Multifunctional printing positioning machine and production process of multifunctional printing positioning machine

A production process and positioning machine technology, which is applied to printing machines, rotary printing machines, printing, etc., can solve the problems of poor air permeability, many processes, time-consuming, labor-intensive and money-consuming, etc., to improve air permeability, overcome slow speed, and save consumption Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

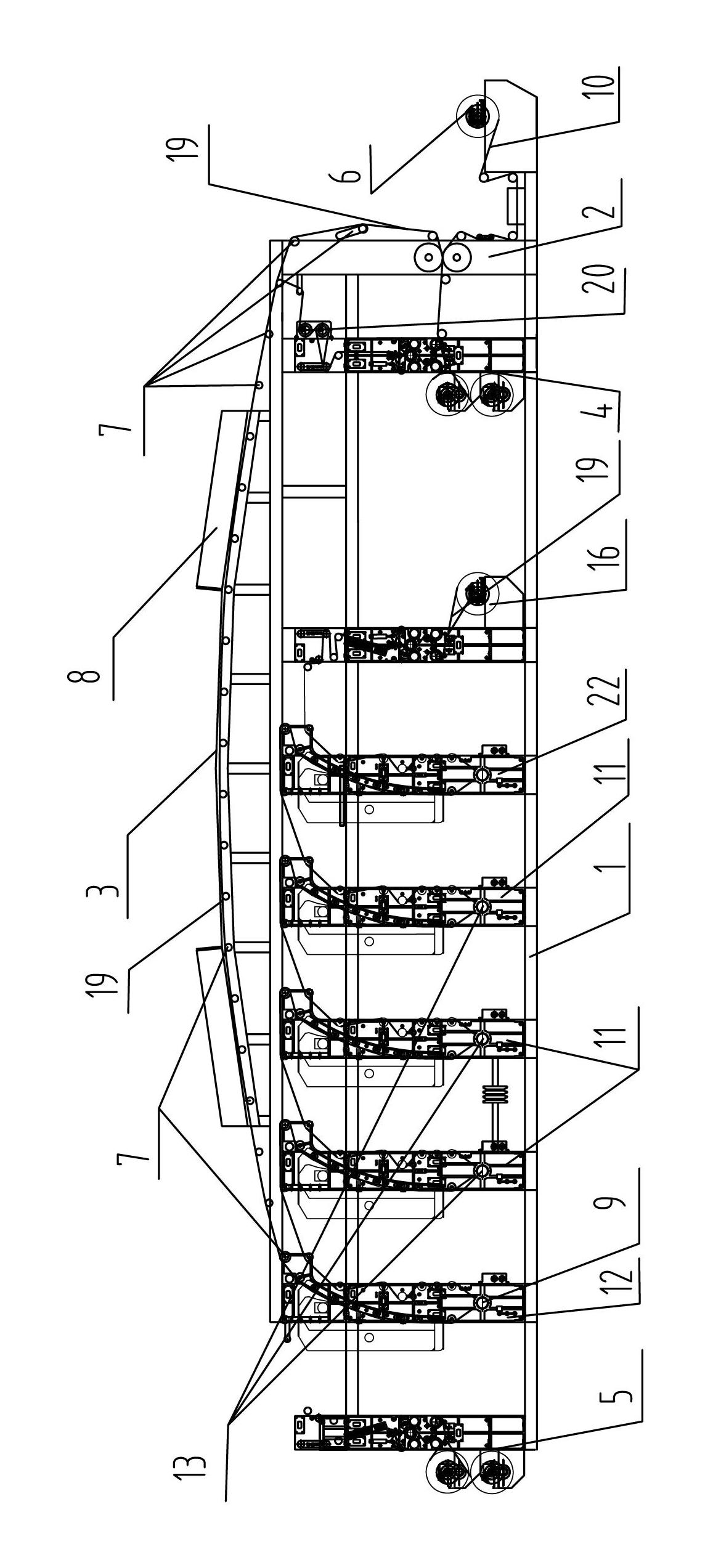

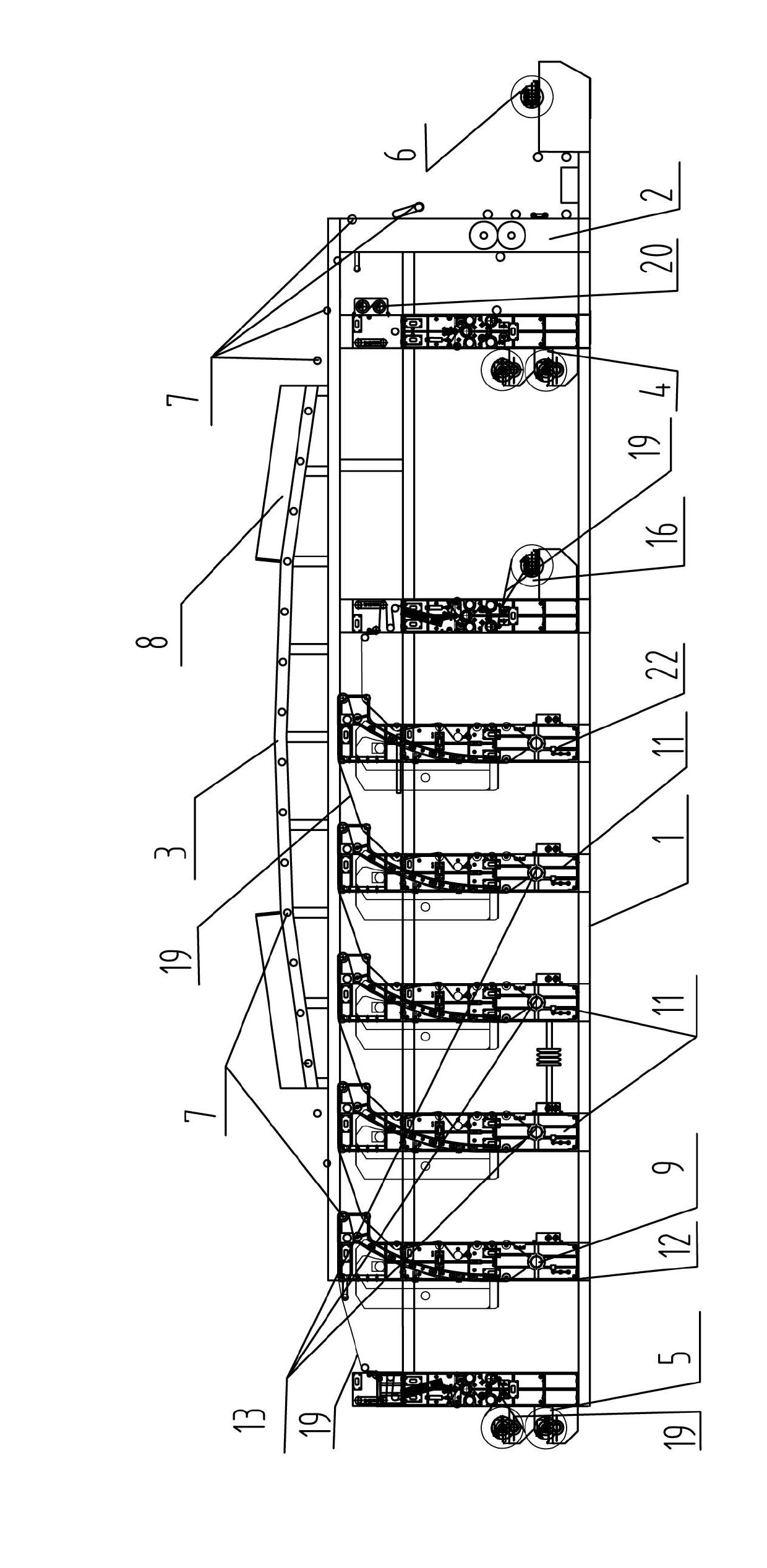

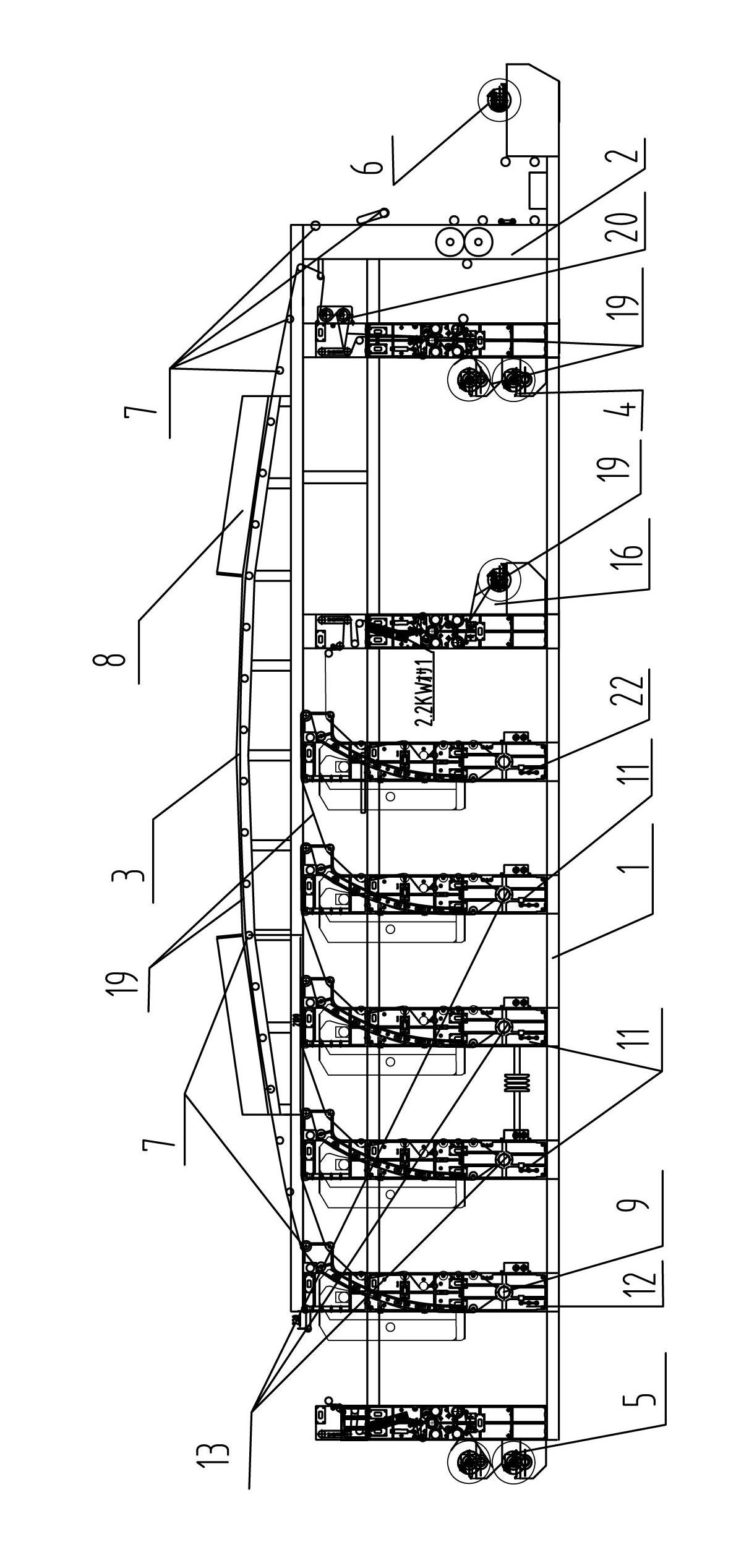

[0026] A kind of multifunctional printing positioning machine of the present embodiment, such as figure 2 , 4 As shown in , 5, a multi-color thermal transfer positioning machine that adopts printing and composite hot-press transfer technology, including a printing machine 1, a feeding device 6, a composite hot-press transfer device 2, a drying system 3, a cooling device 20 and a winding Device 4, wherein one side of the printing machine 1 is sequentially installed with a winding device 4, a composite hot-press transfer device 2 and a discharge device 6; the drying system 3 is erected on the printing machine 1, the winding device 4 and the upper top of the composite heat transfer device 2, and are fixedly connected with the printing machine 1, the winding device 4 and the composite heat transfer device 2 respectively; the top of the winding device 4 is fixedly connected with the cooling device 20. The drying system 3 includes a conveying roller 7 and an oven 8 erected on the ...

Embodiment 2

[0029] A kind of multifunctional printing positioning machine of the present embodiment, such as figure 1 , 4As shown in , 5, a multi-color heat transfer positioning machine that adopts printing and composite heat transfer technology, including a printing machine 1, a feeding device 6, a composite heat transfer device 2, a drying system 3, a cooling device 20 and a winding device 4, wherein one side of the printing machine 1 is sequentially installed with a winding device 4, a composite hot-press transfer device 2 and a discharge device 6; the drying system 3 is erected on the printing machine 1, the winding device 4 and the The upper top of the composite thermal pressure transfer device 2 is fixedly connected with the printing machine 1 , the winding device 4 and the composite thermal pressure transfer device 2 respectively; the top of the winding device 4 is fixedly connected with the cooling device 20 . The drying system 3 includes a conveying roller 7 and an oven 8 erecte...

Embodiment 3

[0034] A kind of multifunctional printing positioning machine of the present embodiment, such as figure 1 , 4 As shown in , 5, a multi-color heat transfer positioning machine that adopts printing and composite heat transfer technology, including a printing machine 1, a feeding device 6, a composite heat transfer device 2, a drying system 3, a cooling device 20 and a winding device 4, wherein one side of the printing machine 1 is sequentially installed with a winding device 4, a composite hot-press transfer device 2 and a discharge device 6; the drying system 3 is erected on the printing machine 1, the winding device 4 and the The upper top of the composite thermal pressure transfer device 2 is fixedly connected with the printing machine 1 , the winding device 4 and the composite thermal pressure transfer device 2 respectively; the top of the winding device 4 is fixedly connected with the cooling device 20 . The drying system 3 includes a conveying roller 7 and an oven 8 erect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com