Method for dyeing yarn containing cellulose fiber by reactive dye

A technology of cellulose fibers and reactive dyes, applied in the field of textile printing and dyeing, can solve the problems of lack of process methods, inability to dye dark colors, unstable quality, etc., achieve a wide range of dye selection, easy handling by operators, and simple baking methods Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

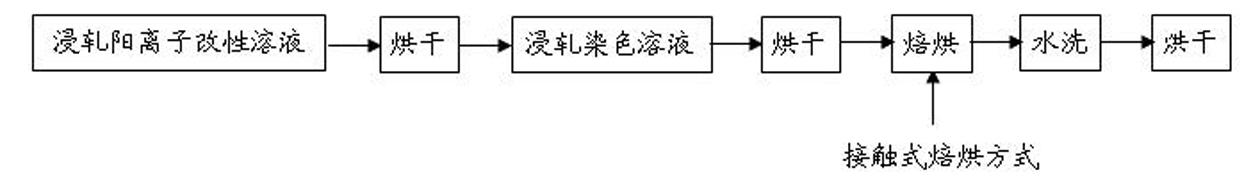

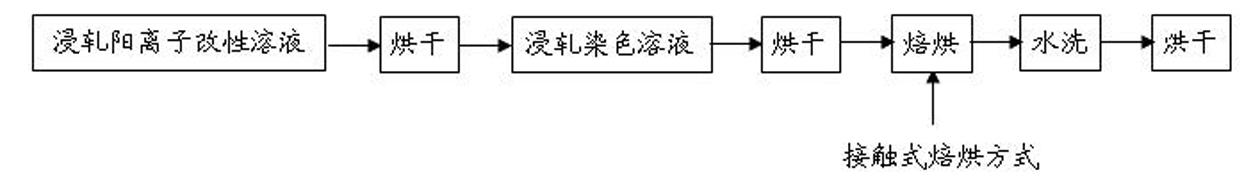

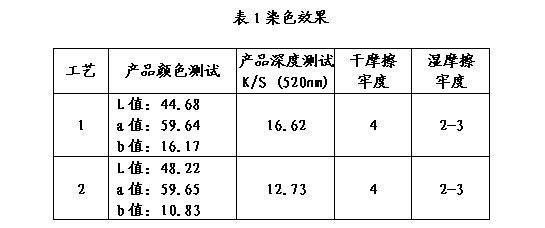

[0014] Below in conjunction with accompanying drawing, through specific embodiment——32 s The specific implementation process of the reactive dye continuous pad dyeing of 2 pure cotton dyed yarns is described further to the present invention. process such as figure 1 As shown, the main process conditions are as follows:

[0015] 1. Padding cationic modification solution. The raw cotton yarn that has been pre-scoured is dipped and rolled in a cationic modification solution. The composition of cationic modification solution is: cationic modifier CL-200 20g / L, caustic soda 20g / L, non-ionic penetrant AG-310 3g / L.

[0016] 2. Drying: Yarn is dried by steam drum.

[0017] 3. Padding dyeing solution: one dipping and one padding of the yarn with reactive dye dyeing solution. The composition of the dyeing solution is: reactive dye red P-2B 100% 20g / L.

[0018] 4. Drying: After the yarn is pre-dried by an infrared pre-drying device, it is dried by a steam dryer.

[0019] 5. Baking...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com