Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

59results about How to "Consistent flow" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

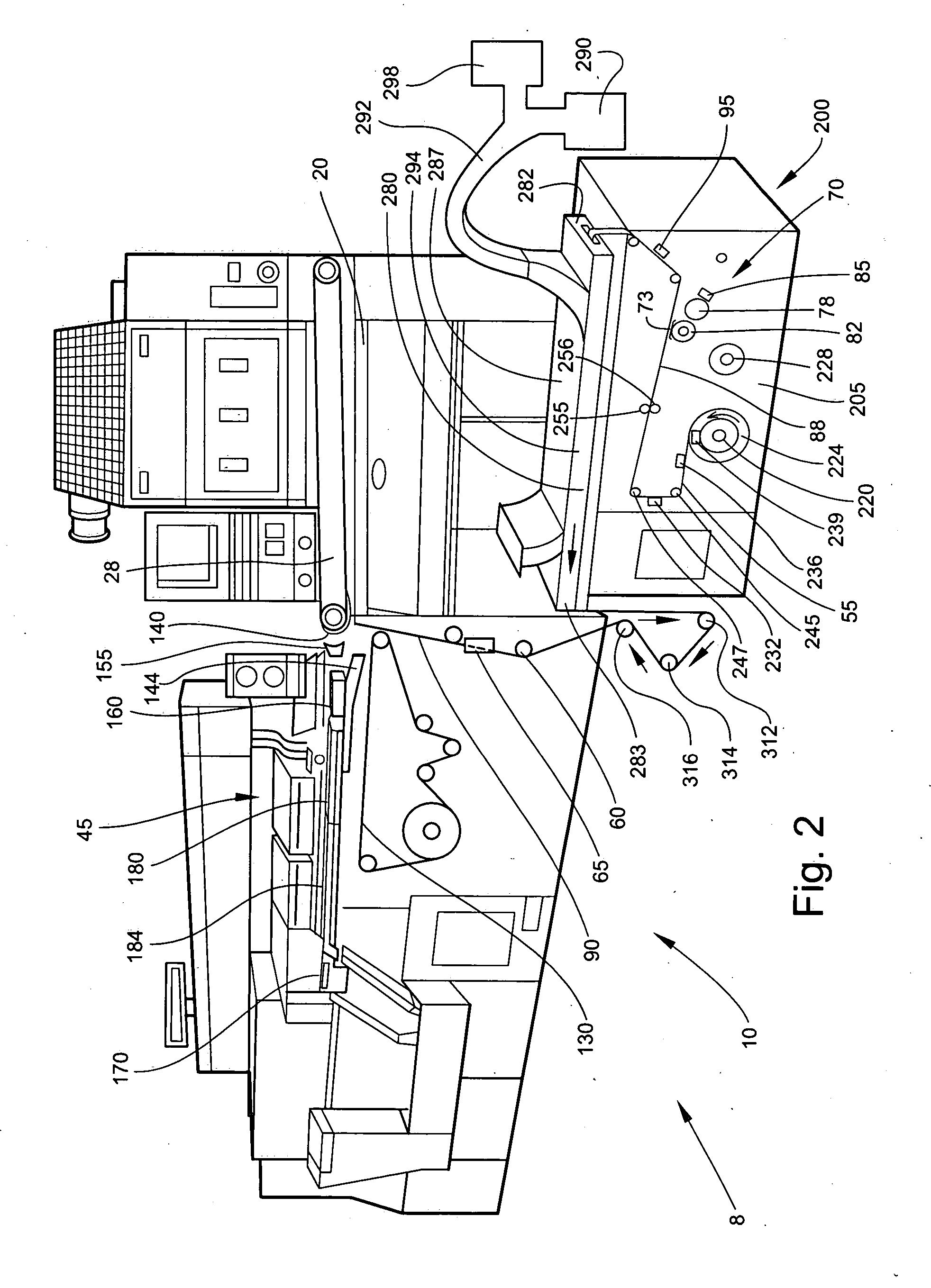

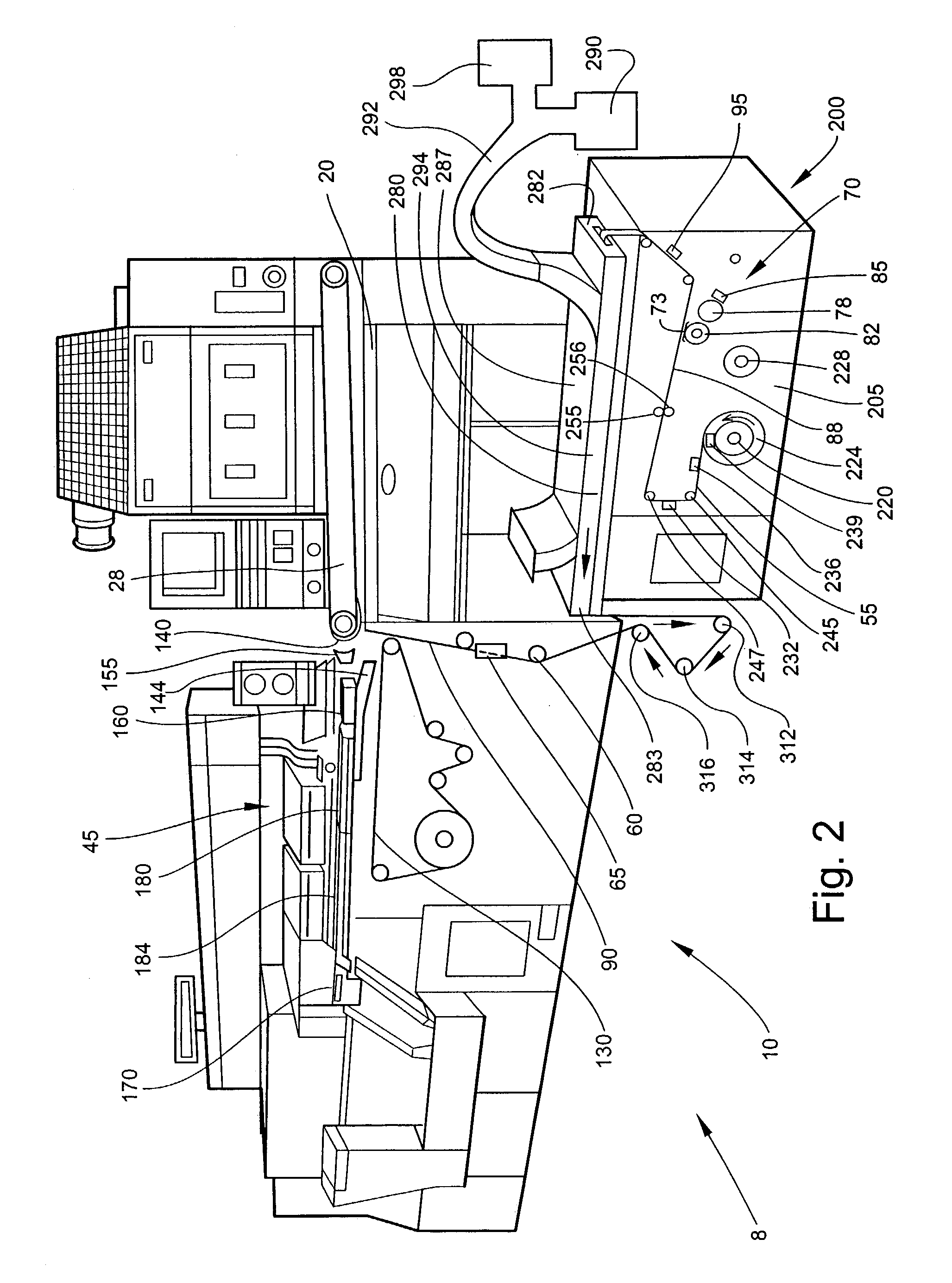

Materials, equipment and methods for manufacturing cigarettes

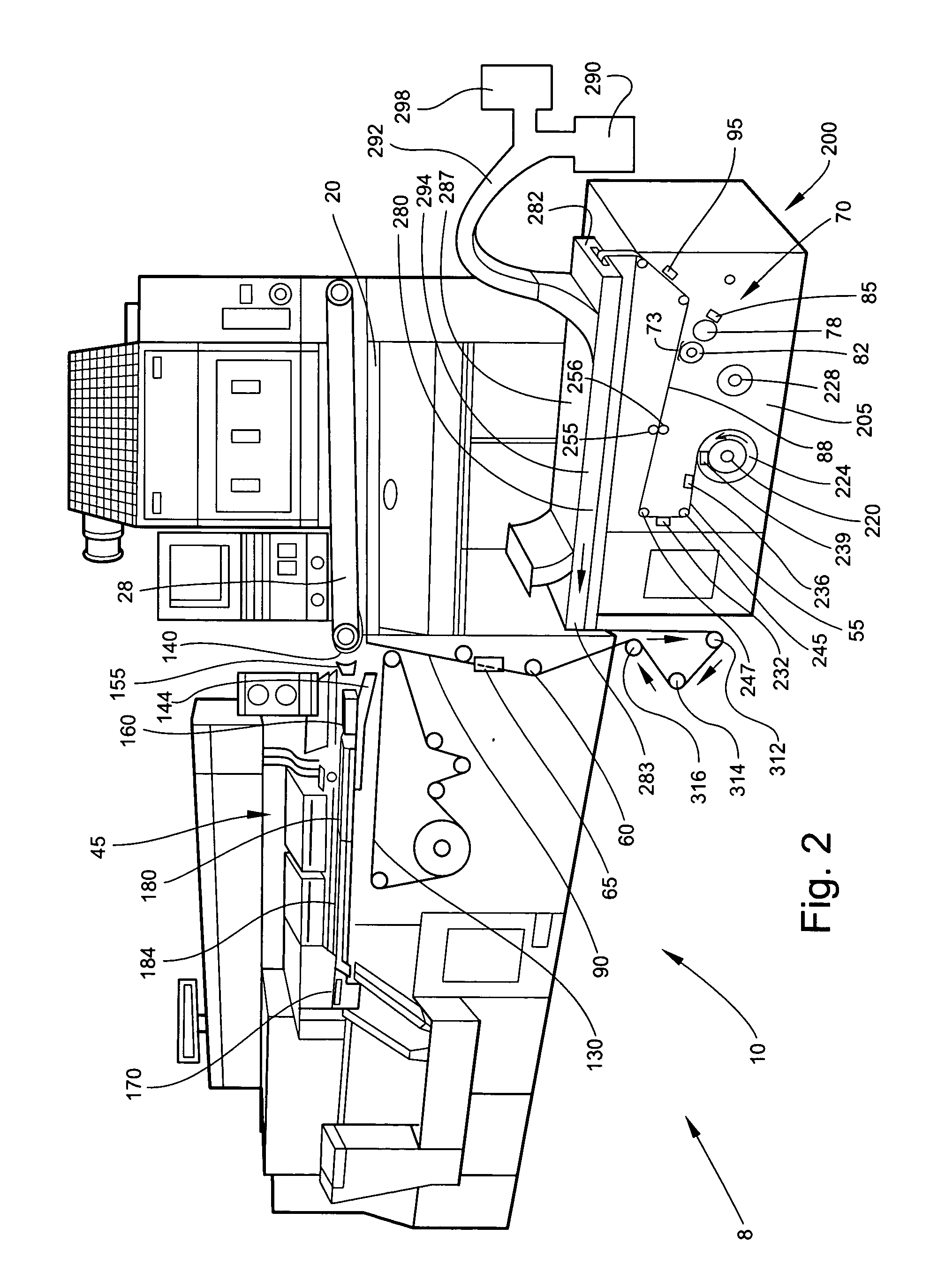

ActiveUS20050076929A1Minimize and avoid and prevent transferConsistent flowNon-fibrous pulp additionNatural cellulose pulp/paperBobbinAssembly systems

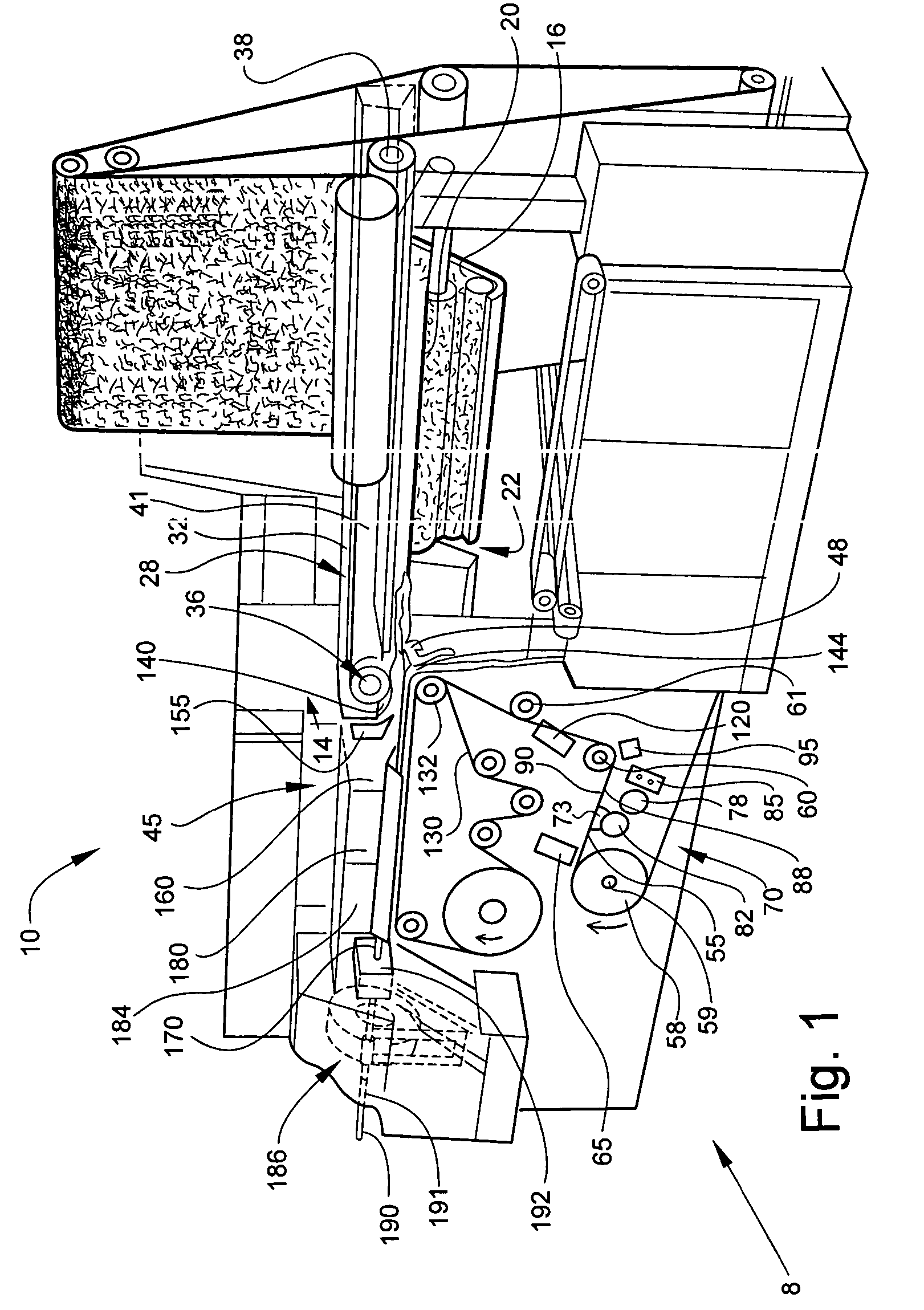

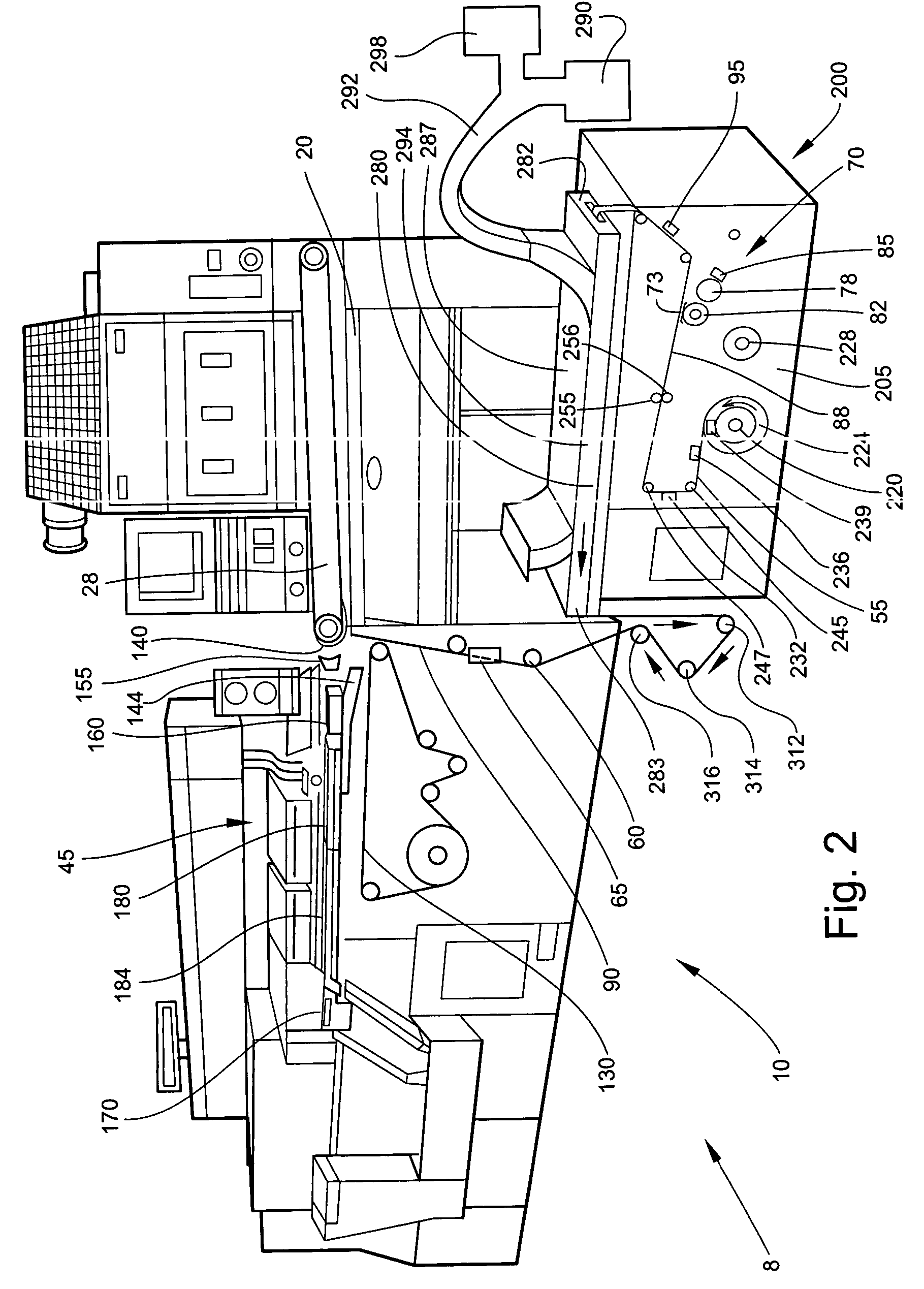

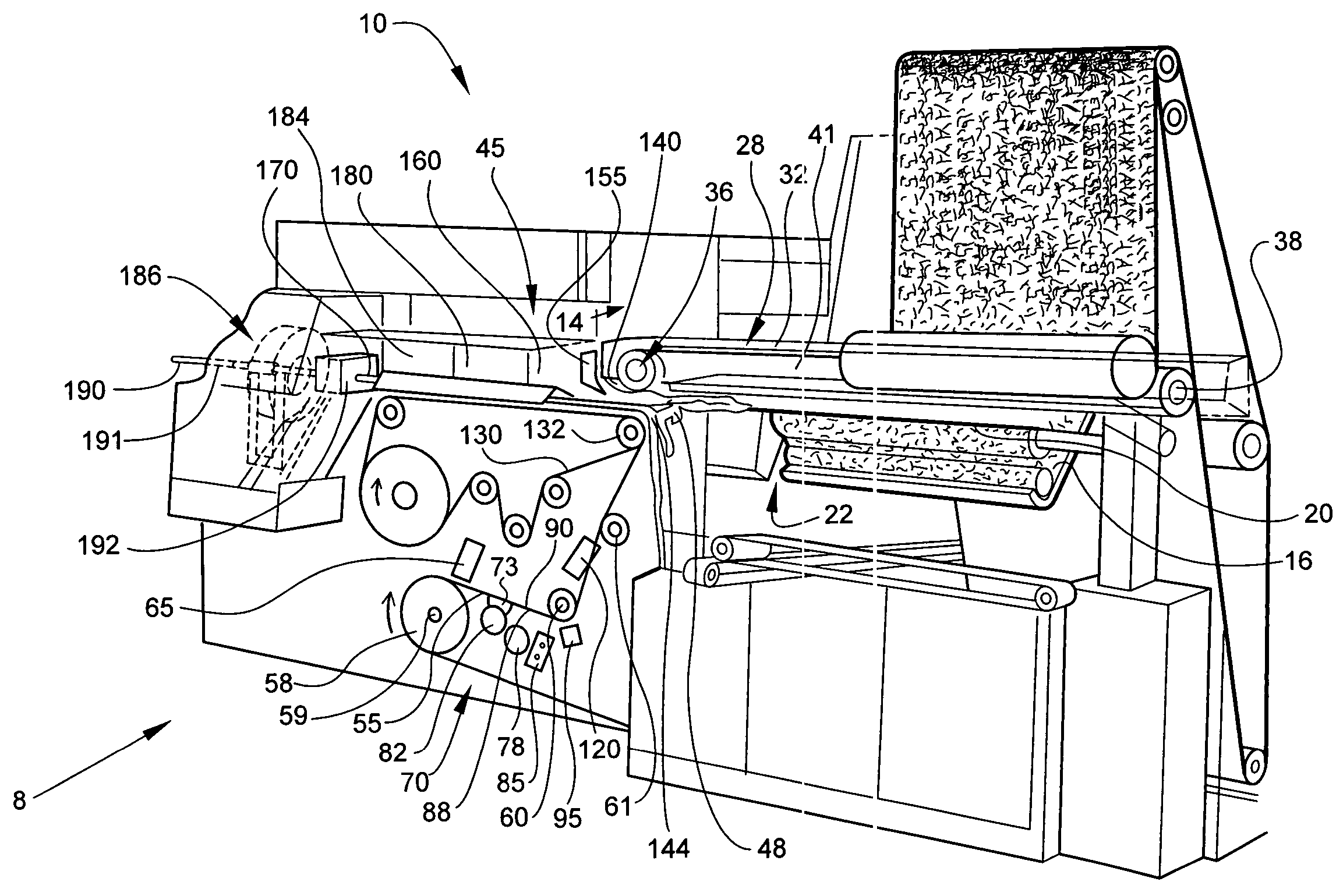

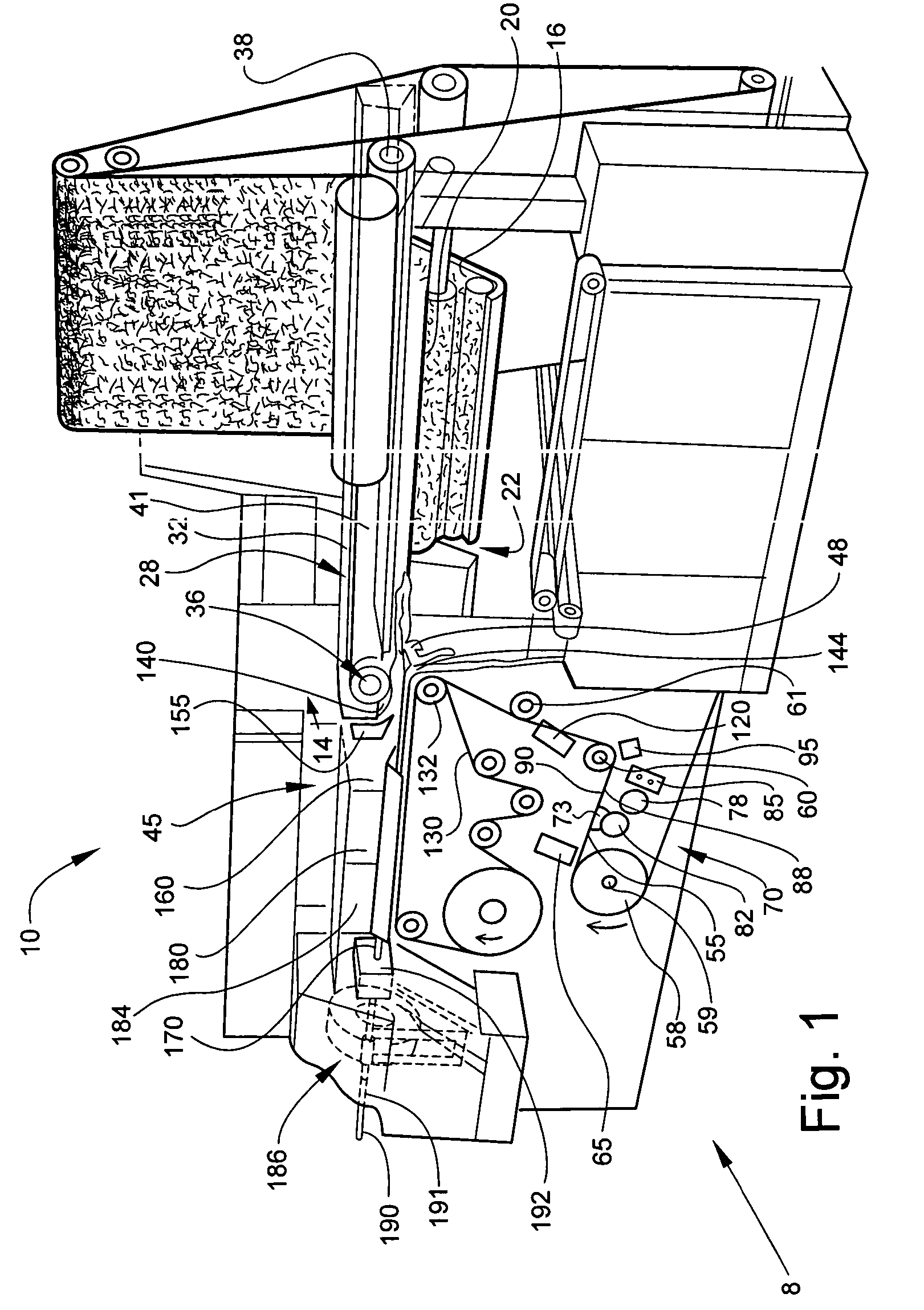

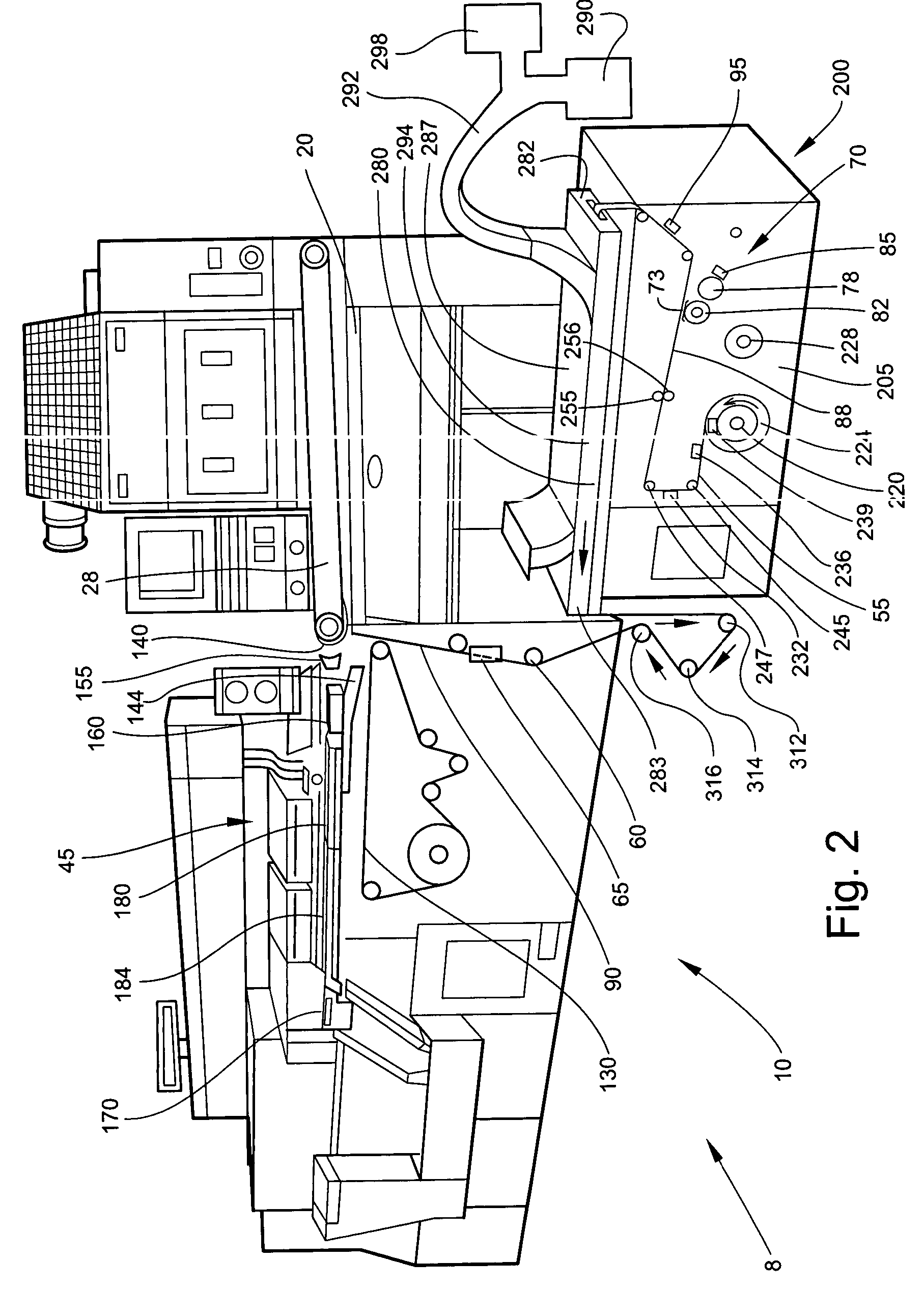

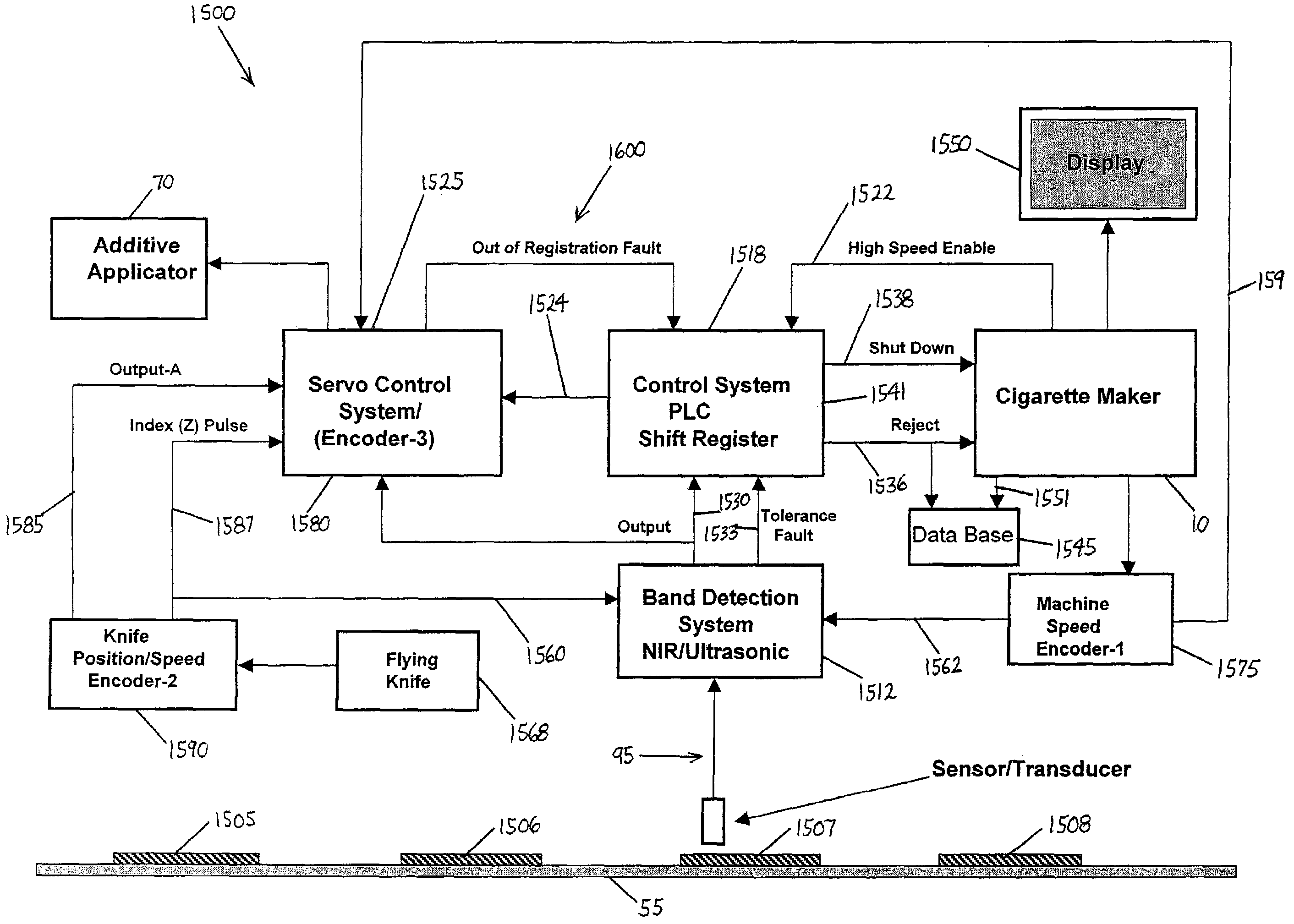

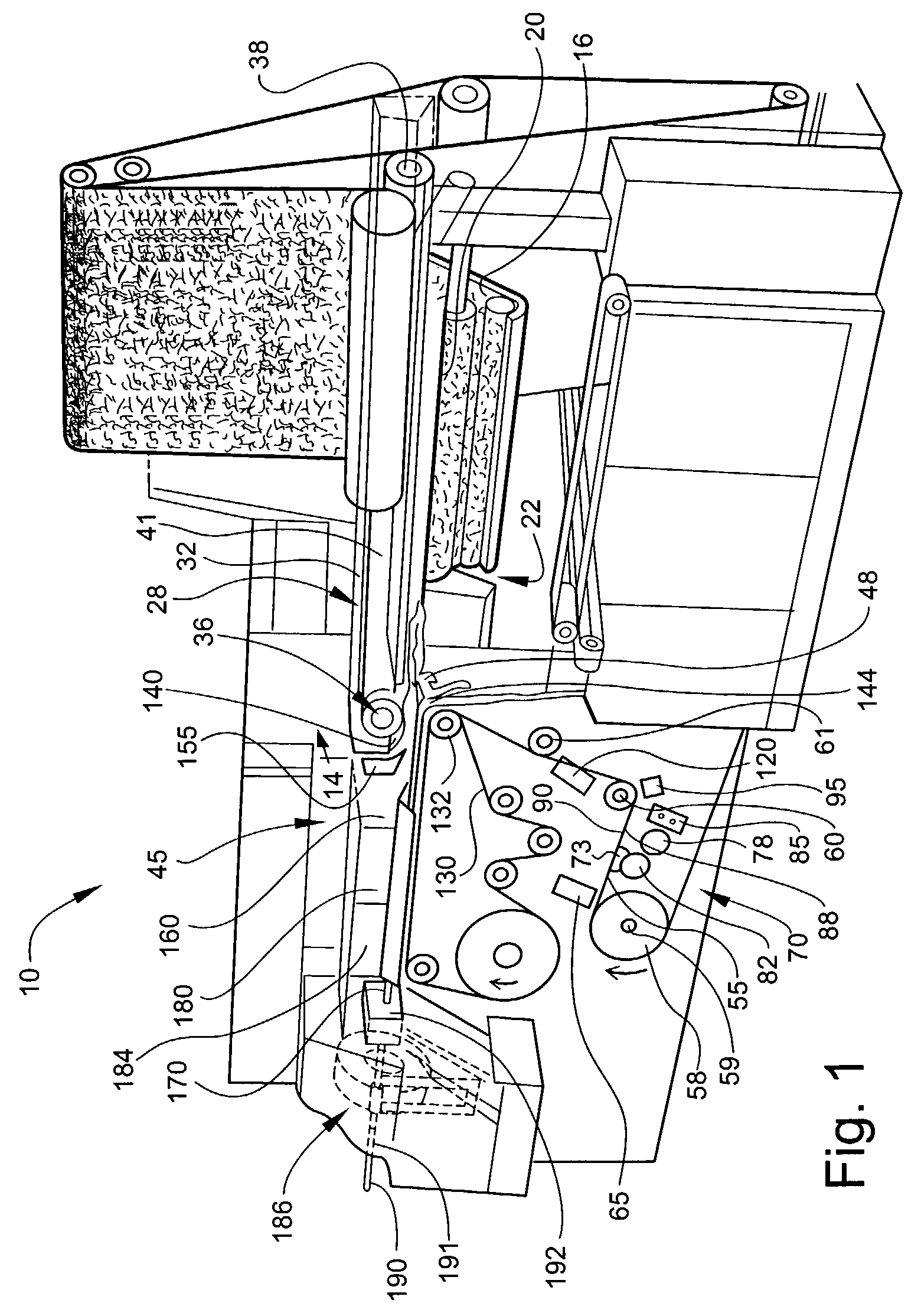

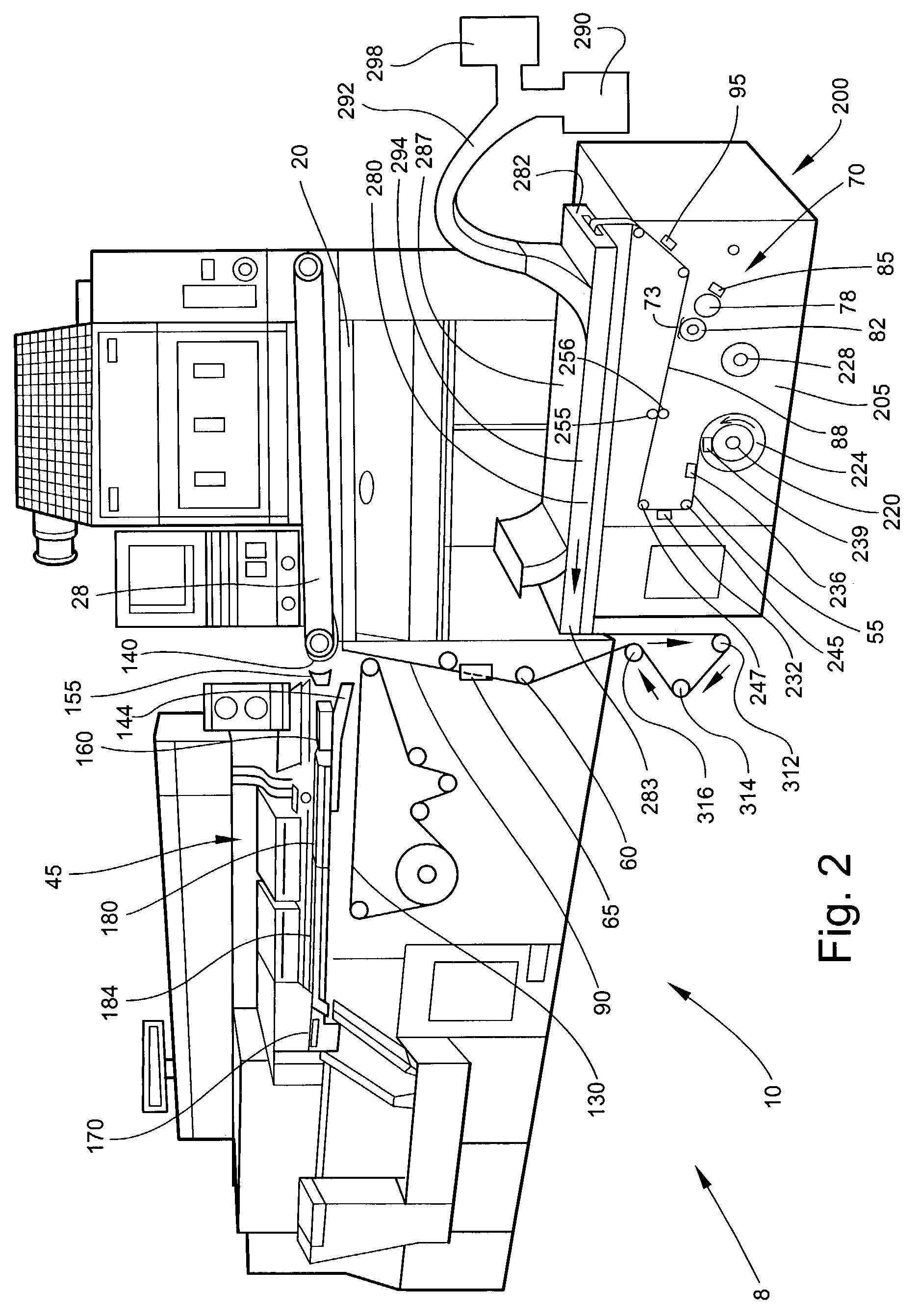

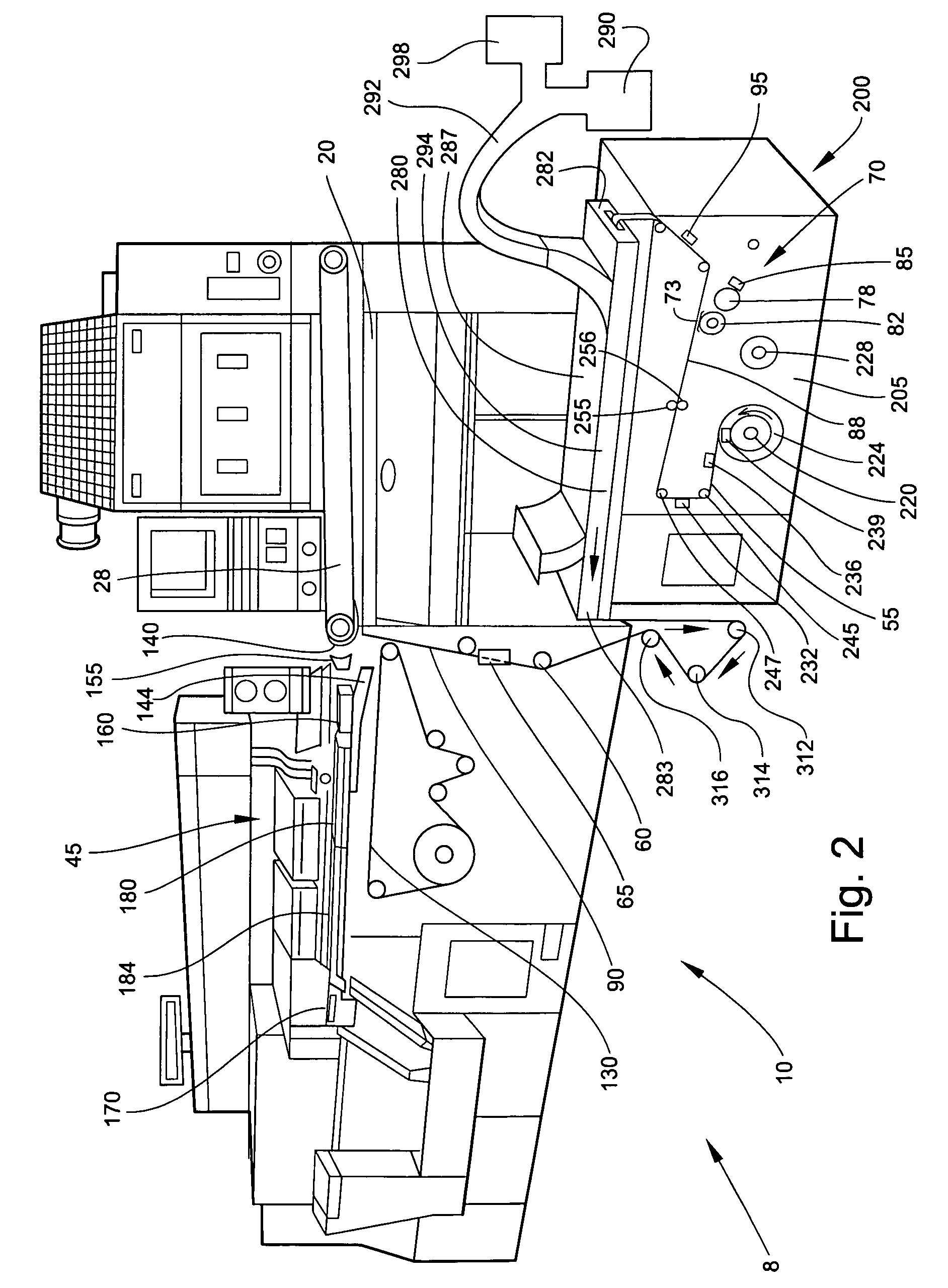

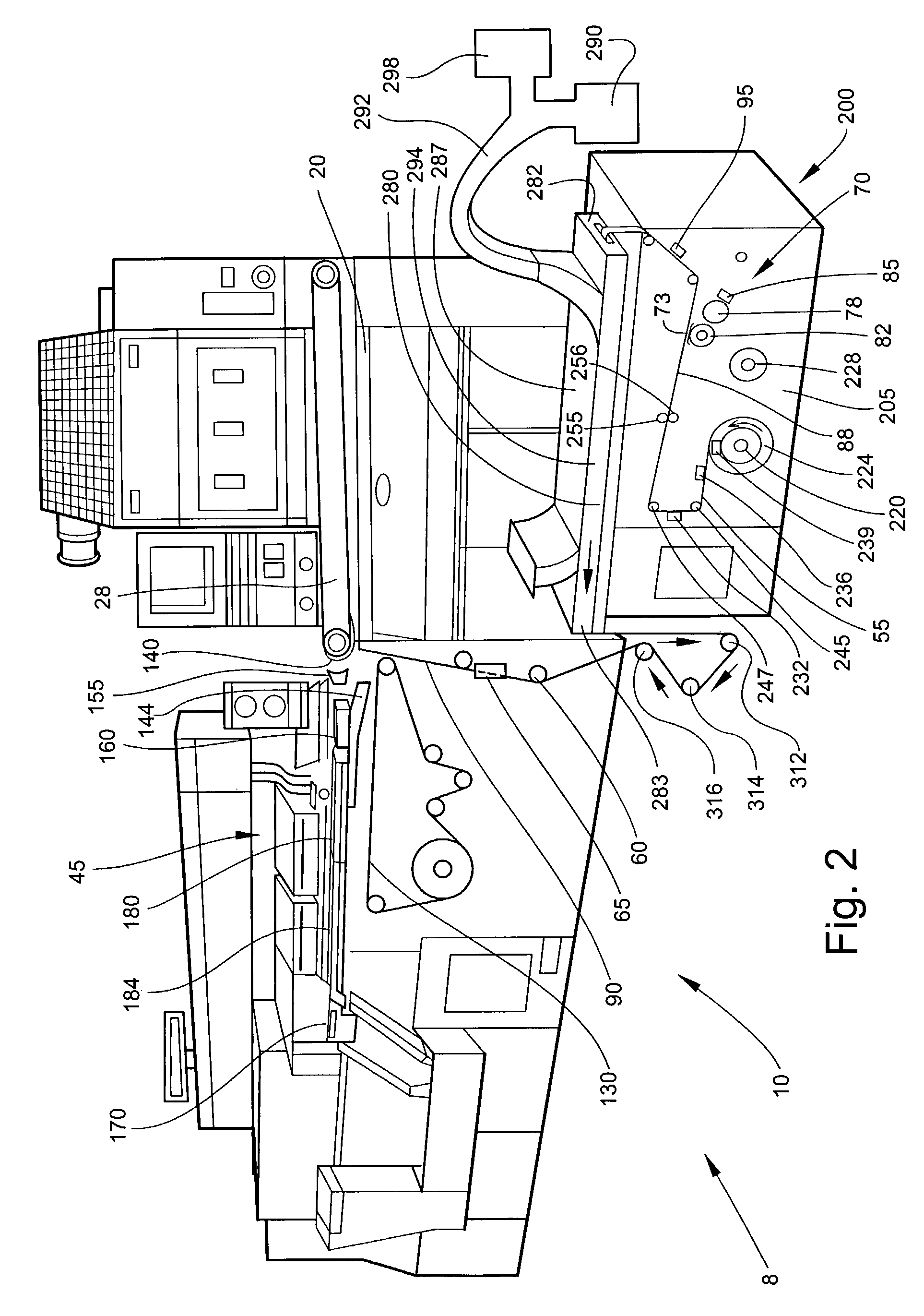

Cigarettes are manufactured using modified automated cigarette making apparatus. Those cigarettes possess smokable rods having paper wrapping materials having additive materials applied thereto as patterns. The additive materials, which can have the forms of liquid or paste formulations (e.g., aqueous formulations incorporating starch or modified starch), are applied to a continuous paper web on the cigarette making apparatus. The formulation is applied to the paper web using application apparatus possessing rollers a series of roller. For example, additive material is applied to the roll face of a transfer roller due to roll interaction of that transfer roller with a pick-up roller; roll interaction of the transfer roller with an application roller causes transfer of the additive material from the transfer roller to the application roller; and additive material from the application roller is transferred to the paper web that passes between the application roller and a back-up roller. A radiant dryer is used to dry the additive material that has been applied to the paper web. The radiant dryer is located on one component of a two component assembly that is used to manufacture cigarettes. A first component of the two component assembly provides a source of paper web, applies additive material to that web in a pattern and dries the paper web; while a second component receives the paper web, supplies tobacco filler and manufactures a cigarette rod from the paper web and tobacco filler. An alternate assembly system provides a source of paper web, applies additive material to that web in a pattern, dries the paper web, and winds the treated paper web on to a bobbin; and that bobbin is later used to provide a source of paper web on a cigarette making machine unrolls that bobbin, receives the treated paper web from that bobbin, supplies tobacco filler and manufactures a cigarette rod from the paper web and tobacco filler. Spectrometric techniques are used to ensure proper registration of the additive material on the cigarette rods so manufactured, and to ensure proper quality of those cigarettes.

Owner:R J REYNOLDS TOBACCO COMPANY

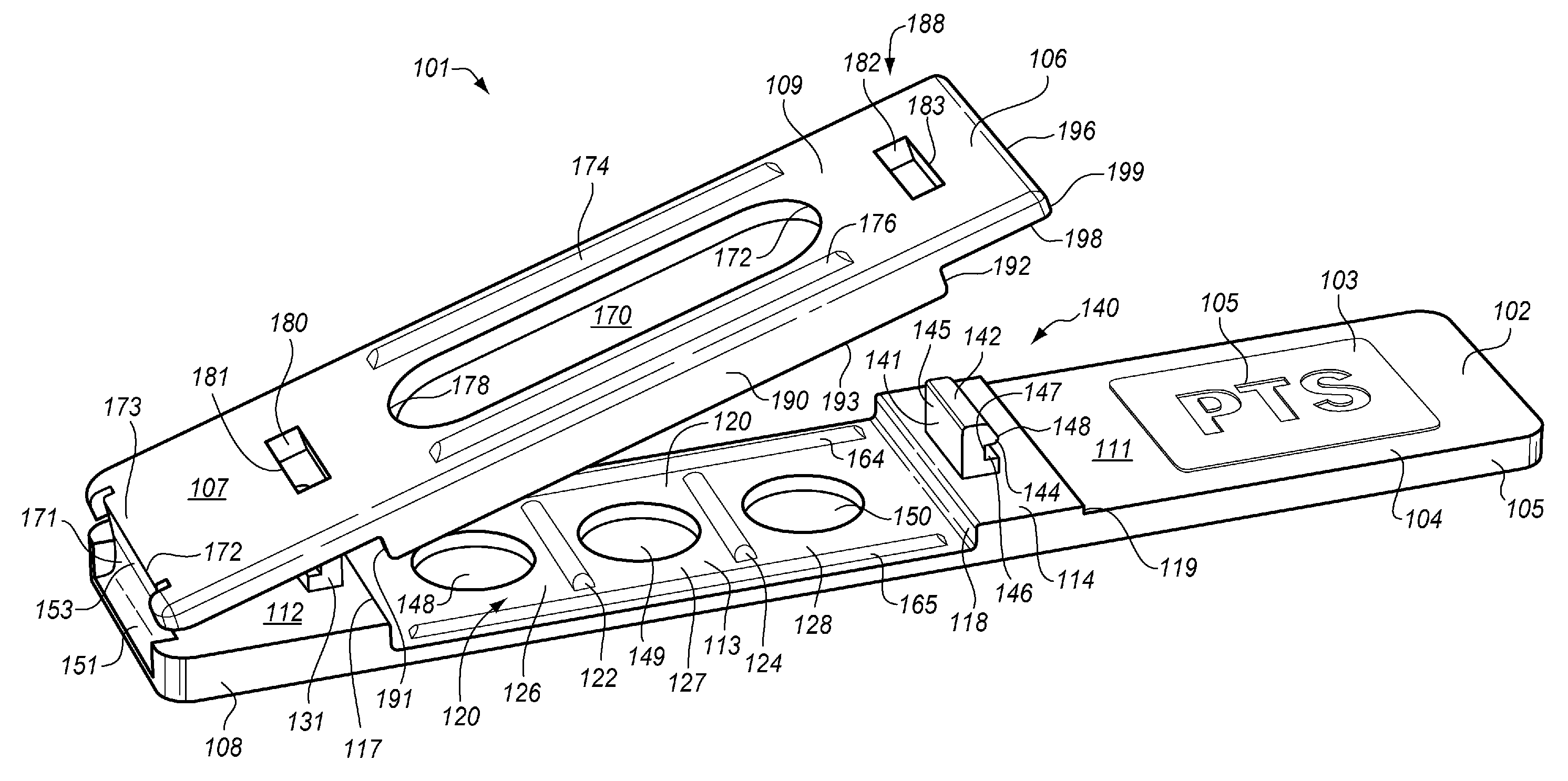

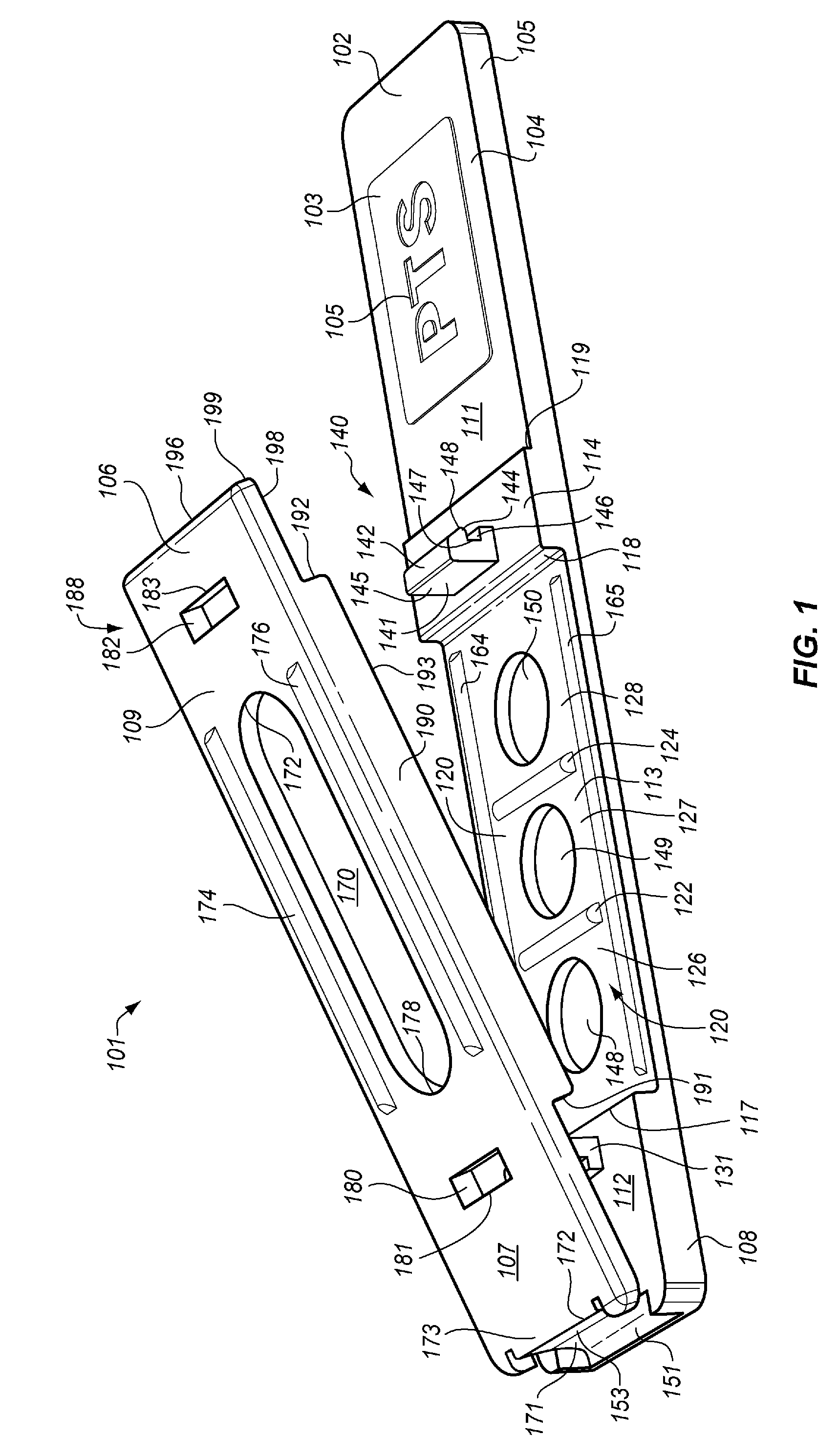

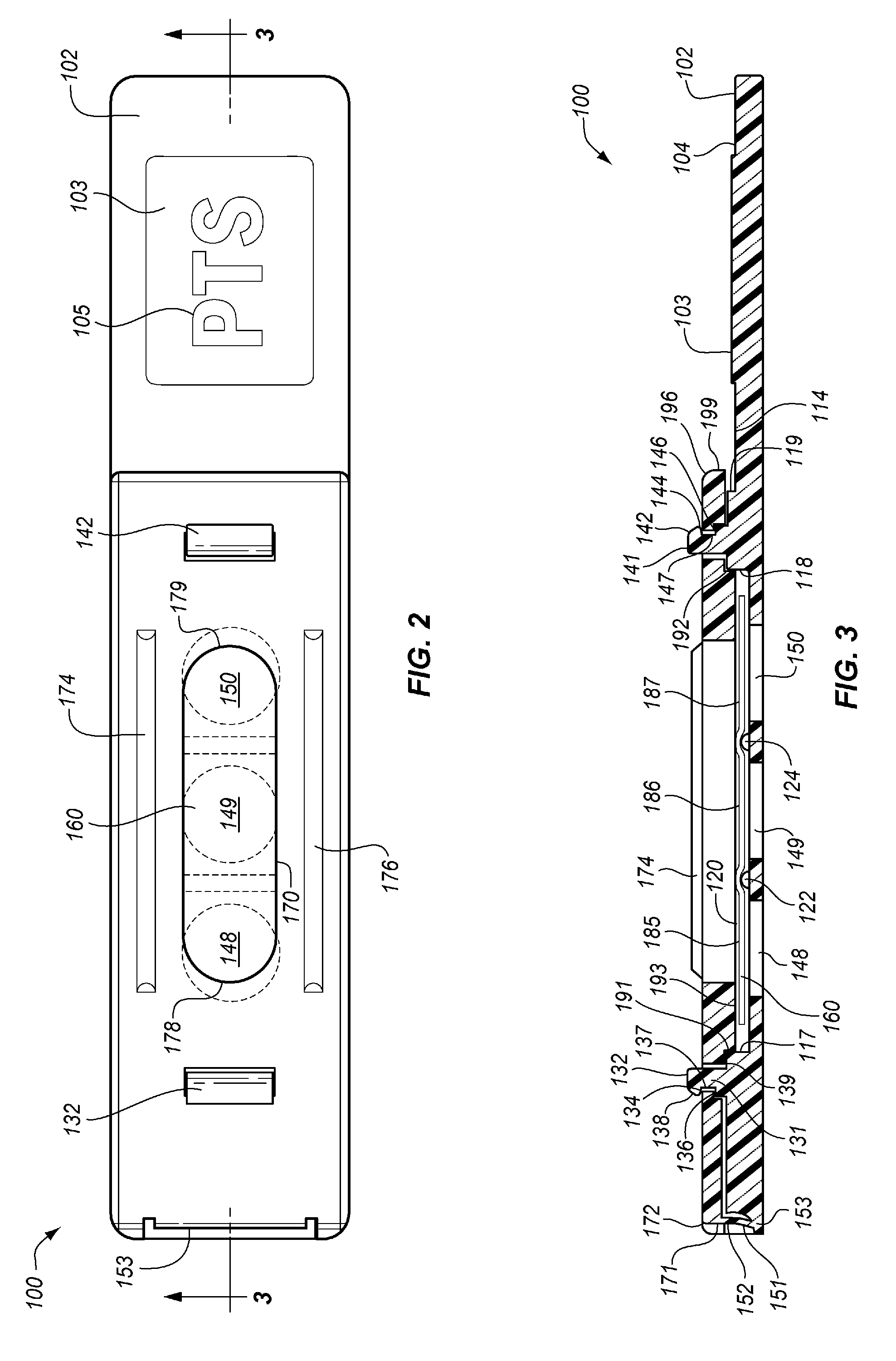

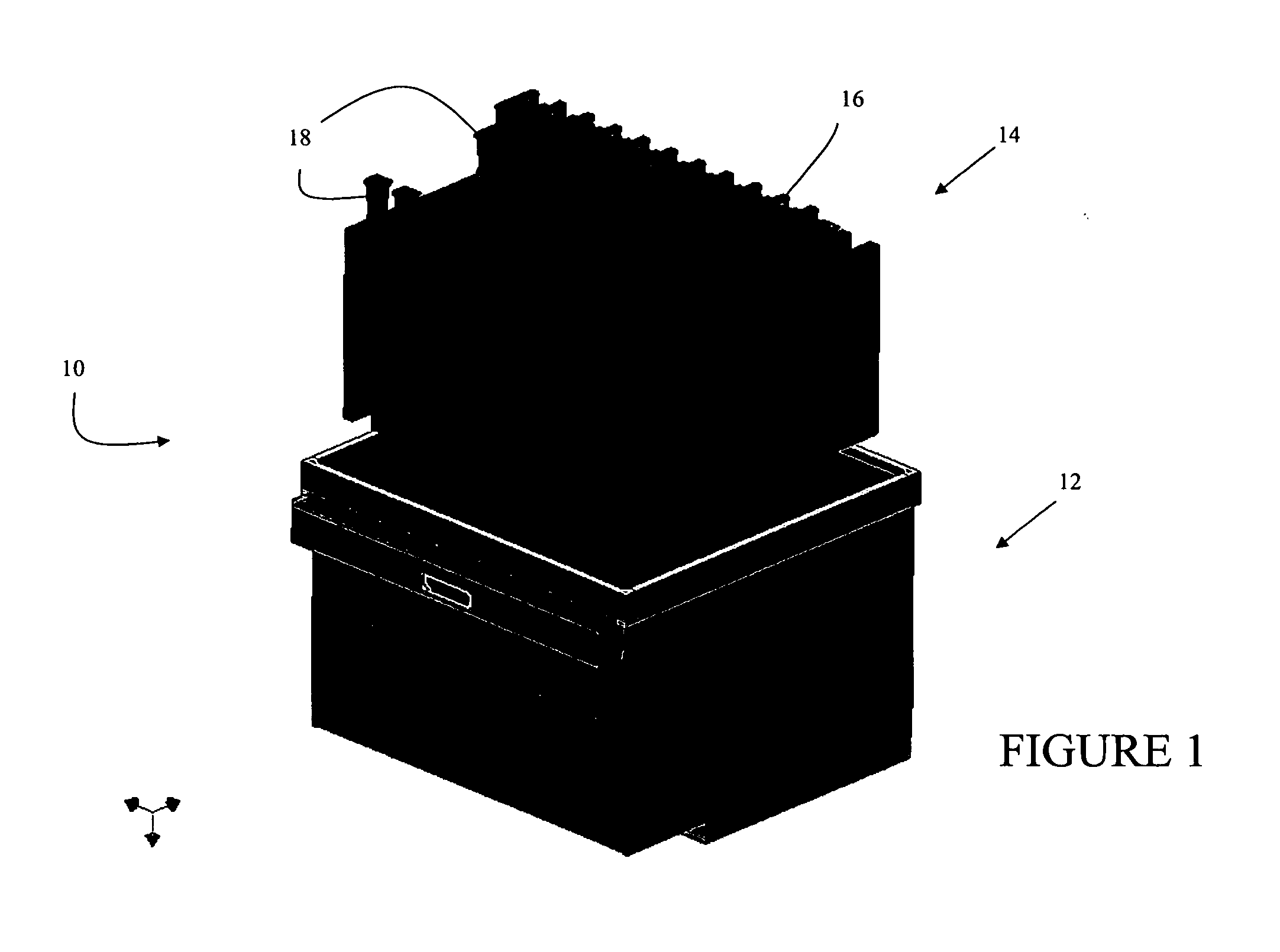

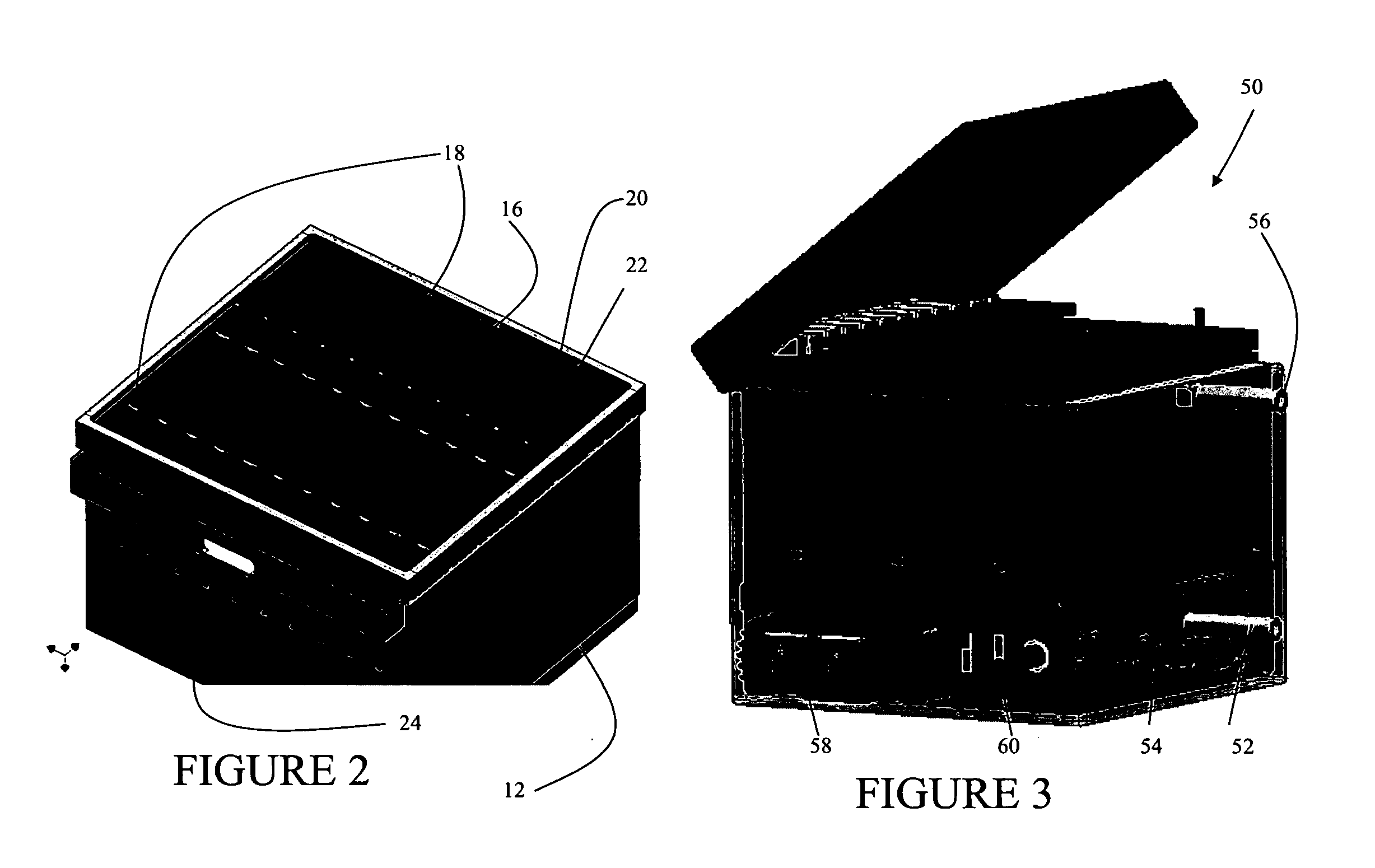

Dry test strip with controlled flow and method of manufacturing same

ActiveUS20080112848A1Improve repeatability and accuracyAccurately controlMaterial analysis by observing effect on chemical indicatorDisease diagnosisAutomotive engineeringFluid compartments

Owner:POLYMER TECH SYST

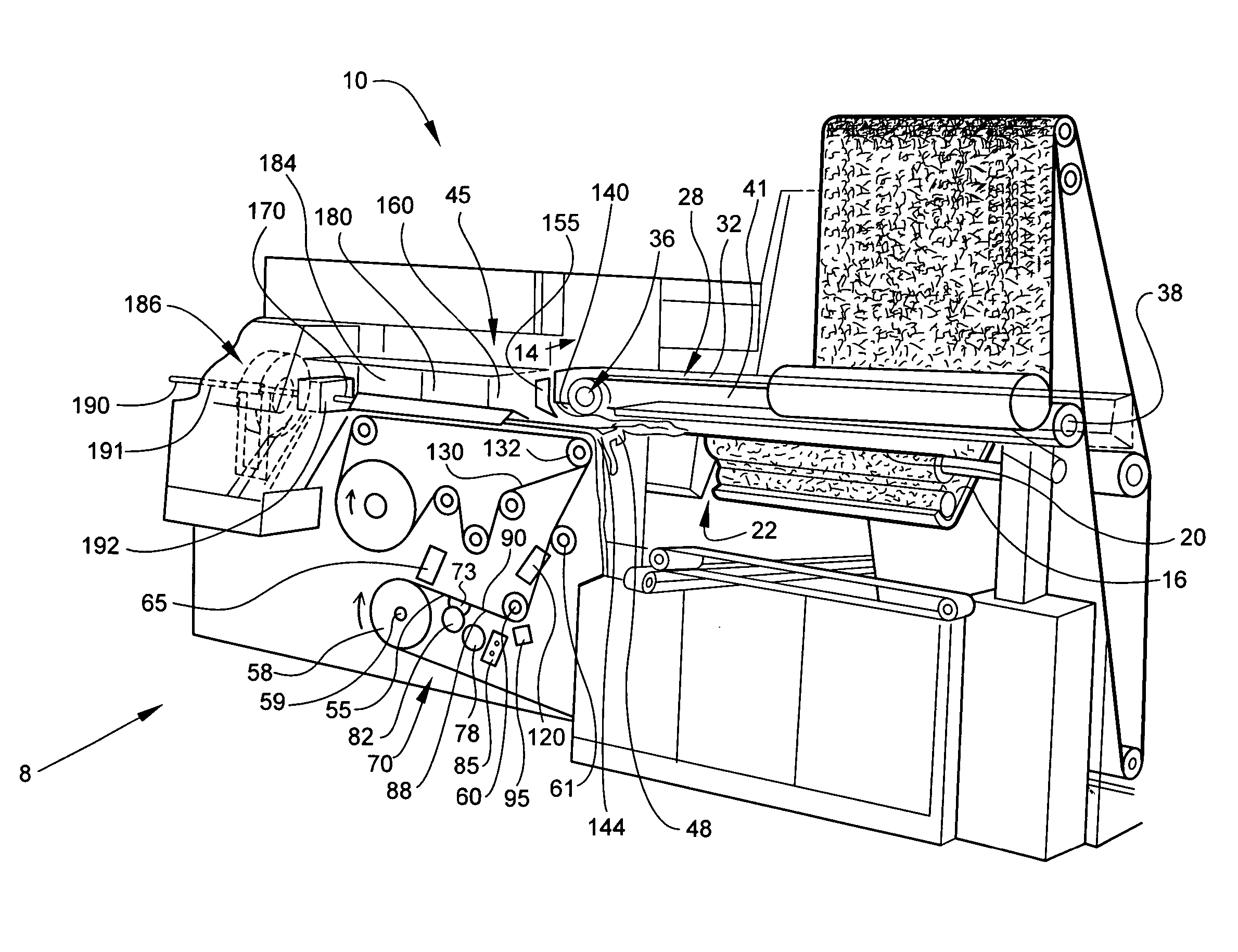

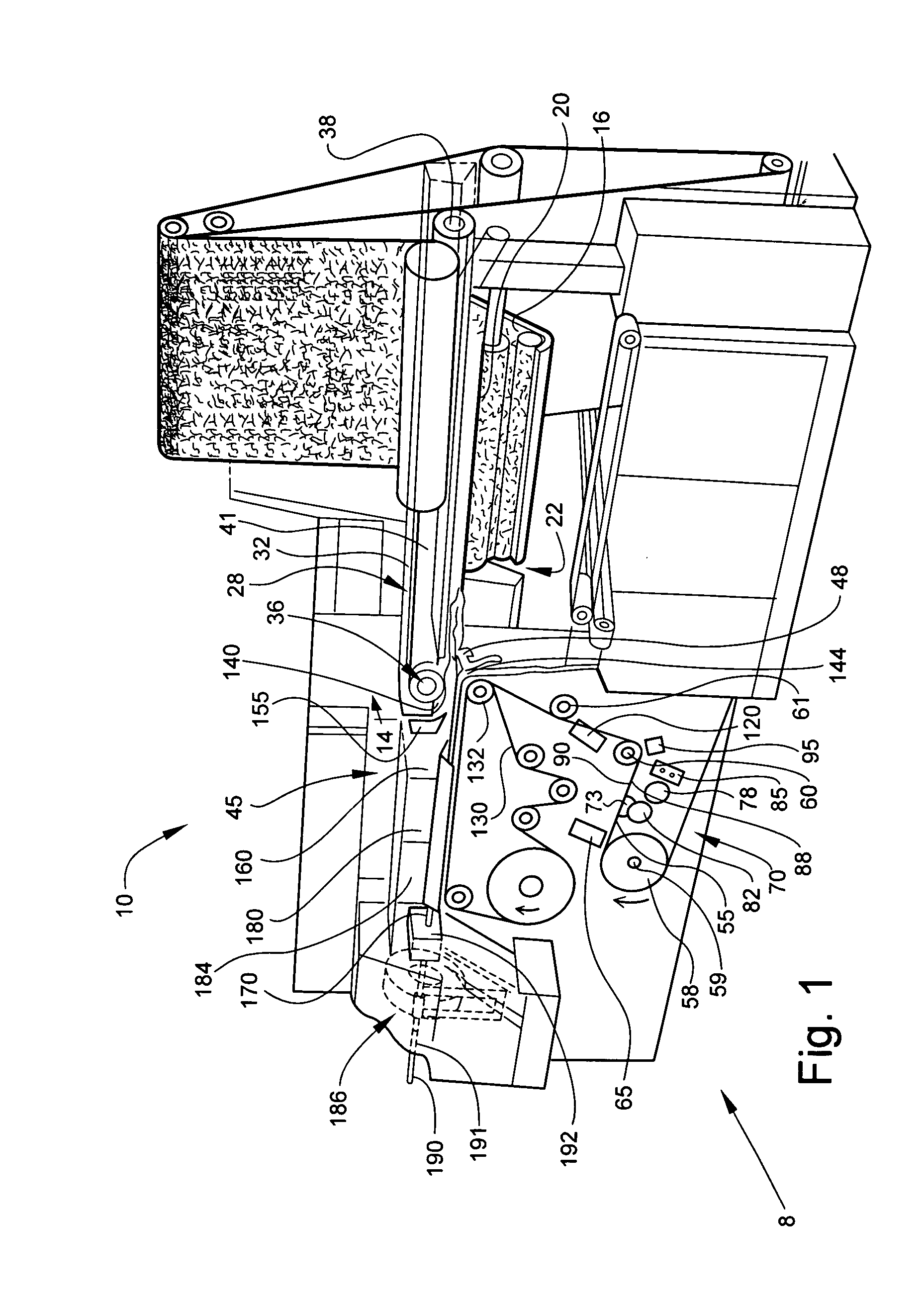

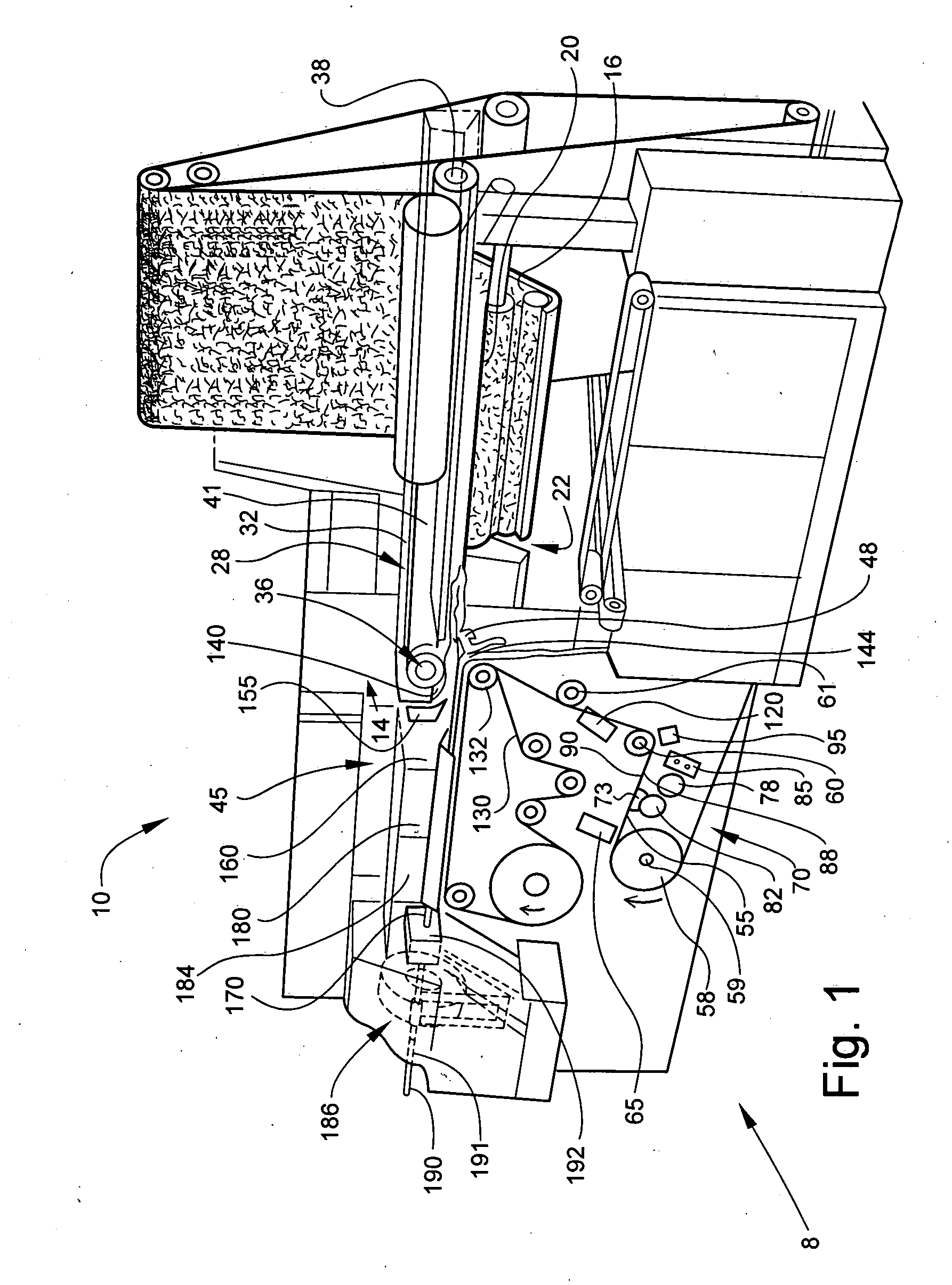

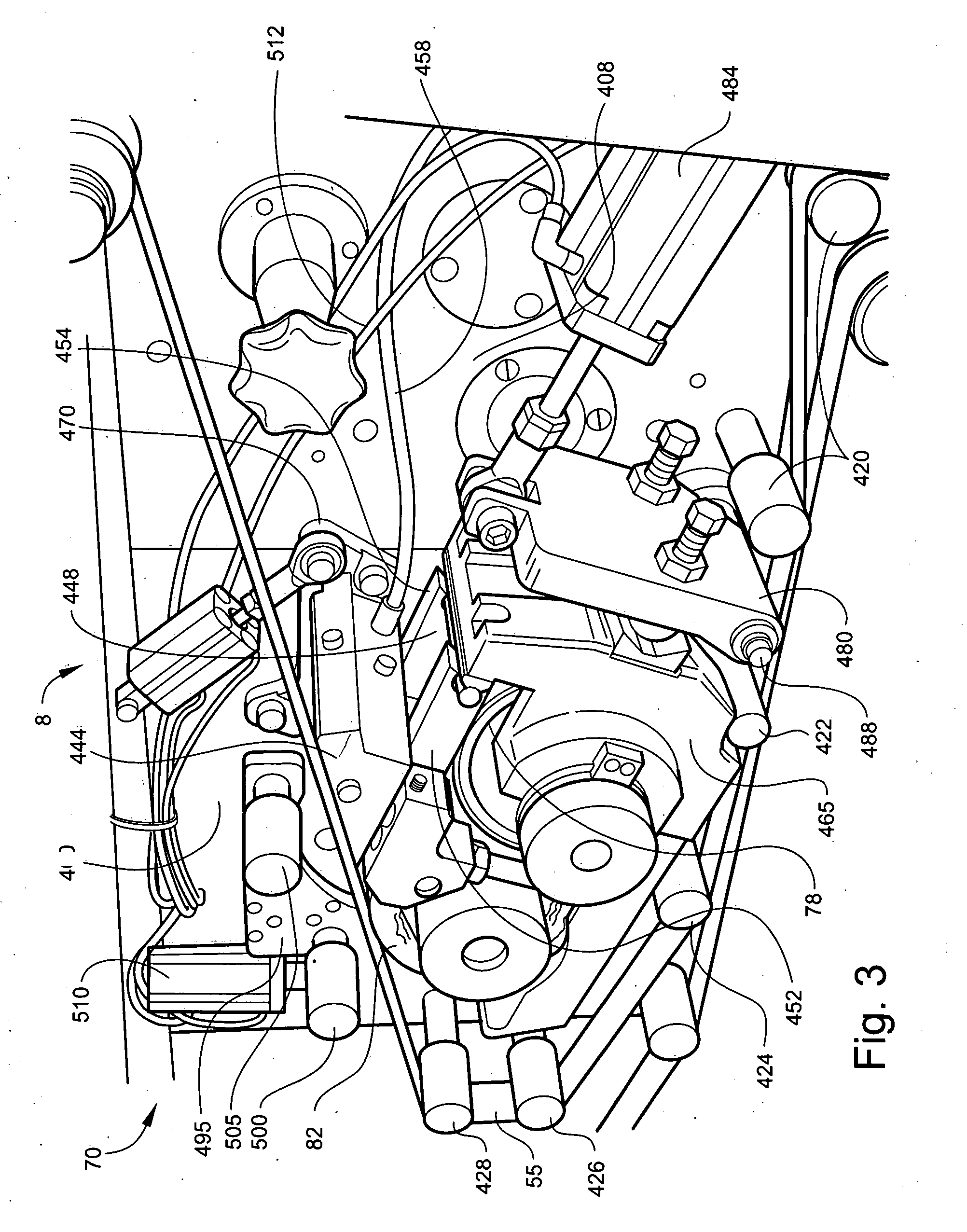

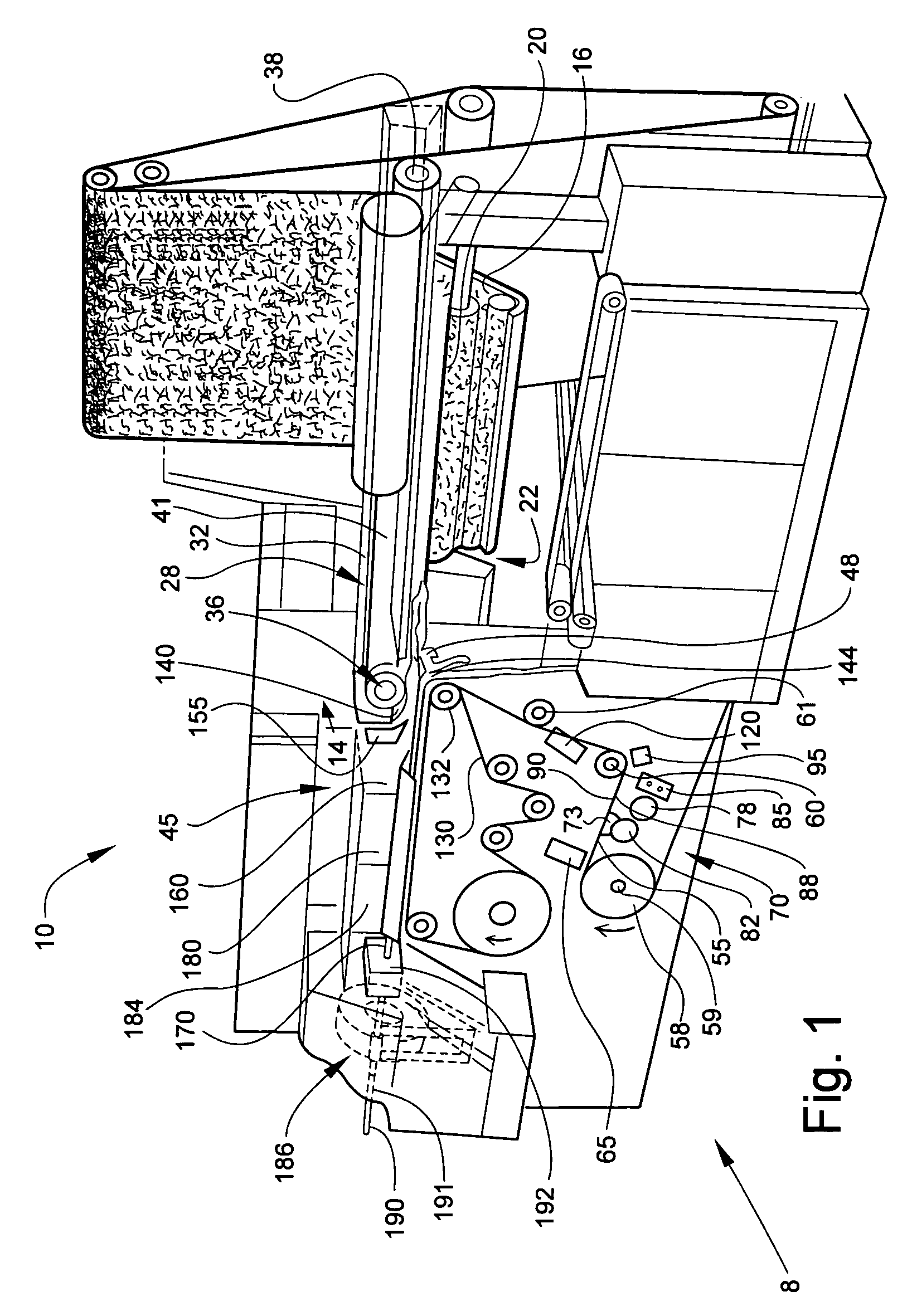

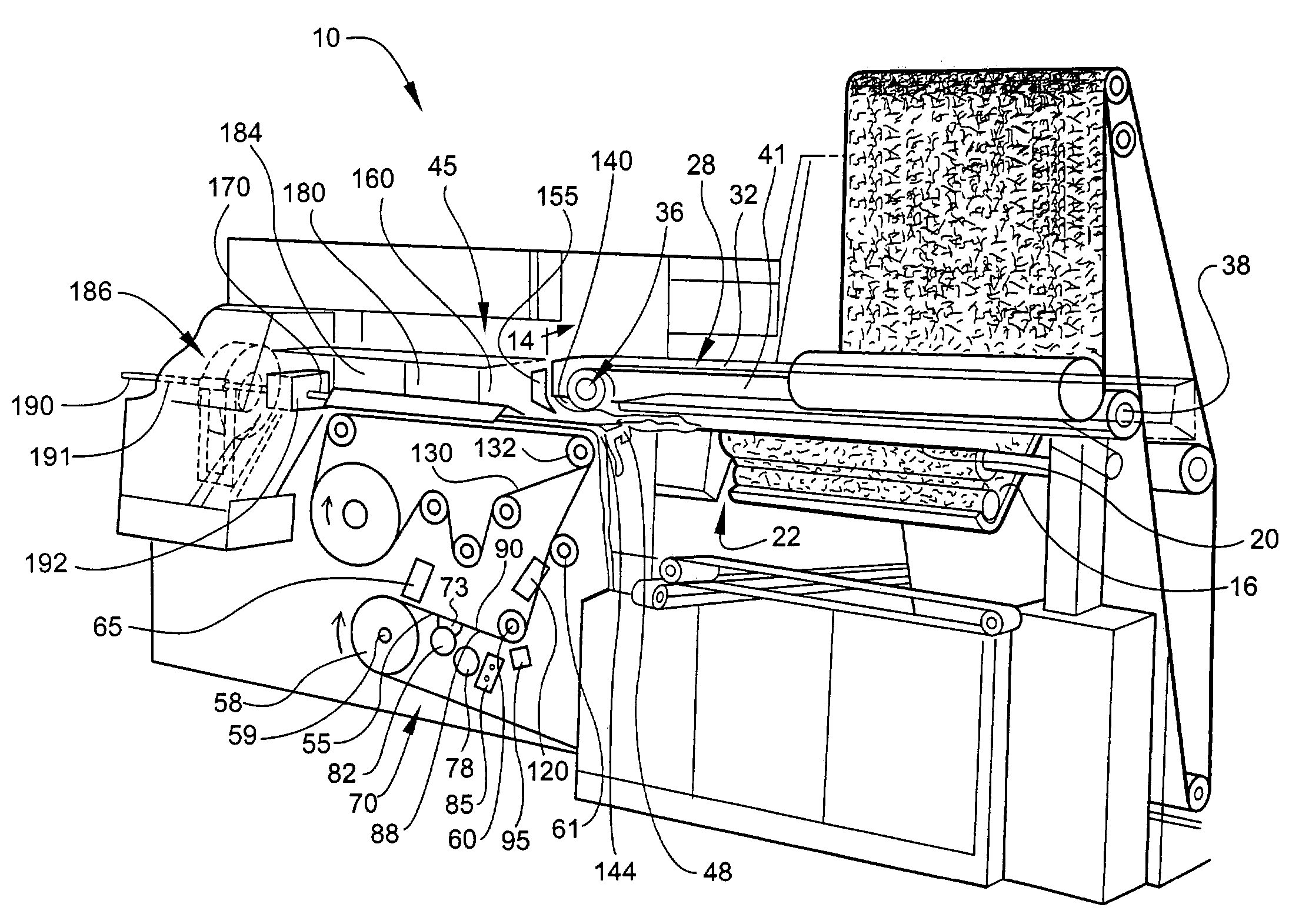

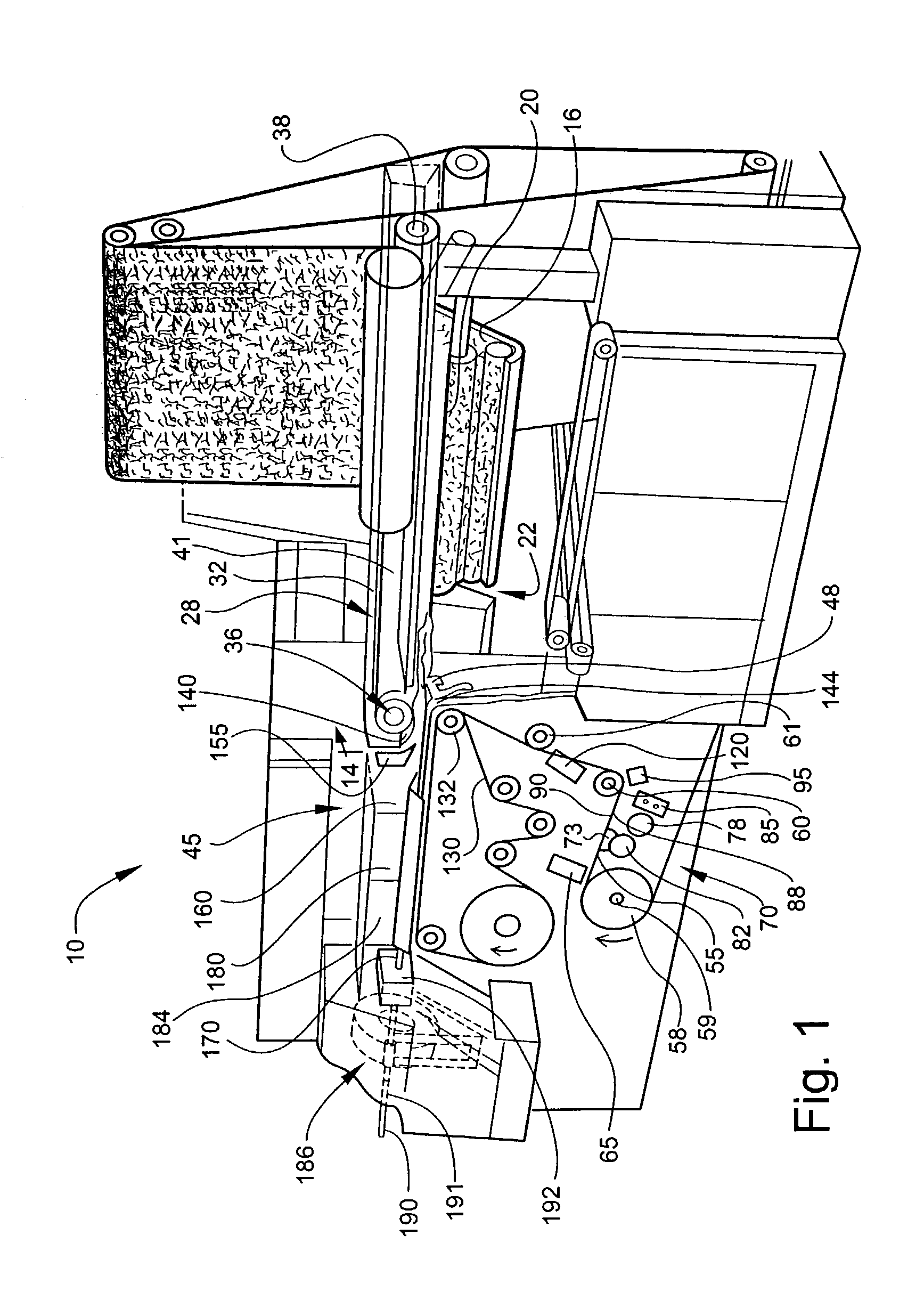

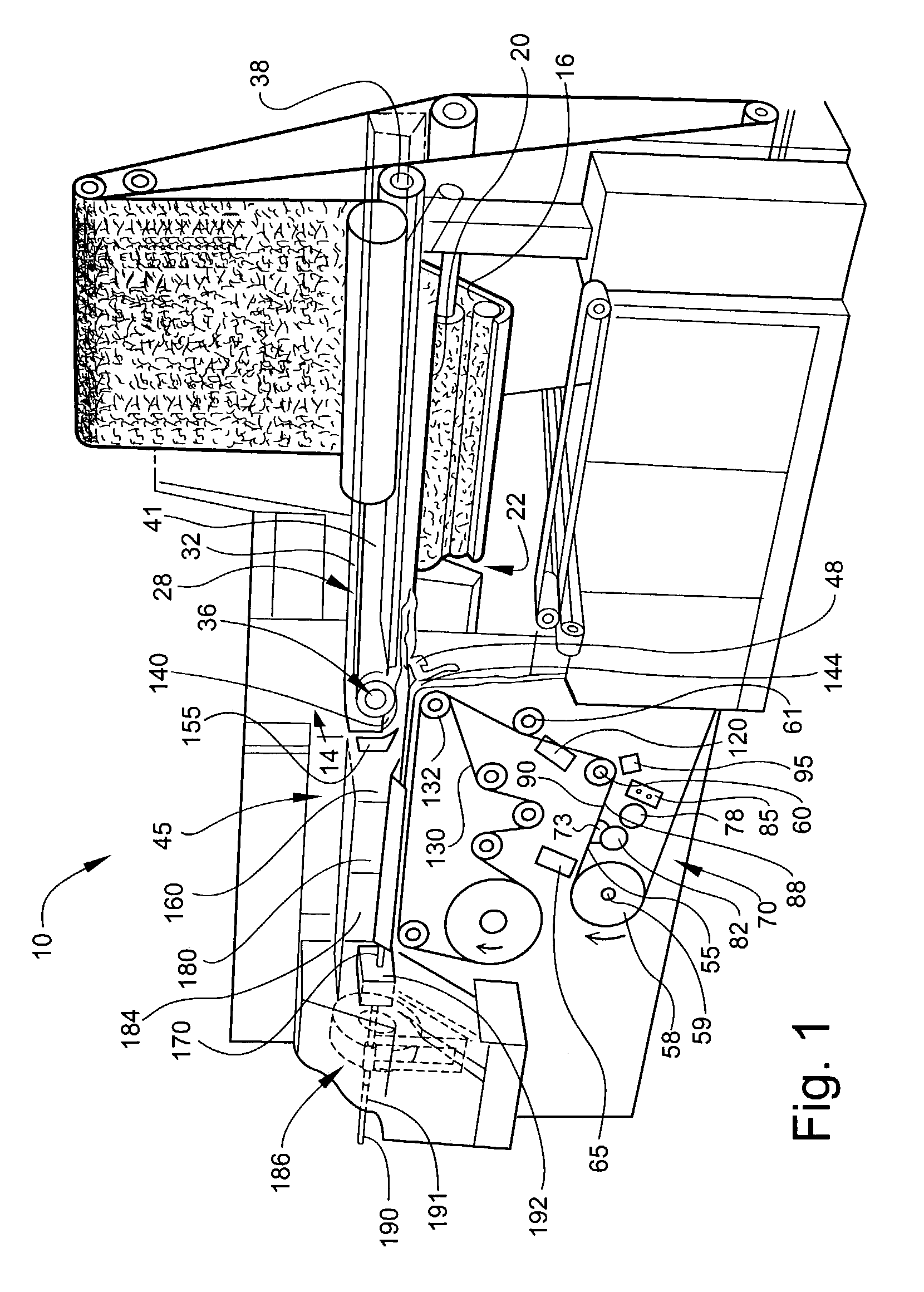

Equipment and methods for manufacturing cigarettes

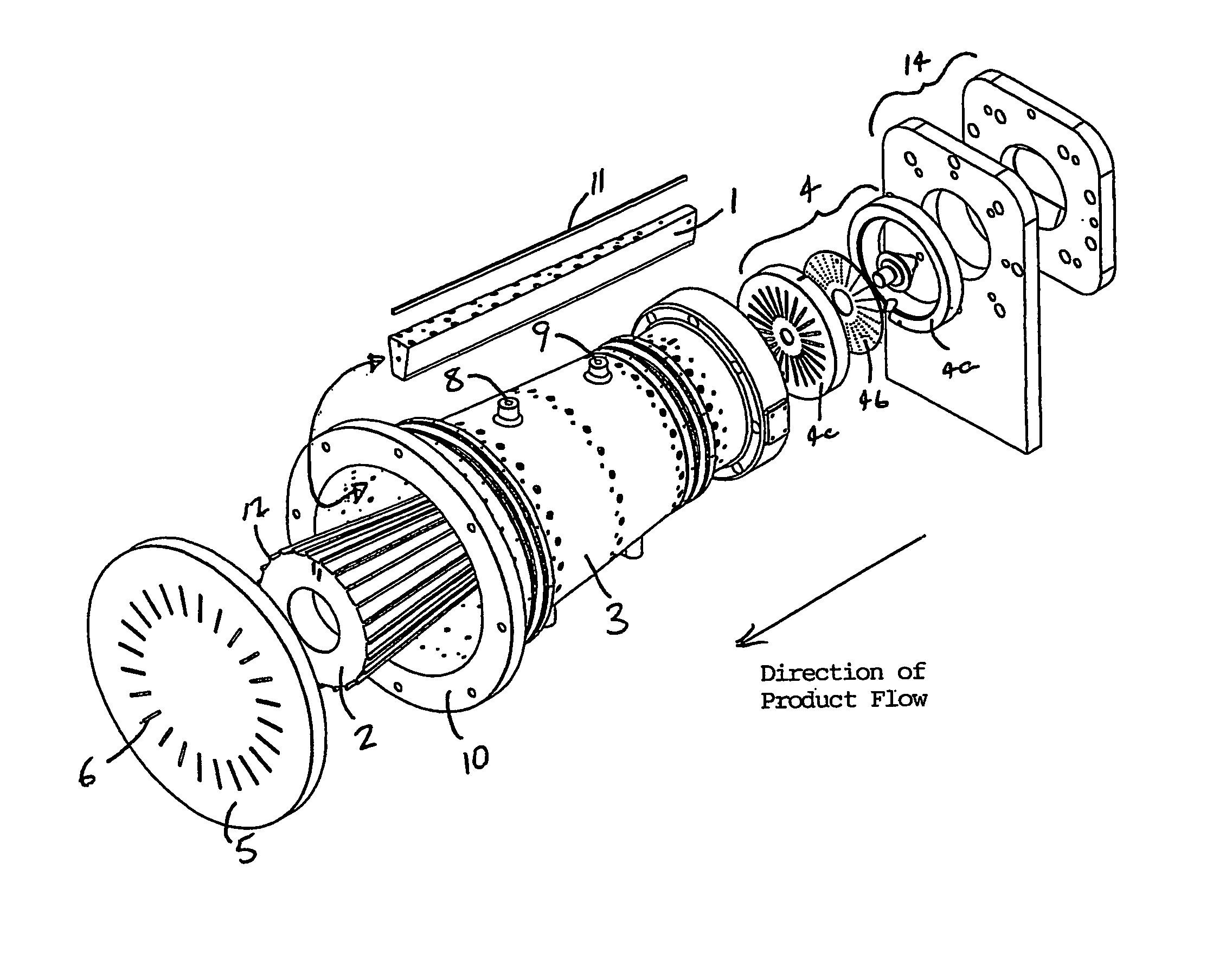

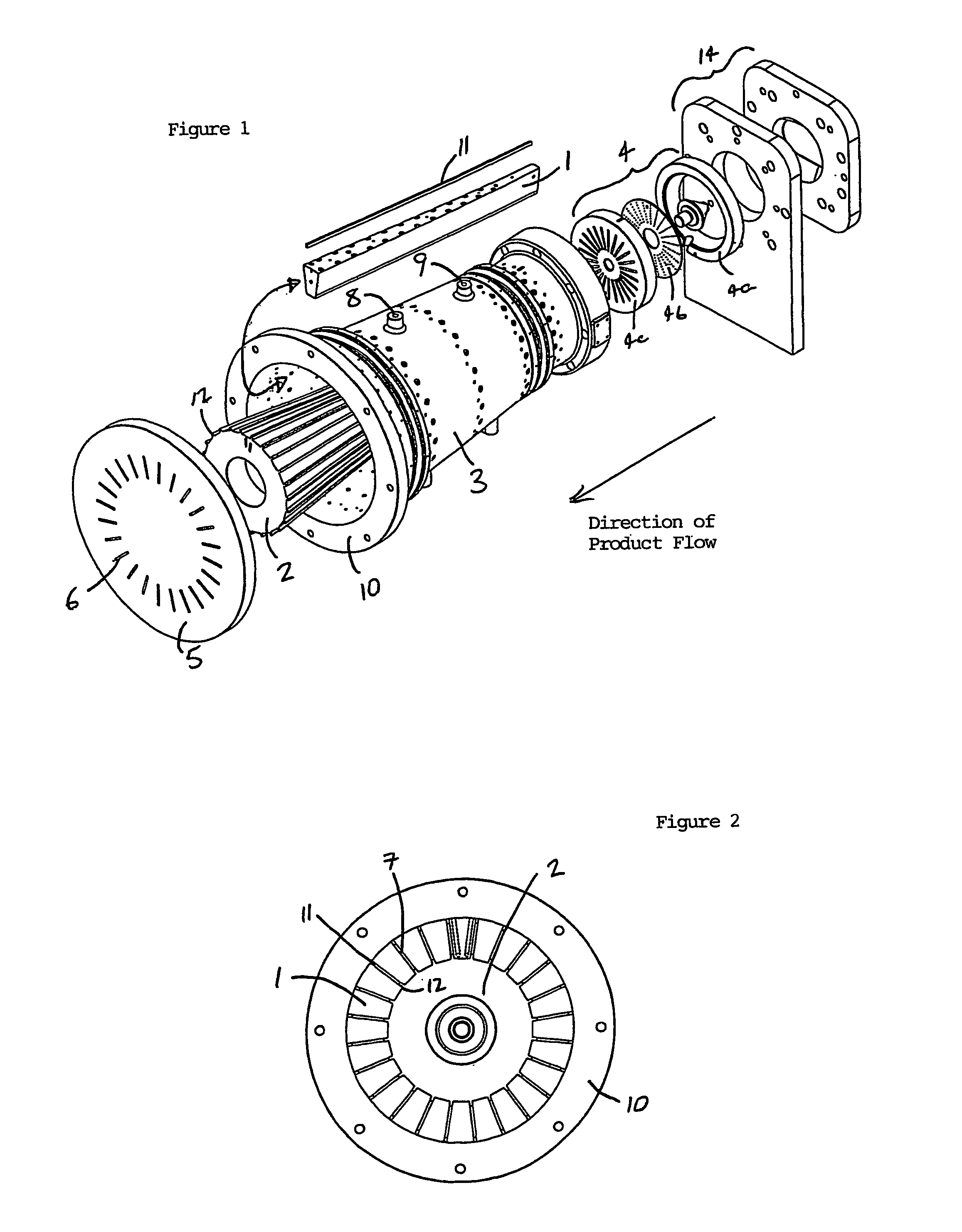

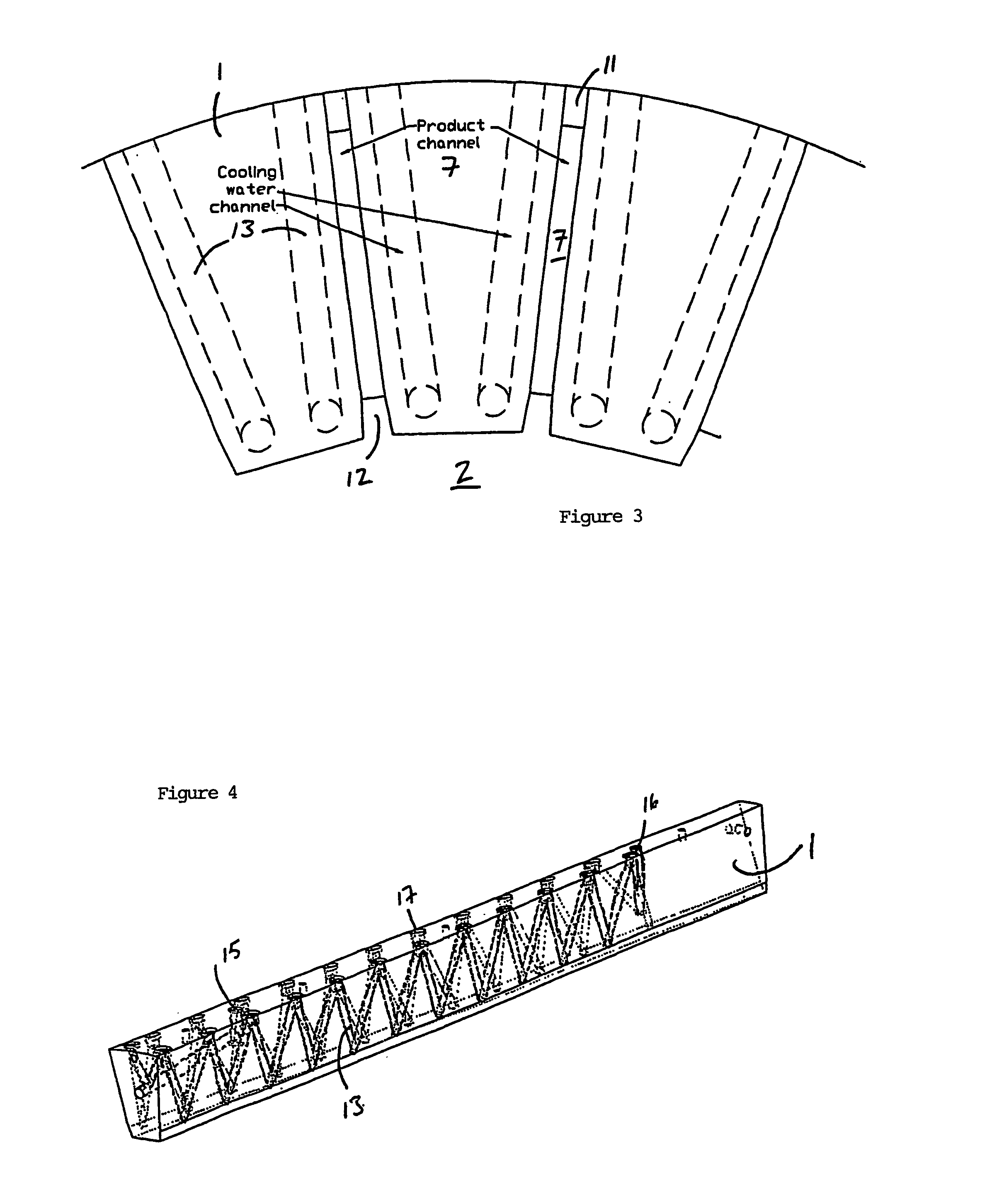

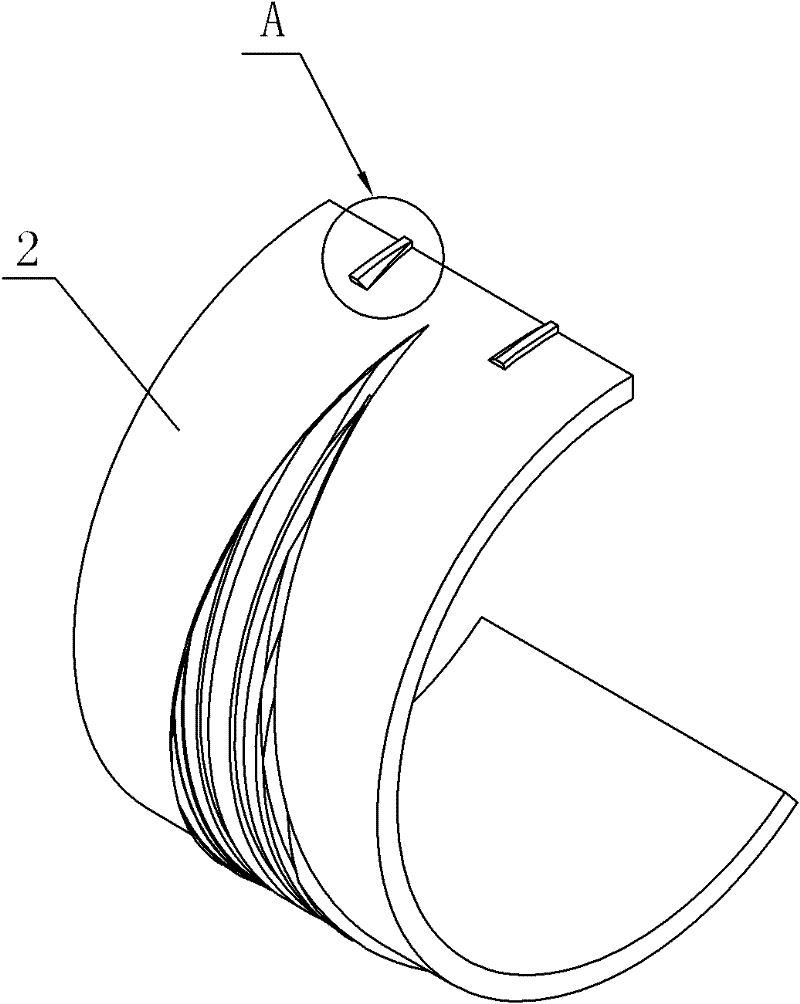

ActiveUS20050039764A1Easy transferConsistent flowCigar manufactureCigarette manufactureMechanical engineeringIndustrial engineering

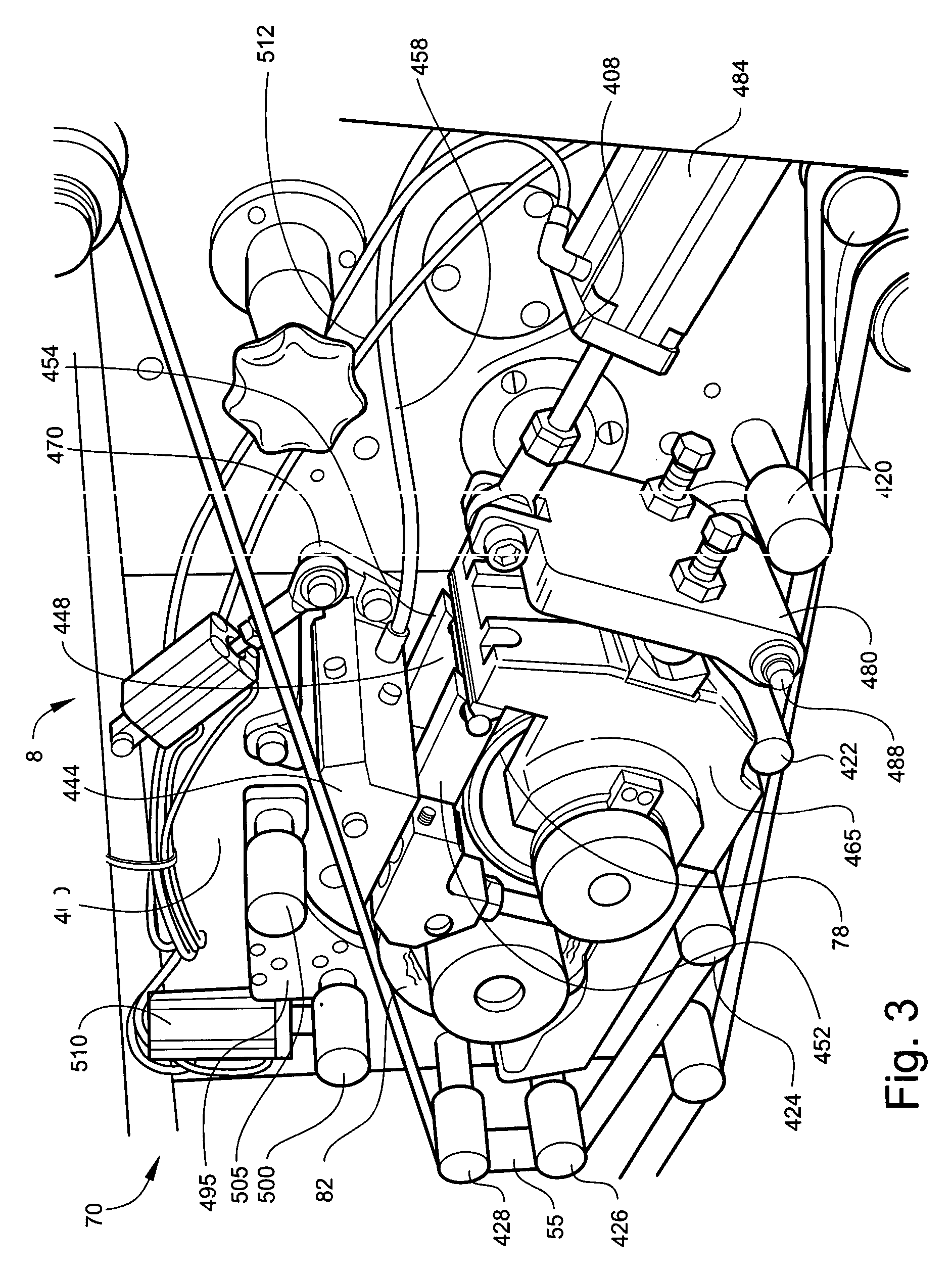

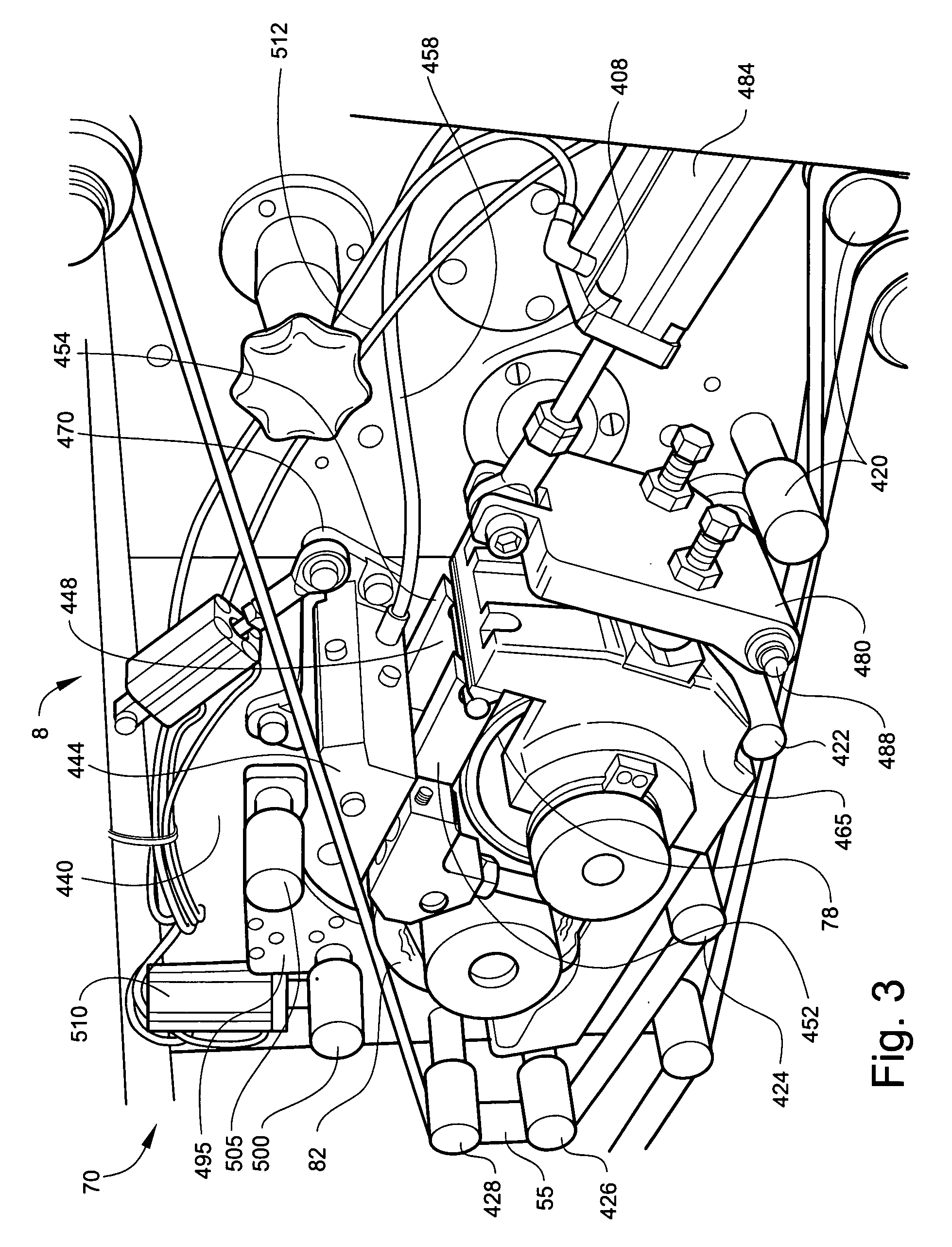

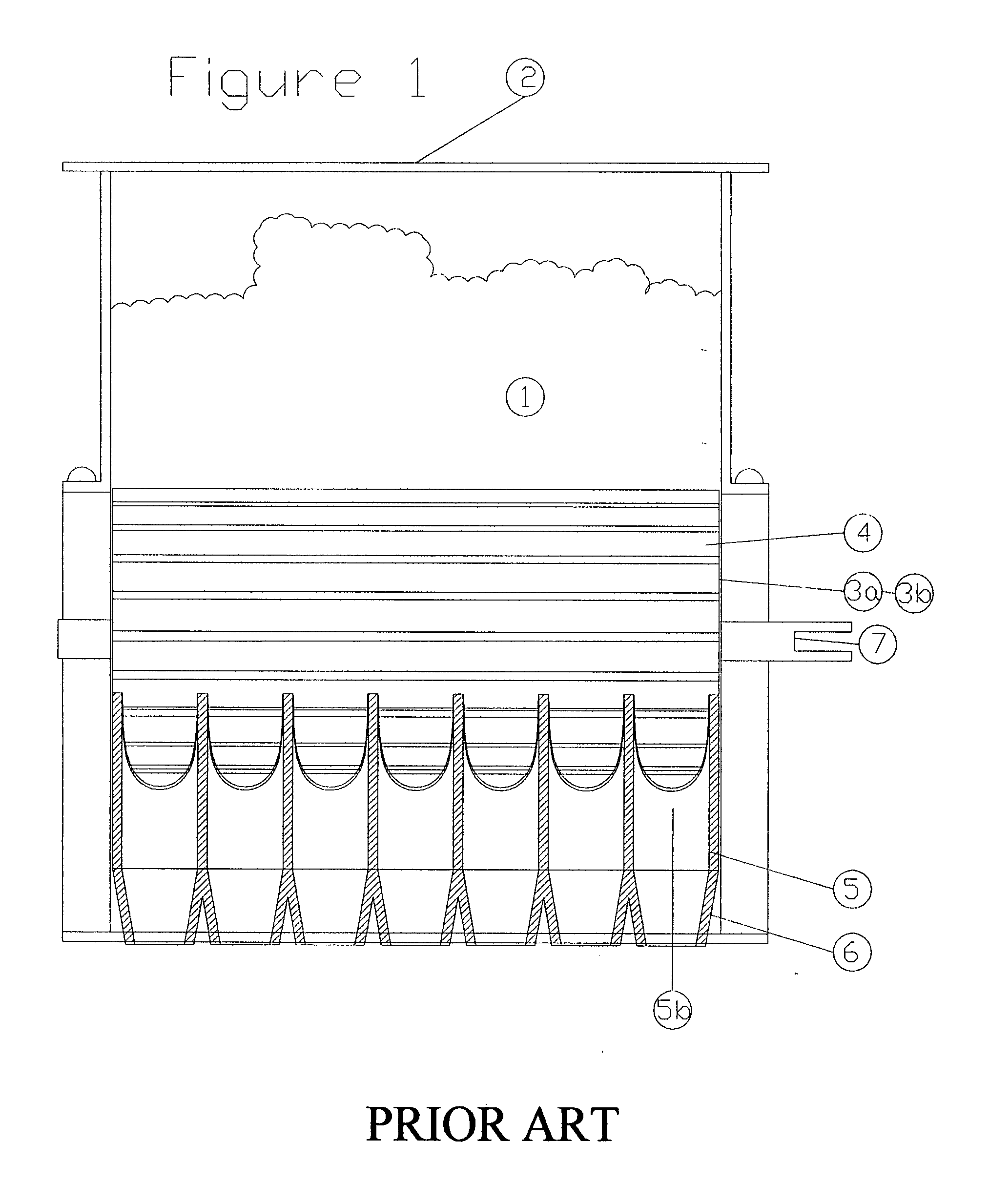

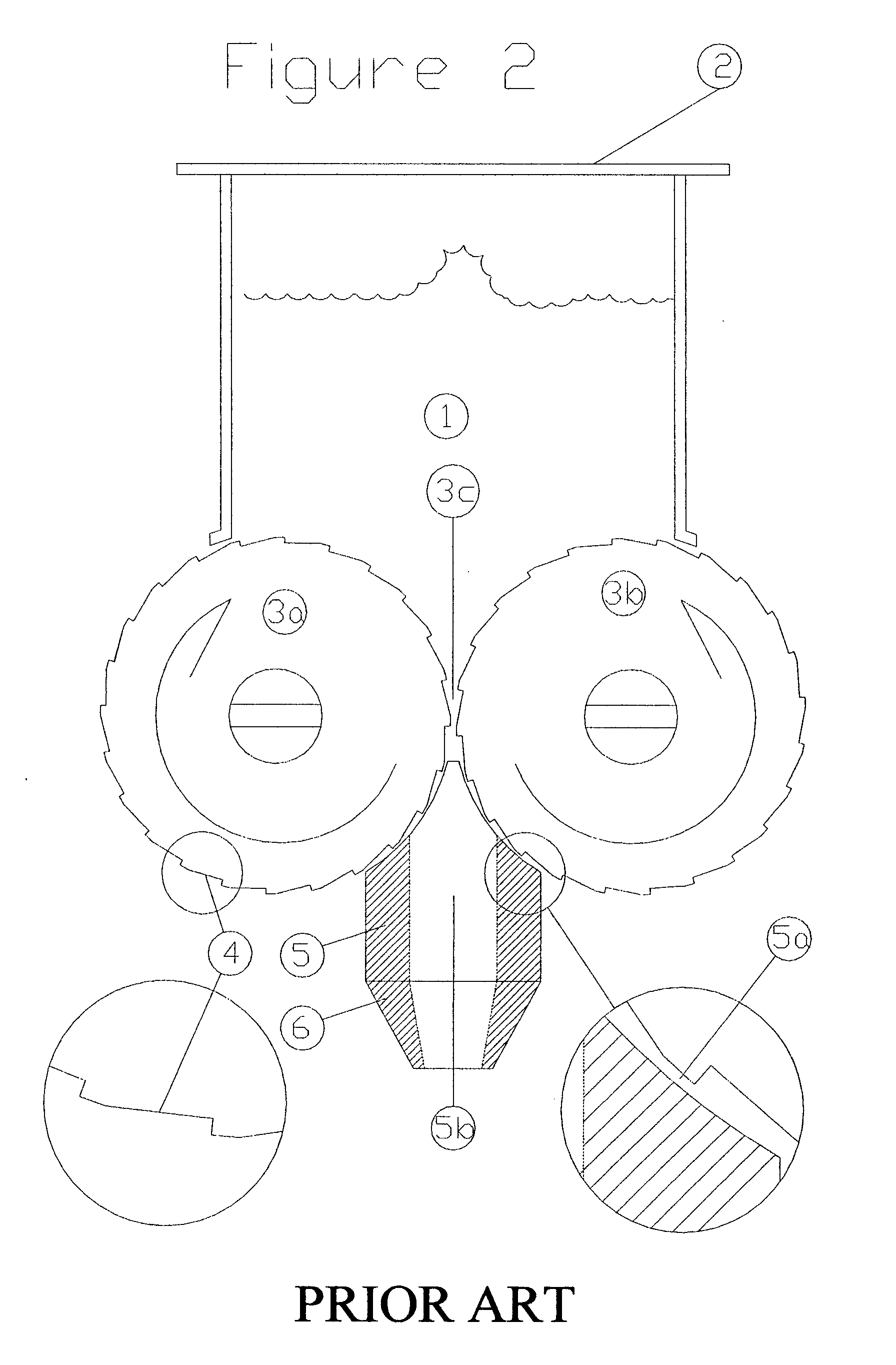

Cigarettes are manufactured using modified automated cigarette making apparatus. Those cigarettes possess smokable rods having paper wrapping materials having additive materials applied thereto as patterns. The additive materials, which can have the forms of liquid or paste formulations (e.g., aqueous formulations incorporating starch or modified starch), are applied to a continuous paper web on the cigarette making apparatus. The formulation is applied to the paper web using application apparatus possessing rollers, and one of those rollers has a series of pockets in its roll face to receive additive formulation from a reservoir and to define the pattern of the formulation on the paper. For example, additive material located in the recessed pockets of a first roller is transferred in a controlled manner to the roll face of a second roller in roll contact with that first roller; and the additive material on the roll face of the second roller is transferred to desired locations on the surface of the paper web. The formulation also can be applied to a continuous moving paper web using an application apparatus possessing four rollers. For example, additive material is applied to the roll face of a transfer roller due to roll interaction of that transfer roller with a pick-up roller; roll interaction of the transfer roller with an application roller causes transfer of the additive material from the transfer roller to the application roller; and additive material from the application roller is transferred to the paper web that passes between the application roller and a back-up roller. A radiant dryer is used to dry the additive material that has been applied to the paper web. The radiant dryer is located on one component of a two component assembly that is used to manufacture cigarettes. A first component of the two component assembly provides a source of paper web, applies additive material to that web in a pattern and dries the paper web; while a second component receives the paper web, supplies tobacco filler and manufactures a cigarette rod from the paper web and tobacco filler. Spectrometric techniques are used to ensure proper registration of the additive material on the cigarette rods so manufactured, and to ensure proper quality of those cigarettes.

Owner:R J REYNOLDS TOBACCO COMPANY

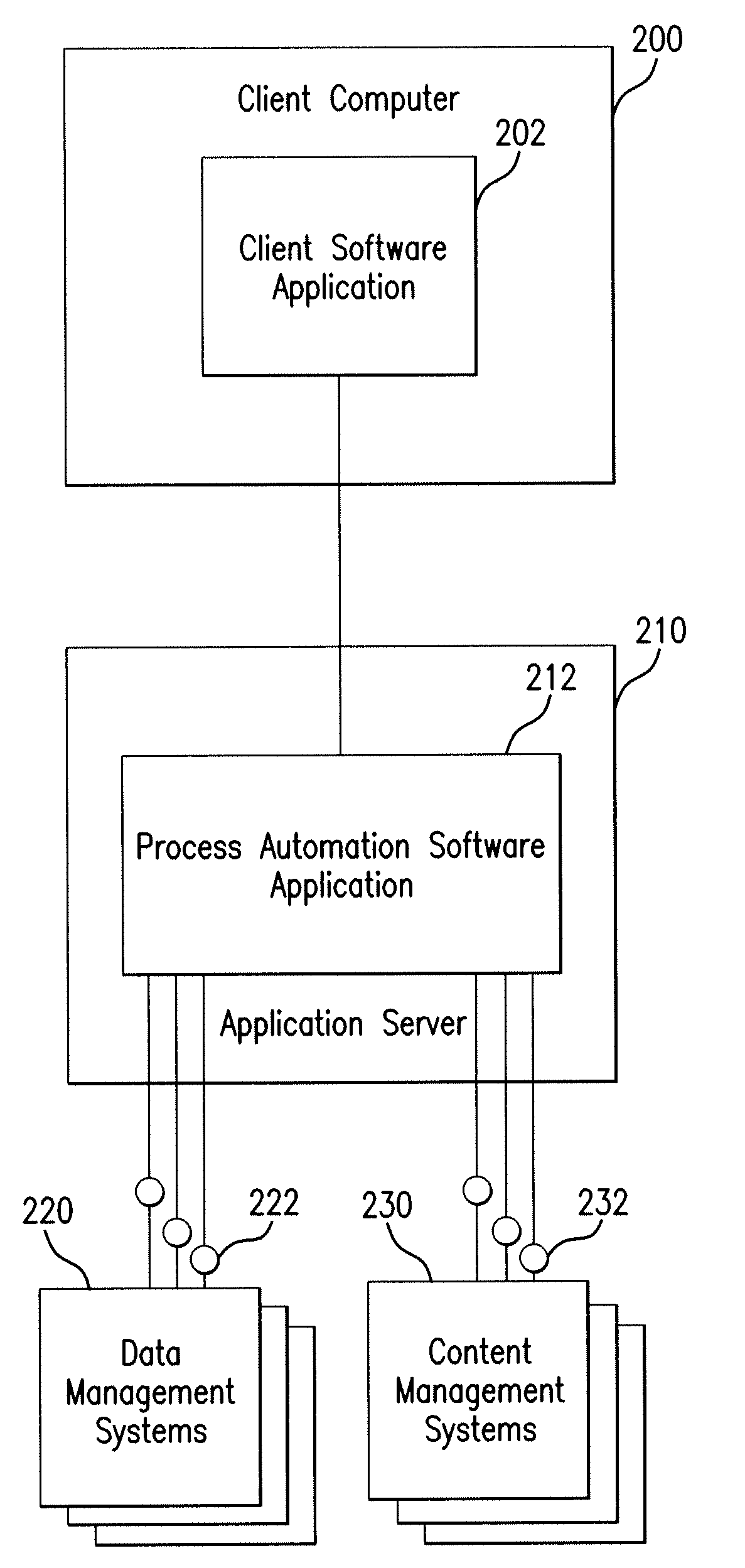

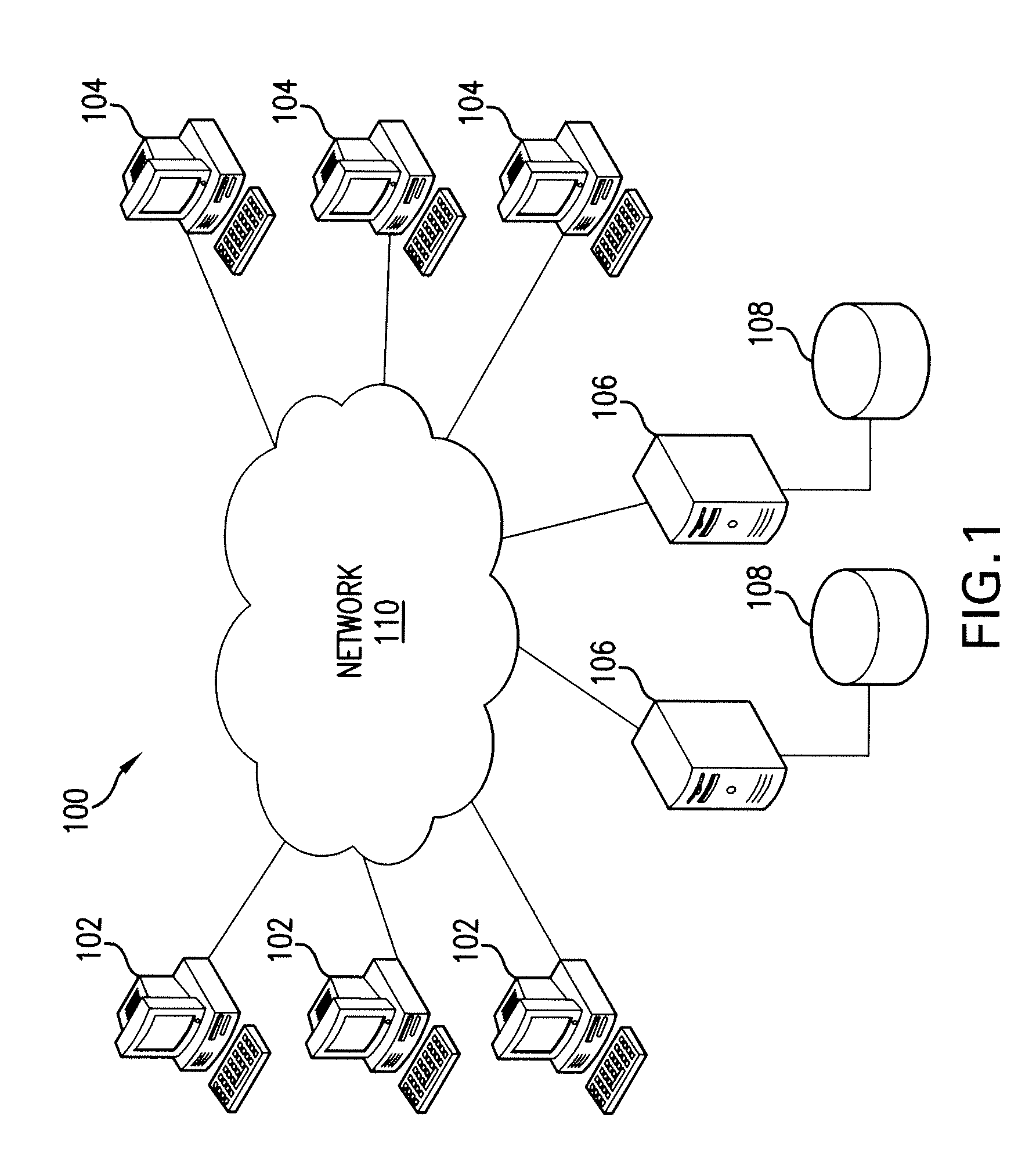

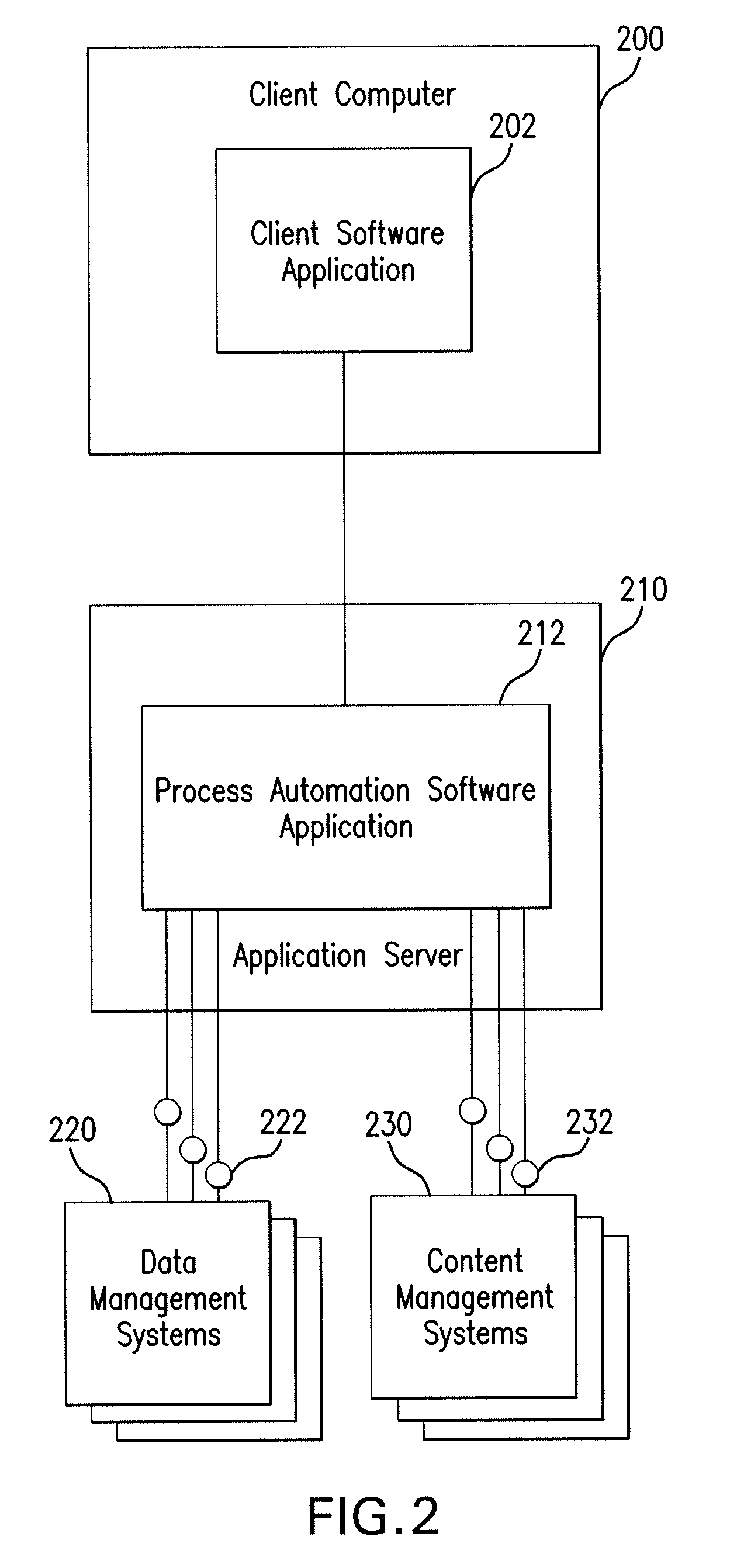

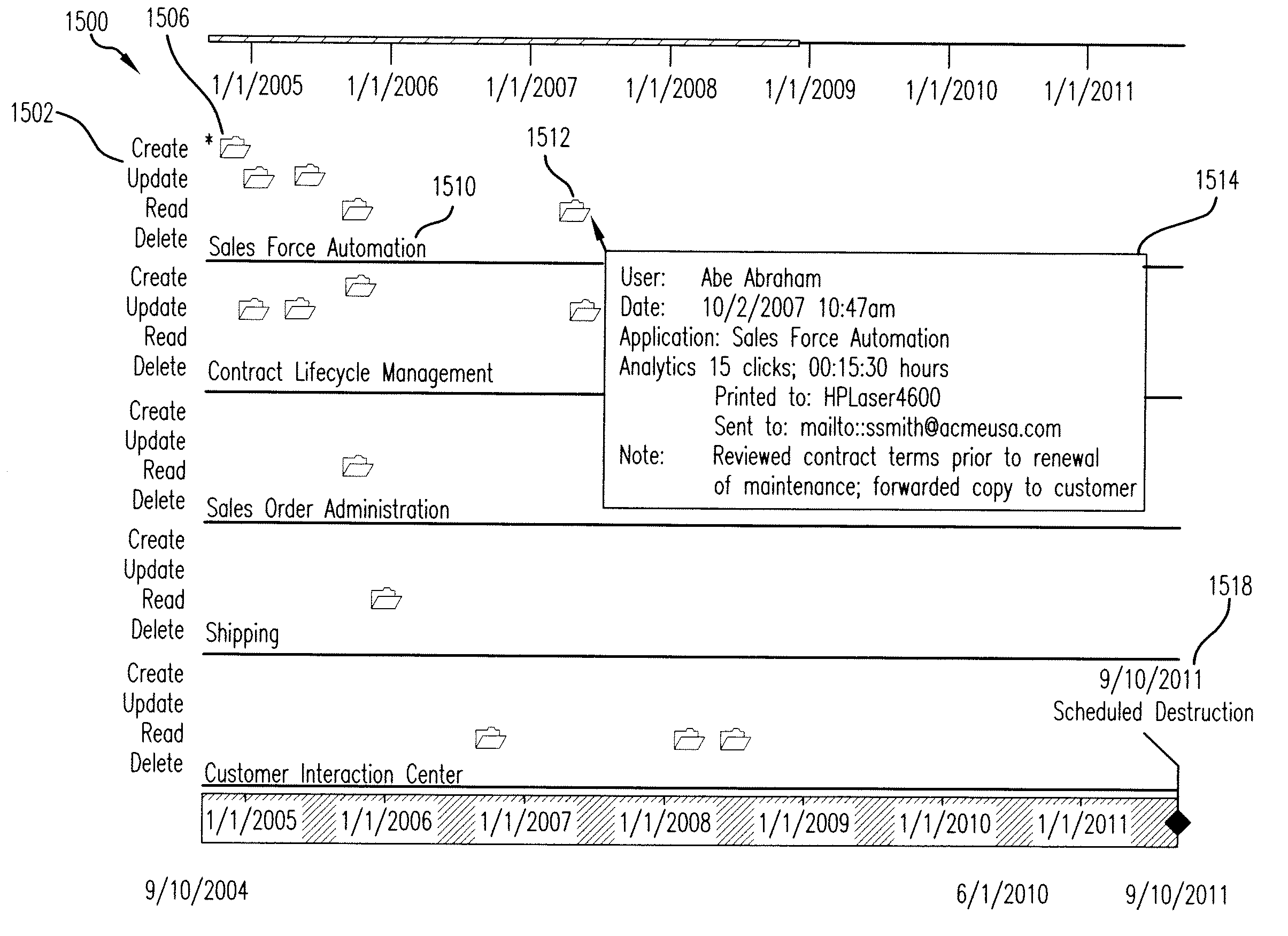

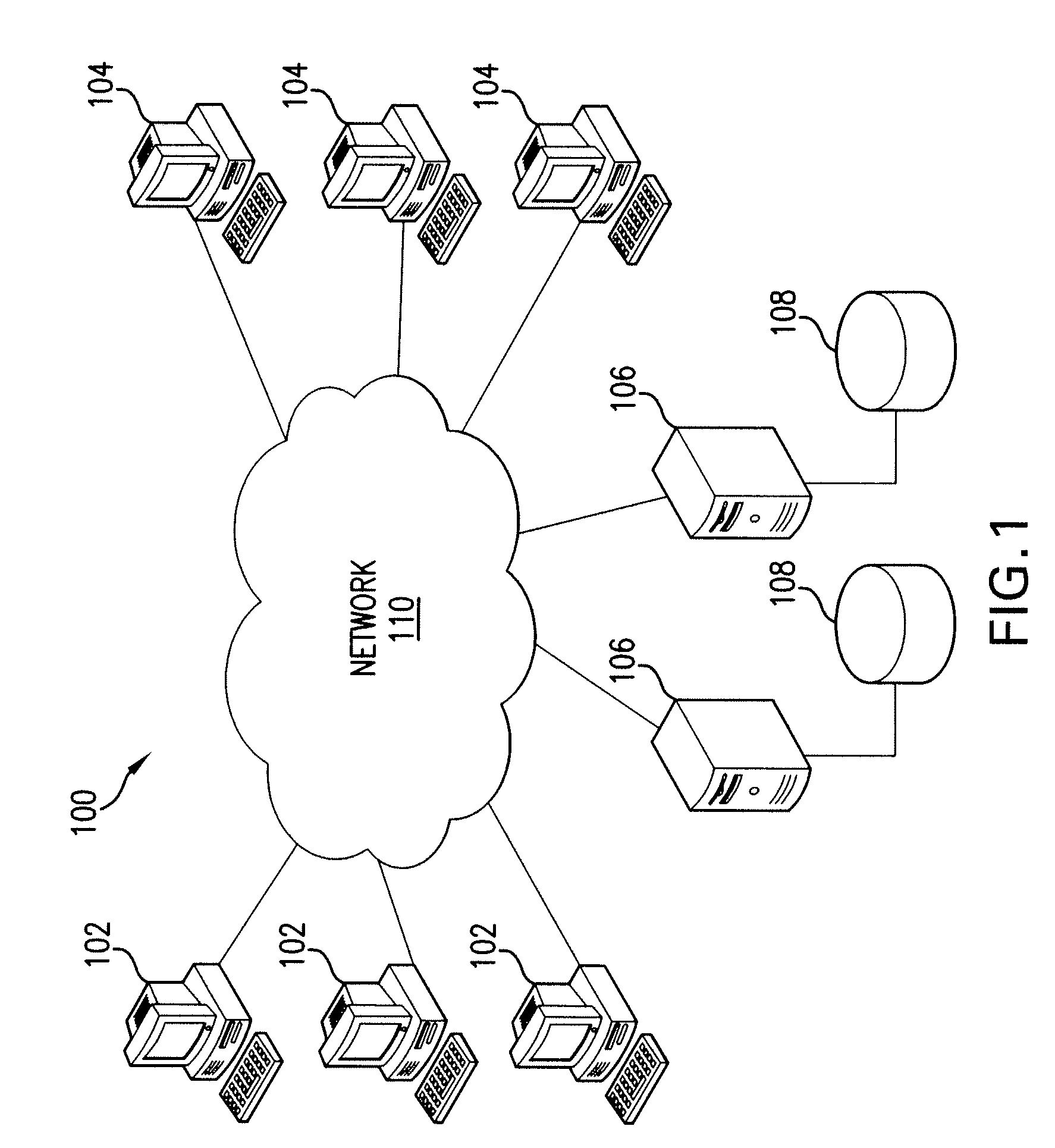

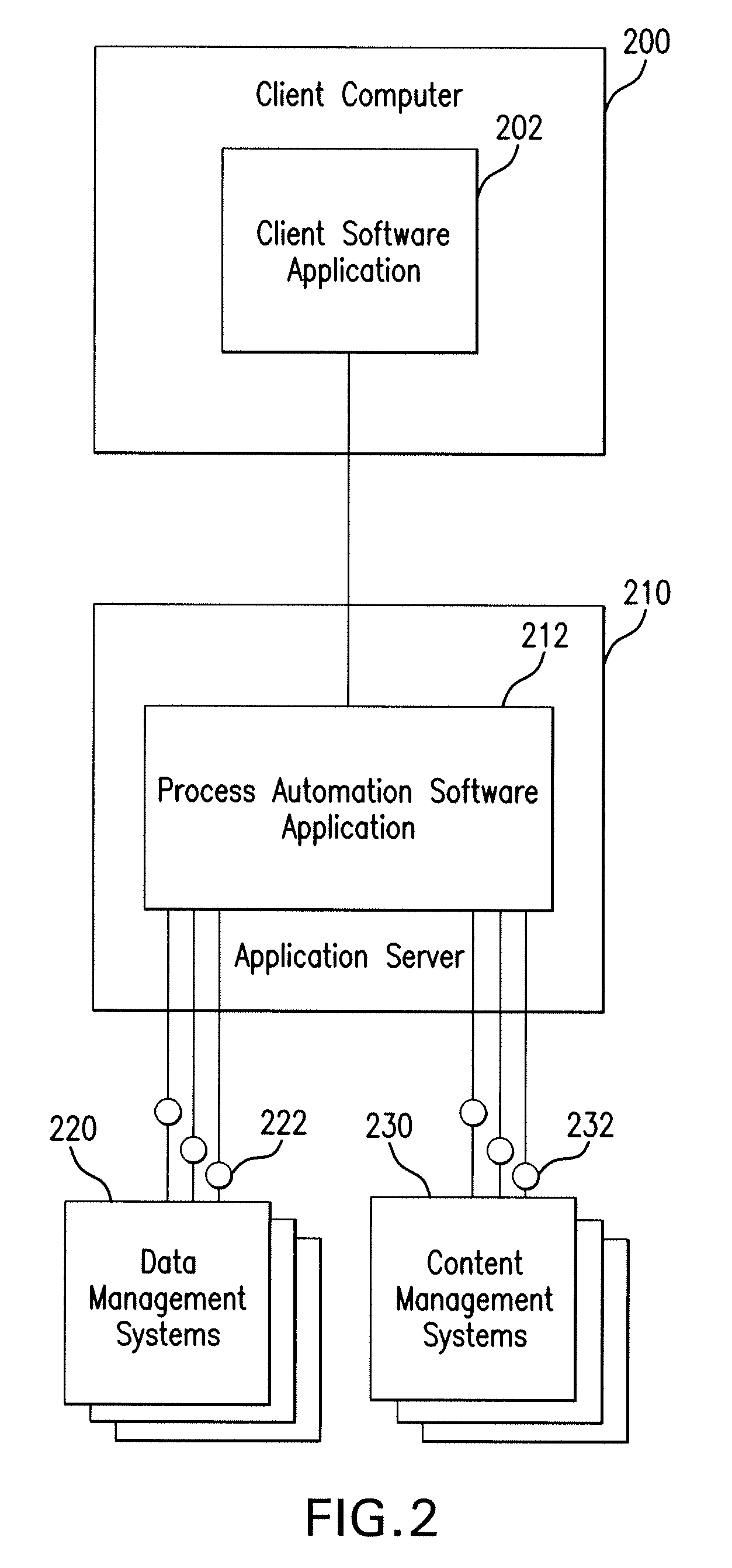

Method and system for managing enterprise content

A method and system for providing a consistent flow documents and data content across different organizational units of a company or agency where the documents and data come from different enterprise systems and data stores but are related to linked processes that share models for organizing the content in the business context and in a format that enables a user to relate the content to the process step or steps they are performing. The system includes a network service that enables a configuration utility to automatically discover the objects and metadata and provides for a mapping of selected fields of the metadata to regions displayed in the user interface view with provision for filtering the data by mapping selected fields to a user input form. Thereby, a business analyst can create solutions without writing and maintaining complex program logic for each combination of presentation environment, enterprise system and data store.

Owner:OPEN TEXT SA ULC

Cigarette and wrapping materials therefor

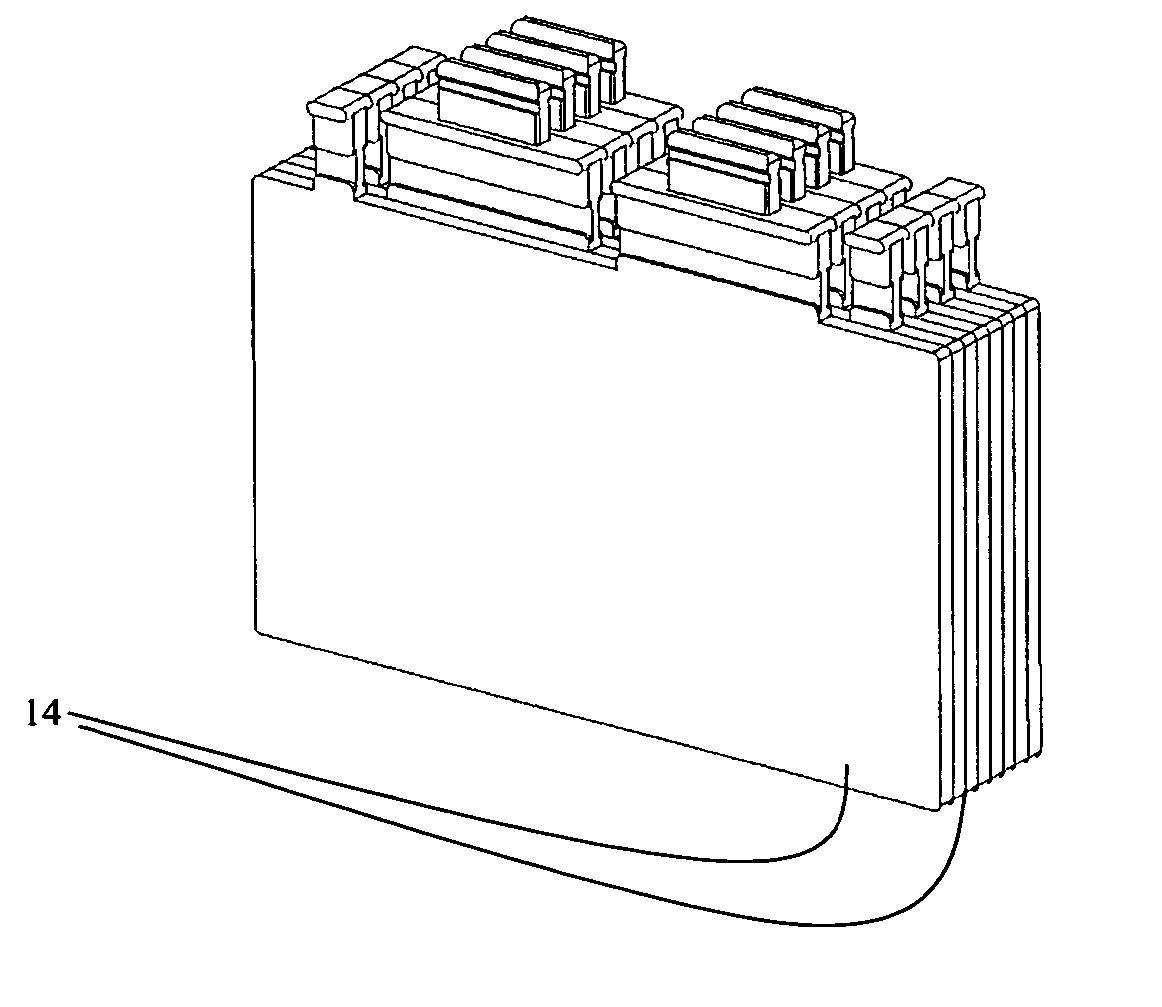

ActiveUS7234471B2Easy transferConsistent flowNon-fibrous pulp additionNatural cellulose pulp/paperBobbinPulp and paper industry

Owner:R J REYNOLDS TOBACCO COMPANY

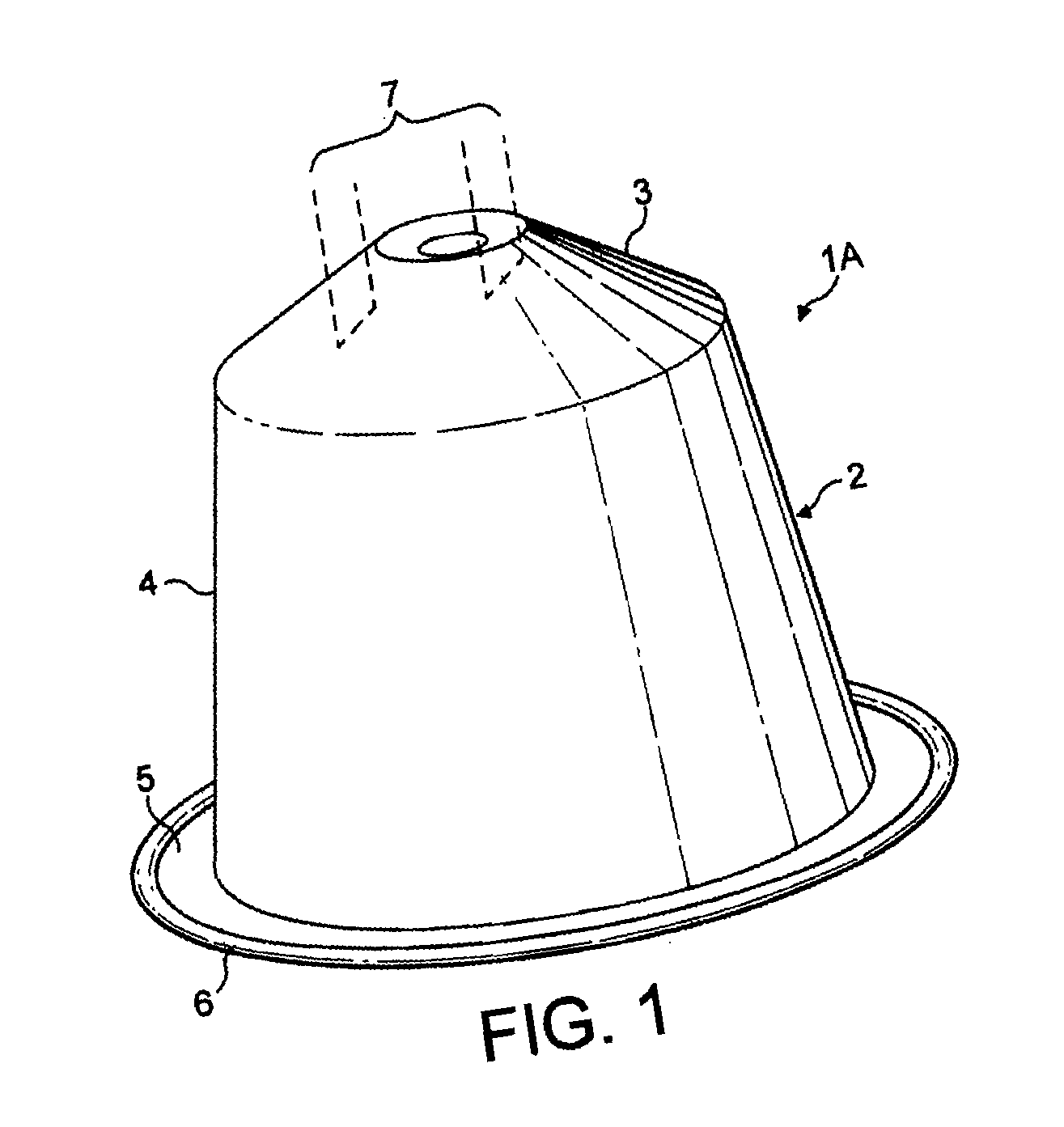

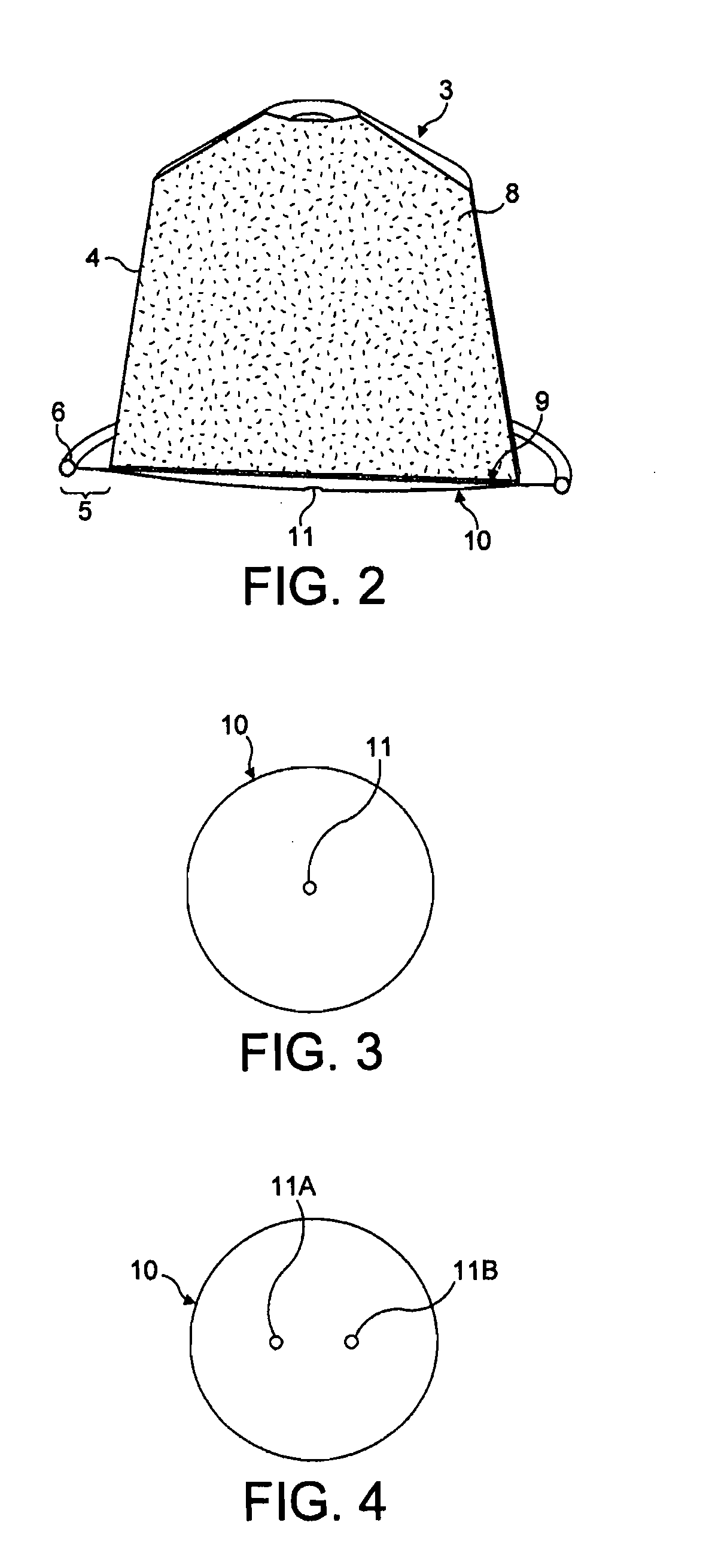

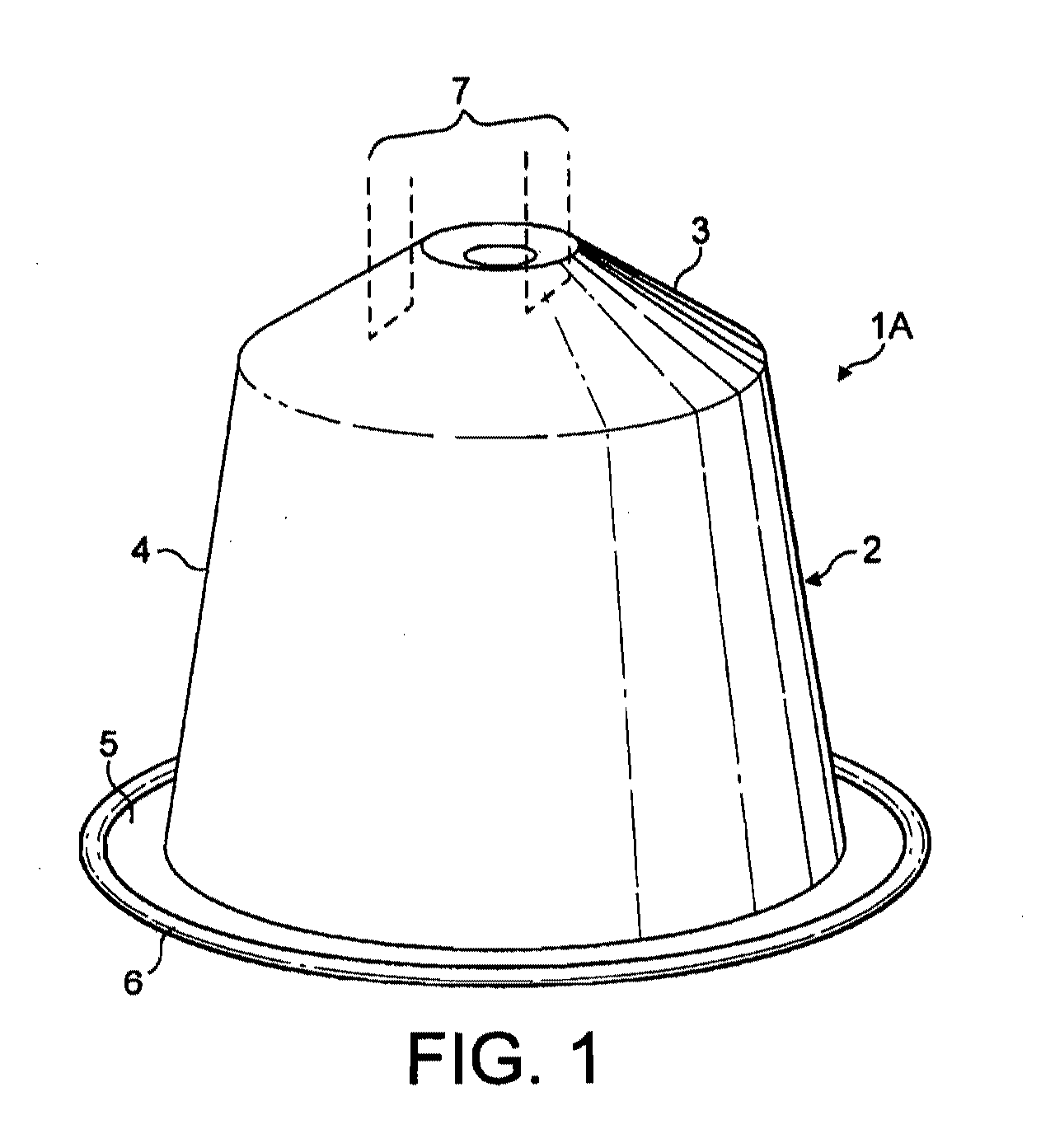

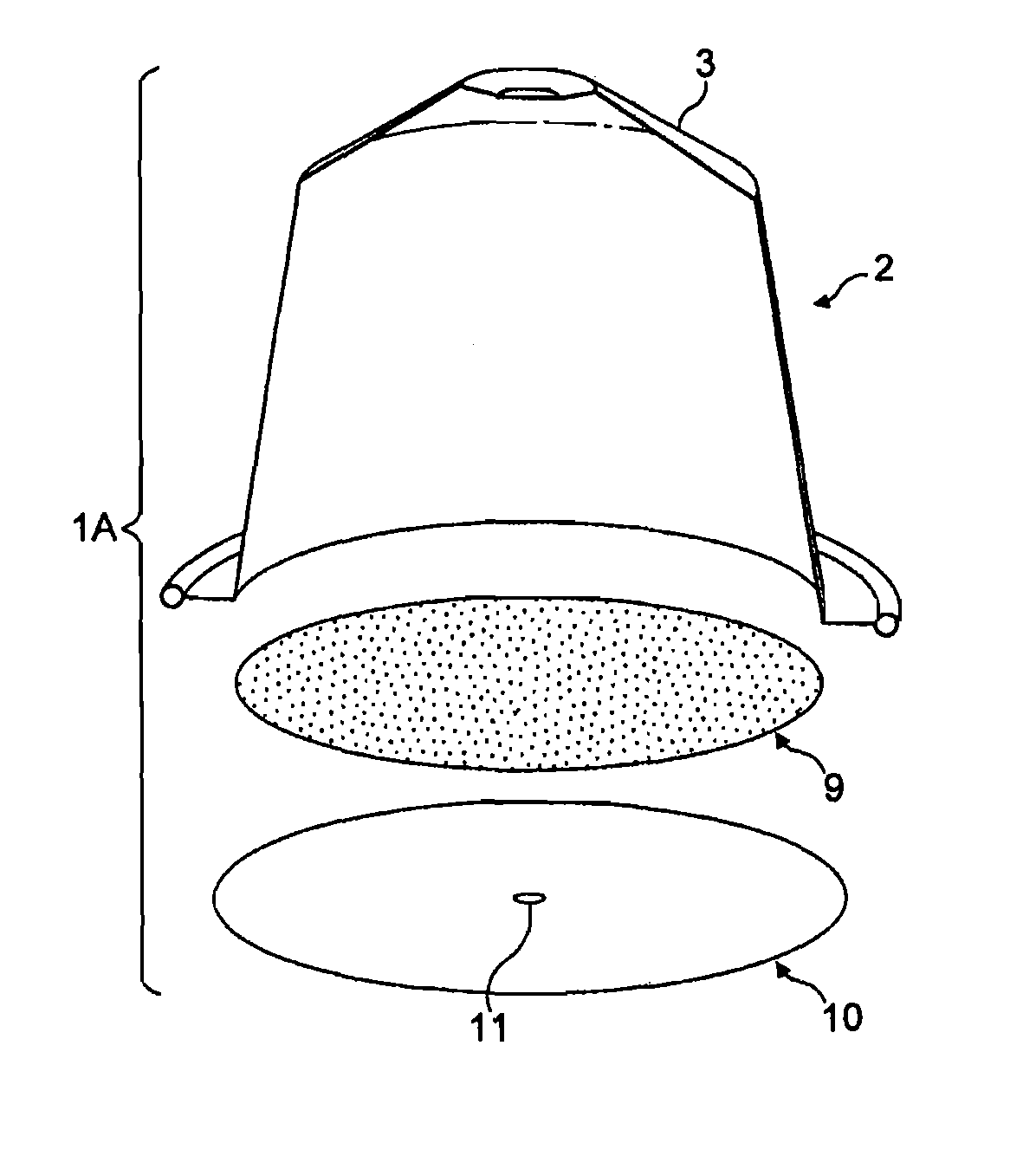

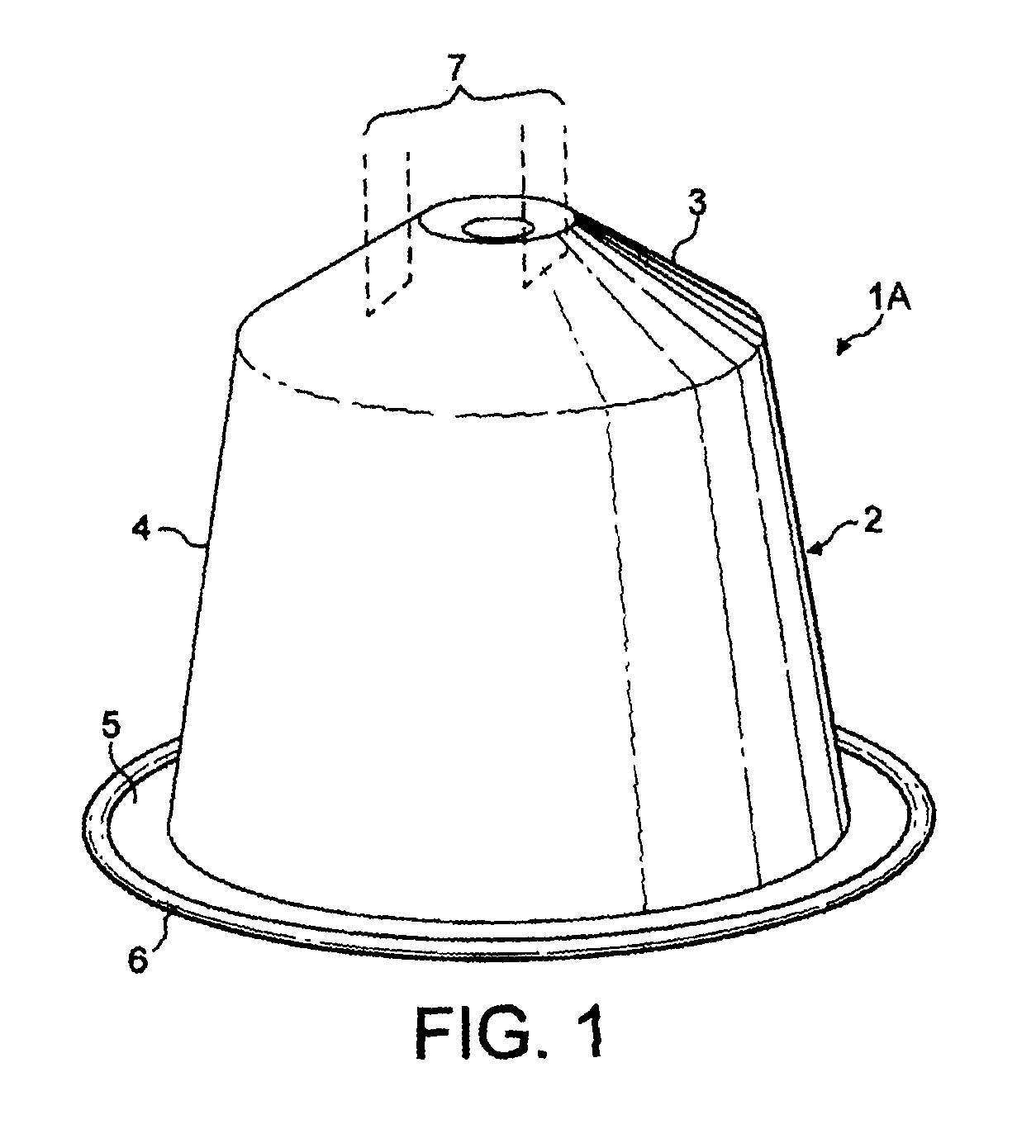

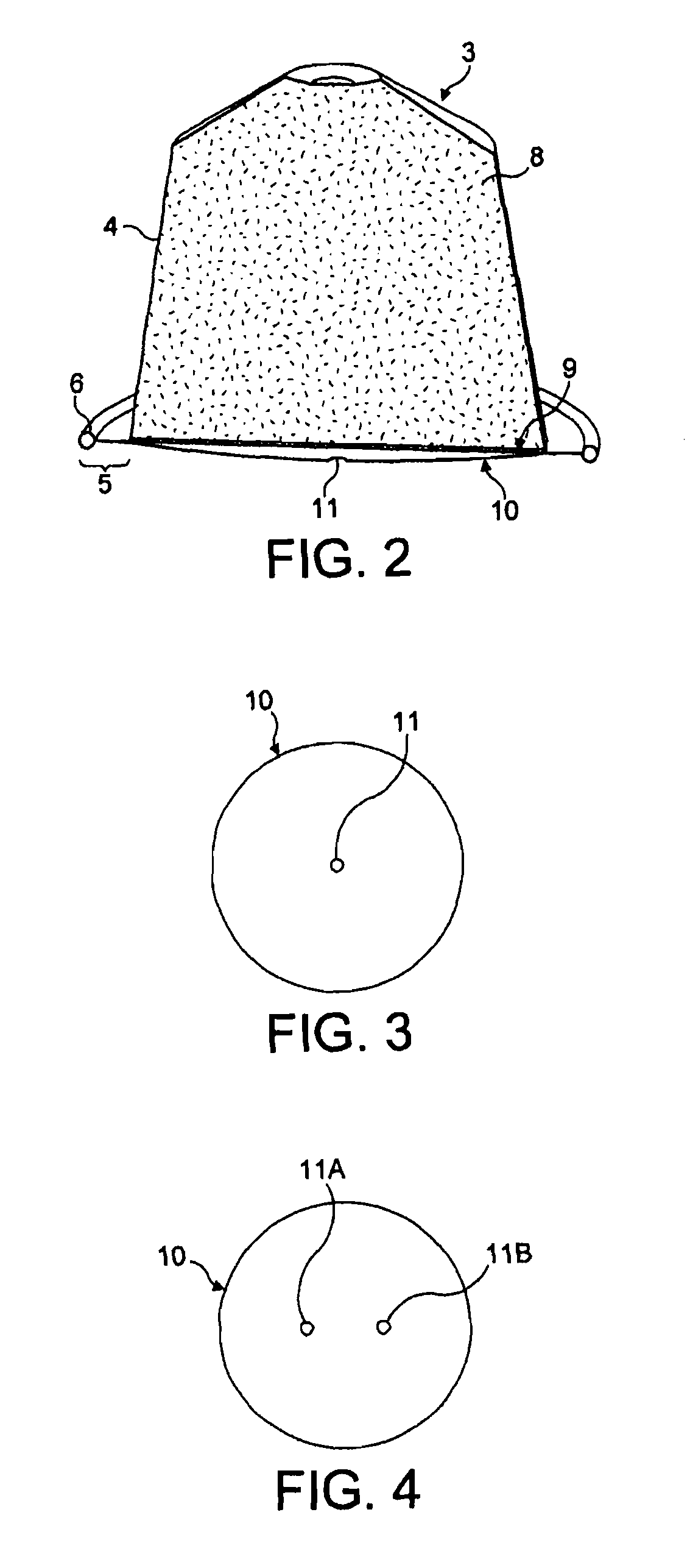

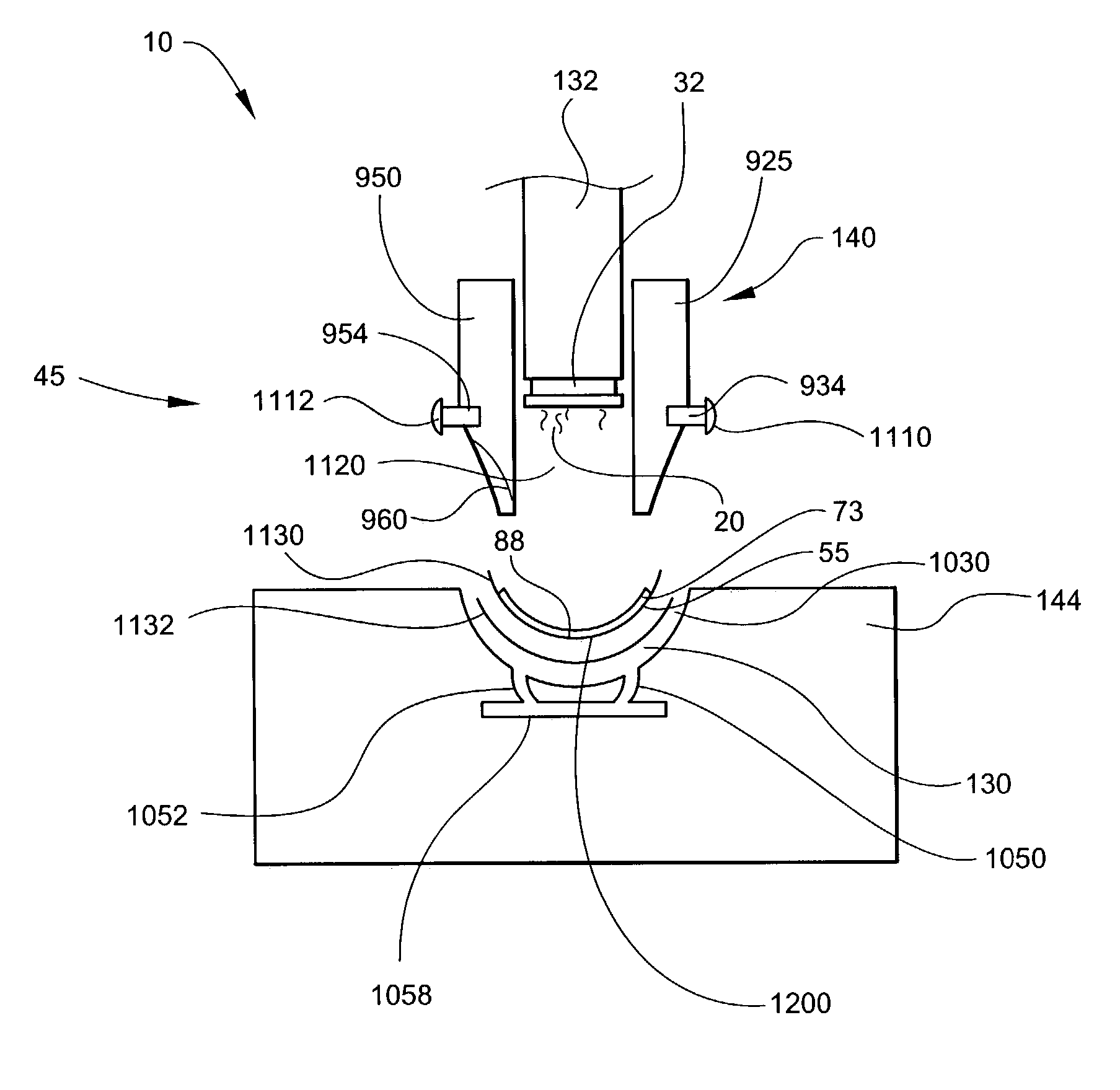

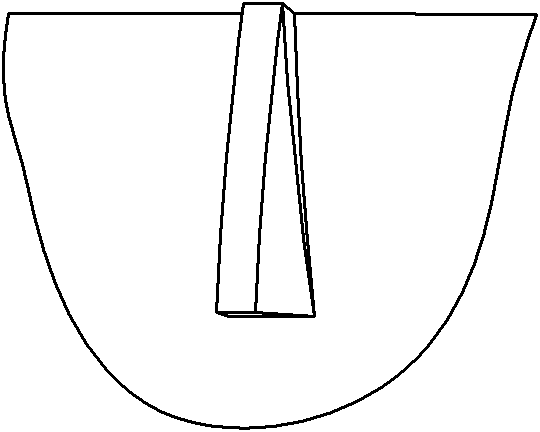

Capsule for preparing coffee in a device comprising a cartridge holder with relief and recessed elements

ActiveUS20100239717A1Consistent flowBeverage vesselsPackaging foodstuffsAdditive ingredientEngineering

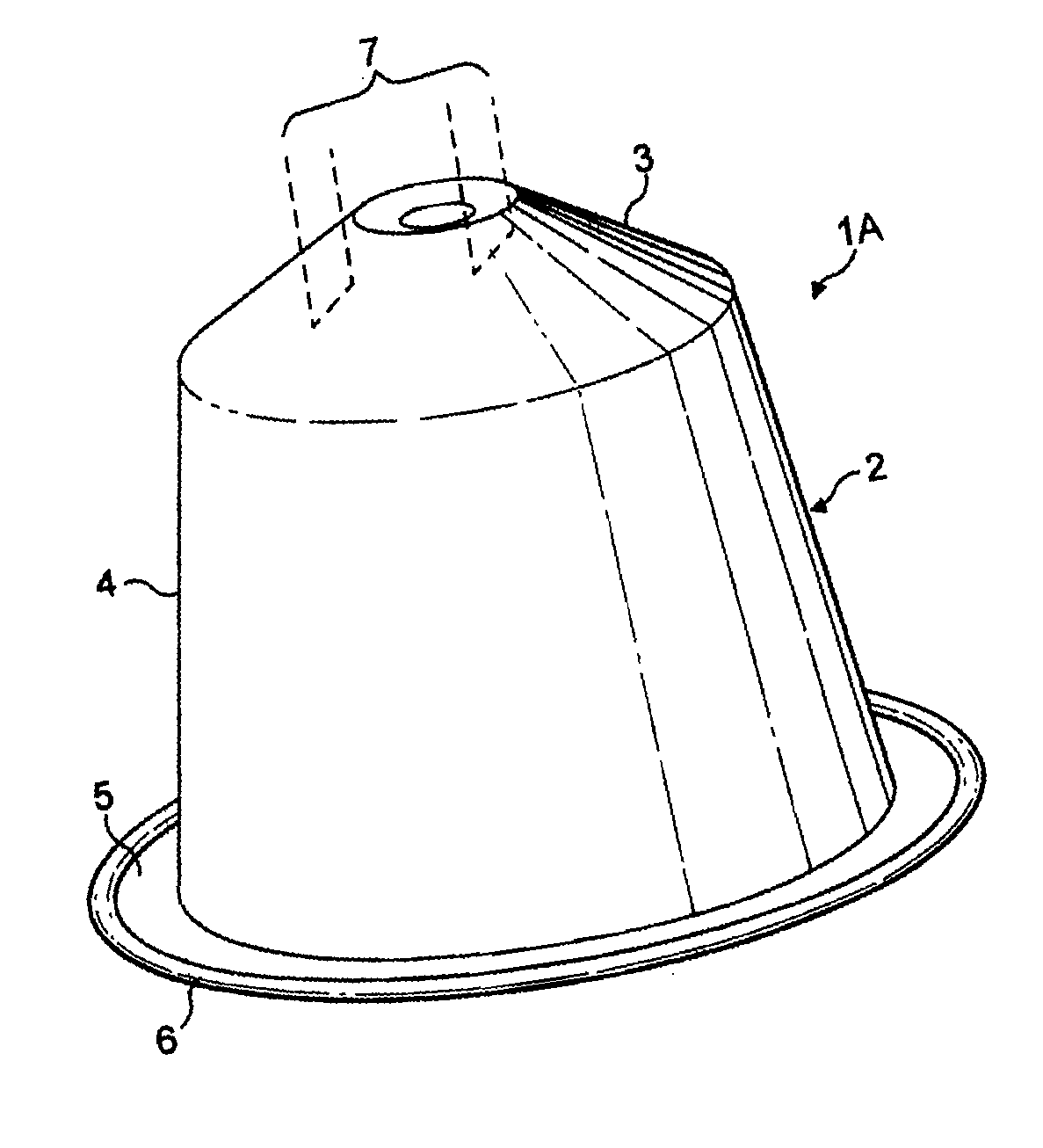

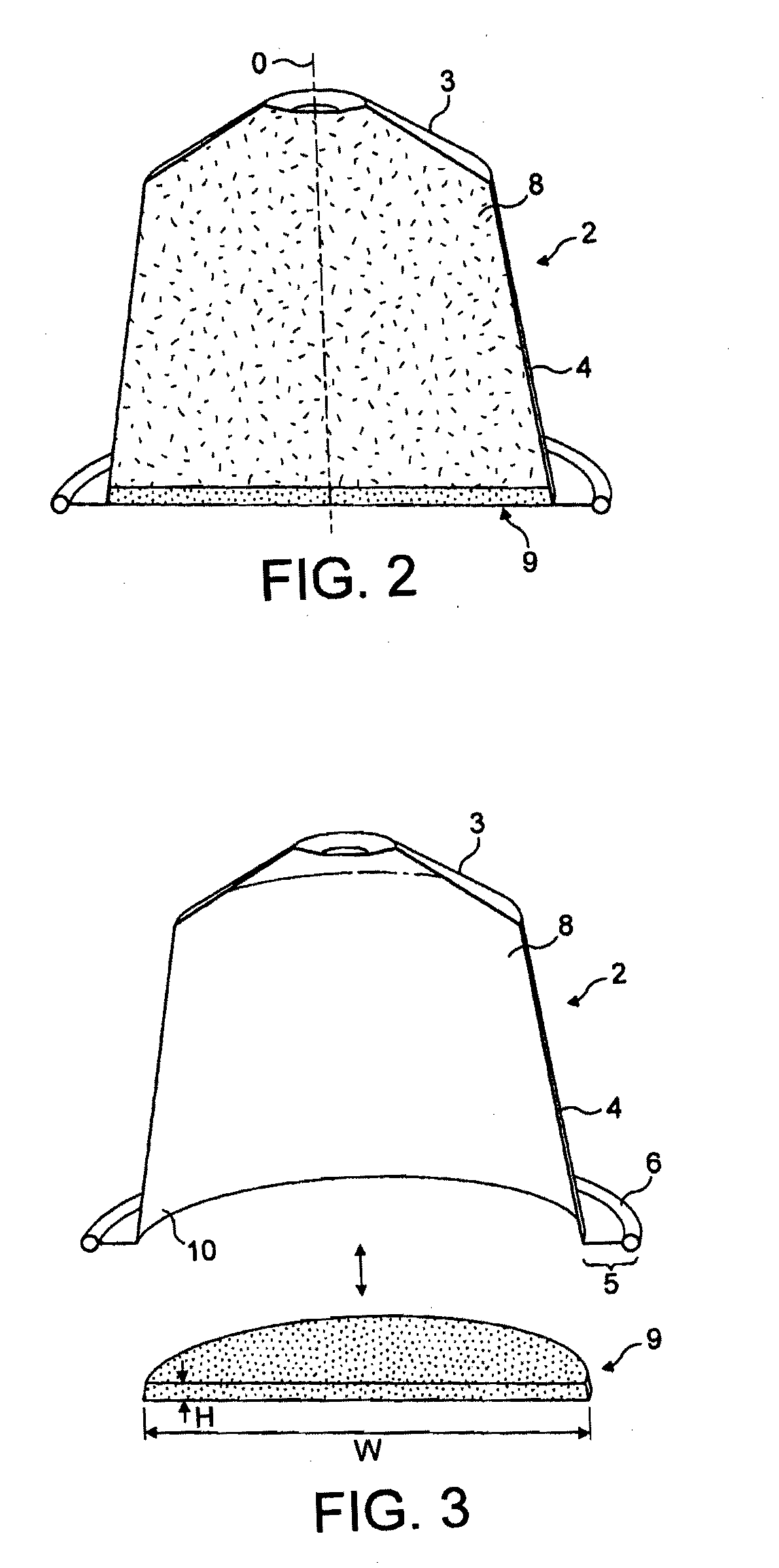

A capsule for the production of a beverage in a beverage production machine comprising a capsule holder with relief and recessed elements. The capsule includes an inverted cup-shaped body forming a chamber containing beverage ingredients; a bottom injection wall; a sidewall; and a delivery wall which is sealed to the body. The delivery wall is configured and dimensioned to include a calibrated orifice or perforating means to provide a calibrated orifice with the beverage delivery wall not being tearable against the capsule holder during extraction. The wall also provides through the restriction created by the calibrated orifice a certain back pressure which generates an elevated pressure in the capsule during extraction. Also, a system and method for producing a beverage from the capsules of the invention.

Owner:SOC DES PROD NESTLE SA

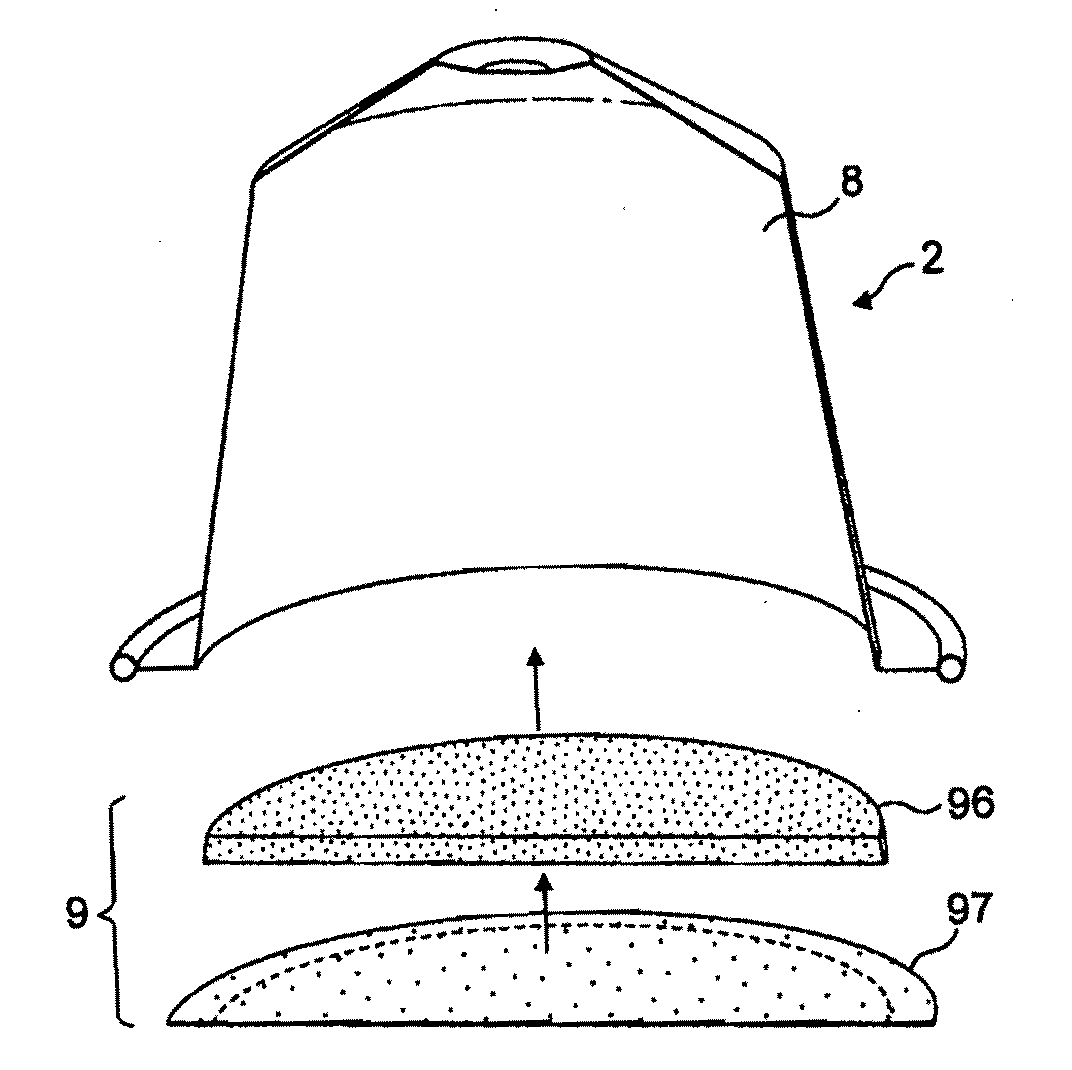

Capsule with filtering insert for preparing a coffee beverage

ActiveUS20100239733A1Consistent flowBeverage vesselsPackagingAdditive ingredientBiomedical engineering

A capsule for the production of a beverage from a beverage production machine that provides a capsule holder with relief and recessed elements. The capsule includes an inverted cup-shaped body forming a chamber containing a beverage forming ingredient, a bottom injection wall, a sidewall and a flange-like rim; and a delivery wall which is sealed to the body and comprises a relatively flat outer surface extending from the central axis of the capsule to the flange-like rim of the body and at least one portion of porous material capable of providing a backpressure that is greater than the backpressure of the beverage forming ingredient in the chamber. Also, a system and method for the production of a beverage from the previously described capsule.

Owner:SOC DES PROD NESTLE SA

Equipment for manufacturing cigarettes

InactiveUS7195019B2Easy transferConsistent flowCigar manufactureCigarette manufacturePulp and paper industryPaper sheet

Cigarettes are manufactured using modified automated cigarette making apparatus. Those cigarettes possess smokable rods having paper wrapping materials having additive materials applied thereto as patterns. The additive materials, are applied to a continuous paper web on the cigarette making apparatus. The formulation can be applied to the paper web using application apparatus possessing rollers, and one of those rollers has a series of pockets in its roll face to receive additive formulation from a reservoir and to define the pattern of the formulation on the paper. The automated cigarette making apparatus can comprise multiple components. A first component of the assembly provides a source of paper web, applies additive material to that web in a pattern and dries the paper web; while a second component receives the paper web, supplies tobacco filler and manufactures a cigarette rod from the paper web and tobacco filler.

Owner:R J REYNOLDS TOBACCO COMPANY

Capsule for preparing coffee in a device comprising a cartridge holder with relief and recessed elements

ActiveUS8956672B2Consistent flowBeverage vesselsPackaging foodstuffsAdditive ingredientBiomedical engineering

A capsule for the production of a beverage in a beverage production machine comprising a capsule holder with relief and recessed elements. The capsule includes an inverted cup-shaped body forming a chamber containing beverage ingredients; a bottom injection wall; a sidewall; and a delivery wall which is sealed to the body. The delivery wall is configured and dimensioned to include a calibrated orifice or perforating means to provide a calibrated orifice with the beverage delivery wall not being tearable against the capsule holder during extraction. The wall also provides through the restriction created by the calibrated orifice a certain back pressure which generates an elevated pressure in the capsule during extraction. Also, a system and method for producing a beverage from the capsules of the invention.

Owner:SOC DES PROD NESTLE SA

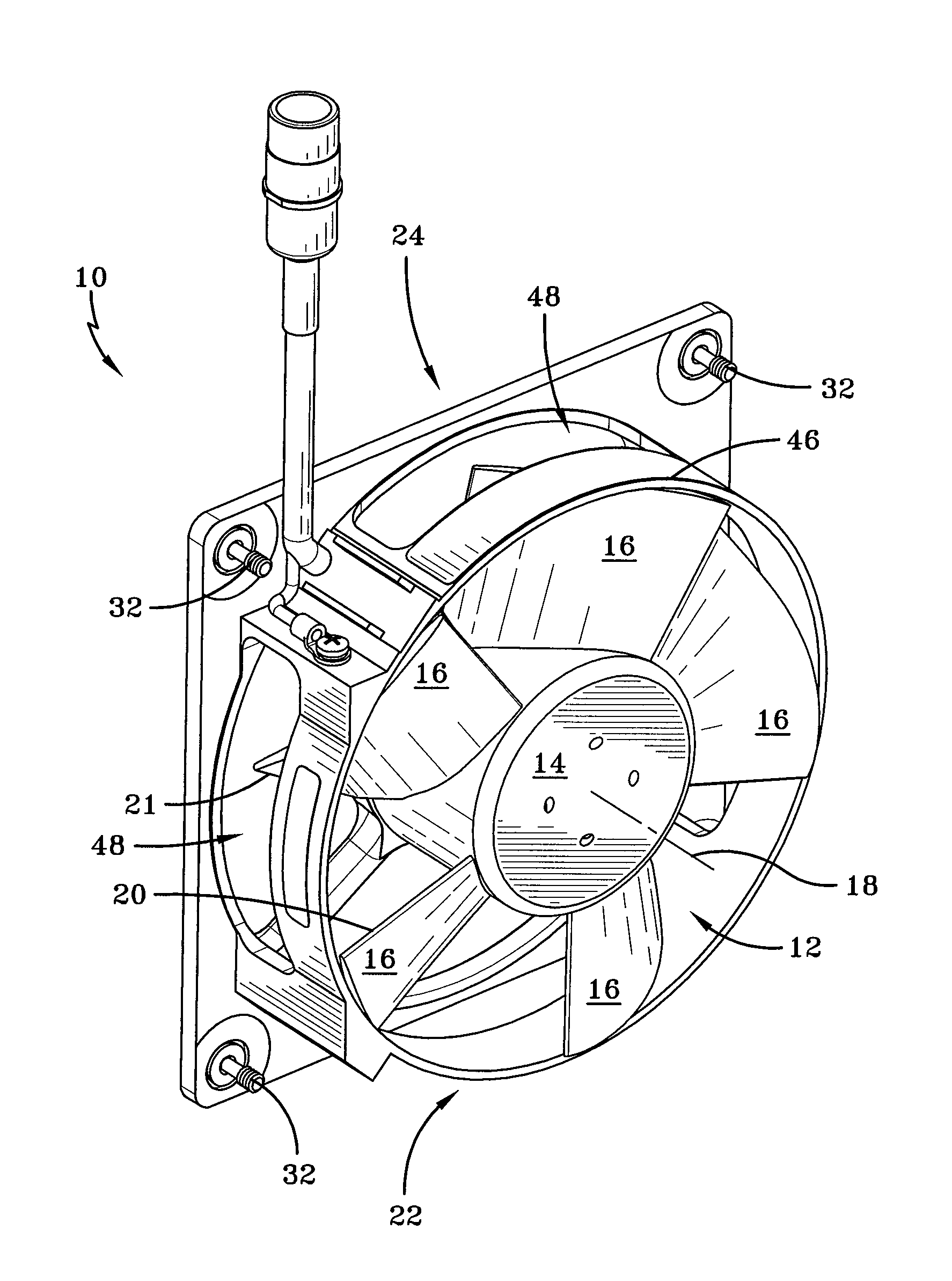

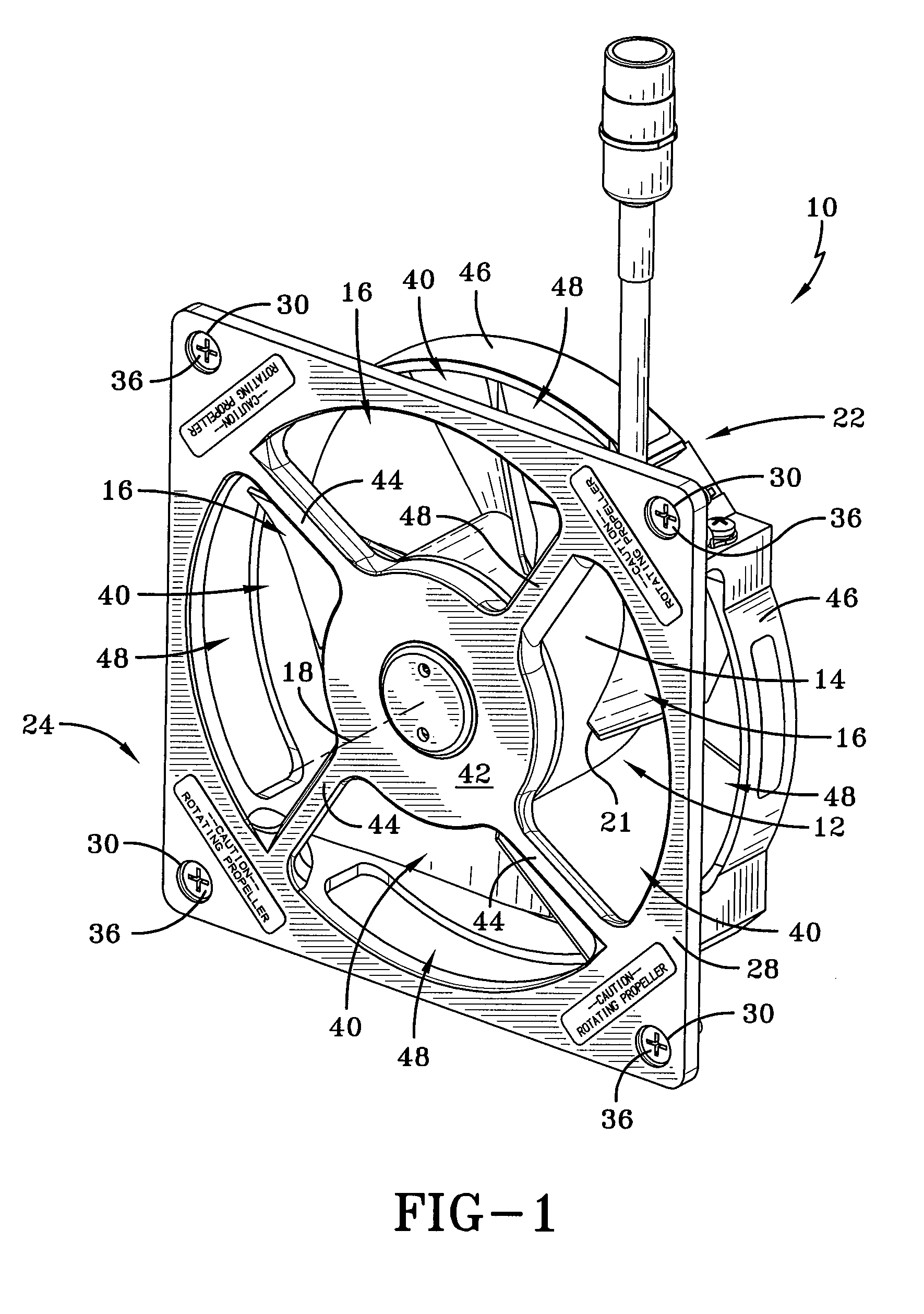

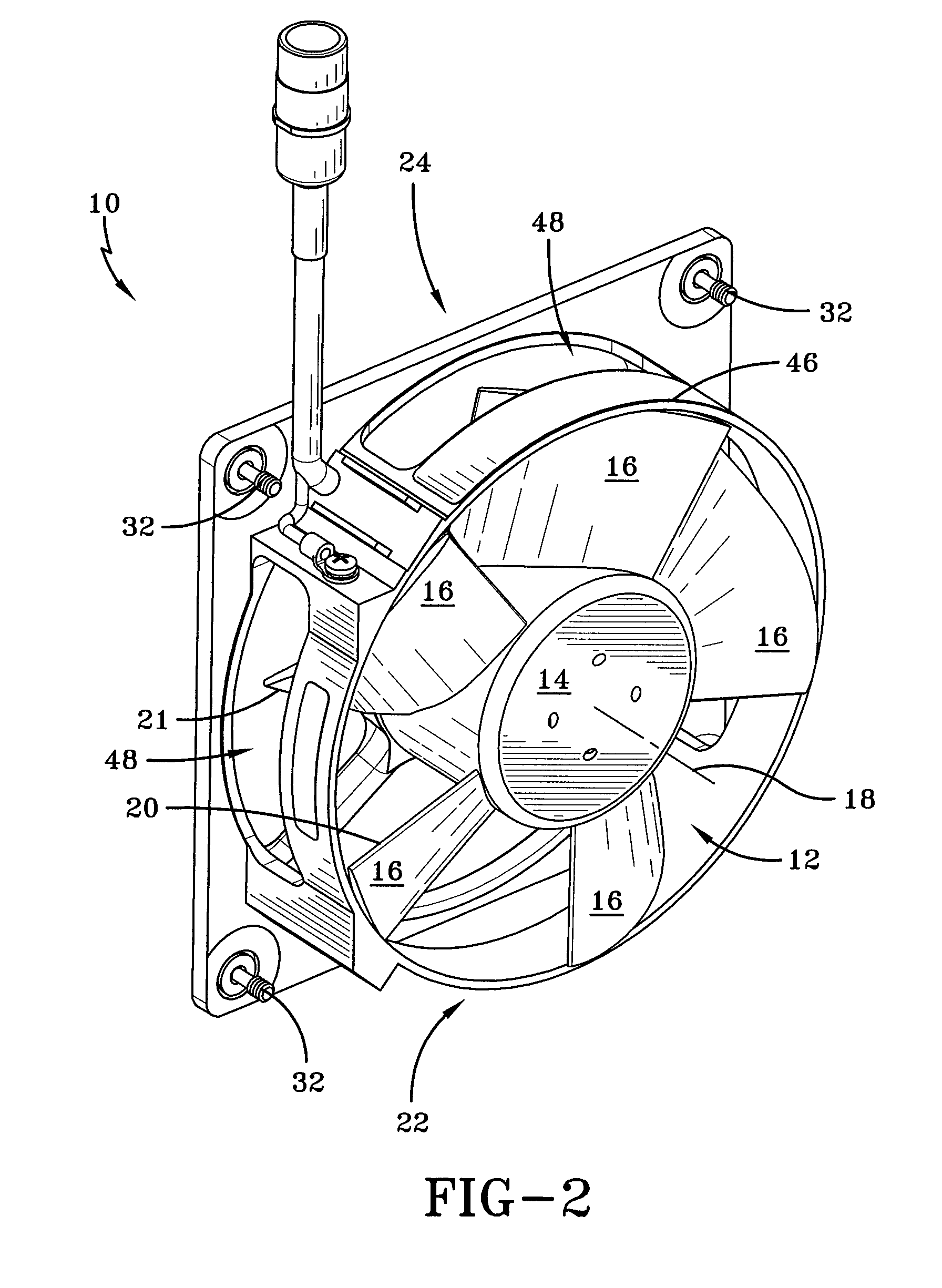

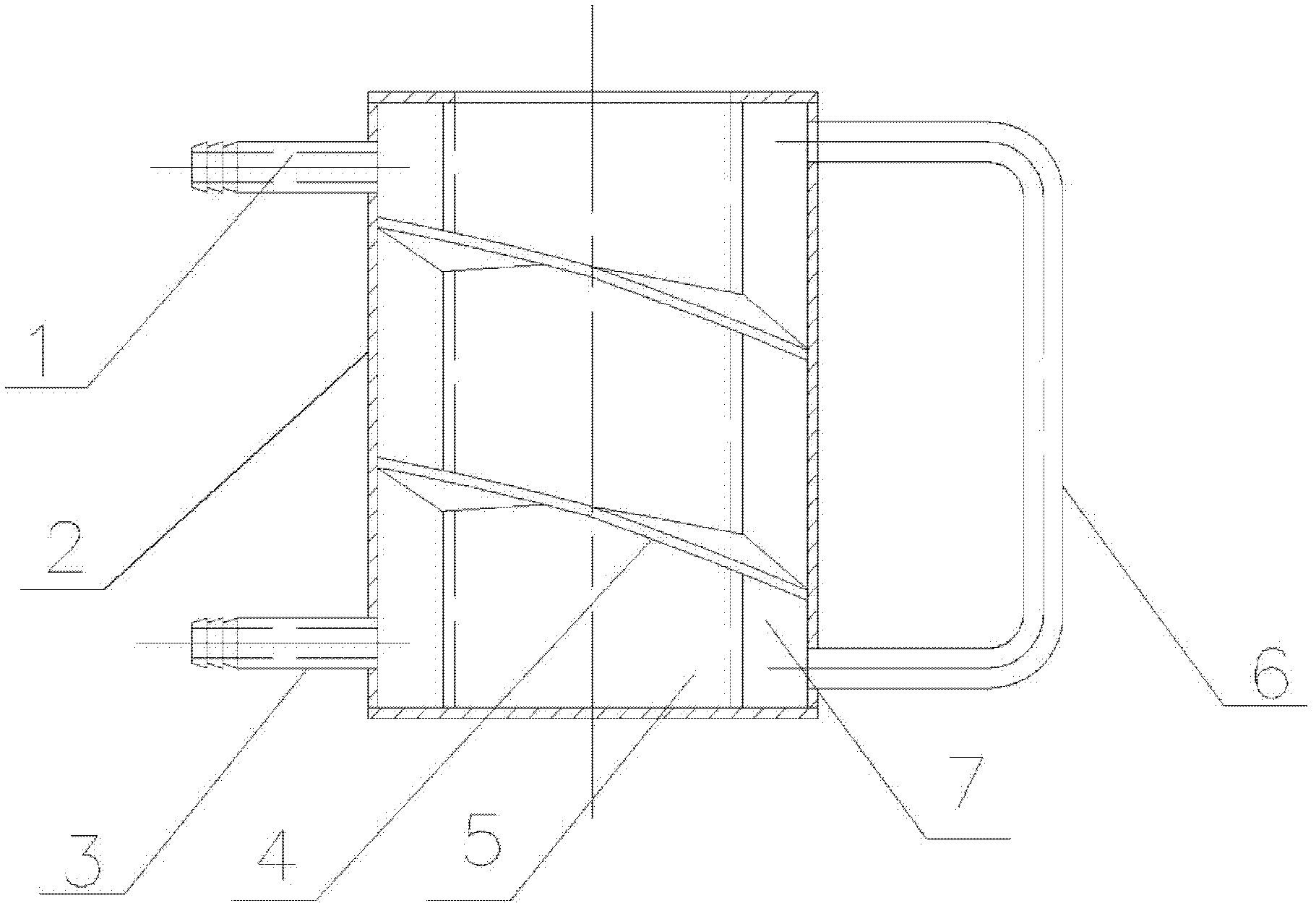

Peripheral discharge tube axial fan

A mixed flow fan assembly includes an electric motor, an impeller having a hub enclosing the motor, and a plurality of fan blades spaced circumferentially around the hub. The fan assembly also includes an axis of rotation extending through the hub, an annular venturi radially surrounding the impeller, and a mounting plate with an opening to allow for axial airflow positioned on one open end of the venturi. The venturi has at least one elongated slot to allow for radial airflow from the fan assembly, the slot being oriented substantially perpendicular to the axis of rotation and having a generally rectangular shape. Rotation of the hub and the fan blades caused by the electric motor generates both axial and radial airflow through the fan assembly.

Owner:AMETEK INC

Method and system for managing enterprise content

A method and system for providing a consistent flow documents and data content across different organizational units of a company or agency where the documents and data come from different enterprise systems and data stores but are related to linked processes that share models for organizing the content in the business context and in a format that enables a user to relate the content to the process step or steps they are performing. The system includes a network service that enables a configuration utility to automatically discover the objects and metadata and provides for a mapping of selected fields of the metadata to regions displayed in the user interface view with provision for filtering the data by mapping selected fields to a user input form. Thereby, a business analyst can create solutions without writing and maintaining complex program logic for each combination of presentation environment, enterprise system and data store.

Owner:OPEN TEXT CORPORATION

Materials, equipment and methods for manufacturing cigarettes

ActiveUS20050076925A1Easy transferConsistent flowCigar manufactureCigarette manufactureBobbinPulp and paper industry

Cigarettes are manufactured using modified automated cigarette making apparatus. Those cigarettes possess smokable rods having paper wrapping materials having additive materials applied thereto as patterns. The additive materials, which can have the forms of liquid or paste formulations (e.g., aqueous formulations incorporating starch or modified starch), are applied to a continuous paper web on the cigarette making apparatus. The formulation is applied to the paper web using application apparatus possessing rollers a series of roller. For example, additive material is applied to the roll face of a transfer roller due to roll interaction of that transfer roller with a pick-up roller; roll interaction of the transfer roller with an application roller causes transfer of the additive material from the transfer roller to the application roller; and additive material from the application roller is transferred to the paper web that passes between the application roller and a back-up roller. A radiant dryer is used to dry the additive material that has been applied to the paper web. The radiant dryer is located on one component of a two component assembly that is used to manufacture cigarettes. A first component of the two component assembly provides a source of paper web, applies additive material to that web in a pattern and dries the paper web; while a second component receives the paper web, supplies tobacco filler and manufactures a cigarette rod from the paper web and tobacco filler. An alternate assembly system provides a source of paper web, applies additive material to that web in a pattern, dries the paper web, and winds the treated paper web onto a bobbin; and that bobbin is later used to provide a source of paper web on a cigarette making machine unrolls that bobbin, receives the treated paper web from that bobbin, supplies tobacco filler and manufactures a cigarette rod from the paper web and tobacco filler. Spectrometric techniques are used to ensure proper registration of the additive material on the cigarette rods so manufactured, and to ensure proper quality of those cigarettes.

Owner:R J REYNOLDS TOBACCO COMPANY

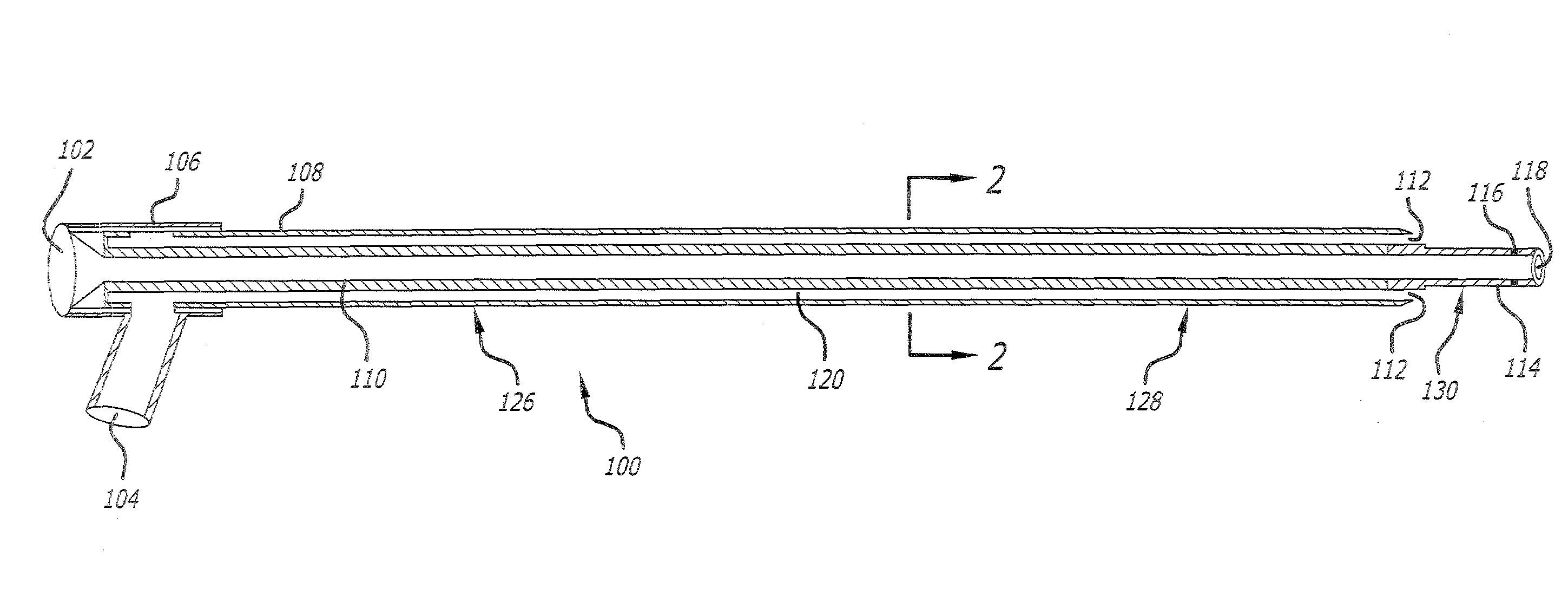

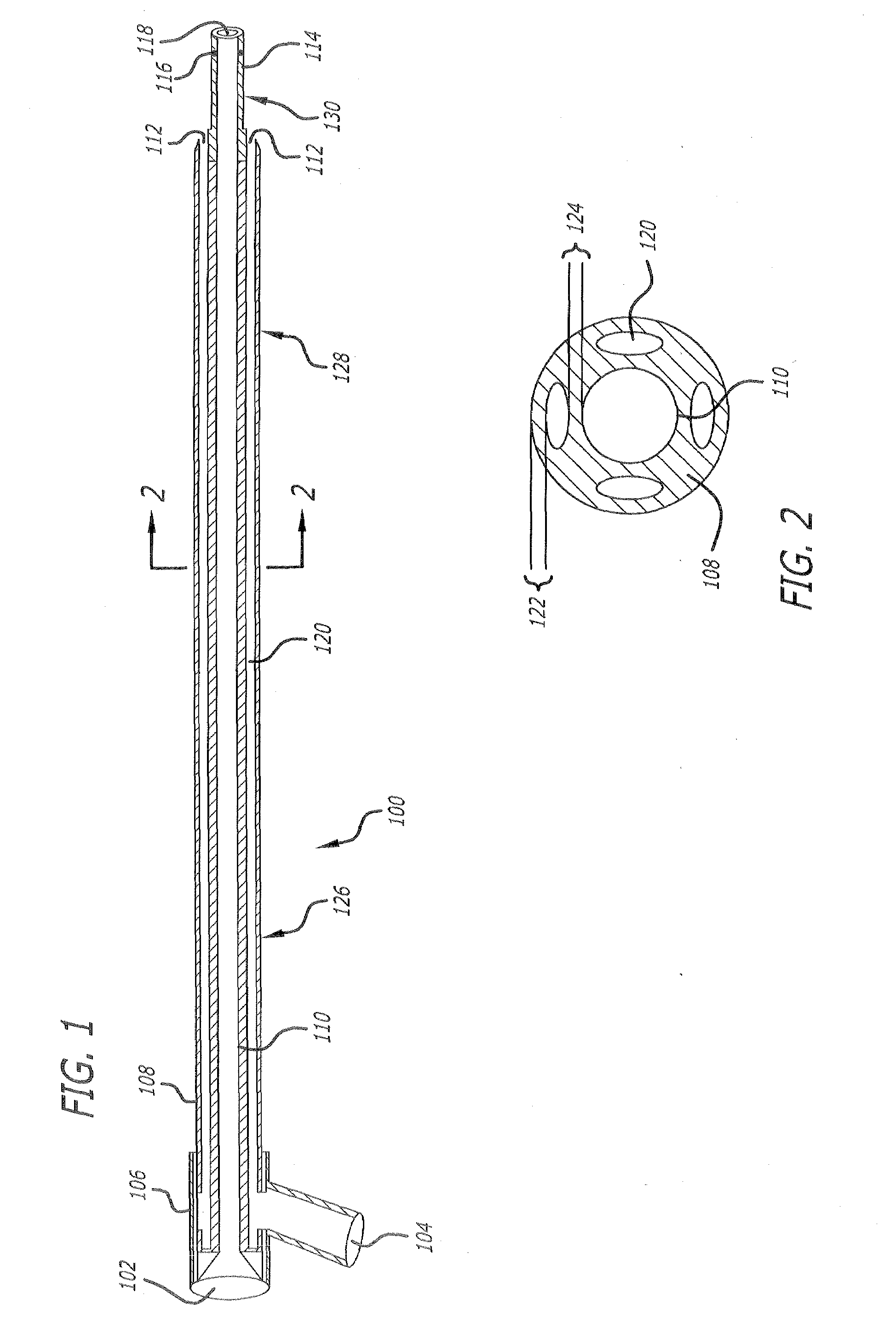

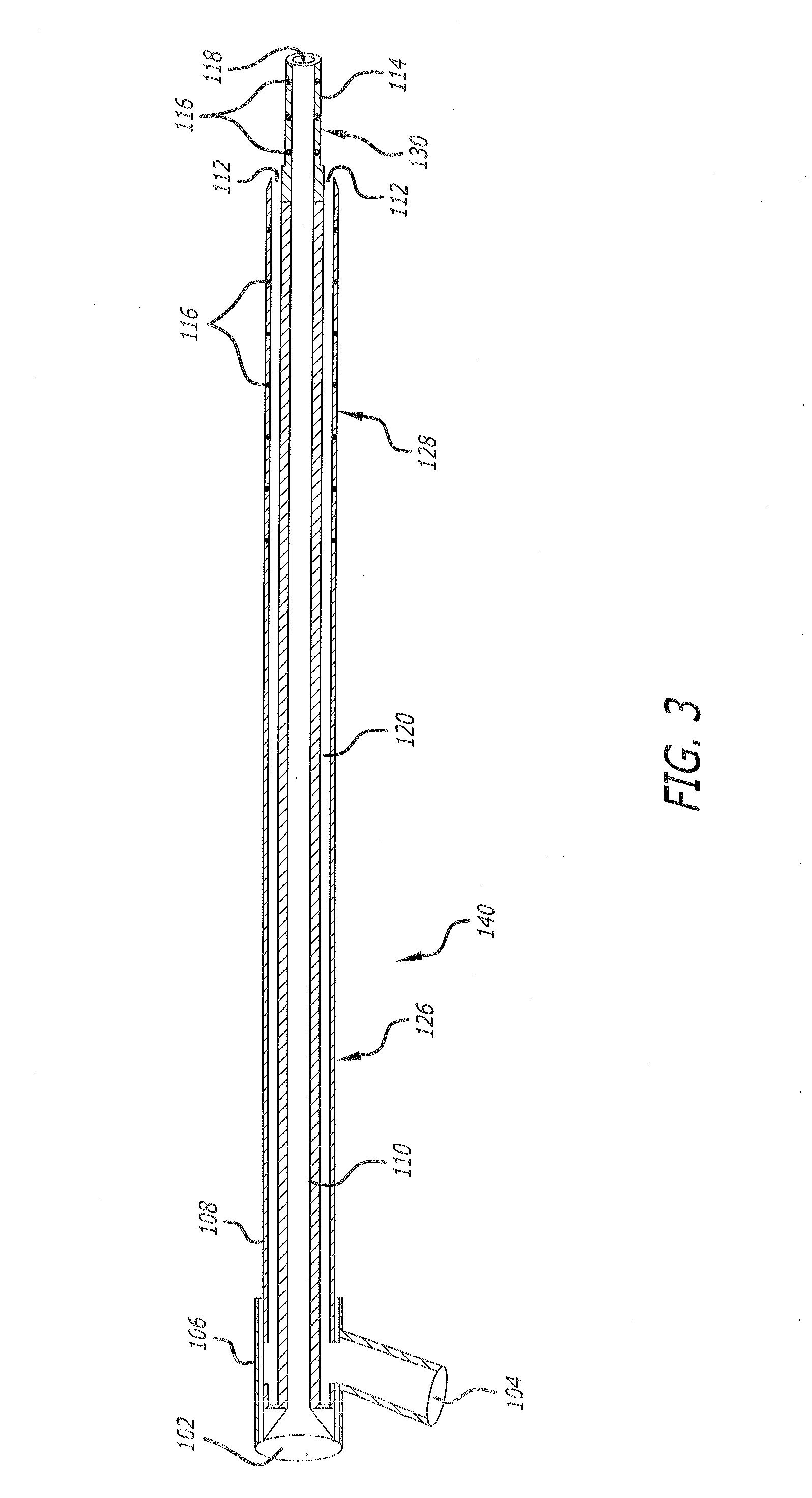

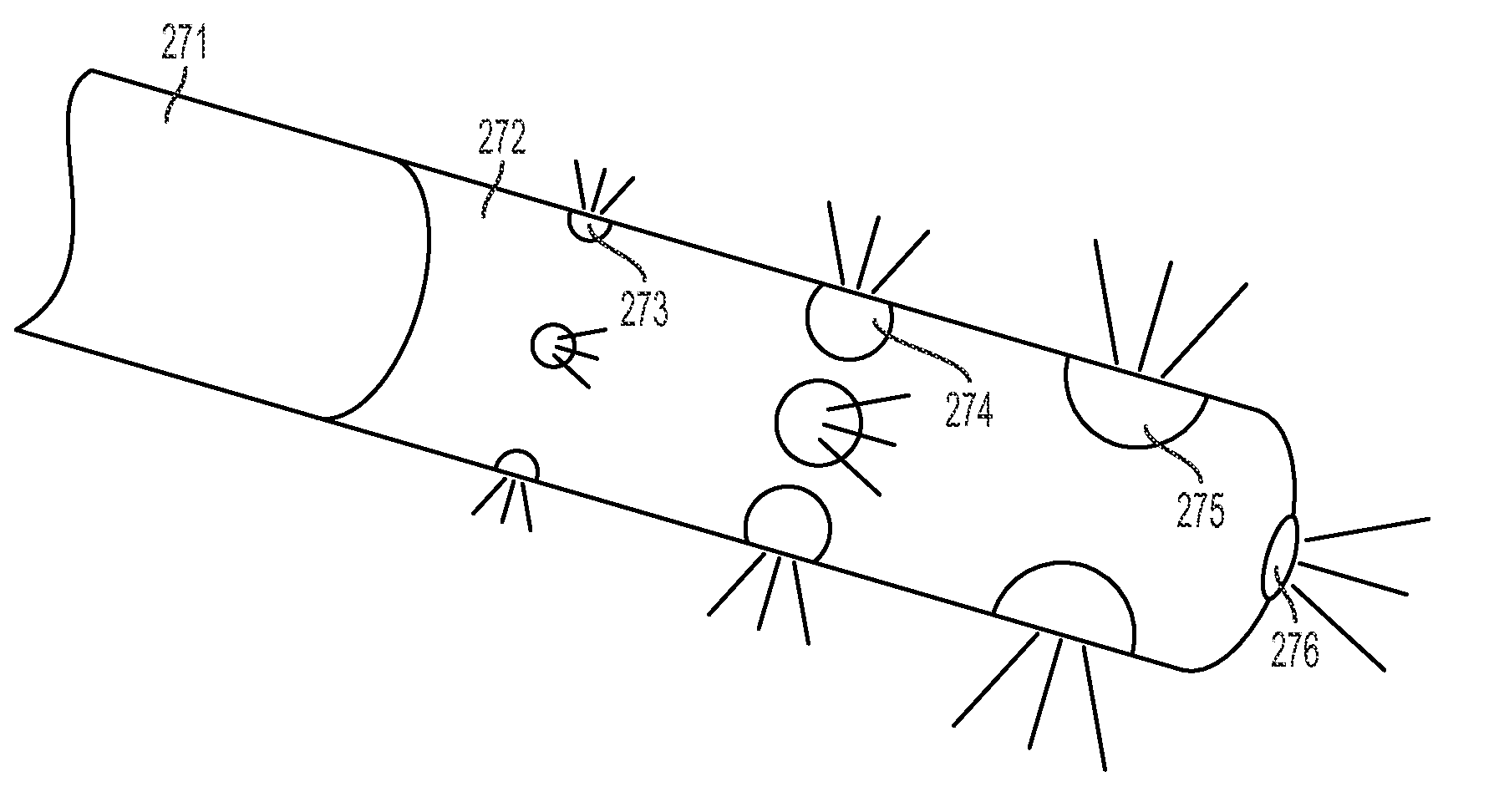

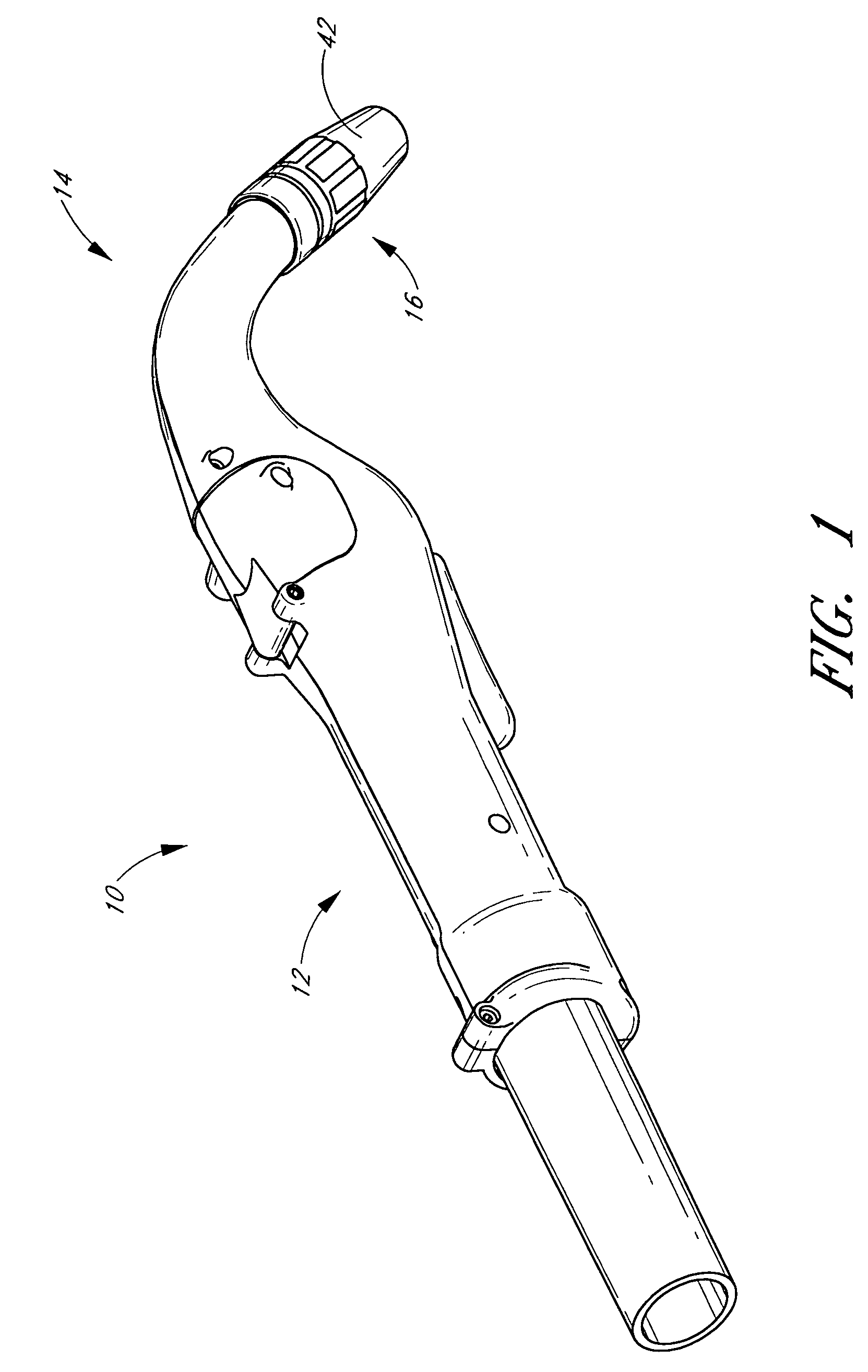

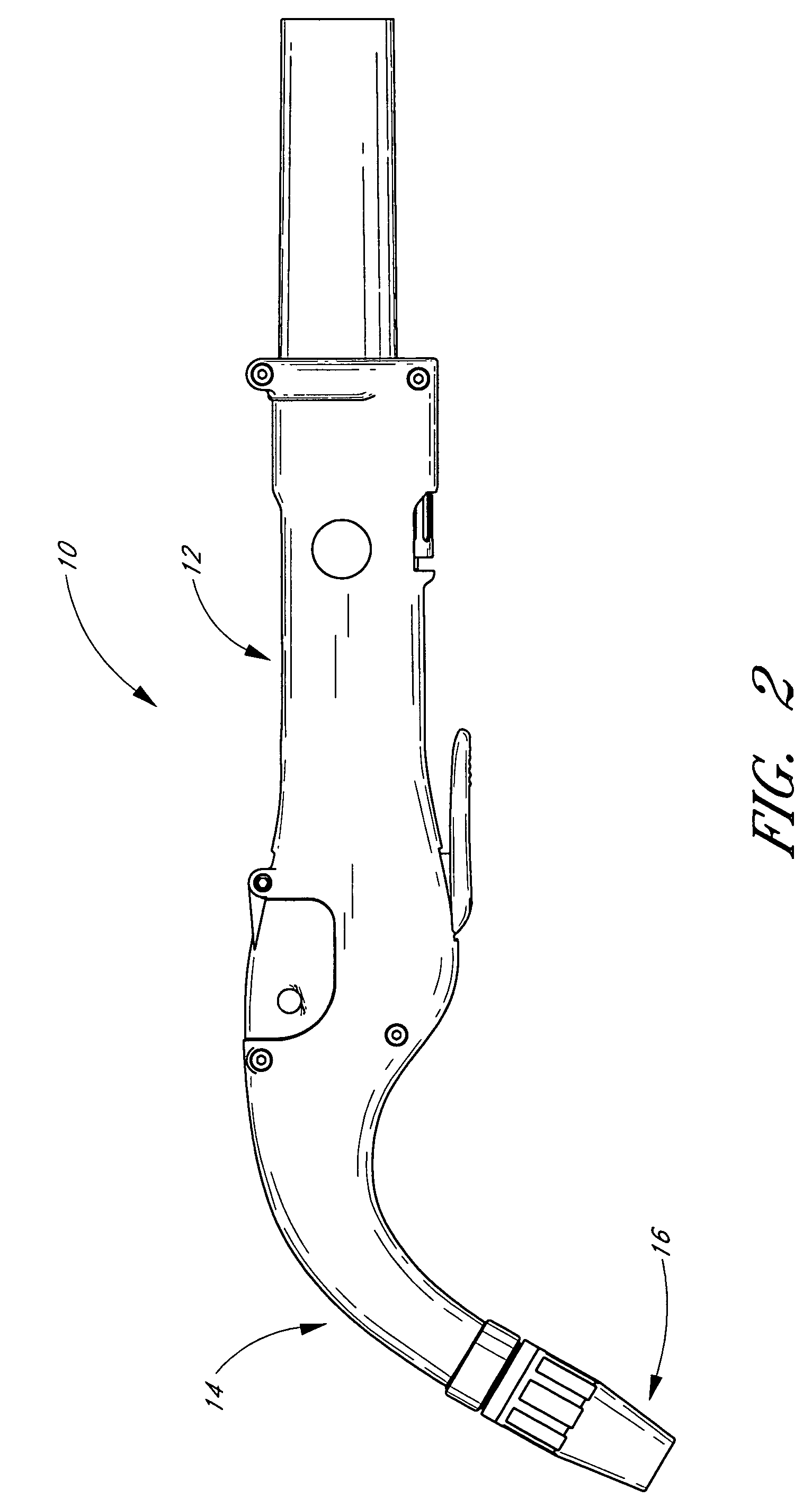

Diagnostic catheter

InactiveUS20080255447A1Reduce the possibilityImproved contrast visualizationMulti-lumen catheterMedical devicesContrast ratioBlood stream

A diagnostic catheter having both a guidewire lumen and at least one contrast lumen is disclosed. In one embodiment, the contrast lumens allow the user to deliver contrast to a target area within the patient without removing the guidewire. Preferably, a plurality of contrast exit ports are included along the length of the catheter body to evenly and consistently distribute contrast into the blood stream, thereby providing improved visualization during radioscopy.

Owner:EDWARDS LIFESCIENCES CORP

Equipment and methods for manufacturing cigarettes

InactiveUS20070051381A1Easy transferConsistent flowCigar manufactureCigarette manufacturePulp and paper industry

Cigarettes are manufactured using modified automated cigarette making apparatus. Those cigarettes possess smokable rods having paper wrapping materials having additive materials applied thereto as patterns. The additive materials, which can have the forms of liquid or paste formulations, can be applied to the paper web using application apparatus possessing rollers. One of those rollers can have a series of pockets in its roll face to receive additive formulation from a reservoir and to define the pattern of the formulation on the paper. A radiant dryer can be used to dry the additive material that has been applied to the paper web. The radiant dryer can be located on one component of a two component assembly that is used to manufacture cigarettes. Spectrometric techniques can be used to ensure proper registration of the additive material on the cigarette rods so manufactured, and to ensure proper quality of those cigarettes.

Owner:R J REYNOLDS TOBACCO COMPANY

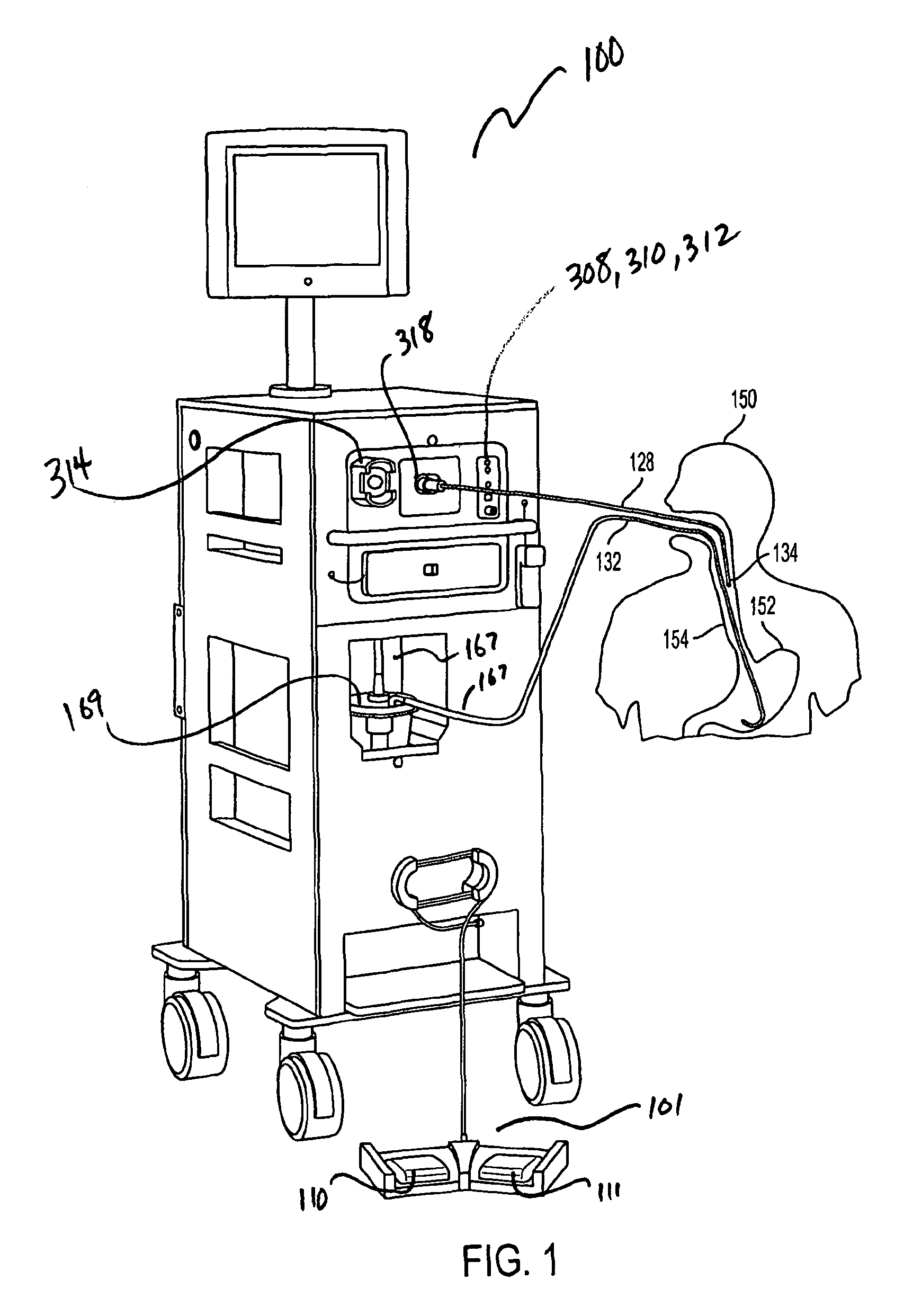

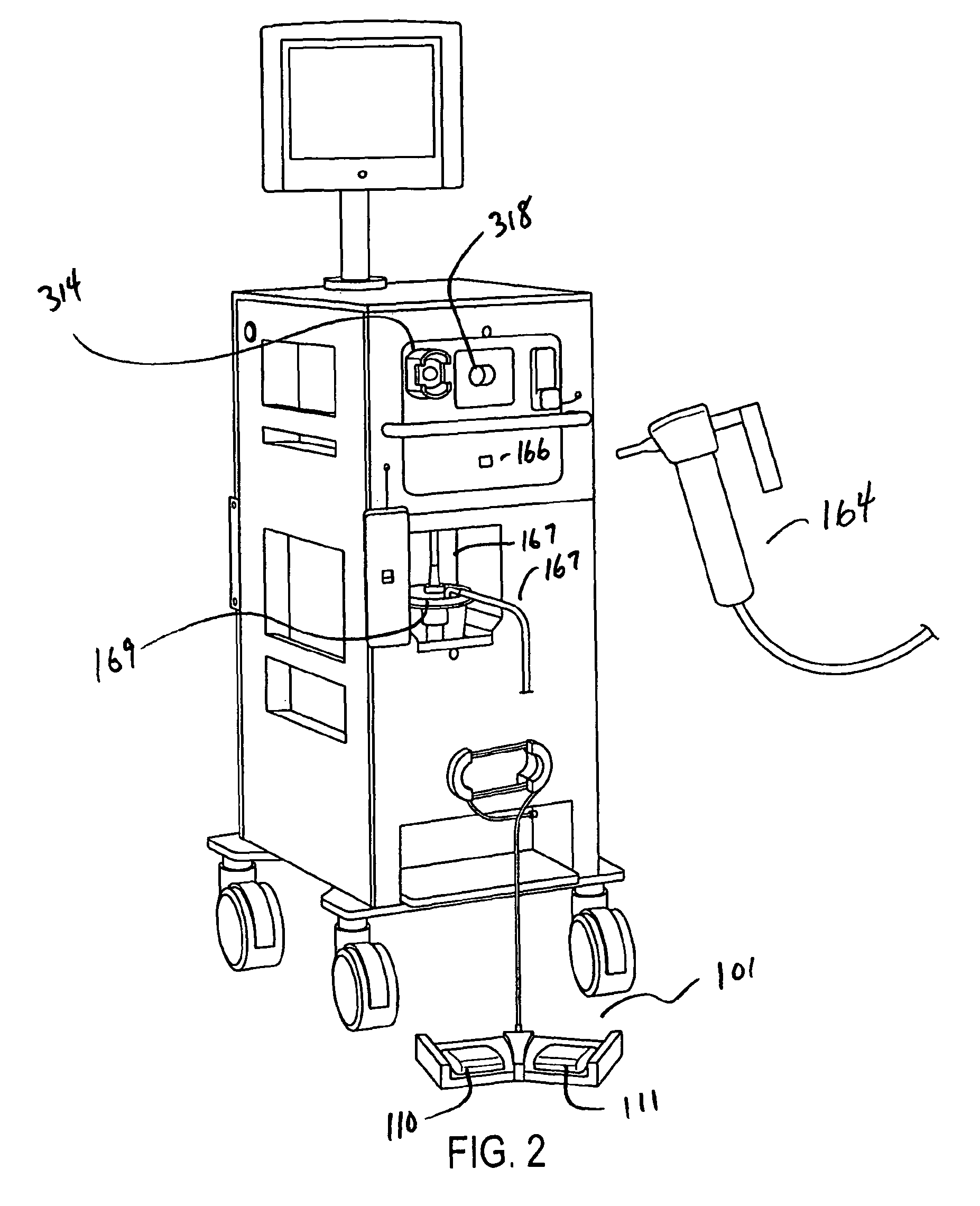

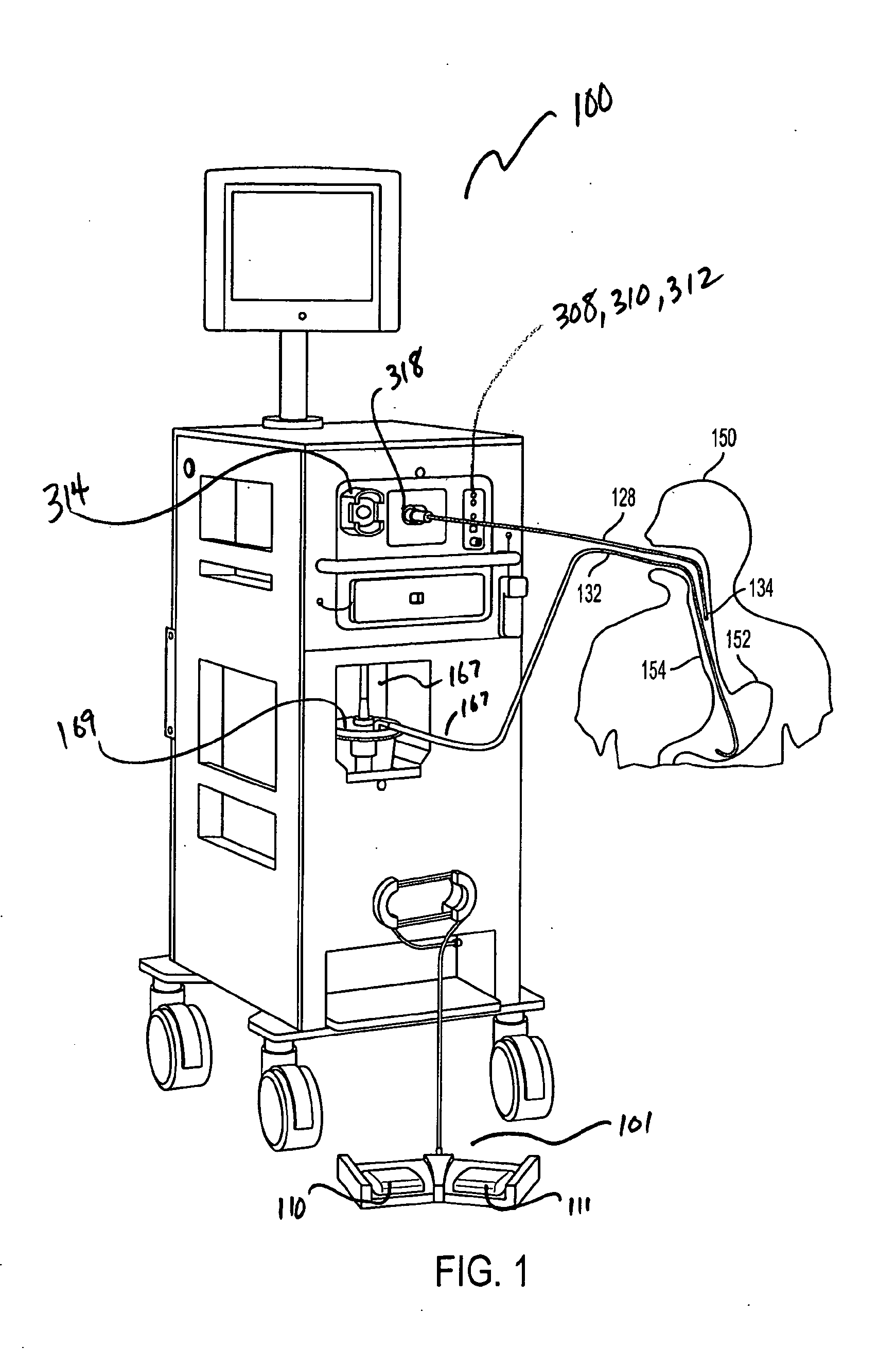

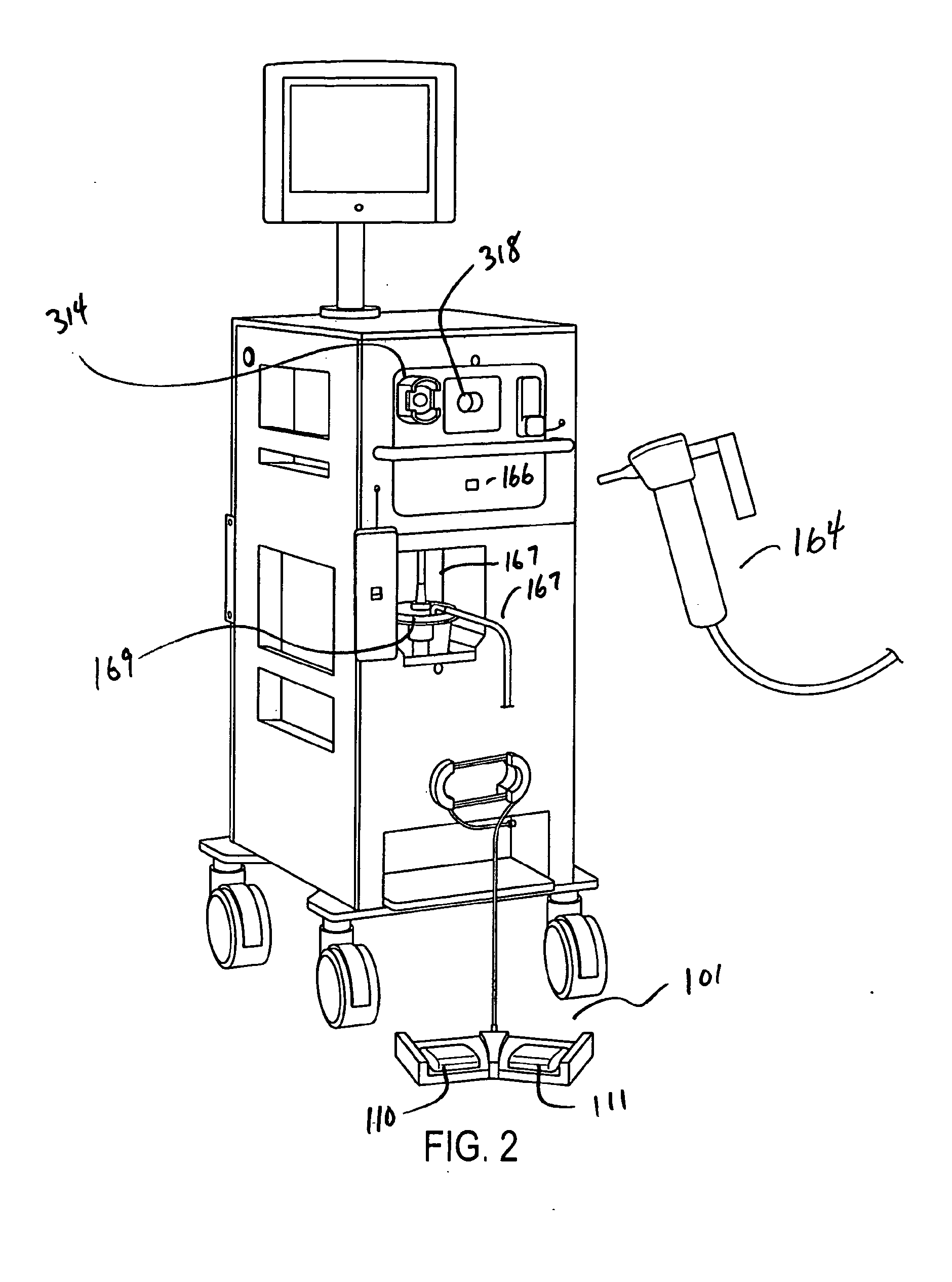

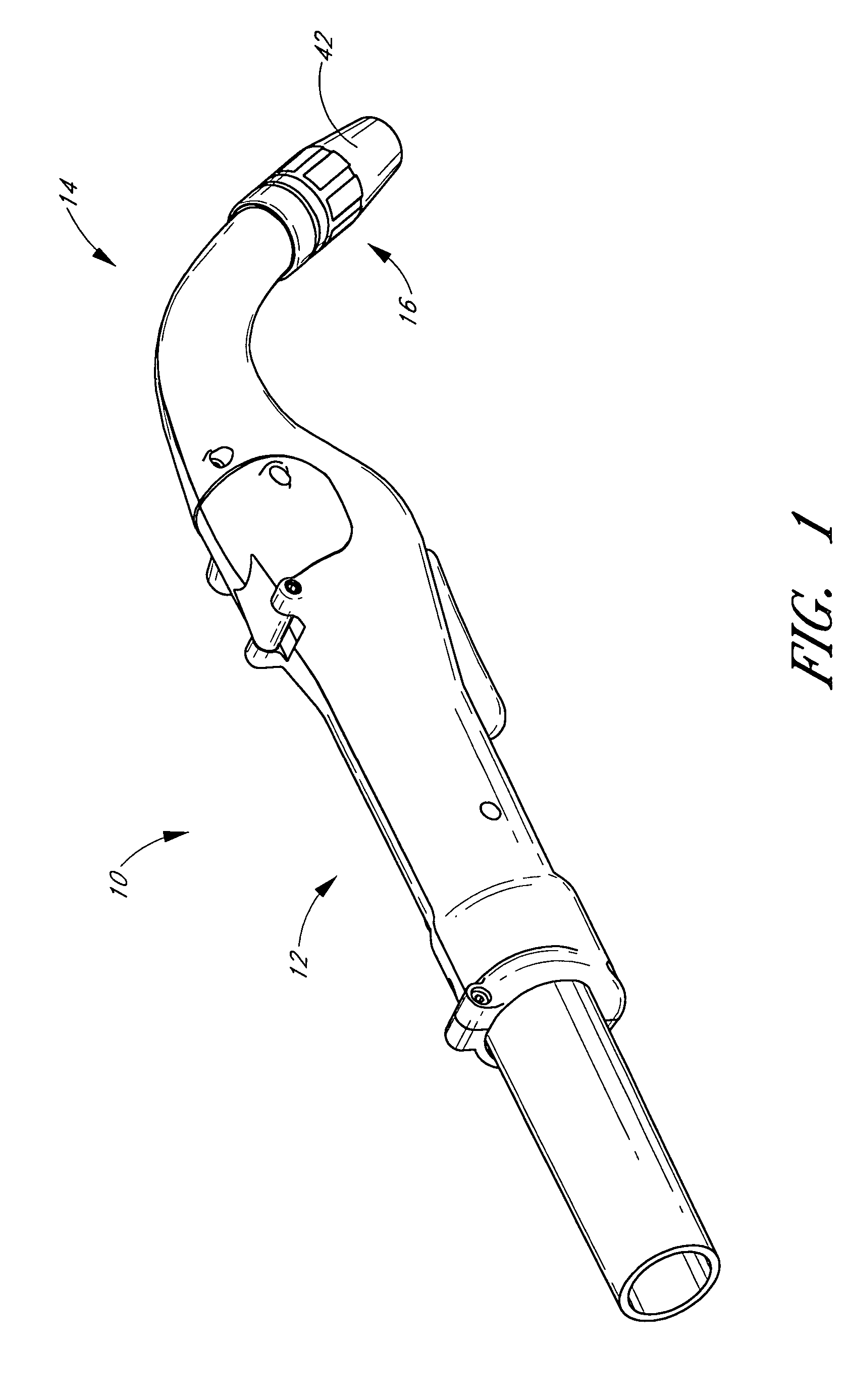

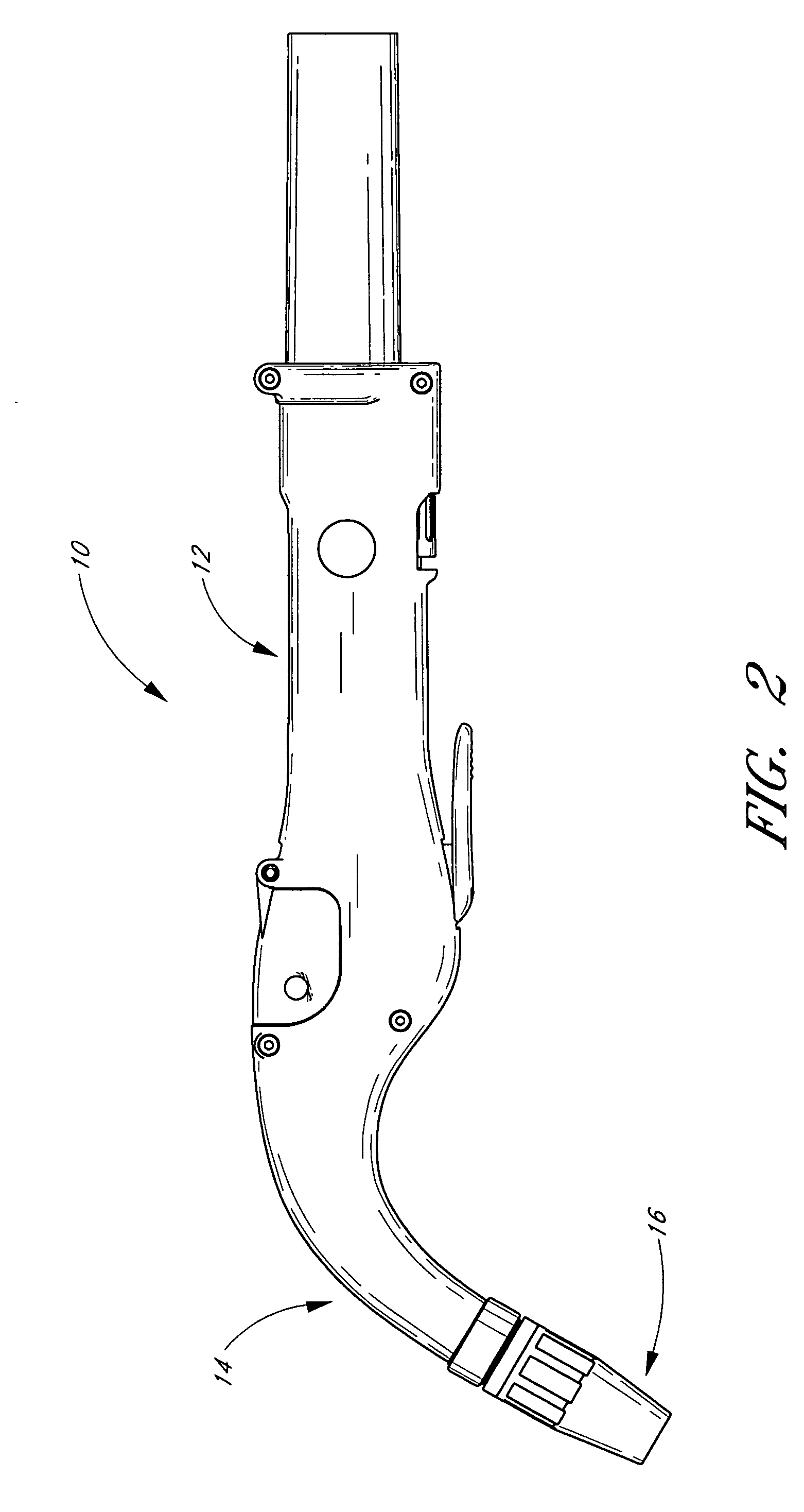

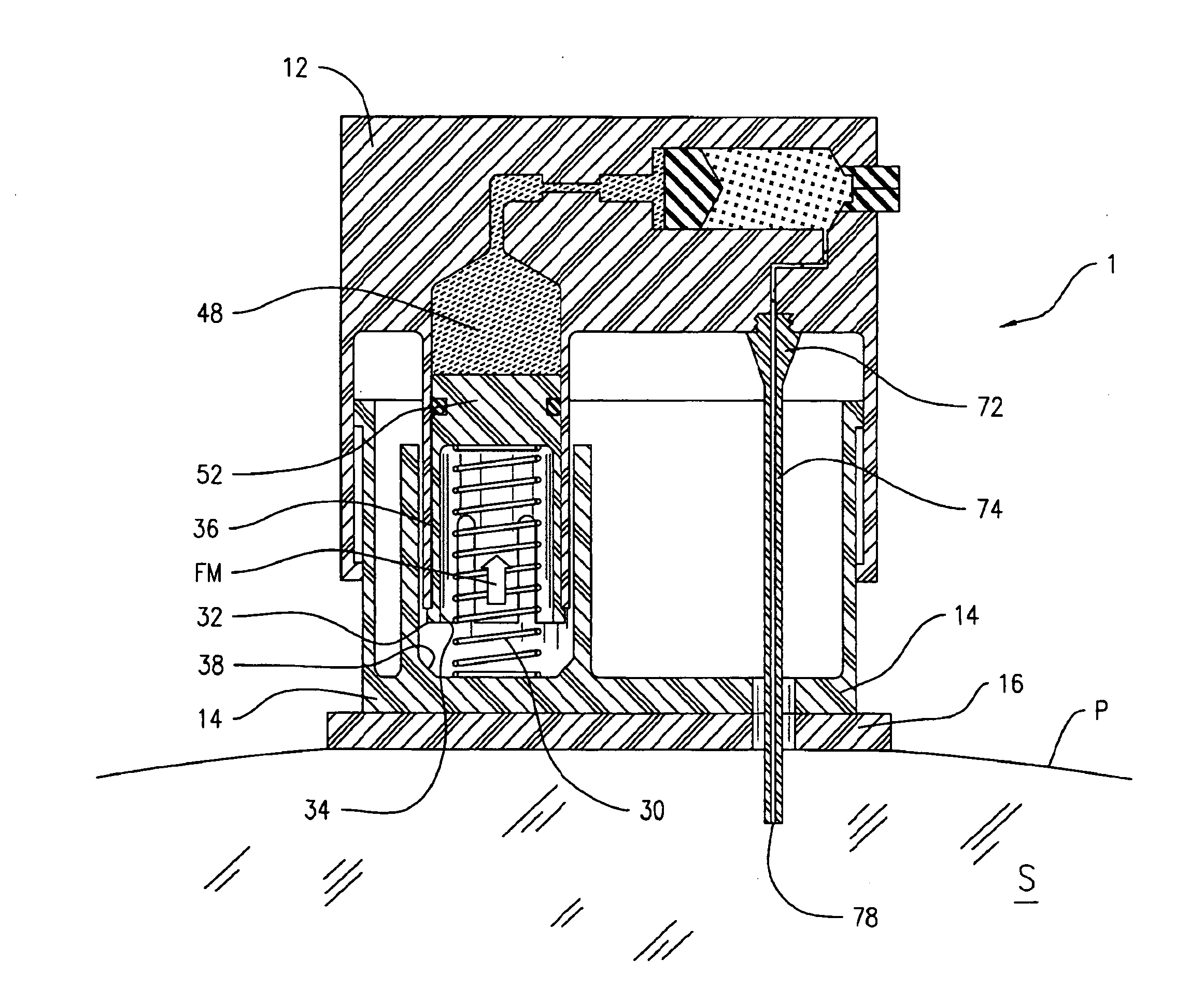

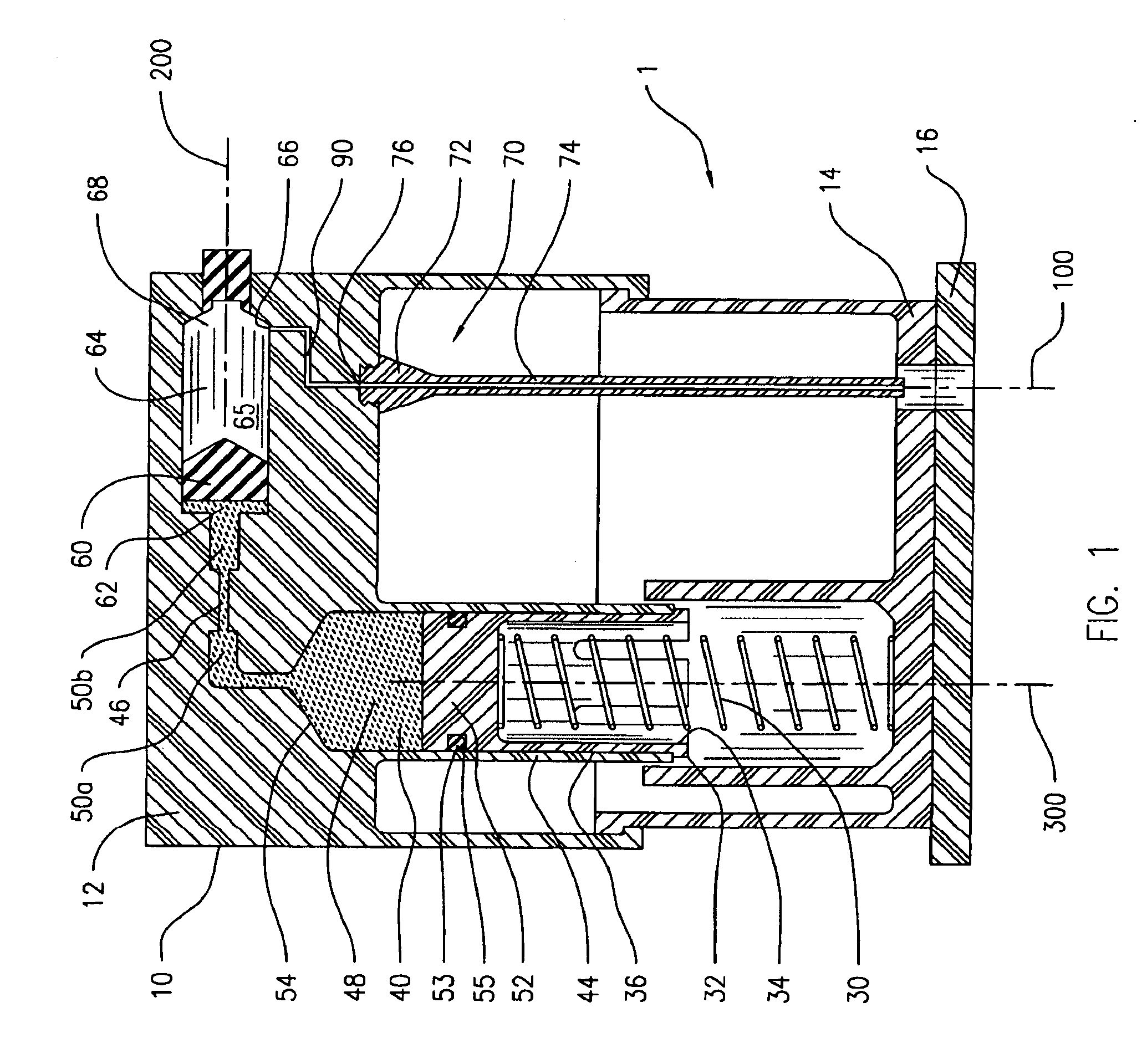

Cryosurgery system

A cryosurgery system for application of medical-grade liquid nitrogen to a treatment area via a small, low pressure, open tipped catheter. The system includes a console, including a touch panel computer, a cryogen module, a suction module and an electronics module, and a disposable spray kit. Features include optional low cryogen flow setting to reduce the cryogen flow rate by 50%, improved cryogen flow consistency reducing pressure pulses and peaks, an integrated suction pump for improved consistency and self-checks, specified vent tube areas and corresponding maximum expected pressures during cryospray procedure; optional pressure sensing capability to monitor pressure during a treatment, and novel catheter designs of multilayer and flexible construction providing a variety of spray patterns.

Owner:CSA MEDICAL

Equipment and methods for manufacturing cigarettes

InactiveUS7077145B2Minimize and avoid and prevent transferConsistent flowLiquid surface applicatorsCigar manufacturePack materialPulp and paper industry

Cigarettes manufactured using modified automated cigarette making apparatus can possess smokable rods having paper wrapping materials having additive materials applied as patterns. The additive materials, which can have the forms of liquid or paste formulations, are applied to a continuous paper web. The formulation can be applied to the paper web using application apparatus possessing rollers. One of those rollers can have a series of pockets in its roll face to receive additive formulation from a reservoir and to define the pattern of the formulation on the paper. A radiant dryer can be used to dry the additive material applied to the paper web. The radiant dryer can be located on one component of a two component assembly used to manufacture cigarettes.

Owner:R J REYNOLDS TOBACCO COMPANY

Cryosurgery System

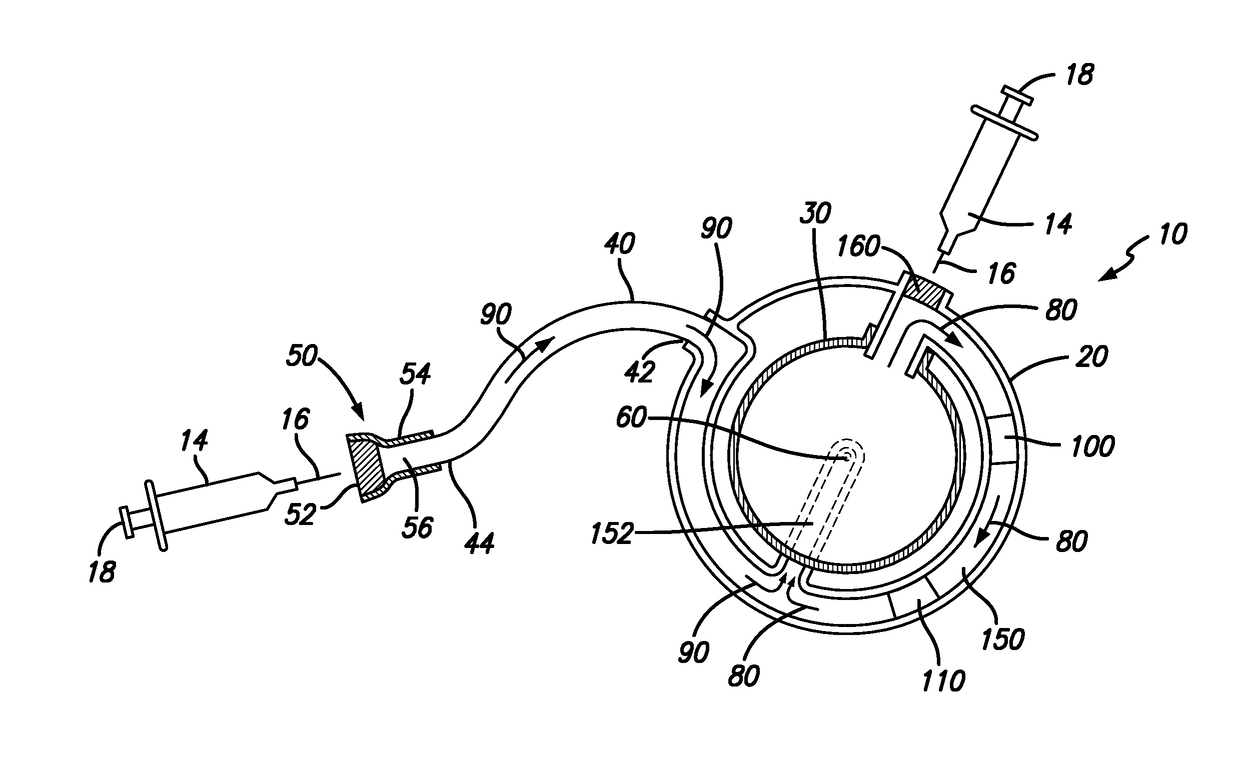

ActiveUS20130253491A1Easy flow controlImproved delivery catheterEndoscopesCatheterPressure senseEngineering

A cryosurgery system for application of medical-grade liquid nitrogen to a treatment area via a small, low pressure, open tipped catheter. The system includes a console, including a touch panel computer, a cryogen module , a suction module and an electronics module, and a disposable spray kit. Features include optional low cryogen flow setting to reduce the cryogen flow rate by 50%, improved cryogen flow consistency reducing pressure pulses and peaks, an integrated suction pump for improved consistency and self-checks, specified vent tube areas and corresponding maximum expected pressures during cryospray procedure; optional pressure sensing capability to monitor pressure during a treatment, and novel catheter designs of multilayer and flexible construction providing a variety of spray patterns.

Owner:CSA MEDICAL

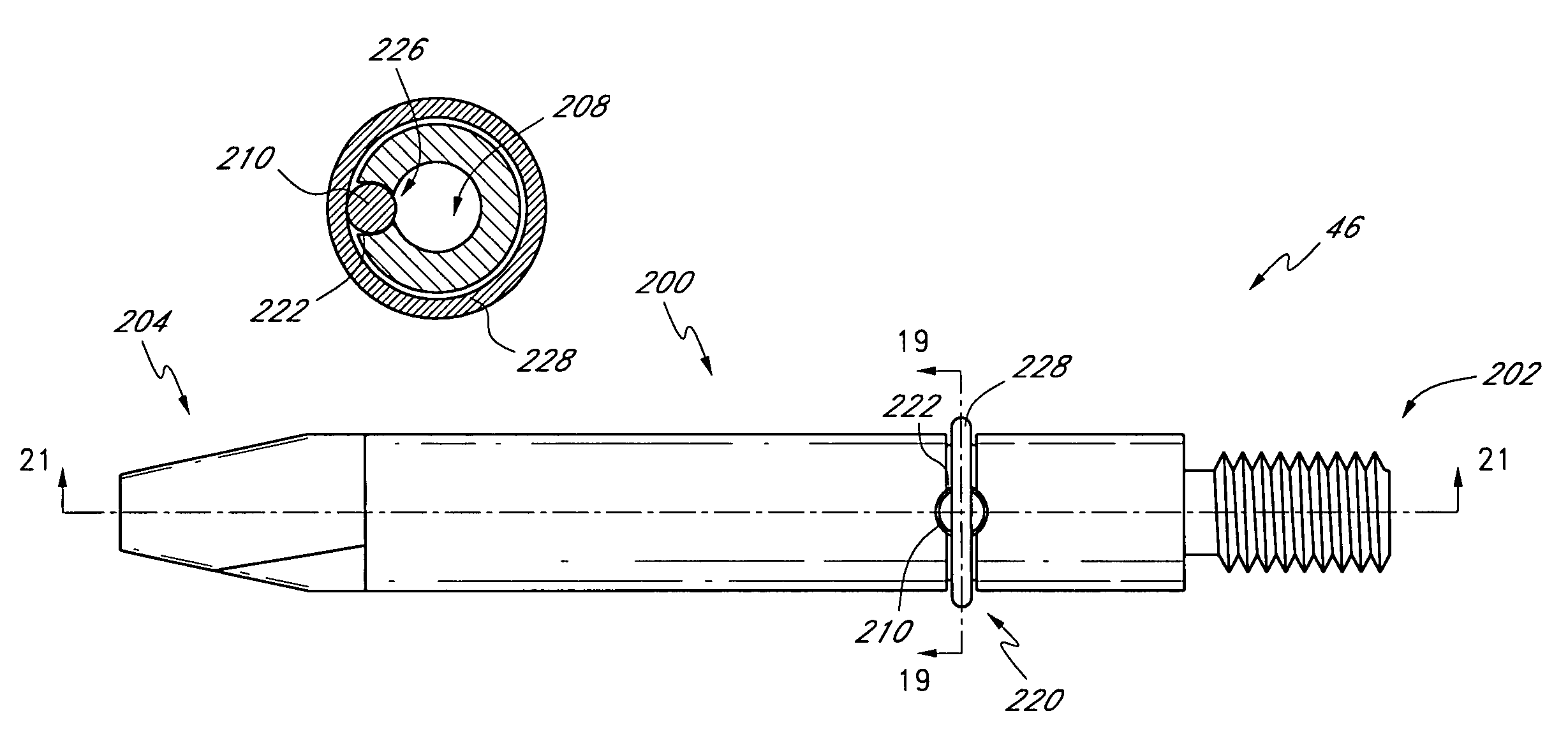

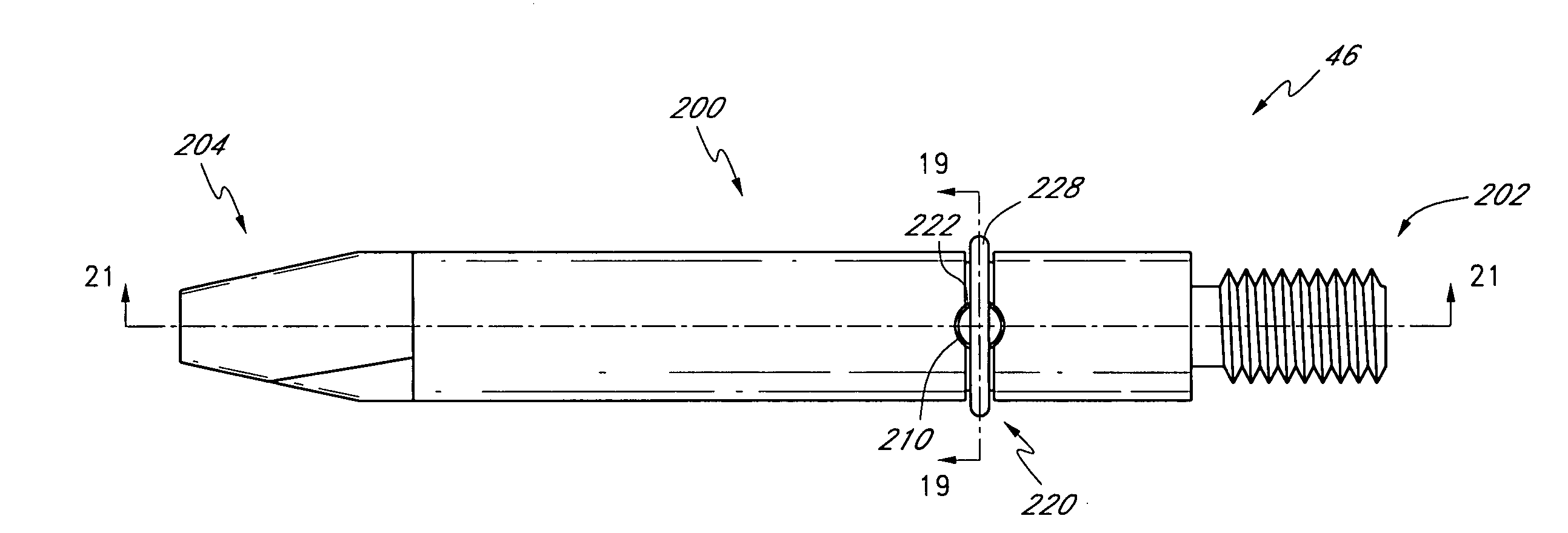

Welding gun contact tip

InactiveUS7271366B2Increase exposureConsistent flowSupport devices with shieldingEngineeringContact element

A contact tip for a welding gun includes an elongate body having a first end, a second end, and a first opening extending longitudinally between the first end and the second end. The elongate body has an outer surface and an inner surface. The elongate body has a second opening extending radially through a side portion of the elongate body between the outer surface and the inner surface. At least a portion of the second opening is configured to support a contact element. A contact element is configured to be supported within at least a portion of the second opening of the elongate body and extend at least partially into the first opening of the elongate body. A retention member is configured to couple the contact element with the elongate body.

Owner:M K PRODS

Garniture web control

ActiveUS7275549B2Minimize and avoid and prevent transferConsistent flowCigarette manufacturePulp and paper industryPaper sheet

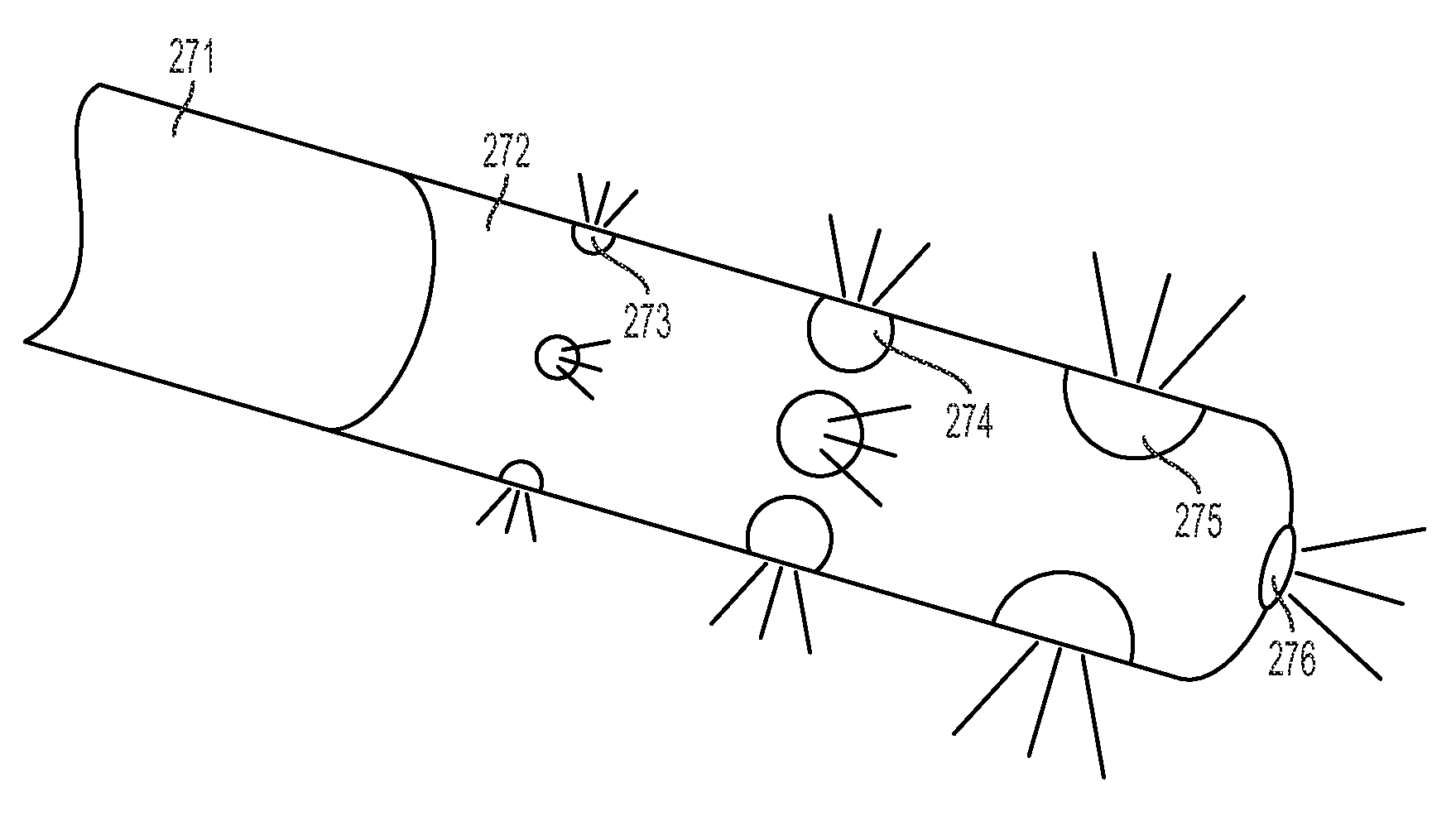

Cigarettes are manufactured using modified automated cigarette making apparatus. Those cigarettes possess smokable rods having paper wrapping materials having additive materials applied thereto as patterns. The additive materials, which can have the forms of liquid or paste formulations, are applied to a continuous paper web on the cigarette making apparatus. The formulation is applied to the paper web using application apparatus possessing rollers, and one of those rollers has a series of pockets in its roll face to receive additive formulation from a reservoir and to define the pattern of the formulation on the paper. A modified figure rail assembly and garniture entrance cone provide air flow toward the paper web being advanced through the garniture region of the cigarette making apparatus. Downwardly directed air exiting a plurality of air outlets in the finger rail create a zone of air turbulence the advancing paper web to maintains the paper web a distance away from the upper surface so that the additive material is retained on the paper web. Air exiting slots in the upper or top face of the garniture entrance cone also assist in maintaining the paper web away from the finger rail assembly. A radiant dryer is used to dry the additive material that has been applied to the paper web. The radiant dryer is located on one component of a two component assembly that is used to manufacture cigarettes. A first component of the two component assembly provides a source of paper web, applies additive material to that web in a pattern and dries the paper web; while a second component receives the paper web, supplies tobacco filler and manufactures a cigarette rod from the paper web and tobacco filler. Spectrometric techniques are used to ensure proper registration of the additive material on the cigarette rods so manufactured, and to ensure proper quality of those cigarettes.

Owner:R J REYNOLDS TOBACCO COMPANY

Electrode structure for a electrochemical cells

InactiveUS20050139466A1Minimize the possibilityMaintaining desirable internal resistanceFuel and primary cellsElectrode carriers/collectorsInternal resistanceElectrochemical cell

Electrodes for electrochemical cells are provided herein, particularly magnesium and magnesium alloy electrodes. In one aspect of the invention, electrodes are formed by thixotropic molding. Such electrodes, particularly formed of magnesium or magnesium based alloys, have desirable microstructures that alleviate the problems of reaction product adhesion, thereby allowing consistent flow of reaction product and minimizing the likelihood of reaction product clogging and maintaining desirable internal resistance. In addition, the electrodes formed herein have a microstructure that resists flaking.

Owner:MORRIS WILLIAM M

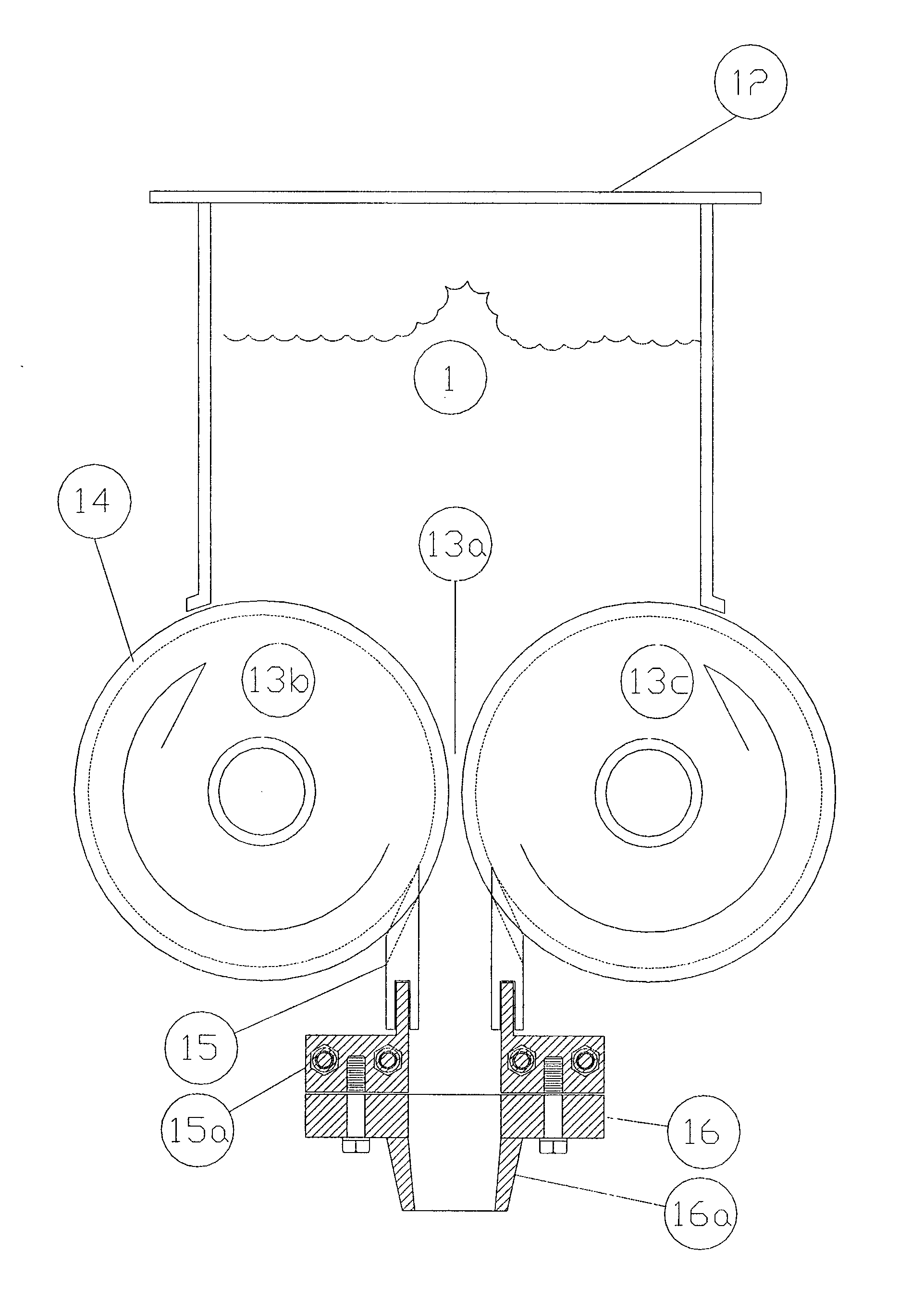

Multi-channel cooling die

InactiveUS7275927B2Reduces extrudate flow path distanceReduced operational downtimeConfectioneryMeat processingEngineeringFood extrusion

A cooling die, for use in the manufacture of extruded food products, the cooling die including: a plurality of core members forming a main body portion of the cooling die between die inlet and outlet ends and arranged about an axis of the die in neighboring relationship; a plurality of extrudate flow channels extending through the cooling die from the inlet end to the outlet end, defined by gaps between neighboring ones of said core members; at least one bore in each said core member through which coolant may flow; an enclosing structure adapted to secure the core members against radial movement relative to the die axis; means for connecting the cooling die to an outlet of a food extruder, a cooling fluid source and a cooling fluid receptacle; and extrudate flow distribution means, located adjacent the inlet end, adapted to direct extrudate from the outlet of the food extruder into selected ones of said extrudate flow channels.

Owner:MARS INC

Device for controlled metering of semi solid food products

ActiveUS20080135582A1Little and no resulting damageEasy to operateLarge containersVolume meteringSemi solidEngineering

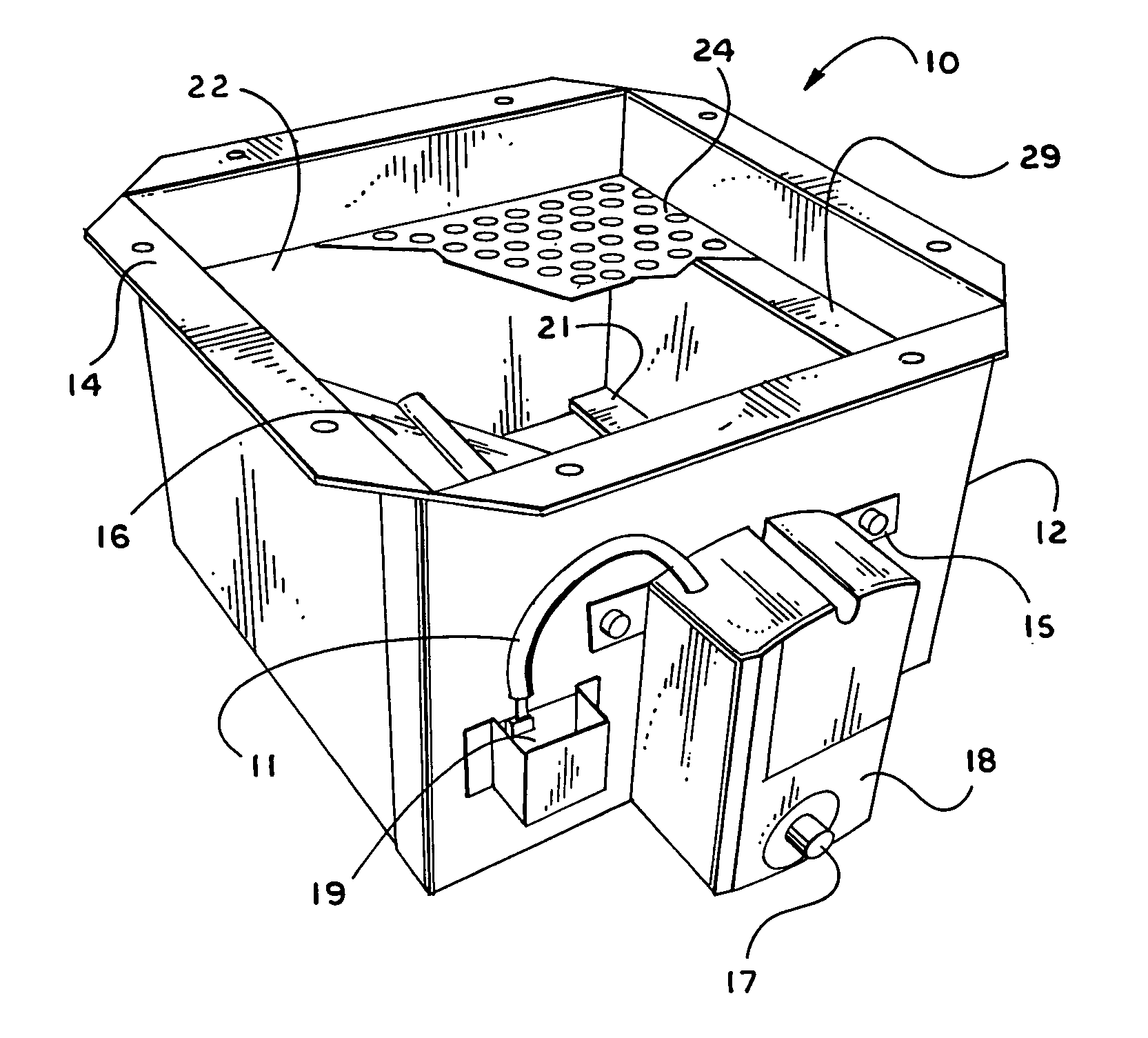

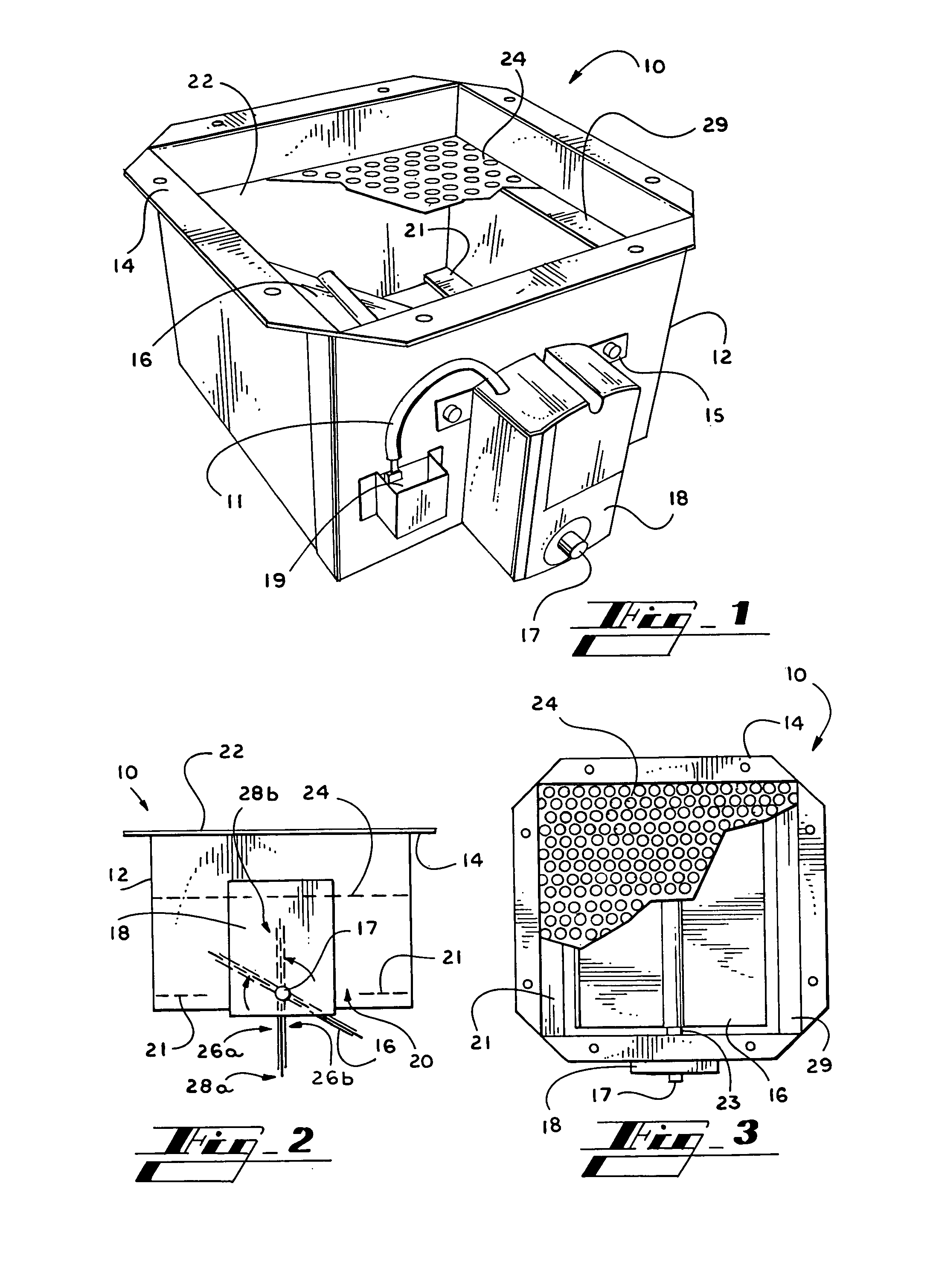

A device that provides better movement of semi solid materials such as but not limited to food products for metered dispensing. The device is able to take bulk semi solid material, entrain or draw the material into the device and add pressure to the semi solid material so that the semi solid material may be passed thru a nozzle or controlled discharge metering device or orifice. The rollers have circumferential grooved profiles and scrapers that are able to actively remove the semi-solid materials from the grooved profiles. The emitted semi solid material can then be more accurately applied or portioned in a metered fashion. Typical applications include but are certainly not limited to the production of cookies from bulk dough, the application of icing to a cake base / body / top or perimeter, metering of dough for bread or rolls so as to allow for a cutting device to cut off into uniform pieces.

Owner:SCHMIDT NORMAN

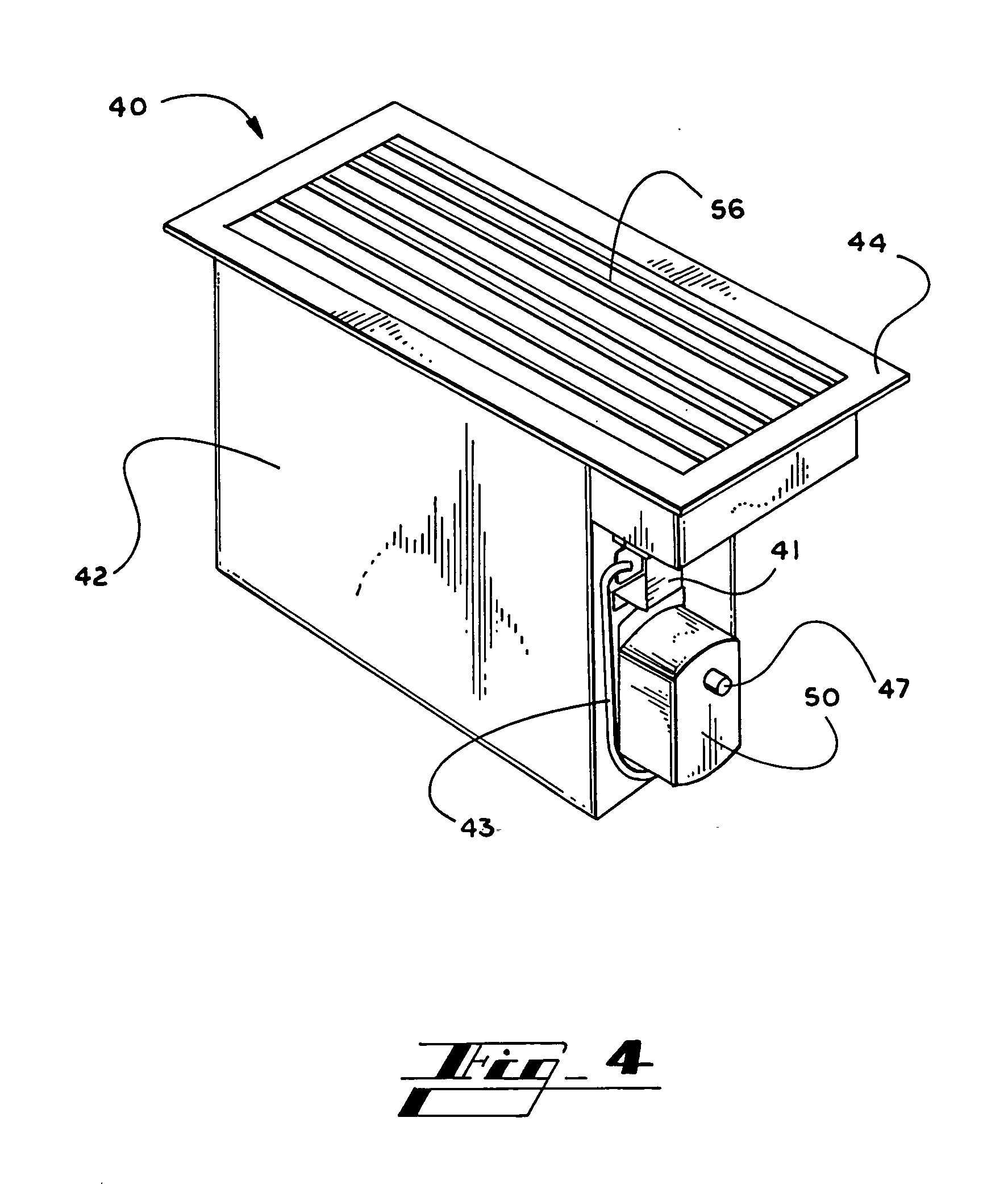

Modular floor terminal with damper

InactiveUS20050266792A1Easy to installConsistent flowDucting arrangementsMechanical apparatusThermostatActuator

A modular floor terminal mounted in the floor of an occupied space for delivering air from an underfloor air plenum to the occupied space. The modular floor terminal includes a square or rectangular housing with an air inlet at the bottom and an air outlet at the top. A rotating damper is positioned in the housing between the air inlet and the air outlet. The position of the damper is controlled by an actuator which is in turn controlled by a thermostat / controller in the occupied space above the floor.

Owner:E H PRICE

Welding gun contact tip

InactiveUS20050230373A1Increase exposureConsistent flowSupport devices with shieldingContact elementSoldering gun

According to one embodiment of the invention, a contact tip for a welding gun comprises an elongate body having a first end, a second end, and a first opening extending longitudinally between the first end and the second end. The elongate body has an outer surface and an inner surface. The elongate body has a second opening extending radially through a side portion of the elongate body between the outer surface and the inner surface. At least a portion of the second opening is configured to support a contact element. A contact element is configured to be supported within at least a portion of the second opening of the elongate body and extend at least partially into the first opening of the elongate body. A retention member is configured to couple the contact element with the elongate body.

Owner:M K PRODS

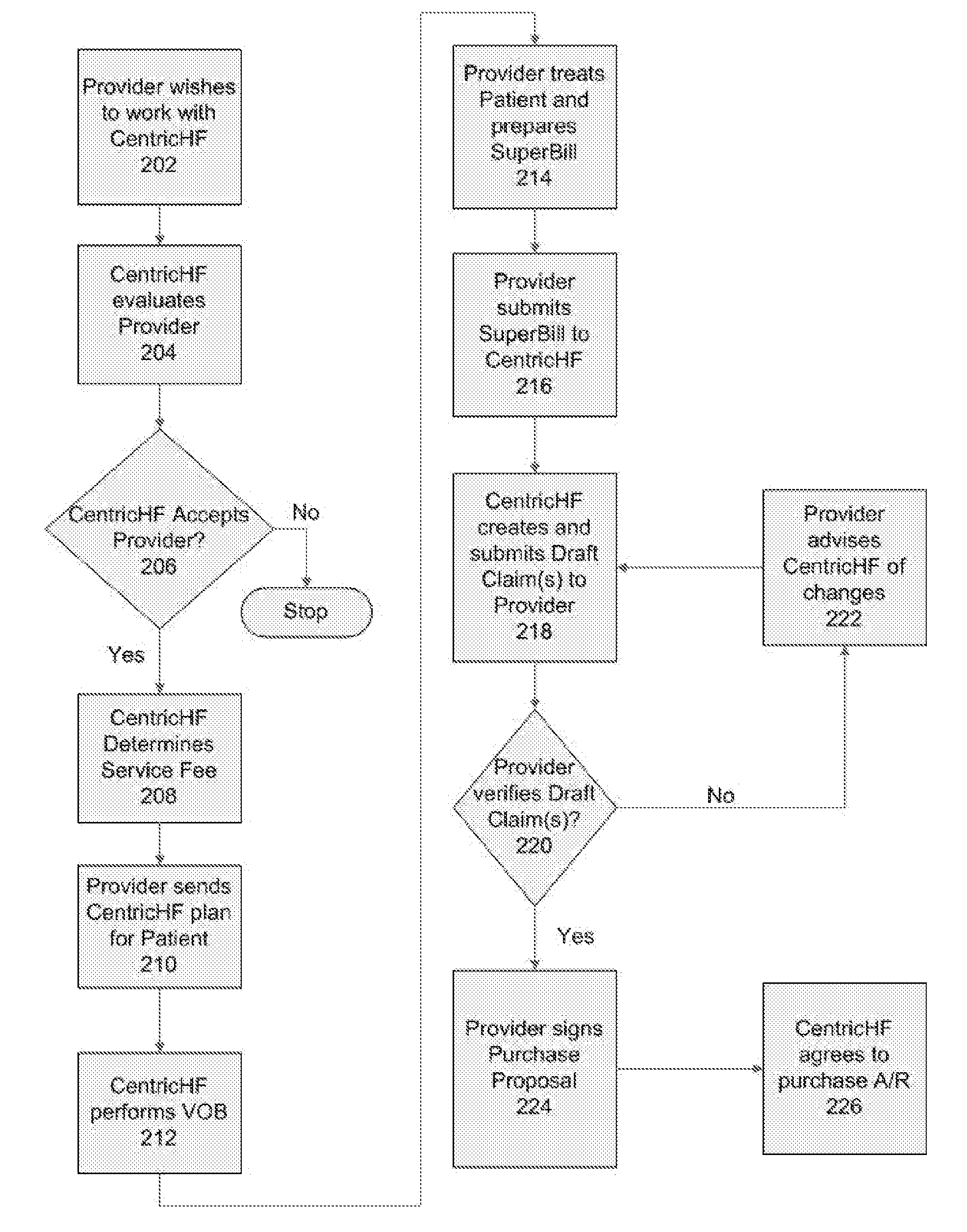

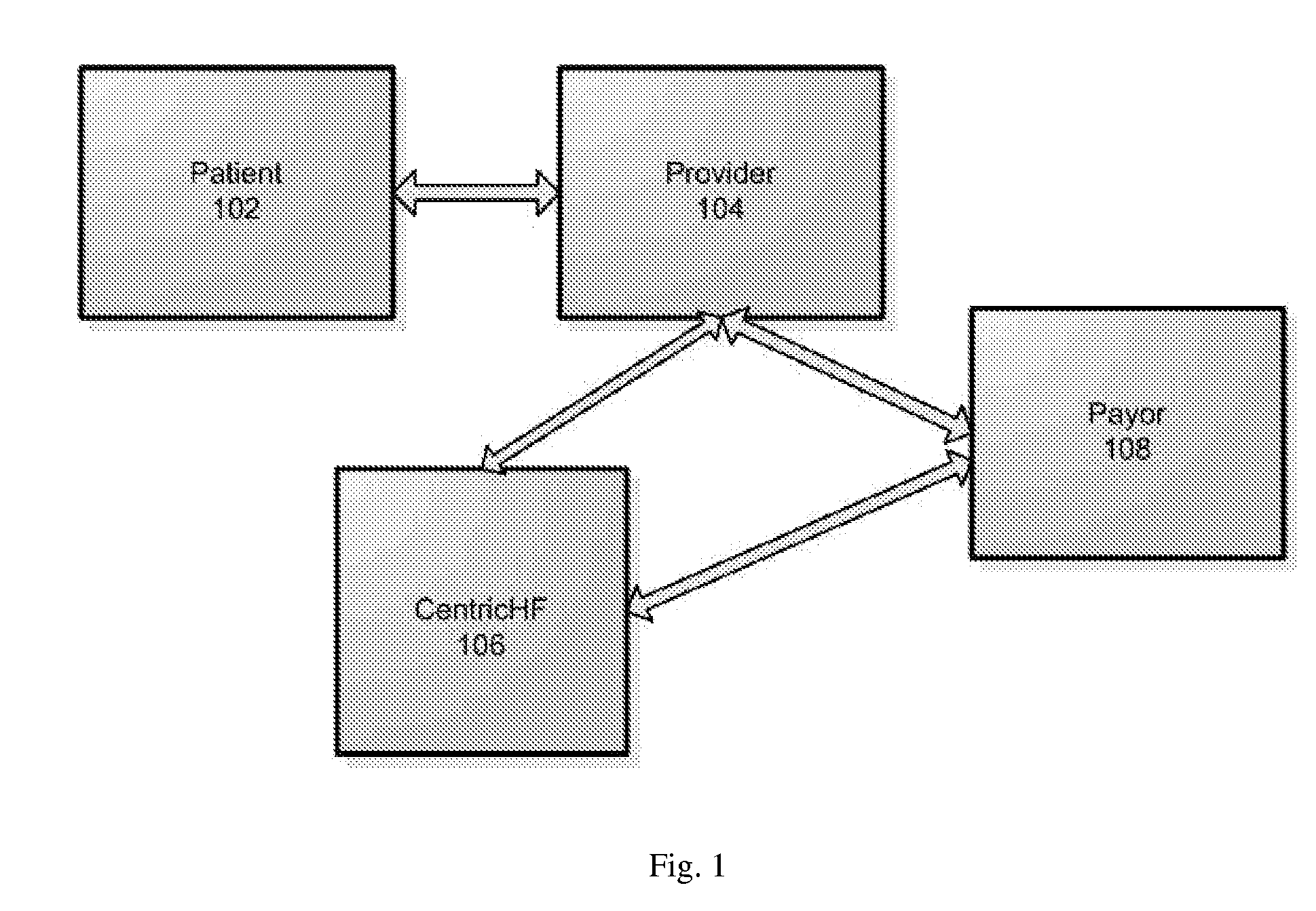

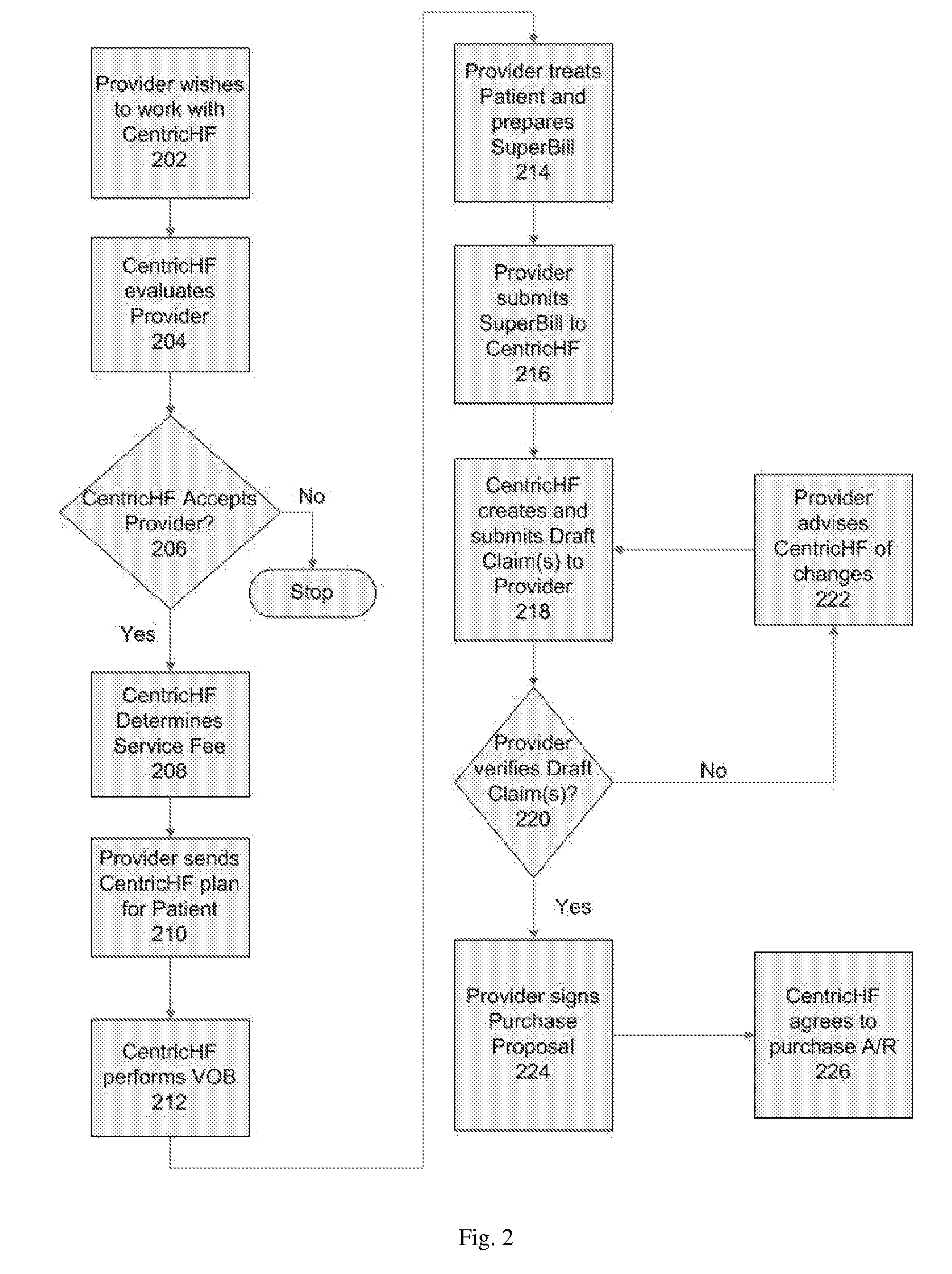

Health Care Payment Single Payor Facilitation System And Method

InactiveUS20080103826A1Accelerate reimbursementExcessive overheadFinanceData acquisition and loggingPaymentFamily medicine

Owner:CENTRIC HEALTH FINANCE

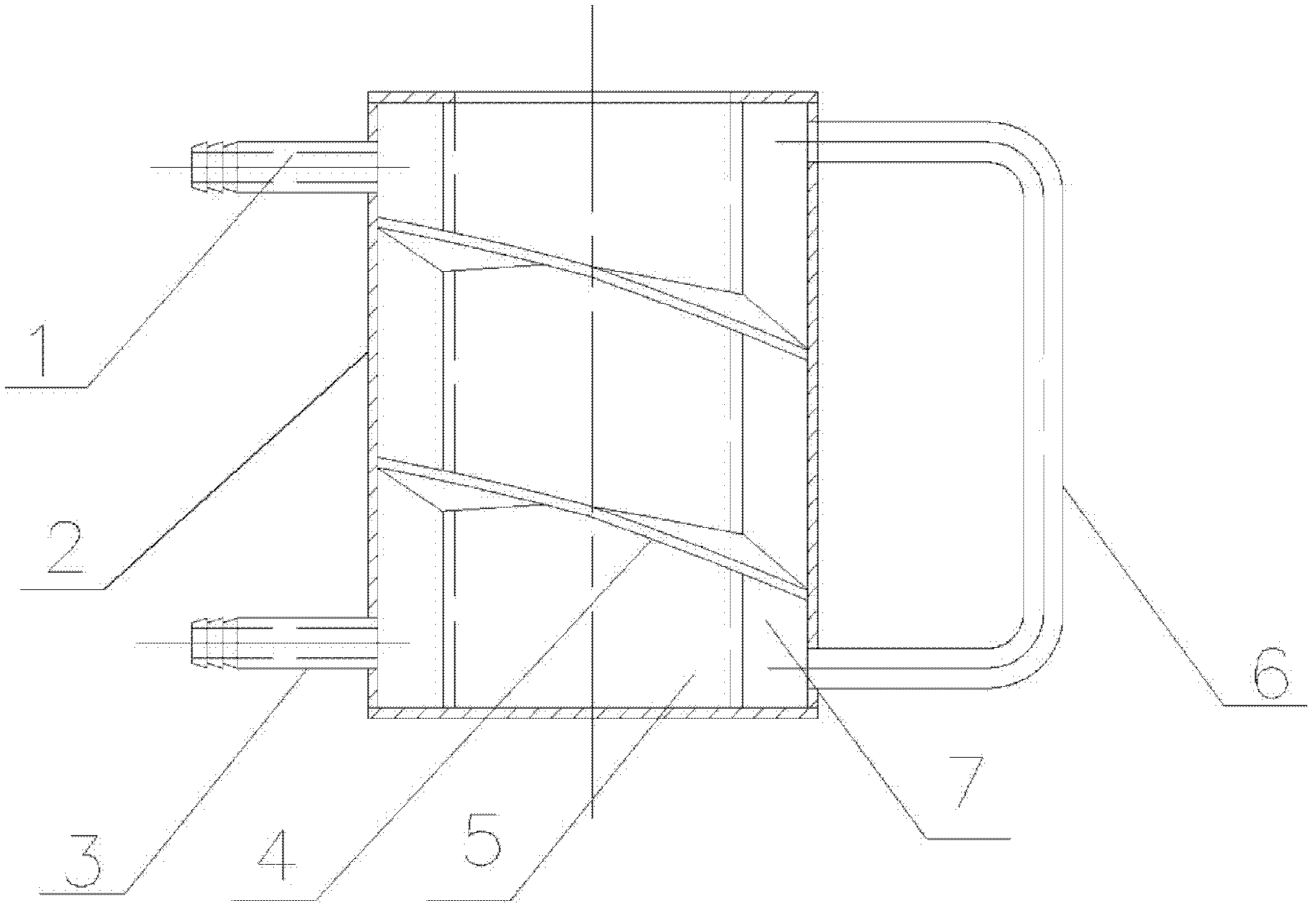

Constant-temperature device for measuring liquid viscosity

The invention provides a constant-temperature device for measuring liquid viscosity. The constant-temperature device for testing liquid viscosity can effectively control a temperature of a sample needing to be tested in liquid viscosity measurement, and guarantee the accuracy of measured data. The constant-temperature device for testing liquid viscosity comprises a sample measuring cup and a constant-temperature water bath. The constant-temperature water bath comprises a bath tank and a circulating pump which is connected to the bath tank through a pipe and is utilized for driving a liquid in the bath tank to flow circularly. The bath tank of the constant-temperature water bath is provided with a water inlet and a water outlet. The sample measuring cup comprises an inner cylinder and an outer cylinder, wherein the outer cylinder is coaxially sleeved on the inner cylinder. The inner cylinder is utilized for loading a liquid sample. The outer cylinder is provided with a water outlet pipe and a water inlet pipe. The water inlet pipe is connected to the water outlet of the constant-temperature water bath. The water outlet pipe is connected to the water inlet of the constant-temperature water bath. An interlayer space between the inner cylinder and the outer cylinder forms a constant temperature layer. The constant temperature layer is communicated with the bath tank of the constant-temperature water bath by the water outlet pipe and the water inlet pipe.

Owner:CHONGQING POLYCOMP INT

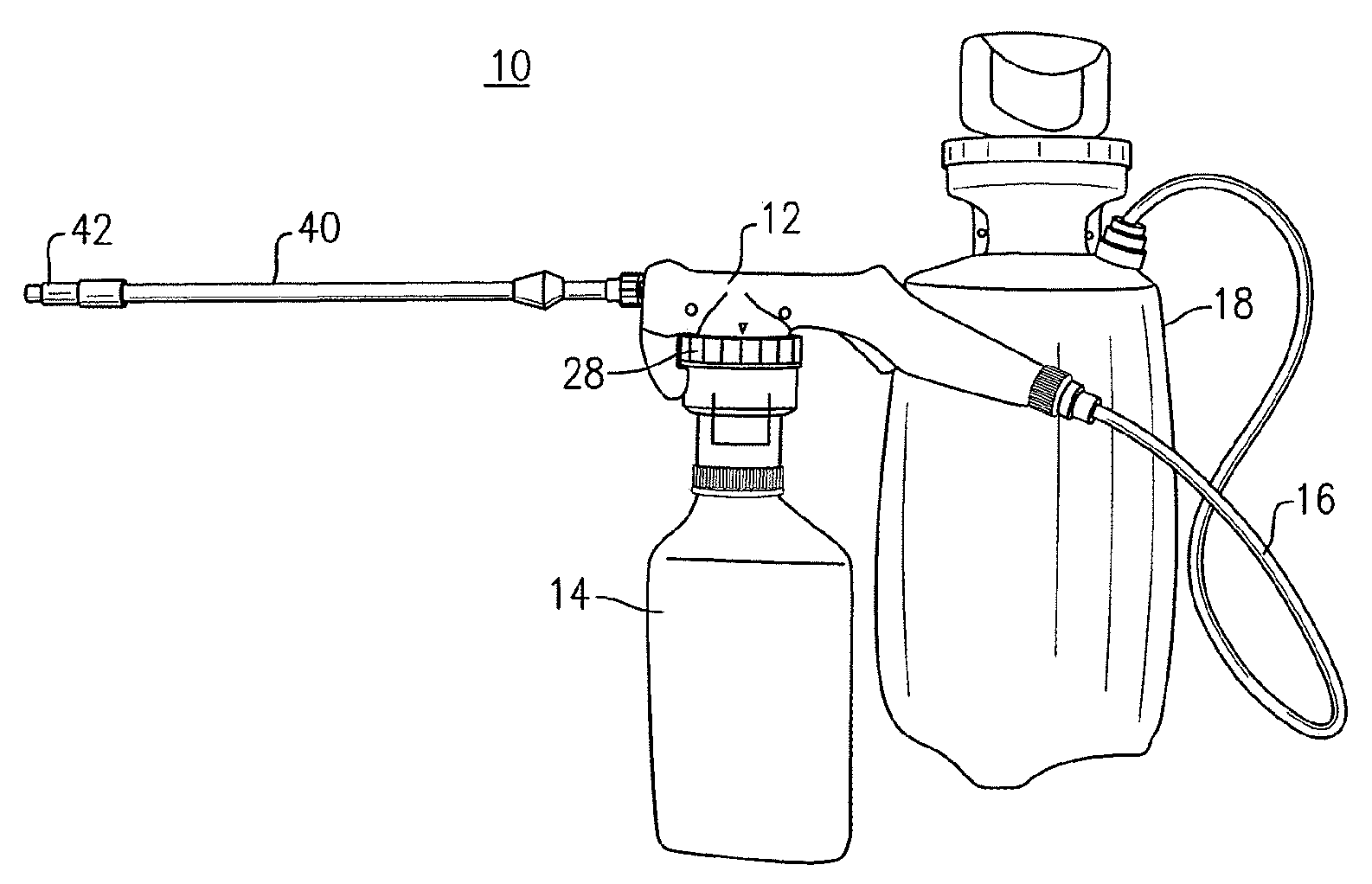

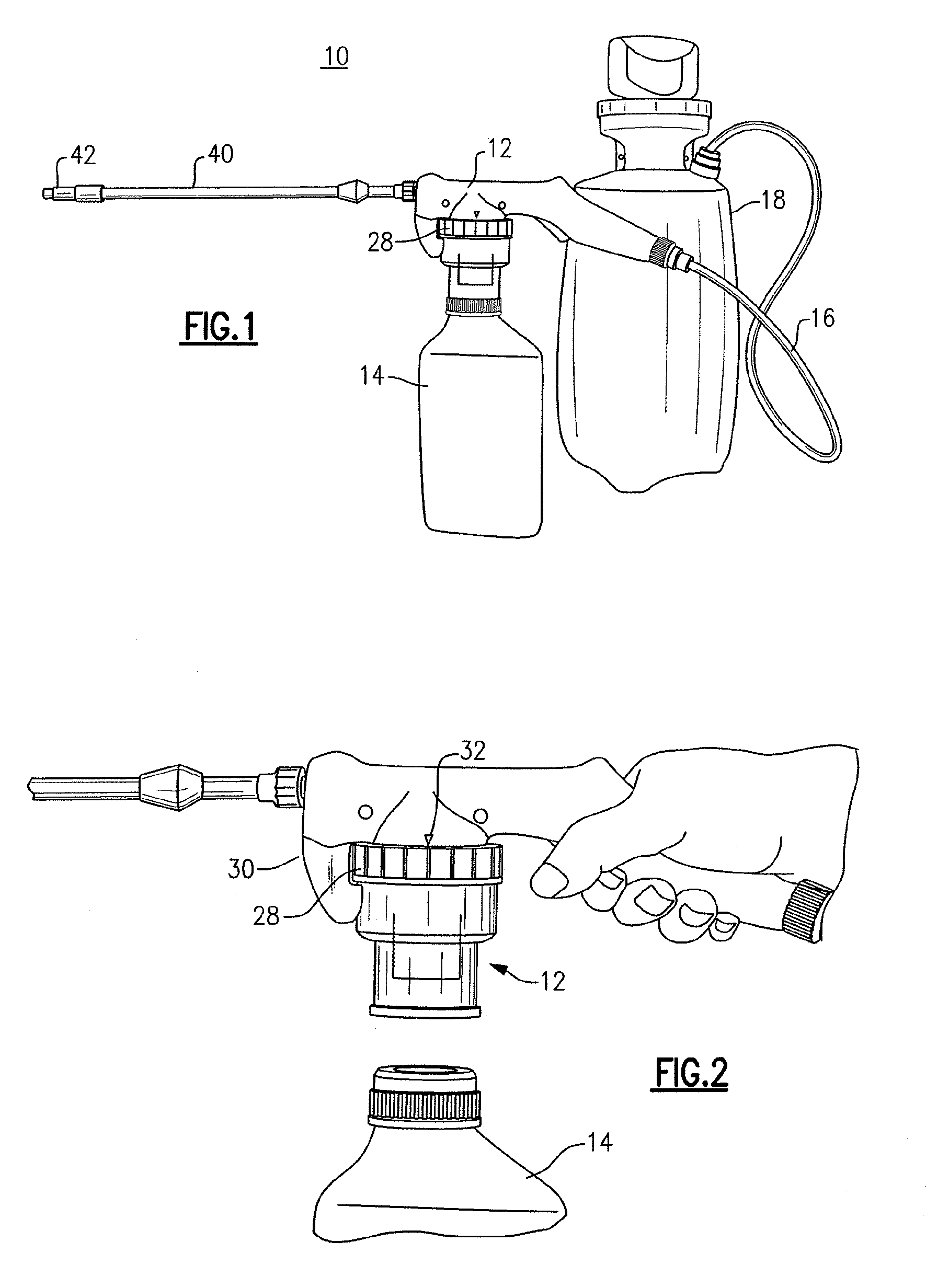

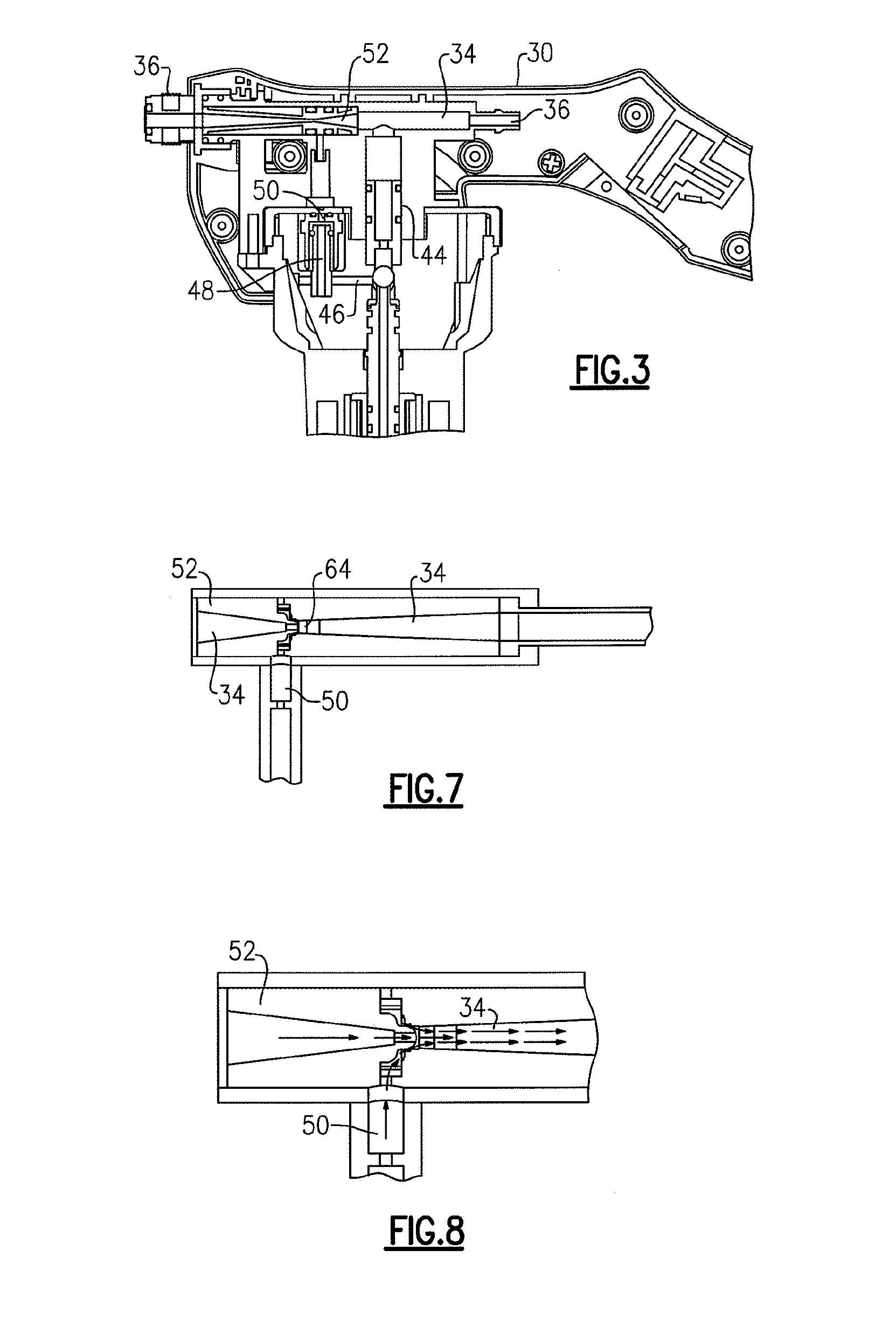

Sprayer

ActiveUS20100059605A1Accurate and reliable adjustmentConsistent flowFlow mixersTransportation and packagingSprayerEngineering

A sprayer system having a sprayer assembly adaptable to a variety of sizes and shapes of containers. The sprayer assembly includes a dual venturi in the flow conduit to provide even pressure and consistent flow in the spray volume. A metering device is coupled to the flow conduit for accurate and reliable regulation of mixture ratios. A dip tube, coupled to the fluid conduit, is adaptable to a variety of container orifices. In addition to acting as a conduit for passage of concentrate into the sprayer assembly, the dip tube may also be used as a cutting device to open the container into which it will be inserted. By adapting to a variety of container orifices, the dip tube allows the sprayer assembly to fit to a variety of containers.

Owner:THE FOUNTAIN HEAD GROUP INC

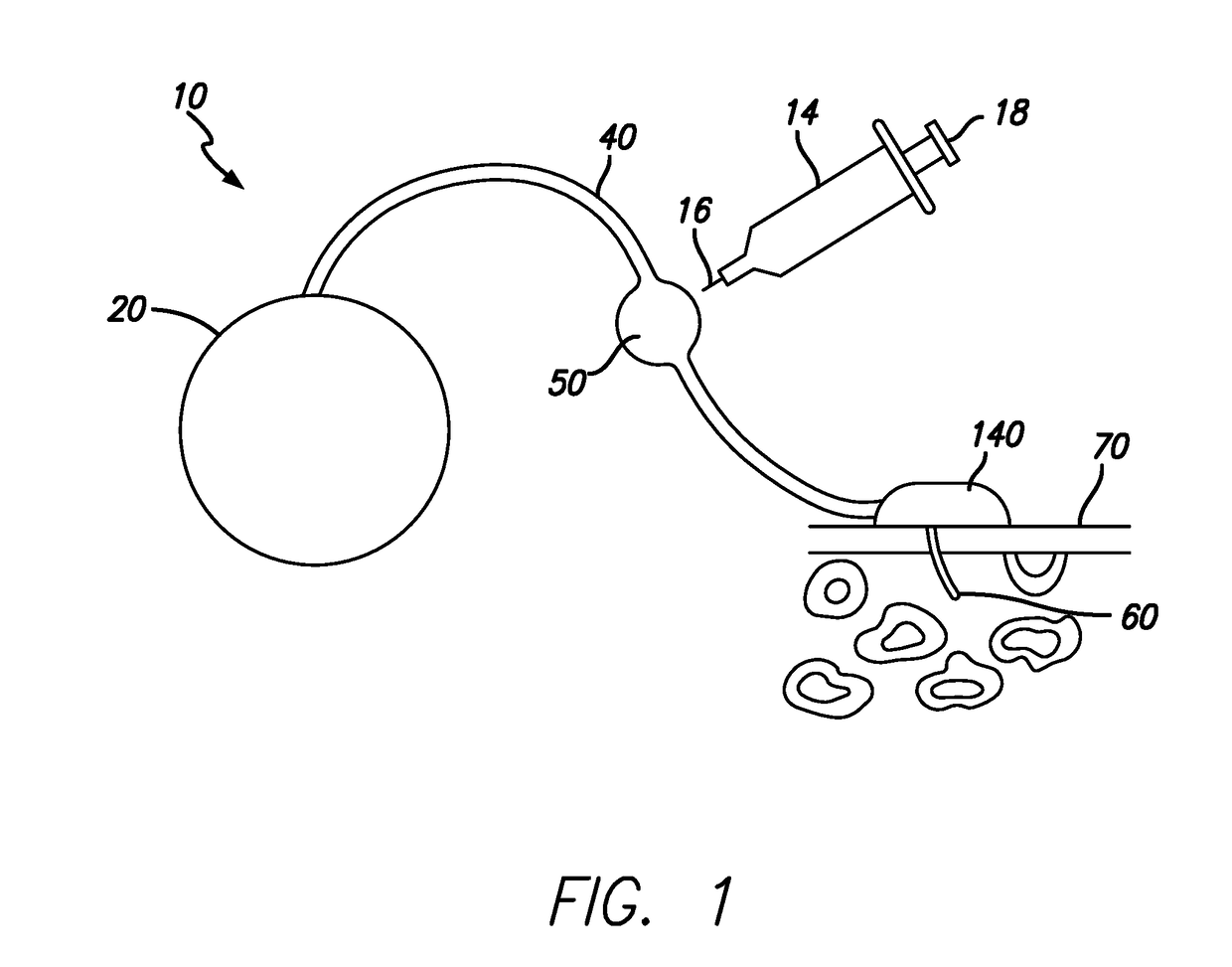

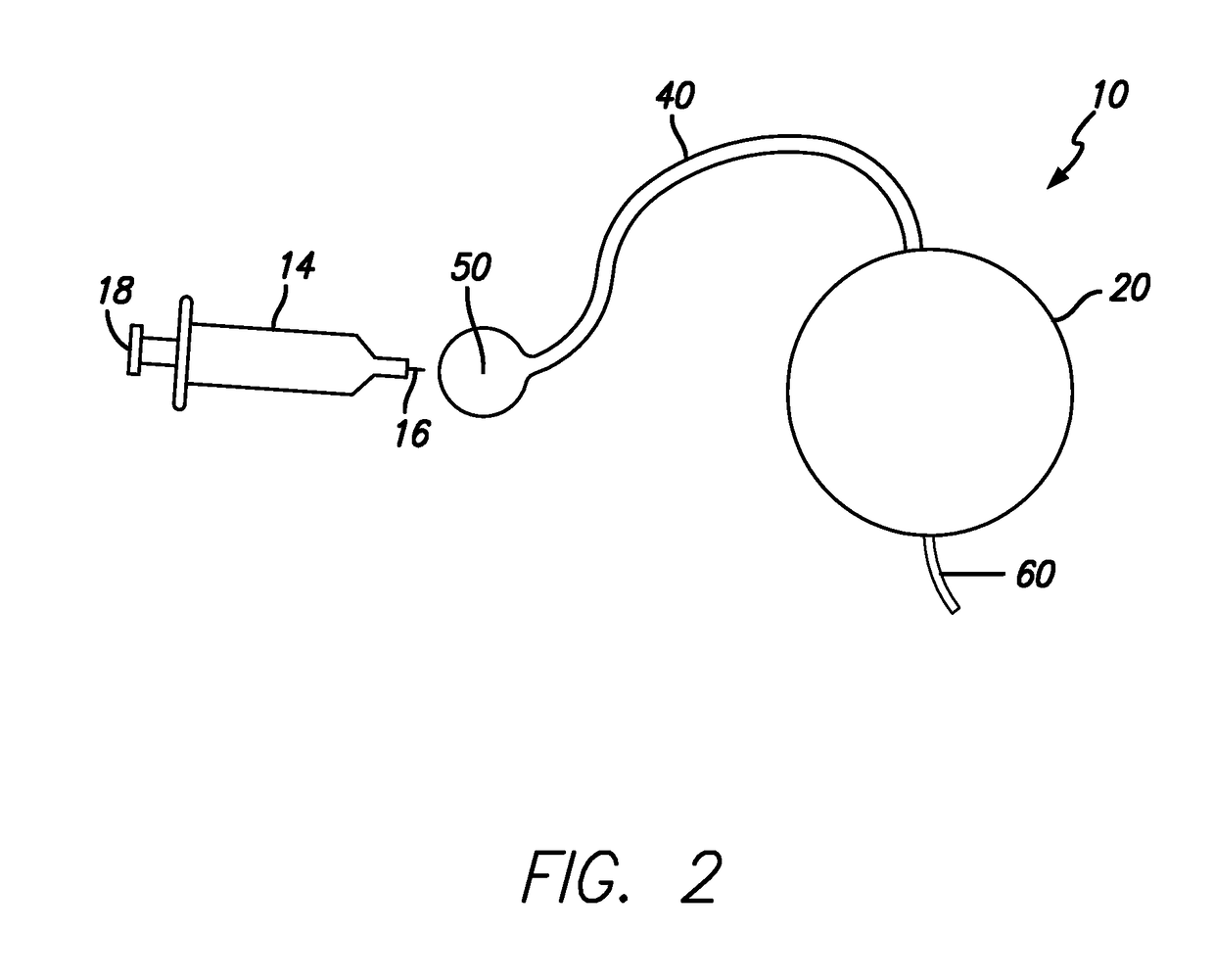

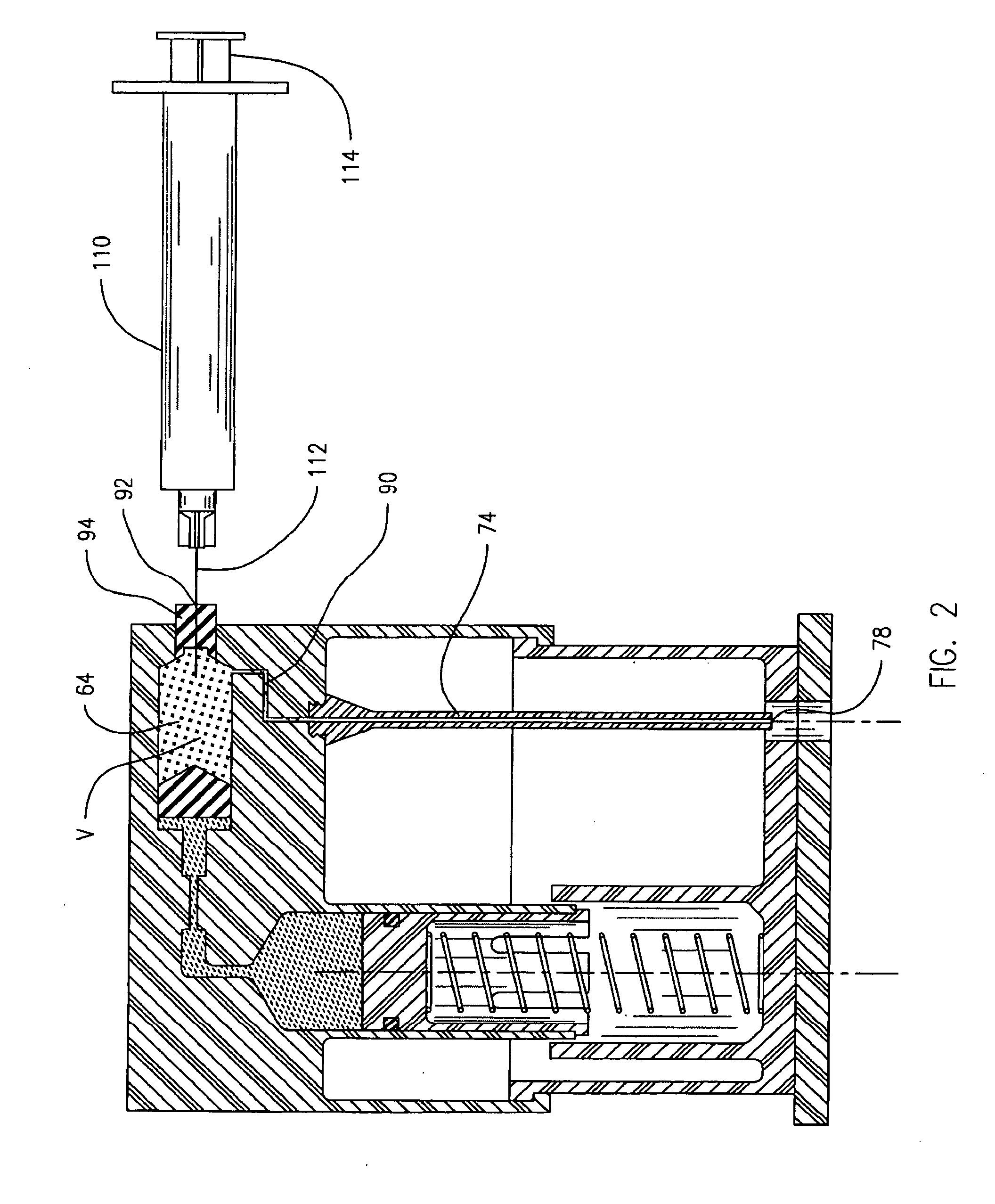

Low cost fluid delivery device

ActiveUS20180036475A1Simple and inexpensive fluid deliveryConsistent flowPressure infusionFlow controlExtra doseBiomedical engineering

Embodiments of the invention described herein include low cost infusion devices having basal and / or bolus fluid delivery options. Embodiments of the device include a housing, a reservoir to contain the fluid, a source of pressure to exert a force to expel the fluid contained in the reservoir, a bolus port adapted to receive an optional extra dose of fluid, and a cannula in fluid communication with the reservoir and the bolus port. The cannula is adapted for insertion into the user's skin for delivery of the fluid to the user's body. The device can provide a continuous delivery of the fluid along a first fluid flow path from the reservoir to the cannula and the optional extra dose of fluid along a second fluid flow path from the bolus port to the cannula.

Owner:MEDTRONIC MIMIMED INC

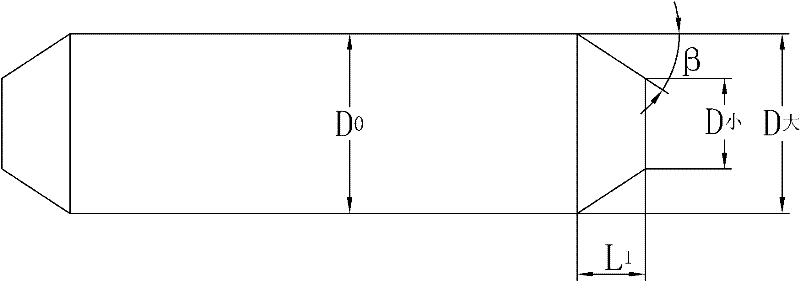

Forming method of no-material-head shaft piece by cross wedge rolling

The invention discloses a forming method of a no-material-head shaft piece by cross wedge rolling. The forming method is characterized in that firstly the two ends of a blank are rolled into a linear frustum shape with an inward large head and an outward small head, simultaneously the whole length of the blank keep constant, then the blank with the two ends shaped like the linear frustum is rolled in the mold from the central section of the blank to the two ends of the blank according to the conventional cross wedge rolling method, and the no-material-head shaft piece meeting the requirementsis obtained. The forming method has the advantages that as the two ends of the blank are rolled into the linear frustum shape with the inward large head and the outward small head firstly in the rolling, consistent flowing between surface metal and core metal of a rolled piece in the following rolling process is guaranteed, the end part of the rolled piece generates a concave core, so that the rolled piece does not generate material heads, the material utilization rate is improved, the production cost is reduced, and the surface quality of the rolled shaft piece is good. In the forming method, the material utilization rate can be improved by more than 95%.

Owner:山东泰金精锻股份有限公司

Hands-free intramuscular injection device

InactiveUS20100185177A1Easy to operateLess fluctuation in rateAutomatic syringesMedical devicesIntramuscular injectionHydraulic circuit

An injection device for hands-free, transdermal injection of a liquid medicament, configured for easy handling and for manipulation by the use of the hand or fingers of the medical technician The device includes a housing having a base for attachment of the housing to the skin of a patient, an injection needle, and a reservoir for containing a vaccine. The device also has a means for expressing the vaccine from the reservoir through the injection needle that includes a mechanical force means for storing potential energy and exerting a mechanical force, and a hydraulic force means for transmitting the mechanical force into a hydraulic force. The hydraulic force is exerted onto the vaccine in the reservoir, thereby pressurizing and passing the vaccine through the injection needle. The mechanical force means is typically a mechanical spring, and the hydraulic force means is typically a closed hydraulic circuit.

Owner:CHILDRENS HOSPITAL MEDICAL CENT CINCINNATI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com