Aid for dyeing cotton textiles, preparation method and dyeing method thereof

A technology for cotton textiles and auxiliaries, which is applied in the field of cotton textile dyeing and cotton textile dyeing auxiliaries, can solve the problems of colored wastewater polluting the environment, low dyeing percentage, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

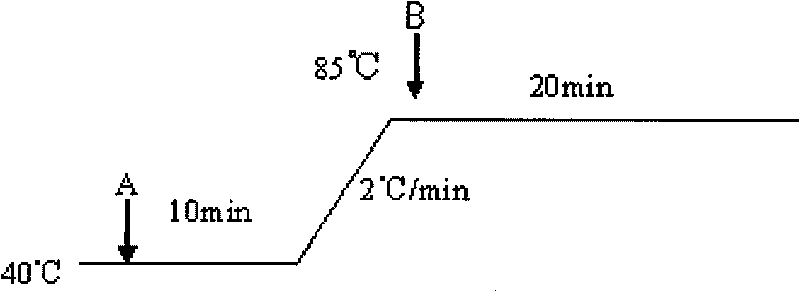

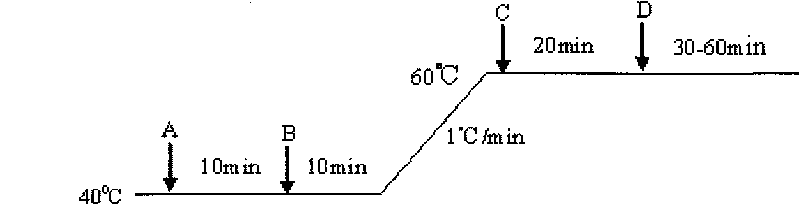

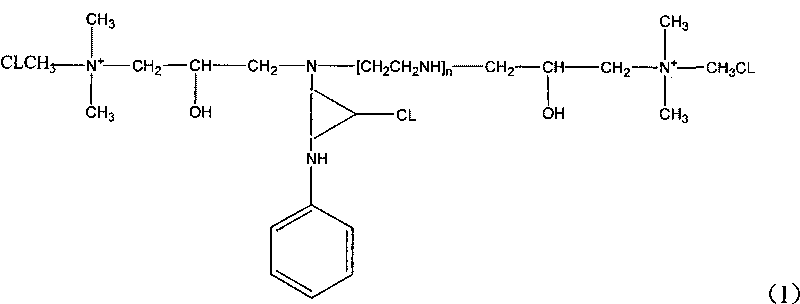

[0034] The present invention is used for the preparation method of the auxiliary agent of cotton textile dyeing, specifically implements according to the following steps:

[0035] Step 1: According to mass percentage, weigh 7.0%-8.0% of 3-chloro-2-hydroxypropyltrimethylammonium chloride, 1.0%-2.0% of sodium hydroxide, 1.0%-4.0% of polyamine, 3.0%-4.0% cyanuric chloride, 0%-2.0% aniline, 0.5%-1.0% sodium carbonate, 11%-12% deionized water a (room temperature), 4.0%-5.0% deionized Water b (room temperature), 65.5%-67.5% deionized water c (1°C-2°C), the total amount of the above-mentioned components is 100%, and the polyamines are selected from ethylenediamine, diethylenetriamine, tetra One of ethylene pentamine, polyethylene polyamine, etc. Sodium carbonate was dissolved in deionized water b to obtain an aqueous sodium carbonate solution.

[0036] Step 2: Under stirring conditions, add the deionized water a weighed in step 1 to the reaction kettle, and add the 3-chloro-2-hydro...

Embodiment 1

[0053] Step 1: Dissolve 18.8 kg of 3-chloro-2-hydroxypropyltrimethylammonium chloride and 4 kg of sodium hydroxide in 30 kg of deionized water, stir at 30°C for 30 minutes, and then add 3.05 kg of ethylene glycol amine, the temperature of the system was raised to 90°C under stirring conditions, and the temperature was kept for 4 hours; 9.2 kg of cyanuric chloride was added to the above system, and after dissolving, 177.75 kg of ice water with a temperature of 1°C-2°C was added to make the system temperature Keep it below 5°C, and as the process proceeds, slowly add 7 kg of sodium carbonate aqueous solution (made by dissolving 2.25 kg of sodium carbonate in 12.75 kg of deionized water) to adjust the pH value of the system to about 5.0; the pH value of the system is basically constant When it does not change, add 4.7 kg of aniline to keep the temperature of the system at about 40°C. As the reaction progresses, slowly add 8 kg of the above-mentioned sodium carbonate aqueous soluti...

Embodiment 2

[0070]Step 1: Dissolve 18.8 kg of 3-chloro-2-hydroxypropyltrimethylammonium chloride and 4 kg of sodium hydroxide in 30 kg of deionized water, stir at 30°C for 30 minutes, and then add 3.05 kg of ethylene glycol amine, the temperature of the system was raised to 90°C under stirring conditions, and the temperature was kept for 4 hours; 9.2 kg of cyanuric chloride was added to the above system, and after dissolving, 177.75 kg of ice water with a temperature of 1°C-2°C was added to make the system temperature Keep it below 5°C, and as the process proceeds, slowly add 7 kg of sodium carbonate aqueous solution (made by dissolving 2.25 kg of sodium carbonate in 12.75 kg of deionized water) to adjust the pH value of the system to about 5.0; the pH value of the system is basically constant When it does not change, add 4.7 kg of aniline to keep the temperature of the system at about 40°C. As the reaction progresses, slowly add 8 kg of the above-mentioned sodium carbonate aqueous solutio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com