A kind of dyeing method of berberine to acetin fiber

A technology of acetocyanine fiber and dyeing method, applied in dyeing method, textile and papermaking, etc., can solve problems such as undeveloped berberine, improve dyeing percentage and dyeing fastness, expand application field, adsorption capacity and The effect of electrostatic attraction enhancement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

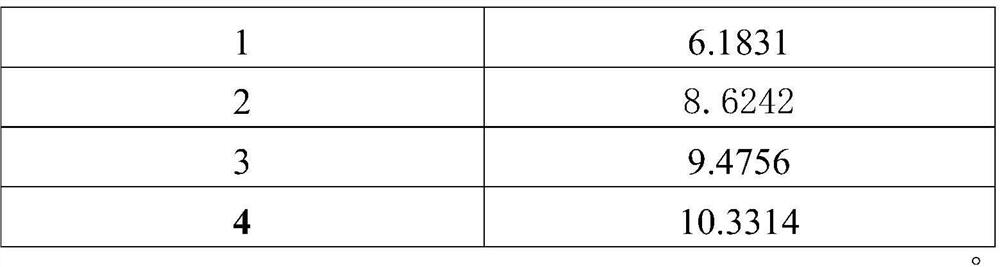

[0021] Example 1: The effect of different pretreatment processes on the dyeing effect of acetonitrile fiber

[0022] Adopt (1) separate ionic liquid treatment, (2) separate nitrilase treatment, (3) ionic liquid and nitrilase combined process, respectively to pretreat the acetonitrile fiber, the above three different pretreatments The fiber is dyed with berberine, the method is as follows:

[0023] Step a. Pretreatment process:

[0024] (1) The individual ionic liquid treatment process is: the mass fraction of monoallyl-3-methylimidazolium chloride salt ionic liquid is 90%, bath ratio is 1:45, treated at 60°C for 30 minutes, and the sample is taken out, absolute ethanol Wash 3 times, wash with water.

[0025] (2) The treatment process of nitrilase alone is as follows: nitrilase dosage is 6% owf, pH=7.0, bath ratio 1:40, treatment at 45°C for 30 minutes, washing with water, and drying.

[0026] (3) The combined pretreatment process of ionic liquid and nitrilase is: ①The mass fraction of...

Embodiment 2

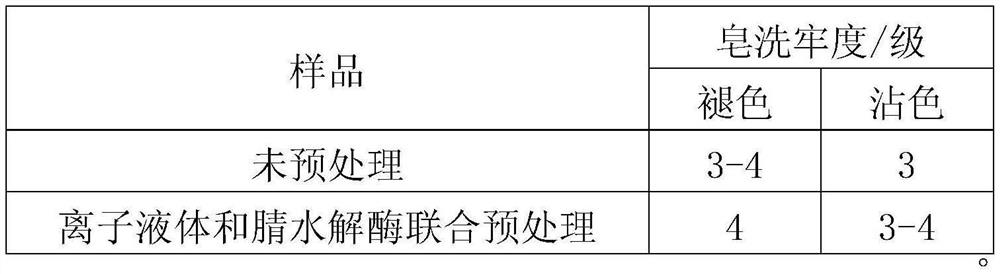

[0033] Example 2: The effect of the amount of ionic liquid on the dyeing performance of acetonitrile fiber.

[0034] A dyeing method of berberine to acetonitrile fiber is as follows:

[0035] Step a. Pretreatment process: ①, the mass fraction of 1-allyl-3-methylimidazolium chloride salt ionic liquid is 80%-95%, bath ratio is 1:45, treated at 60°C for 30min, and the sample is taken out, Wash with absolute ethanol 3 times and then with water. ②The dosage of nitrilase is 6% owf, pH=7.0, bath ratio 1:40, treatment at 45℃ for 30min, washing with water and drying.

[0036] Step b. Dyeing process: berberine dosage 3% owf, pH=4, bath ratio 1:30, dyeing at room temperature, heating at 1°C / min to 90°C, holding for 60 minutes, washing with water, and drying.

[0037] Using the above process, the dosage of 1-allyl-3-methylimidazolium chloride salt ionic liquid was adjusted, and its effect on the dyeing performance of acetate fiber was tested. The results are shown in Table 2.

[0038] Table 2. Th...

Embodiment 3

[0041] Example 3: The effect of the amount of nitrilase on the dyeing performance of acetonitrile fiber.

[0042] A method for dyeing acetonitrile fiber with berberine, the method is as follows:

[0043] Step a. Pretreatment process: ①The mass fraction of 1-allyl-3-methylimidazolium chloride salt ionic liquid is 90%, bath ratio is 1:45, treated at 60℃ for 30min, take out the sample, and wash 3 with absolute ethanol Time, wash. ②The dosage of nitrilase is 4%owf-10%owf, pH=7.0, bath ratio 1:40, treatment at 45℃ for 30min, wash with water, and dry.

[0044] Step b. Dyeing process: berberine dosage 3% owf, pH=4, bath ratio 1:30, dyeing at room temperature, heating at 1°C / min to 90°C, holding for 60 minutes, washing with water, and drying.

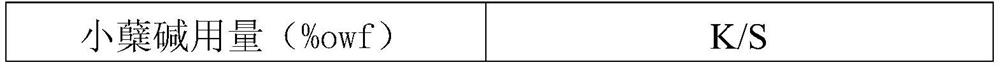

[0045] Using the above process, adjust the amount of nitrilase, and test its effect on dyeing performance, as shown in Table 3.

[0046] Table 3. The effect of nitrilase dosage on dyeing performance.

[0047] Nitrilase dosage (%owf) K / S 47.9154 68....

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com