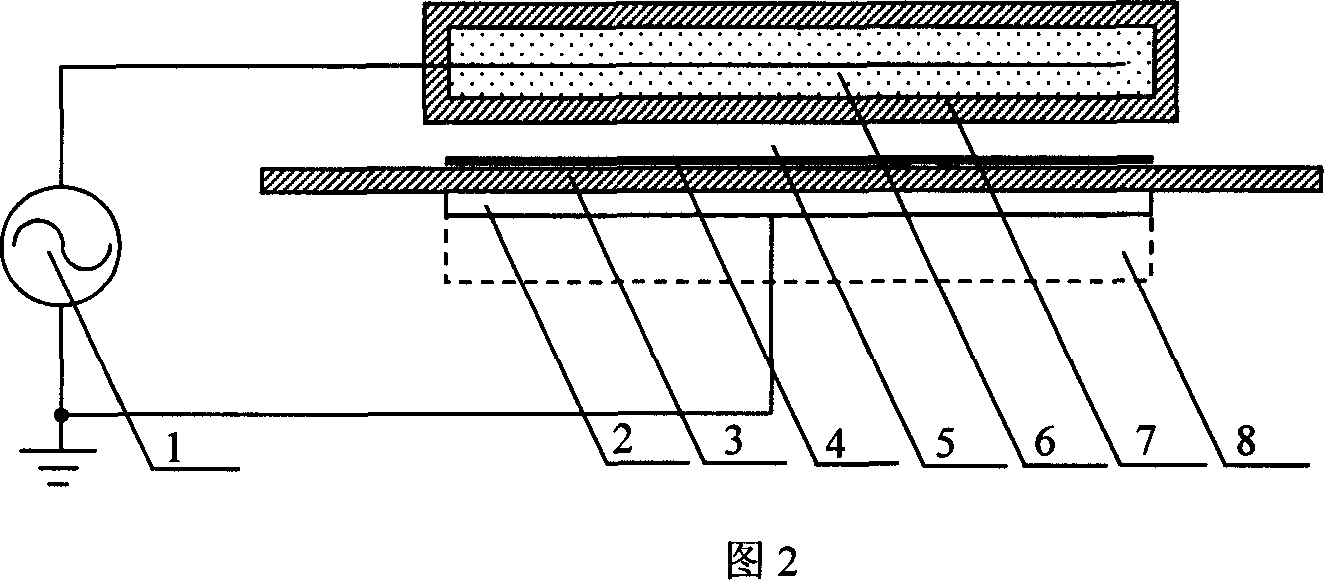

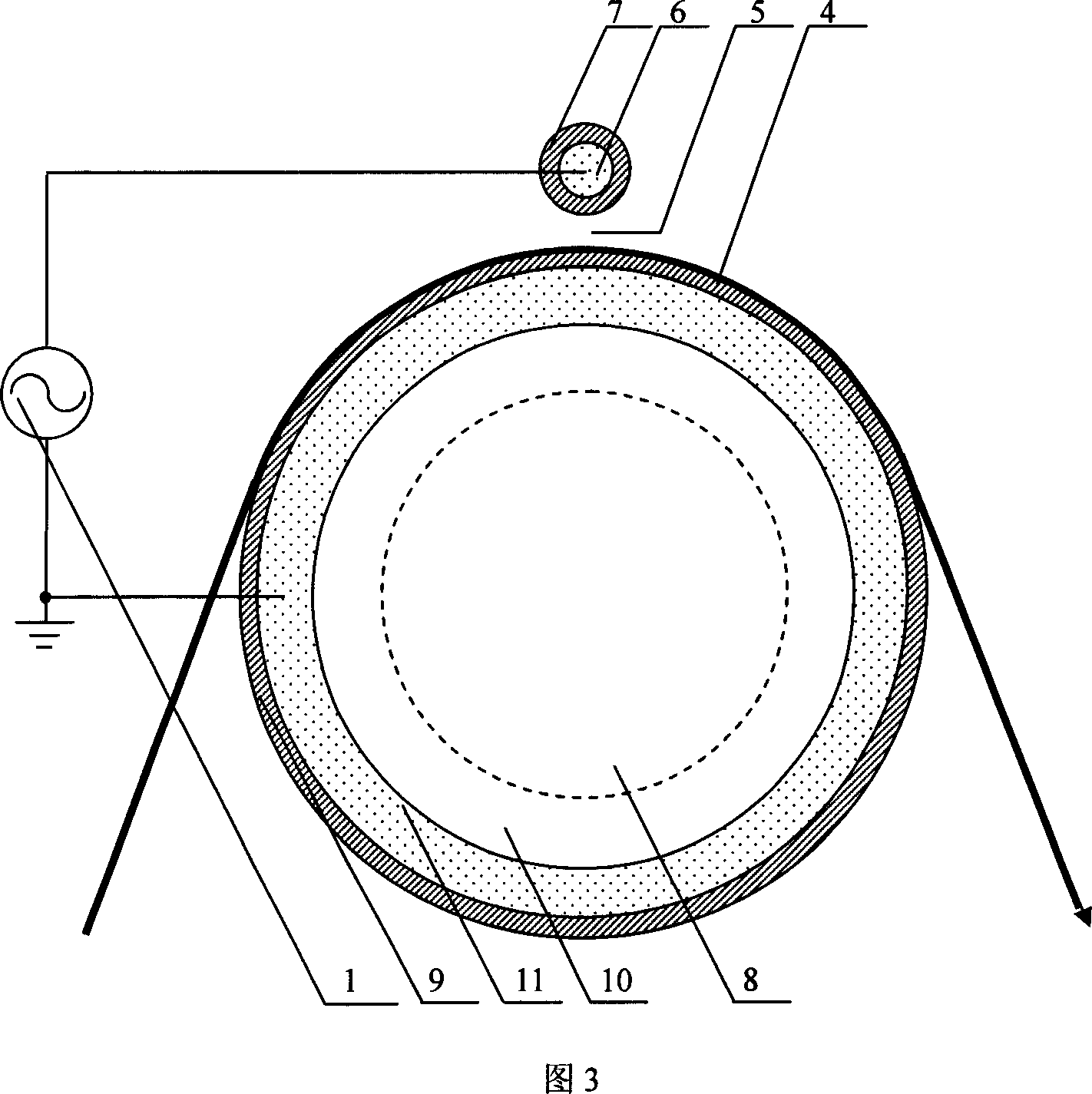

ActiveCN1932132AEvenly distributedSimple structurePhysical treatmentHigh frequency powerHigh pressure

The present invention belongs to the field of gas discharge technology, and relates to a plasma surface treatment equipment for textiles and non-woven fabric. Said plasma surface treatment equipment for textiles and non-woven fabric includes high-frequency power supply, high-voltage electrode and grounding electrode. The high-voltage electrode is at least one medium tube whose interior is filled with metal powder and sealed or one metal tube whose exterior is covered with silicone rubber, the high-voltage end of said high-frequency power supply is inserted into the medium tube interior by means of conducting wire, and the grounding electrode is a metal electrode covered with medium plate or a metal rod whose exterior is covered with silicone rubber tube, the grounding end of said high-frequency power supply is connected with metal electrode by means of conducting wire. Said invention can be used for making large-area plasma surface treatment of textiles, non-woven fabric and paper material, etc.

Owner:NANJING SUMAN PLASMA TECH CO LTD

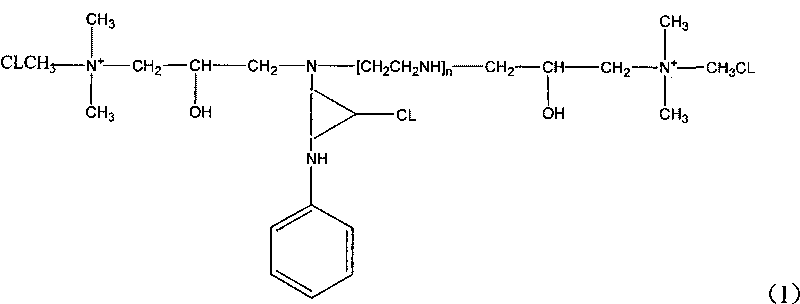

Aid for dyeing cotton textiles, preparation method and dyeing method thereof

InactiveCN101736613AIncrease the percentage of dyeingImprove color fixation percentageOrganic compound preparationDyeing processStructural formulaAniline

The invention discloses an aid for dyeing cotton textiles shown in a structural formula (I), and also discloses a method for preparing the aid. The method comprises the following steps: weighing 7.0 to 8.0 percent of 3-chloro-2-hydroxypropyl trimethylammonium chloride, 1.0 to 2.0 percent of sodium hydroxide, 1.0 to 4.0 percent of polyamine, 3.0 to 4.0 percent of cyanuric chloride, 0 to 2.0 percent of aniline, 0.5 to 1.0 percent of sodium carbonate, 11 to 12 percent of normal temperature deionized water a, 4.0 to 5.0 percent of normal temperature deionized water b, and 65.5 to 67.5 percent of deionized water c at 1 to 2 DEG C; dissolving the sodium carbonate in the deionized water b to prepare aqueous solution of sodium carbonate; adding the deionized water a, the 3-chloro-2-hydroxypropyl trimethylammonium chloride and the sodium hydroxide to a reaction kettle, and stirring the mixture; adding the polyamine to the reaction kettle, and heating the kettle to 85 to 90 DEG C to perform reaction for 3 to 5 hours; adding the deionized water c and the cyanuric chloride to perform reaction for 2 to 4 hours, dripping the aqueous solution of sodium carbonate to enable the pH value to be between 4 and 6 so as to prepare the aid. The aid can be used for performing pad dyeing and dip dyeing on the cotton textiles. The aid, the preparation method and the dyeing method improve the dyeing percentage and fixation percentage of active pigment for cotton, and reduce the discharge value of waste pigment.

Owner:XI'AN POLYTECHNIC UNIVERSITY

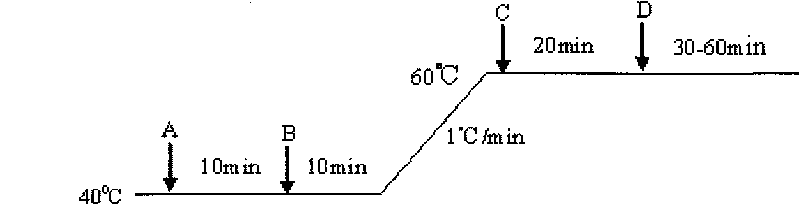

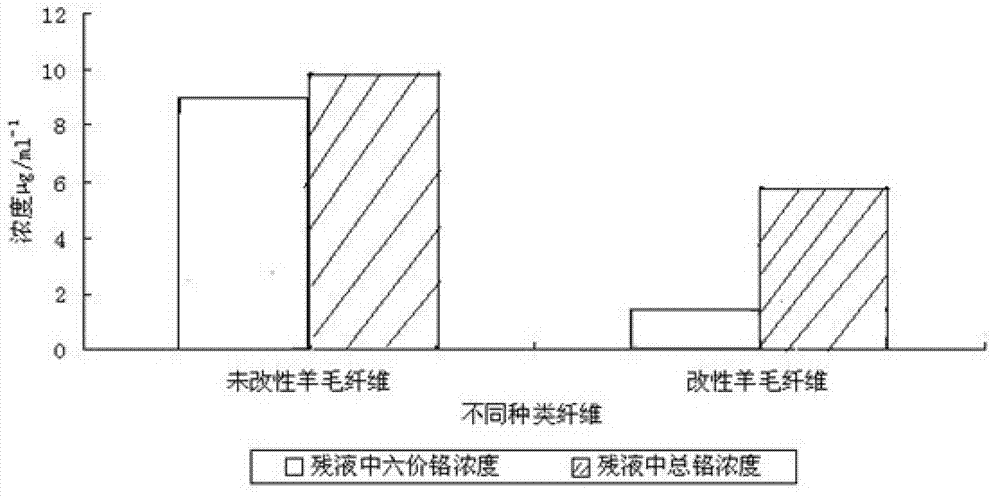

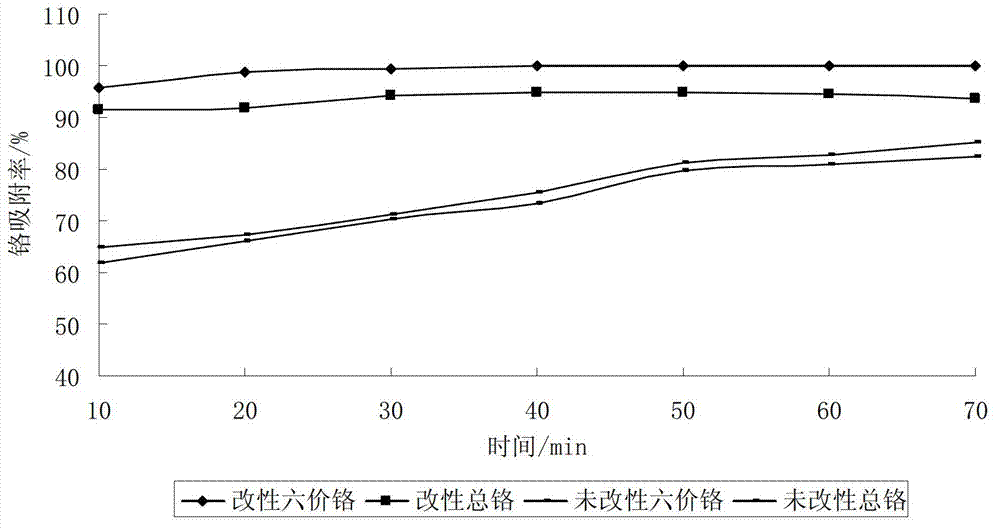

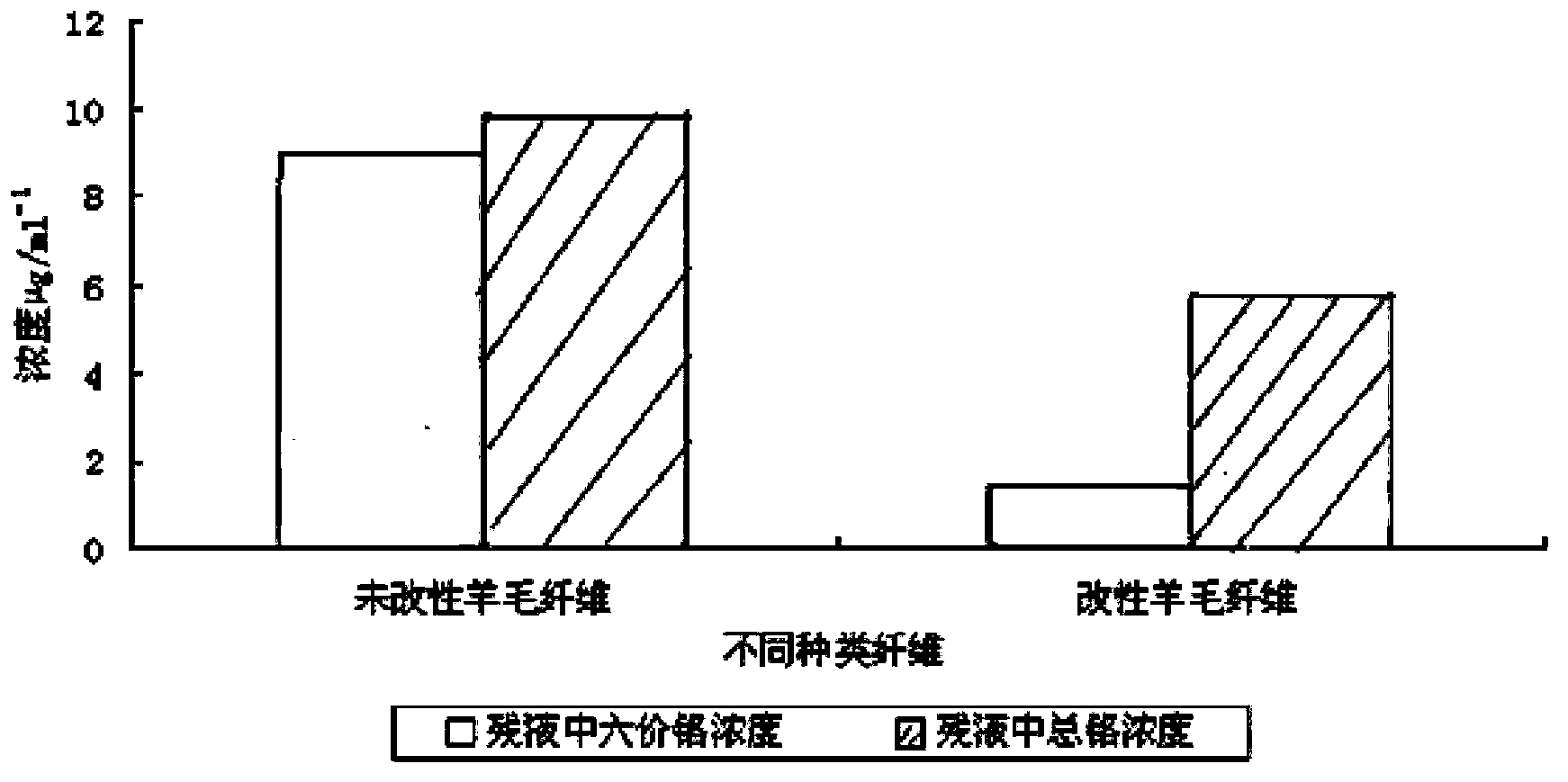

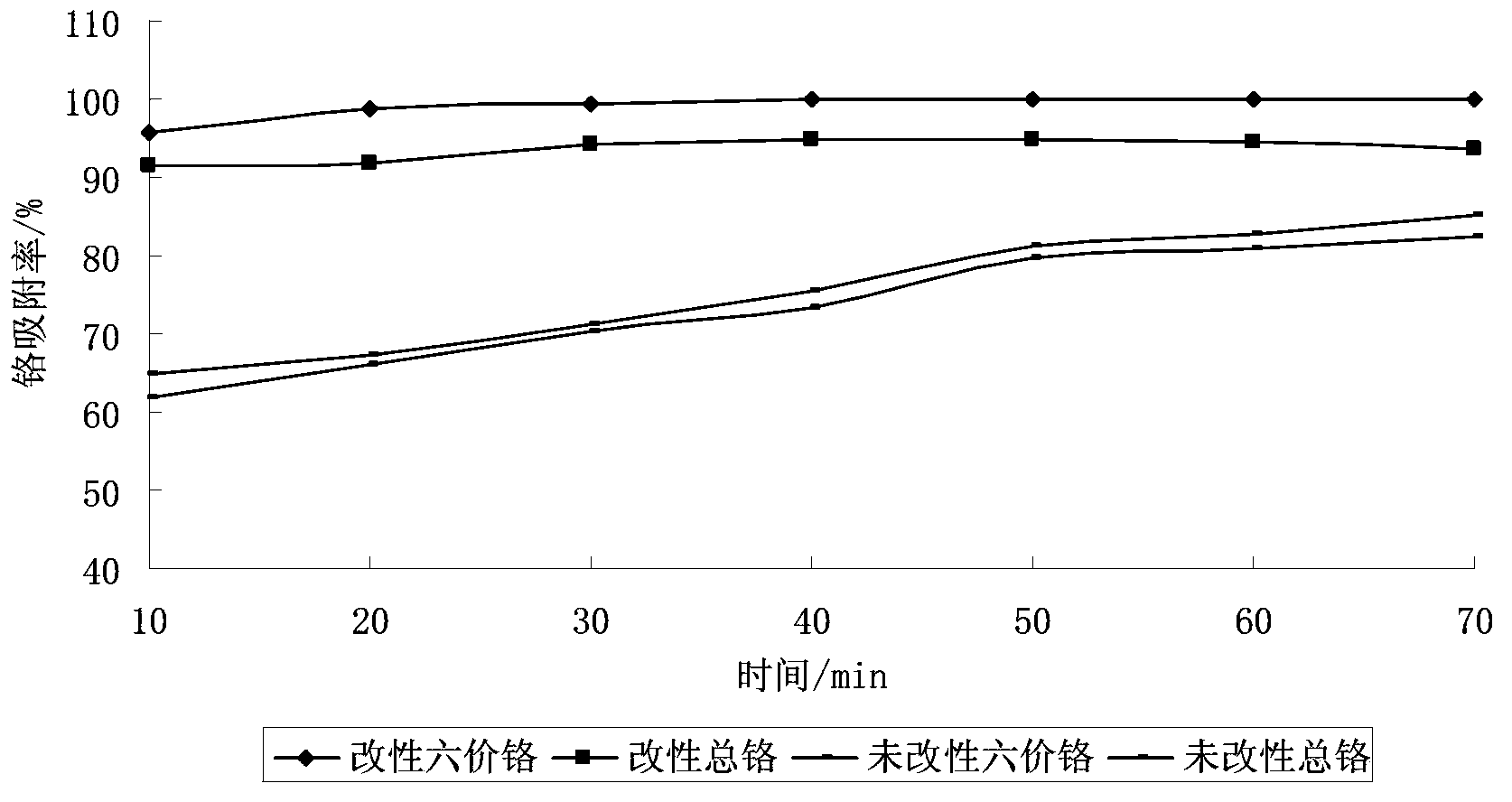

Preparation method and application method of low-temperature low-chromium dyeing auxiliary agent of acidic medium dye for wool

InactiveCN102817251AEfficient reuseReduce pollutionDepsipeptidesPeptide preparation methodsCross-linkKeratin

The invention discloses a preparation method and an application method of a low-temperature low-chromium dyeing auxiliary agent of an acidic medium dye for wool. The preparation method comprises the steps that: 1, protein powder is prepared by using waste duck feather, wherein (1) the duck feather is subjected to pretreatment; (2) the suck feather is subjected to a dissolving treatment; and (3) duck feather protein powder is prepared; 2, a sodium hydroxide solution is prepared, and the sodium hydroxide solution is used for dissolving the duck feather protein powder; 3, sodium hydroxide, triethanolamine, and epichlorohydrin are adopted for preparing a cationic quaternary ammonium salt cross-linking modification agent WLS; and 4, the low-temperature low-chromium dyeing auxiliary agent for the acidic medium dye is prepared. The auxiliary agent can be used as a wool modification agent. After wool fibers are modified, wool fiber dyeing properties of acidic medium dyes are greatly improved, dye uptake percentage rate can be improved, mordant absorption performance of the dye is improved, chromium pollution in dye wastewater is reduced, wool fiber low-temperature low-chromium dyeing is realized, and waste duck feather keratin is effectively utilized. After modification, the wearability of wool products is improved.

Owner:XI'AN POLYTECHNIC UNIVERSITY

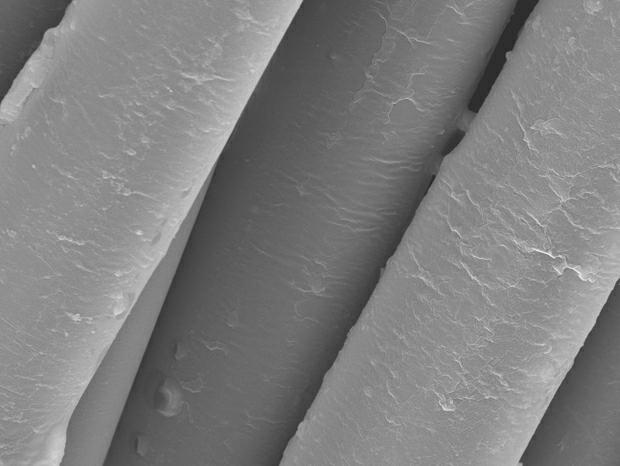

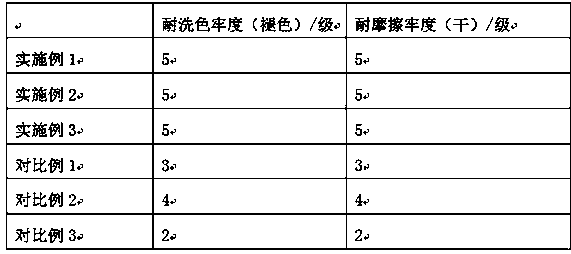

Modifying and dyeing method for polyamide textile by using tetrabutyl titanate and reactive dye

InactiveCN102330362AImprove antibacterial propertiesOptimizing the Finishing ProcessFibre typesDyeing processPolymer scienceAlcohol

The invention discloses a modifying and dyeing method for a polyamide textile by using tetrabutyl titanate and reactive dye, comprising the following steps of: repeatedly washing the polyamide textile in ultrasonic oscillation at the temperature of 60-90 DEG C by respectively using deionized water and absolute ethyl alcohol with mass concentration of 95%, and drying; then, processing the polyamide textile with the tetrabutyl titanate and the reactive dye; finally, washing the polyamide textile for 10-30 minutes with a cleaning solution at the temperature of 95 DEG C according to a bath ratio of 1:30-50, repeatedly washing the polyamide textile by respectively using hot water and cool water, and drying or naturally airing the polyamide textile to get the modified and dyed polyamide textile. With the method provided by the invention, production procedures are greatly simplified, material cost is saved, and additional value of products is improved. The modified and dyed polyamide textilehas excellent color fastness to dry and wet frictions, scrubbing and lighting; and polyamide textile has higher dye uptake and is dyed uniformly, after being washed for 30 times, the dyed polyamide textile still has better antibacterial property.

Owner:福建金苑服饰有限公司

Water-saving dyeing process of cheese

InactiveCN103806308ASoft touchThe color difference between the inner and outer layers is not obviousDyeing processYarnElectricity

The invention provides a water-saving dyeing process of cheese, and the cheese is dyed by yarn pretreatment, dyeing and dyeing postprocessing. According to the water-saving dyeing process of the cheese, a refining agent is chosen to replace caustic soda and hydrogen peroxide of a traditional process for the yarn pretreatment, and the refining agent can ensure that yarn is soft in hand feeling, is unconspicuous in inner and outer-layer color difference, and is basically free of reparation and broken end phenomenon, a woven fabric is smooth, the weight loss rate is reduced to about 3%, acid pickling is not needed, the time is short, and is shortened by 30 minutes to 1 hours compared with that of the traditional process, so that the water, electricity and time are saved, the bleaching consumption is low, the dyeing quality is good, and the comprehensive cost is low. At the same time, in the water-saving dyeing process of the cheese, a neutral electrolyte is added for accelerating the dying in a diffusion stage, the dye uptake of the cheese is ensured, and the problems of dyeing defects, deep and shallow strips, great inner and outer-layer difference and the like can be avoided.

Owner:WUHU FUCHUN DYEING & WEAVING

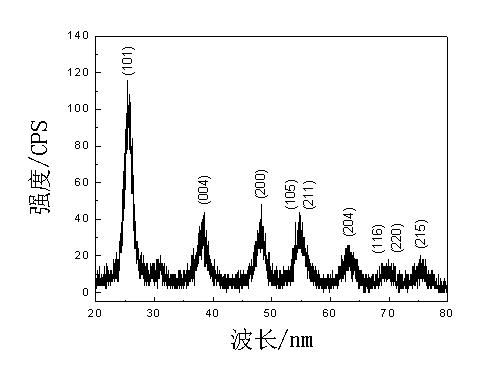

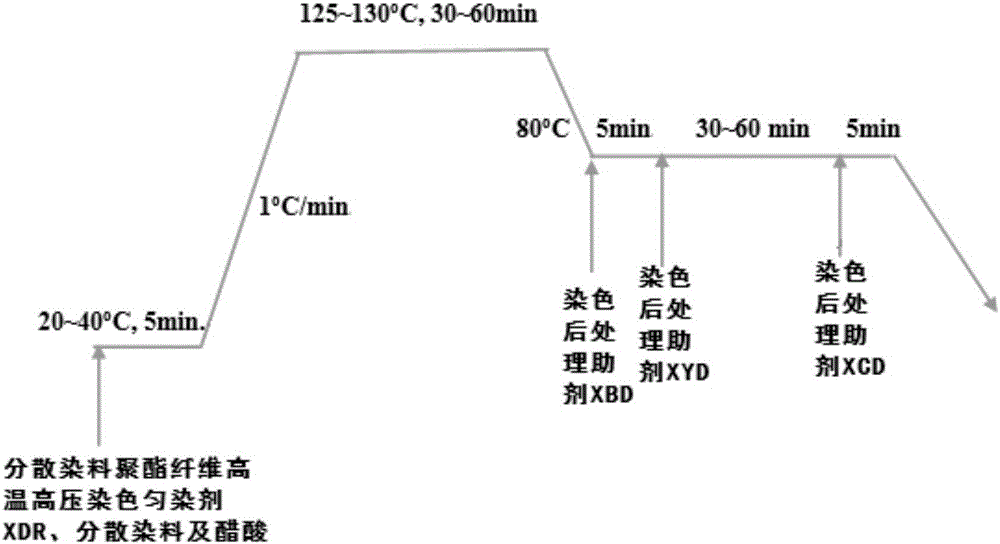

Preparation method and application of leveling agent for high-temperature and high-pressure dyeing of polyester fibers by disperse dyes

The invention discloses a preparation method and application of a leveling agent XDR for high-temperature and high-pressure dyeing of polyester fibers by disperse dyes. The preparation method is mainly characterized in that fatty alcohol-polyoxyethylene ether, alkyl sodium sulfonate, alkyl sulfate sodium, fatty amine polyoxyethylene ether, urea and purified water are uniformly mixed to obtain the leveling agent XDR for high-temperature and high-pressure dyeing of polyester fibers by disperse dyes. The invention also discloses a method for dyeing polyester fibers and polyester fiber blended products by use of the leveling agent XDR for high-temperature and high-pressure dyeing of polyester fibers by disperse dyes. After adoption of the prepared leveling agent XDR for high-temperature and high-pressure dyeing of polyester fibers by disperse dyes, the oriented adsorption density of surfactant molecules on the surfaces of disperse dyes particles is remarkably improved, the interfacial tension between the dye particles and water and the average grain diameters of the dyes particles are obviously reduced, the solubility of the dyes and the dyeing percentage of the dyes to the fibers are remarkably improved, and agglomeration of the dyes and nonuniform dyeing can be dramatically reduced.

Owner:XI'AN POLYTECHNIC UNIVERSITY

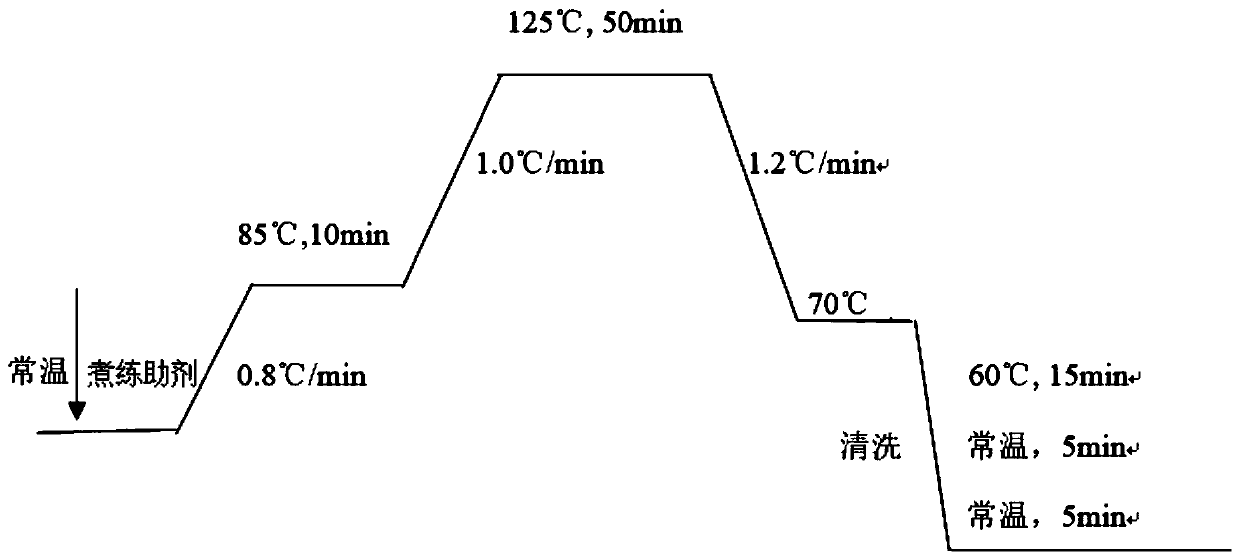

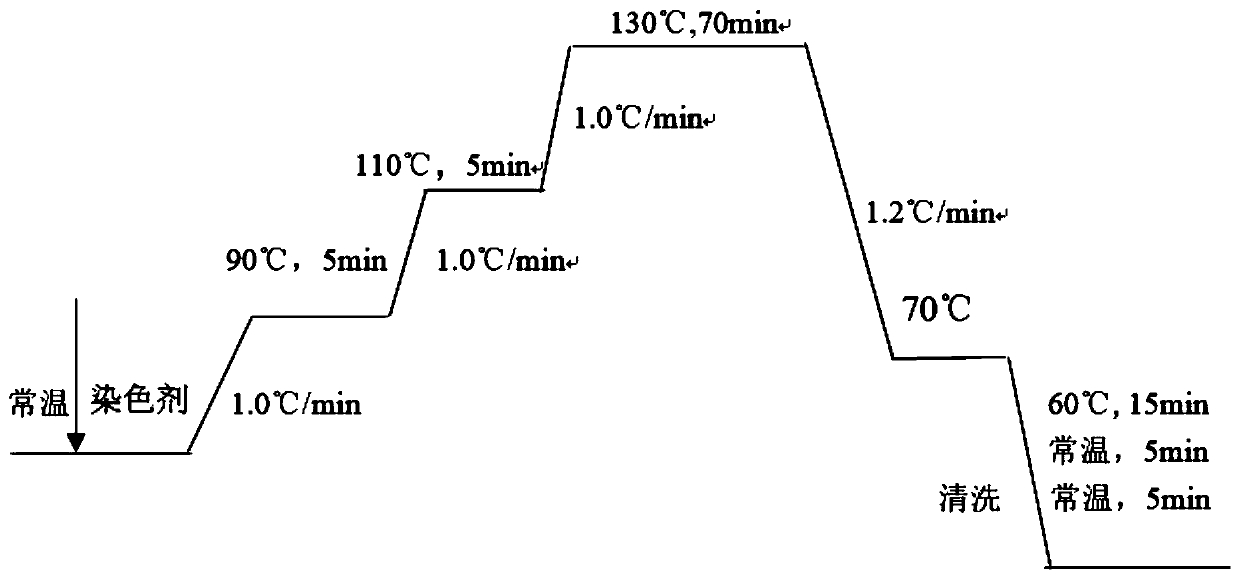

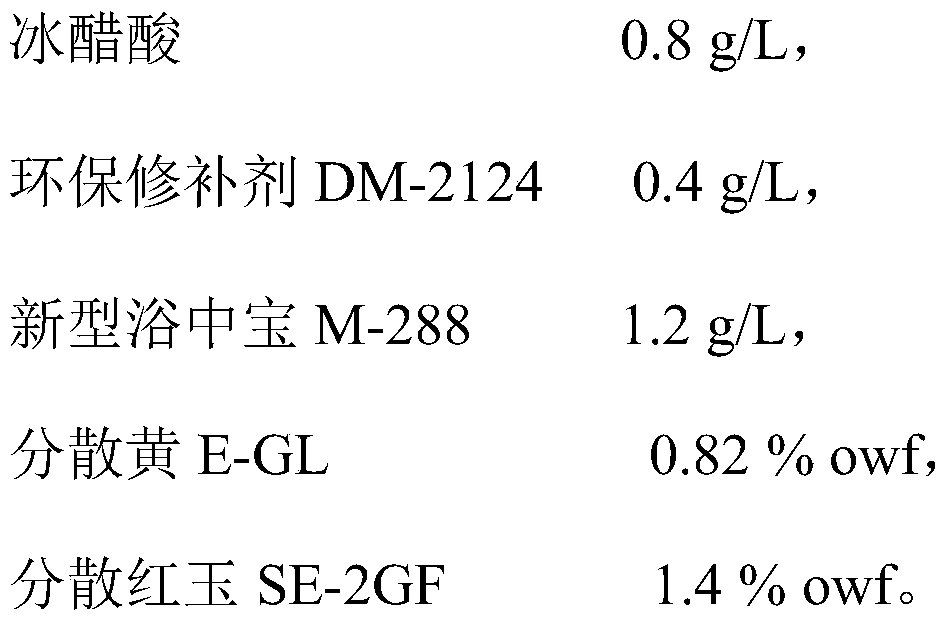

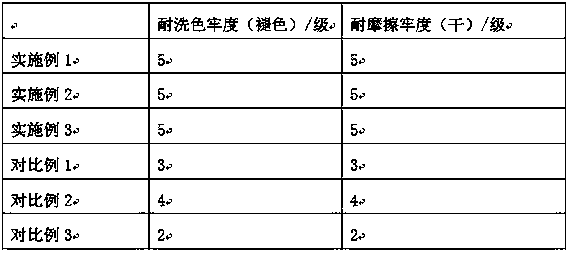

Low-temperature dyeing process of modified polyester and wool interwoven fabric through one-bath process

InactiveCN103243589AAvoid damageIncrease the percentage of dyeingDyeing processPolyesterColour fastness

The invention discloses a low-temperature dyeing process of modified polyester and wool interwoven fabric through a one-bath process, which comprises the following steps of: (1) putting pre-treated gray cloth into bath solution in a dyeing cylinder at 35-45 DEG C, then, adding auxiliaries, adding reactive dyes after operating for a certain time, and adding electrolyte salt after operating for a certain time, wherein the bath ratio is 1:50; (2) uniformly increasing the temperature to 70-80 DEG C, and keeping the temperature for 35-50min; and (3) decreasing the temperature to 55-65 DEG C so as to obtain cloth, wherein the auxiliaries comprise an acidity regulator and an anti-precipitation agent; and the electrolyte salt is sodium chloride. By means of the manner, the dyeing process disclosed by the invention is capable of reducing fibre damage and saving energy; furthermore, the dye uptake, the levelling property and the colour fastness of the fabric are improved; and the operation is convenient and the environmental protection is facilitated.

Owner:CHANGSHU ZHONGWANG JINGWEI WEAVING

Dyeing and finishing technology for PFY (polyester filament yarn) Huayao fabric

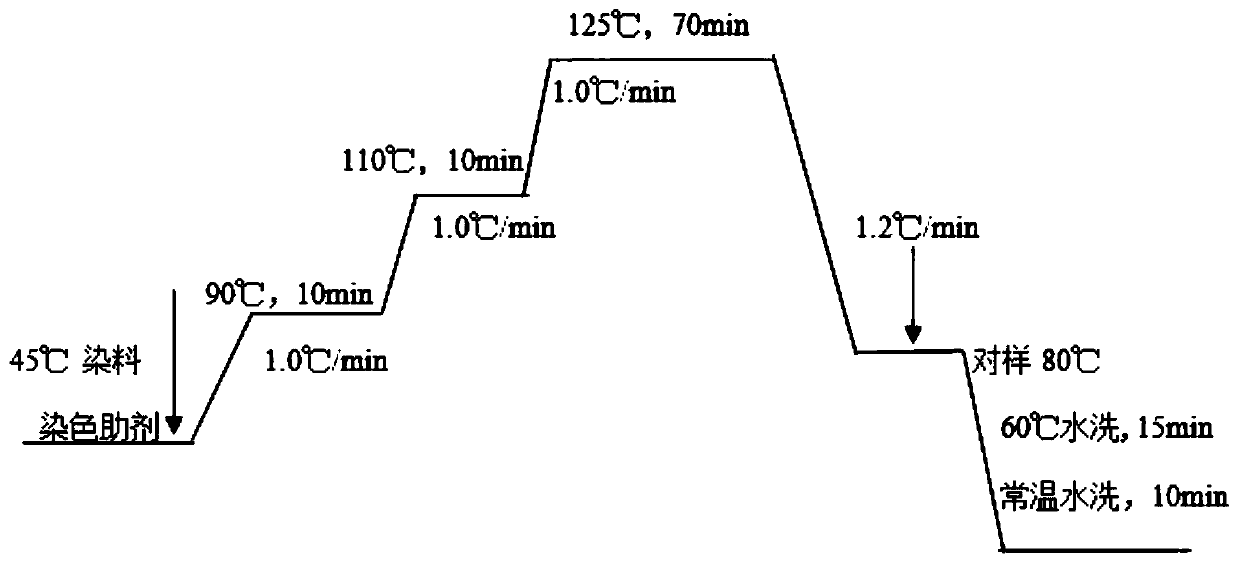

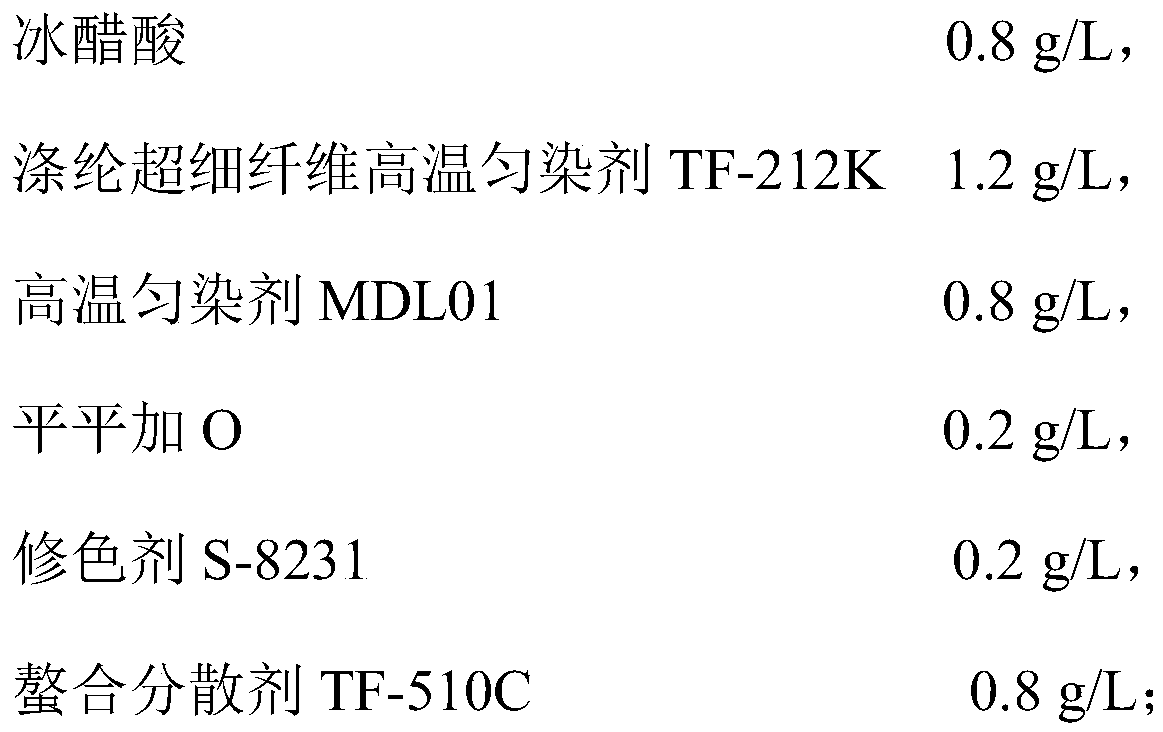

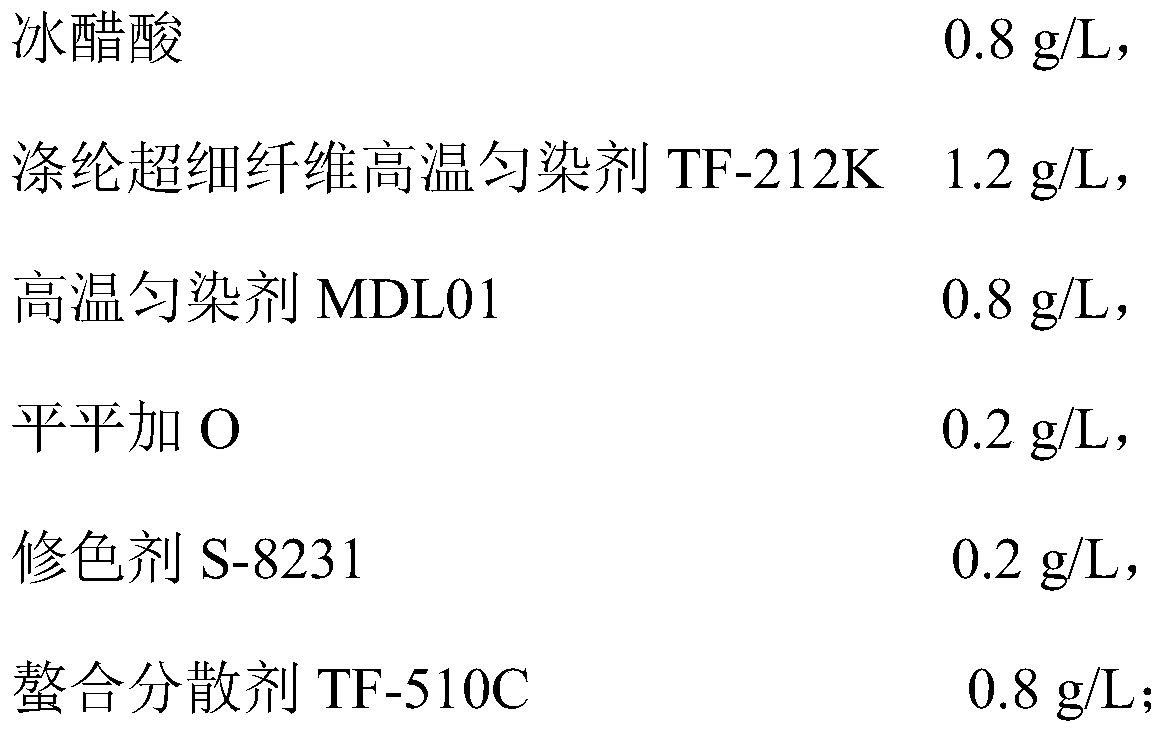

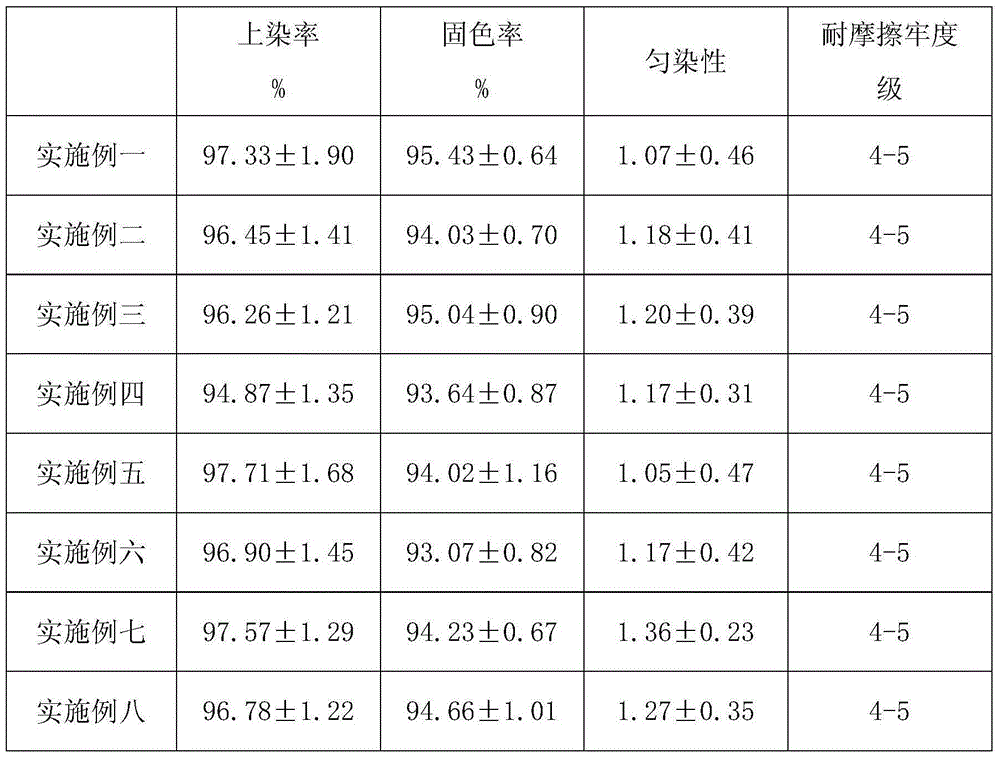

InactiveCN110331599AGood initial dyeing effectSmall color differenceSucessive textile treatmentsTwo or more solvent application treatmentDisperse dyeColour fastness

The invention discloses a dyeing and finishing technology for PFY (polyester filament yarn) Huayao fabric. The technology comprises an open-width desizing process, a dyeing process and a setting process; a dyeing agent adopted in the dyeing process comprises a dyeing auxiliary and a dye, the dye is a disperse dye, and the dyeing process adopts a high-temperature and high-pressure overflow dyeing machine for dyeing; the initial dyeing temperature of the dyeing process is 90 DEG C, and the heat insulation time is 10 min; the formula of the dyeing auxiliary comprises components as follows: glacial acetic acid with concentration of 0.8 g / L, a superfine polyester fiber high-temperature levelling agent TF-212K with concentration of 1.2 g / L, a high-temperature levelling agent MDL01 with concentration of 0.8 g / L, peregal O with concentration of 0.2 g / L, a color-remanding agent S-8231 with concentration of 0.2 g / L and a chelating disperse agent TF-510C with concentration of 0.8 g / L. With formulation of the appropriate open-width desizing process, dyeing process and setting process, the dyeing effect of the fabric is improved, dyeing uniformity is good, so that the fabric has high color fastness, good color repeatability and good dimensional stability, touches good and meets the related wearing requirement.

Owner:吴江市平望漂染厂有限公司

Novel levelling agent for dyeing pure cotton and dyeing method thereof

The invention discloses a novel levelling agent for dyeing pure cotton and a dyeing method thereof and belongs to the pure cotton printing and dyeing industry. The levelling agent comprises the following components in percentage by weight: 5-9% of methylene-bis naphthalene sulfonate, 7-10% of lignosulphonate, 2-6% of anhydrous sodium sulphate, 1-3% of carboxymethyl cellulose, 0.5-1% of chondroitin sulfate, 0.1-0.3% of triethanolamine and the balance of water. The invention further discloses a dyeing process of the levelling agent. By virtue of the novel levelling agent for dyeing pure cotton and a dyeing method thereof, the dyeing time can be shortened, the pure cotton fabric has an excellent levelling effect, and further the levelling agent has fixation, pliancy and antibiotic effects on the pure cotton fabric, is capable of improving the process efficiency and has favorable market popularization value.

Owner:HUZHOU NANXUN HONGLIANG TEXTILE

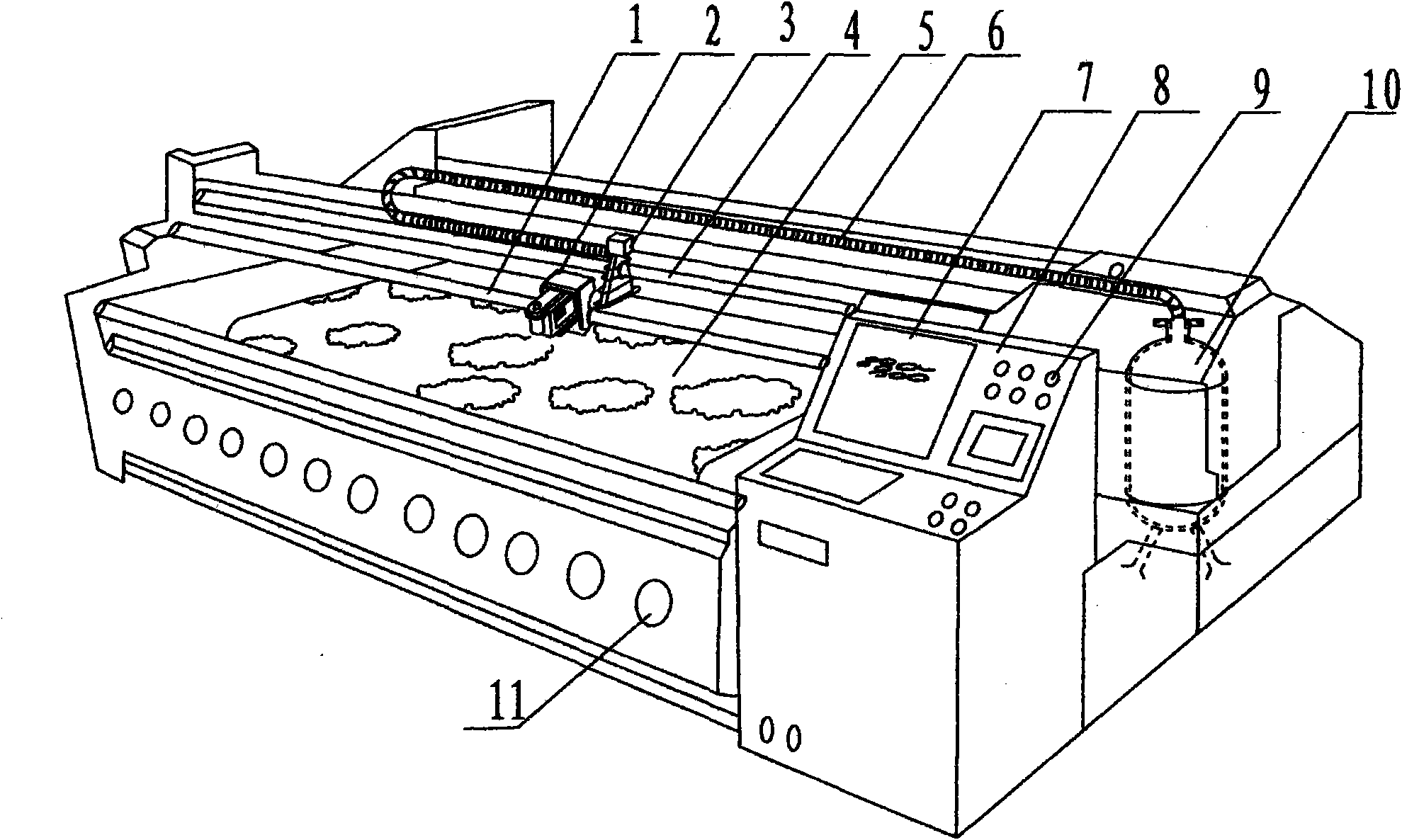

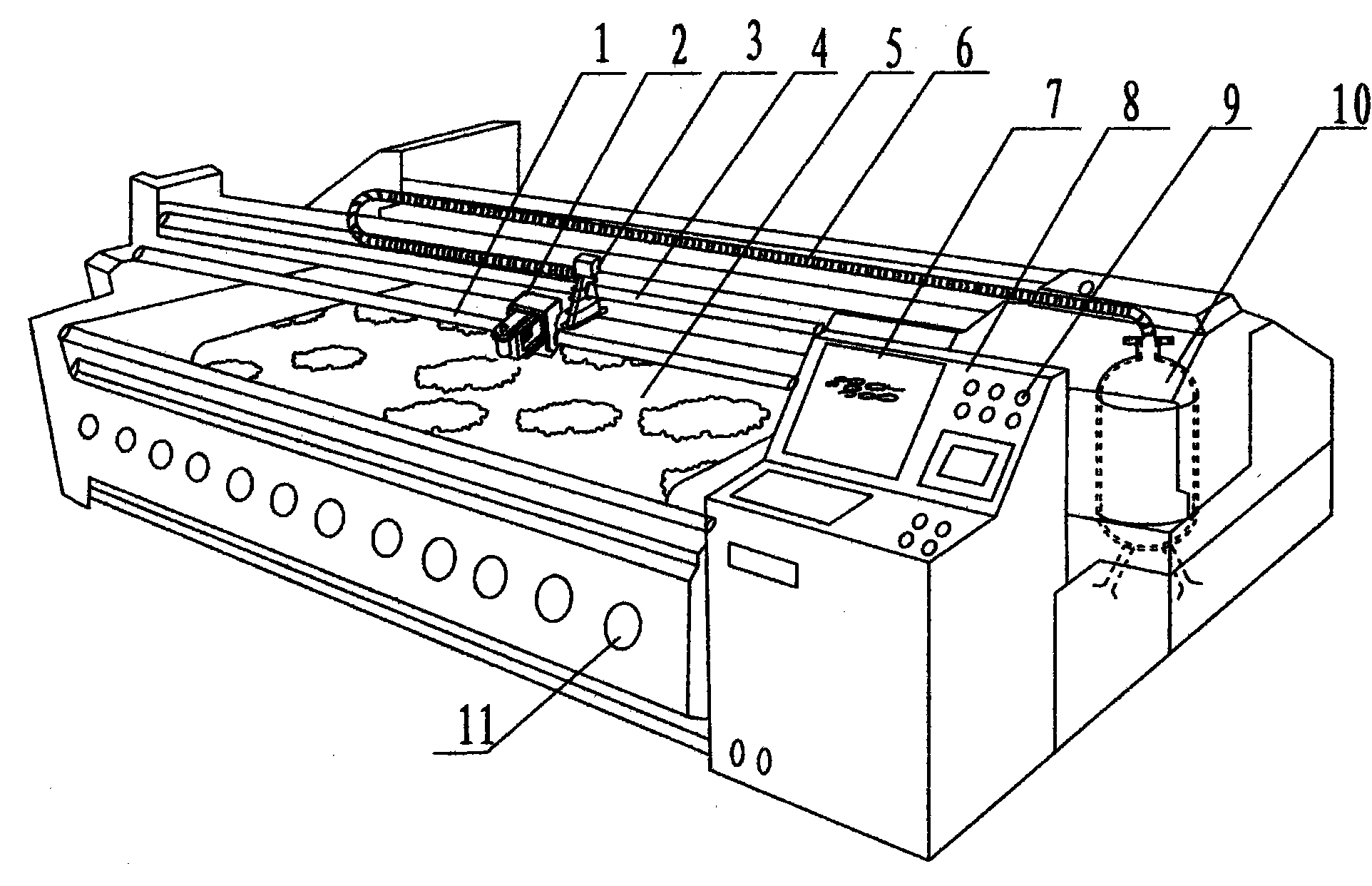

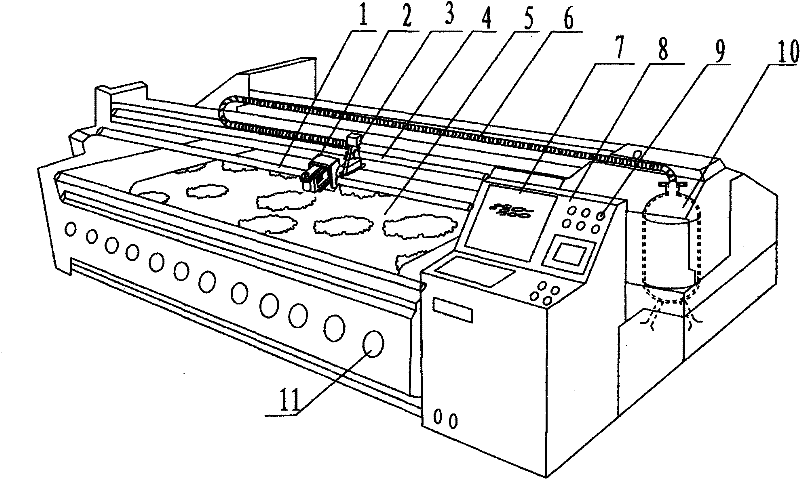

Fabric printing and dyeing device with electron accelerator mechanism

InactiveCN102009534AImprove dyeing effectIncrease apparent depthTypewritersOther printing apparatusElectron radiationColor printing

The invention provides a fabric printing and dyeing device, comprising a printing head guide rail, an ink jet type color printing head, a control cabinet display screen, a control cabinet, an exhaust fan and an electronic accelerator mechanism, wherein the electronic accelerator mechanism comprises an electronic accelerator launching gun, a launching gun guide rail, a radial transmission channel and an electronic accelerator; the printing head guide rail is arranged to be vertical to an advancing direction of a fabric during printing and dyeing, and the launching gun guide rail is arranged in parallel to the printing head guide rail. When the fabric is longitudinally wound forwards, the fabric is firstly modified through high-velocity electron radiation below the launching gun of the electronic accelerator, and then printed and dyed by the ink jet type color printing. The fabric printing and dyeing device can improve the dyeing property of the fabric and obviously improve the dyeing color fastness, and can be used for only dyeing the parts of the fabric, to be cut, therefore dyes are saved and waste water treatment is reduced.

Owner:LANYAN GROUP

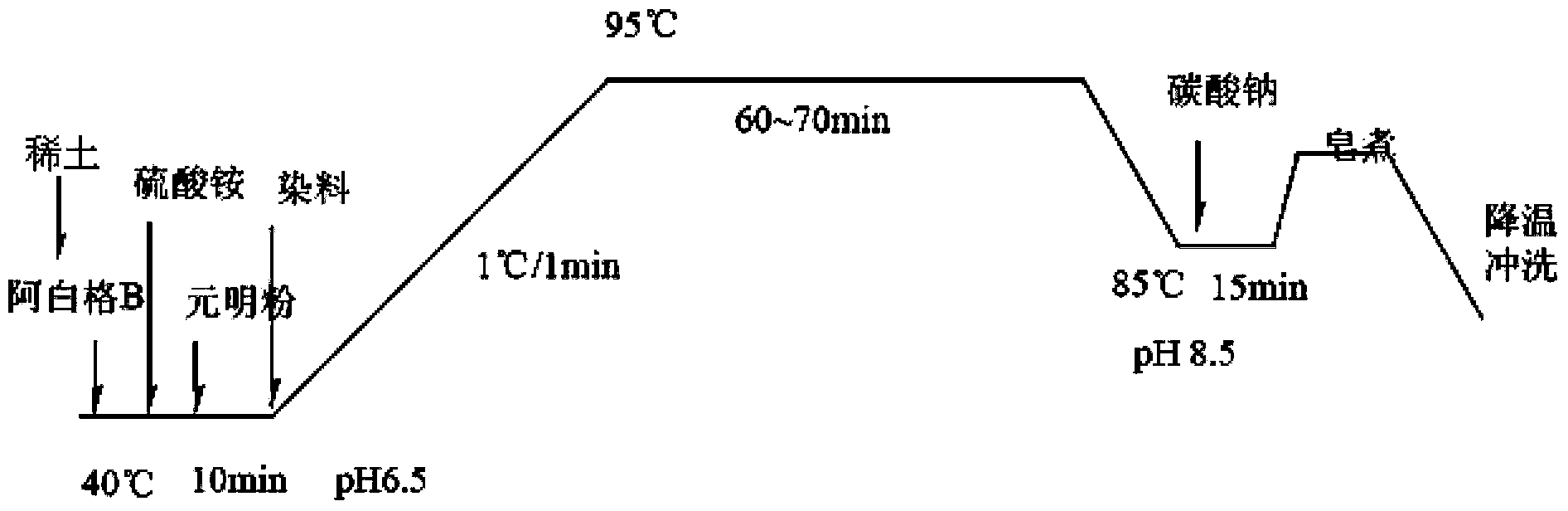

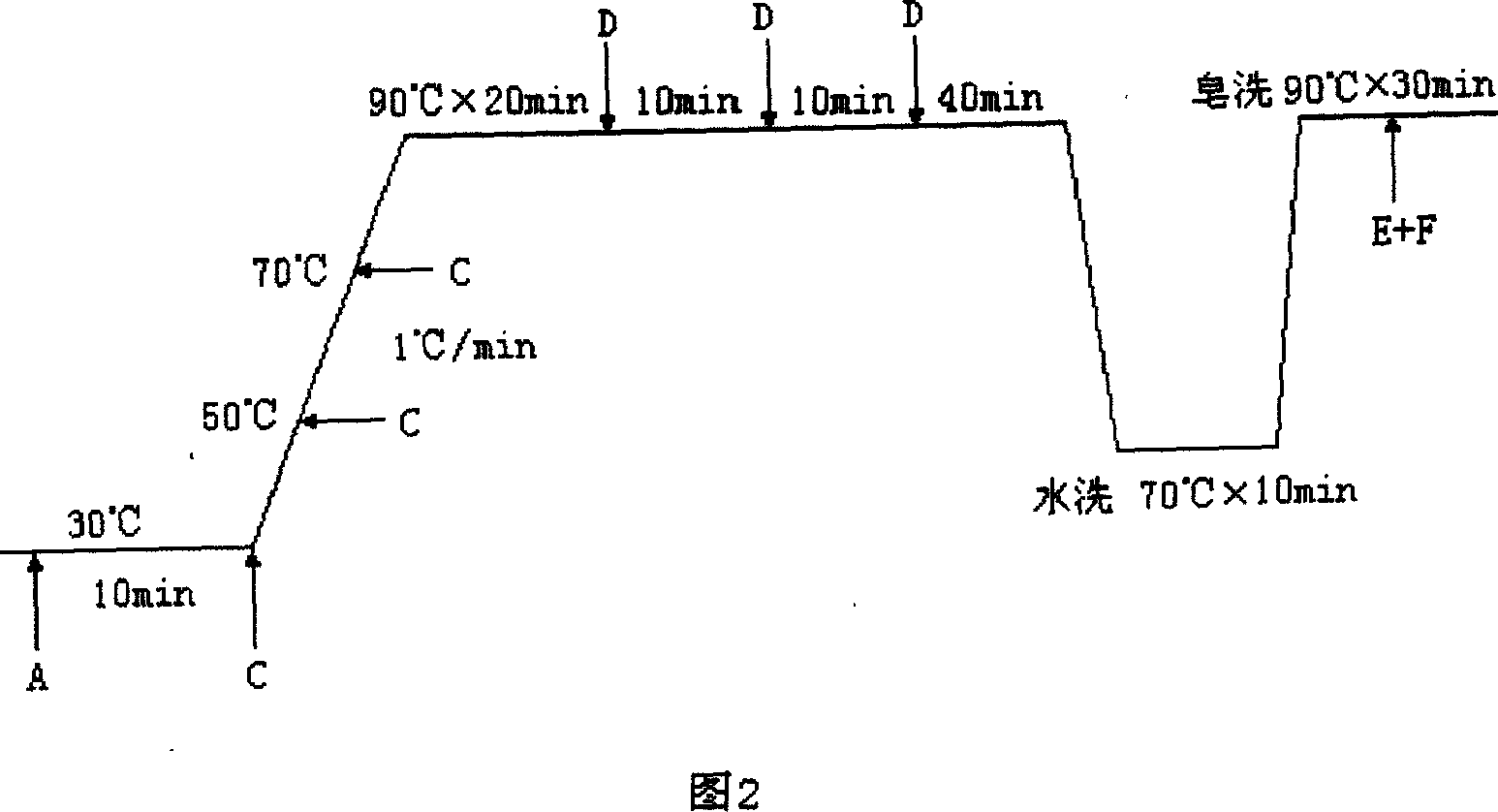

Cashmere fiber dyeing process based on lanasol dye

The invention discloses a cashmere fiber dyeing process based on a lanasol dye. The cashmere fiber dyeing process comprises the following steps: S1, adding cashmere fibers and a bath liquor to a vat, wherein the bath ratio of the dye liquor is 1: 40; S2, increasing the temperature to 40 DEG C, adjusting the pH value of the dye liquor to 6.5, orderly adding a rare earth solution, Albegal B, anhydrous sodium sulphate and the lanasol dye; S3, gradually heating the dye liquor and preserving heat, keeping the temperature at 95 DEG C and preserving heat for 60-70 min; S4, reducing the temperature to 85 DEG C, adjusting the pH value of the dye liquor to 8.5 and maintaining for 10-15 min; S5, continuously reducing the temperature to the range from 20 to 30 DEG C, and flushing the cashmere fibers to finish dyeing. The cashmere fiber dyeing process provided by the invention is simple and has little harm on the cashmere fibers; the dyed finished product is bright and full in color, good in color fastness and soft in hand feeling. Moreover, rare earth chloride is further added to the dye so as to further improve the dye uptake of the cashmere fibers.

Owner:张家港市金太阳帽业有限公司

Ultrasonic wave dyeing method

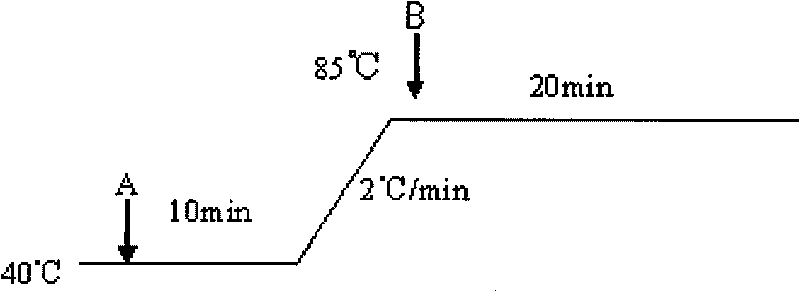

InactiveCN102465407AGood dispersionIncrease the percentage of dyeingDyeing processVibration treatmentMetallurgyMegasonic cleaning

The invention discloses an ultrasonic wave dyeing method, comprising the steps of: A, putting a prepared dye into an ultrasonic wave cleaner, and increasing a temperature to reach 65 DEG C; and B, putting a fabric in, starting a 40 KHz ultrasonic wave, gradually heating in a manner of raising 0.5 DEG C per minute until the temperature is 90 DEG C, and gradually cooling to 50 DEG C in a manner of reducing 1.5 DEG C per minute. According to the ultrasonic wave dyeing method, the penetrating power of the dye can be improved, the dyed fabric is not easy to fade and is washing-resistant, and the dyeing is uniform.

Owner:杨国栋

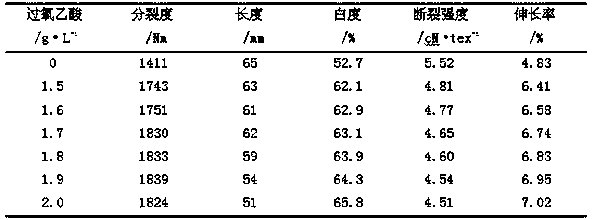

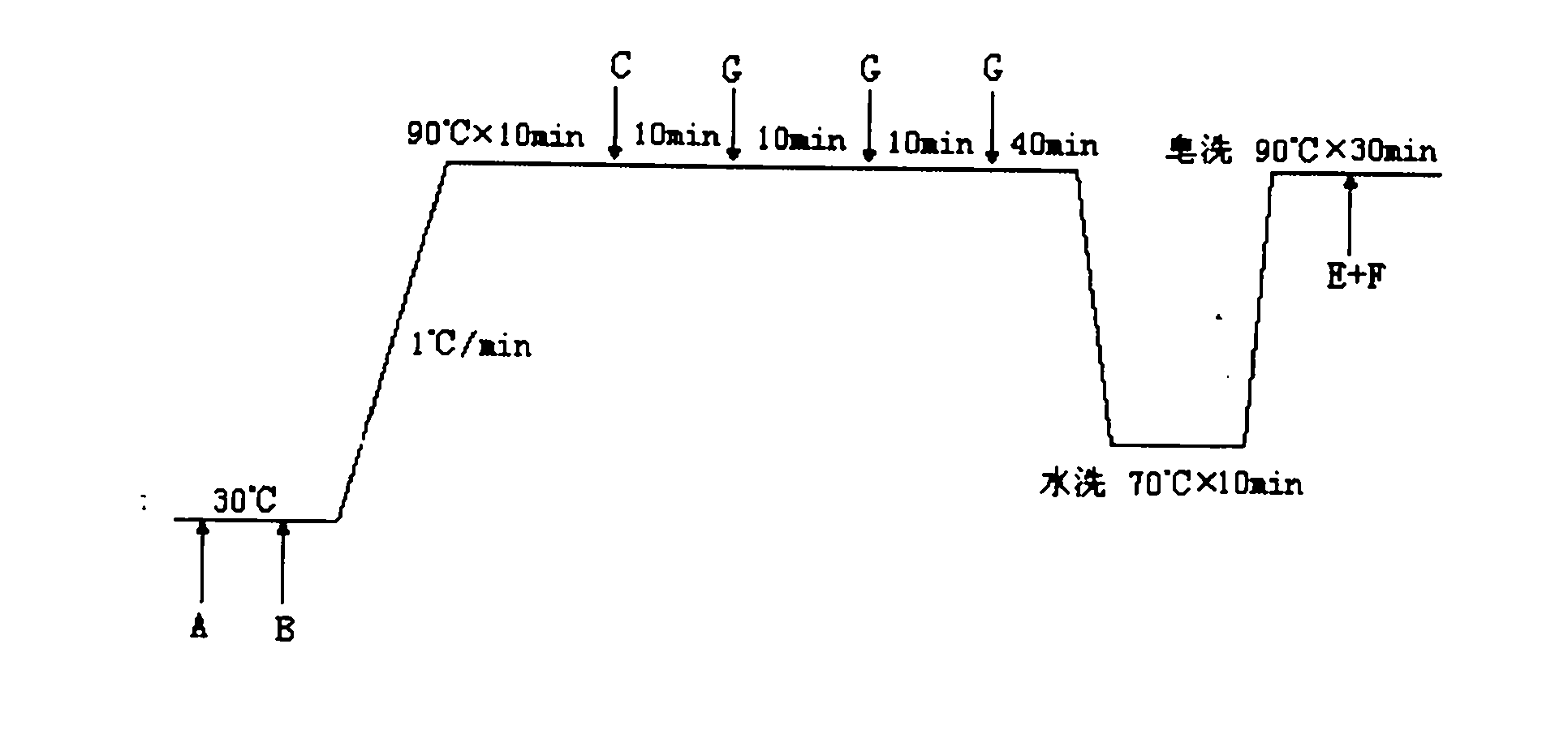

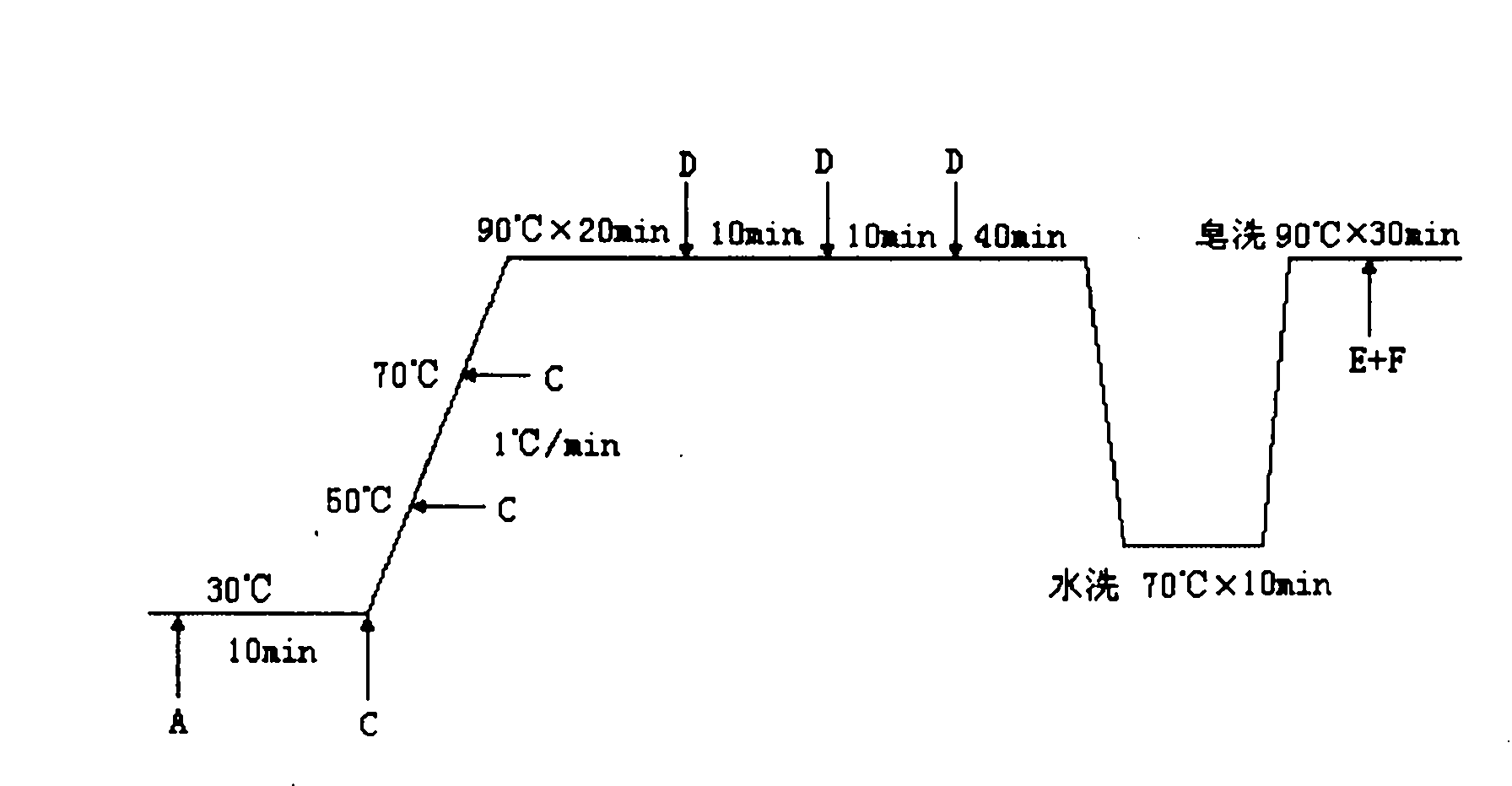

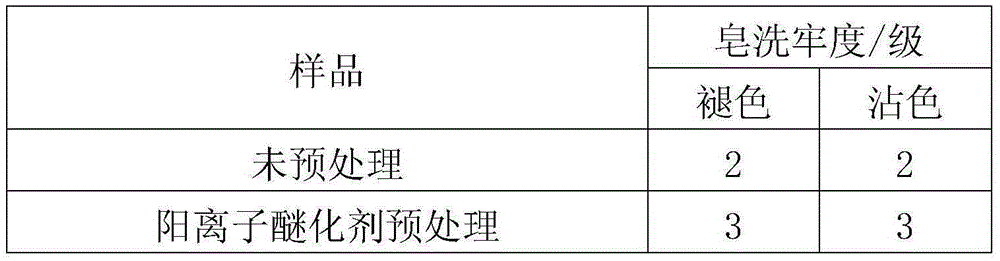

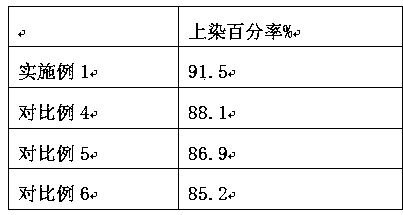

Method for improving dyeing performance of flax short fiber

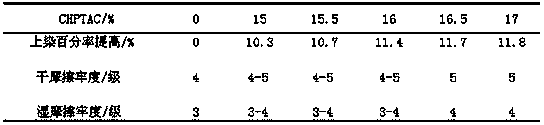

The invention discloses a method for improving dyeing performance of flax short fiber. According to the method, the flax short fiber is taken as a raw material and is dipped in a penetrant JFC solution, treated through cationic modification, washed with warm water, neutralized with peroxyacetic acid, washed with warm water, dyed with active dyes, washed with cold water, subjected to high-temperature soaping, washed with cold water, dewatered and dried. The method has the advantages that the flax short fiber has positive charge through cationic modification, adsorption of anionic dye is increased, the dyeing percentage is increased by 10.3%-11.8%, the softness and the extensibility are increased, the split degree and the spinnability of the short fiber are improved, the dry and wet rubbingfastness is improved by 0.5-1 grade after dyeing, the method is more environmentally friendly than a conventional dyeing process of the flax short fiber, and the processing and application performanceare improved. The physical indexes and the appearance quality of produced combed short flax high-count yarn meet the requirements of knitted fabric and are equally matched with long flax with the same linear density.

Owner:QIQIHAR UNIVERSITY

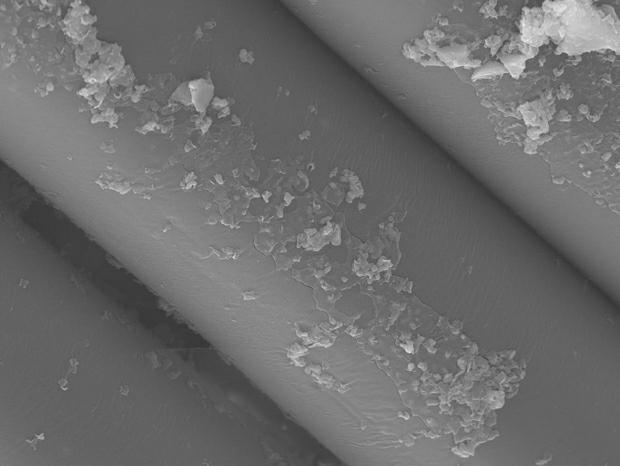

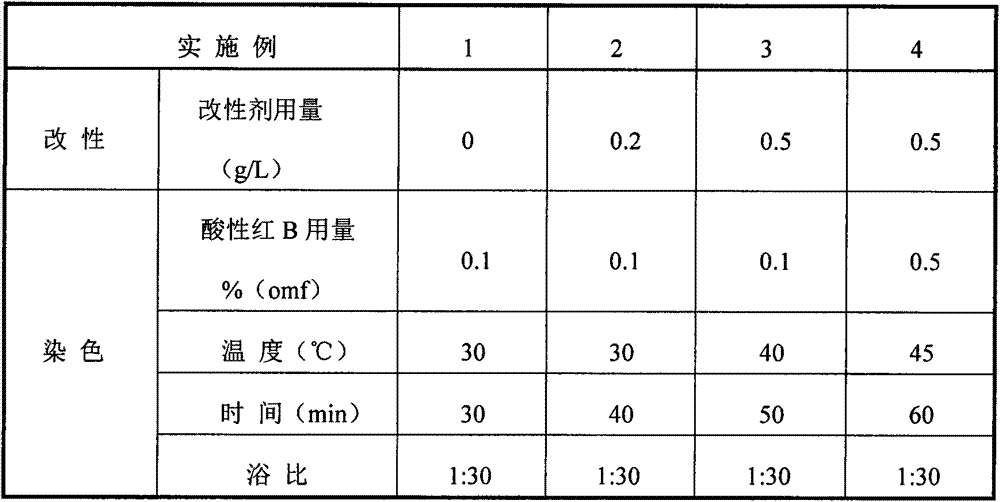

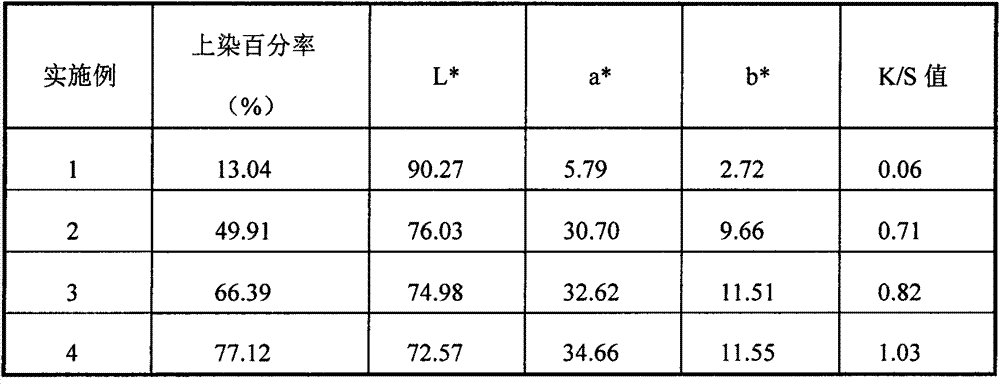

Acidic dye dyeing method of modified apocynum venetum fibers

InactiveCN104846664AIncrease the percentage of dyeingImprove dyeing performanceDyeing processVegetal fibresElectrostatic attractionDyeing

The invention relates to an acidic dye dyeing method of modified apocynum venetum fibers and belongs to the technical field of spinning printing and dyeing. The apocynum venetum fibers are subjected to polymer nano-particle modification and are dyed by using an acidic dye, so that the dyeing capability of the dye is improved. The acidic dye dyeing method has the advantages that (1) after the apocynum venetum fibers are subjected to cation nano-particle modification, the apocynum venetum fibers can be combined with the acidic dye through an electrostatic attraction effect; the dyeing percentage of the dye is improved, the problem that apocynum venetum cannot be dyed by the acidic dye is solved, and certain theoretical foundation is provided for researching the dyeing performance of the apocynum venetum fibers; (2) the dyeing performance of the apocynum venetum fibers is improved and the utilization rate of the dye is improved, so that the problem that apocynum venetum is difficult to dye is effectively solved, and the apocynum venetum and a blended product thereof are more widely applied.

Owner:TIANJIN POLYTECHNIC UNIV

Method for improving polyimide fiber basic dyeing performance

The invention belongs to the field of light chemical industry and relates to a method for improving the dyeing performance of polyimide fiber basic dyes. That is, under the action of a catalyst, the polyimide fiber is modified by carboxylation, and then the carboxylated polyimide fiber is dyed by adding a carrier in the basic dyeing bath. Under the action of the catalyst, the terminal anhydrides of the polyimide fiber molecules are hydrolyzed into carboxyl groups, which can increase the dyeing seat, and the cations on the dye molecules can be ionically bonded with the carboxyl groups generated by the hydrolysis of the fiber molecule terminal anhydrides. The method of the present invention can effectively improve the Deep dyeing and color fastness of polyimide fiber dyed with basic dyes.

Owner:SHAOXING UNIVERSITY

Dyeing method for improving color fastness of polyester woven ribbon

Owner:界首市远航织带有限公司

Dyeing auxiliary and application thereof to dyeing assistance of disperse dyes

The invention discloses a dyeing auxiliary and an application thereof to dyeing assistance of disperse dyes. The dyeing auxiliary comprises following components in percentage by mass: 40%-68% of polyoxyethylene aliphatic alcohol ether, 2%-4% of polyoxyethylene stearate, 5%-8% of triethylene glycol monobutyl ether, 5%-12% of N-alkyl betaine, 6%-10% of polyamide-polyamine-epichlorohydrin and 3%-5% of chitosan. According to the dyeing auxiliary, polyoxyethylene aliphatic alcohol ether is taken as a main component, polyoxyethylene stearate is added to realize compounding synergistic interaction with polyoxyethylene aliphatic alcohol ether, and therefore, the solubilizing dyeing effect of the dyeing auxiliary is improved; the dyes are promoted to be more powerfully combined with fibers with addition of triethylene glycol monobutyl ether, cloud point of polyoxyethylene aliphatic alcohol ether is increased with addition of N-alkyl betaine, contact probability of the dyes and the fibers is increased with addition of polyamide-polyamine-epichlorohydrin, diffusion rate of the dyes in the fibers is increased with addition of chitosan, and dye uptake of the dyes is increased.

Owner:卢梅雅

Dyeing assistants for soybean fiber, and dyeing technique

Owner:XI'AN POLYTECHNIC UNIVERSITY

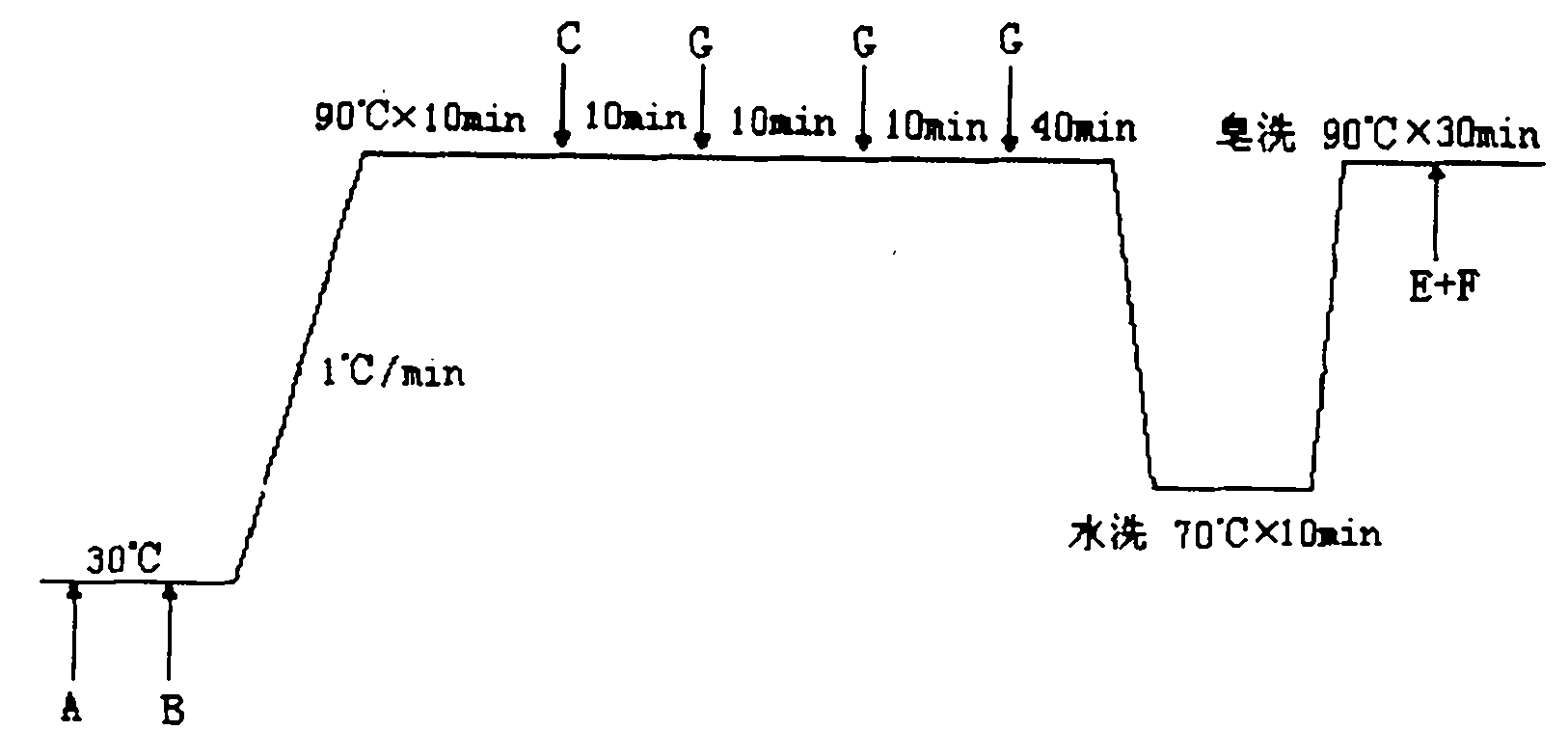

Method for dyeing phase-change temperature-adjustable viscose fiber with erythrosine

InactiveCN105401466ARealize ecological dyeingNotable dyeing qualityDyeing processEcological environmentHigh color

The invention discloses a method for dyeing a phase-change temperature-adjustable viscose fiber with erythrosine. The method is characterized in that the phase-change temperature-adjustable viscose fiber is pretreated with a cationic etherifying agent so as to allow the surface of the treated phase-change temperature-adjustable viscose fiber to be positively charged, so pigment adsorption capability is substantially enhanced, electrostatic attraction to pigment negative ions is realized, and the number of dye sites for dye up-take of erythrosine on the phase-change temperature-adjustable viscose fiber is increased, so the dye up-take rate and color fastness are substantially improved. Therefore, the method realizes ecological environment-friendly high-color-yield dyeing of the phase-change temperature-adjustable viscose fiber with the erythrosine pigment.

Owner:SHAOXING UNIVERSITY +1

Dyeing and finishing technology for high-elastic habijabi fabric

InactiveCN110184828AReduce water consumptionReduce steam consumptionDry-cleaning apparatus for textilesDyeing processDisperse dyeEngineering

The invention discloses a dyeing and finishing technology for a high-elastic habijabi fabric. The dyeing and finishing technology comprises a pretreatment process, a dyeing process and a setting process, wherein the pretreatment process comprises an open-width desizing process, a machine cylinder cloth scouring process, a pre-setting process and a slack alkali peeling process which are conducted in sequence; a dyeing agent adopted in the dyeing process is prepared from a dyeing additive and dyes which are disperse dyes; in the dyeing process, dyeing is conducted by using a high-temperature andhigh-pressure airflow dyeing machine, when the temperature of a dyeing vessel of the dyeing machine reaches 45 DEG C, the dyeing additive and the disperse dyes start to be injected respectively, andthe pH value of the dyeing bath is 5-6. Through the reasonable design of the pretreatment, dyeing and setting processes, the dyeing effect on the fabric can be improved, the dyeing uniformity and thecolor fastness of the fabric can meet requirements of customers, moreover, the elasticity of the fabric cannot be damaged, and the fabric is high in deformation memory property, soft in handfeel and high in dimensional stability.

Owner:SUZHOU XINMIN PRINTING&DYEING CO LTD

Dyeing technology for polyester woven tape with high color fastness

InactiveCN108978280AImprove hydrophilicityReduce the conditions of useGrip property fibresDyeing processColour fastnessPolyester

The invention discloses a dyeing technology for polyester woven tape with high color fastness, and relates to the technical field of biological environmental protection. The dyeing technology comprises the steps that the polyester woven tape is subjected to modification treatment so as to obtain the modified polyester woven tape, the modified polyester woven tape is dyed by adopting a radix scutellariae dye and then is taken out, and air drying is carried out at the ventilation position. The dyeing technology has the advantages that modification treatment is carried out on polyester, so that the hydrophilicity is greatly improved, the surface affinity is obviously improved, the combination of the polyester woven tape and the radix scutellariae dye can be promoted, and therefore the color fastness is improved.

Owner:HEFEI SHENGDA GARMENT ACCESSORIES CO LTD

Dyeing auxiliary for disperse dye and application thereof in assistance for disperse dye in process of dyeing wool

InactiveCN109518480AImprove dye uptakeIncrease the speed of diffusionDyeing processDisperse dyeBetaine

The invention discloses a dyeing auxiliary for disperse dye and application thereof in assistance for disperse dye in the process of dyeing wool. The dyeing auxiliary is prepared from the following components in percentage: 40-60 percent of polyoxyethylene fatty alcohol ether, 5-8 percent of triethylene glycol momobutyl ether, 3-7 percent of octadecyl betaine, 2-4 percent of hexadecylpyridinium bromide, 6-8 percent of polyamide polyamine epichlorohydrine, 2-4 percent of chitosan and 3-9 percent of poloxamer. According to the dyeing auxiliary, polyoxyethylene fatty alcohol ether is used as a main ingredient, dye and fibers can be effectively combined by adding triethylene glycol momobutyl ether, the cloud point of polyoxyethylene fatty alcohol ether is improved by adding octadecyl betaine and hexadecylpyridinium bromide, and the solubilizing and dyeing effect of the dyeing auxiliary can be reinforced; and the contact between dye and fibers can be prolonged by adding the polyamide polyamine epichlorohydrine, the dispersing speed of dye in fibers can be accelerated by adding chitosan, and the dyeing percentage of dye can be increased.

Owner:卢梅雅

A method for improving light fastness of thpc flame retardant fabric

ActiveCN106400461BIncreased wicking capacityIncrease the percentage of dyeingPhysical treatmentDry-cleaning apparatus for textilesEngineeringLow temperature plasma

Owner:新乡市新科防护科技有限公司

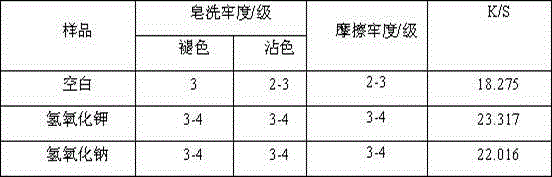

Preparation method and application method of low-temperature low-chromium dyeing auxiliary agent of acidic medium dye for wool

InactiveCN102817251BEfficient reuseReduce pollutionPeptide preparation methodsDepsipeptidesAqueous sodium hydroxideDyeing wastewater

The invention discloses a preparation method and an application method of a low-temperature low-chromium dyeing auxiliary agent of an acidic medium dye for wool. The preparation method comprises the steps that: 1, protein powder is prepared by using waste duck feather, wherein (1) the duck feather is subjected to pretreatment; (2) the suck feather is subjected to a dissolving treatment; and (3) duck feather protein powder is prepared; 2, a sodium hydroxide solution is prepared, and the sodium hydroxide solution is used for dissolving the duck feather protein powder; 3, sodium hydroxide, triethanolamine, and epichlorohydrin are adopted for preparing a cationic quaternary ammonium salt cross-linking modification agent WLS; and 4, the low-temperature low-chromium dyeing auxiliary agent for the acidic medium dye is prepared. The auxiliary agent can be used as a wool modification agent. After wool fibers are modified, wool fiber dyeing properties of acidic medium dyes are greatly improved, dye uptake percentage rate can be improved, mordant absorption performance of the dye is improved, chromium pollution in dye wastewater is reduced, wool fiber low-temperature low-chromium dyeing is realized, and waste duck feather keratin is effectively utilized. After modification, the wearability of wool products is improved.

Owner:XI'AN POLYTECHNIC UNIVERSITY

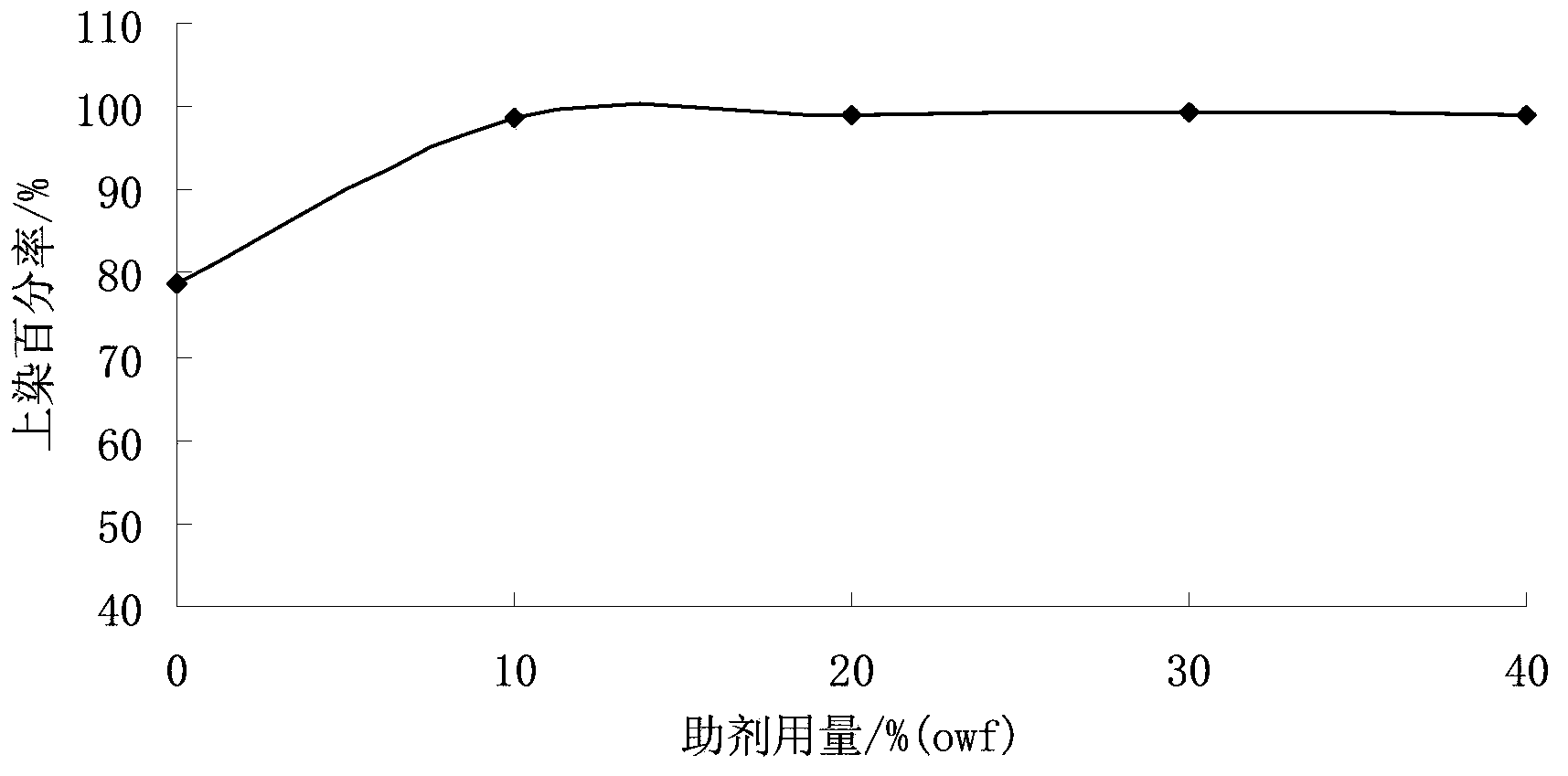

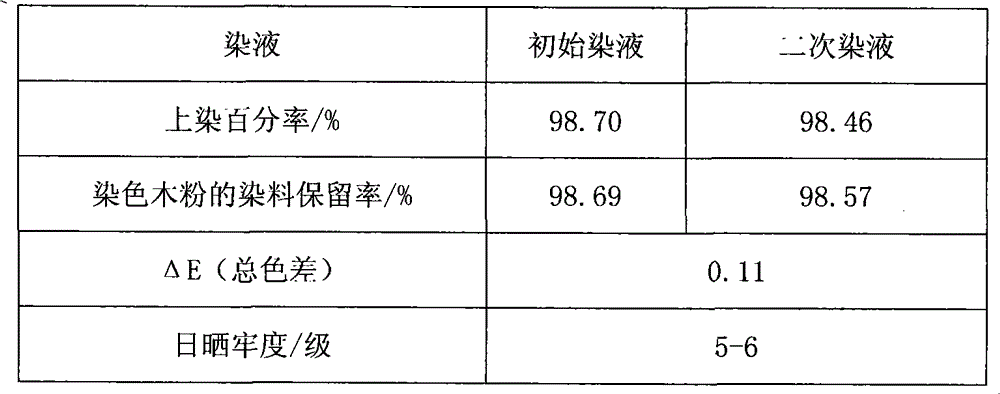

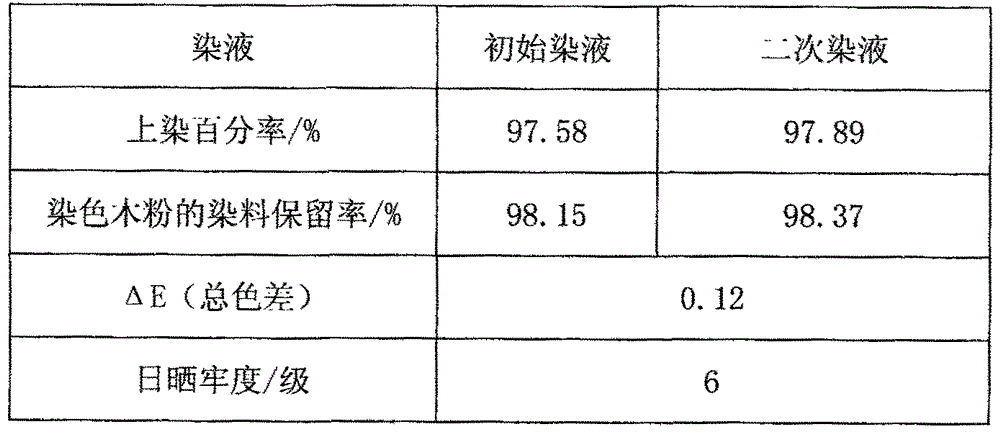

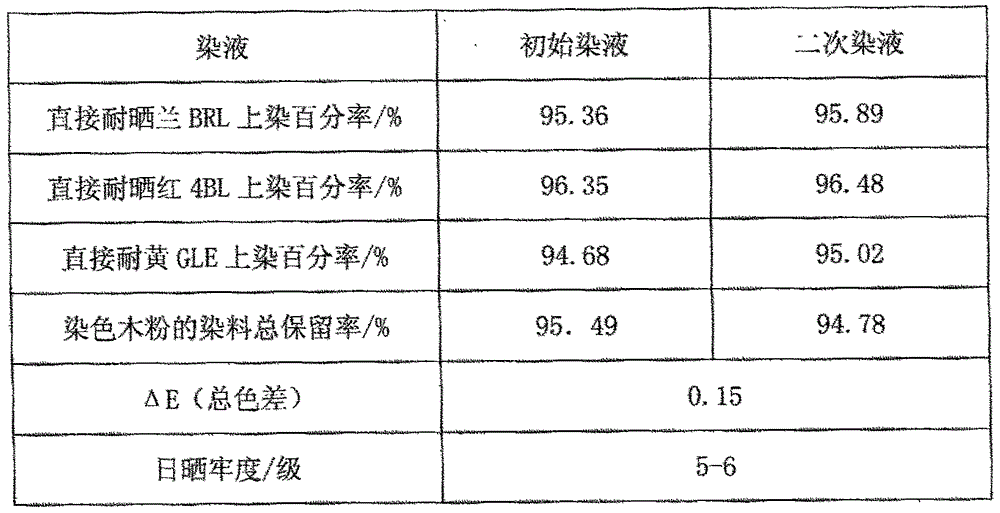

A low-wastewater-emission dyeing method of wood powder for high-fastness color wood-plastic composite materials

The invention discloses a dyeing method with low waste water discharge of wood meal for a colorful wood-plastic composite material with high fastness. The dyeing method comprises the following steps of: step 1, carrying out graft modification treatment on the wood meal for the wood-plastic composite material by a positive ion modifier; step 2, directly dyeing the wood meal subjected to the graft modification treatment by a dye in a sun-proof series; step 3, washing the dyed and dehydrated wood meal with hot water once so as to remove non-sessile dye and improve the fastness of the dyed wood meal; and step 4, adding residual dyeing liquid with the dye concentration consistent to that of the dye in the step 2 into the modified wood meal in the step 1, dyeing the modified wood meal with the residual liquid by a dyeing method in the step 2, and washing the dyed wood meal according to the step 3, and circulating the step 1 to the step 4. With the adoption of the dyeing method provided by the invention, the dye enters the inner part of fibers of the wood meal, and is not only adhered to the surface of the wood meal, so that the coloring force can be improved, and the bright colorful wood-plastic material can be obtained. The dyeing method can be used for improving sun-proof fastness and the water immersion fastness of the dyed wood meal or the wood-plastic material.

Owner:文水平

A kind of dyeing method of cotton, linen and wool fiber blended interweaving fabric

ActiveCN103382667BImprove processing and refining effectAddressing the Adequacy InsufficiencyDyeing processVegetal fibresAcetic acidMoisture

The invention relates to a dyeing method for blended and interwoven fabric of cotton fiber, linen fiber and wool fiber. The method includes (1) soaking the blended and interwoven fabric in water, adding a refining agent, penetrant and sodium carbonate, heating, keeping warm, injecting water, adding acetic acid, heating and keeping warm; (2) soaking the fabric processed through the step (1) in water, adding a wool resist agent and mirabilite, heating, keeping warm and discharging dye liquid; (3) soaking the fabric processed through the step (2) in water, then adding a soaping agent, heating, keeping warm, cooling, discharging liquid and washing; (4) soaking the fabric processed through the step (3) in water, then adding sodium carbonate, sodium chloride and a dye-fixing agent, heating, keeping warm and finally washing, dewatering, drying and fixing patterns softly. The dyeing method is low in dyeing temperature and simple to operate and has a low requirement on a device. The blended and interwoven fabric of the cotton fiber, the linen fiber and the wool fiber and dyed through the method has good dyeing homochromatic property and color fastness, is good in moisture absorbing and perspiration performance and is skin-friendly fabric.

Owner:上海嘉麟杰纺织科技有限公司

Scutellaria baicalensis dyeing process of polyester ribbon

The invention discloses a scutellaria baicalensis dyeing process of a polyester ribbon and relates to the technical field of biological environmental protection. The scutellaria baicalensis dyeing process comprises the following steps: (1) scutellaria baicalensis dye preparation; (2) steam treatment; (3) dyeing. The scutellaria baicalensis dyeing process disclosed by the invention has the advantages that when a polyester ribbon dye is prepared, a pigment contained in scutellaria baicalensis is taken as a natural dye; the scutellaria baicalensis is non-toxic and harmless, has a certain healthcare effect on a human body and has relatively good wetting and dyeing effects when being taken as a dye component of the polyester ribbon; the obtained polyester ribbon is soft and comfortable.

Owner:HEFEI SHENGDA GARMENT ACCESSORIES CO LTD

Deoiling agent for viscose fabric cold pad-batch one-bath method production process, and application method of deoiling agent

InactiveCN106498778ASimple recipeImprove bindingDry-cleaning apparatus for textilesDyeing processOrganosolvViscose

The invention provides a deoiling agent for a viscose fabric cold pad-batch one-bath method production process. The deoiling agent is prepared from the following raw materials in percentage by weight: 5 to 15 percent of polyoxyethylene fatty alcohol sodium sulfate, 1 to 35 percent of AEO-9, 5 to 10 percent of an organic solvent and the balance of water. The deoiling agent is applied to one-bath method viscose fabric treatment, the viscose fabric is pretreated and dyed by a cold pad-batch process and the process is subjected to optimal research, so that the hand feeling and the hair effect of the viscose fabric can be greatly improved, the dyeing percentage of the dye on the viscose fabric is increased, and various fastness comprising rubbing fastness and washing fastness of the fabric are high. The fabric is pretreated and dyed simultaneously by the cold pad-batch process, so that a large amount of water, dye and additives are saved, energy loss and waste water discharge are reduced, the problems of high pollution discharge and high energy consumption of the printing and dyeing link are solved, and the production cost is greatly reduced.

Owner:ZHONGYUAN ENGINEERING COLLEGE

Dyeing assistants for soybean fiber, and dyeing technique

The present invention relates to a soybean protein fiber dyeing adjuvant. It is characterized by that it contains 0.50-0.8% (on weight of fabric) of alkyl-polyoxyethylene non-ionic surfactant, 10-30g / l of anhydrous sodium sulfate, it uses formic acid to regulate pH value of dye bath to 4.5-5.5, then uses caustic soda to regulate pH value of dye bath to 11. Besides, in said adjuvant 0.25-0.505 (on weight of fabric) of aluminium salt is also contained; the described aluminium salt is any one of aluminium sulfate, aluminium trichloride and alum or their mixture. Said invention also provides the concrete steps of said dyeing process by using said dyeing adjuvant and soybean protein fiber.

Owner:XI'AN POLYTECHNIC UNIVERSITY

Fabric printing and dyeing device with electron accelerator mechanism

InactiveCN102009534BImprove dyeing effectIncrease apparent depthTypewritersOther printing apparatusColor printingElectron radiation

The invention provides a fabric printing and dyeing device, comprising a printing head guide rail, an ink jet type color printing head, a control cabinet display screen, a control cabinet, an exhaust fan and an electronic accelerator mechanism, wherein the electronic accelerator mechanism comprises an electronic accelerator launching gun, a launching gun guide rail, a radial transmission channel and an electronic accelerator; the printing head guide rail is arranged to be vertical to an advancing direction of a fabric during printing and dyeing, and the launching gun guide rail is arranged inparallel to the printing head guide rail. When the fabric is longitudinally wound forwards, the fabric is firstly modified through high-velocity electron radiation below the launching gun of the electronic accelerator, and then printed and dyed by the ink jet type color printing. The fabric printing and dyeing device can improve the dyeing property of the fabric and obviously improve the dyeing color fastness, and can be used for only dyeing the parts of the fabric, to be cut, therefore dyes are saved and waste water treatment is reduced.

Owner:LANYAN GROUP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com