Reactive dye ultra-short rapid dyeing and fixation technology method

A reactive dye and rapid dyeing technology, which is applied in the fields of dyeing, textiles and papermaking, can solve the problems of not being able to summarize optimization and improvement well, and achieve the effect of shortening the auxiliary time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0056] Example 1 Dyeing cotton knit fabric with ultra-short fast dyeing and fixation technology with reactive dyes

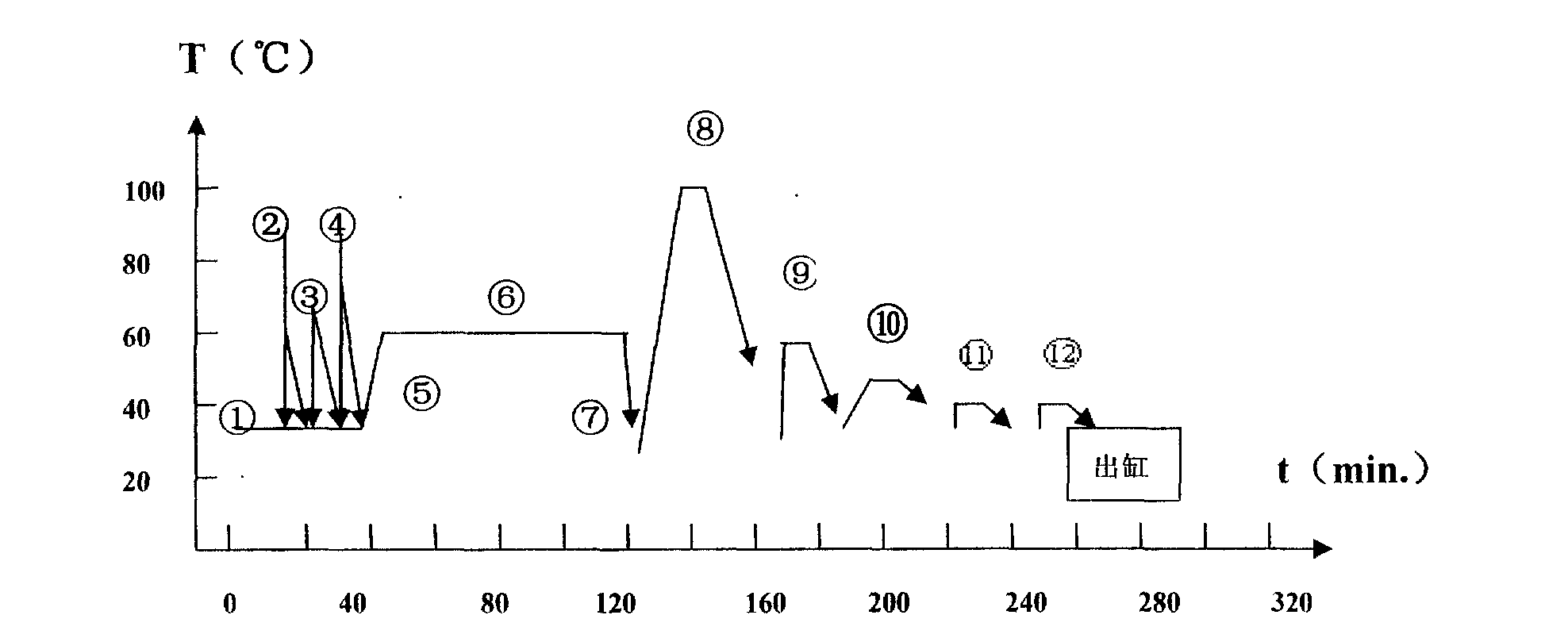

[0057] In an old-fashioned Taiwan Heyi four-window U-shaped cylinder, there are 305Kg pre-treated small circular knitting machines 32 S Knitted cotton jersey ready to be dyed a bright red. The number of pieces is: gray cloth / auxiliary material: 24 / 7; a certain dye 150% SF-3B red 33.15g / kg, 150% SF-3R yellow 17.96g / kg, yuanming powder 600g / kg, (180Kg in total) ), Accelerator: 37.5g / kg (11.5Kg in total). Now with reference to claim 2.1 method and description attached figure 1 The technical process, the specific operation is:

[0058] Add cold water to the vat, the bath ratio is about 10; turn on the main pump and other normal operations; the dye is melted in a small bucket in advance and then poured into the chemical vat, the return water is appropriate, and the steam is heated to an appropriate temperature until the dye is completely dissolved. Add it to the ...

example 2

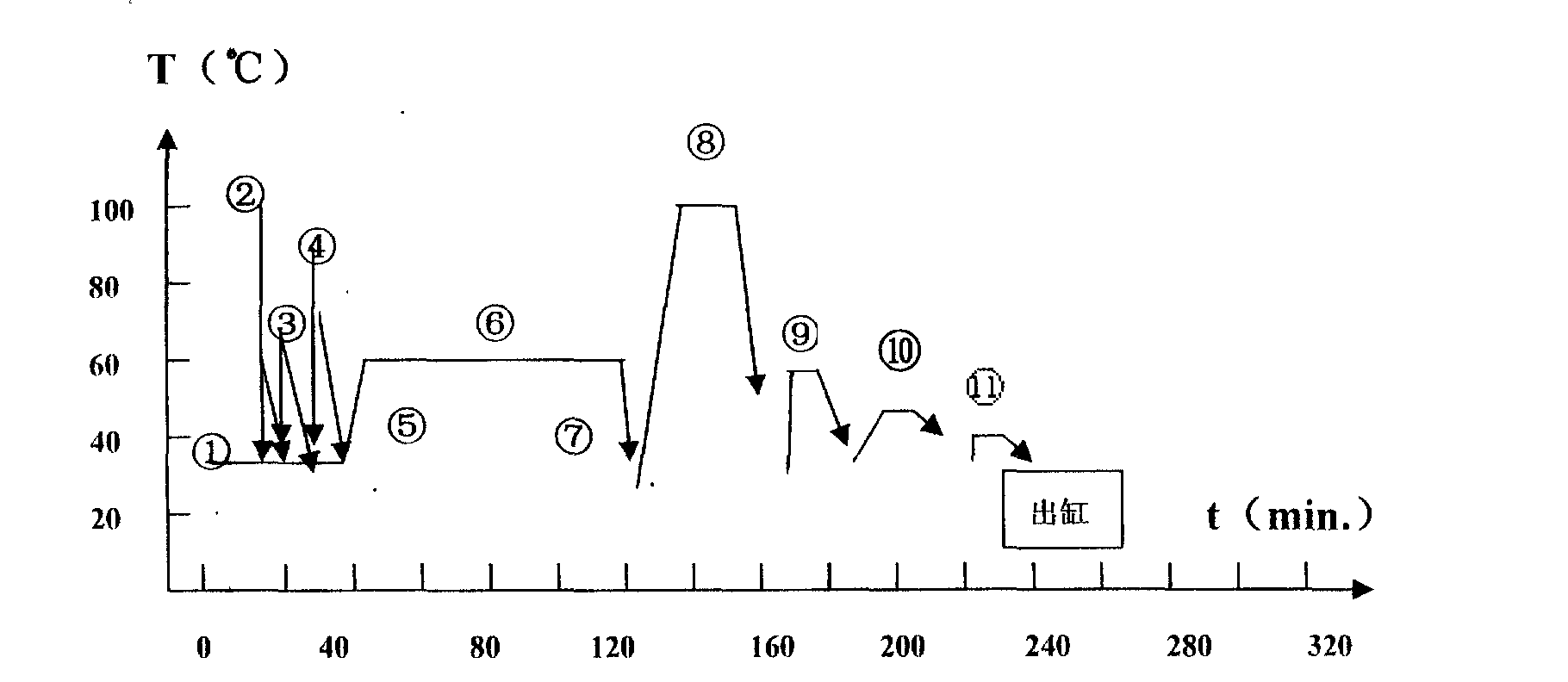

[0059] Example 2 Dyeing cotton jersey with reactive dye pretreatment / dyeing one-bath method ultra-short fast dyeing fixation process technology

[0060] Completely follow the materials, feeding and operation steps and procedures of Example 1, but the dyed object is replaced by the same specification rough cloth without any pretreatment; the amount of red and yellow dyes is properly adjusted, and the amount is reduced; Self-made one-bath auxiliaries containing appropriate amount of pectinase, protease, amylase, other related enzymes, related coenzymes, surface or additives, stabilizers, functional additives, etc.; when adding softener in post-treatment, reduce the amount appropriately. The obtained result is the same as Example 1, but the hand feeling is softer and fuller; there is no obvious cottonseed hull trace. The saving situation is more than 30 tons of water than example 1, more than 1.5 tons of steam, more than 150 degrees of electricity, and time saving of 2 to 3 hours...

example 3

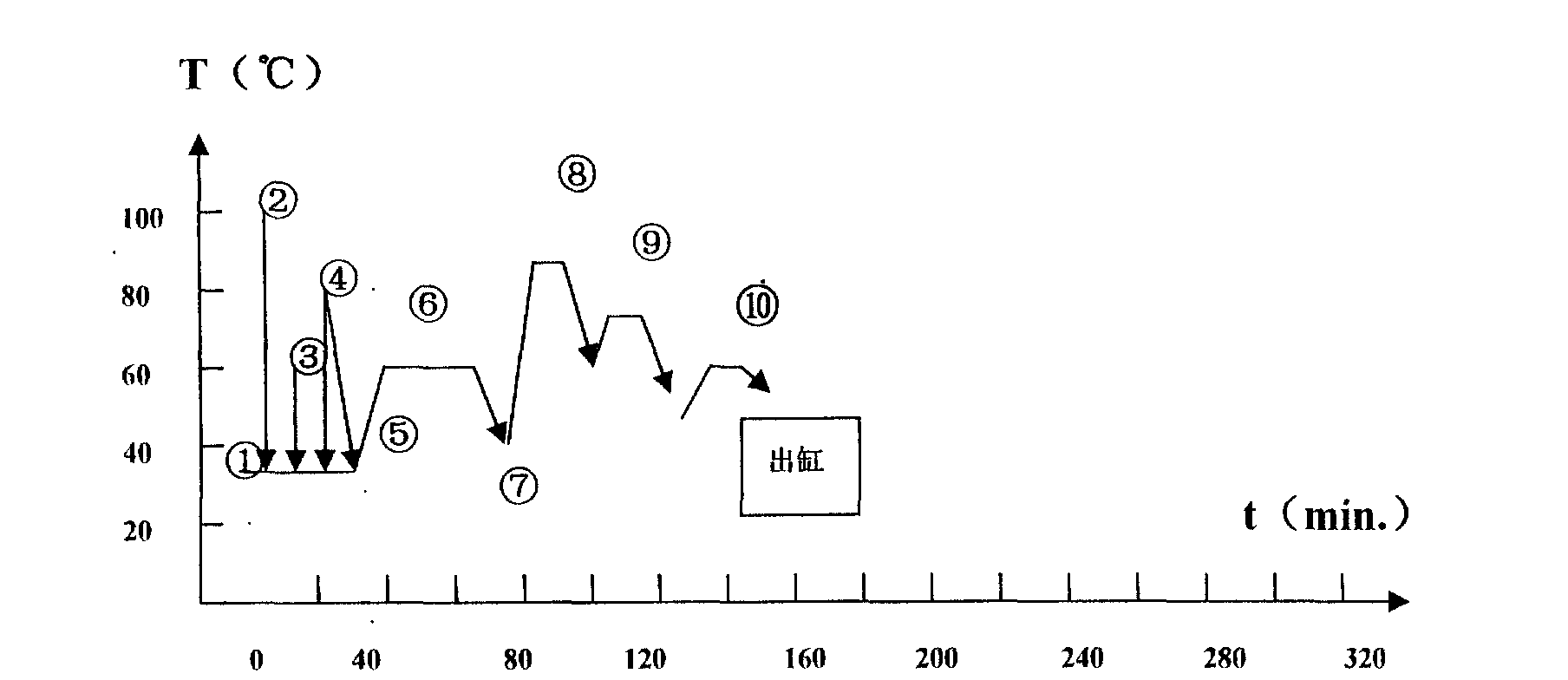

[0061] Example 3 Dye cotton knit rib jersey with reactive dye pretreatment / dyeing / enzyme polishing one-bath method ultra-short fast dyeing and fixation process technology

[0062] Completely follow the materials, feeding and operation steps and procedures of Example 1, but the dyed object is replaced by a certain specification rib blank cloth without any pretreatment; the amount of red and yellow dyes is properly adjusted, and the amount is reduced; Self-made one-bath additives containing appropriate amount of pectinase, protease, amylase, certain type of cellulase, other related enzymes, coenzymes, surface or property agents, stabilizers, functional additives, etc.; , reduce the amount appropriately. The obtained result is the same as Example 1; the cloth surface has better luster and softer hand feeling; there is no obvious cottonseed husk trace. It takes less than 5 and a half hours; the energy saving and emission reduction is greater than that of Example 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com