Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

69results about How to "Maintain tensile strength" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Paper tissue having enhanced softness

InactiveUS6344111B1Increase softnessMaintain tensile strengthNon-fibrous pulp additionNatural cellulose pulp/paperFiberUltimate tensile strength

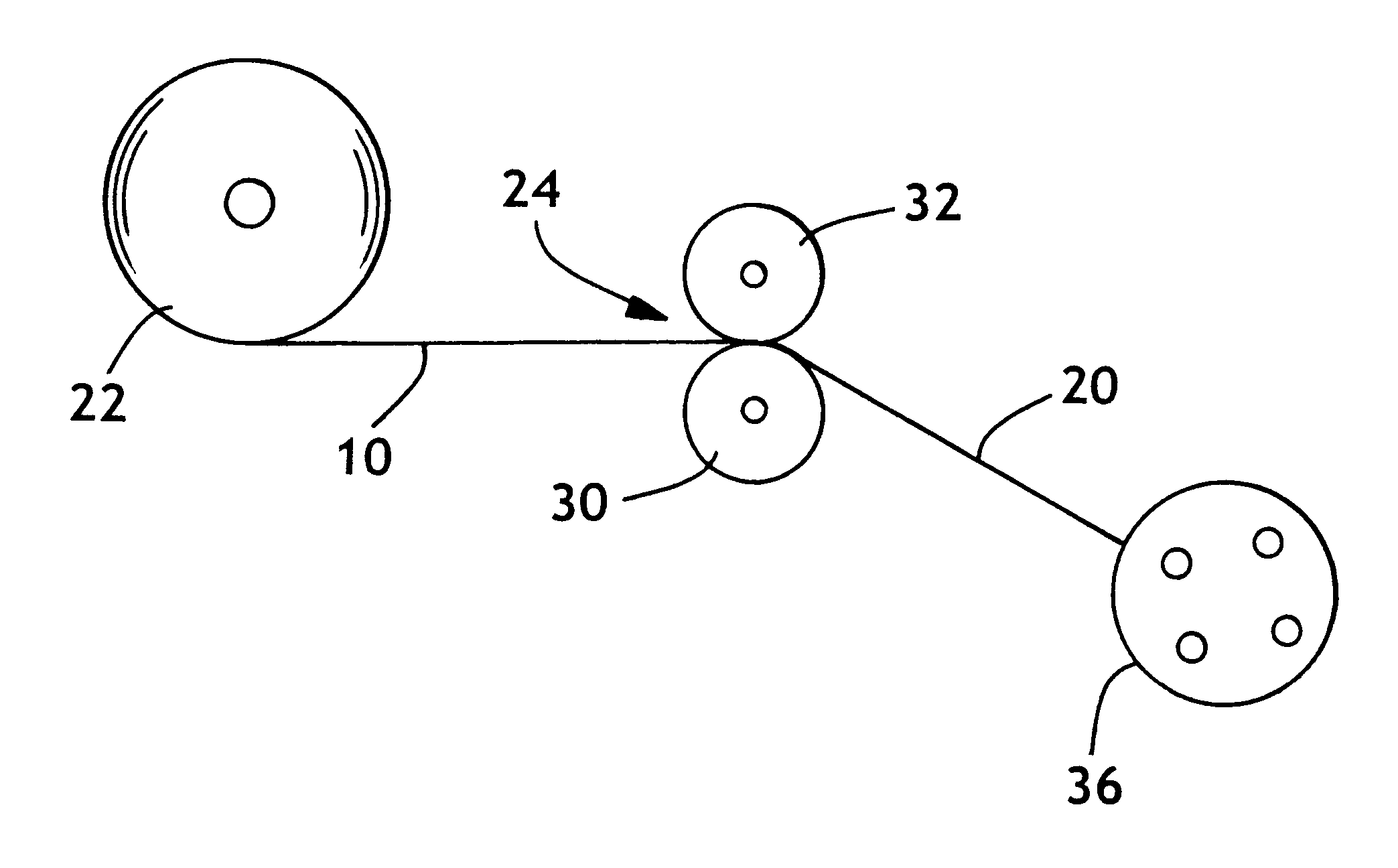

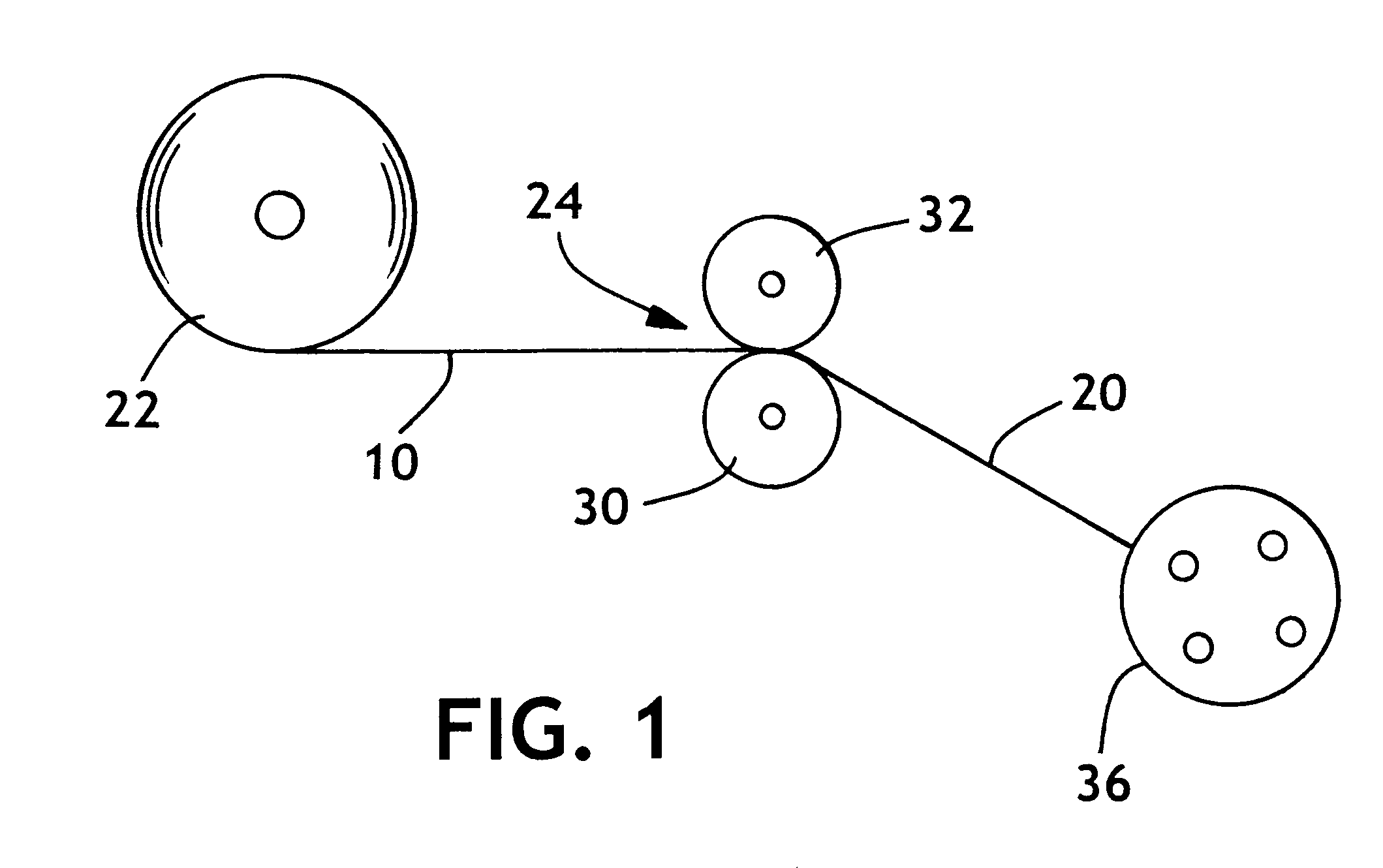

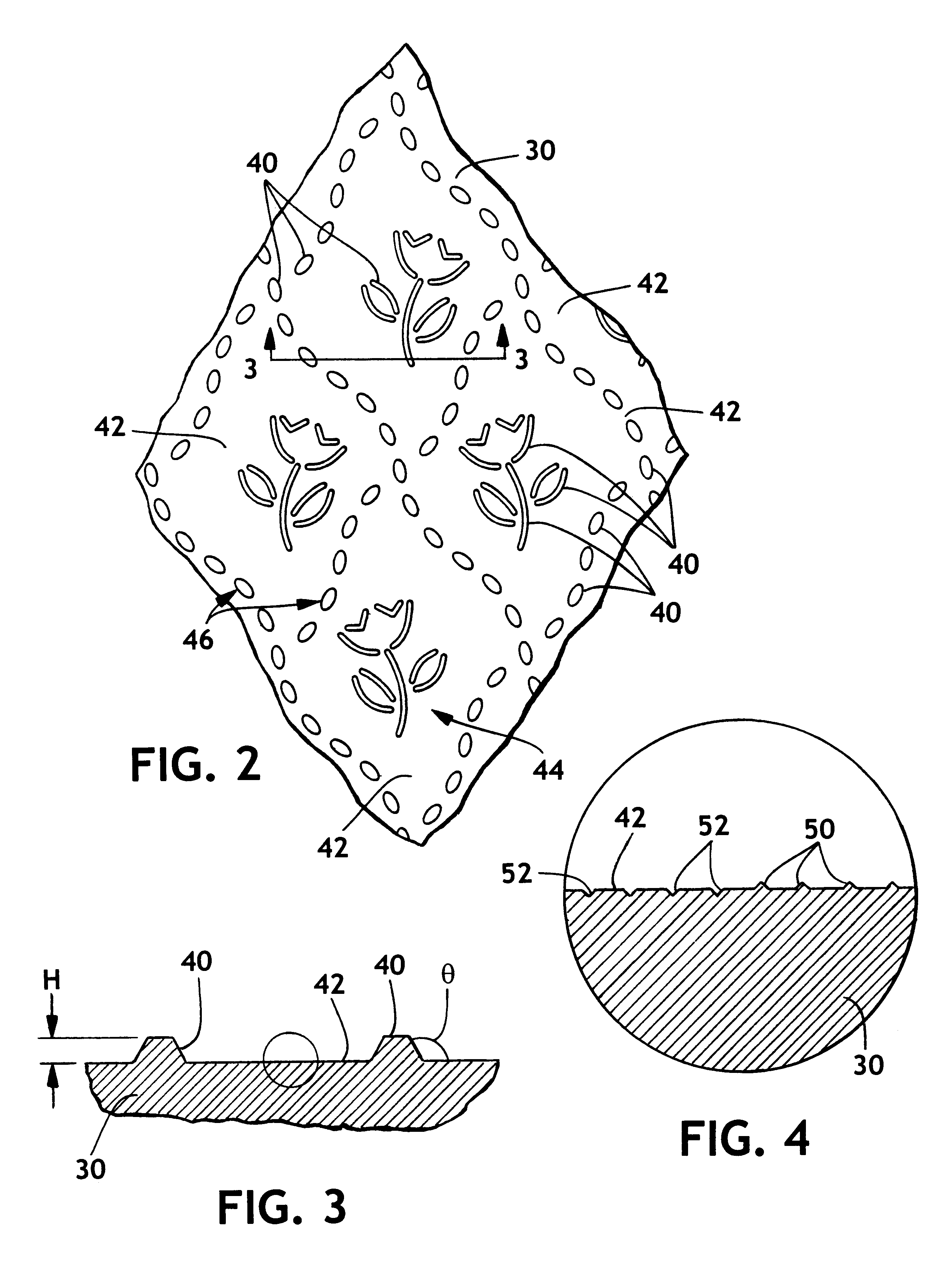

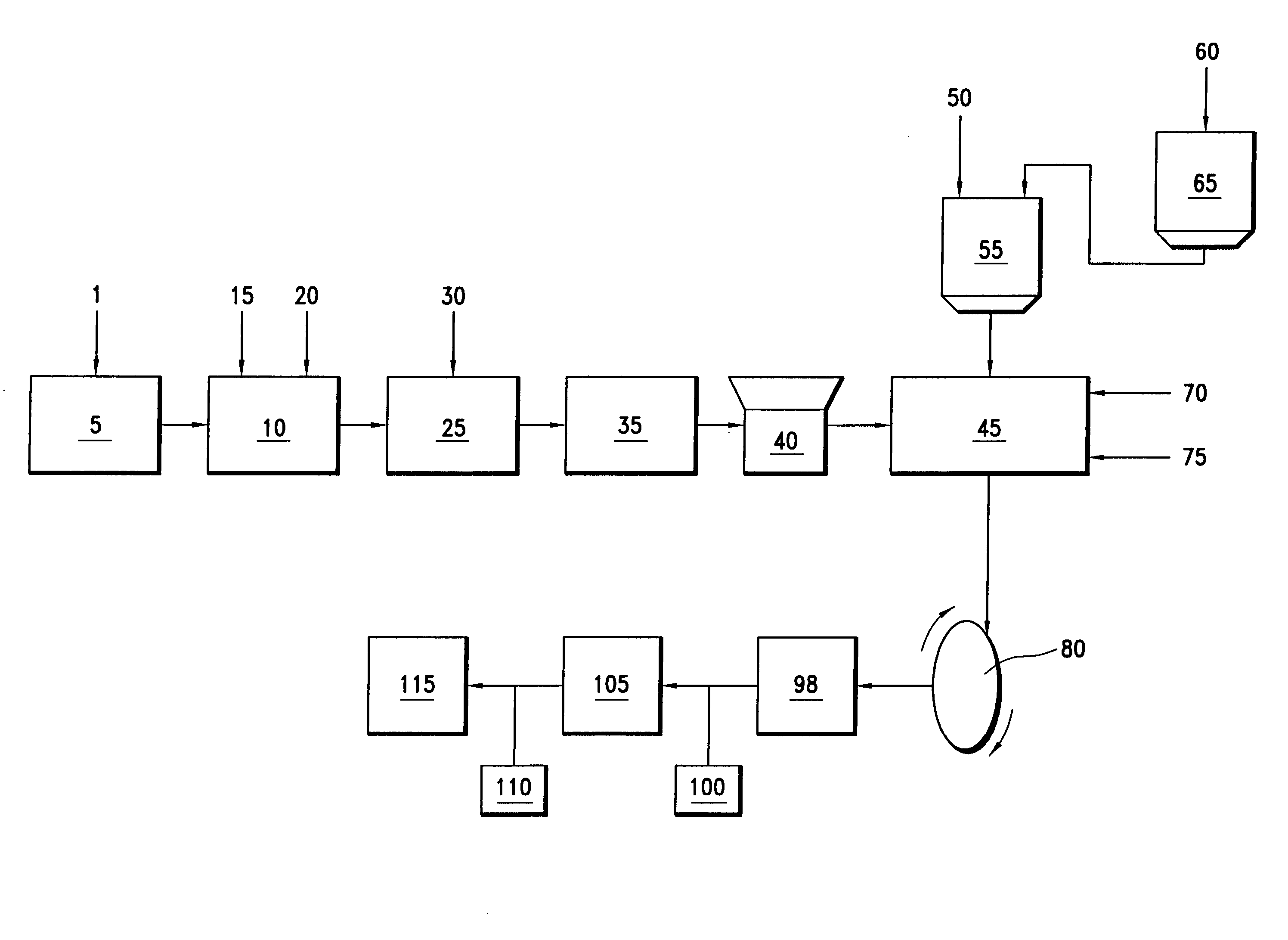

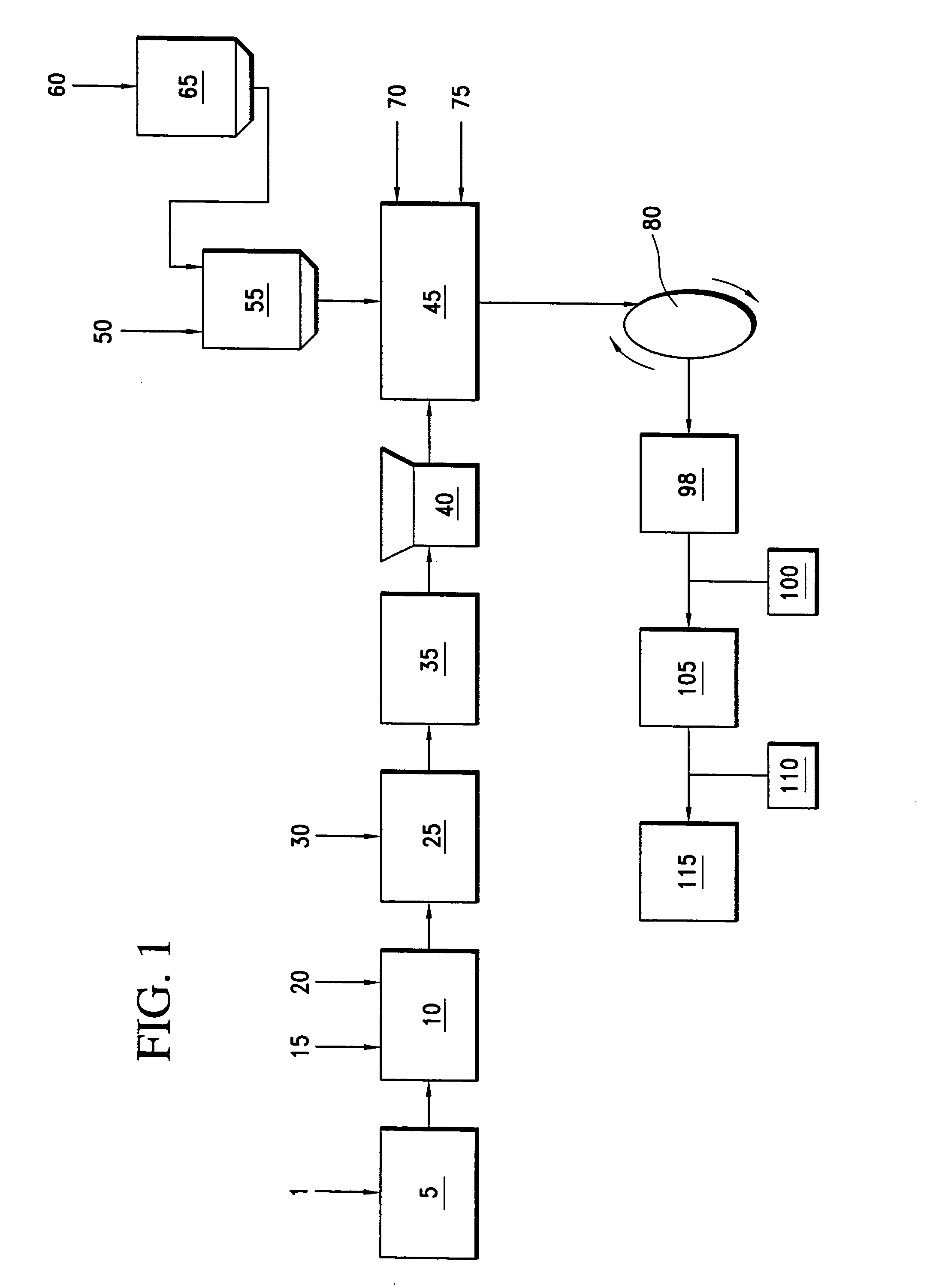

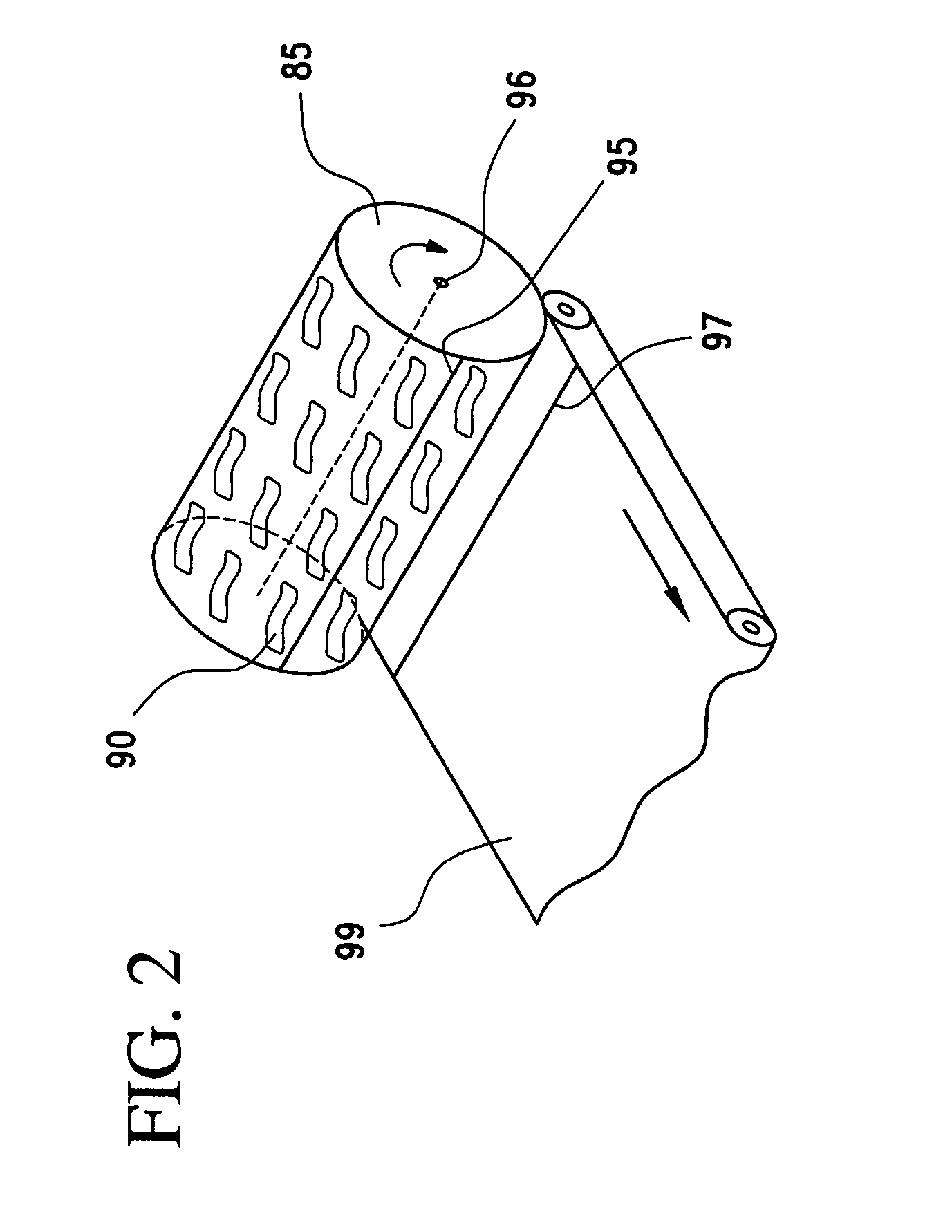

A novel paper article, a method of making a paper product, and an embossing roll are disclosed for providing a paper surface region having a minority of fiber to fiber bonds broken in the paper surface region to a depth less than about 0.02 mm from the paper surface. In one aspect, the roughened embossing roll includes protuberances or depressions sized at less than about 0.1 mm. In one aspect, the roughened embossing roll includes protuberances or depressions adapted to produce paper product surface deformations in the paper surface, wherein the paper product surface deformations are invisible to an unaided human eye. The present invention provides a paper product having higher perceived softness while maintaining tensile strength.

Owner:KIMBERLY-CLARK WORLDWIDE INC

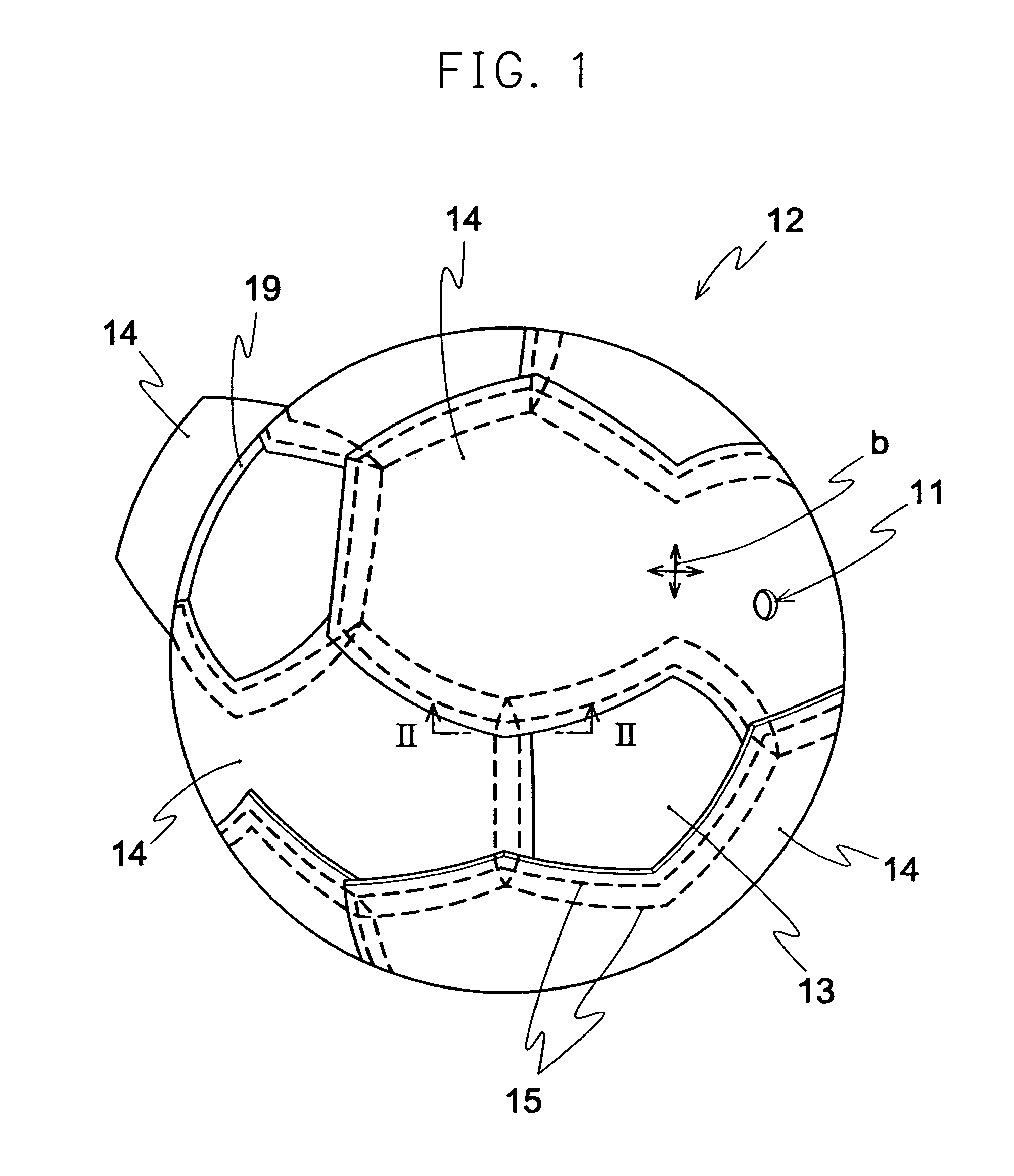

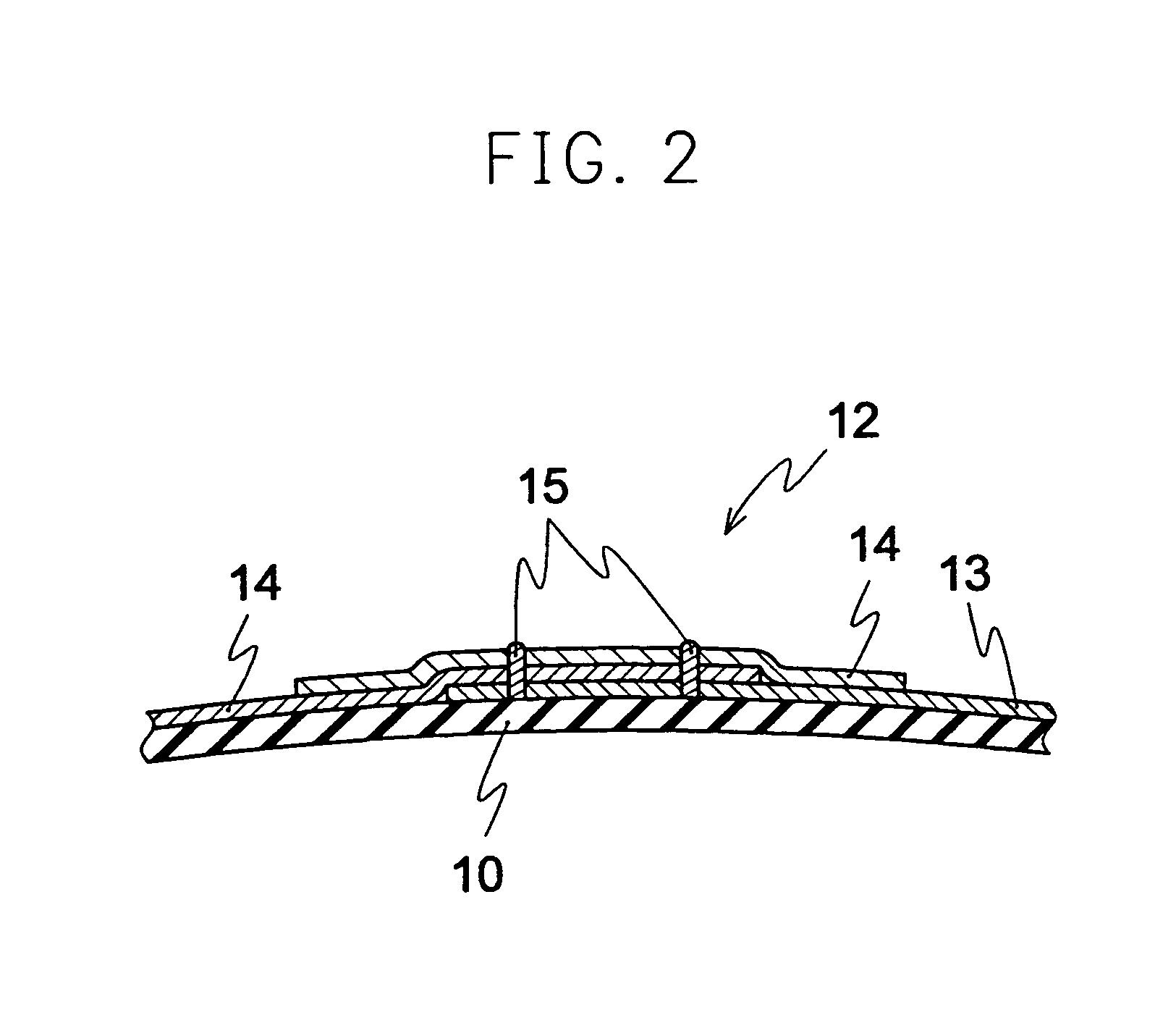

Ball for ball game and method for manufacturing the same

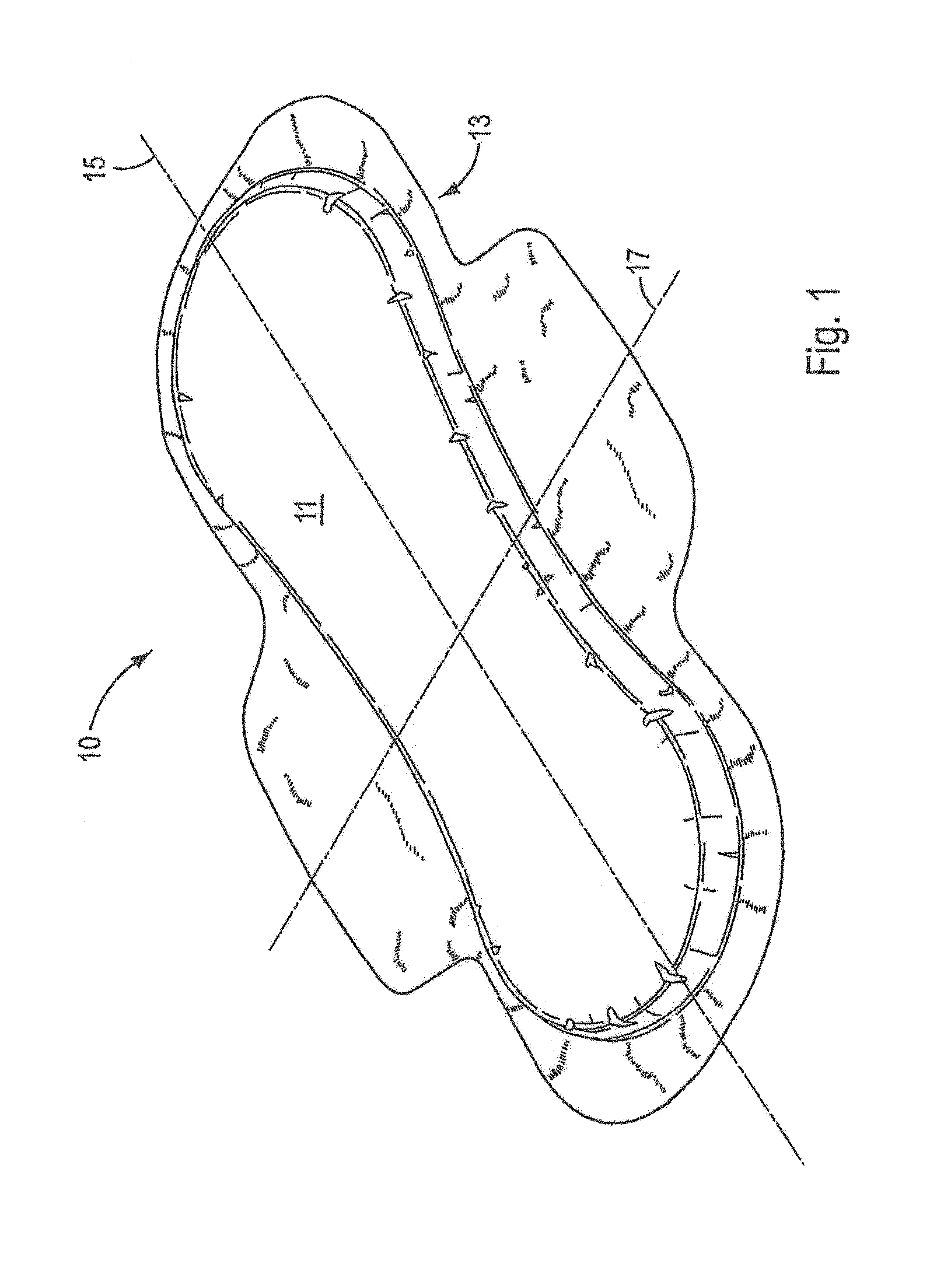

InactiveUS6971965B1Increase the number ofMaintain tensile strengthHollow inflatable ballsHollow non-inflatable ballsBall gameSpherical shaped

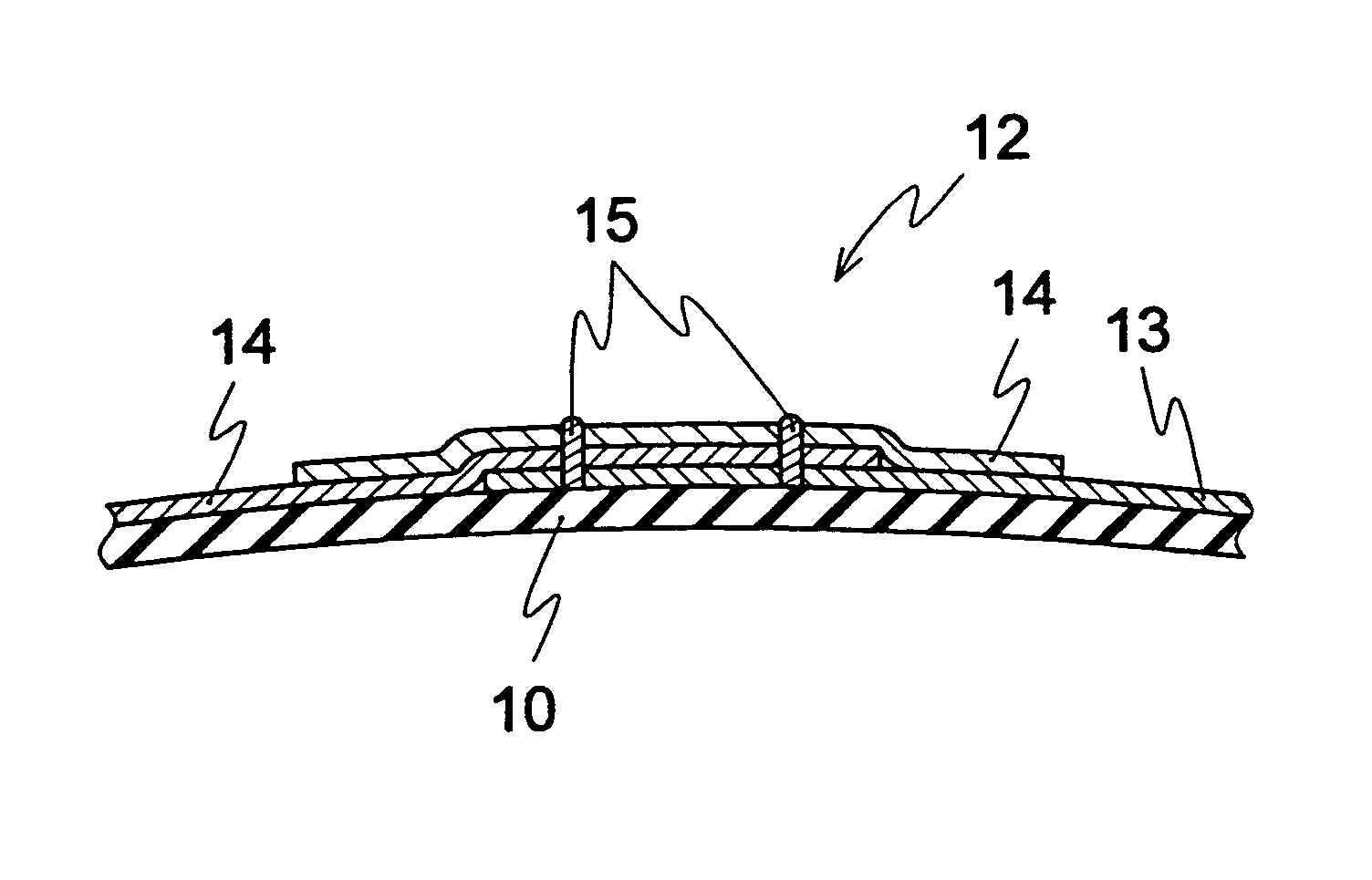

To provide a ball for ball game and a method for manufacturing the ball having superior sphericity, an ability to retain its original shape, durability, and soft feel. The fabric layer (12) is formed by sewing with a sewing machine for instance pentagonal first fabric pieces (13) together with composite shaped second fabric pieces (14) in which two hexagons are connected with each other, so that a spherical shape is formed. The marginal edge of the first and second fabric pieces are superimposed in the spherical surface direction, so that corner portions thereof are temporarily attached. Temporary attachment is achieved by inserting the needle into the needle through hole formed in the corner of the first and second fabric pieces, and welding by means of ultra sonic wave, such that the first and second fabric pieces (13, 14) are accurately aligned. The temporarily attached fabric pieces sewn together using a sewing machine along the guiding line (17) for sewing printed beforehand on the surface of the fabric pieces (13, 14).

Owner:MOLTEN CORPORATION +1

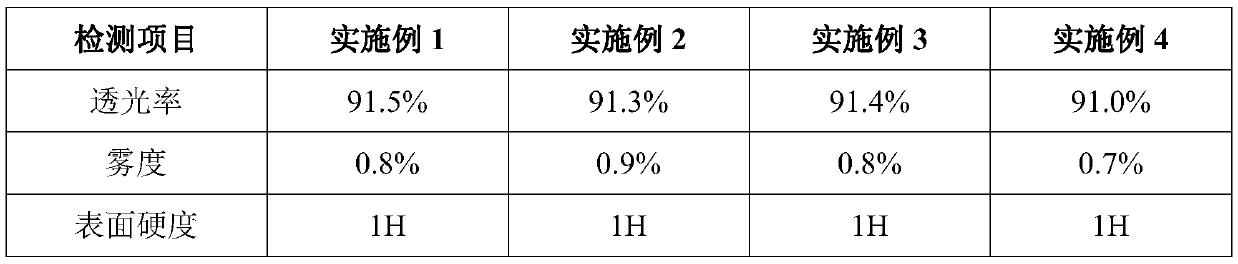

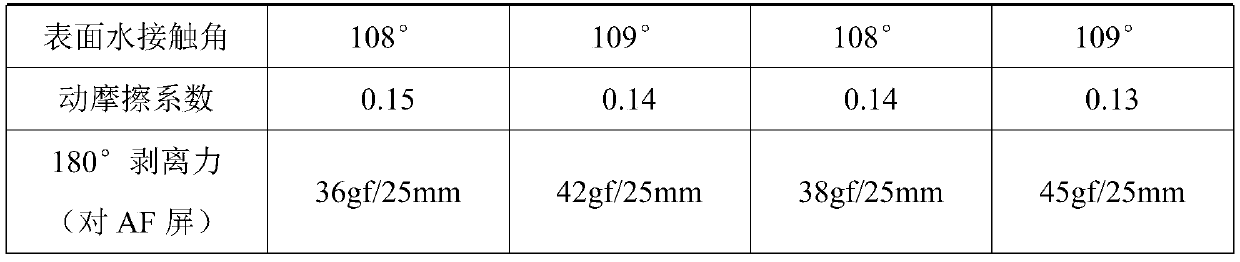

Anti-fingerprint TPU protective film for 3D curved screen and preparation method of anti-fingerprint TPU protective film

PendingCN111484810AGood optical performanceImprove smoothnessNon-macromolecular adhesive additivesMacromolecular adhesive additivesPolyesterColloidal silica

The invention discloses an anti-fingerprint TPU protective film for a 3D curved screen. The protective film comprises a low-viscosity protective film, an anti-fingerprint UV hardening coating, an optical hard TPU resin film layer, an optical-grade high-viscosity silica gel pressure-sensitive adhesive layer and a fluorine element release film which are attached from top to bottom; the anti-fingerprint UV hardening coating is formed by coating an anti-fingerprint UV hardening coating; the optical hard TPU resin film layer is formed by coating optical hard TPU glue, the optical-grade high-viscosity silica gel pressure-sensitive adhesive layer is formed by coating an optical-grade high-viscosity silica gel pressure-sensitive adhesive; the anti-fingerprint UV hardening coating is prepared fromthe following components: UV prepolymer resin, an acrylate reactive diluent, a photoinitiator, a slipping aid and a first solvent, the optical-grade hard TPU glue is formed by polymerizing polyisocyanate, polyester polyol and a chain extender in a second solvent under the action of a first catalyst; the optical-grade high-viscosity silica gel pressure-sensitive adhesive is composed of silica gel resin, a cross-linking agent, an anchoring agent and a second catalyst. The anti-fingerprint TPU protective film for a 3D curved screen has the properties of fingerprint resistance, scratch resistance,difficulty in bursting and good fitting property of the curved screen.

Owner:GUANGDONG BANGGU FILM COATING INNOVATION ACAD CO LTD

Meat-containing, strip-shaped food product and method of making same

ActiveUS7282235B2Good strength and integrityReduce breakageAnimal feeding stuffMeat processingWater activityAdditive ingredient

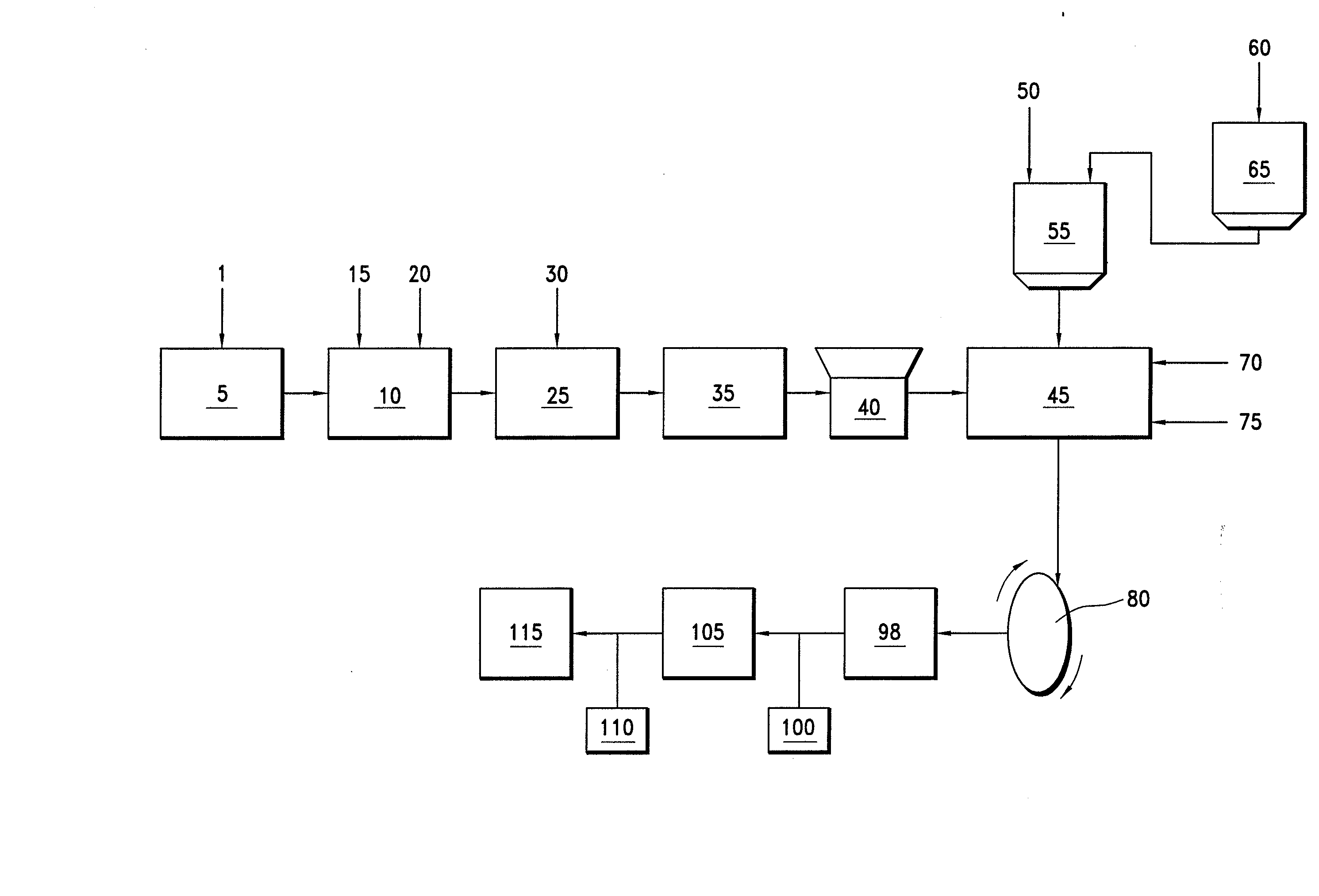

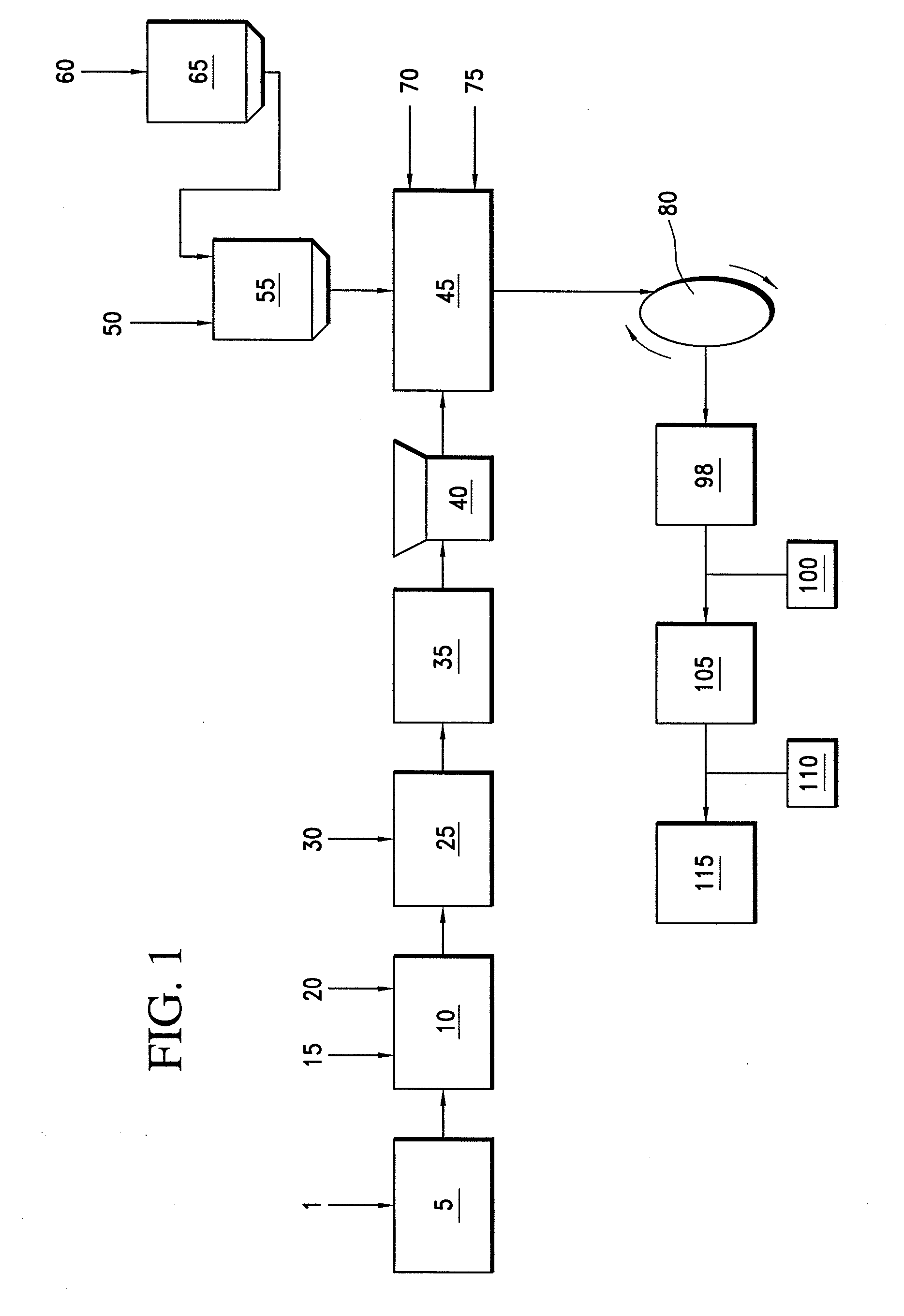

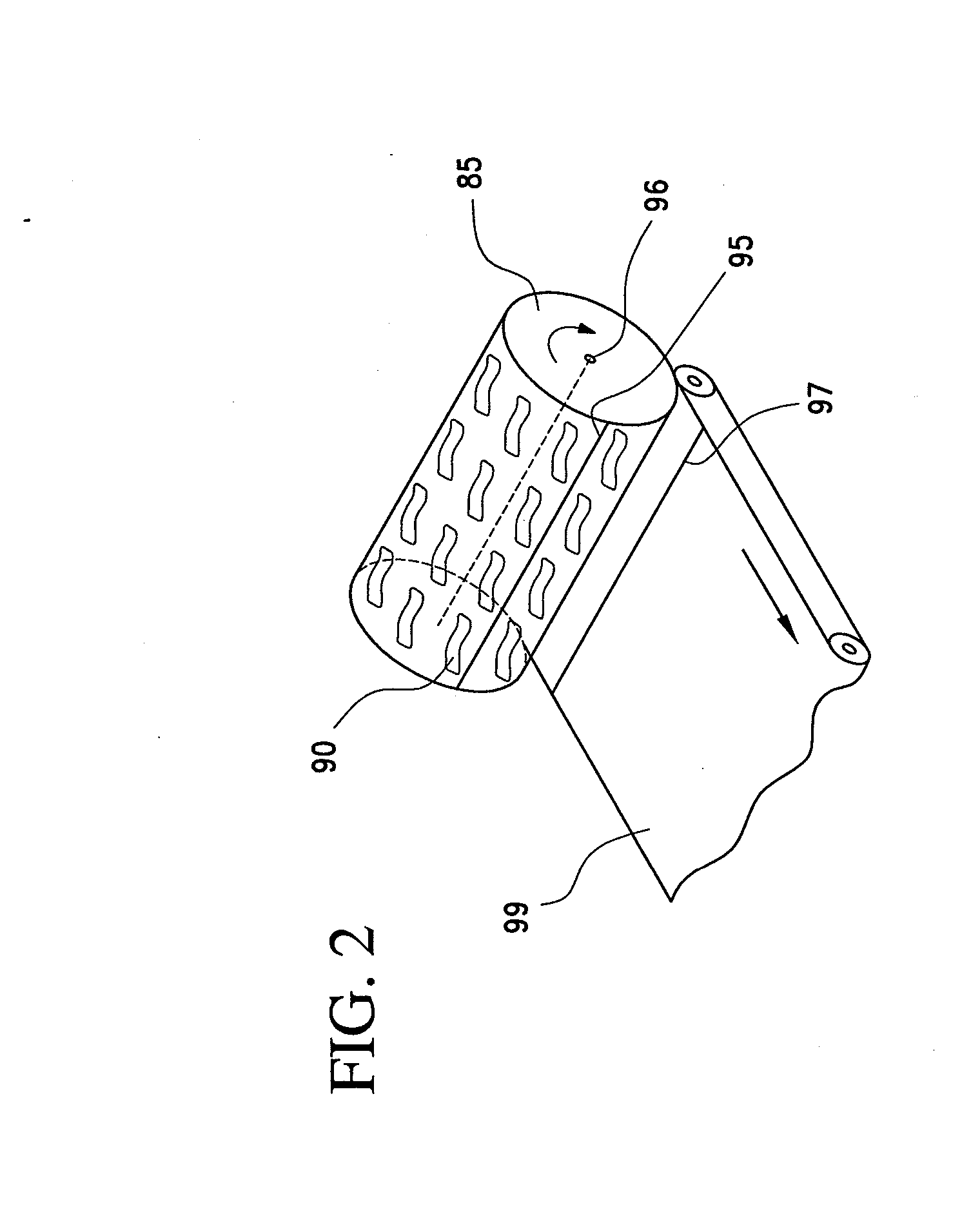

A flexible, strip-shaped food product is made by comminuting substantially frozen meat and heating the comminuted meat to at least partially denature the meat proteins and cooling the cooked meat. About 4% by weight to about 45% by weight of wheat flour is admixed with the cooked meat, along with other ingredients, to form a dough. Use of the wheat flour unexpectedly increases tensile strength of the dough and products baked from the dough, and maintains flexibility of the strip-shaped food products over an extended period of time. Cooking of the meat in the presence of salt unexpectedly increases water activity of the pieces, resulting in a product that has a skin and a moist middle, while maintaining tensile strength. The dough is rotary-molded into strip-shaped pieces. The rotary mold may have angled die cups. The strip-shaped dough pieces are then baked and dried.

Owner:BIG HEART PET INC

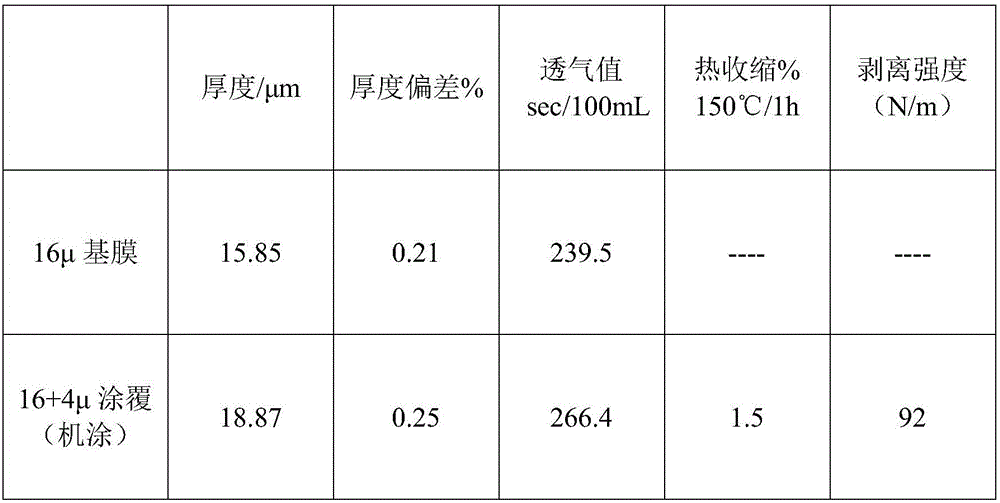

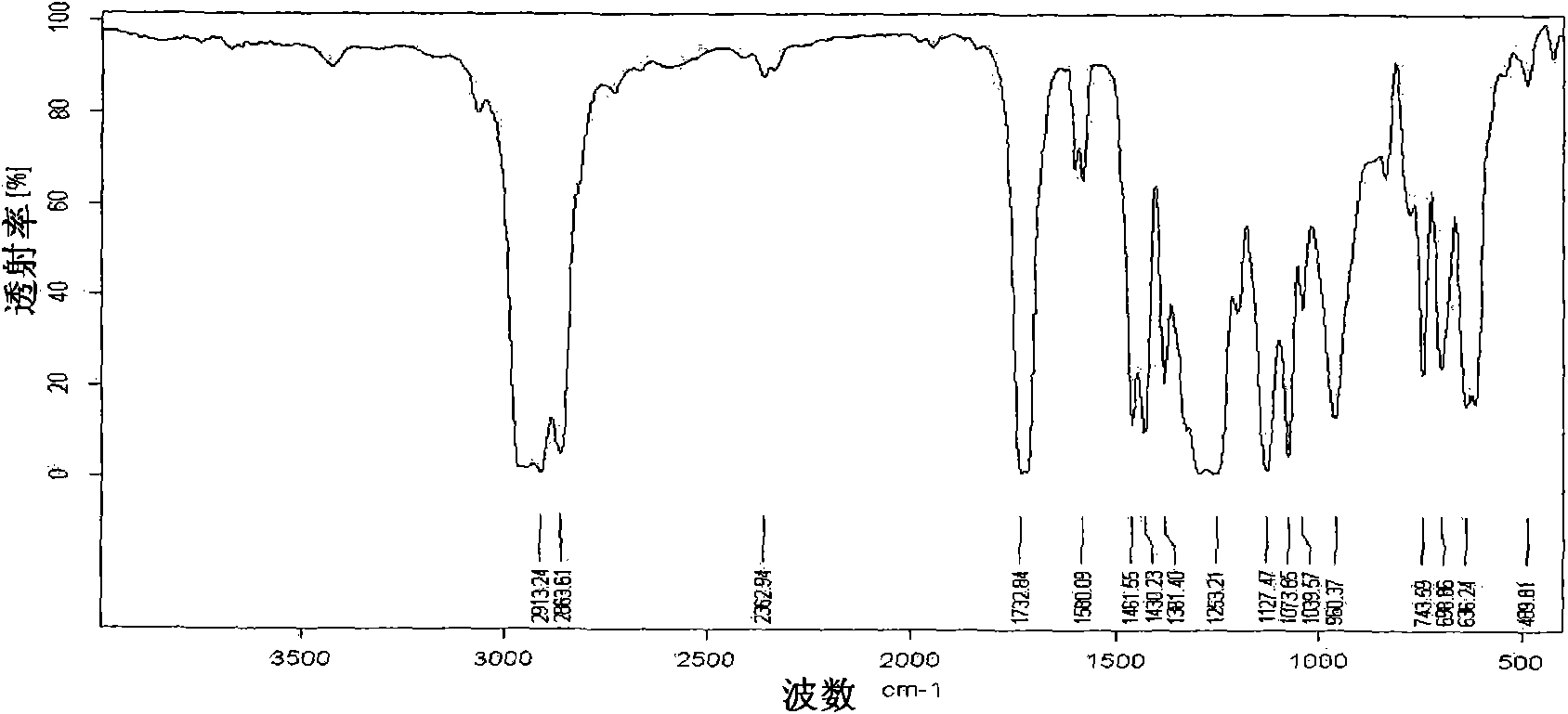

Adhesive for lithium ion battery ceramic diaphragm and preparation method of adhesive

ActiveCN105778834ASmall particle sizeHigh bonding strengthEster polymer adhesivesPolymer scienceAdhesive

The invention relates to an adhesive for a lithium ion battery ceramic diaphragm and a preparation method of the adhesive. The preparation method includes: adopting a method of emulsion polymerization; mixing acrylic acid type soft monomer and hard monomer in a specific proportion through dispersing effect of a compound emulsifier to form stable latex bundle; under action of an initiator, enabling polymerization monomer to be polymerized in the latex bundle to form a stable polymer emulsion. Through formed copolymer, the adhesive has high wettability and initial adhesion, and certain hardness and tensile strength are maintained, so that the adhesive has excellent binding strength, low coating viscosity and high mechanical strength. In addition, the adhesive emulsion has excellent performance in dispersing ceramic particles, the preparation method is simple and environment-friendly, and requirements on heat resistance of a base material are lowered greatly.

Owner:BLUE OCEAN & BLACK STONE TECH CO LTD FUJIAN

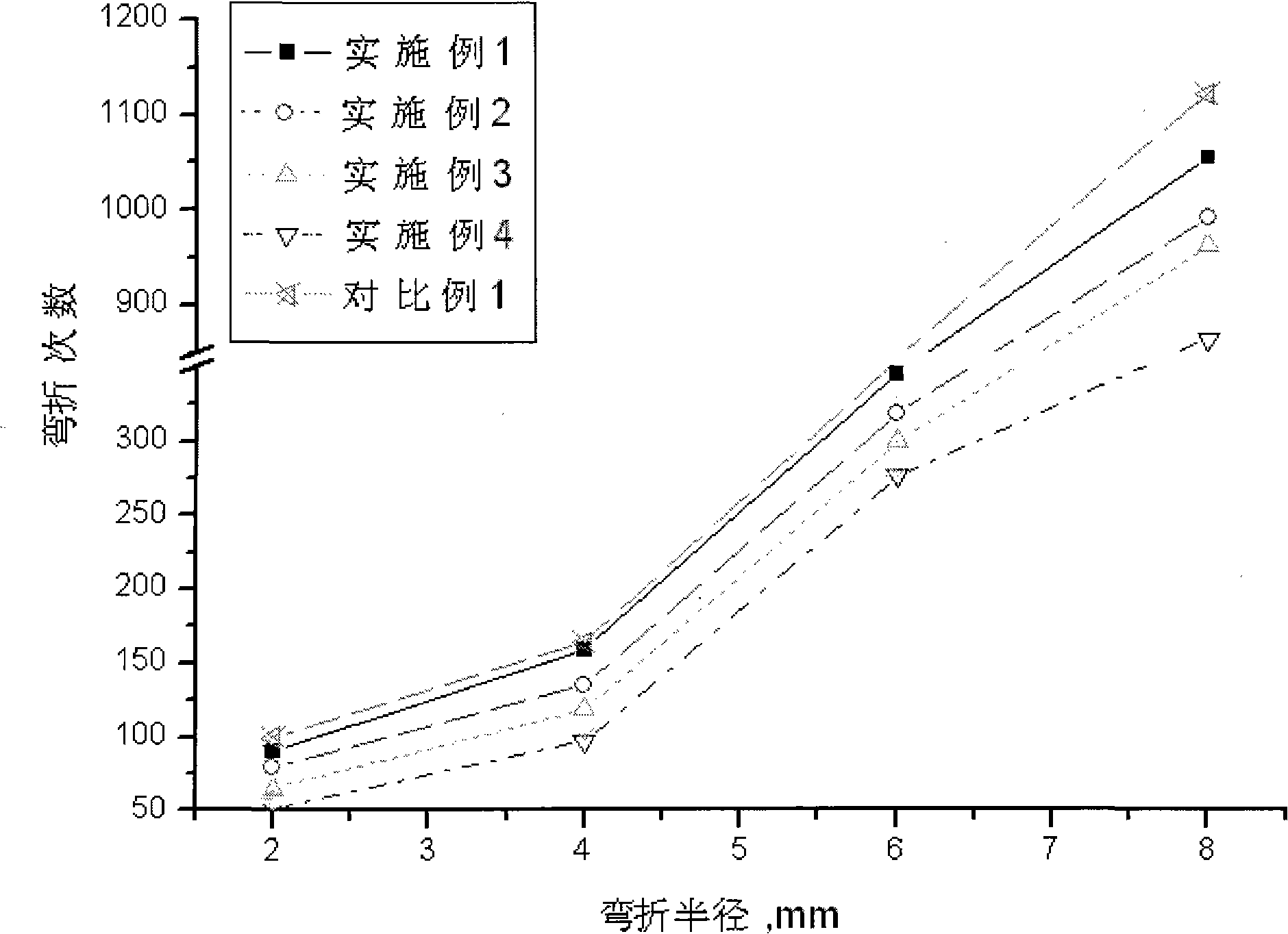

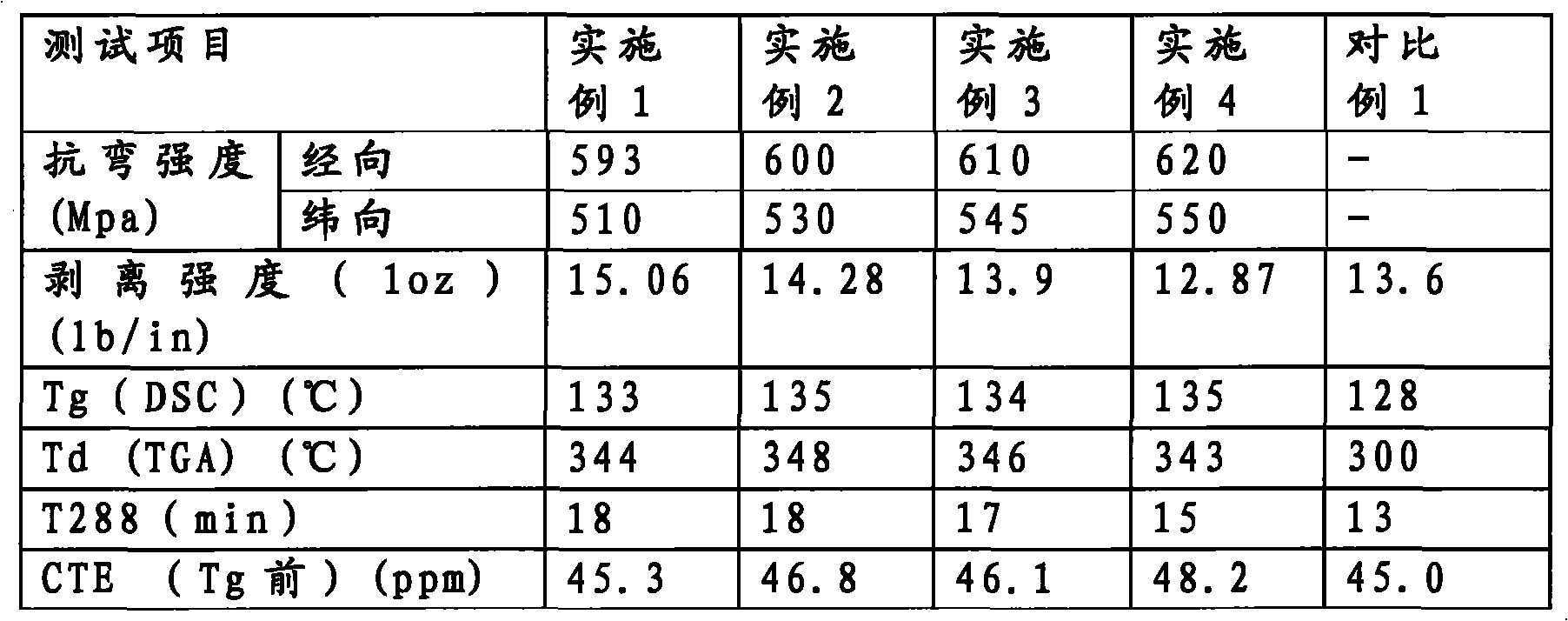

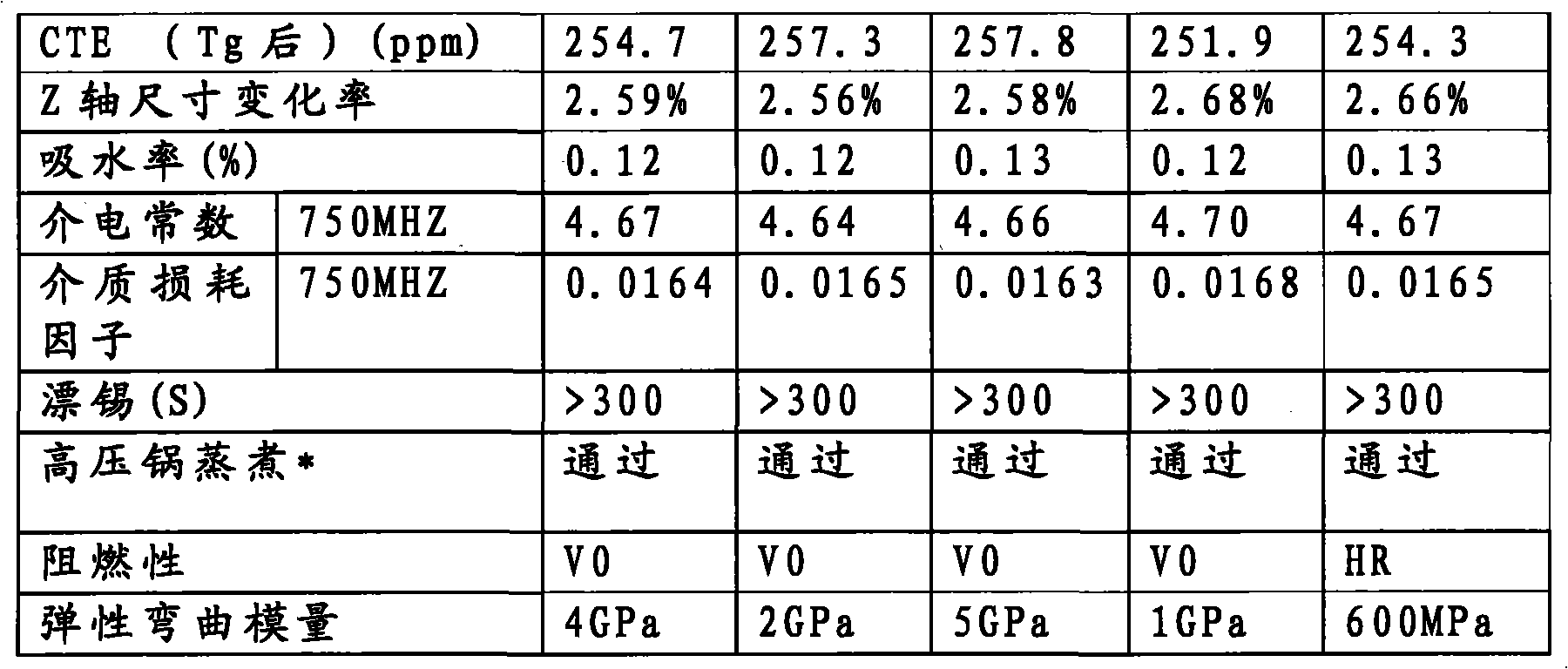

Manufacturing method of copper-clad plate and glue solution for copper-clad plate

ActiveCN101808466AFlexibleReduce manufacturing costPrinted circuit manufactureEpoxy resin adhesivesEpoxyGlass fiber

The invention relates to a manufacturing method of a copper-clad plate and glue solution for the copper-clad plate. The manufacturing method takes glass cloth as base cloth and successively comprises the steps of preparing glue solution, sizing base cloth and hot forming. The glue solution comprises 100 parts of epoxy resin, 10-40 parts of organic fire retardant, 1-30 parts of curing agent, 0.005-0.05 part of curing accelerator and 10-50 parts of dissolvent, wherein the epoxy resin is composed of 25-75 wt% of nitrile rubber modified epoxy resin and 25-75 wt% of bromination epoxy resin, and the content of nitrile rubber in the nitrile rubber epoxy resin is 30-60%. The invention provides a 'semi-soft plate' with medium elasticity bending modulus. The semi-soft plate has certain flexibility, has the supporting performance provided by a rigid copper-clad plate, is especially suitable for electronic connection devices without very high flexibility requirements and has the advantages of low manufacturing cost and convenient installation and connection.

Owner:VENTEC ELECTRONICS SUZHOU

Absorbent laminate with multiple substrates

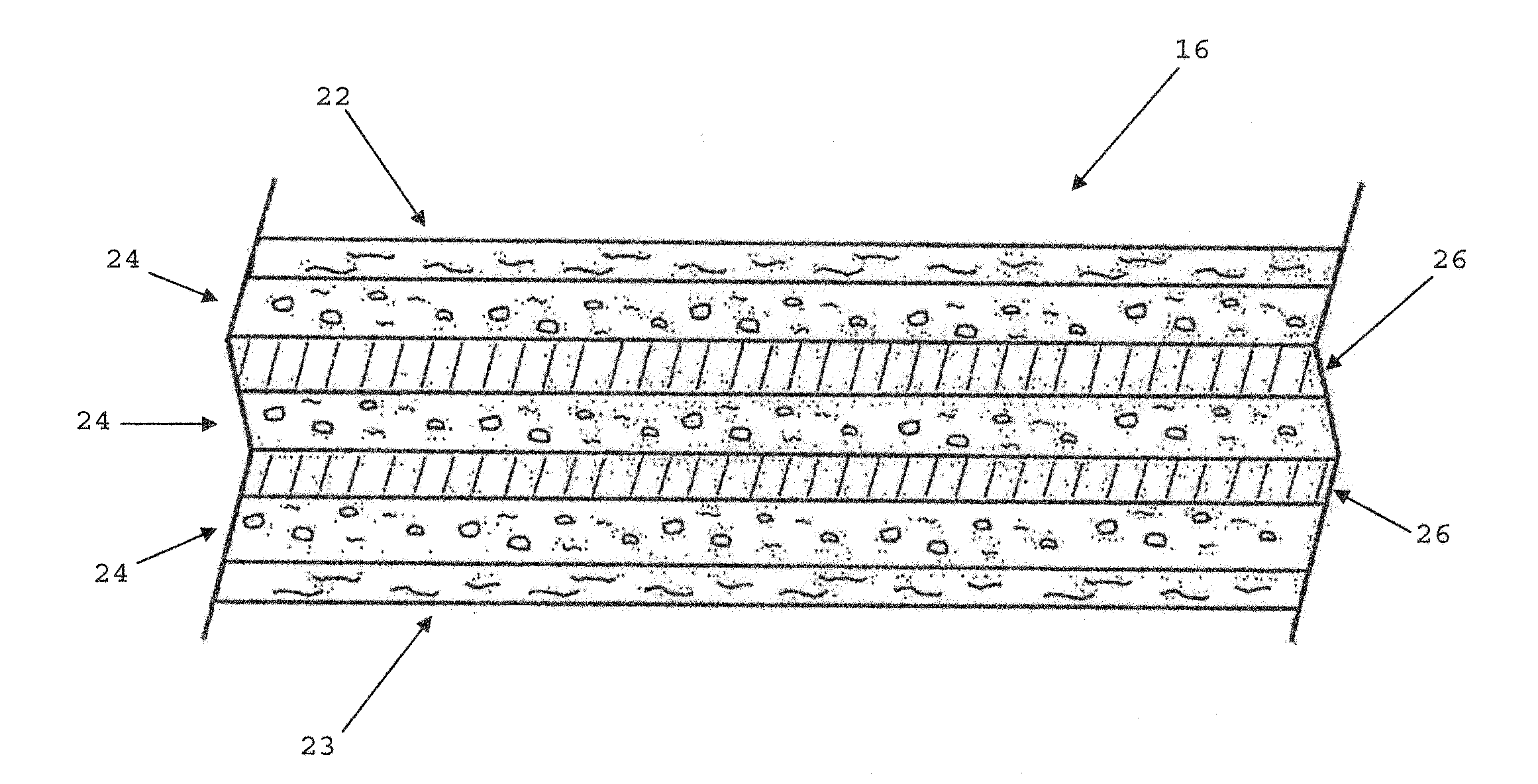

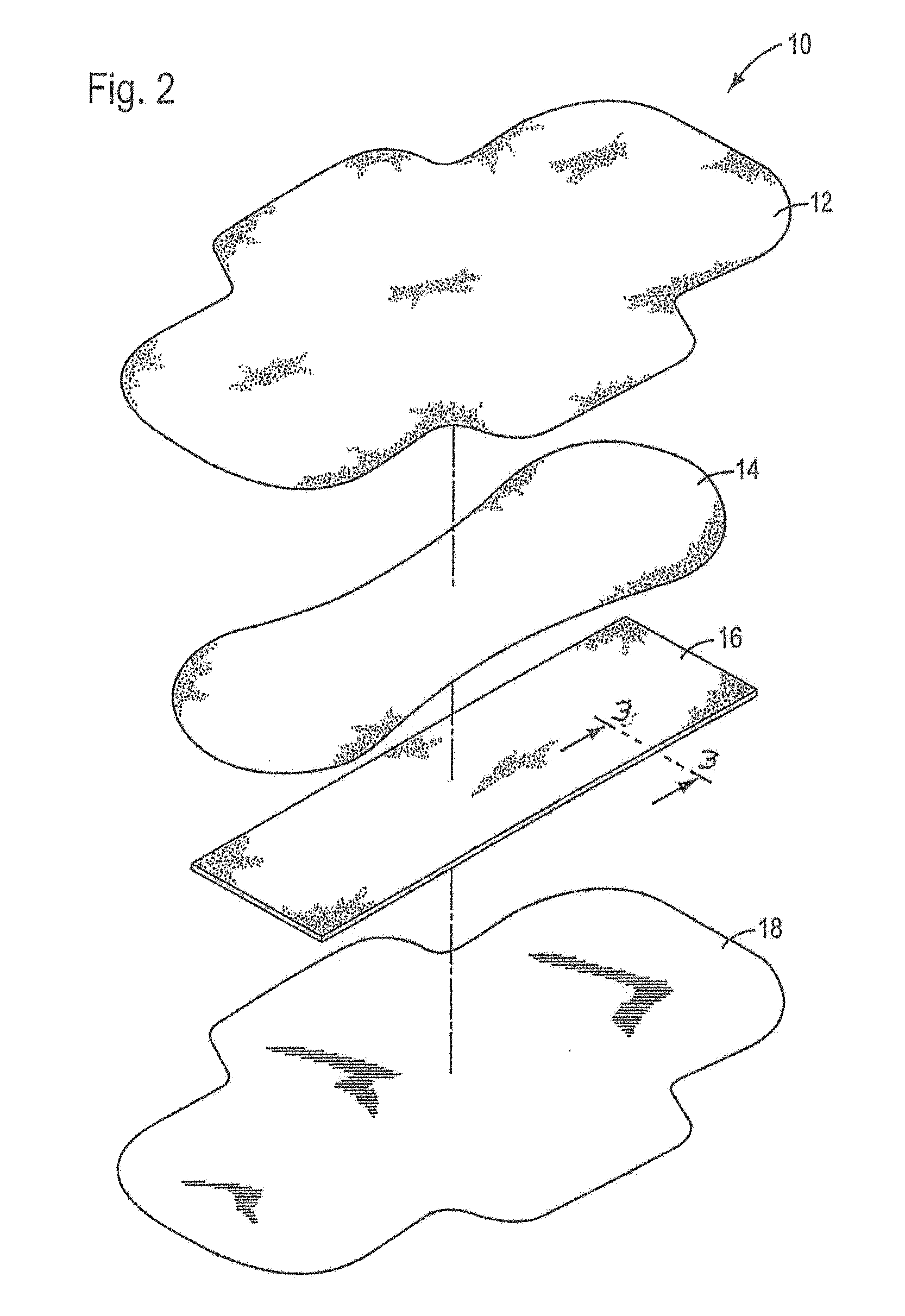

ActiveUS20160220427A1High tensile strengthWeak in tensileSpecial paperAbsorbent padsParticulatesAdhesive

The present invention relates to an absorbent laminate structure, and disposable absorbent article incorporating the structure, wherein first and second absorbent matrices comprising particulate superabsorbent polymeric material and filamentary adhesive are arranged between two outer substrate layers. The relatively porous, intermediate or central substrate layer, positioned between the absorbent matrices, promotes liquid transport within the laminate structure.

Owner:EAM

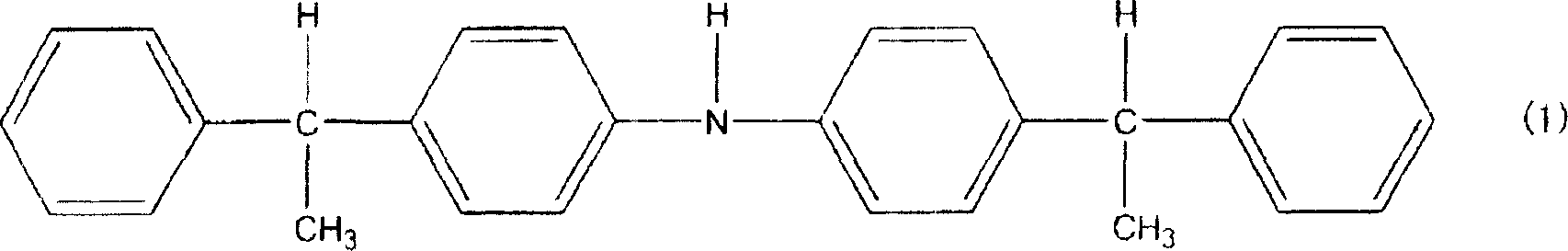

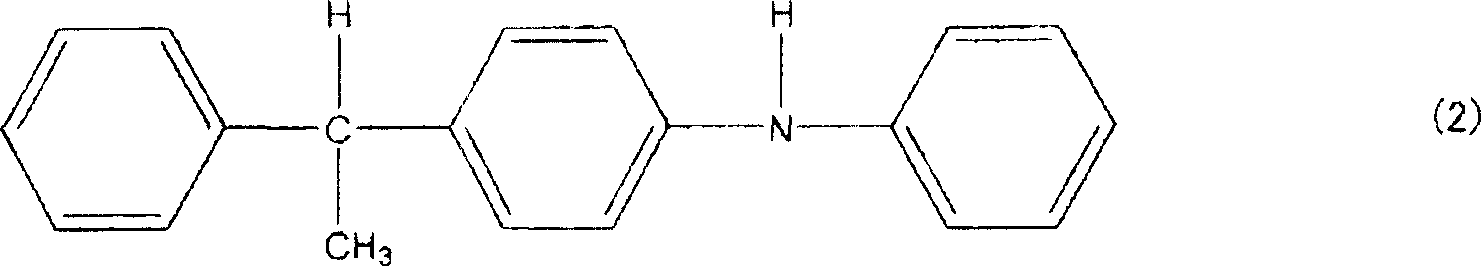

Acrylic rubber composition and acrylic rubber crosslinked product

It is to provide an acrylic rubber composition which provides an acrylic rubber vulcanizate retaining high tensile strength and modulus even if a long-termthermal load is applied and contains no component limited by environmental regulations. The above object is attained by an acrylic rubber composition comprising 100 parts by weight of a carboxyl group-containing acrylic rubber and 0.3 to 8 parts by weight of a styrenated diphenylamine compound, and by an acrylic rubber composition further comprising 0.05 to 20 parts by weight of a crosslinking agent besides the above components.

Owner:ZEON CORP

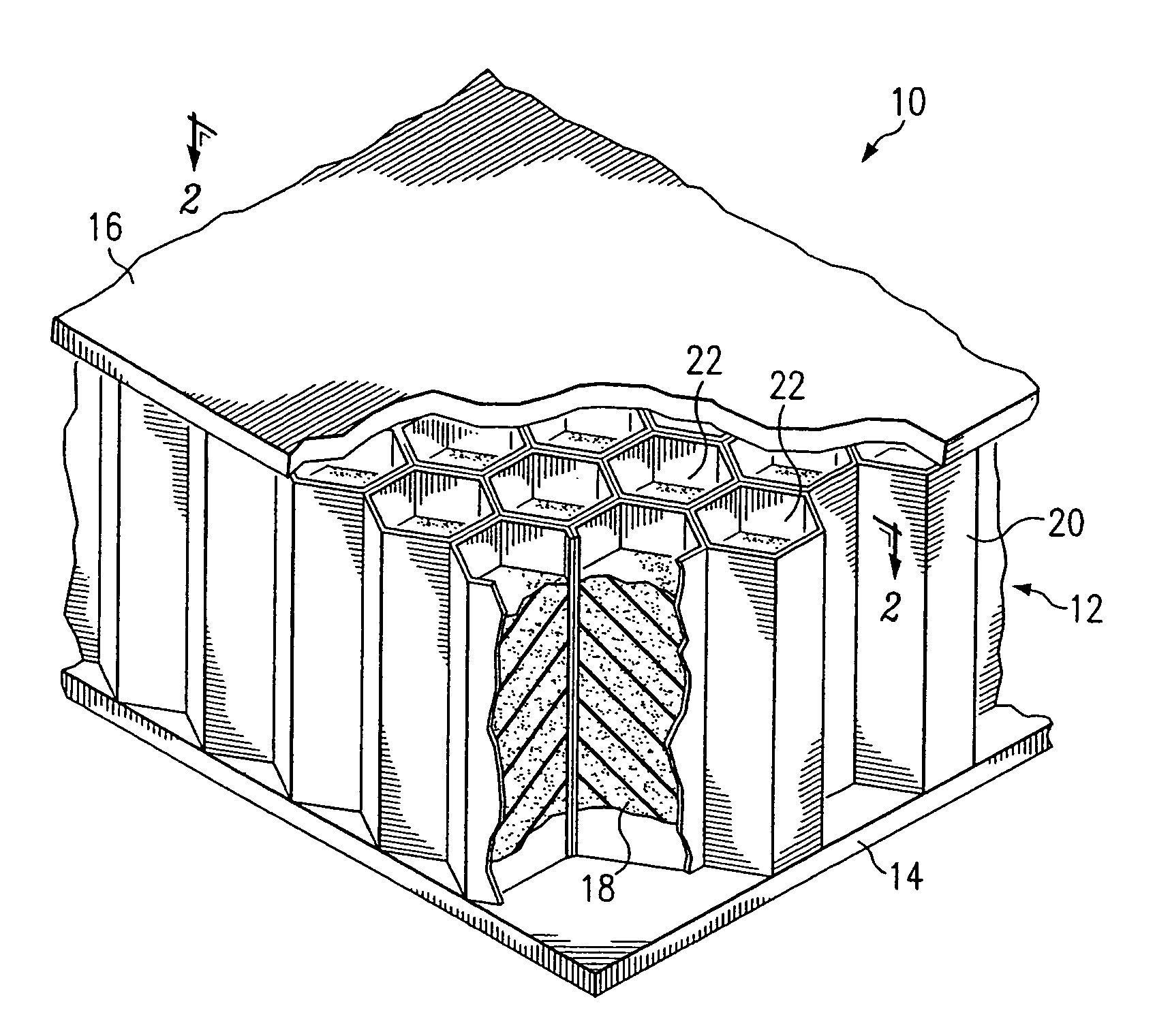

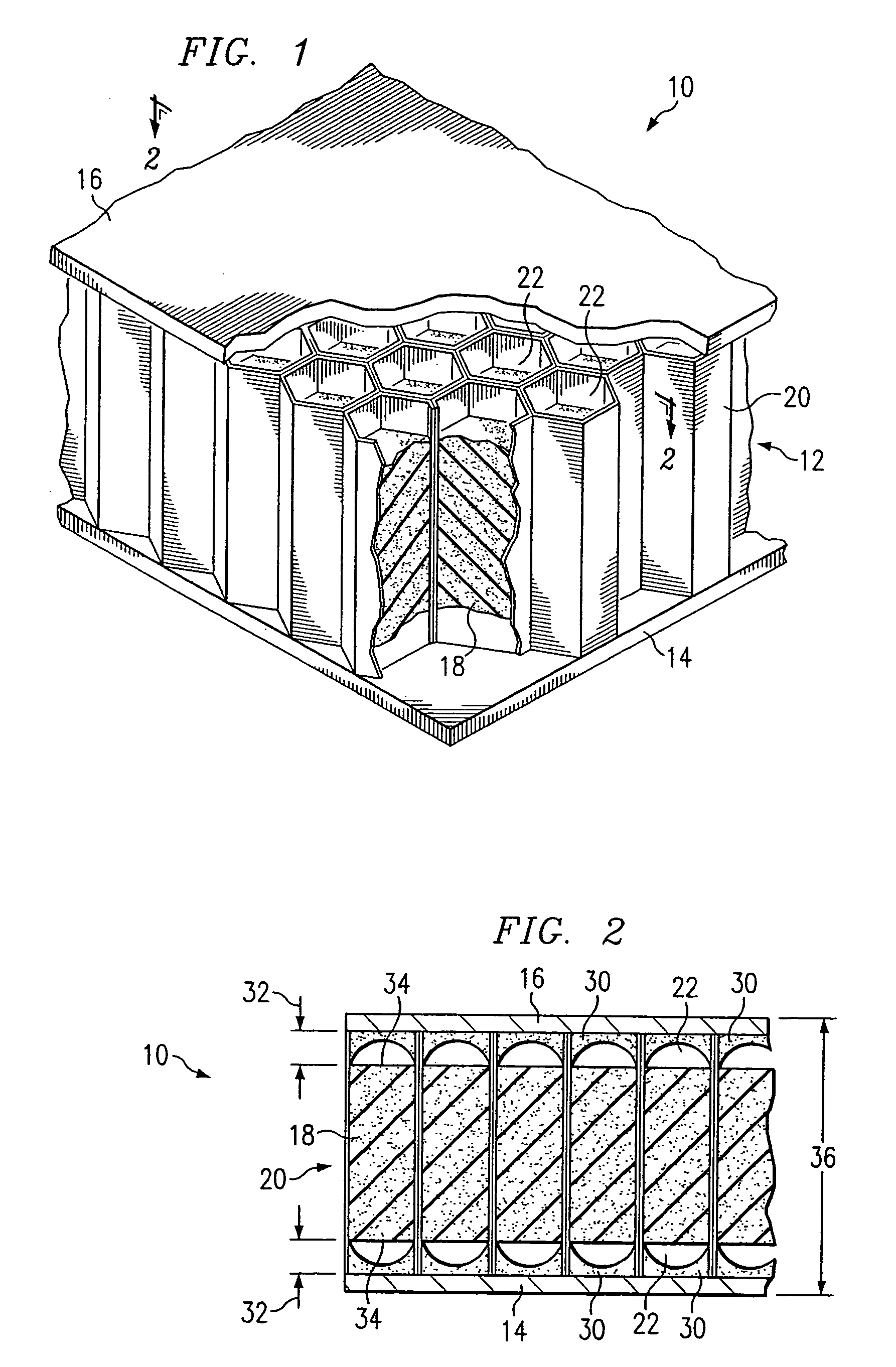

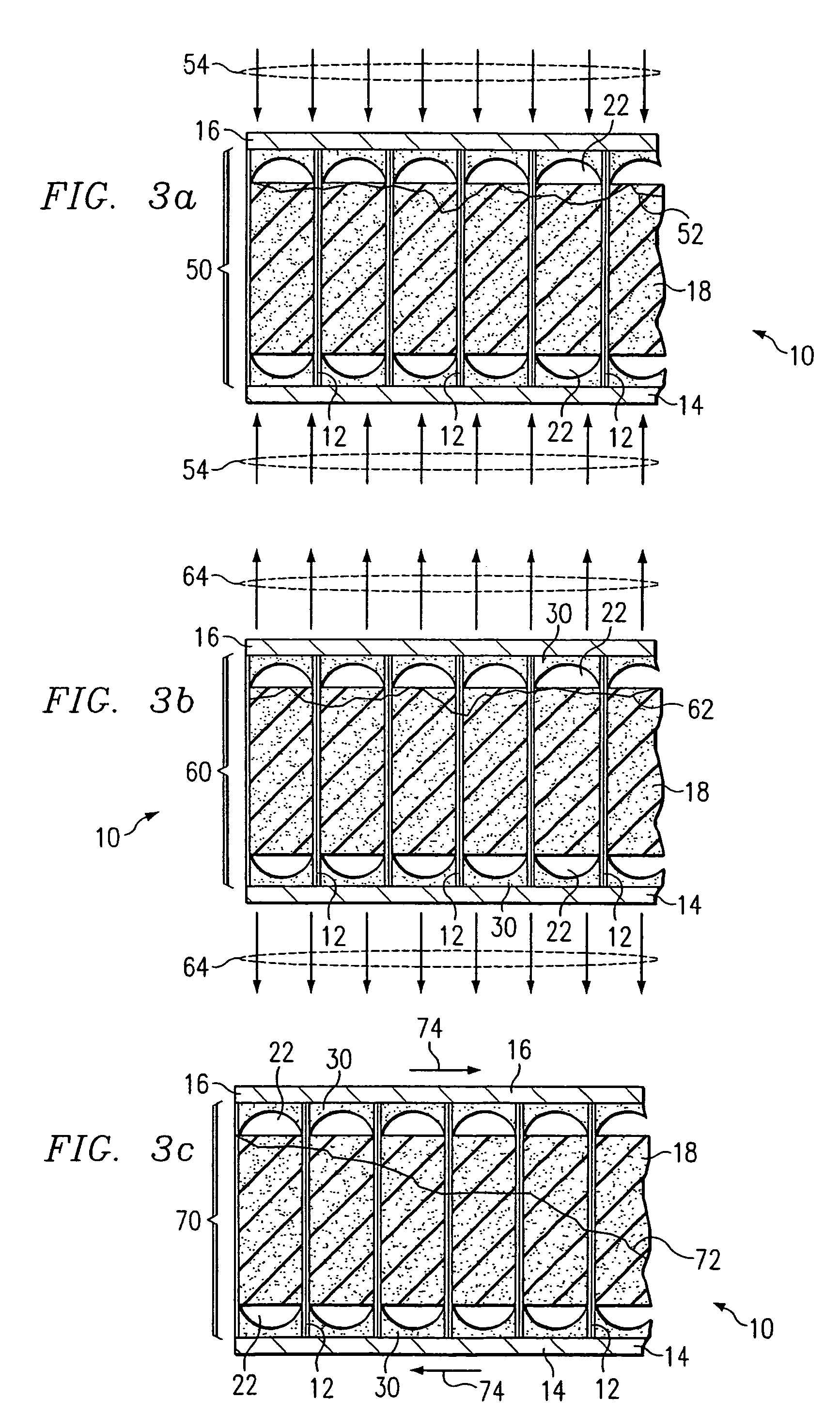

End gaps of filled honeycomb

ActiveUS7575650B1Improve thermal performanceReduced cryopumpingConstruction materialLaminationAdhesiveHoneycomb

A sandwich panel includes a honeycomb core of a plurality of cells. A first skin is adhered to a first surface of the honeycomb core with an adhesive. A second skin is adhered to a second surface of the honeycomb core with the adhesive. The plurality of cells extend longitudinally between the first and second skins. The first and second skins adhere to the honeycomb core to form a sandwich panel having a surface area of at least 2.25 square feet. A foam fill is disposed within the cells of the honeycomb core. The foam fill and the honeycomb core define a first gap region proximate to the first skin and a second gap region proximate to the second skin.

Owner:NORTHROP GRUMMAN SYST CORP

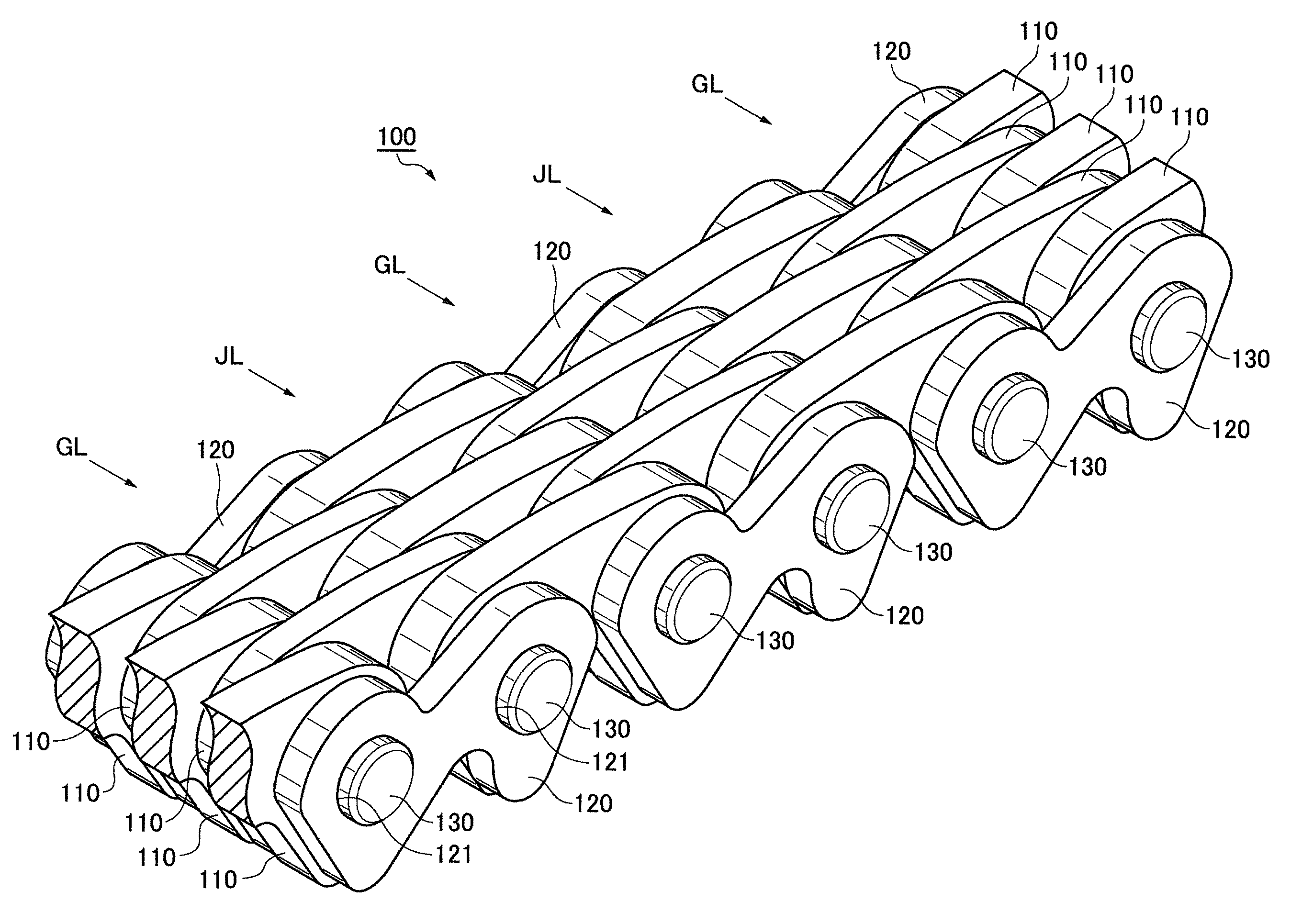

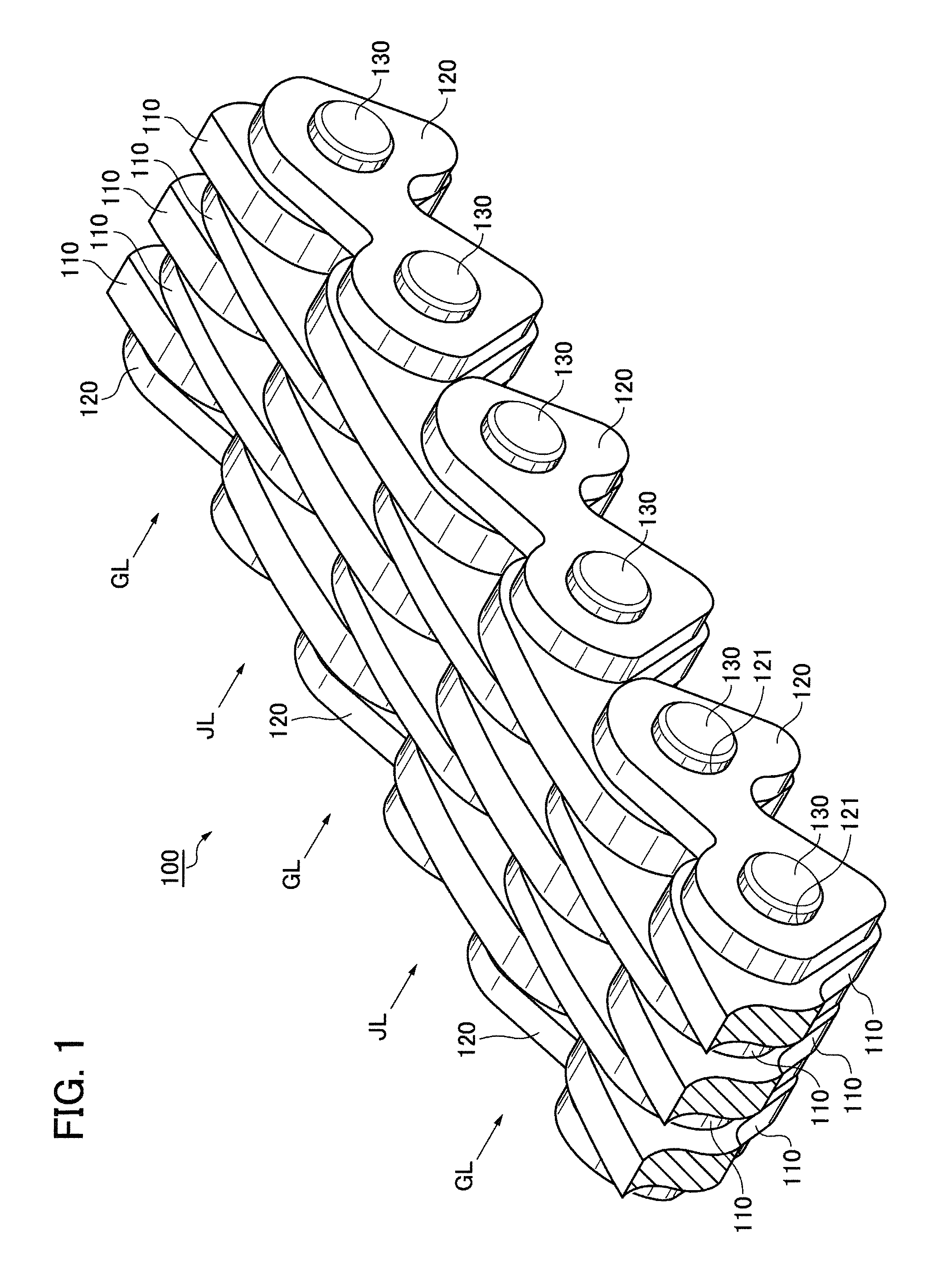

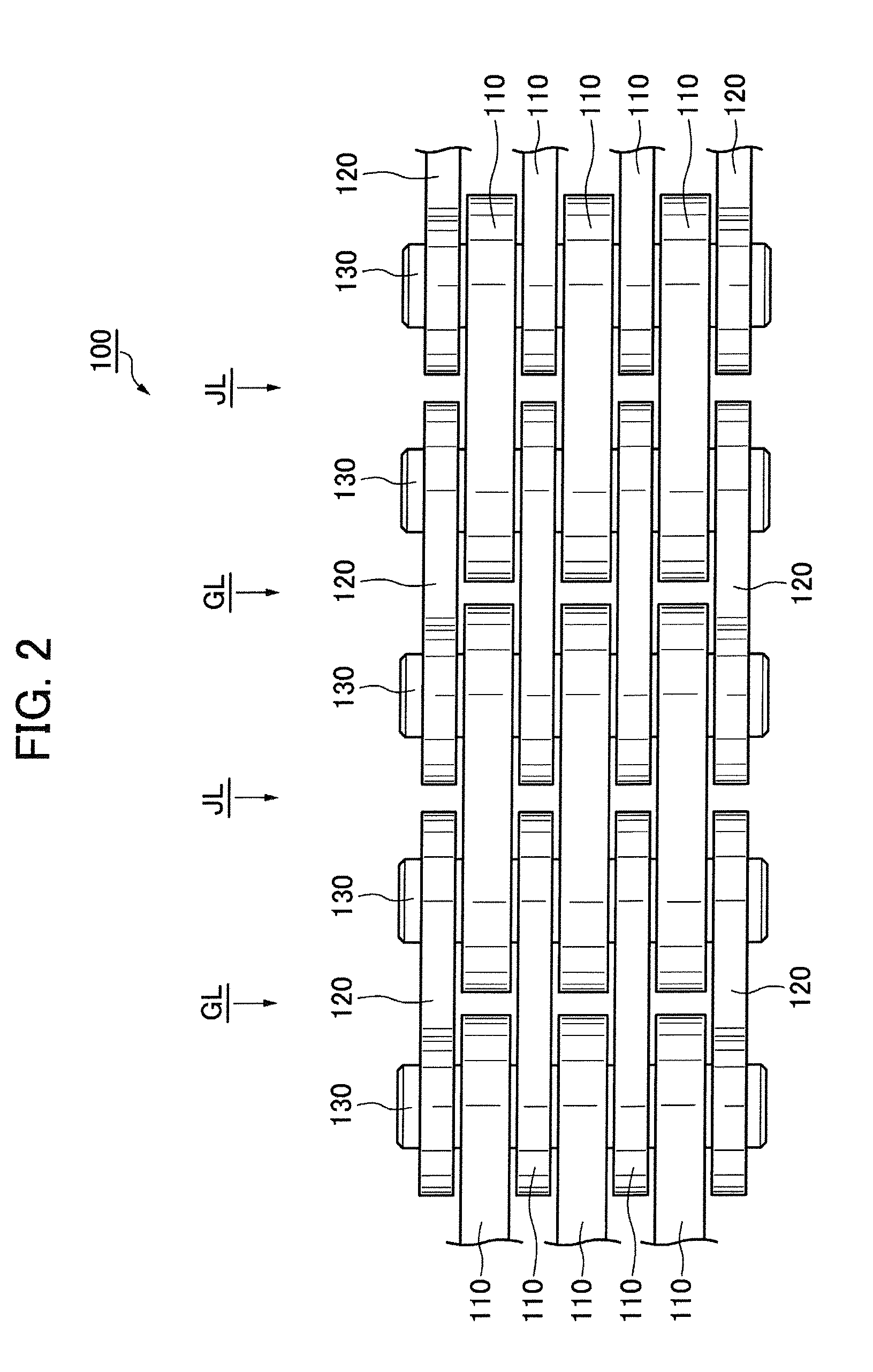

Silent chain

A silent chain includes guide plates each of which has a cut-away portion on its inner side and a cut-away portion on its outer side for allowing elastic deformation of the guide plate in the longitudinal direction of the chain so that bowing of the connecting pins of the chain is reduced, and galling of the connecting pins and unbalance of the loads on the link plates of the chain are suppressed. The deepest parts of the respective cut-away portions are longitudinally offset from each other so that longitudinal elastic deformation can occur without impairing the tensile strength of the guide plate.

Owner:TSUBAKIMOTO CHAIN CO

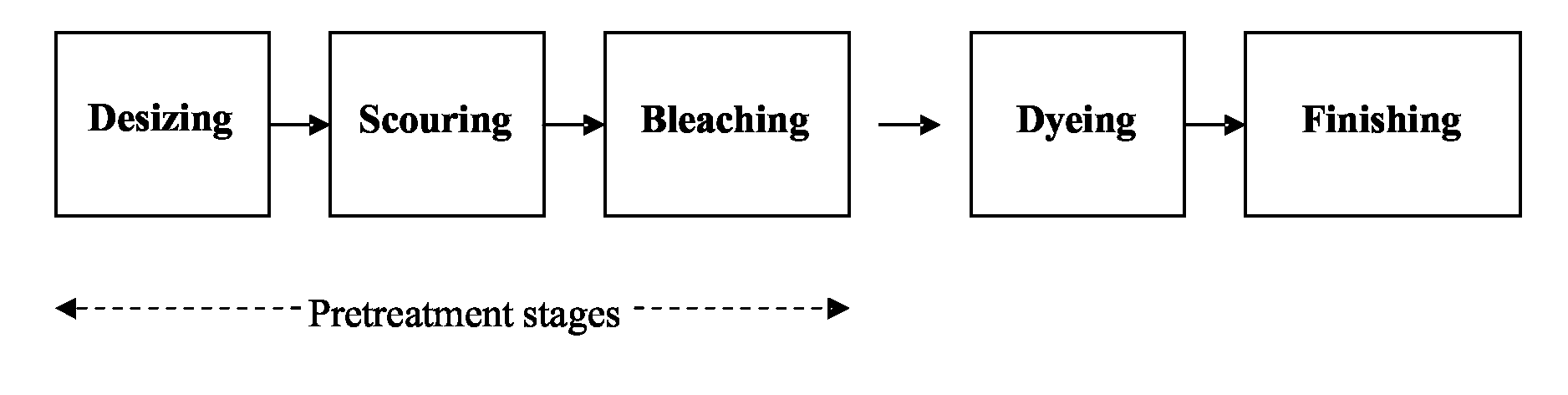

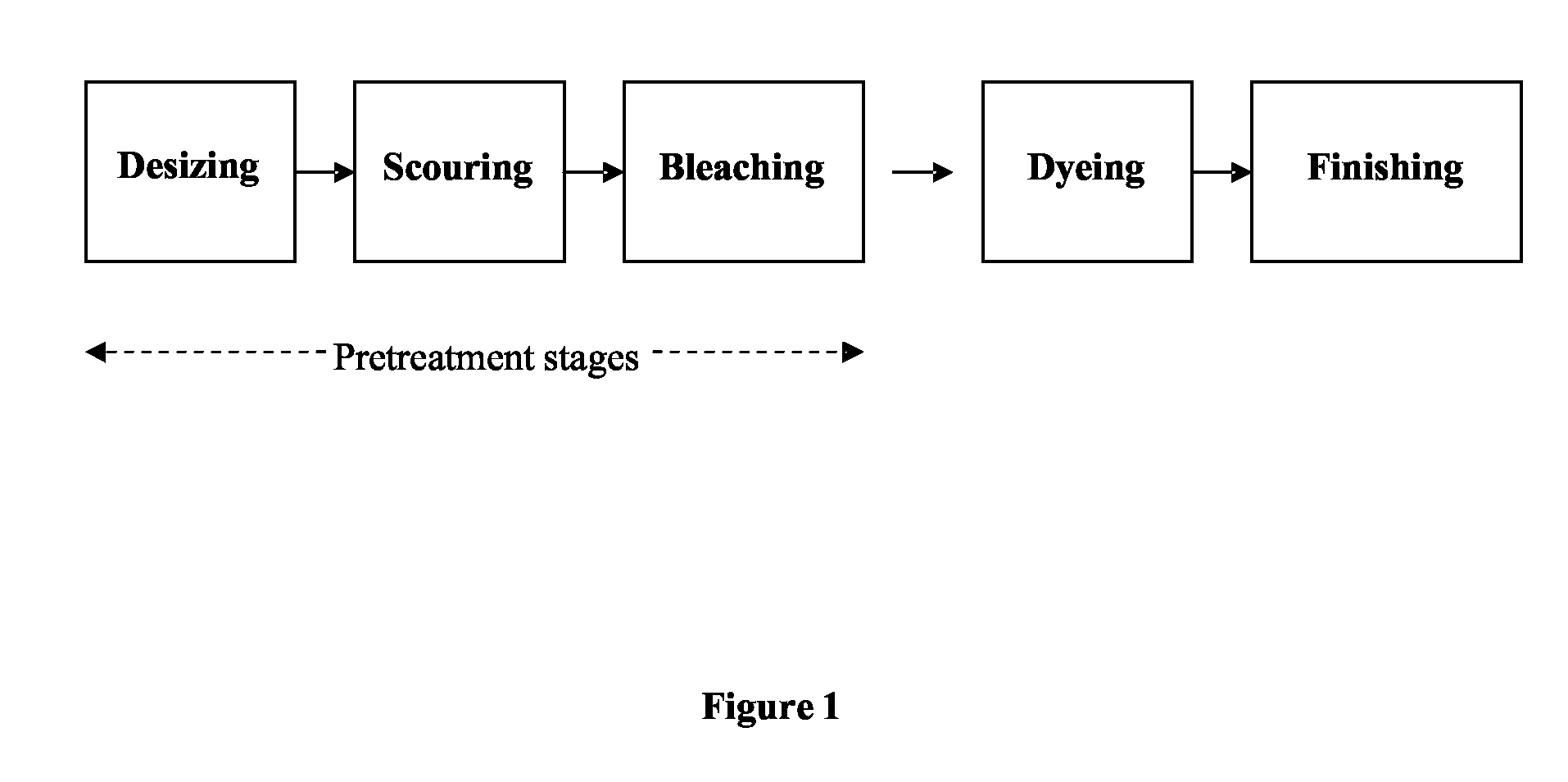

Process For Pretreatment of Cellulose-Based Textile Materials

InactiveUS20090311931A1Sufficient whiteness and wettabilityMaintain tensile strengthWarp knittingDry-cleaning apparatus for textilesEnzymePre treatment

The invention is related to mild pretreatment or preparation process as well as combined scoring and bleaching composition for cellulose-based textile material. The process comprises a sequential or simultaneous scouring step with an enzyme composition acting on the non-cellulosic material on outer layers of cellulosic fibers and a reducing bleaching step with a reducing bleaching agent. The reducing bleaching agent is preferably dithionite. In the process no adjustment of pH and temperature are required. The process is environmentally friendly because no causticizing and oxidizing agents are required to achieve the desired lightness and wettability. Due to the mild pretreatment conditions tensile strength of the fabric is better than that achieved with conventional pretreatments.

Owner:VALTION TEKNILLINEN TUTKIMUSKESKUS

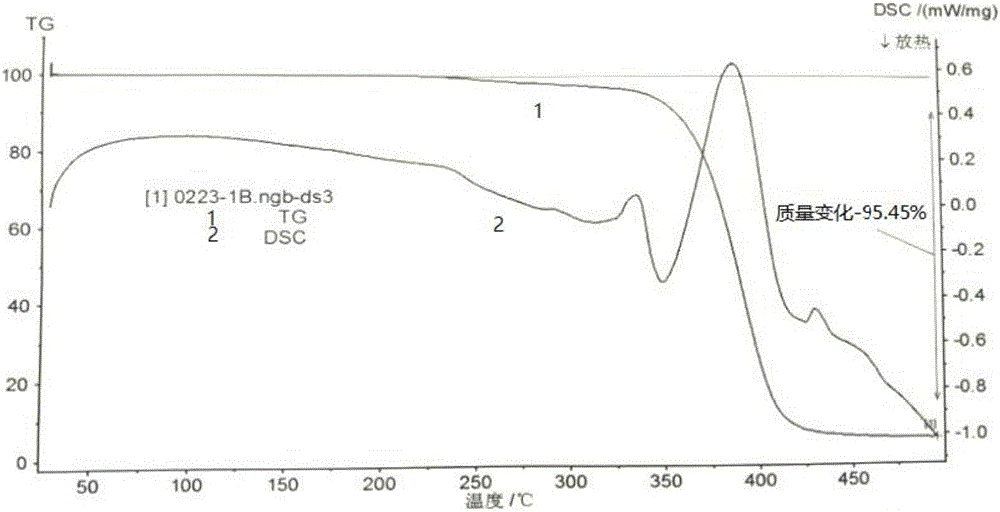

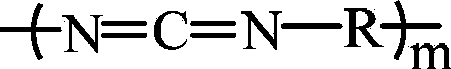

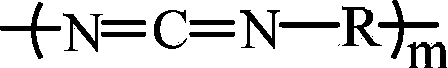

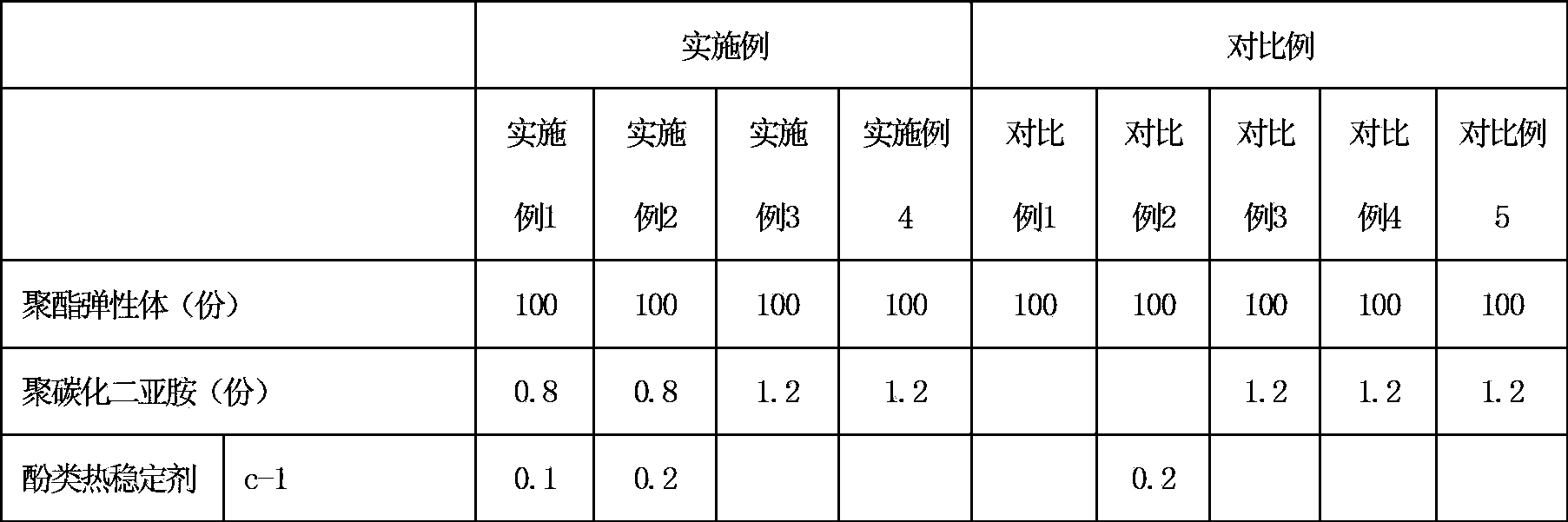

Hydrolysis resistant high temperature resistant thermoplastic polyester elastomer composition

The invention provides a hydrolysis resistant high temperature resistant thermoplastic polyester elastomer composition including 100 parts by weight of polyester elastomer (A); 0.01-10 parts by weight of poly carbodiimide (B); 0.01 to 0.5 part by weight of a phenolic heat stabilizer (C); 0.01 to 0.5 part by weight of a thio ester heat stabilizer (D); and 0.01 to 0.5 part by weight of an aromatic amine heat stabilizer (E). The hydrolysis resistant high temperature resistant thermoplastic polyester elastomer composition still can effectively maintain the tensile strength and elongation at break in the long time exposure to hygrothermal environment, after 90 days of hydrolysis resistance test of the composition dipping in hot water at the temperature of 95 DEG C, the tensile strength is maintained above 25Mpa, the elongation at break is remained above 482%; and after 168h of heat resistance test at the temperature of 158 DEG C, the tensile strength is maintained above 81%, so that the hydrolysis resistant high temperature resistant thermoplastic polyester elastomer composition can be applied in higher-end areas.

Owner:SINOTEX INVESTMENT & DEV CO LTD

Meat-containing, strip-shaped food product and method of making same

ActiveUS20080020117A1Good strength and integrityReduce breakageDough treatmentFatty substance preservation using additivesAdditive ingredientWater activity

A flexible, strip-shaped food product is made by comminuting substantially frozen meat and heating the comminuted meat to at least partially denature the meat proteins and cooling the cooked meat. About 4% by weight to about 45% by weight of wheat flour is admixed with the cooked meat, along with other ingredients, to form a dough. Use of the wheat flour unexpectedly increases tensile strength of the dough and products baked from the dough, and maintains flexibility of the strip-shaped food products over an extended period of time. Cooking of the meat in the presence of salt unexpectedly increases water activity of the pieces, resulting in a product that has a skin and a moist middle, while maintaining tensile strength. The dough is rotary-molded into strip-shaped pieces. The rotary mold may have angled die cups. The strip-shaped dough pieces are then baked and dried.

Owner:BIG HEART PET INC

Preparation method of high-strength MC nylon modified fiber composite base material

The invention discloses a preparation method of a high-strength MC nylon modified fiber composite base material. The method includes: preparing graphene oxide high in oxidation degree; modifying the graphene oxide; preparing a high-strength MC nylon composite junction brick. The preparation method has the advantages that asphalt-based carbon fibers are used to increase the mechanical performance of the material, harmful gas and dust substances in tail gas can be absorbed and removed greatly, and the prepared MC nylon is good in comprehensive performance; auxiliary materials such as plasticizer, anti-aging agent, self-made modified hydrotalcite, attapulgite, nano titanium dioxide, nano cerium oxide and accelerant are used in a coordinated manner, the components of the material are reasonable and scientific in proportion, and the added components can effectively guarantee that the material protected by the components is hard to combust and the material combusted under excessively high temperature is prevented from generated gas harmful to human bodies; compared with the hydrotalcite used in the current market, the material has evident high temperature resistance, fire resistance and flame retardance.

Owner:SUZHOU RUI TE JIE CHEM PROD CO LTD

Process of regenerating waste medicine packing aluminium plastic sheet

InactiveCN101020183ARestore does not appearImprove qualitySolid waste disposalNon-surface-active detergent solventsOrganic solventChemical reaction

The process of regenerating waste medicine packing aluminum-plastic sheet includes setting waste medicine packing aluminum-plastic sheet in some liquid at temperature over 60 deg.c to separate plastic layer from the aluminum layer, winding the separated plastic layer from the aluminum layer separately onto two drums, stoving the aluminum foil and washing in non-protonic organic solvent to eliminate residual adhesive, and adhering the cleaned aluminum foil to plastic film with new polyurethane adhesive to form the regenerated aluminum-plastic sheet. The present invention has complete stripping of aluminum foil and complete cleaning, and the regenerated aluminum-plastic sheet has high quality the same as new one.

Owner:刘继福

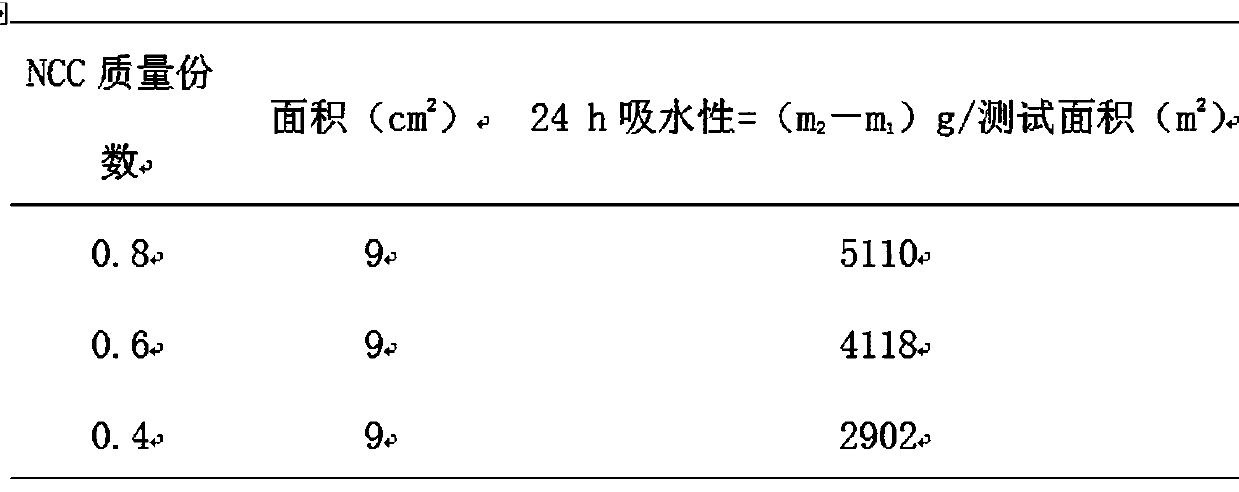

Three-dimensional seawater evaporator and applications thereof

PendingCN111072087ASimple structureReduce volumeGeneral water supply conservationSeawater treatmentSeawaterEvaporator

The invention discloses a three-dimensional seawater evaporator and applications thereof. The three-dimensional seawater evaporator comprises a channel structure with moisture absorption and transportation effects, and a reactor unit with photothermal conversion effect, wherein the reactor unit is located at one end of the channel structure, the channel structure and the reactor unit form a three-dimensional structure, and the reactor unit comprises macromolecule functionalized paper. The three-dimensional seawater evaporator disclosed by the invention has the characteristics of simple structure, small size, three-dimensional omnidirectivity and the like; and by reasonably designing the composition, the shape and size of the channel and the composition, the geometric structure and the likeof the reactor unit, high efficiency and high ion interception in the sea water desalination process can be realized, so that the three-dimensional seawater evaporator has wide application prospect in the field of seawater desalination.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

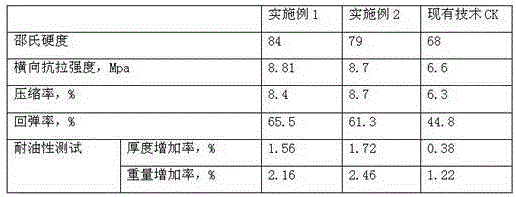

A preparing method of an oil-proof modified composite environment-friendly rubber base material

A preparing method of an oil-proof modified composite environment-friendly rubber base material is disclosed. The method includes preparing graphene oxide having a high oxidation degree, modifying the graphene oxide and preparing the oil-proof modified composite environment-friendly rubber base material. The base material adopts pitch-based carbon fibers to enhance mechanical properties, and can greatly adsorb and clean harmful gas and dust compounds in tail gas. Prepared MC nylon has an advantage of good comprehensive properties. The base material can be used for works under various bad conditions. Added components can effectively ensure no easy combustion of a protected material, and do not generate gas harmful to human bodies during combustion at overhigh temperatures. Compared with hydrotalcite in the market at present, the base material has obvious advantages in the fields of high-temperature resistance, fire protection and flame retardance.

Owner:常熟市瑞思知识产权服务有限公司

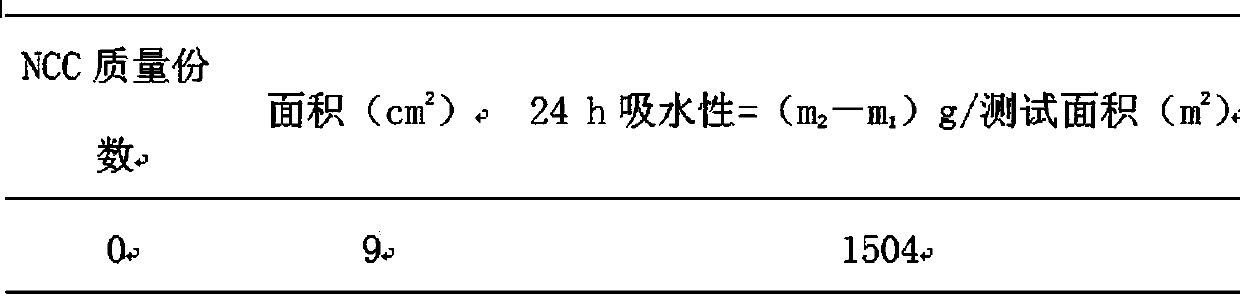

Medical wound dressing containing nano polysaccharides

InactiveCN108030954AFast absorptionRelieve painPharmaceutical delivery mechanismBandagesCelluloseMechanical property

The invention provides medical wound dressing containing nano polysaccharides, and belongs to the technical field of medical wound dressing. The medical wound dressing comprises wet dressing, and thewet dressing is hydrocolloid dressing or hydrogel dressing or silicon gel dressing or alginate dressing. The medical wound dressing is characterized in that nano polysaccharide compounds or derivatives are also added to the wet dressing, and the added nano polysaccharide compounds or derivatives are one or more of cellulose, starch, chitin, chitosan or derivatives; the particle size of the polysaccharide compounds or derivatives is 200nm-1000nm; and the parts by mass of the polysaccharide compounds or derivatives and the wet dressing are respectively 0.1-20 parts and 70-115 parts. The medicalwound dressing provided by the invention has the advantages that the nano polysaccharides and the wet dressing are mixed, so that the wound dressing can quickly absorb wound exudate and has good moisture keeping performance; and furthermore, the mechanical performance of the dressing can be enhanced in an auxiliary mode.

Owner:义乌市中科院兰州化物所功能材料中心

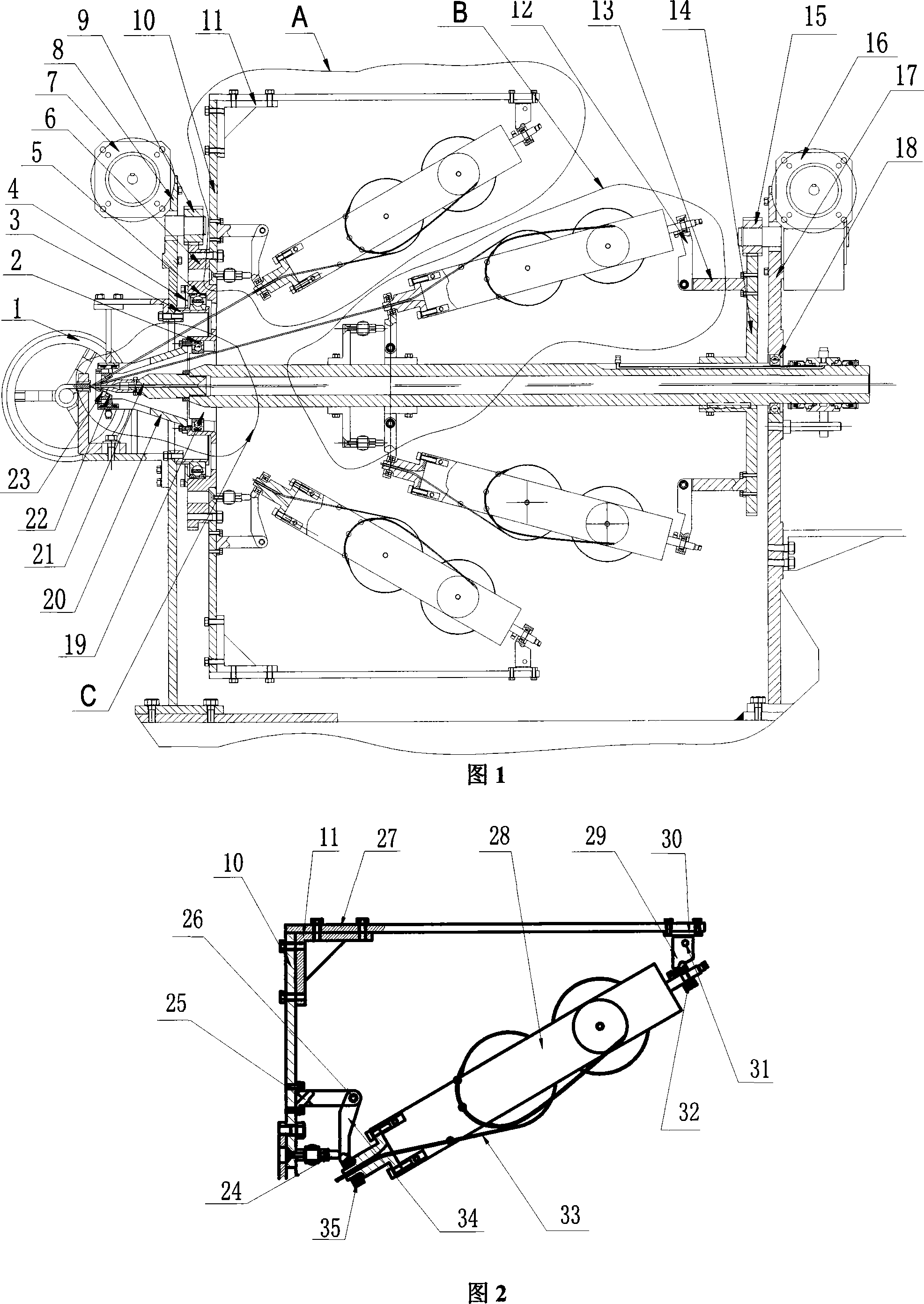

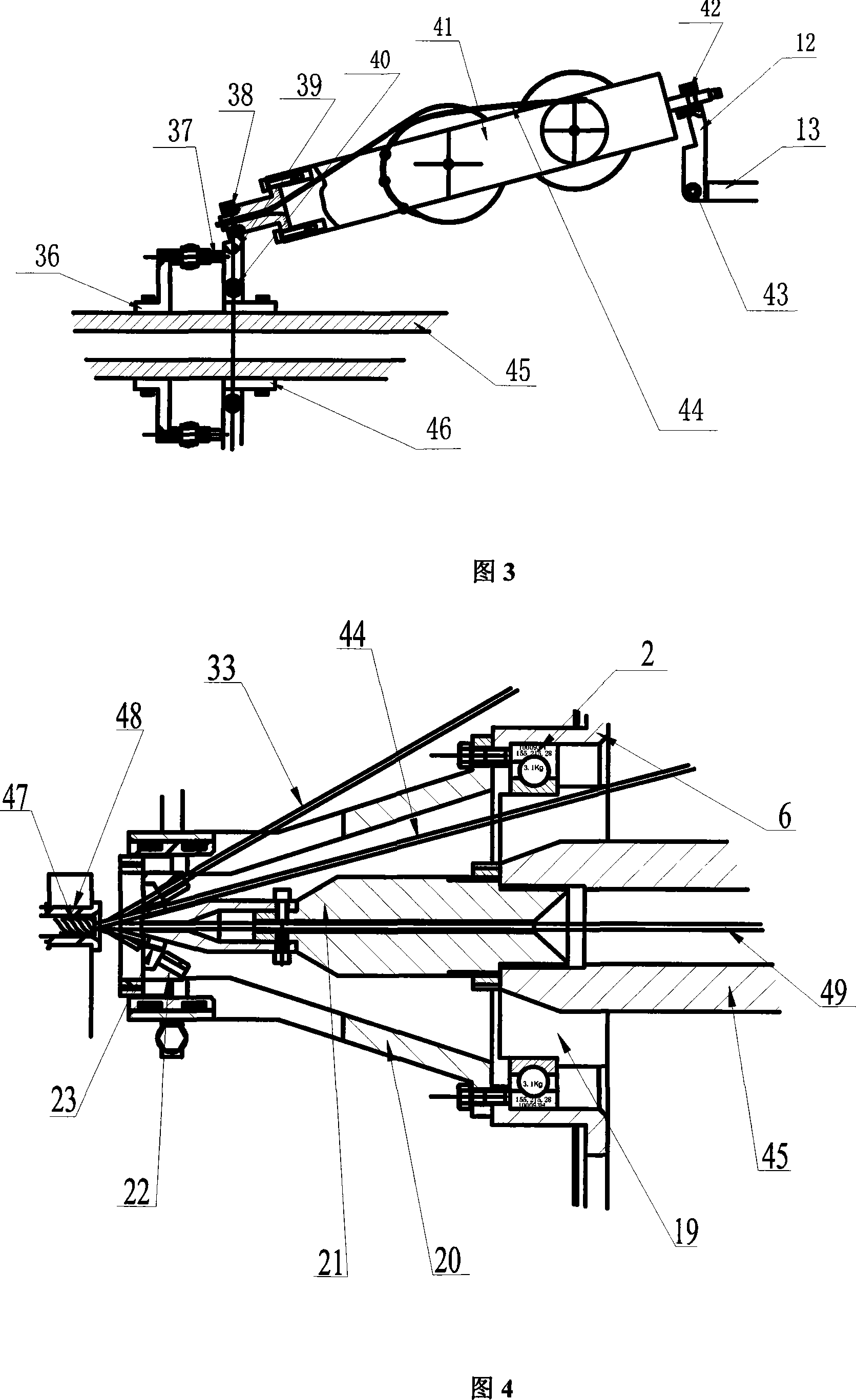

Multi-strand reed numerical control machine steel wire tension detection and rotary rope-twisting device

InactiveCN101071086AChange wire pathShorten the manufacturing cycleTension measurementNumerical controlAviation

The invention relates to a reed numerically-controlled machine tool steel wire tensity examination and the revolving twist. Rope installment, which belongs to the area of many reed numerically-controlled machine tool process technology. This invention installment mainly includes the reducing decelerate the electrical machinery, the transmission gear gudgeon, the steel wire tensity sensor system, the steel wire guide mechanism and so on. Its characteristic is as follows: the servo decelerates electrical machinery is one or two, the transmission gear including the drive gear and the driven gear is one pair or two pairs, and the gudgeon is one decked or double-decked. Because this invention installment s simply to be controlled, it raises the steel wire introduction's efficiency and many reed production's efficiency, reduces the labor intensity, and avoids the steel wire having the plastic deformation. Besides it raises many reed product manufacture qualified rate and the service life, and can survey the steel wire's actual tensity, thus it guaranteed each steel wire's tensity uniformly and so on. Therefore this invention may widely used in many reed processing profession, many reed which is produced by this invention can be widely applied in the frequency reciprocating motion equipment of the high sky in the automobile, aviation, machinery department and so on.

Owner:CHONGQING UNIV

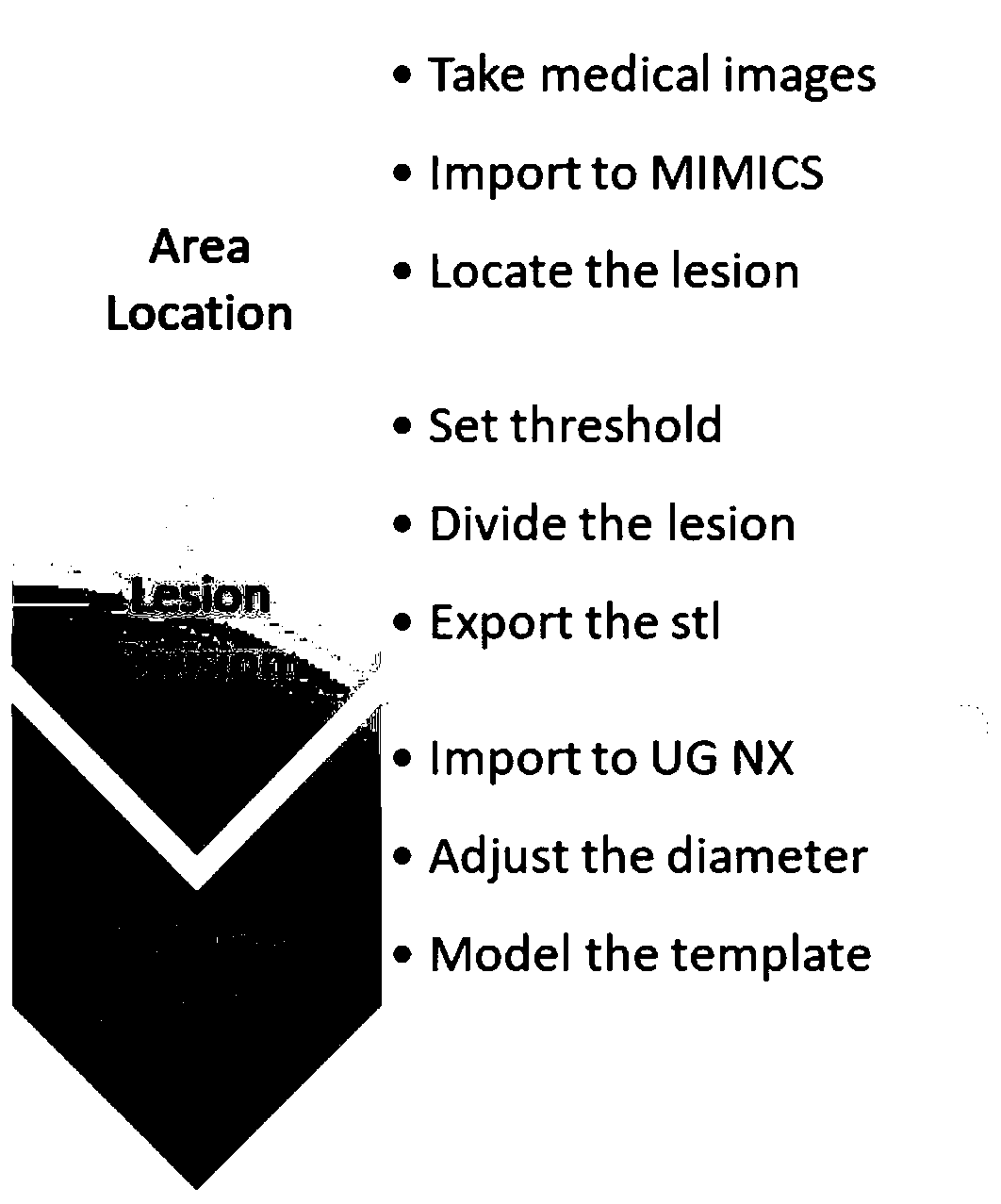

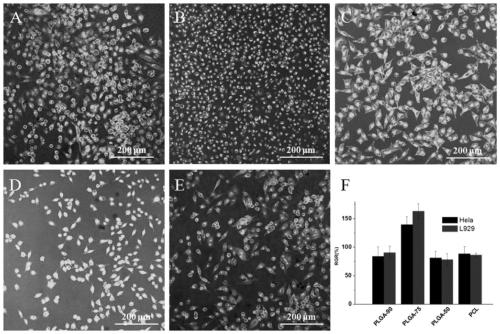

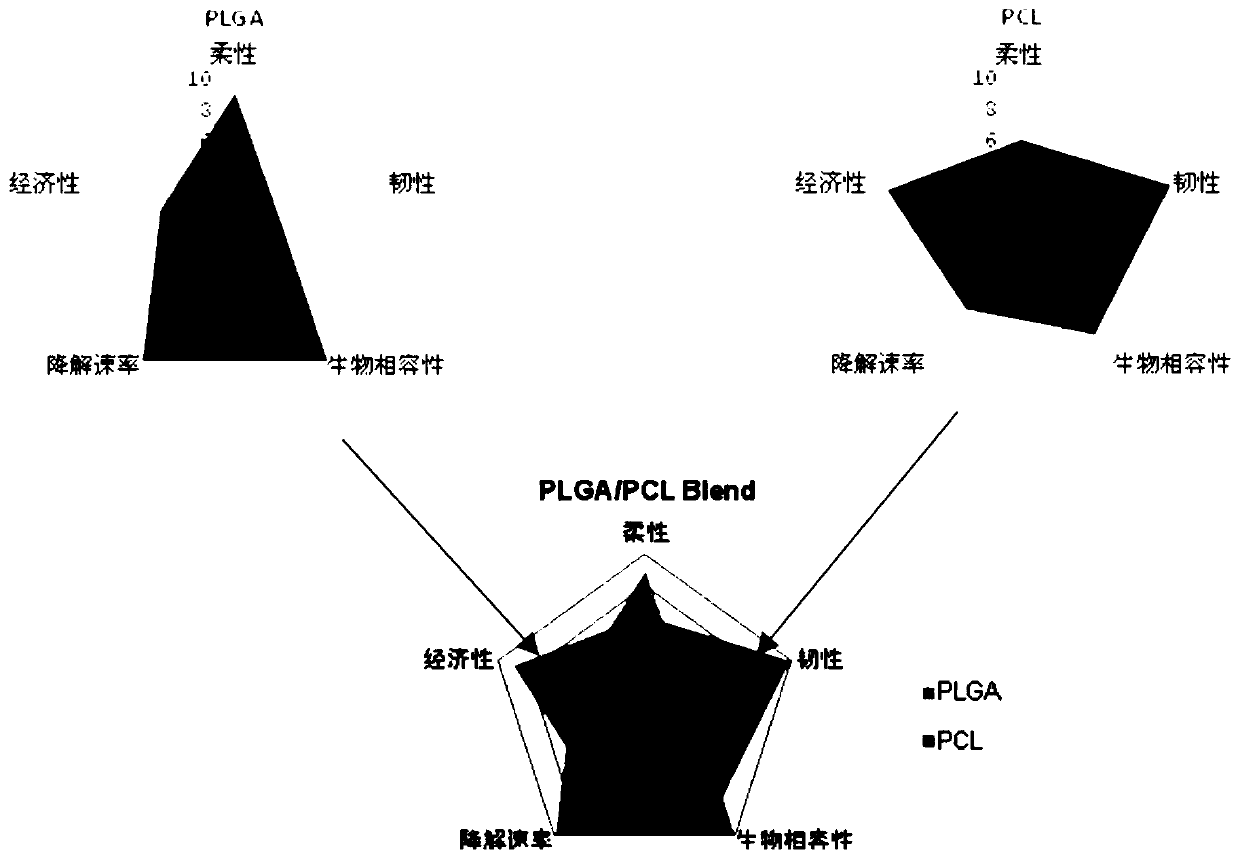

Biodegradable tissue engineering urethral stent and preparation method thereof

InactiveCN111450317AImprove toughnessStay flexibleStentsAdditive manufacturing apparatusUrethral stentsGlycolates

The invention discloses a biodegradable tissue engineering urethral stent and a preparation method thereof. The biodegradable tissue engineering urethral stent is made of a copolymer formed by polylactic acid-co-glycolate, polycaprolactone and a solubilizer according to the weight ratio of 70 to 30 to (2-10). The preparation method of the biodegradable tissue engineering urethral stent comprises the following steps of a) blending preparation of a modified material solution, b) medical image processing and modeling, c) 3D template printing and d) stent preparation. PLGA and PCL biodegradable polymers are subjected to solution co-mixing modification, and triethyl citrate is added as the solubilizer, and the blending ratio and the content of the solubilizer are adjusted, so that the toughnessof the modified material is relatively and greatly improved while the flexibility and the tensile strength are kept; and based on a 3D printing technology and in combination with medical image data and software processing, a soluble template can be printed for the focus of a patient, and the personalized tissue engineering urethral stent is prepared.

Owner:ZHEJIANG SINOU ENVIRONMENTAL PROTECTION EQUIP CO LTD

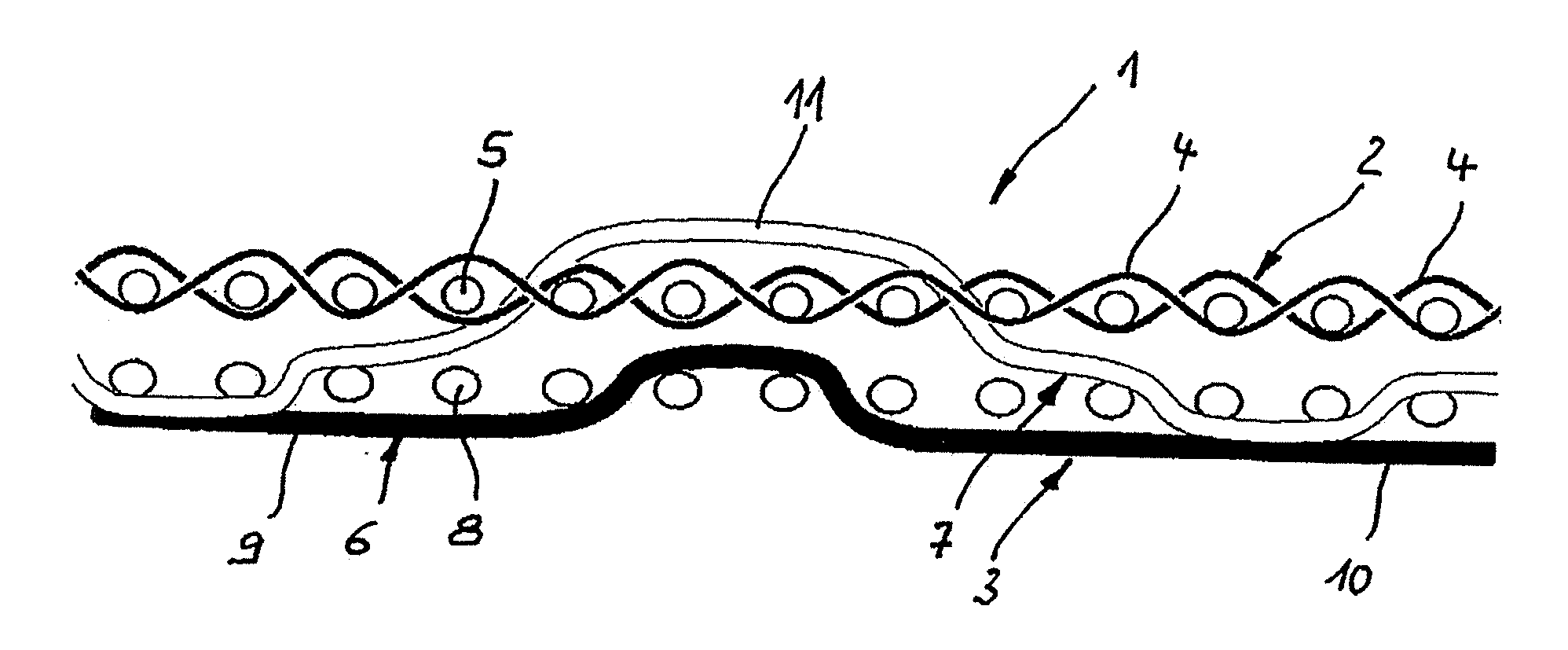

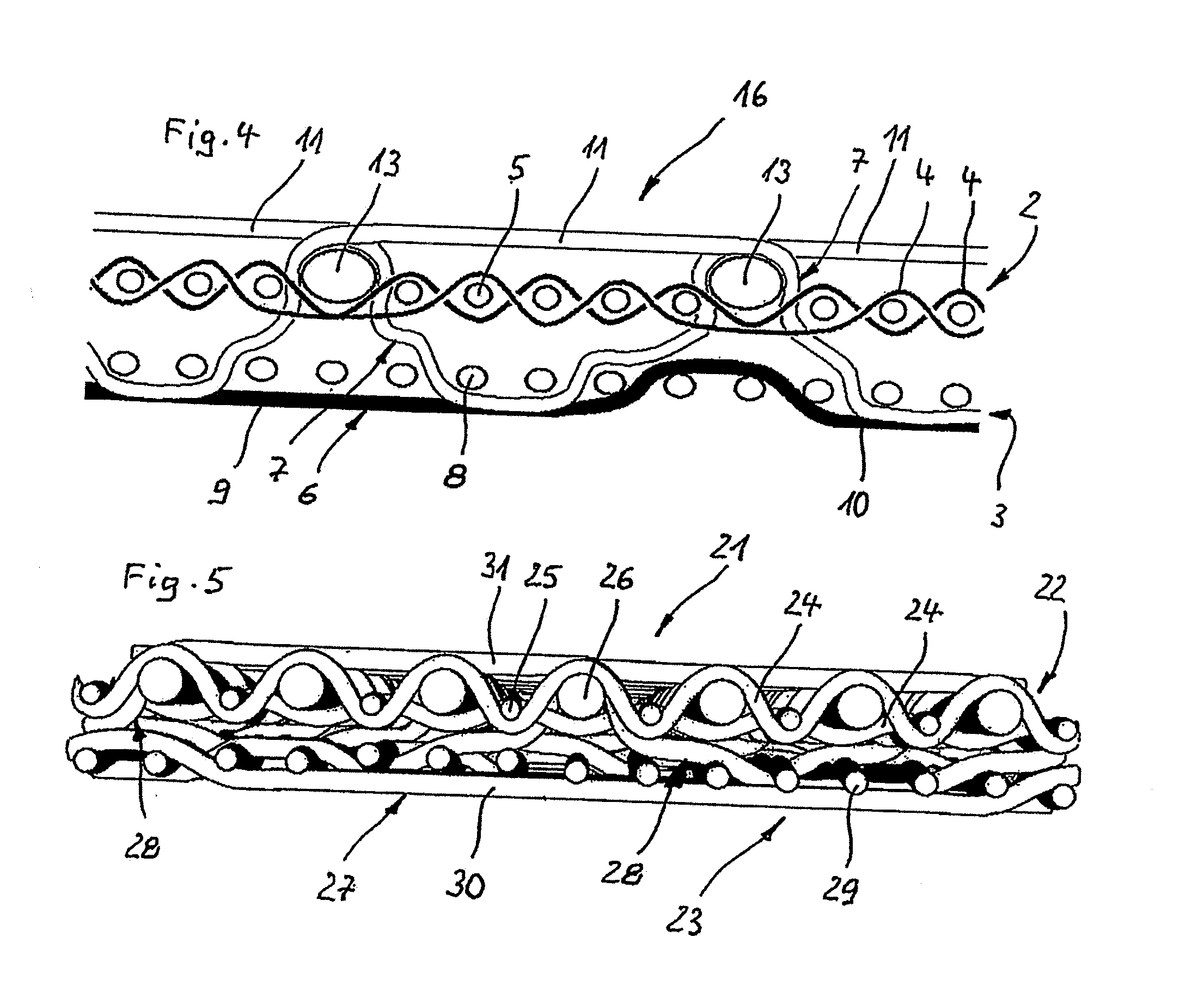

Fabric for forming a paper web having an embossed surface

InactiveUS20130220475A1Less effectIncrease volumeMachine wet endMulti-ply fabricsPulp and paper industryWoven fabric

The invention relates to a fabric for forming a fibrous paper web having an embossed surface. The fabric comprises longitudinal and transverse threads interwoven with one another in a weave repeat defining a machine side and a paper side. Some of the longitudinal threads form embossing threads having projecting paper side floats on the paper side of the fabric passing over more than one transverse thread. The fabric comprises a first woven fabric layer forming the paper side on its outside and having longitudinal and transverse first threads interwoven with one another and a second woven fabric layer forming the machine side on its outside and having longitudinal and transverse second threads interwoven with one another. At least some of the longitudinal second threads form embossing threads, which penetrate the first woven fabric layer for forming the paper side floats and connect the two woven fabric layers.

Owner:HEIMBACH GMBH & CO KG

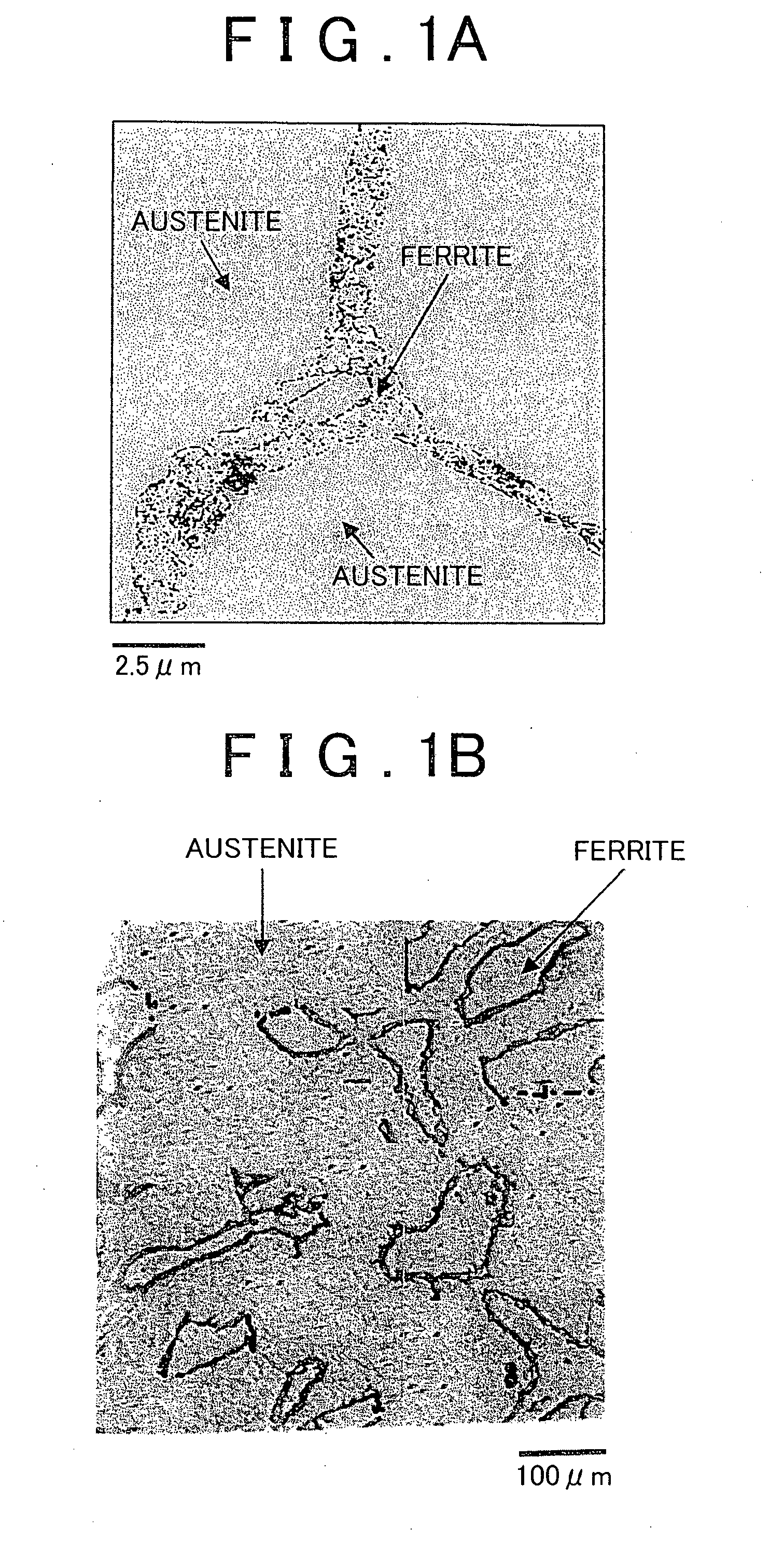

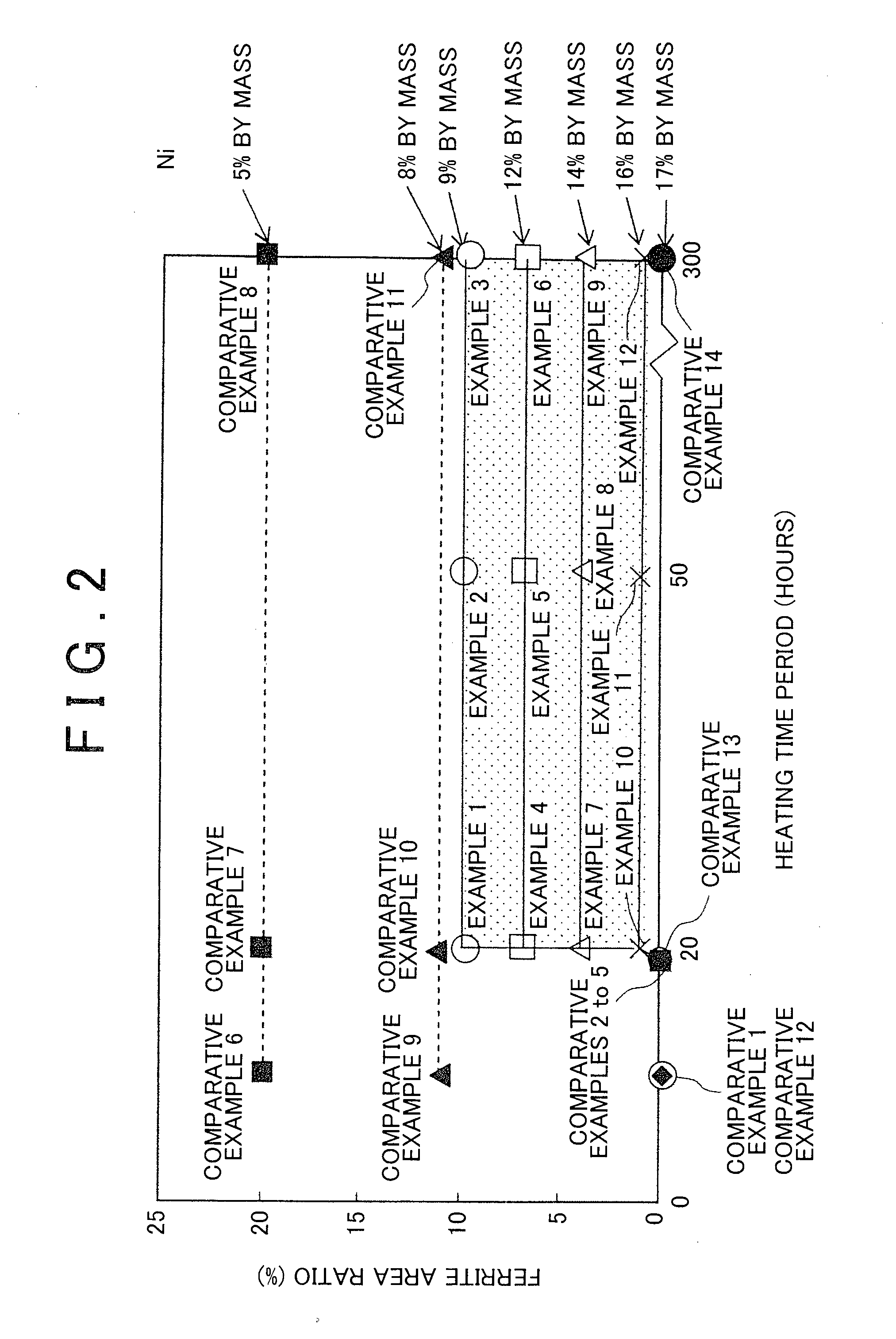

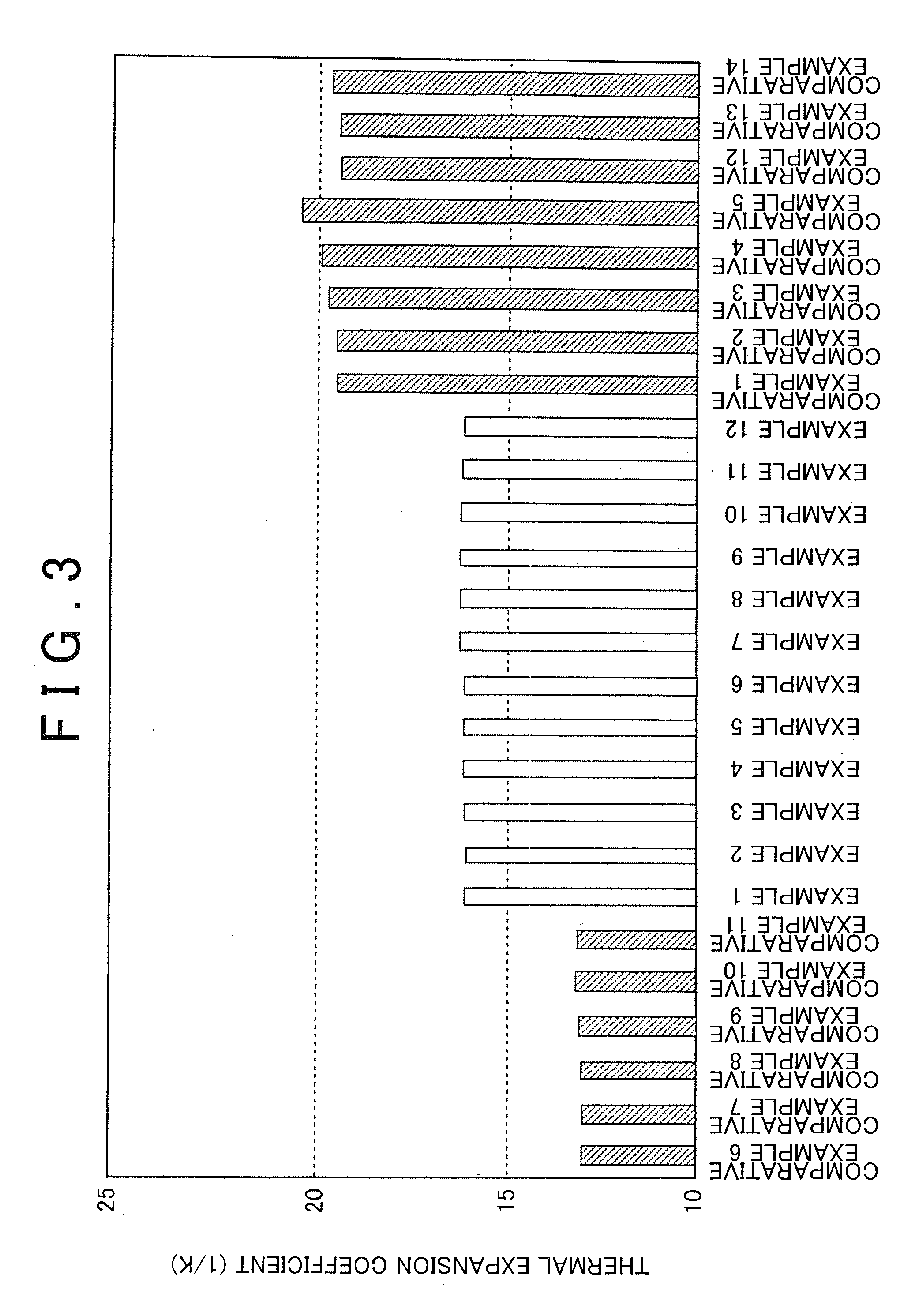

Austenitic heat-resistant cast steel and method for manufacturing the same

An austenitic heat-resistant cast steel includes 0.1 to 0.6% by mass of C, 1.0 to 3.0% by mass of Si, 0.5 to 1.5% by mass of Mn, 0.05% by mass or less of P, 0.05 to 0.3% by mass of S, 9 to 16% by mass of Ni, 14 to 20% by mass of Cr, 0.1 to 0.2% by mass of N, and the balance of iron and inevitable impurities, in which a matrix structure of the austenitic heat-resistant cast steel is configured of austenite crystal grains, and a ferrite phase is dispersed and interposed between the austenite crystal grains so as to cover the austenite crystal grains.

Owner:TOYOTA JIDOSHA KK +1

Shell powder filler having high beta-nucleation effect on polypropylene and preparation method for filler

InactiveCN102532716AHigh β-nucleation efficiencyHigh impact strengthPolymer scienceDicarboxylic acid

The invention discloses a shell powder filler having a high beta-nucleation effect on polypropylene and copolymer thereof and a preparation method for the filler. The method comprises the following steps of: dissolving aliphatic dicarboxylic acid in acetone, mixing a solution and shell powder, volatilizing the acetone, and thus obtaining the shell powder filler having the high beta-nucleation effect, wherein a mass ratio of the aliphatic dicarboxylic acid to the shell powder is 1:(5-1,000); and mixing the polypropylene or copolymer thereof and the shell powder filler having the high beta-nucleation effect in a mass ratio of 1:99-5:1, and performing melt extrusion or mixing and pelletizing at the temperature of between 200 and 230 DEG C to obtain shell powder filled polypropylene or copolymer thereof with high beta-crystal content. The shell powder filler having the high beta-nucleation effect is easy to prepare, small in equipment investment, low in energy consumption and cost, wide in raw material source and high in beta-nucleation efficiency, and has the characteristic of reinforcing and toughening the polypropylene or copolymer thereof.

Owner:ZHEJIANG UNIV

Preparation method of tear-resistant modified composite environment-friendly rubber base material

The invention discloses a preparation method of a tear-resistant modified composite environment-friendly rubber base material. The method comprises the following steps: preparing graphene oxide with high oxidation degree; and modifying the graphene oxide to prepare the tear-resistant modified composite environment-friendly rubber base material. In the invention, by adopting asphalt-based carbon fiber, the mechanical property of the material is enhanced, the harmful gases and dust matters in tail gas can be greatly adsorbed and eliminated, and the obtained MC nylon has good overall performance. By cooperatively adopting the main materials including epichlorohydrin rubber, nitrile butadiene rubber, acrylonitrile-butadiene copolymer rubber, diene rubber, styrene butadiene rubber and regenerated rubber, the toughness of the material is greatly improved, and the condition that a conveyer belt is easily broken is effectively solved; meanwhile, gases harmful to a human body are not generated at relatively high temperature; and through perfect fusion of the high-temperature resistance, tear resistance and the like, the tear-resistant modified composite environment-friendly rubber base material provided by the invention can be applied to various severe conditions. The added components not only effectively ensure that the protected material is not burnt easily, and but also avoid the generation of gases harmful to the human body when being burnt at extremely high temperature; and compared with the hydrotalcite currently applied on the market, the tear-resistant modified composite environment-friendly rubber base material has obvious advantages of high-temperature resistance, fireproof property and flame retardance.

Owner:SUZHOU RUI TE JIE CHEM PROD CO LTD

Preparation method and product of sunscreen woven bag flat yarn and woven bag

InactiveCN104372433BWith sun protectionMaintain tensile strengthWoven fabricsMonocomponent polyolefin artificial filamentLinear low-density polyethyleneYarn

The invention discloses a preparation method and product of sunscreen woven bag flat yarn and woven bag. The flat yarn is made of polypropylene, antiaging agent, coupling agent, antioxidant, nano calcium carbonate, polyoxymethylene, linear low density polyethylene , polyethylene wax, ethylene-methyl acrylate copolymer, tributyl citrate, turpentine, ultraviolet absorber and additives are stirred evenly, then plasticized into a molten state at a temperature of 230°C to 240°C, and extruded into a film. It is obtained by cooling, cutting embryo silk, and stretching it into flat yarn. The obtained flat yarn is woven into a sunscreen woven bag. The prepared sunscreen woven bag flat yarn has a good breaking strength retention rate after being exposed to the outdoor atmosphere for one year. and elongation retention at break, and good sun protection performance. The performance and service life of the woven bag after using the flat yarn are improved, and the toughness and tensile strength of the original flat yarn are maintained.

Owner:LIAONING TENGHUA PLASTIC

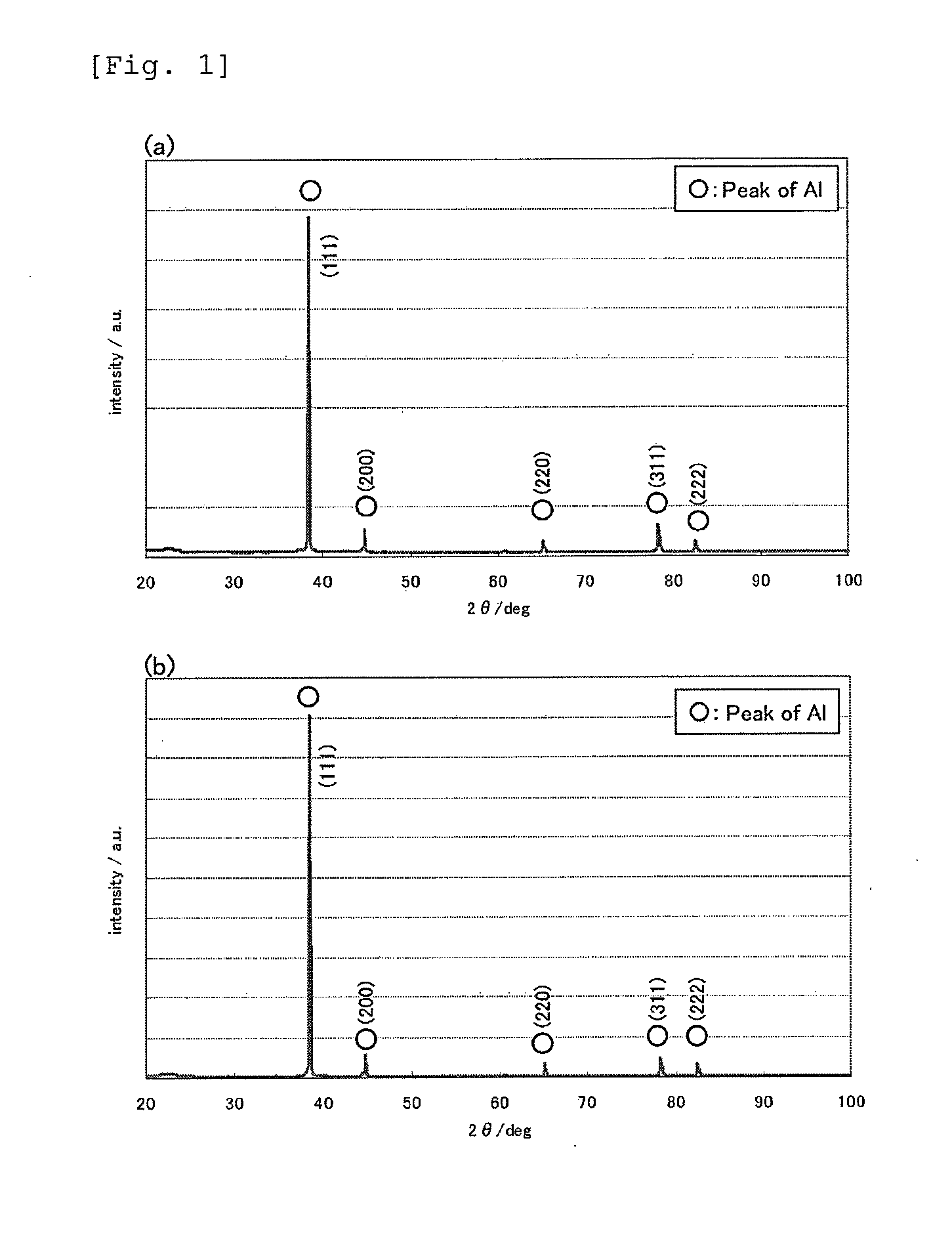

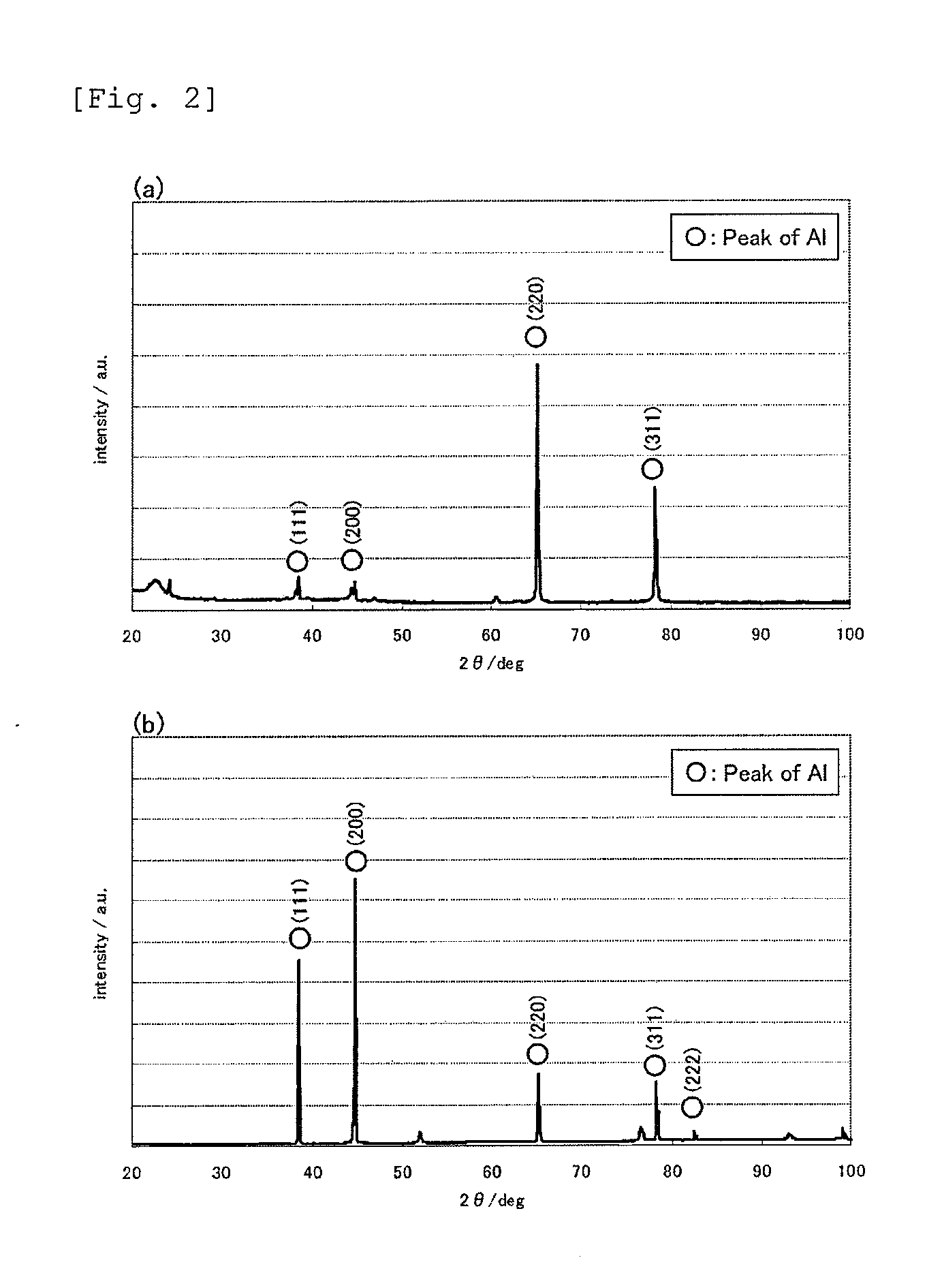

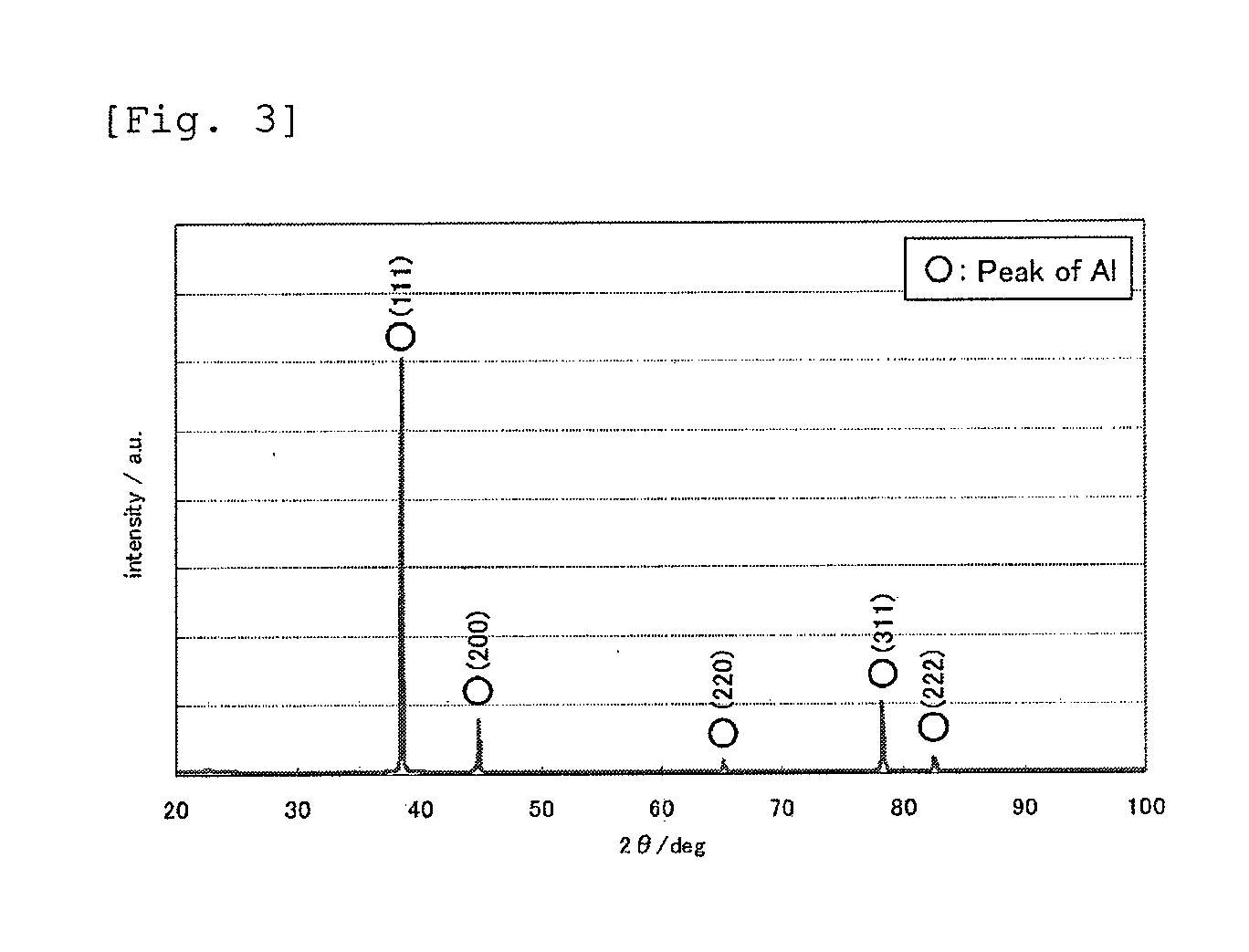

Method for producing aluminum foil

ActiveUS20130224589A1Small sizeHigh energy densityHybrid capacitor electrodesElectrode carriers/collectorsQuaternary ammonium surfactantChemistry

A method for producing an aluminum foil of the present invention is characterized in that an aluminum film is formed on a surface of a substrate by electrolysis using a plating solution containing at least (1) a dialkyl sulfone, (2) an aluminum halide, and (3) at least one nitrogen-containing compound selected from the group consisting of an ammonium halide, a hydrogen halide salt of a primary amine, a hydrogen halide salt of a secondary amine, a hydrogen halide salt of a tertiary amine, and a quaternary ammonium salt represented by the general formula: R1R2R3R4N.X (R1 to R4 independently represent an alkyl group and are the same as or different from one another, and X represents a counteranion for the quaternary ammonium cation), then the film is separated from the substrate to obtain an aluminum foil, and the obtained aluminum foil is subjected to a heat treatment.

Owner:HITACHI METALS LTD

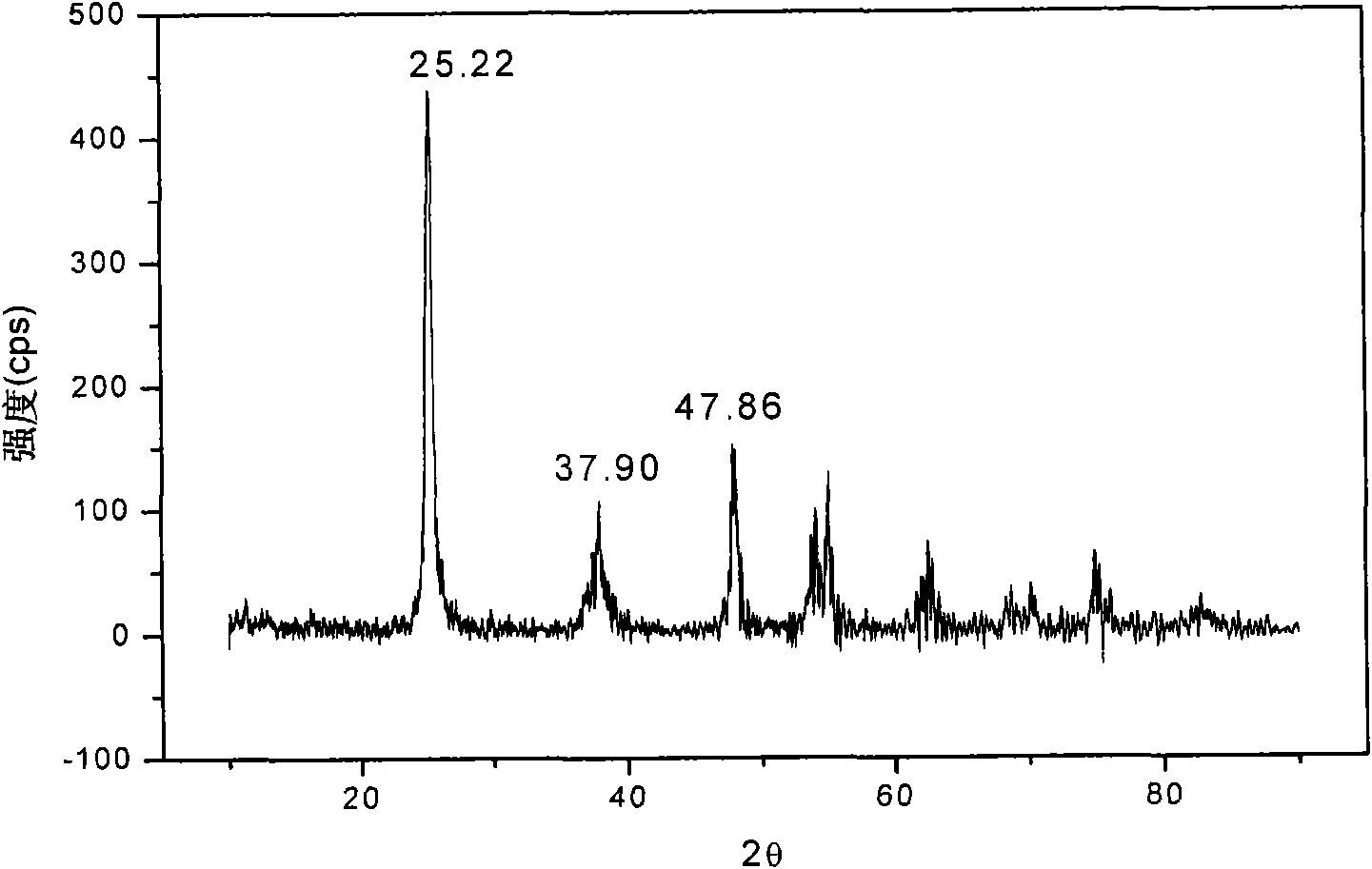

Antimicrobial polyvinyl chloride plastic and preparation method thereof

ActiveCN101580617BReduce utilizationMaintain mechanical propertiesFlat articlesPolyvinyl chlorideResin matrix

The invention discloses an antimicrobial polyvinyl chloride plastic and a preparation method thereof. The antimicrobial polyvinyl chloride plastic comprises a polyvinyl chloride resin matrix, a plastic additive and a nano titanium dioxide photocatalyst which is assembled on the surface of the polyvinyl chloride resin matrix, and is characterized in that the nano titanium dioxide photocatalyst is doped with inorganic non-metallic anions. The nano antimicrobial polyvinyl chloride plastic is non-toxic, has high antibacterial, fungistatic, mildewproof, and anti-fouling functions under the visible light irradiation conditions, and has very strong mildewproof property to the mildew such as aspergillus niger, aspergillus terreus, ruddle penicillium and the like, with the mildewproof grade up to 0, and the killing rate to escherichia coli, candida albicans, staphylococcus aureus, Gram bacteria and the like being larger than 91 percent.

Owner:XINYA ELECTRONICS

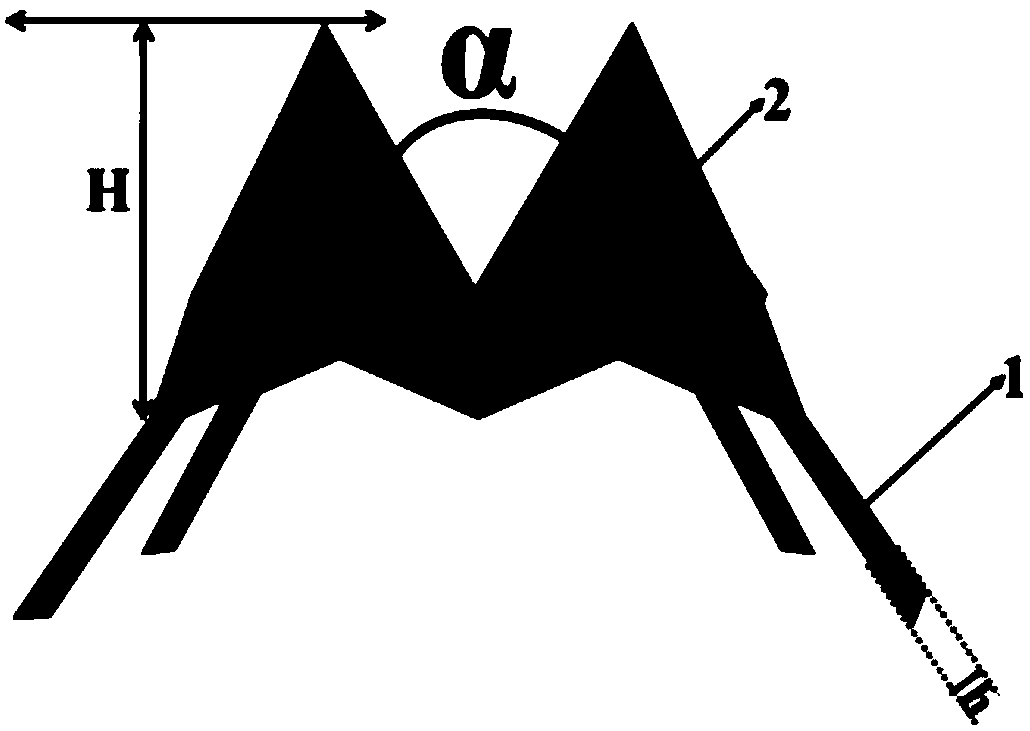

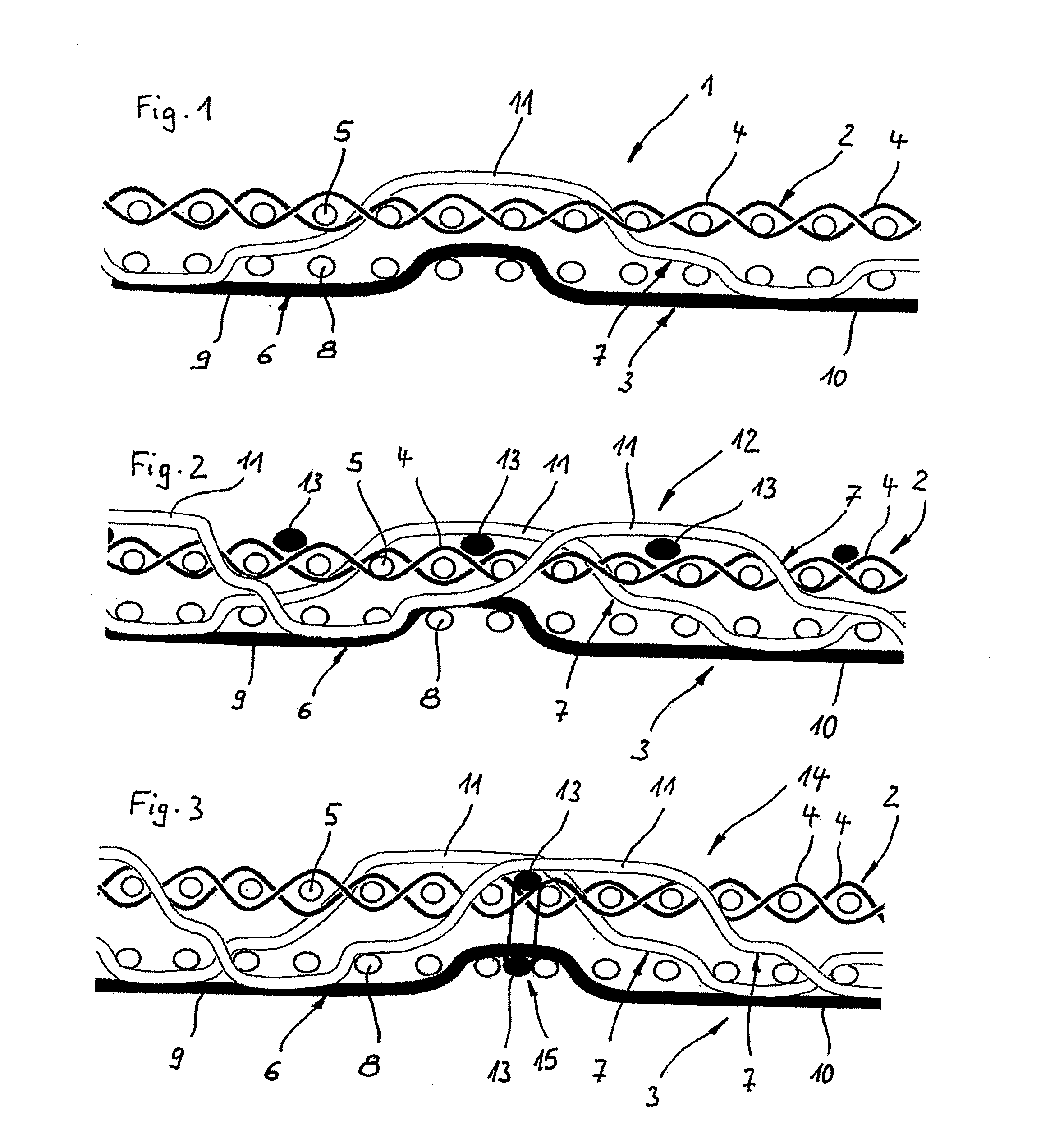

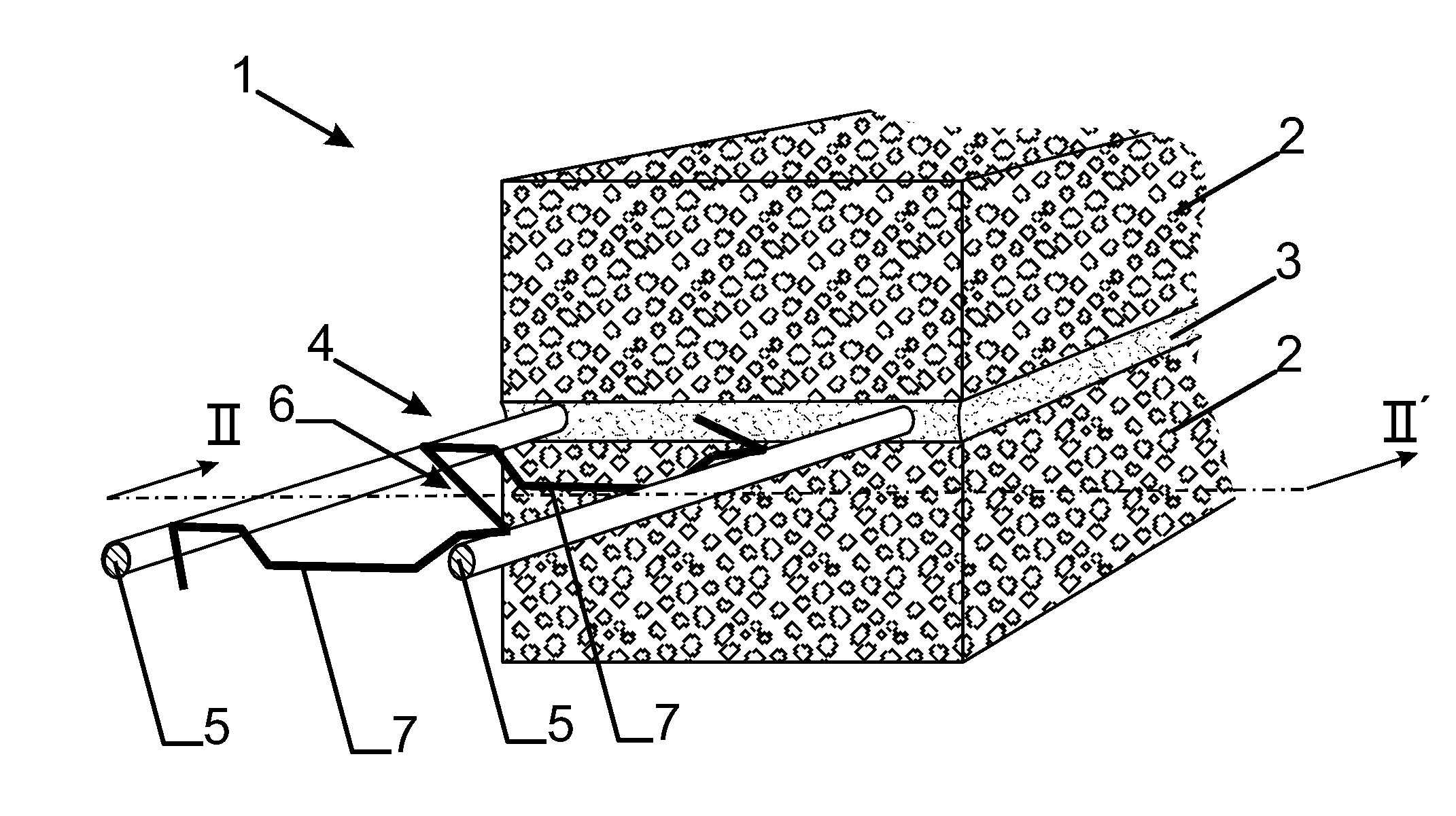

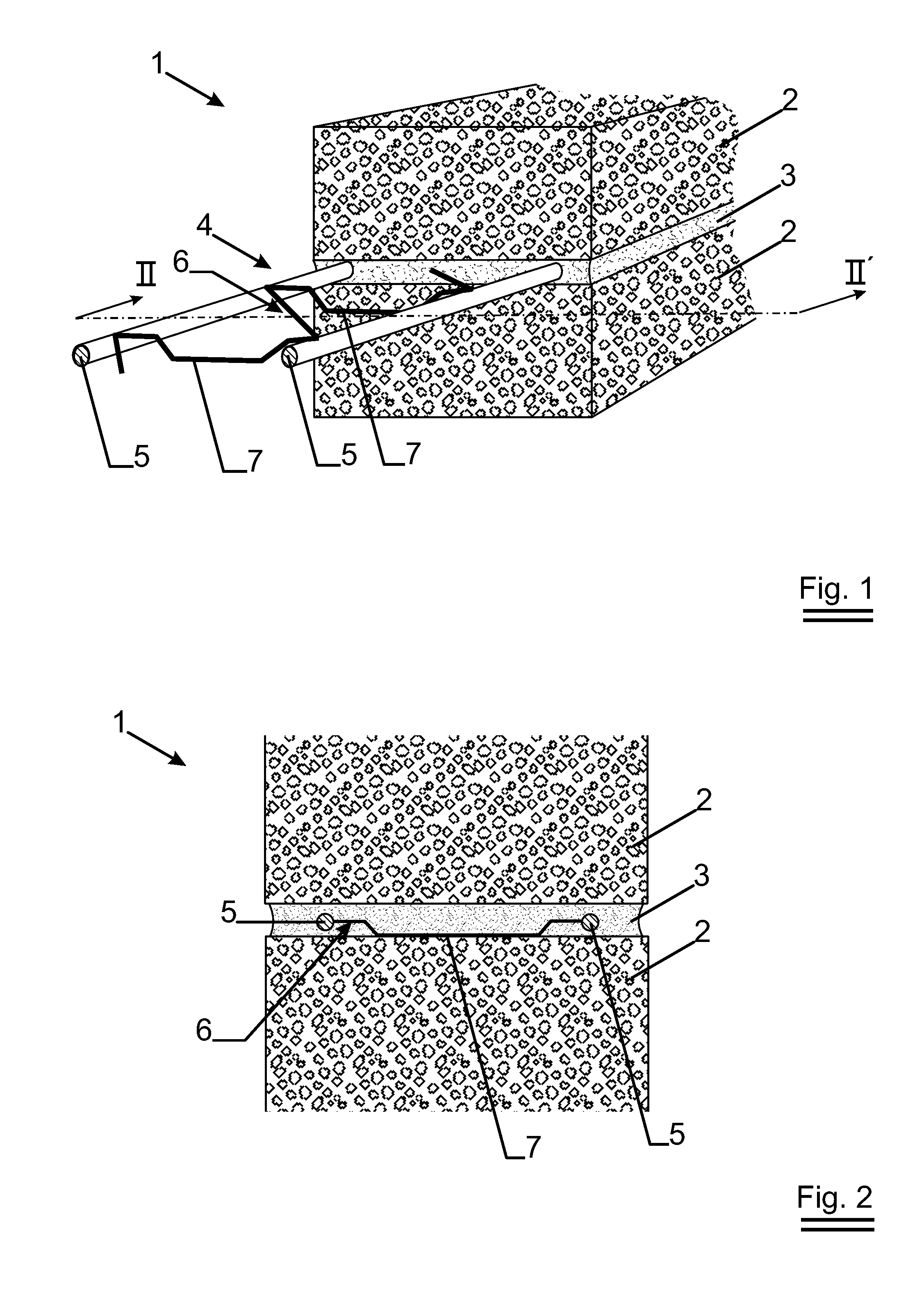

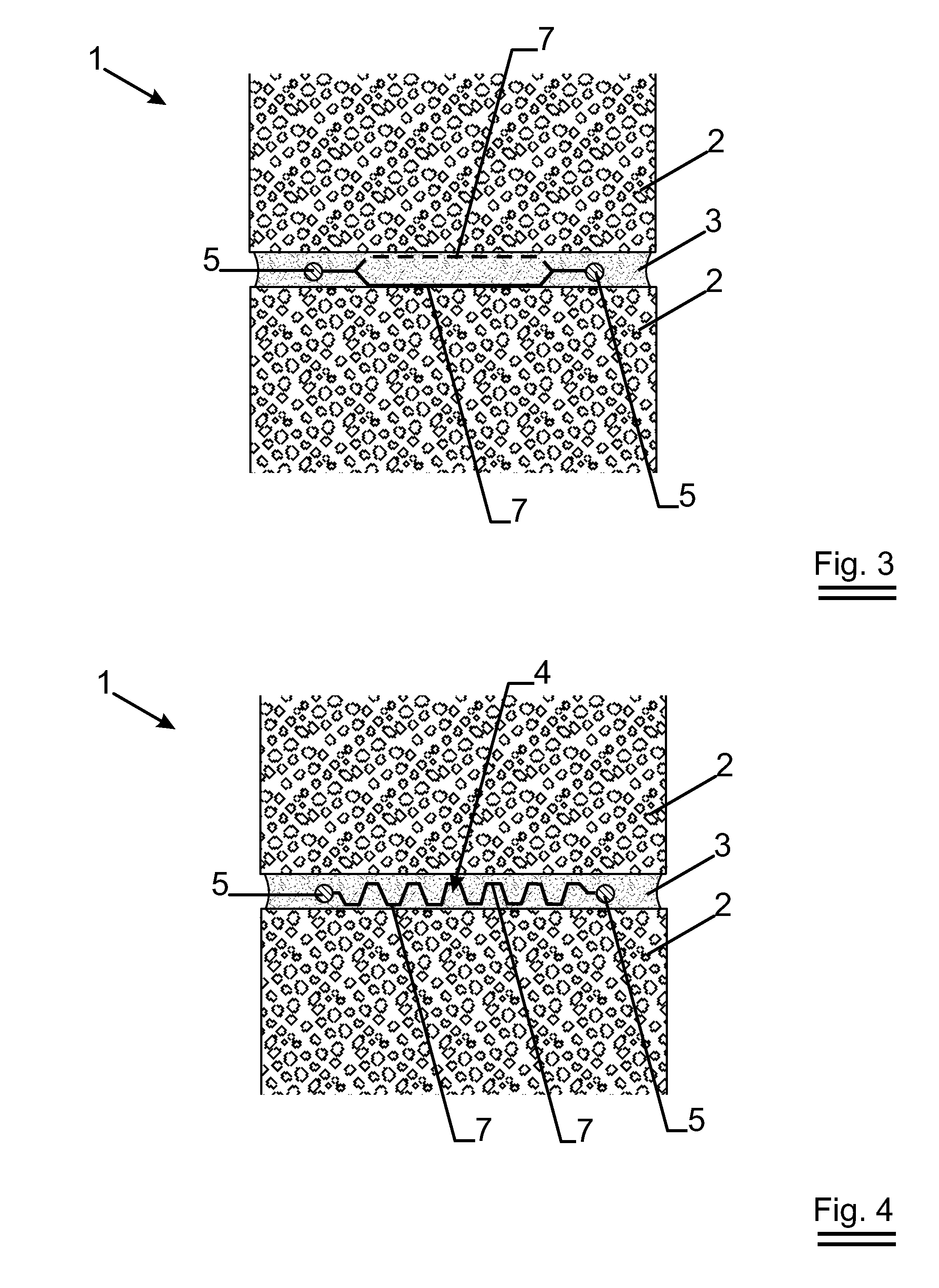

Masonry with steel reinforcement strip having spacers

Masonry (1) comprising layers (2) of bricks and mortar joints (3), whereby at least one mortar joint (3) is reinforced by a reinforcement strip (4), whereby said strip (4) comprises at least two straight, continuous, substantially parallel, steel reinforcement wires (5), which are welded or glued to each other by means of a steel wire connecting structure (6), characterised in that the wire connecting structure (6) is provided with protuberances (7) protruding from the plane comprising said at least two straight reinforcement wires (5) and forming spacing elements (7) which keep the at least two straight reinforcement wires (5) at a specific distance from the layer (2) of bricks below and / or the layer (2) of bricks above said reinforcement strip (4).

Owner:NV BEKAERT SA

Composite material purline for agricultural greenhouse

InactiveCN102634222AMaintain tensile strengthClimate change adaptationGreenhouse cultivationFiberGreenhouse

The invention discloses a flame-resistant, corrosion-resistant, light-weight and high-impact composite material purline for an agricultural greenhouse. According to the technical scheme, the composite material purline is characterized by being prepared from the following raw materials in parts by weight: 30 to 35 parts of unsaturated resin, 10 to 15 parts of low shrinkage agent, 10 to 20 parts of high-impact SBS, 20 to 30 parts of filling, 20 to 30 parts of enhanced fiber, 1 to 2 parts of solidifying agent, 1 to 2 parts of demolding agent, 40 to 60 parts of filling material, 5 to 8 parts of flame retardants, 1 to 2 parts of process additive and 1 to 2 parts of accelerating agent.

Owner:青岛润兴高分子材料有限公司

Preparation method of rapidly dissolving magnesium alloy

The invention discloses a preparation method of a rapidly dissolving magnesium alloy, and belongs to the technical field of metal material corrosion. The method includes the following steps: preparinga magnesium ingot, a nickel ingot, a copper ingot, an iron ingot and a silicon ingot, and after melting part of the magnesium ingot, adding the rest of the alloy ingots for primary smelting and casting to obtain a magnesium alloy intermediate material; and then, after secondarily melting the remaining magnesium ingot, adding the magnesium alloy intermediate for secondary melting and casting to obtain the magnesium alloy material. The corrosion rate of the magnesium alloy is high, which meets the demand for the rapidly dissolving magnesium alloy for industrial production; and besides, the corrosion rate of the magnesium alloy can be adjusted. Under the condition of a 5% NaCl solution at 25 DEG C, the magnesium alloy has the corrosion rate reaching 702-2163 mm / a, the tensile strength reaching 231-283 MPa and the compressive strength reaching 386-456 MPa.

Owner:厦门火炬特种金属材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com