Method for dyeing phase-change temperature-adjustable viscose fiber with erythrosine

A technology of viscose fiber and dyeing method, which is applied in dyeing method, textiles and papermaking, etc. It can solve the problems of long conjugated double bond system, lack, and poor dyeability of erythrosin, so as to expand the application field and enhance the adsorption capacity , Improve the effect of dyeing percentage and color fastness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

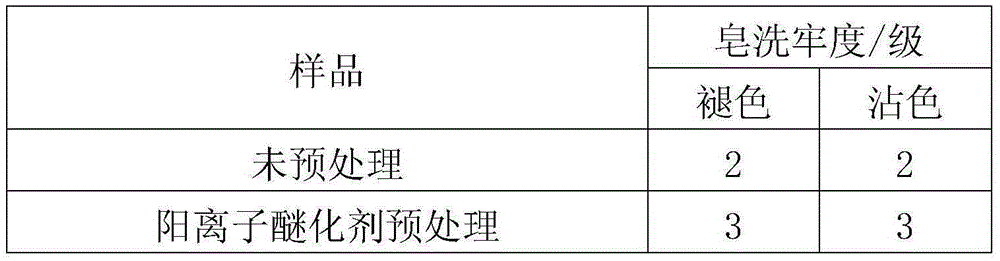

[0020] Embodiment 1: The influence of modifier LD-8202 dosage on dyeing performance.

[0021] A kind of dyeing method of erythrosine to phase change thermoregulation viscose fiber, method is as follows:

[0022] Step a. Pretreatment process: modifier LD-8202 dosage 0-8% owf, soda ash 4g / L, penetrant JFC 1g / L, liquor ratio 1:30, treatment at 80°C for 40min, washing with water, and drying.

[0023] Step b. Dyeing process: use 3% owf of erythrosine, pH = 7, liquor ratio 1:30, dye at room temperature, heat up to 80°C at 1°C / min, keep warm for 60 minutes, wash with water, and dry.

[0024] Using the above process, adjust the amount of modifier LD-8202, and test its influence on the dyeing performance, as shown in Table 1.

[0025] Table 1. Effect of modifier LD-8202 dosage on dyeing performance.

[0026] Modifier dosage (%owf)

[0027] It can be seen from Table 1 that within a certain range, as the amount of modifier LD-8202 increases, the K / S value increases and the co...

Embodiment 2

[0028] Embodiment 2: Effect of different erythrosine dosages on dyeing properties.

[0029] A kind of dyeing method of erythrosine to phase change thermoregulation viscose fiber, method is as follows:

[0030] Step a. Pretreatment process: modifier LD-8202 dosage 6% owf, soda ash 4g / L, penetrant JFC 1g / L, liquor ratio 1:30, treatment at 80°C for 40min, washing with water, and drying.

[0031] Step b. Dyeing process: the amount of erythrosine is 1-7% owf, pH=7, bath ratio 1:30, dyeing at room temperature, heating up to 80°C at 1°C / min, keeping warm for 60 minutes, washing with water, and drying.

[0032] Using the above process, adjust the amount of erythrosine, and test its influence on the dyeing performance, as shown in Table 2.

[0033] Table 2, the influence of the amount of erythrosine on the dyeing performance.

[0034] Dosage of erythrosine (%owf)

[0035] It can be seen from Table 2 that with the increase of the amount of erythrosine, the K / S value increase...

Embodiment 3

[0036] Embodiment 3: Effect of different dyeing temperatures on dyeing properties.

[0037] A kind of dyeing method of erythrosine to phase change thermoregulation viscose fiber, method is as follows:

[0038] Step a. Pretreatment process: modifier LD-8202 dosage 6% owf, soda ash 4g / L, penetrant JFC 1g / L, liquor ratio 1:30, treatment at 80°C for 40min, washing with water, and drying.

[0039] Step b. Dyeing process: erythrosine dosage 3% owf, pH=7, liquor ratio 1:30, dyeing at room temperature, heating up to 40, 60, 80, 100°C at 1°C / min, keeping warm for 60 minutes, washing with water ,drying.

[0040] Using the above process, adjust different temperatures, and test its influence on the dyeing performance, as shown in Table 3.

[0041] Table 3. Effect of dyeing temperature on dyeing performance.

[0042] Dyeing temperature (℃)

[0043] It can be seen from Table 3 that as the dyeing temperature increases, the K / S value further increases, and the K / S value reaches t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com