Active dye ink-jet printing ink and preparation method thereof

A technology of reactive dyes and inkjet printing, which is applied in dyeing, ink, textiles and papermaking, etc. It can solve the problems of damage to inkjet printing equipment, poor storage stability, and high energy consumption, and achieve high color fastness to washing and printing The effect of high pattern precision and pure and saturated color

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] The preparation of embodiment 1 blue reactive dye inkjet printing ink

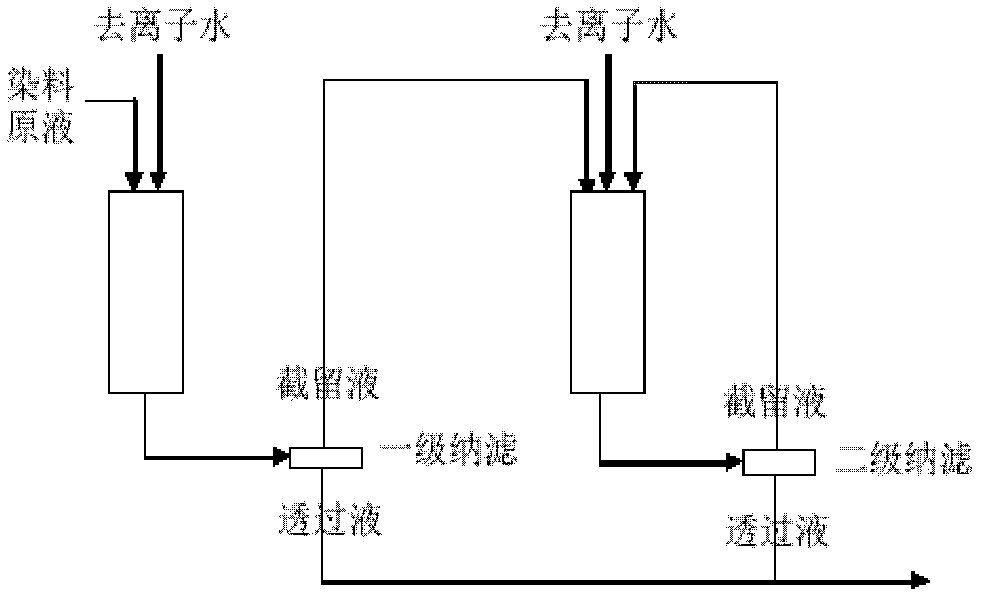

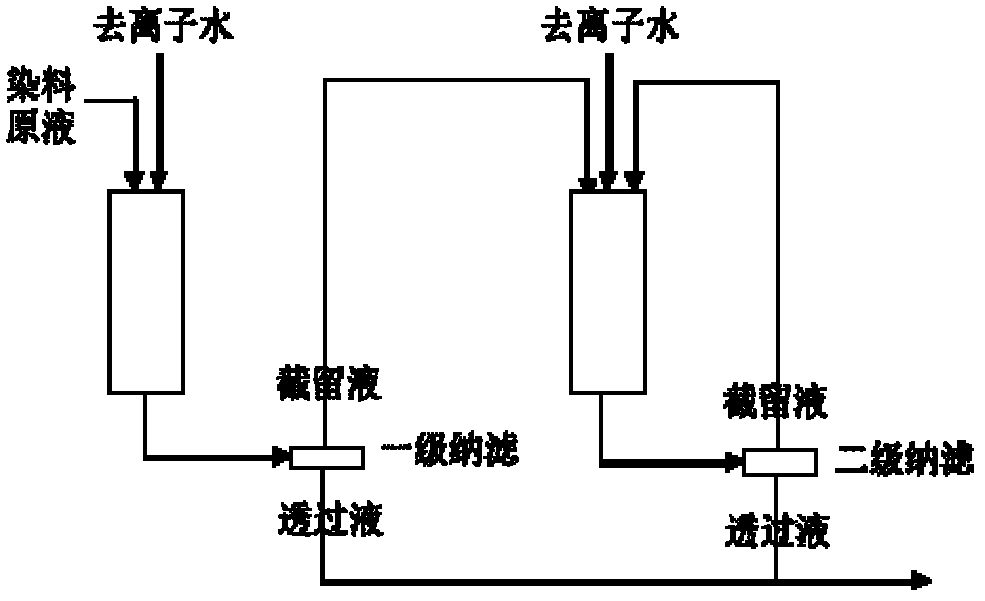

[0034] Purification of blue reactive dyes: First, dissolve C.I. Reactive Blue 13 in deionized water to prepare a dye stock solution, in which the dye concentration is 4%, and then pass through polypropylene with a pore size of 10 μm and 2.5 μm under a working pressure of 1.0 MPa. The hollow fiber microfiltration membrane performs two-stage coarse filtration to remove insoluble solid impurities in the dye stock solution. The dye stock solution after coarse filtration enters a self-made two-stage nanofiltration desalination device (see the schematic diagram in figure 1 ) purification, the nanofiltration pressure is 1.8Mpa. After cyclic desalination for 19 hours, the conductivity of the retentate was measured three times in a row, and the conductivity of the retentate was all lower than 40mS / cm. At this time, the nanofiltration was stopped, and the purified C.I. Reactive Blue 13 concentrate was obtain...

Embodiment 2

[0040] The preparation of embodiment 2 red reactive dye inkjet printing ink

[0041] Purification of red reactive dyes: First, dissolve C.I. Reactive Red 23 dye in deionized water to prepare a dye stock solution, in which the dye concentration is 3%, and then pass the dye stock solution under a working pressure of 1.0MPa, with pore sizes of 10 μm and 2.5 μm in sequence. The polypropylene hollow fiber microfiltration membrane is used for two-stage coarse filtration to remove insoluble impurities. The raw dye solution after coarse filtration is purified by a self-made two-stage nanofiltration desalination device, and the nanofiltration pressure is 1.2MPa. After circulating desalination for 15 hours, the conductivity of the retentate was tested three times in a row, and it was found that the conductivity was lower than 43mS / cm, and the nanofiltration was stopped to obtain the purified C.I. reactive red 23 dye concentrate, in which the reactive dye concentration was 27%.

[0042]...

Embodiment 3

[0047] The preparation of embodiment 3 yellow reactive dye inkjet printing inks

[0048] Purification of yellow reactive dyes: First, dissolve C.I. reactive yellow 81 dye in deionized water to prepare a dye stock solution, in which the dye concentration is 5%, and then pass the dye stock solution under a working pressure of 1.0MPa, with pore sizes of 10 μm and 2.5 μm in sequence. The polypropylene hollow fiber microfiltration membrane is used for two-stage coarse filtration. After coarse filtration, the dye stock solution was purified by a self-made two-stage nanofiltration desalination device. The nanofiltration pressure was 0.8 MPa, and the desalination cycle was performed for 20 hours. Then, the conductivity of the retentate was tested three times in a row, and the measured conductivity was all lower than 39mS / cm. Finally, nanofiltration is stopped to obtain pure C.I. reactive yellow 81 dye concentrate, wherein the reactive dye concentration is 30%.

[0049] Preparation of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

| Surface tension | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com