Antimicrobial polyvinyl chloride plastic and preparation method thereof

A technology of polyvinyl chloride and polyvinyl chloride resin, which is applied in the field of antibacterial PVC plastic film and its preparation, antibacterial plastic and its preparation, and can solve the problems of low solar energy utilization rate, long-term mildew resistance, antibacterial and antifouling inhibition, Problems such as low photon quantum efficiency, achieve the effects of maintaining tensile strength and light transmittance, high antibacterial, and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

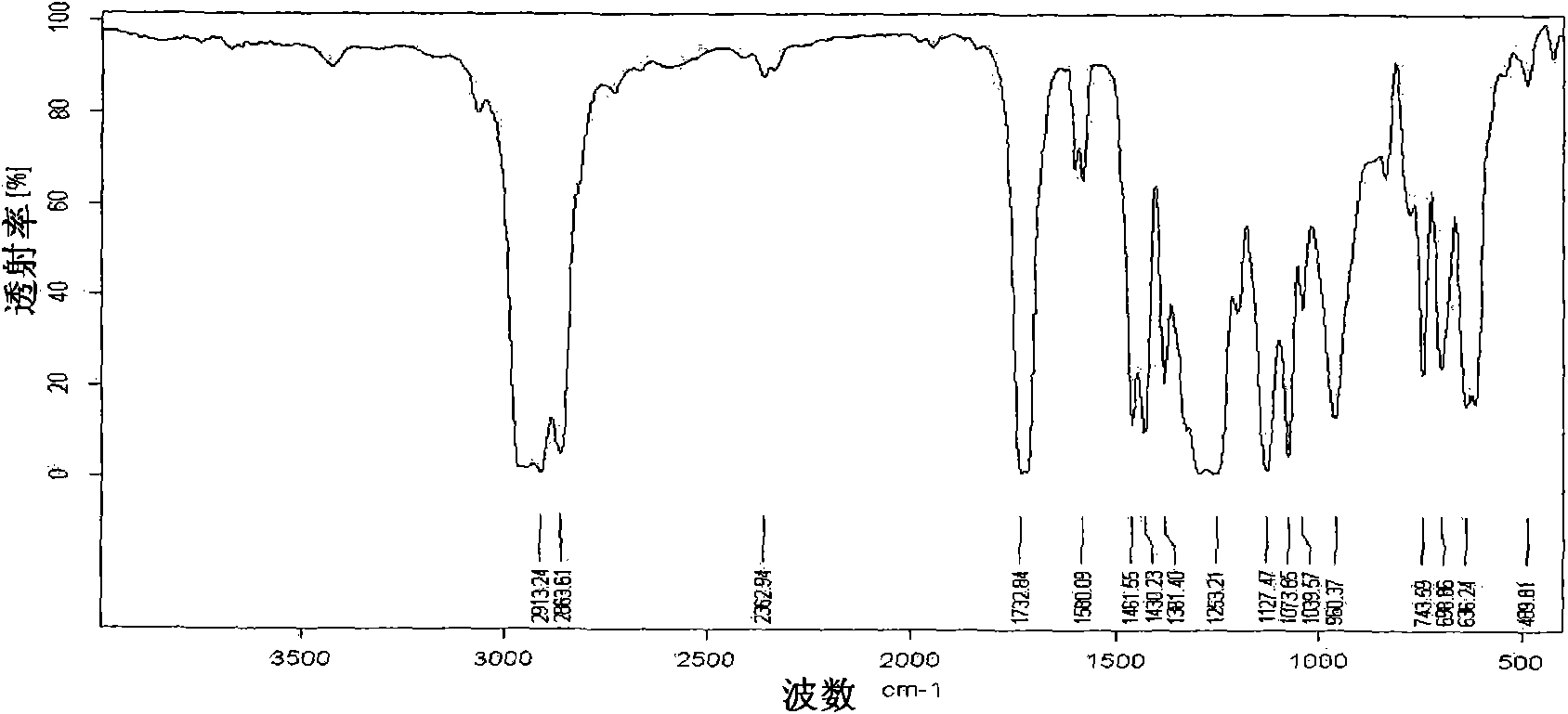

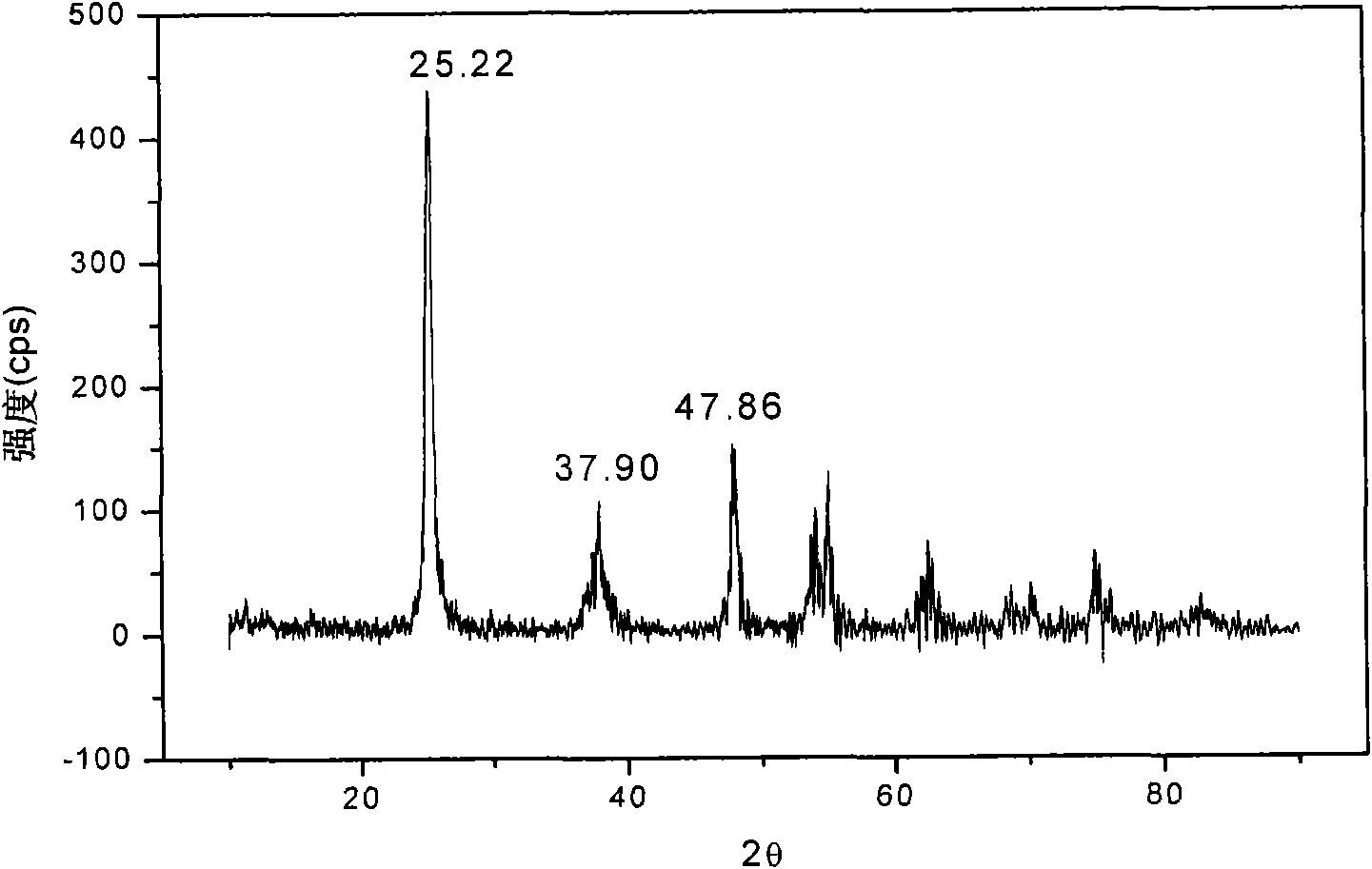

[0028] Add 250L of deionized water to a 1000L reactor, adjust the pH to 2 with concentrated nitric acid, keep the temperature at 80°C, add 10L of 10% titanyl sulfate aqueous solution dropwise at a rate of 1mL / min, stir for 24h, and then add 350L of three Ethylamine, continue to stir at room temperature for 12h, and let stand to separate layers. Take 350L of the light yellow solution in the lower layer and place it in a 500L reactor, add 100g of methacryloxysilane, stir at room temperature for 30min, then add 100kg of light polyvinyl chloride (DP 1300) resin powder, continue stirring for 2h, filter, Dry to obtain antibacterial polyvinyl chloride micropowder.

[0029] 100 parts by weight of the above-mentioned soft polyvinyl chloride (DP 1300) resin micropowder assembled with nitrogen-doped titanium dioxide photocatalyst, wherein about 35nm nano-scale nitrogen-doped titanium dioxide (TiO 2-x N x ) The total amount of the photocatalyst is 1% of the weight of the polyvinyl chlor...

Embodiment 2

[0031] Prepare the soft polyvinyl chloride (DP 1300) resin powder that is assembled with nitrogen-doped titanium dioxide photocatalyst in the same manner as Example 1, the difference is that the titanium dioxide precursor selected is titanyl nitrate; the nitrogen dopant selected is Ethylenediamine.

[0032] 100 parts by weight of soft polyvinyl chloride (DP 1300) resin micropowder assembled with nitrogen-doped titanium dioxide photocatalyst, wherein about 35nm nano-scale nitrogen-doped titanium dioxide (TiO 2-x N x) The total amount of the photocatalyst is 2% of the weight of the polyvinyl chloride resin matrix, and the content of nitrogen in the titanium dioxide photocatalyst is controlled at 8% (weight ratio). Above-mentioned PVC fine powder is blended with the dioctyl phthalate plasticizer of 43 parts by weight, the epoxy soybean oil antioxidant of 3 parts by weight, the liquid barium-zinc composite thermal stabilizer of 1 part by weight, at 110~150 After stirring at a co...

Embodiment 3

[0034] Soft polyvinyl chloride (DP 1300) resin powder assembled with nitrogen-doped titanium dioxide photocatalyst was prepared in the same manner as in Example 1, except that the titanium dioxide precursor was titanium tetrachloride.

[0035] 100 parts by weight of soft polyvinyl chloride (DP 1300) resin micropowder assembled with nitrogen-doped titanium dioxide photocatalyst, wherein about 47nm nano-scale nitrogen-doped titanium dioxide (TiO 2-x N x ) The total amount of the photocatalyst is 4% of the weight of the polyvinyl chloride resin matrix, and the content of nitrogen in the titanium dioxide photocatalyst is controlled at 8% (weight ratio). Above-mentioned PVC micropowder and the dioctyl phthalate plasticizer of 38 weight parts, the dioctyl glutarate plasticizer of 2 weight parts, the dioctyl sebacate plasticizer of 4 weight parts, the dioctyl sebacate plasticizer of 2 weight parts The liquid barium-zinc-calcium heat stabilizer is blended, stirred evenly at a constan...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| control rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com