Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

86results about How to "Easy manufacturability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

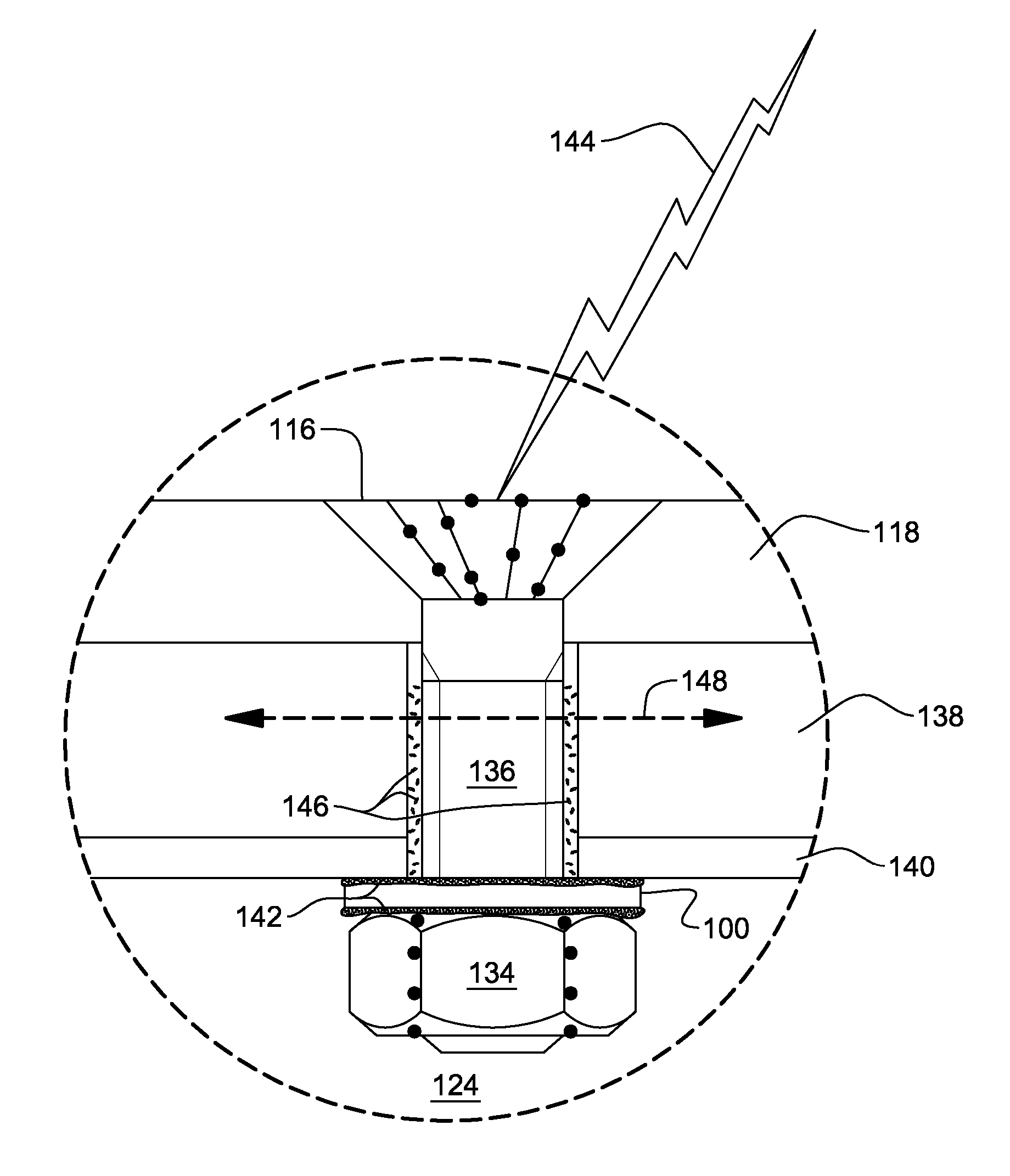

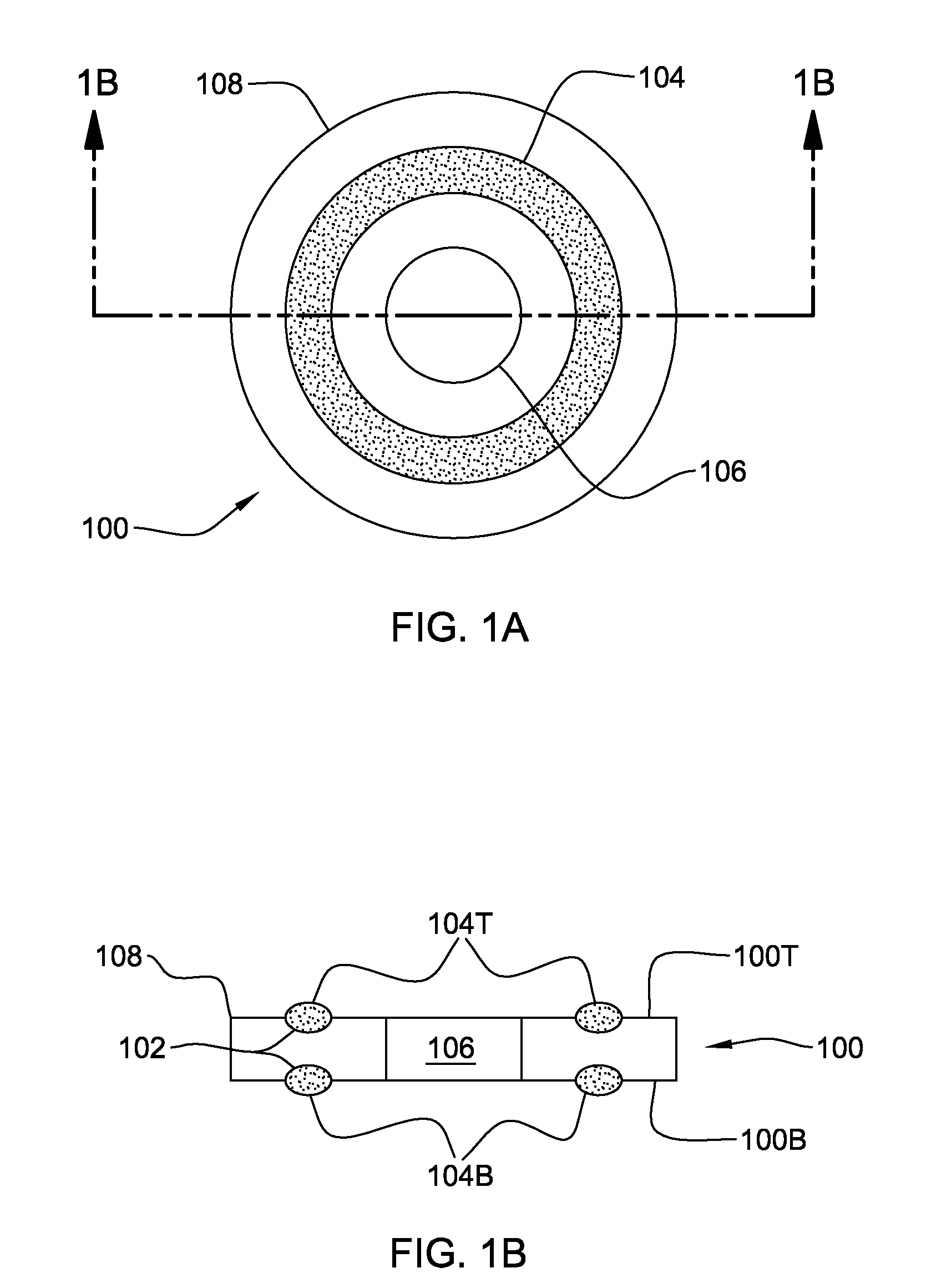

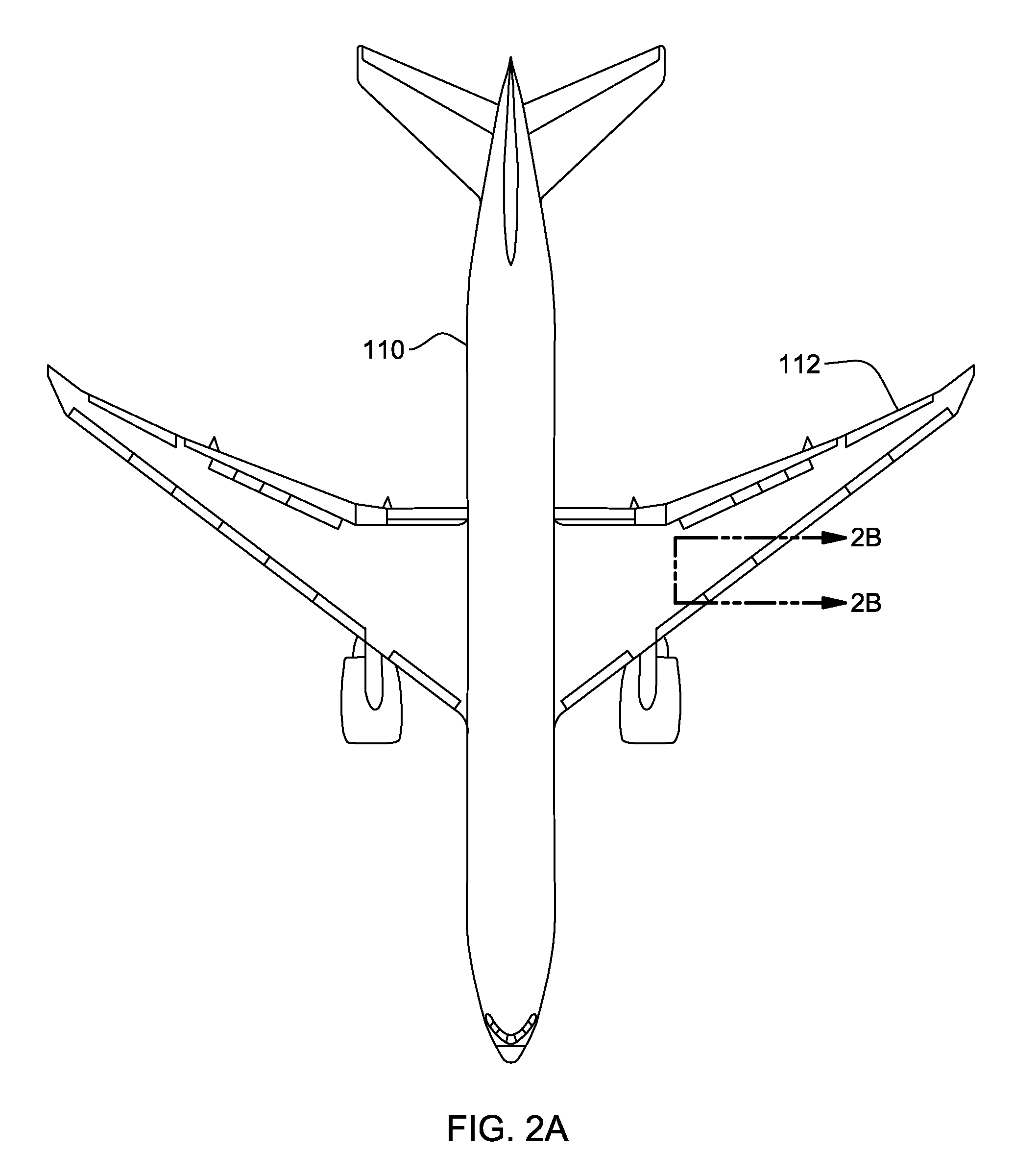

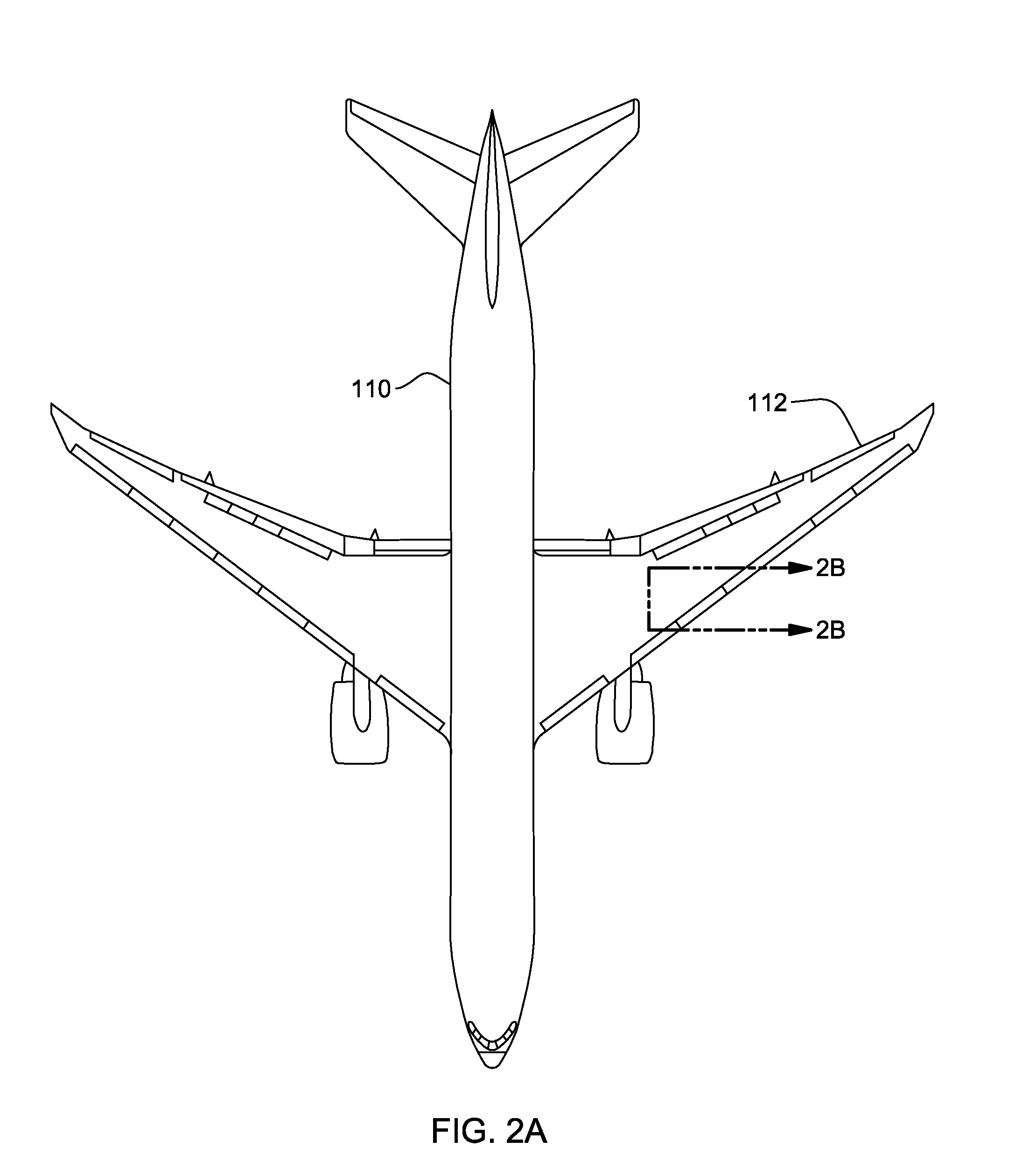

Fastening assembly including washer for sealing the assembly for lightning strike protection in composite structures

InactiveUS7755876B2Voltage potentialEasy to produceWashersAircraft lighting protectorsLightning strikeEngineering

A washer, a fastening assembly including the washer and a composite structure including the washer sealing the assembly for internal lightning strike protection. The washer includes one or more concentric ribs that are dielectric rings on both sides. When used (e.g., with a nut and bolt) internal to a structure, especially a composite structure, the washer seals the fastener hole (i.e., that the bolt passes through) and contains any sparking and hot gasses that may arise in the fastener hole from entering the structure.

Owner:THE BOEING CO

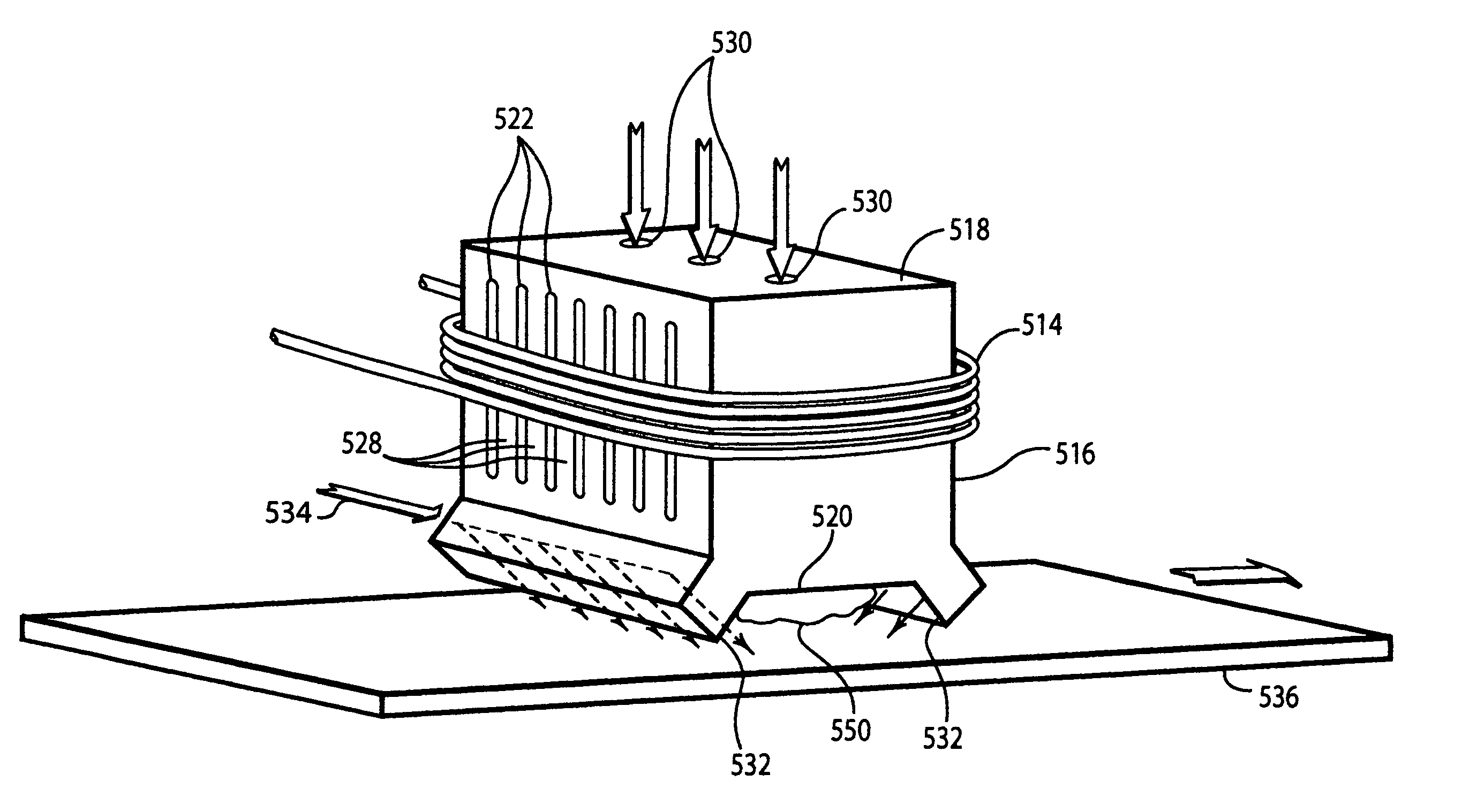

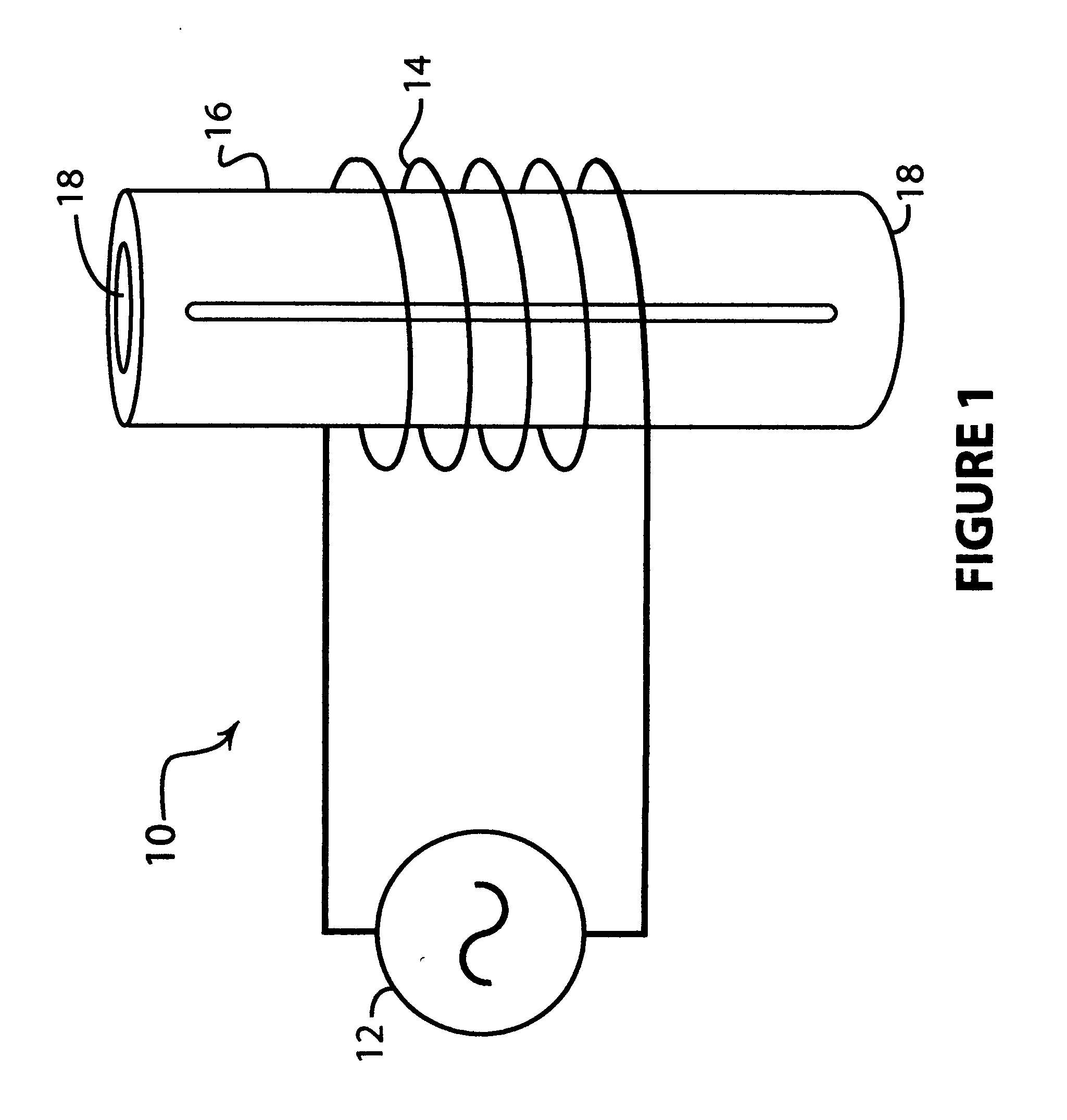

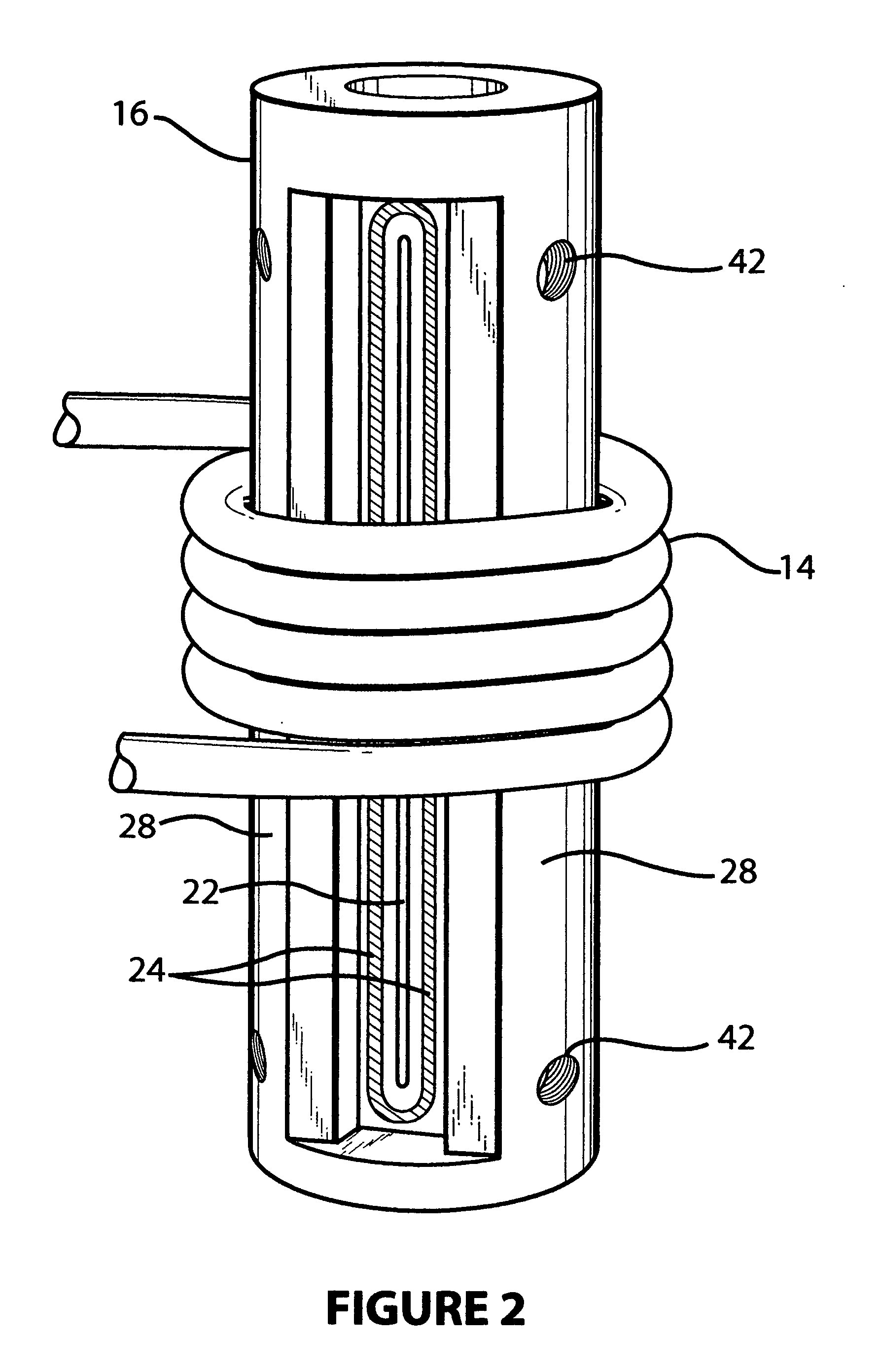

Inductively coupled plasma source using induced eddy currents

InactiveUS20050194099A1Power Loss MinimizationEnhanced performance and durabilityElectric discharge tubesDecorative surface effectsElectricityEddy current

Methods and apparatus are provided for generating an inductively coupled plasma using induced eddy currents. An inductively coupled plasma source of the invention generally comprises a body constructed substantially of a conductive material interrupted by at least one dielectric gap. Radio frequency power is coupled from a current carrier into the conductive body. The one or more dielectric interruptions in the conductive body are disposed so as to cause eddy currents to circulate about portions of the body and thereby couple RF power into a plasma in proximity to the conductive body. By utilizing induced eddy currents to couple power into a plasma, the invention allows for substantial bodies of conductive materials, such as structural metals, to be interposed between the induction coils that receive power from a power generator and the plasma.

Owner:ADVANCED ENERGY IND INC

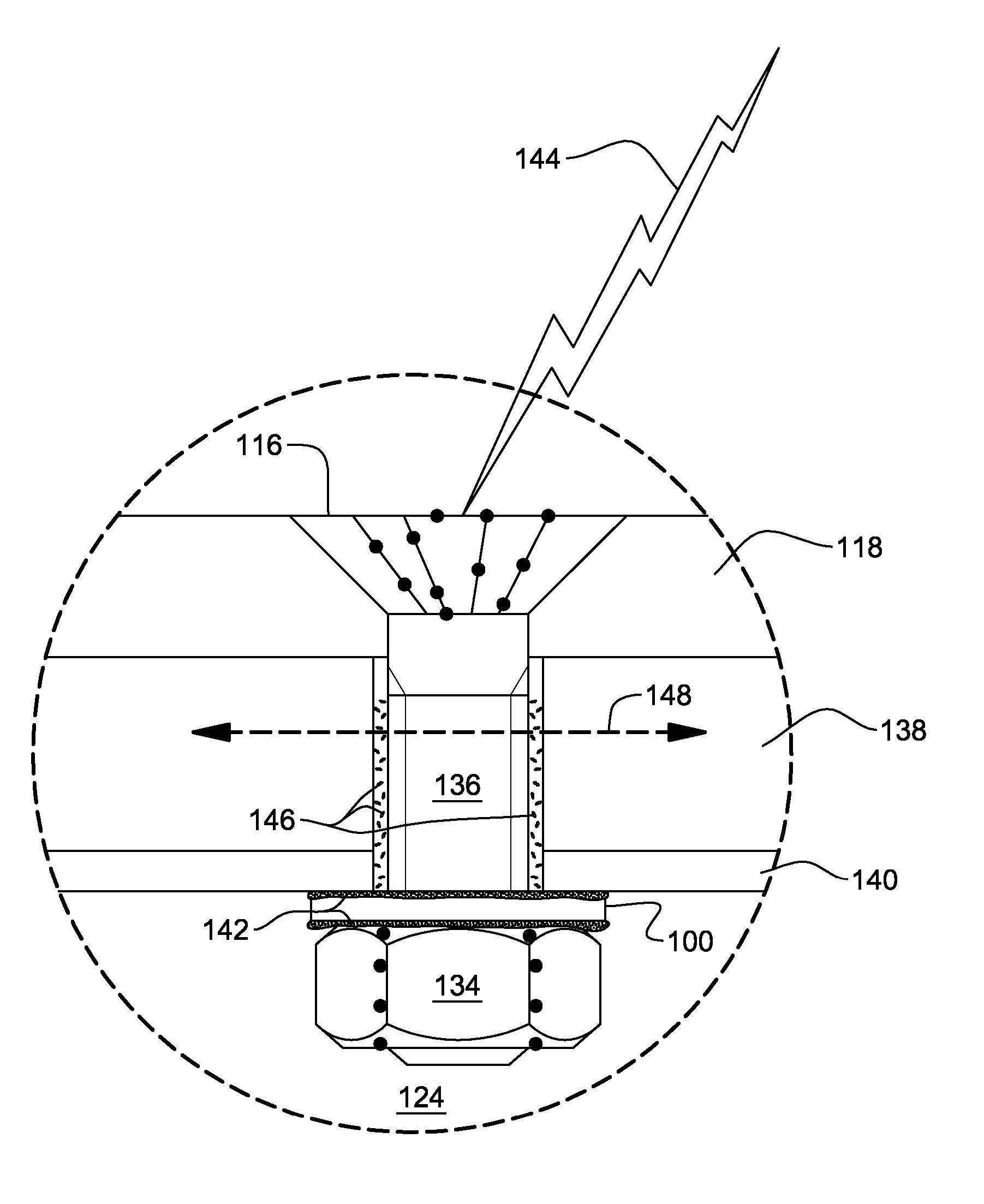

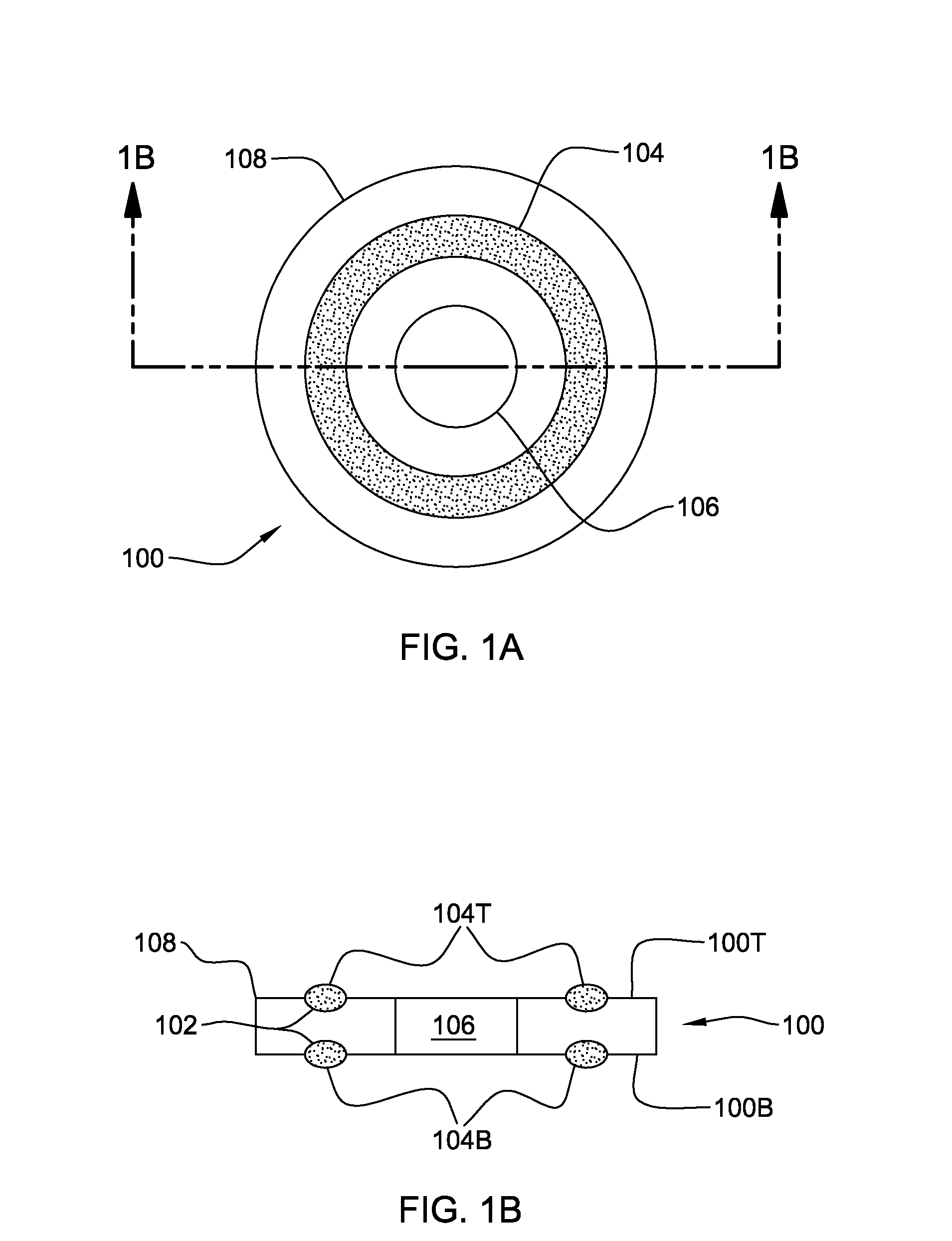

Fastening assembly including washer for sealing the assembly for lightning strike protection in composite structures

InactiveUS20070258182A1Voltage potentialEasy to produceWashersAircraft lighting protectorsLightning strikeInto-structure

A washer, a fastening assembly including the washer and a composite structure including the washer sealing the assembly for internal lightning strike protection. The washer includes one or more concentric ribs that are dielectric rings on both sides. When used (e.g., with a nut and bolt) internal to a structure, especially a composite structure, the washer seals the fastener hole (i.e., that the bolt passes through) and contains any sparking and hot gasses that may arise in the fastener hole from entering the structure.

Owner:THE BOEING CO

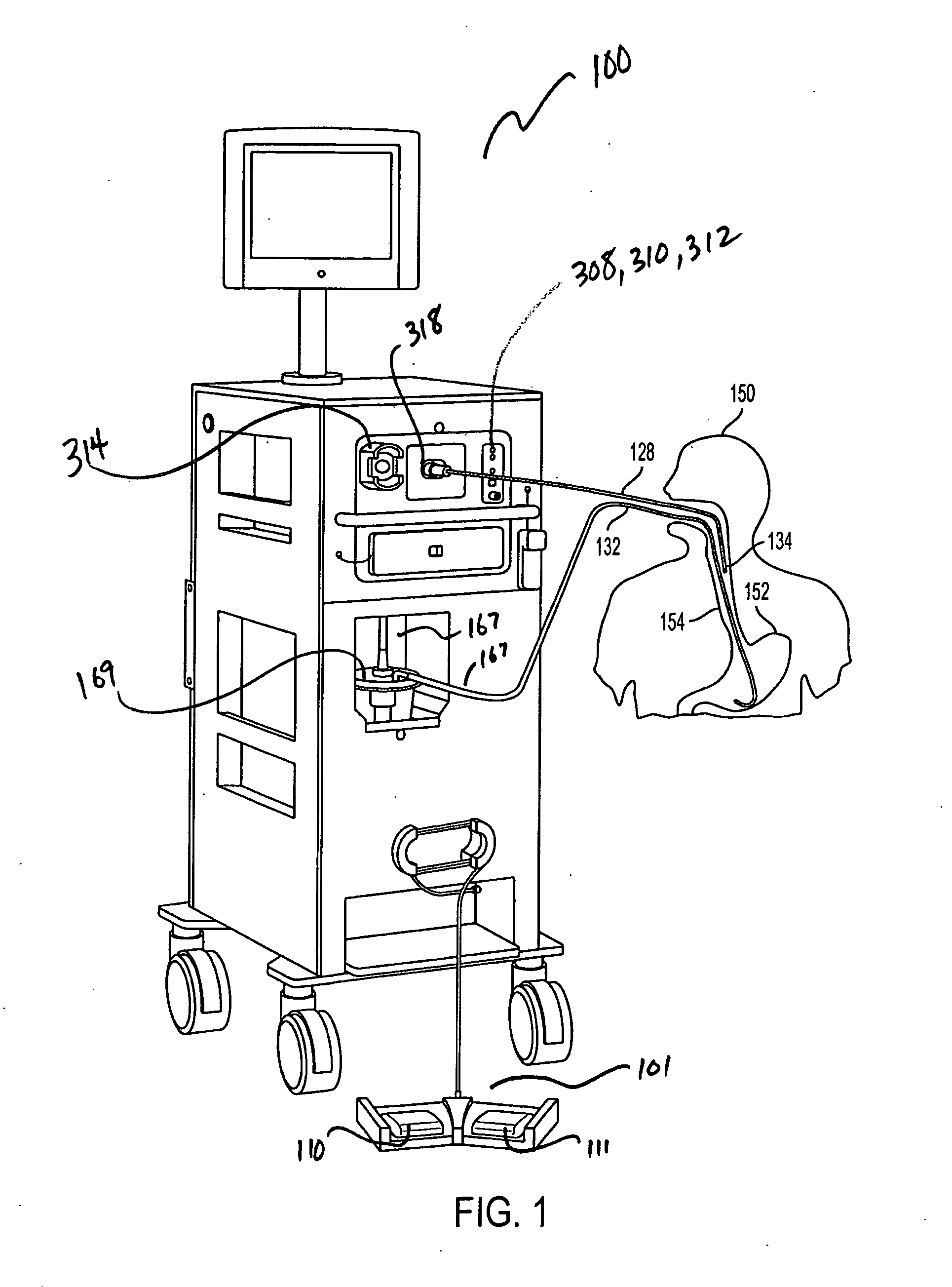

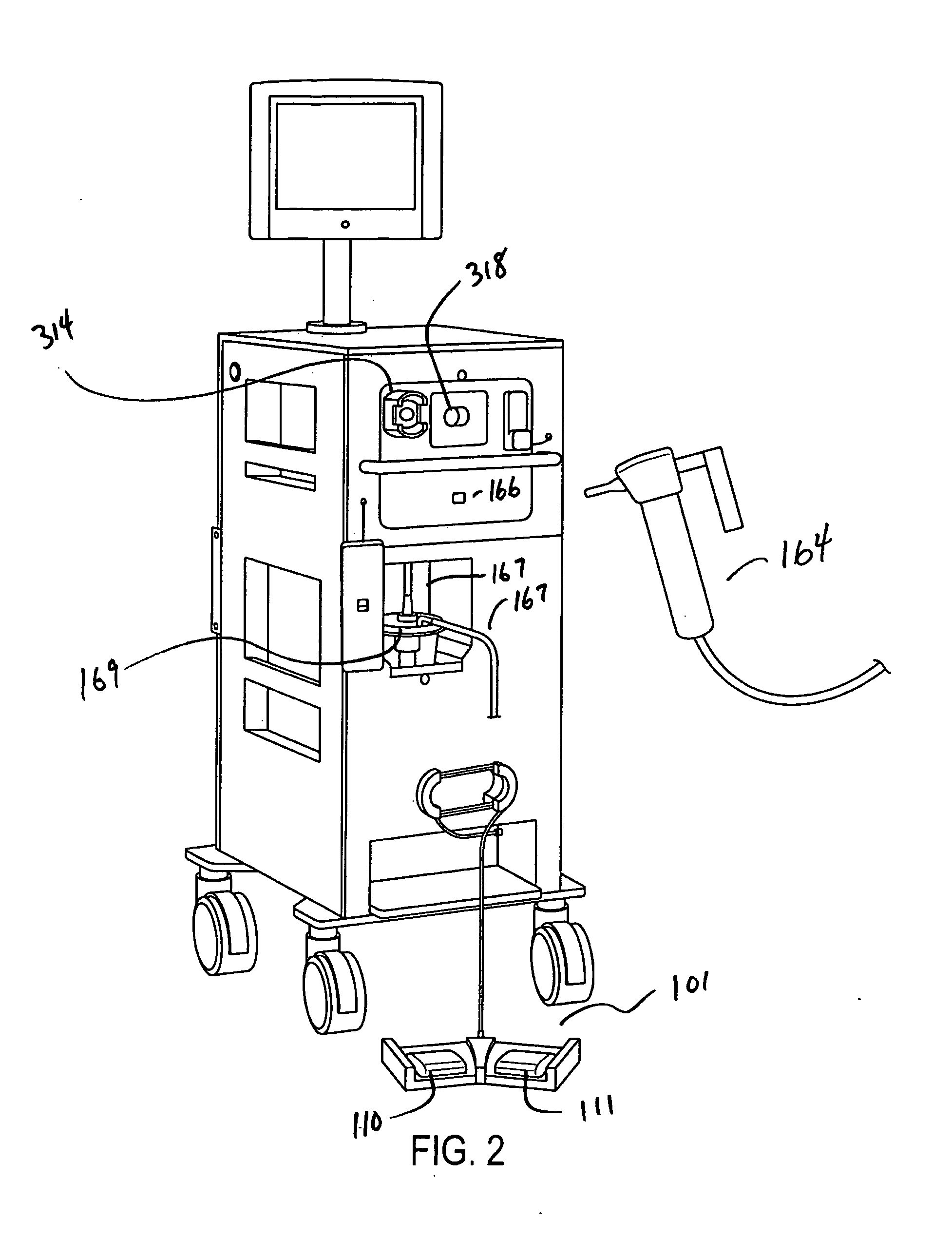

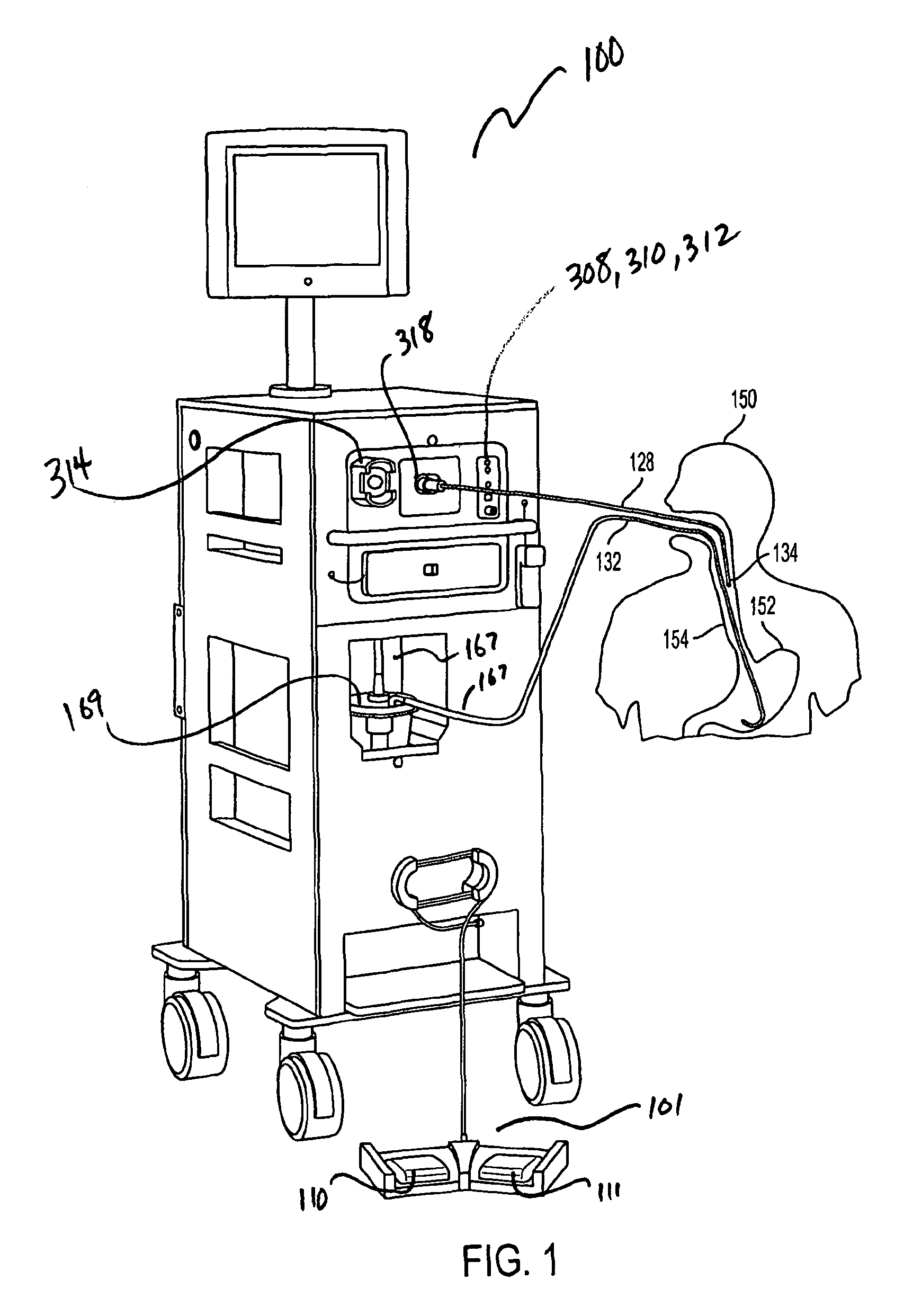

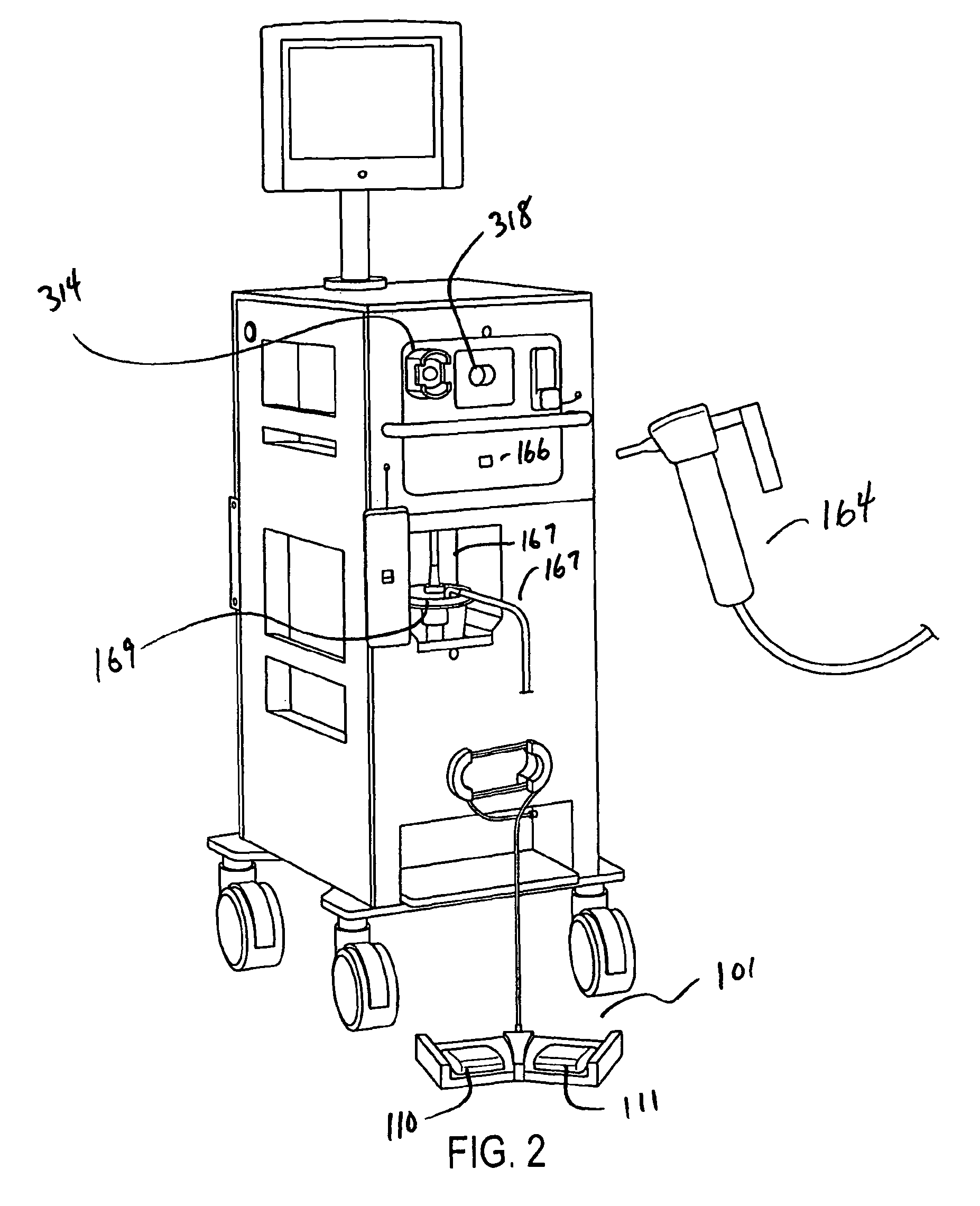

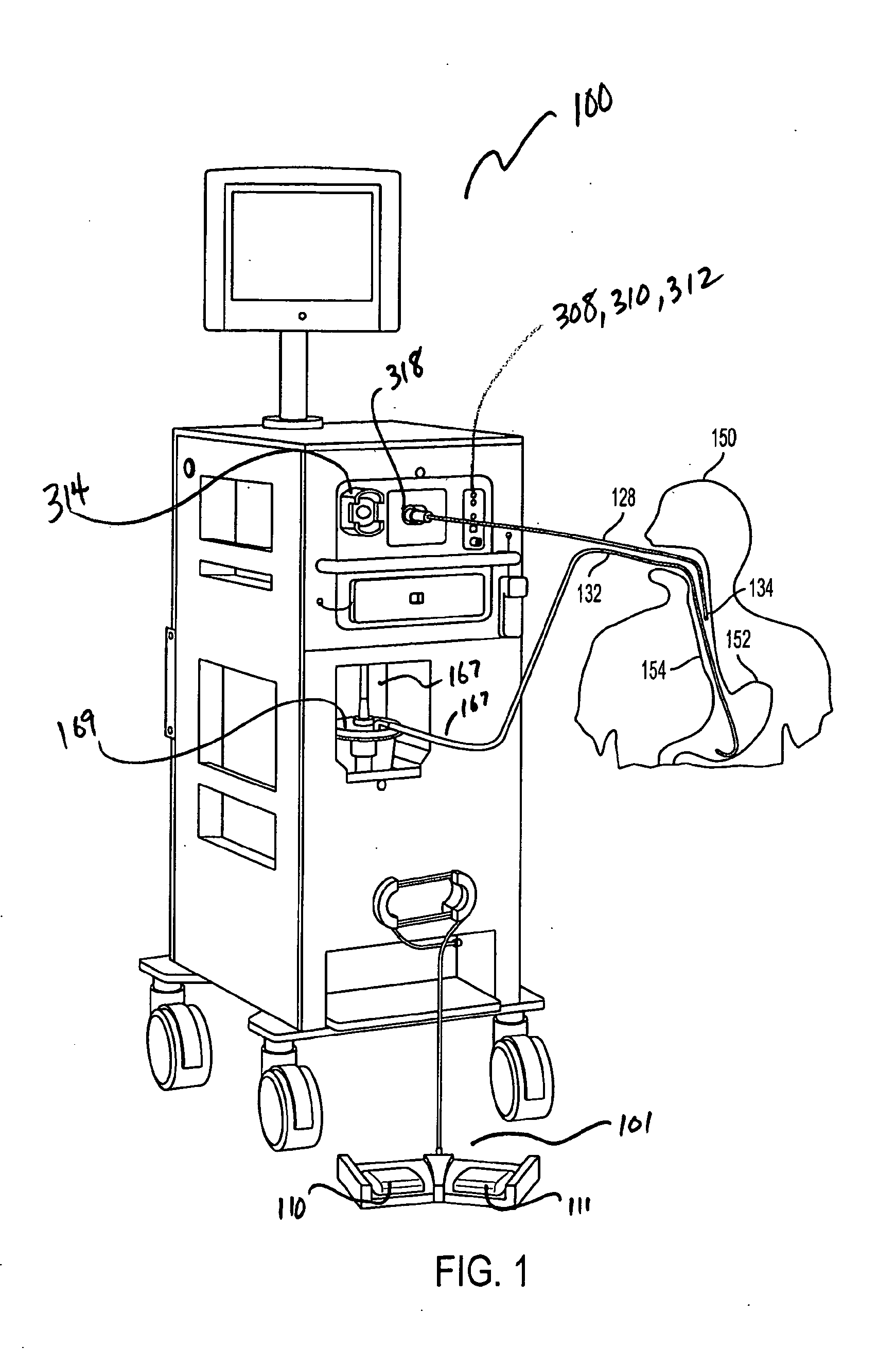

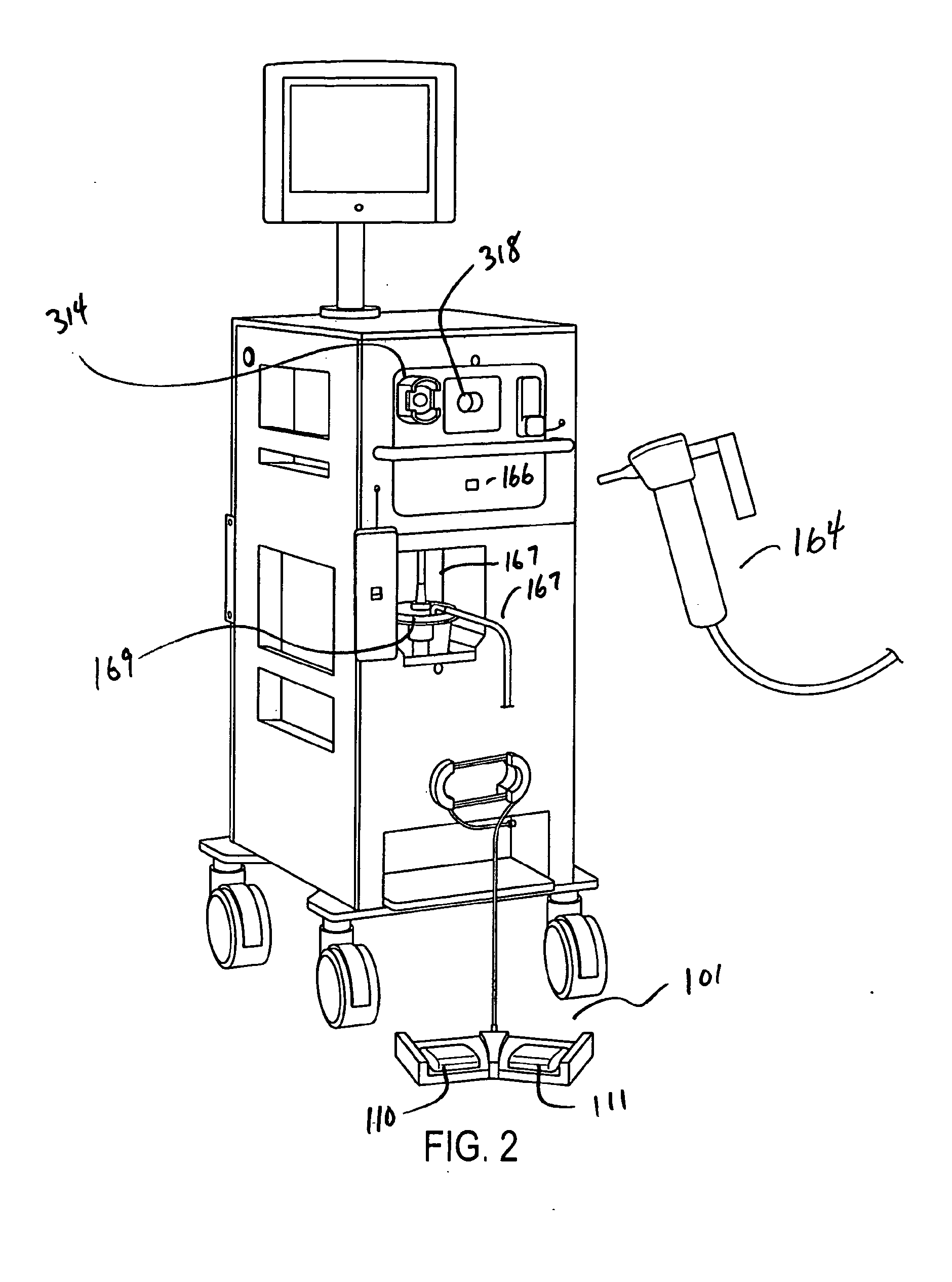

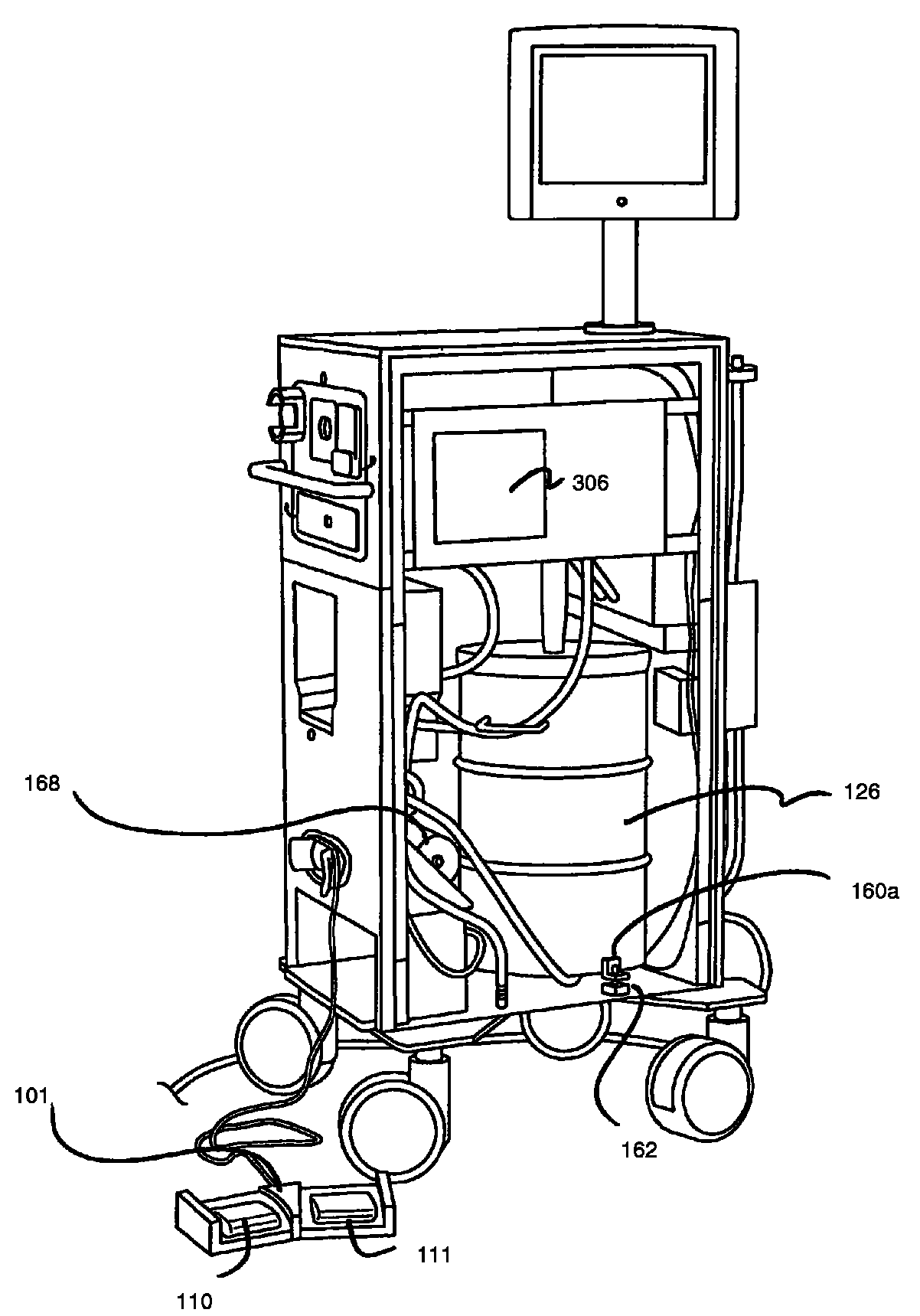

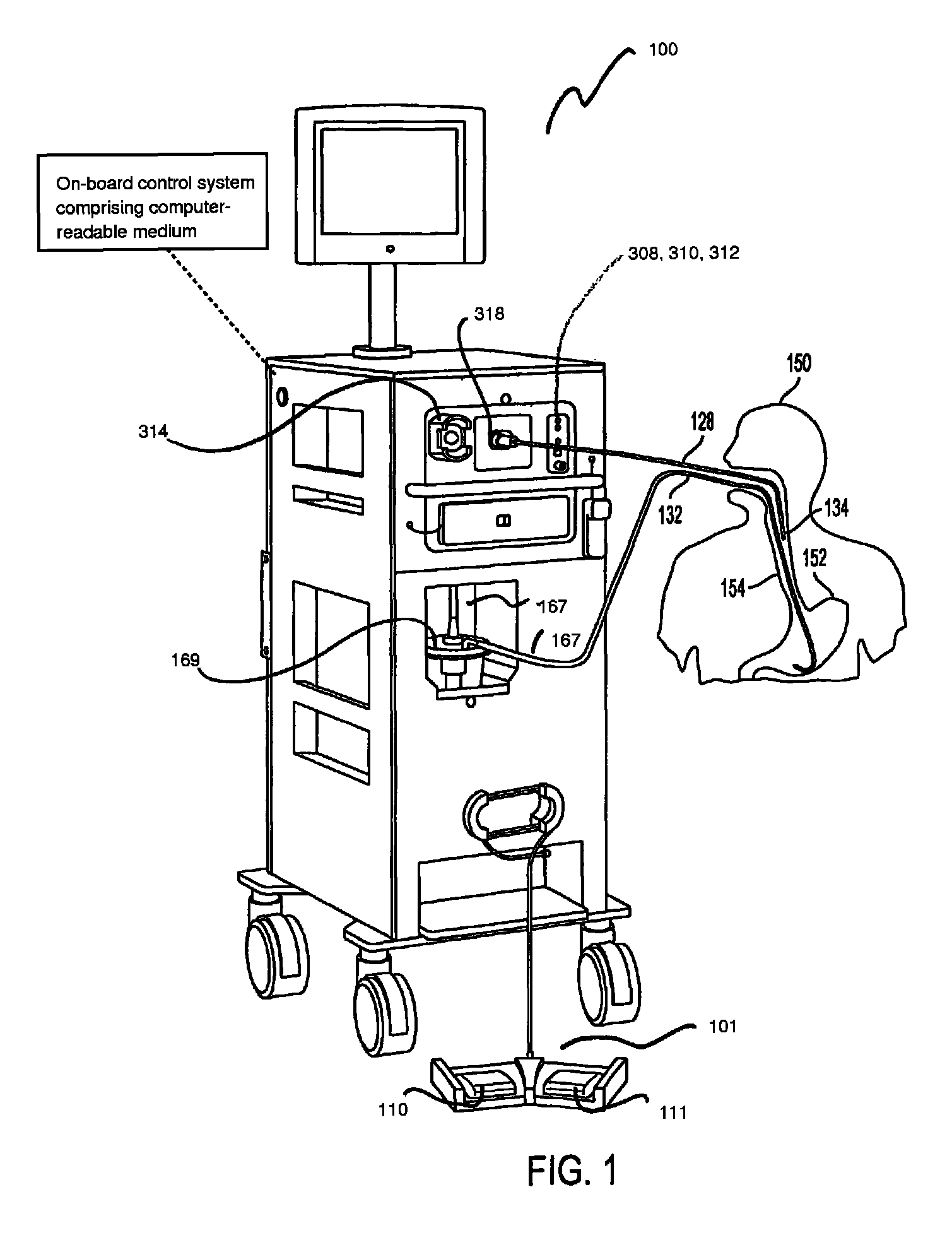

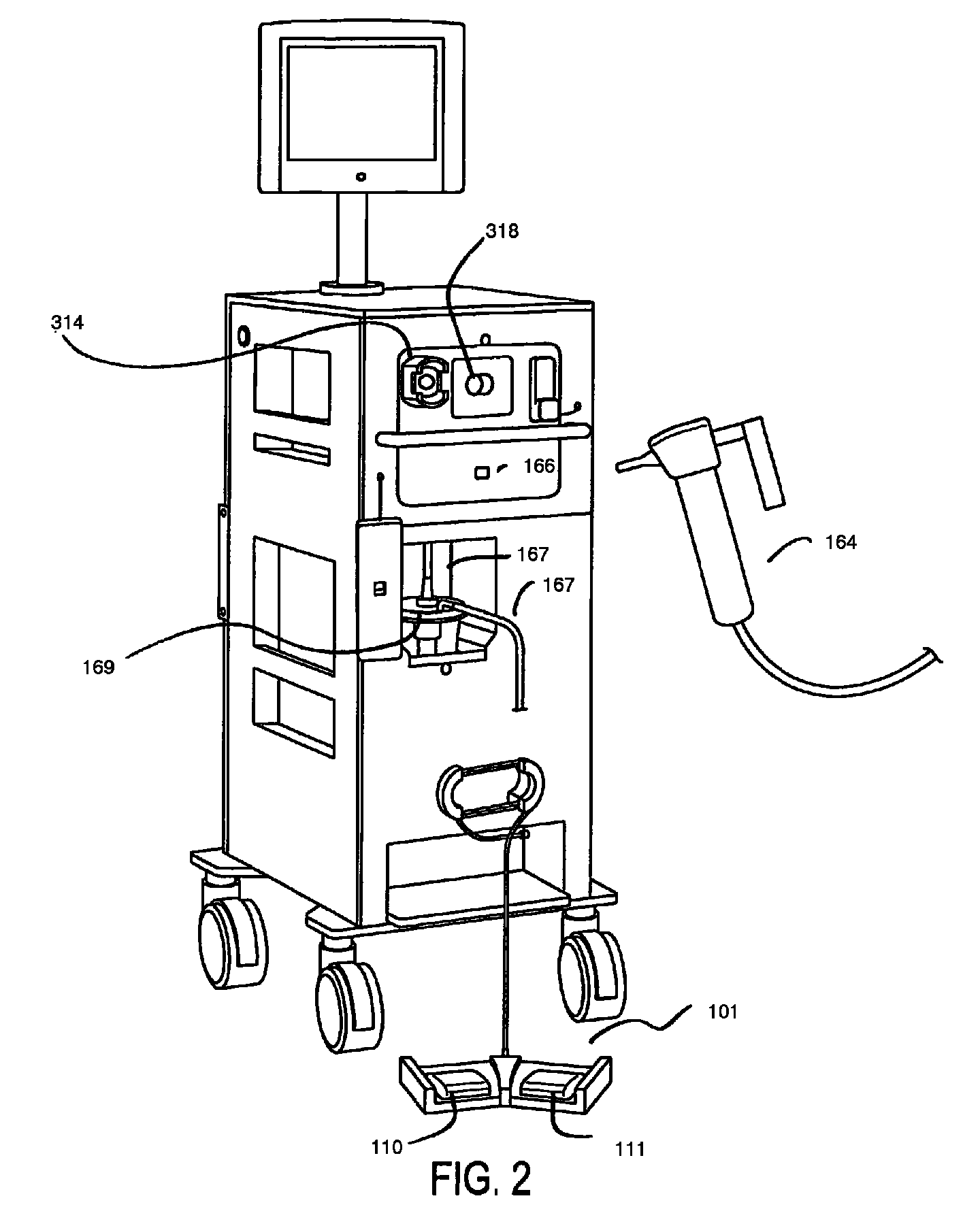

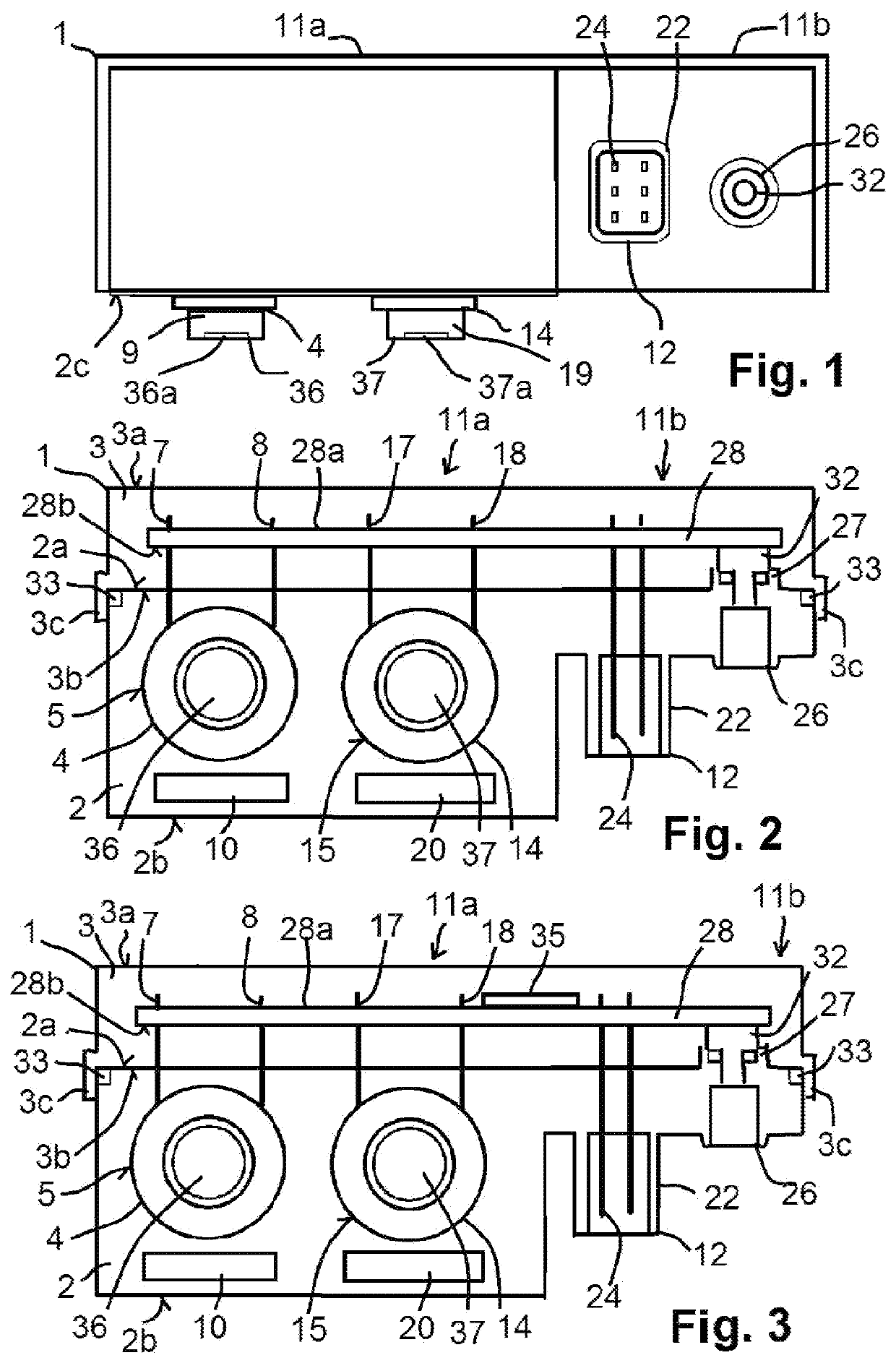

Cryosurgery system

An improved cryosurgical system for application of medical-grade liquid nitrogen to a treatment area via a small, low pressure, open tipped catheter. The system includes a console, including a touch panel computer, a cryogen module, a suction module and an electronics module, all packaged in a mobile cart, and a disposable spray kit. Improved features include optional low cryogen flow setting to reduce the cryogen flow rate by 50%, improved cryogen flow consistency reducing pressure pulses and peaks (improved sensors, control systems, and control algorithms), an integrated suction pump for improved consistency and self-checks, specified vent tube areas and corresponding maximum expected pressures during cryospray procedure; optional pressure sensing capability to monitor pressure during a treatment, and improved catheter design.

Owner:CSA MEDICAL

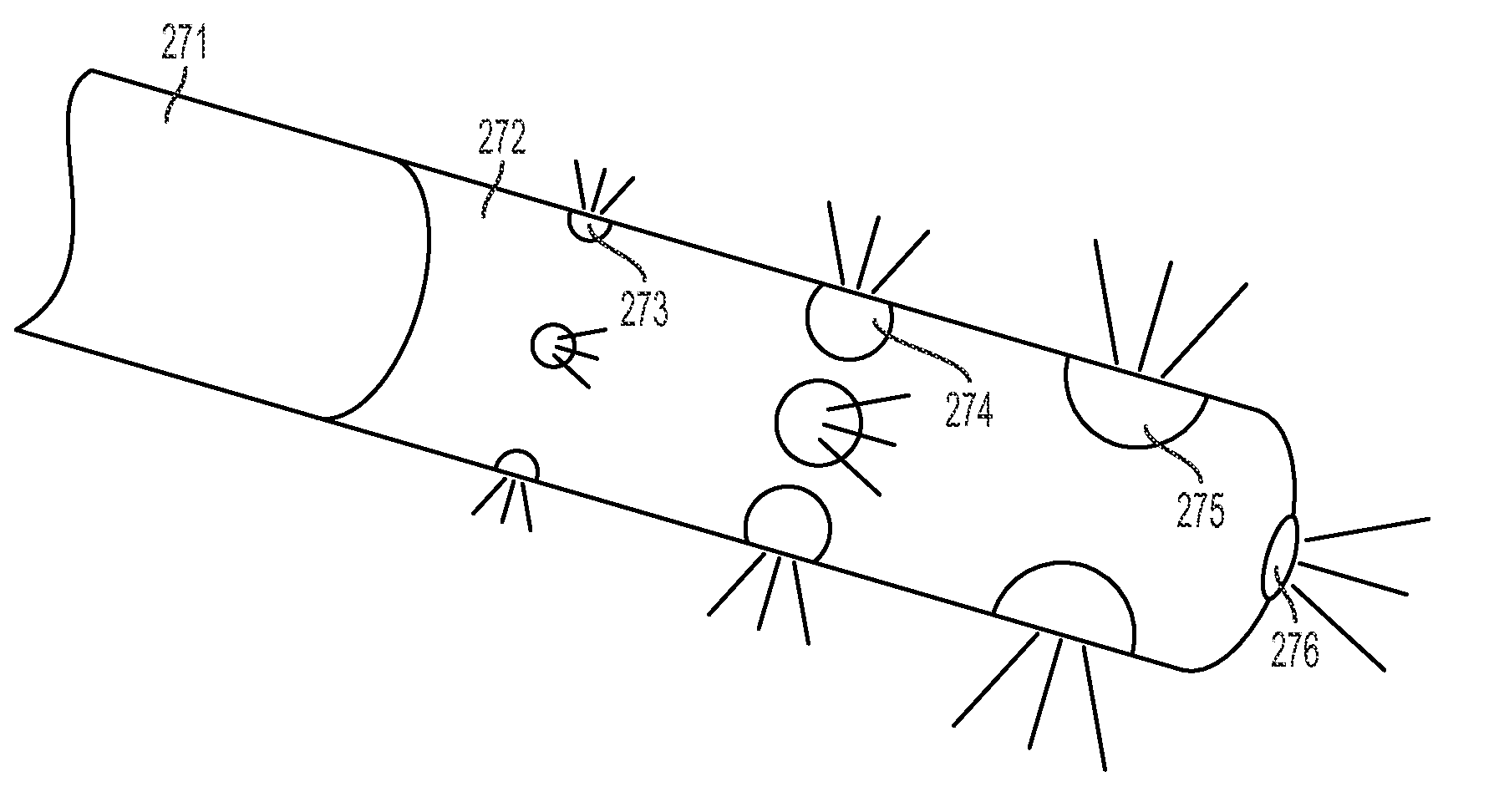

Cryosurgery system

A cryosurgery system for application of medical-grade liquid nitrogen to a treatment area via a small, low pressure, open tipped catheter. The system includes a console, including a touch panel computer, a cryogen module, a suction module and an electronics module, and a disposable spray kit. Features include optional low cryogen flow setting to reduce the cryogen flow rate by 50%, improved cryogen flow consistency reducing pressure pulses and peaks, an integrated suction pump for improved consistency and self-checks, specified vent tube areas and corresponding maximum expected pressures during cryospray procedure; optional pressure sensing capability to monitor pressure during a treatment, and novel catheter designs of multilayer and flexible construction providing a variety of spray patterns.

Owner:CSA MEDICAL

Cryosurgery System

ActiveUS20130253491A1Easy flow controlImproved delivery catheterEndoscopesCatheterPressure senseEngineering

A cryosurgery system for application of medical-grade liquid nitrogen to a treatment area via a small, low pressure, open tipped catheter. The system includes a console, including a touch panel computer, a cryogen module , a suction module and an electronics module, and a disposable spray kit. Features include optional low cryogen flow setting to reduce the cryogen flow rate by 50%, improved cryogen flow consistency reducing pressure pulses and peaks, an integrated suction pump for improved consistency and self-checks, specified vent tube areas and corresponding maximum expected pressures during cryospray procedure; optional pressure sensing capability to monitor pressure during a treatment, and novel catheter designs of multilayer and flexible construction providing a variety of spray patterns.

Owner:CSA MEDICAL

Cryosurgery system

An improved cryosurgical system for application of medical-grade liquid nitrogen to a treatment area via a small, low pressure, open tipped catheter. The system includes a console, including a touch panel computer, a cryogen module, a suction module and an electronics module, all packaged in a mobile cart, and a disposable spray kit. Improved features include optional low cryogen flow setting to reduce the cryogen flow rate by 50%, improved cryogen flow consistency reducing pressure pulses and peaks (improved sensors, control systems, and control algorithms), an integrated suction pump for improved consistency and self-checks, specified vent tube areas and corresponding maximum expected pressures during cryospray procedure; optional pressure sensing capability to monitor pressure during a treatment, and improved catheter design.

Owner:CSA MEDICAL

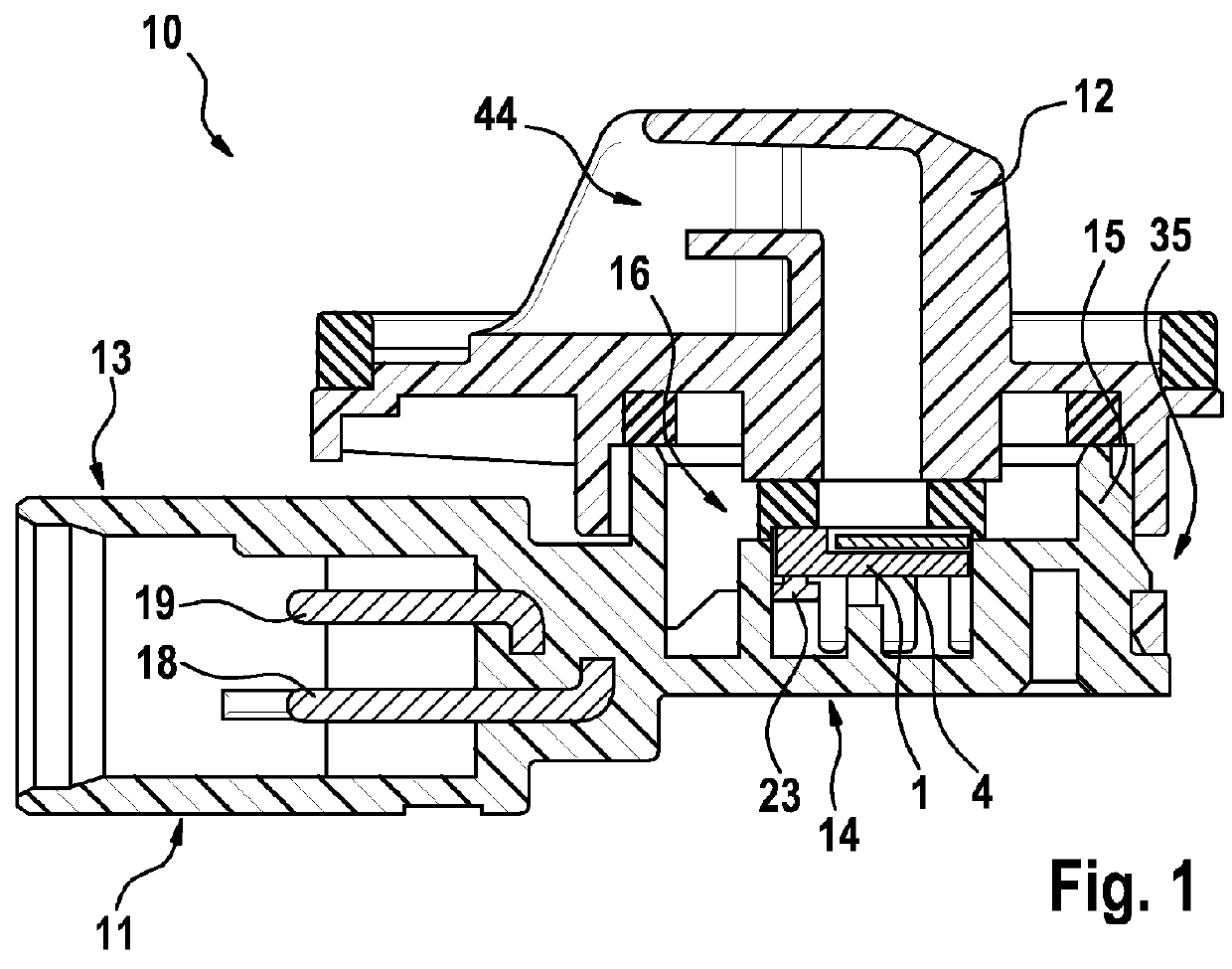

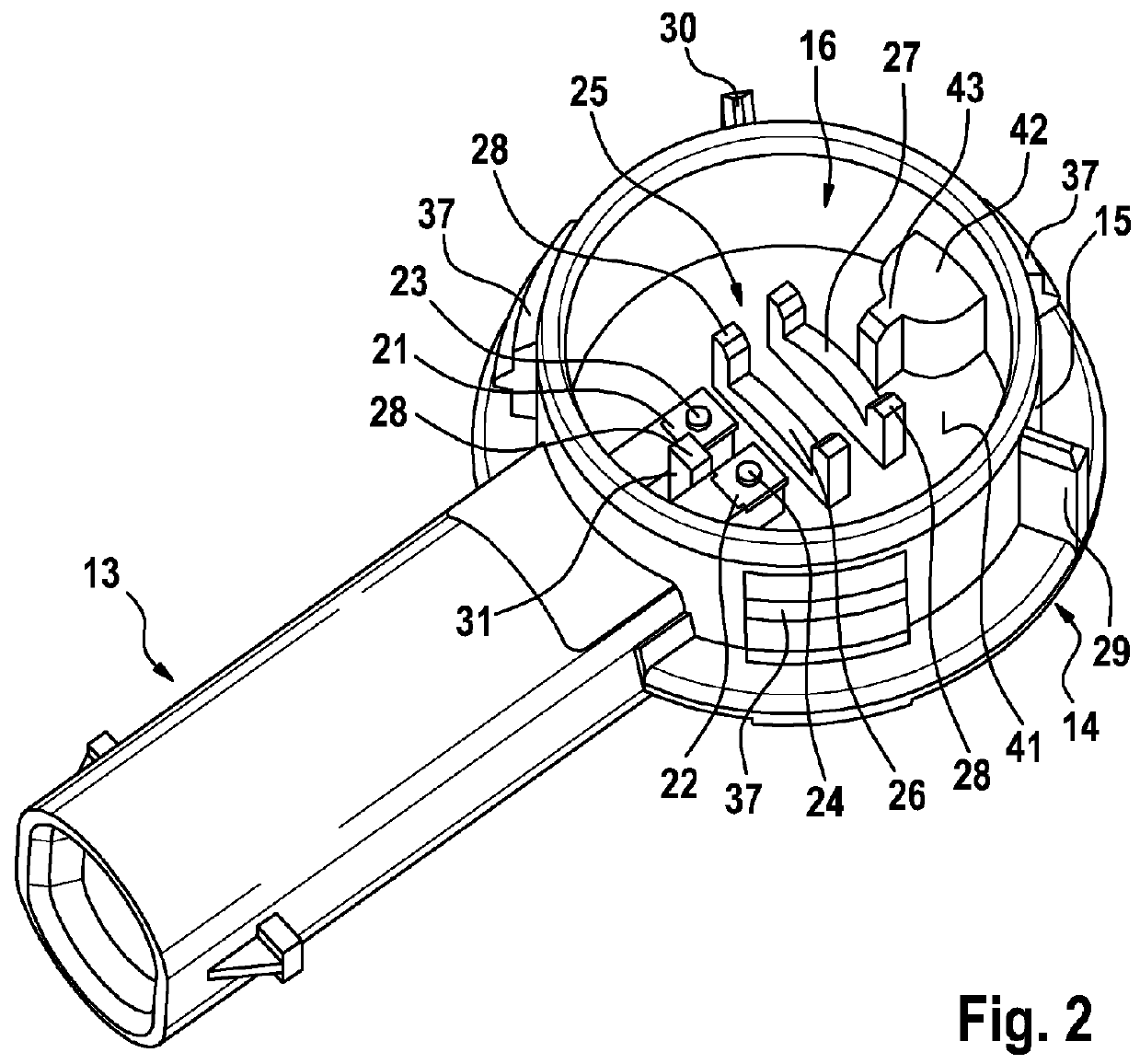

Sensor device, in particular for use in a motor vehicle

ActiveUS9360348B2Easy manufacturabilitySimplifies design and arrangement of plug connectionFluid pressure measurement by mechanical elementsMeasurement apparatus housingsMotor vehicle partEngineering

The invention relates to a sensor device (10), in particular for use in a motor vehicle, having a housing (11) for accommodating a sensor element (1), wherein the sensor element (1) has electrical contact areas (2, 3) which are connected to electrical plug connections (18, 19) arranged in the housing (11) in an electrically conductive manner in the region of contacts (23, 24) of the plug connections (18, 19), wherein a force is applied to the sensor element (1) for the purpose of making electrical contact with a housing element in the direction of the plug connections (18, 19). The invention provides for the electrical plug connections (18, 19) to be arranged in a stationary manner in the housing (11) in the region of the contacts (23, 24) with the electrical contact areas (2, 3) of the sensor element (1), and for a support to be formed between the sensor element (1) and the housing (11) in such a manner that the sensor element (1) has three-point contact in the housing (11).

Owner:ROBERT BOSCH GMBH

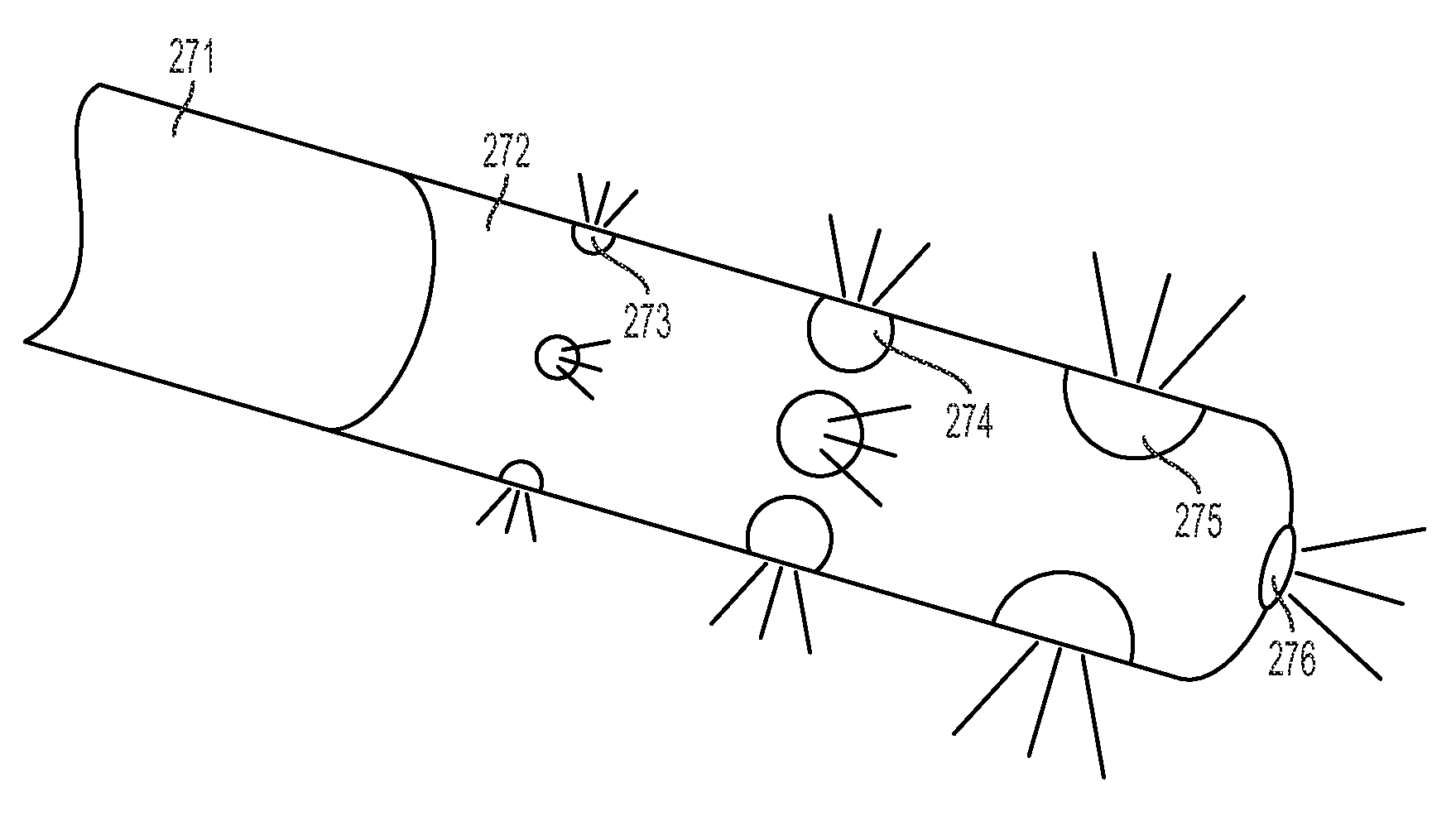

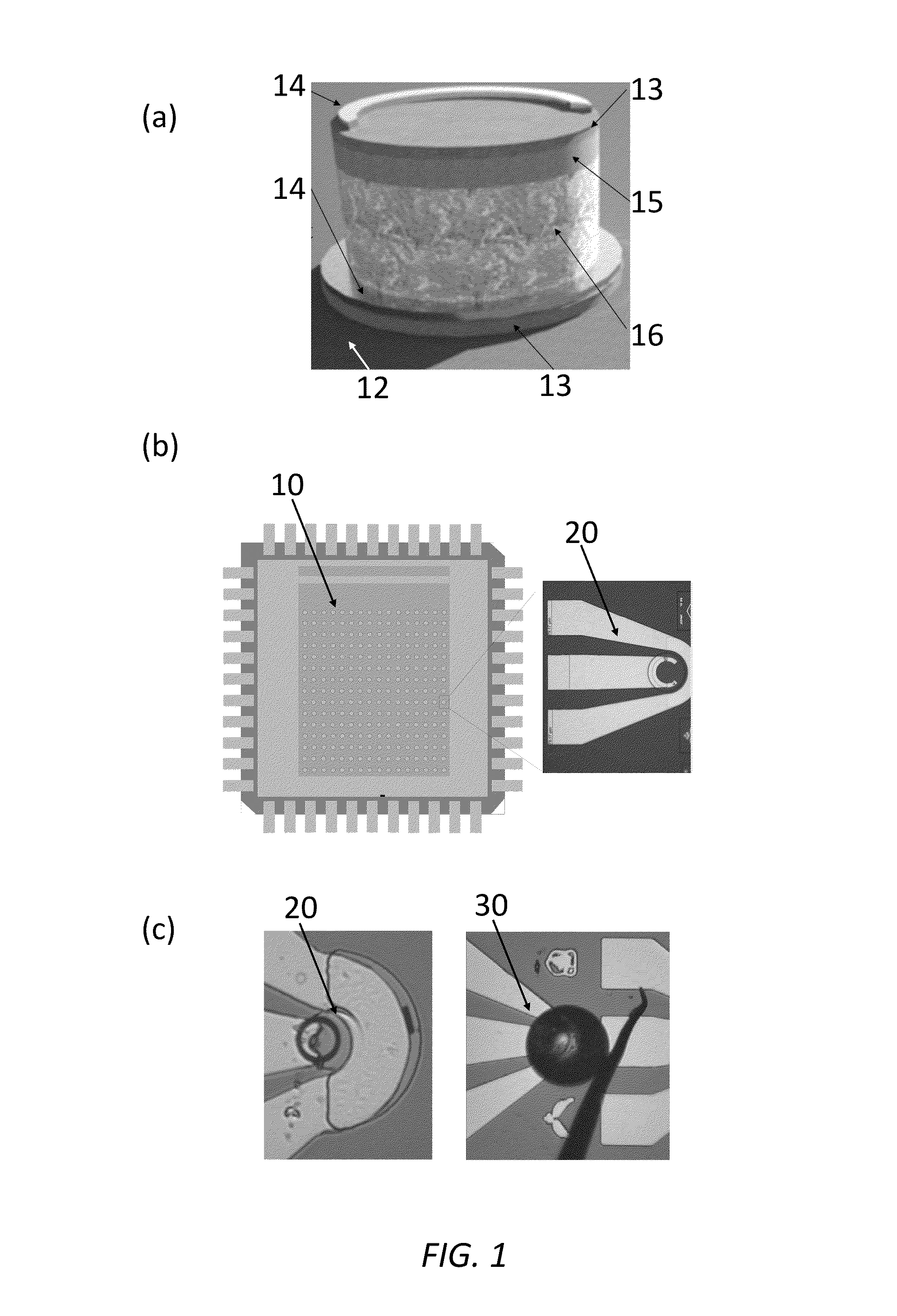

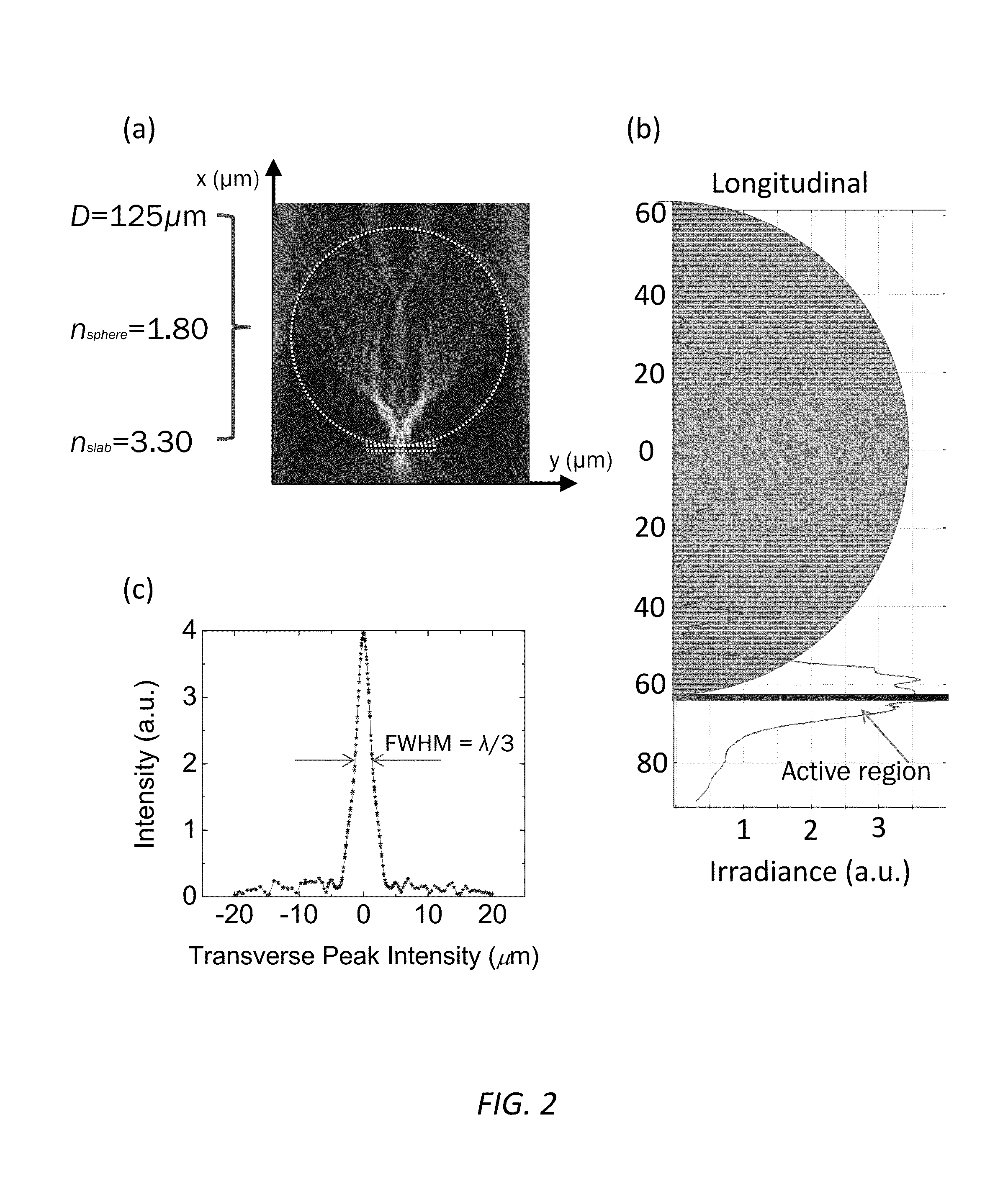

Photodetector focal plane array systems and methods

ActiveUS9362324B1Improve characteristicImprove efficiencySolid-state devicesPretreated surfacesPhotodetectorPhotovoltaic detectors

A photodetector focal plane array system, comprising: a substrate comprising a plurality of photosensitive regions; and a microcomponent disposed adjacent to each of the plurality of photosensitive regions operable for receiving incident radiation and directing a photonic nanojet into the associated photosensitive region. Optionally, each of the microcomponents comprises one of a microsphere and a microcylinder. Each of the microcomponents has a diameter of between between ˜λ and ˜100λ, where λ is the wavelength of the incident radiation. Each of the microcomponents is manufactured from a dielectric or semiconductor material. Each of the microcomponents has an index of refraction of between ˜1.4 and ˜3.5. Optionally, high-index components can be embedded in a lower index material. The microcomponents form an array of microcomponents disposed adjacent to the substrate.

Owner:THE UNIV OF NORTH CAROLINA AT CHAPEL HILL +1

Housing for a centrifugal compressor

ActiveCN101896726AImprove the protective effectReduce collisionPump componentsPumpsEngineeringCentrifugal compressor

The housing for a centrifugal compressor consists of at least two plastic housing parts for accommodating a compressor wheel and for defining a helical compressor duct, an annular space being formed in the housing between the compressor wheel accommodating compartment and the compressor duct, said annular space encircling the compressor wheel and at least one stabilizing element being introduced into it.

Owner:BAYERISCHE MOTOREN WERKE AG

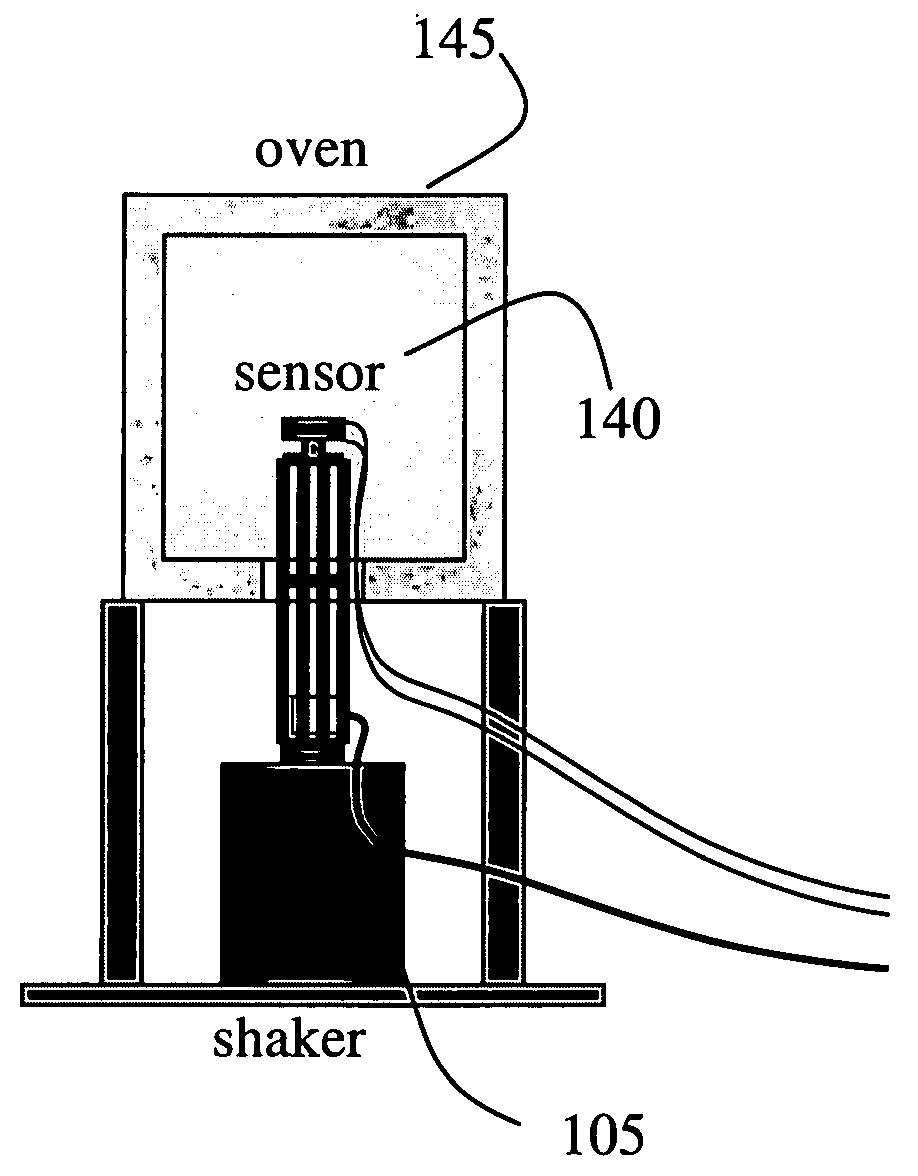

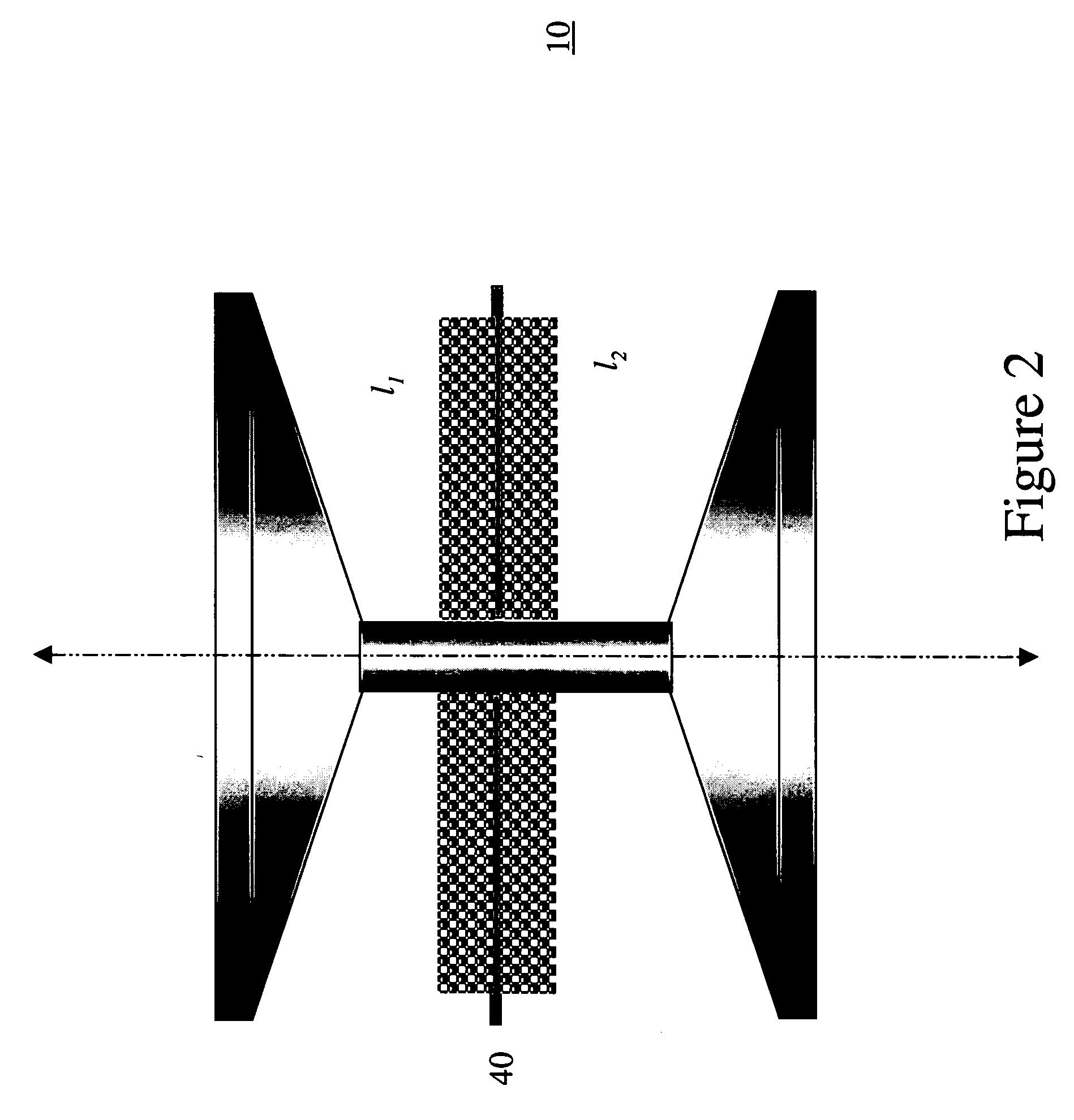

Manufacturing method for high temperature fiber optic accelerometer

ActiveUS7155101B2Easy to manufactureEasy manufacturabilityAcceleration measurement using interia forcesOptical fibre with multilayer core/claddingCircular discAccelerometer

A method of making a fiber optic accelerometer includes (a) drawing an optical fiber through a resin; (b) winding the resin coated fiber onto a disc mounted on an assembly having a central shaft; and (c) curing the resin-coated fiber. The optical fiber may be drawn through a resin by providing a container filled with a resin having an orifice therethrough and drawing the fiber through the orifice. The resin may be cured such that the fiber is bonded to the disc by curing the resin to the fiber and the disc at the same time.

Owner:SCHLUMBERGER TECH CORP

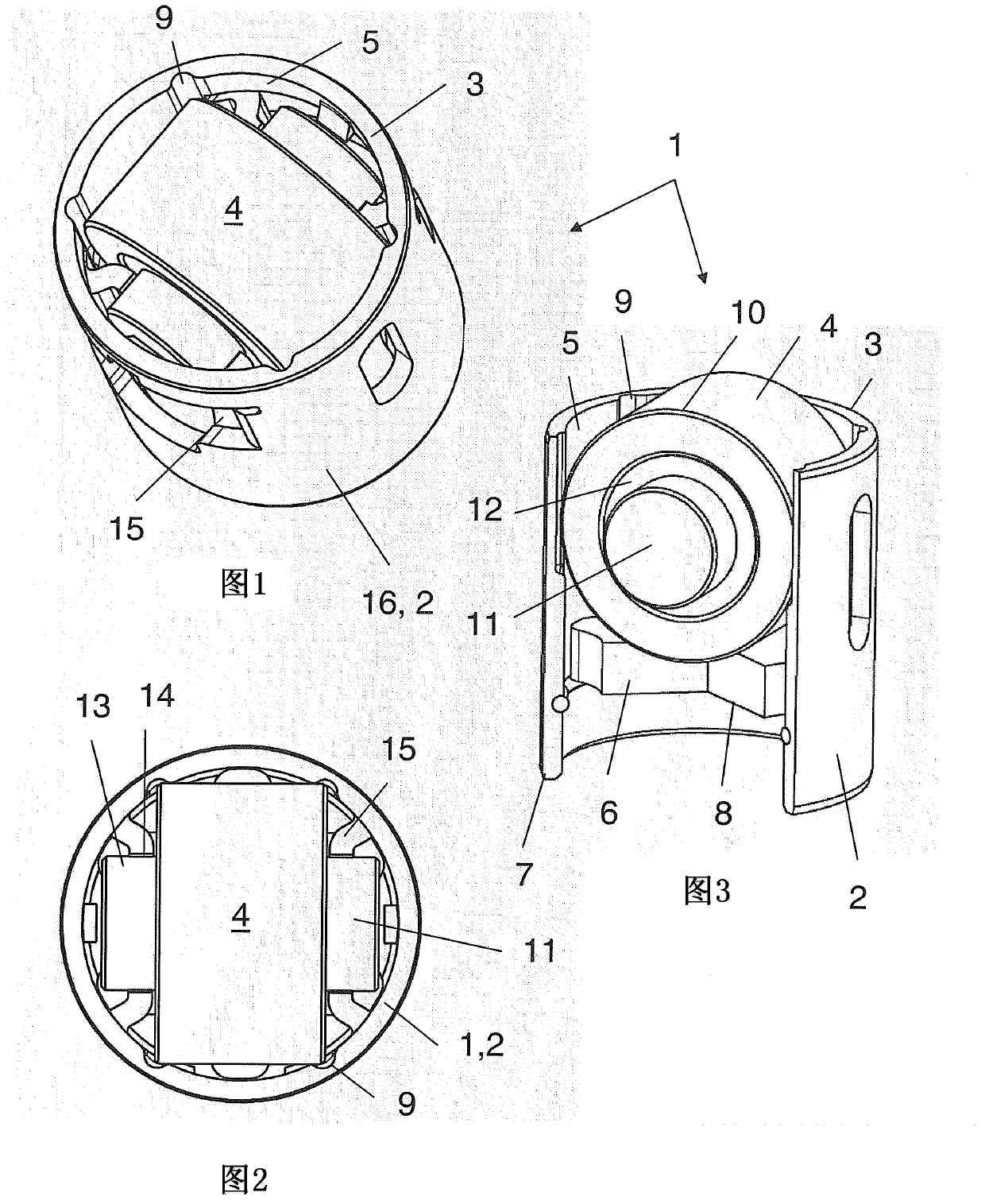

Plunger

InactiveCN103423119AIncrease loadIncrease the rated loadValve arrangementsFuel injecting pumpsEngineeringCam

Provided is a plunger (1) particularly used for a fuel injection pump. The pluger has a housing (2) receiving a roller (4) used for being struck by a cam, wherein the roller is in a cylindrical inner circumference side (5) in a region of a first annular end (3), a bridge piece (6) axially projects through the housing (2) below the roller (4), and a bottom side (8) of the bridge piece faces towards a second annular end (7) of the housing, and functions as a system for a plunger follower. Four notch-like discharges (9) extend along the inner circumference side (5) of the housing (2), and the roller (4) with ring edges (10) projects into the discharges.

Owner:SCHAEFFLER TECH AG & CO KG

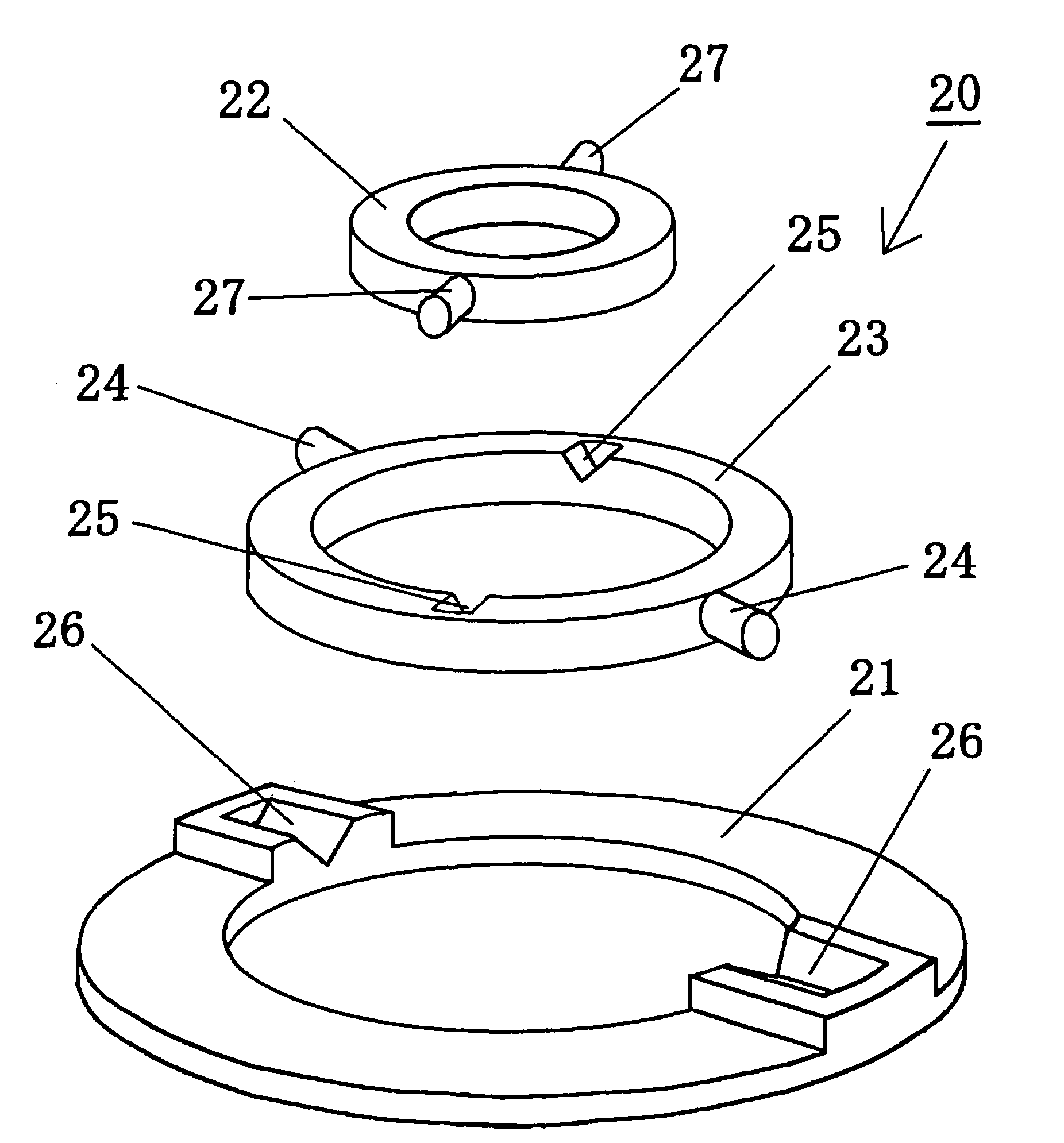

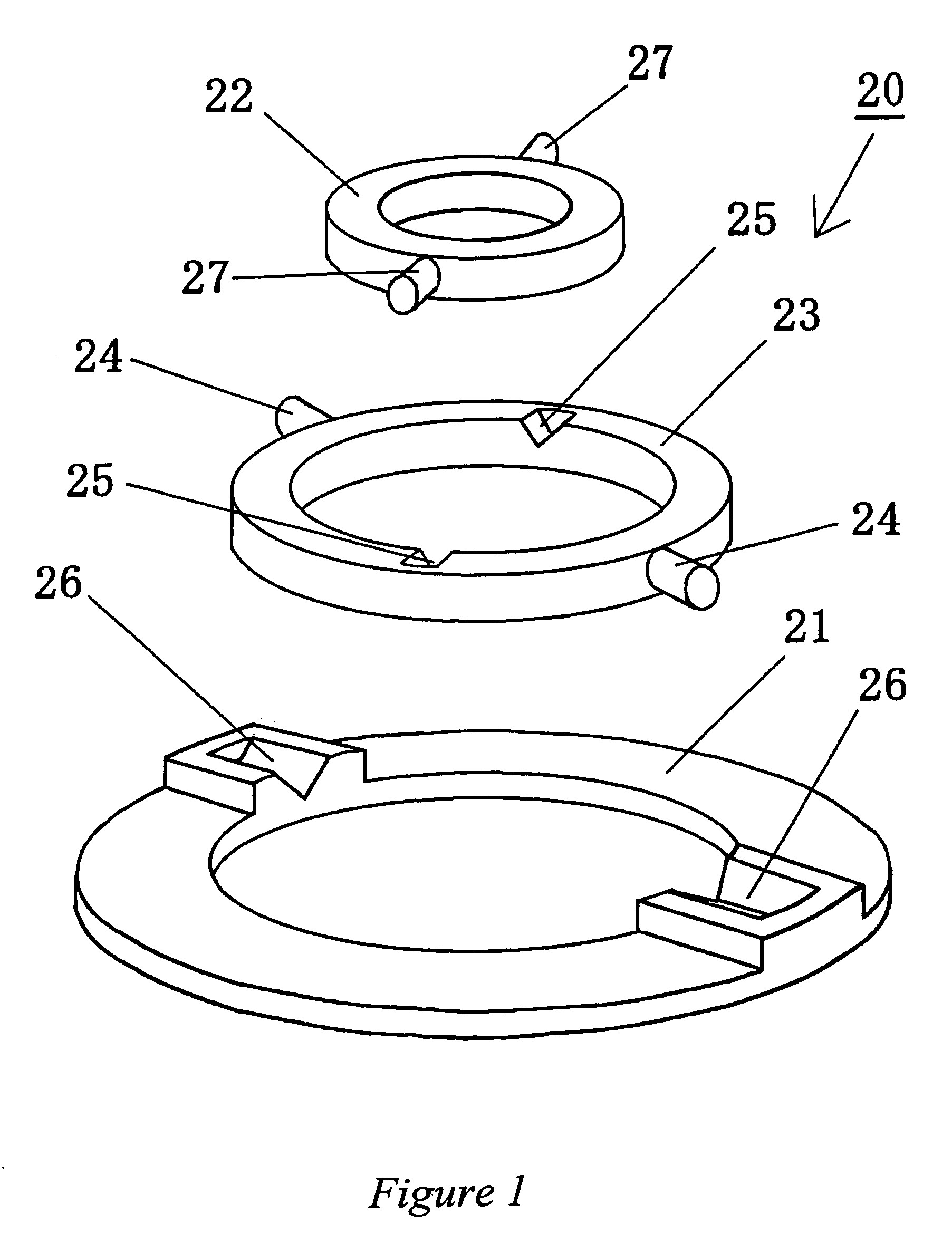

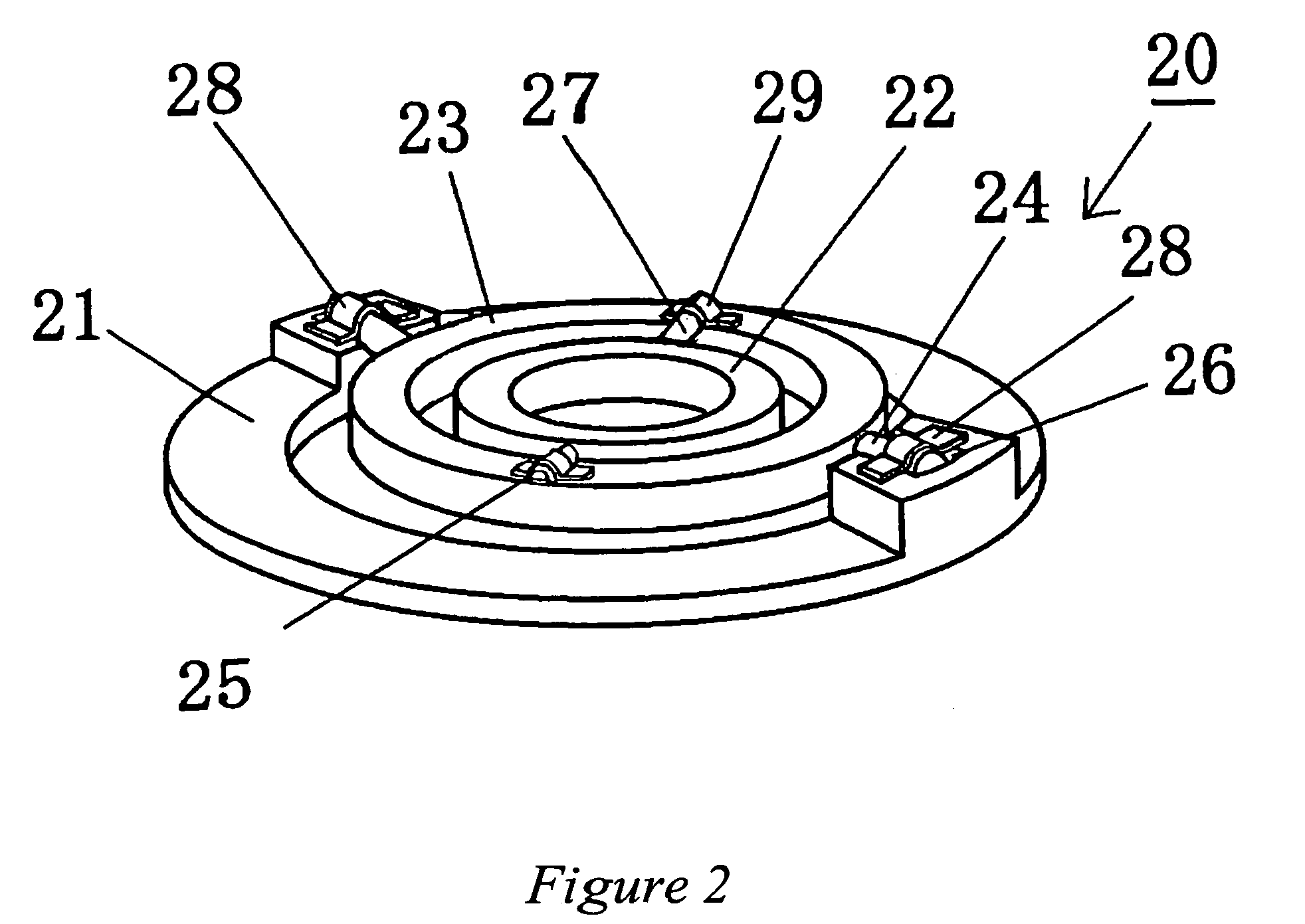

Rotation sensor and coupling for rotation sensor

InactiveUS7174794B2Easy to replaceEasy manufacturabilityYielding couplingSlip couplingCouplingRotation sensor

A coupling includes a first coupling member, a second coupling member, and a third coupling member being located in between the first coupling member and the second coupling member. The third coupling member has formed thereon a first pair of connecting elements diametrically opposed to one another and defining a first axis, and further has formed thereon a second pair of connecting elements diametrically opposed to one another and defining a second axis that is substantially perpendicular to the first axis. The first coupling member has formed thereon a third pair of connecting elements configured to conform to the first pair of connecting elements of the third coupling member. Formed on the second coupling member is a fourth pair of connecting elements configured to conform to the second pair of connecting elements of the third coupling member.

Owner:FURUKAWA ELECTRIC CO LTD

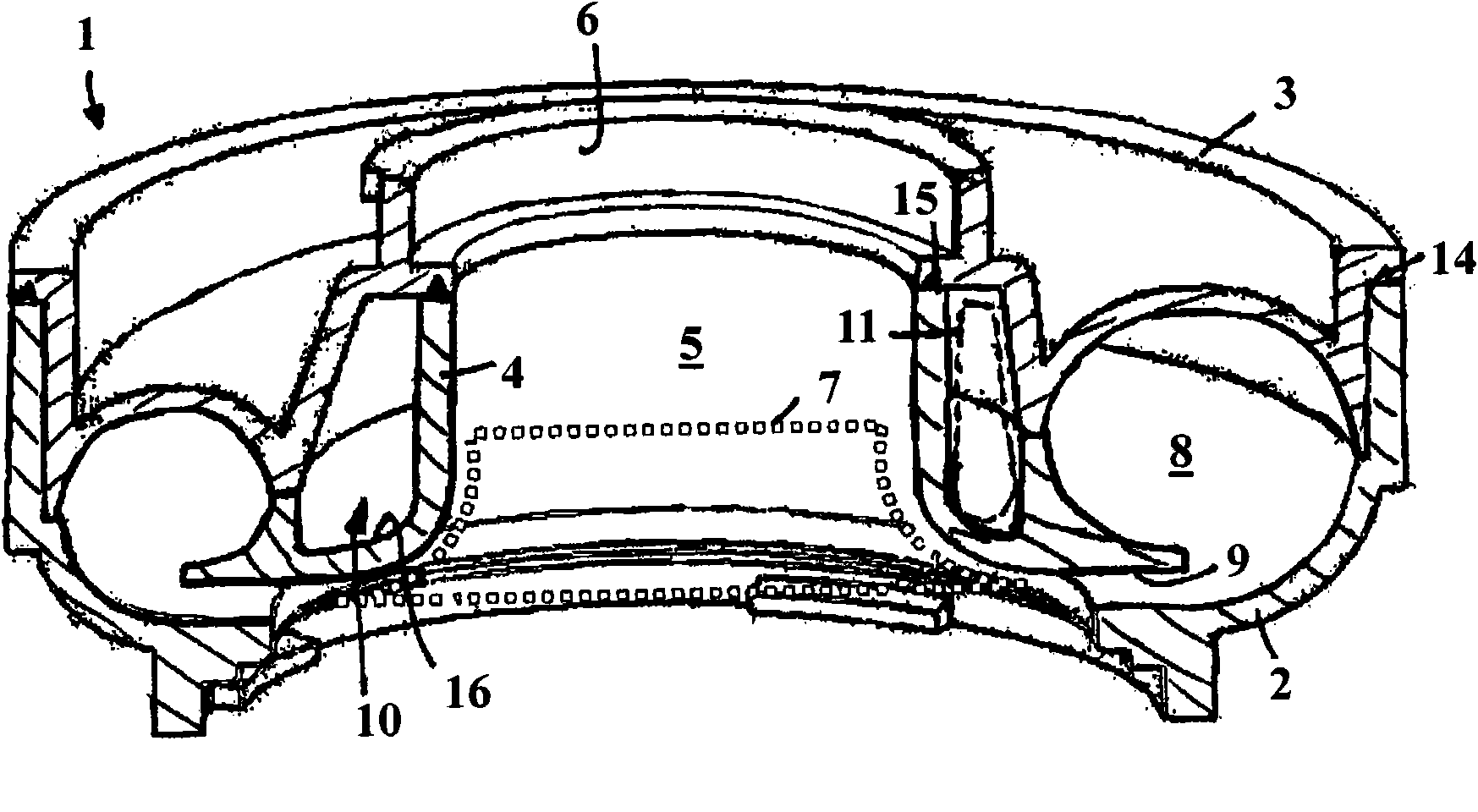

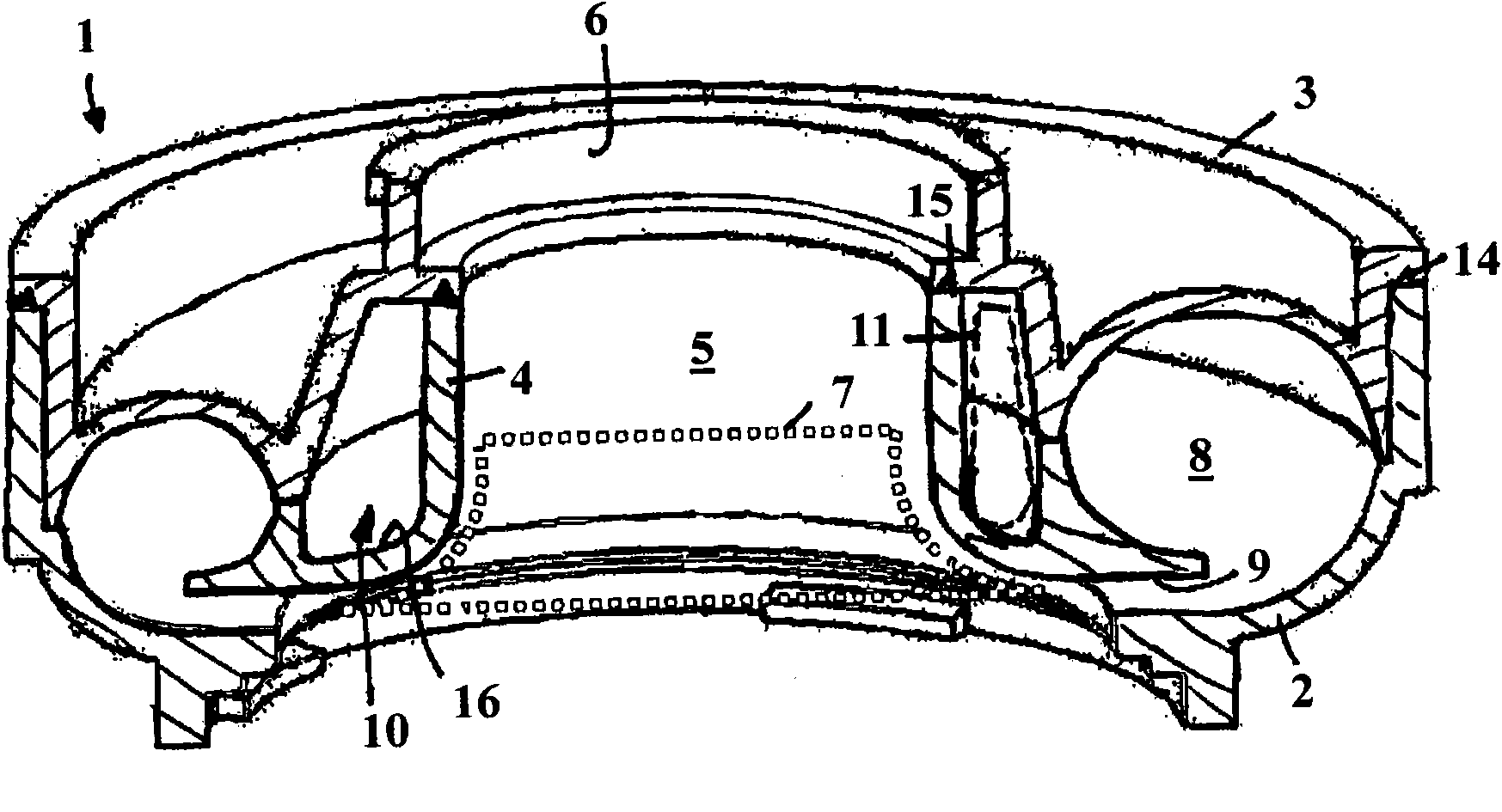

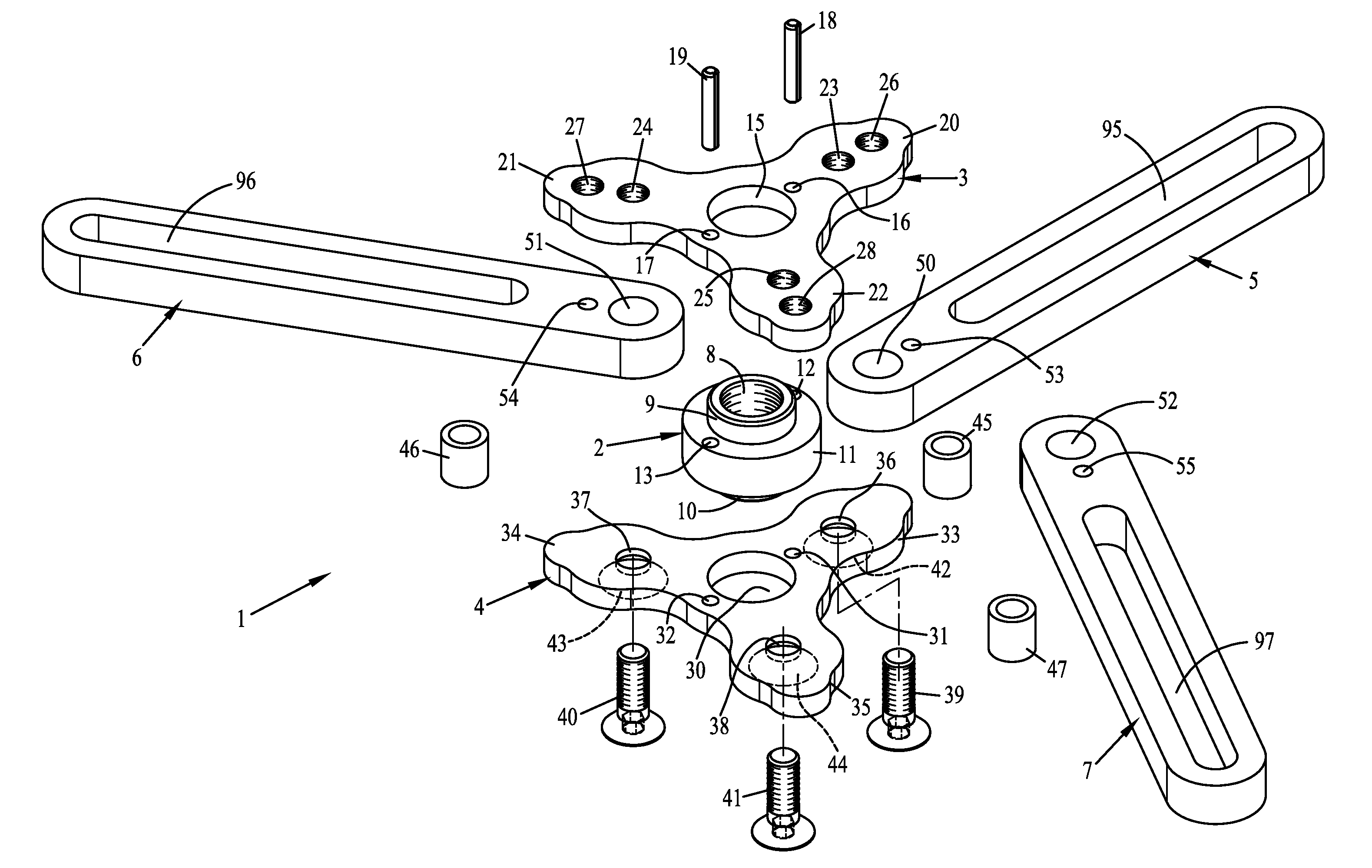

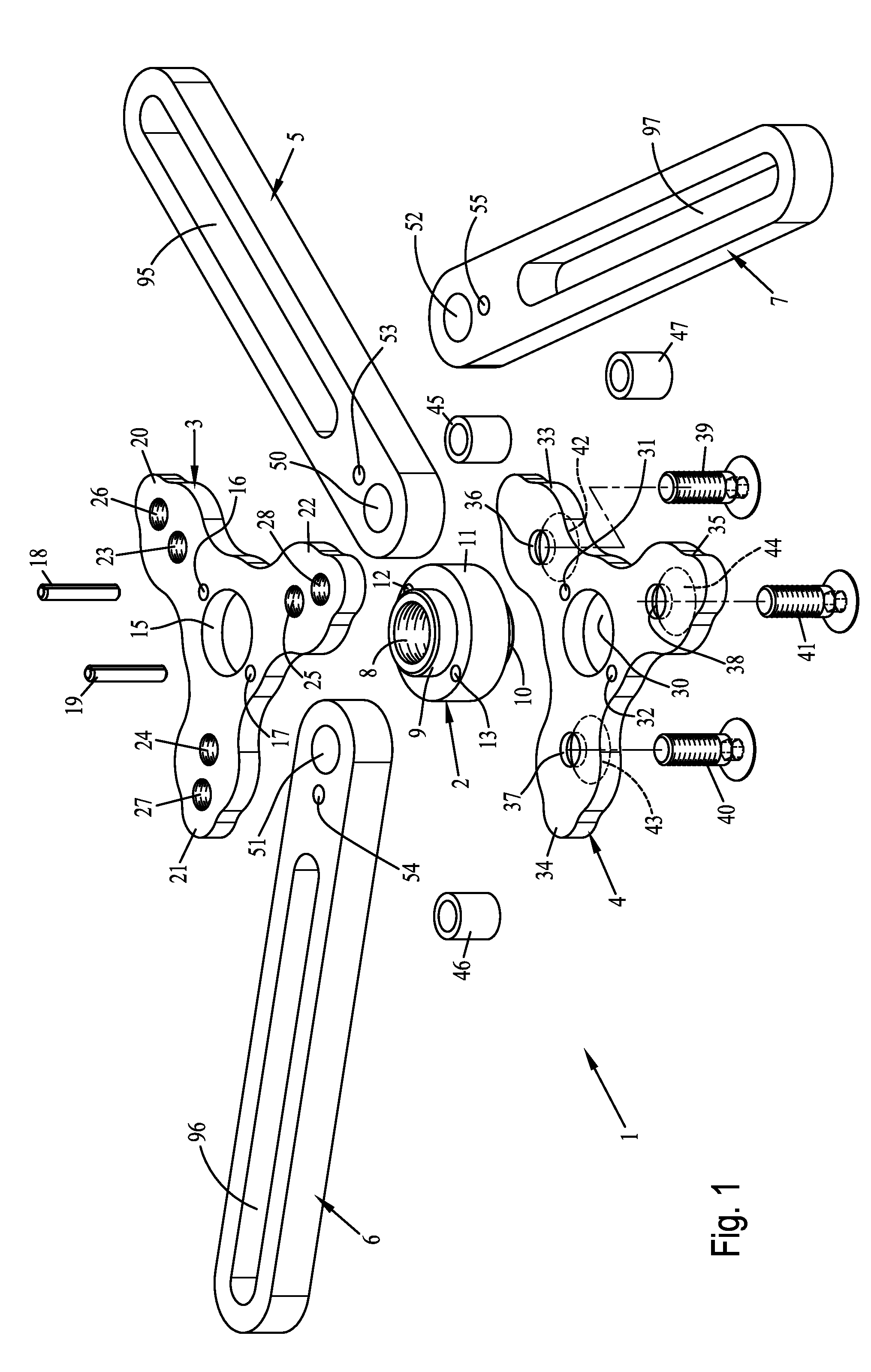

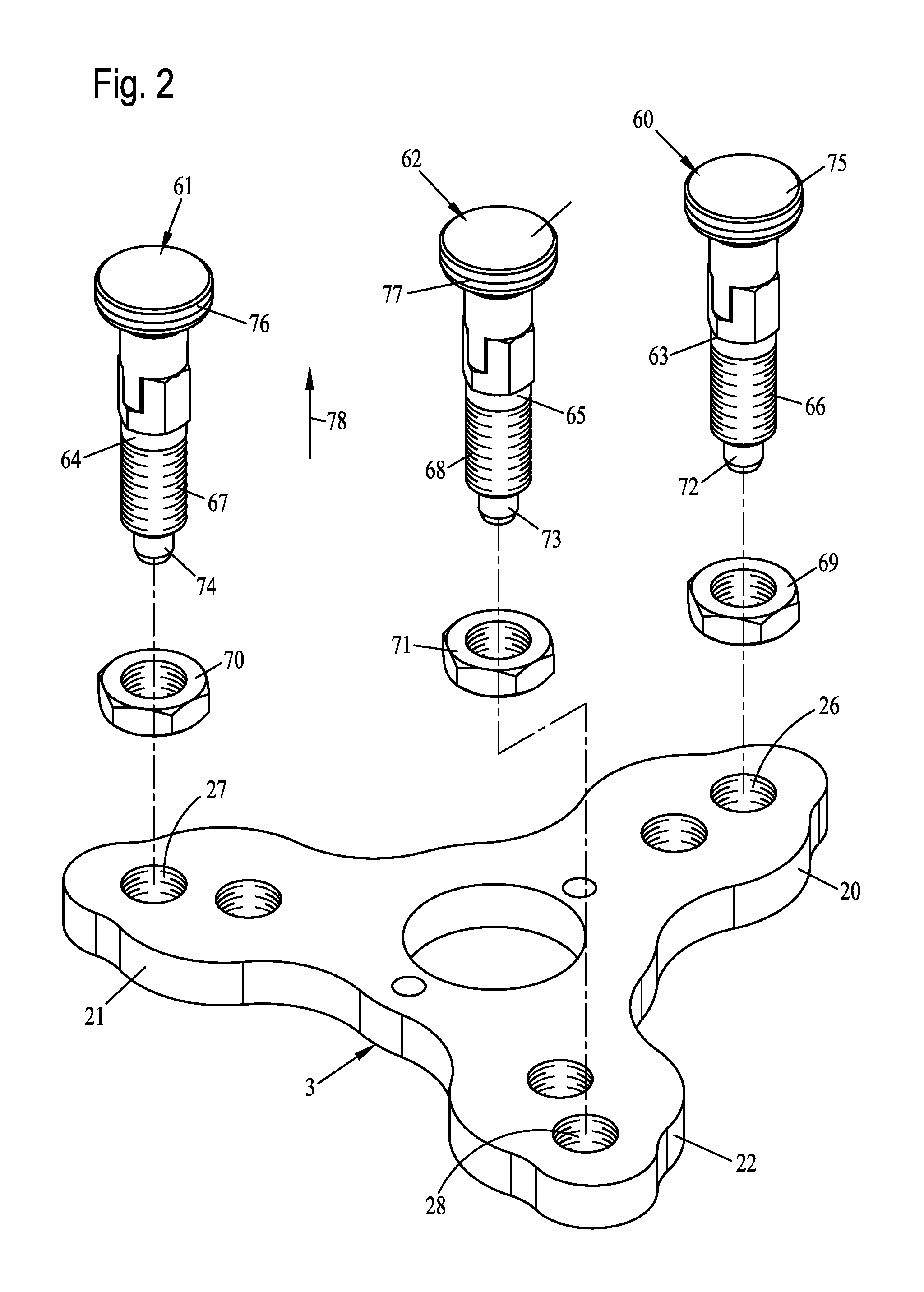

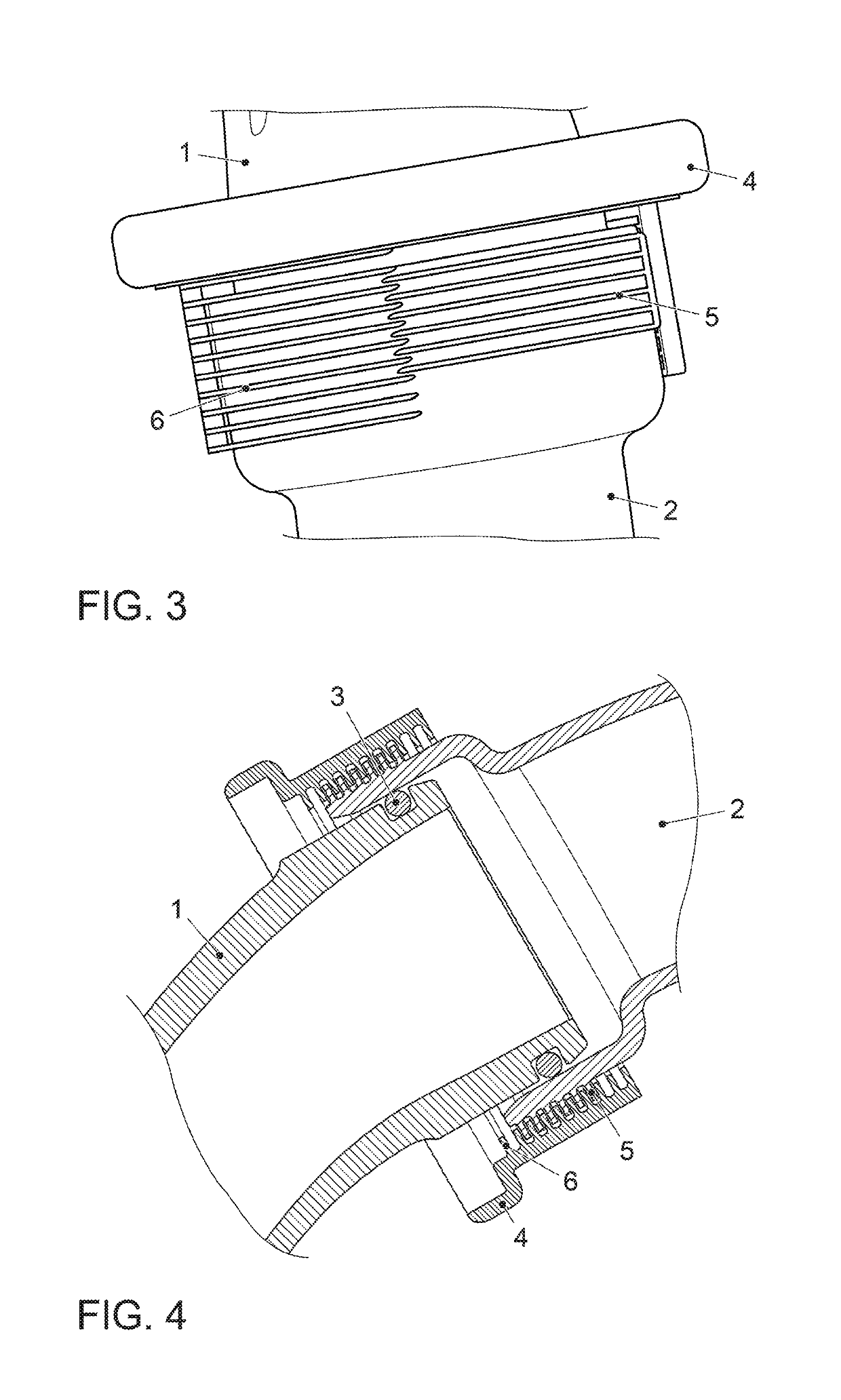

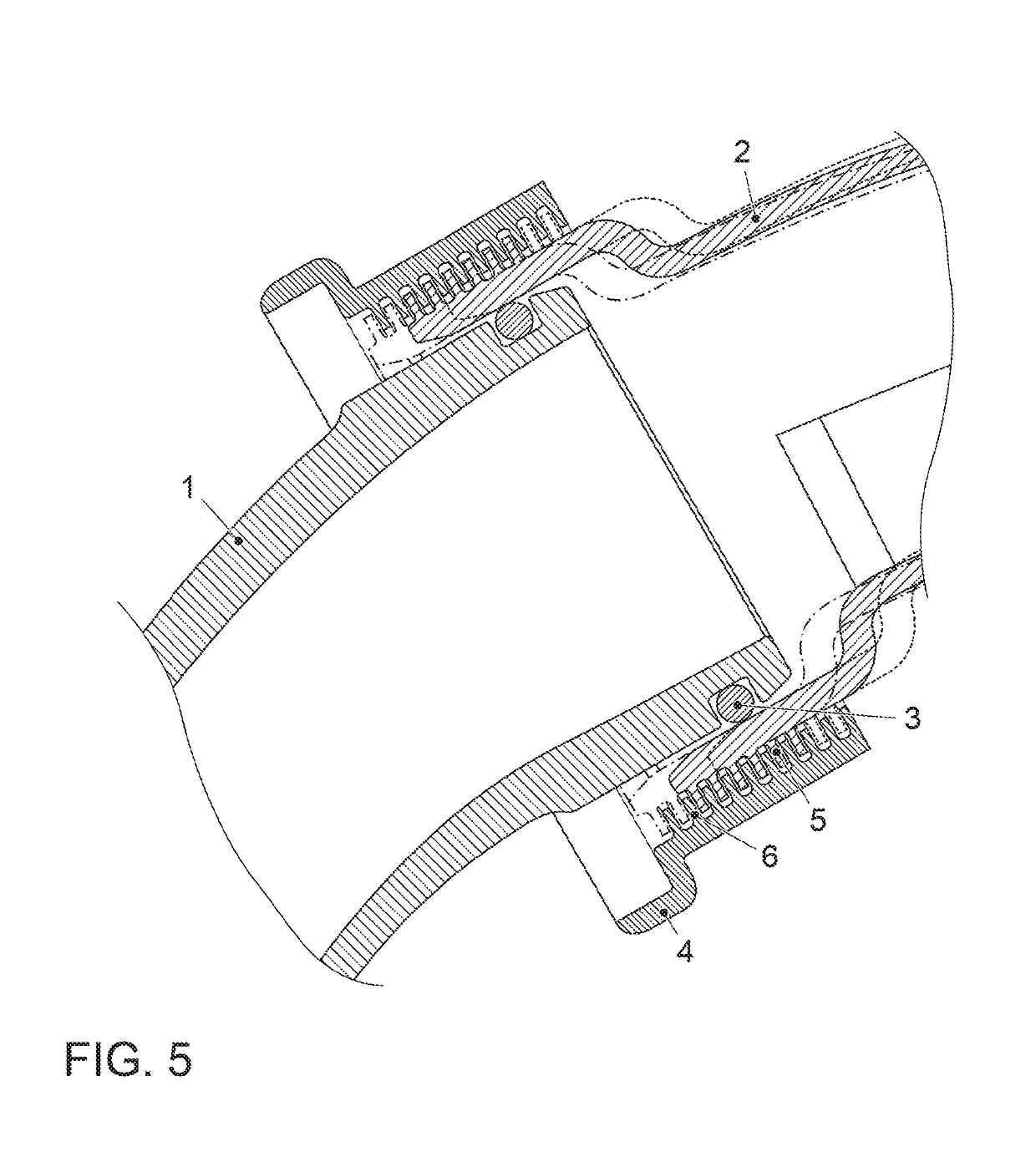

Device for pressing on a double clutch

InactiveUS20120036689A1Easy manufacturabilityHigh inherent stabilityMetal working apparatusMetal-working hand toolsDrive shaftEngineering

A device for pressing a double clutch (130) onto a transmission shaft arranged in a clutch housing (127) of a gearbox. The device is used for different embodiments of the clutch housing (127) of the double clutch transmission. The device includes a plurality of tie bolts (126, 126 / 1), stationarily connectable to the clutch housing (127), a pressing device (100), which is provided with an axially adjustable pressing rod (101) and can be brought into pressing connection with the double clutch (130) and a support device (1) connecting the tie bolts (126, 126 / 1) to the pressing rod. The support device (1) has a central mounting element (2, 3, 4), in which the pressing device (100) is mounted. The support device (1) has a plurality of support arms (5, 6, 7), which each mesh with one of the tie bolts (126, 126 / 1). The support arms (5, 6, 7) are mounted at the mounting element (2, 3, 4) about a pivot axis in parallel to the pressing rod (101) for the alignment of the pressing device (100) with the transmission shaft.

Owner:KLANN SPEZIAL WERKZEUGBAU

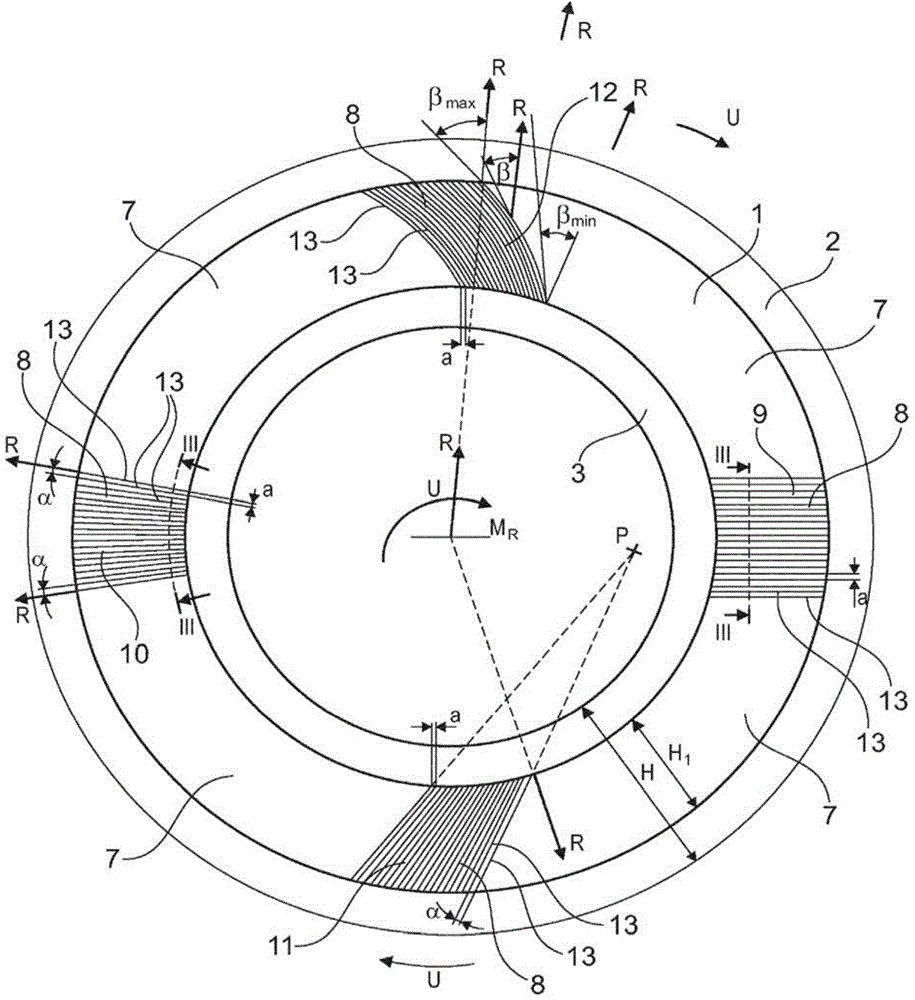

Pneumatic vehicle tyre

Vehicle tyre - in particular pneumatic vehicle tyre - with a profiled tread (2) and two side walls (1), wherein a hatched pattern composed of multiple linear protrusions (13) is formed on at least one side wall (1), which protrusions (13) can be assigned to a set of curves (9, 10, 11, 12) and do not intersect within the surface region (8) of the side wall (1) which is formed with the hatched pattern, wherein the linear protrusions (13) are each formed along their extent with an extent height of h < 0.8 mm measured perpendicularly with respect to the lateral surface contour of the side wall (1), wherein the linear protrusions (13) are each formed with a sectional contour in the cross-sectional planes perpendicular to the main direction of extent of the linear protrusion (13), which sectional contour is formed with a contour profile which is curved towards the interior of the tyre, at least in the outer part of the extent which is formed between the extent height (h / 2) and the extent height h of the linear protrusion (13) and which is formed in such a way that it points away from the tyre, and said sectional contour being formed with an apex point S of the protrusion (13) which is formed in the extent height h.

Owner:CONTINENTAL REIFEN DEUTSCHLAND GMBH

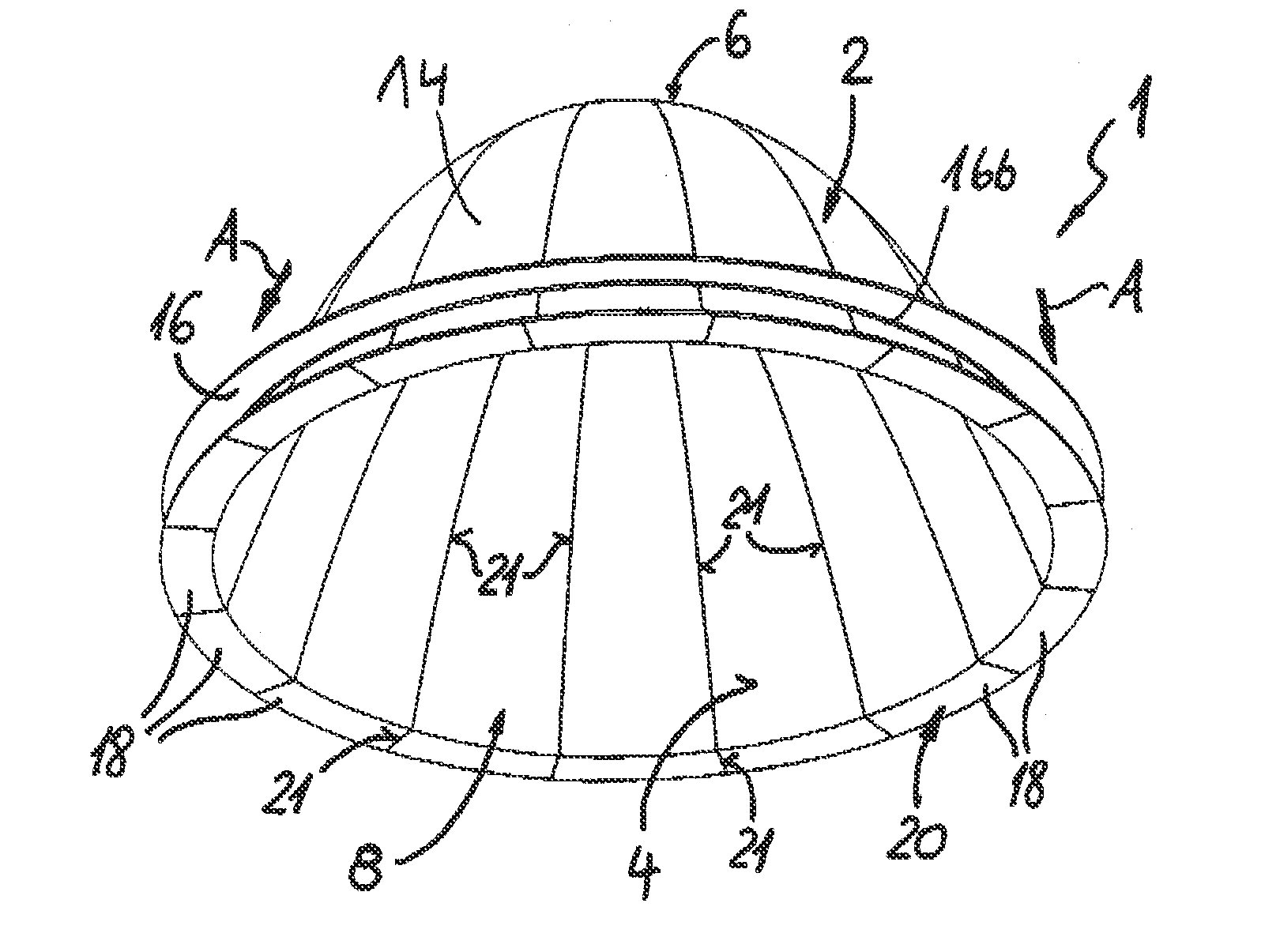

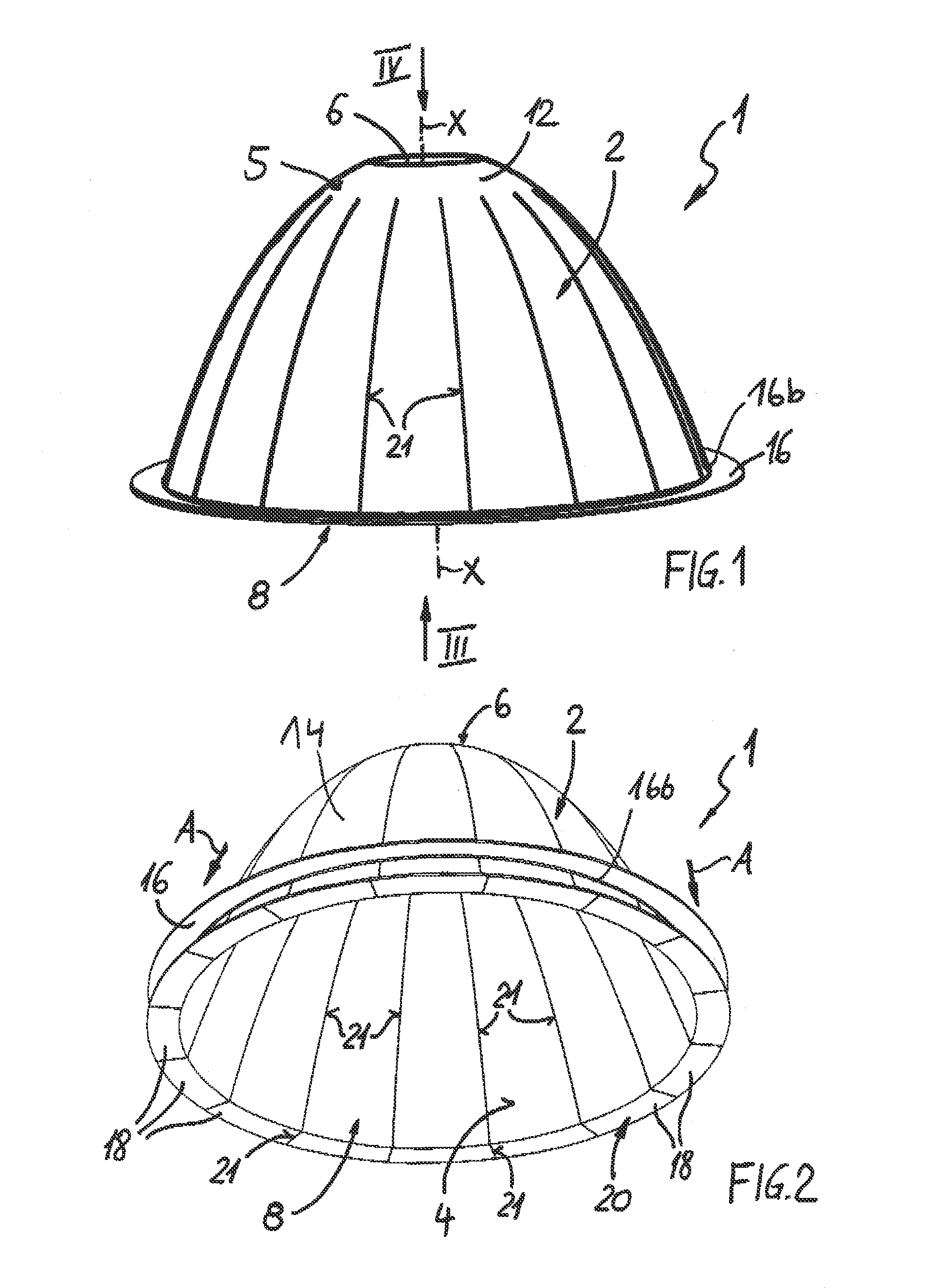

Lamp reflector

A lamp reflector having a reflector body enclosing an inner space, whose peripheral wall forms a lateral surface of a geometrical body with a longitudinal axis. The reflector body has a light exit opening and a base section opposite thereto. The peripheral wall is formed by a wall section forming the base section, and, extending therefrom in the direction of the light exit opening, by circumferential adjacent segments that are separated by slots. The segments are secured to the perimeter of the reflector body via a holding ring that encloses it. On their free ends, the segments have outward angled flange sections that jointly form a circumferential flange rim. In its mounting position, the holding ring is adjacent to the flange rim and is at least force-fitted to the flange rim.

Owner:JORDAN REFLEKTOREN

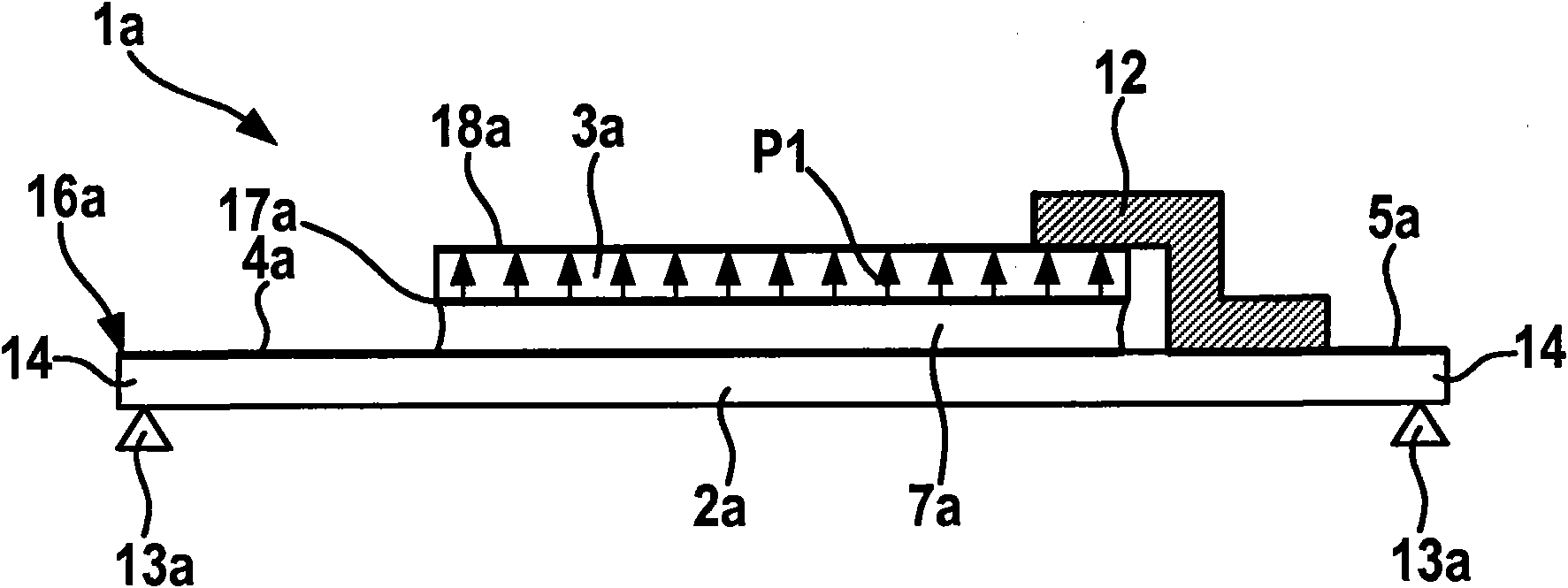

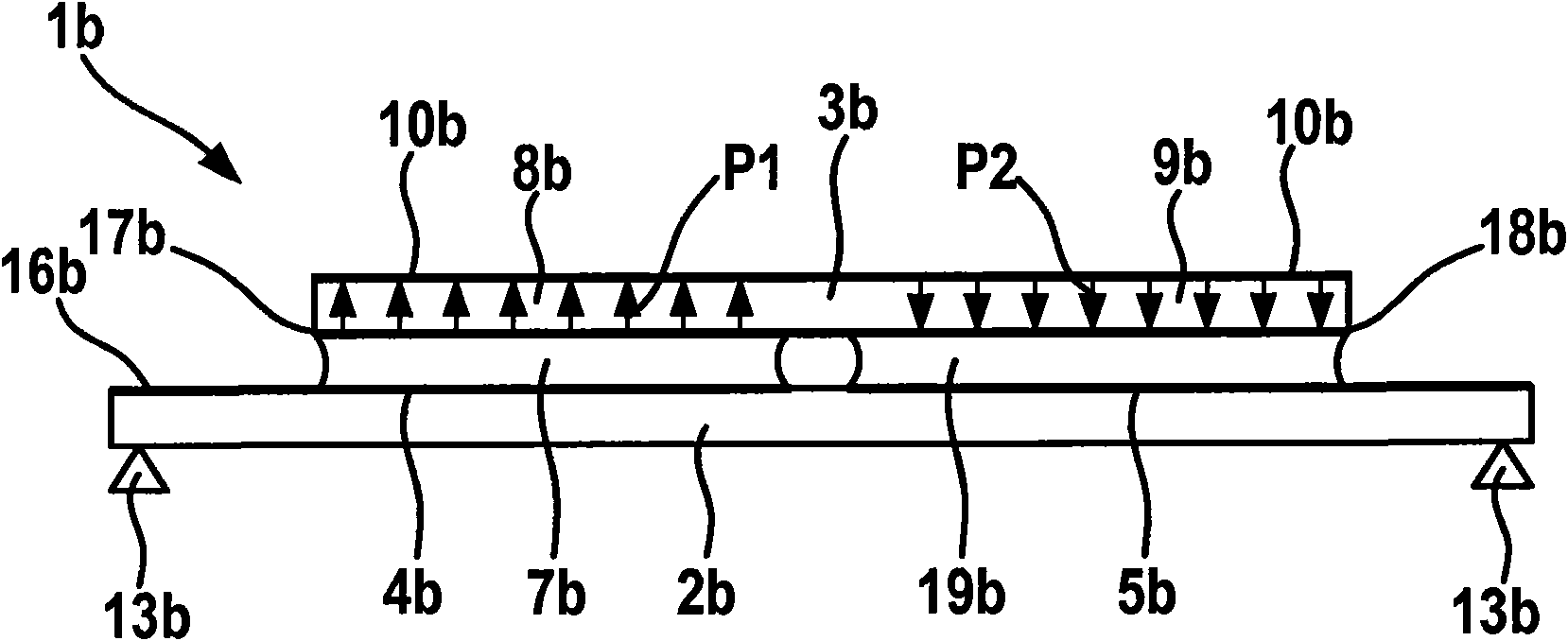

Bender transducer for generating electrical energy from mechanical deformations

ActiveCN101990717AReduce exposureEasy manufacturabilityPiezoelectric/electrostriction/magnetostriction machinesTyre measurementsElectricityTransducer

The invention relates to a bender transducer (1b) for generating electrical energy from mechanical deformations, said bender transducer comprising: a deformable support device (2b) on which a first connecting electrode (4b) and a second connecting electrode (5b) are configured, a piezoelectric element (3b) having at least one first electrode (17b) and a second electrode (18b) and being fastened to the support device (2b), the first connecting electrode (4b) being contacted with the first electrode (17b) of the piezoelectric element (3b) and the second connecting electrode (5b) with the second electrode (18b) of the piezoelectric element (3b). The first connecting electrode (4b) and / or the second connecting electrode (5b) is applied to the support device (2b) as a structured, conductive layer in at least some sections thereof. In particular, the two connecting electrodes (4b, 5b) can be configured as sections of a common layer. The invention further relates to a circuit module having a self-sufficient energy supply and a bender transducer of the above type.

Owner:ROBERT BOSCH GMBH

Manufacturing method for high temperature fiber optic accelerometer

ActiveUS20050016272A1Simple manufacturabilityFacilitate manufacturingAcceleration measurement using interia forcesOptical fibre with multilayer core/claddingCircular discAccelerometer

A method of making a fiber optic accelerometer includes (a) drawing an optical fiber through a resin; (b) winding the resin coated fiber onto a disc mounted on an assembly having a central shaft; and (c) curing the resin-coated fiber. The optical fiber may be drawn through a resin by providing a container filled with a resin having an orifice therethrough and drawing the fiber through the orifice. The resin may be cured such that the fiber is bonded to the disc by curing the resin to the fiber and the disc at the same time.

Owner:SCHLUMBERGER TECH CORP

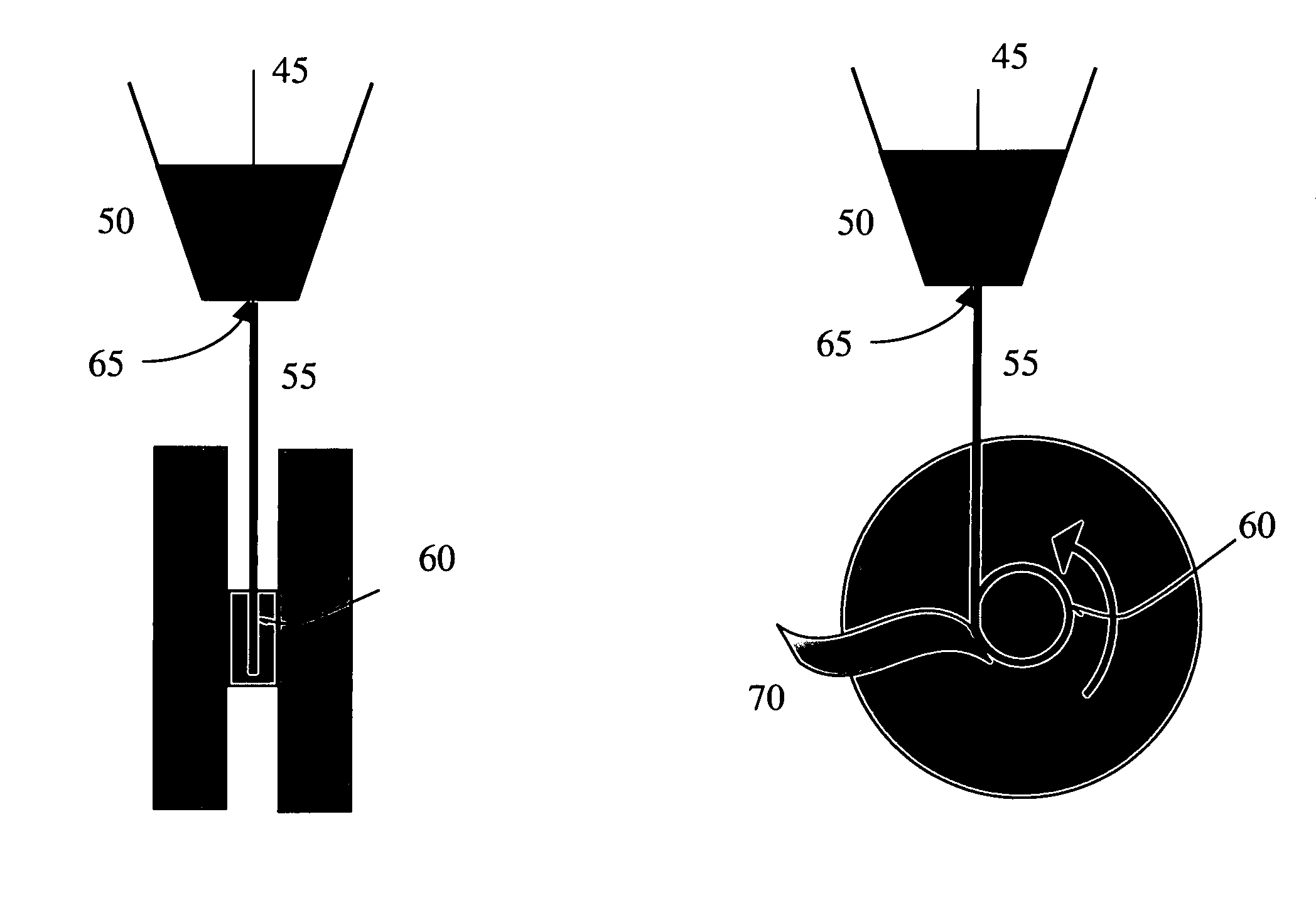

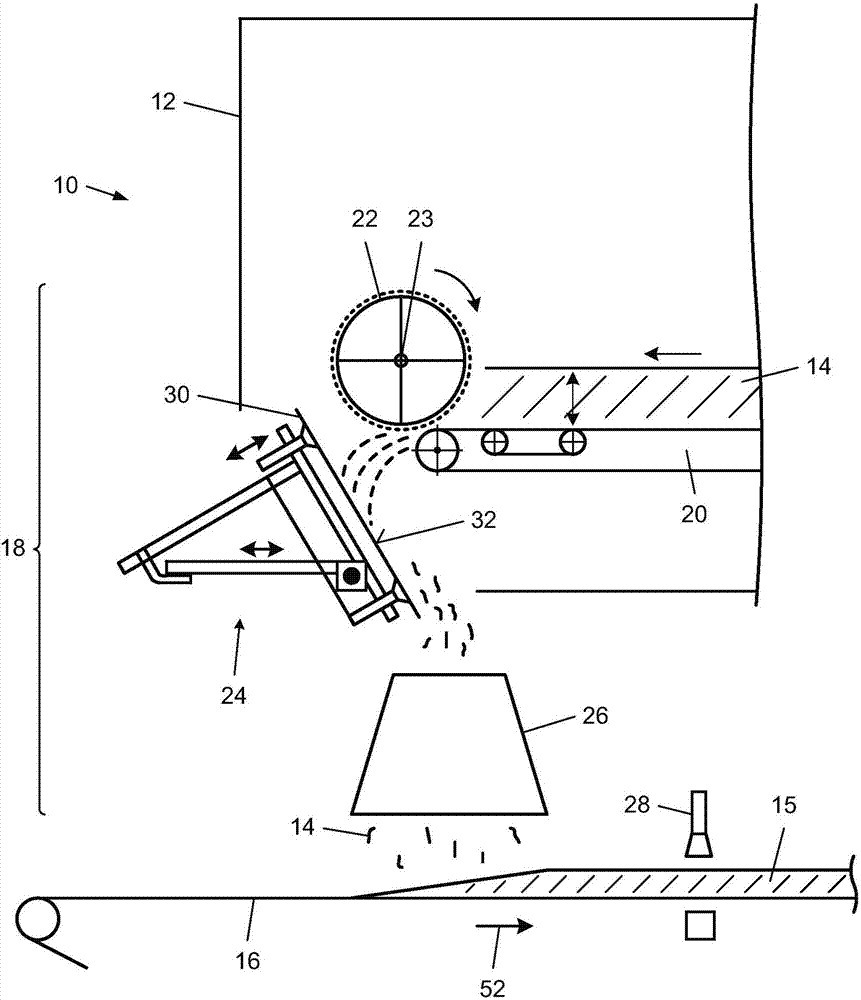

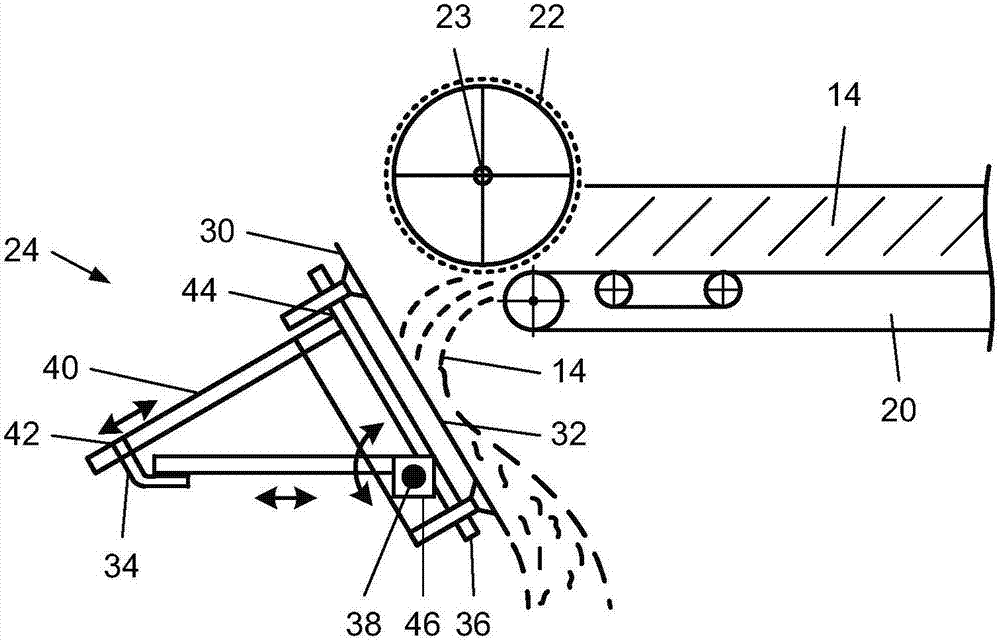

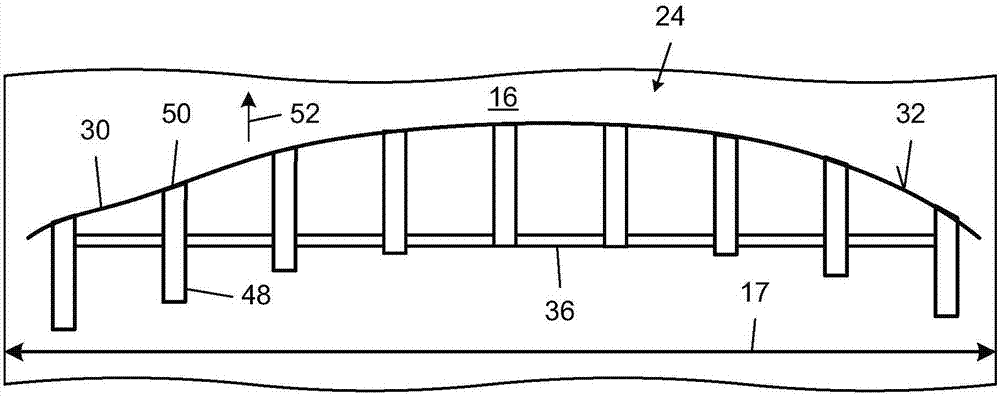

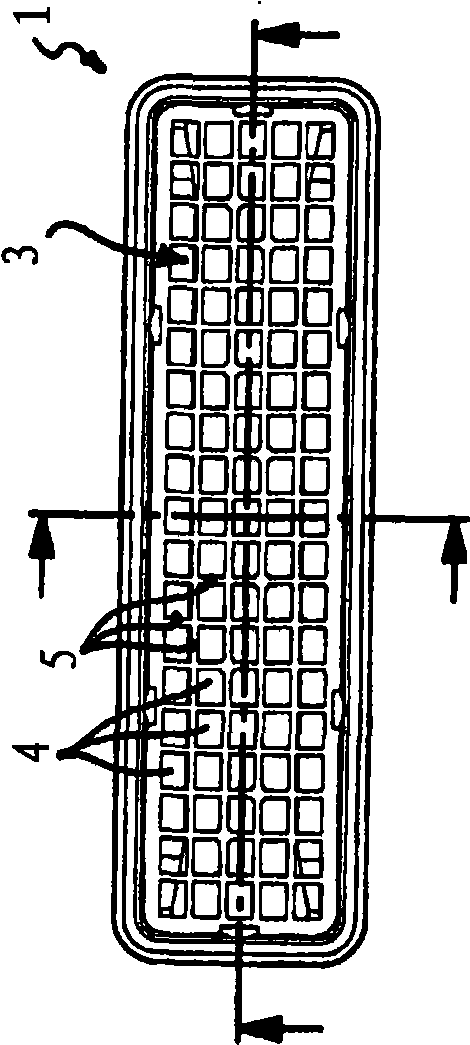

Distributing Apparatus And Method For Supplying Particulate Material Continuously To A Forming Belt

InactiveCN107443539AQuality improvementTilt change or adjustmentDomestic articlesFlat articlesEngineeringMechanical engineering

The invention relates to a spreading device (18) for continuously applying spread material (14) to an endless forming belt (16), comprising: for discharging the spread material from a spread material silo (12) The discharge roller (22); and the guide device (24) arranged between the discharge roller (22) and the forming belt (16) to further convey the unloaded spread material (14), wherein the guide device (24) It is configured to be adjustable in order to influence the spreading accuracy and / or the lateral distribution of the discharged spread (14) across the width (17) of the forming belt (16). The invention also relates to a method for continuously applying a spread material (14) to an endless forming belt (16) and a structure (10) for continuously producing material sheets. With the above devices, methods and structures, it may be possible to compensate for constant errors in the spread.

Owner:DIEFFENBACHER GMBH & CO KG

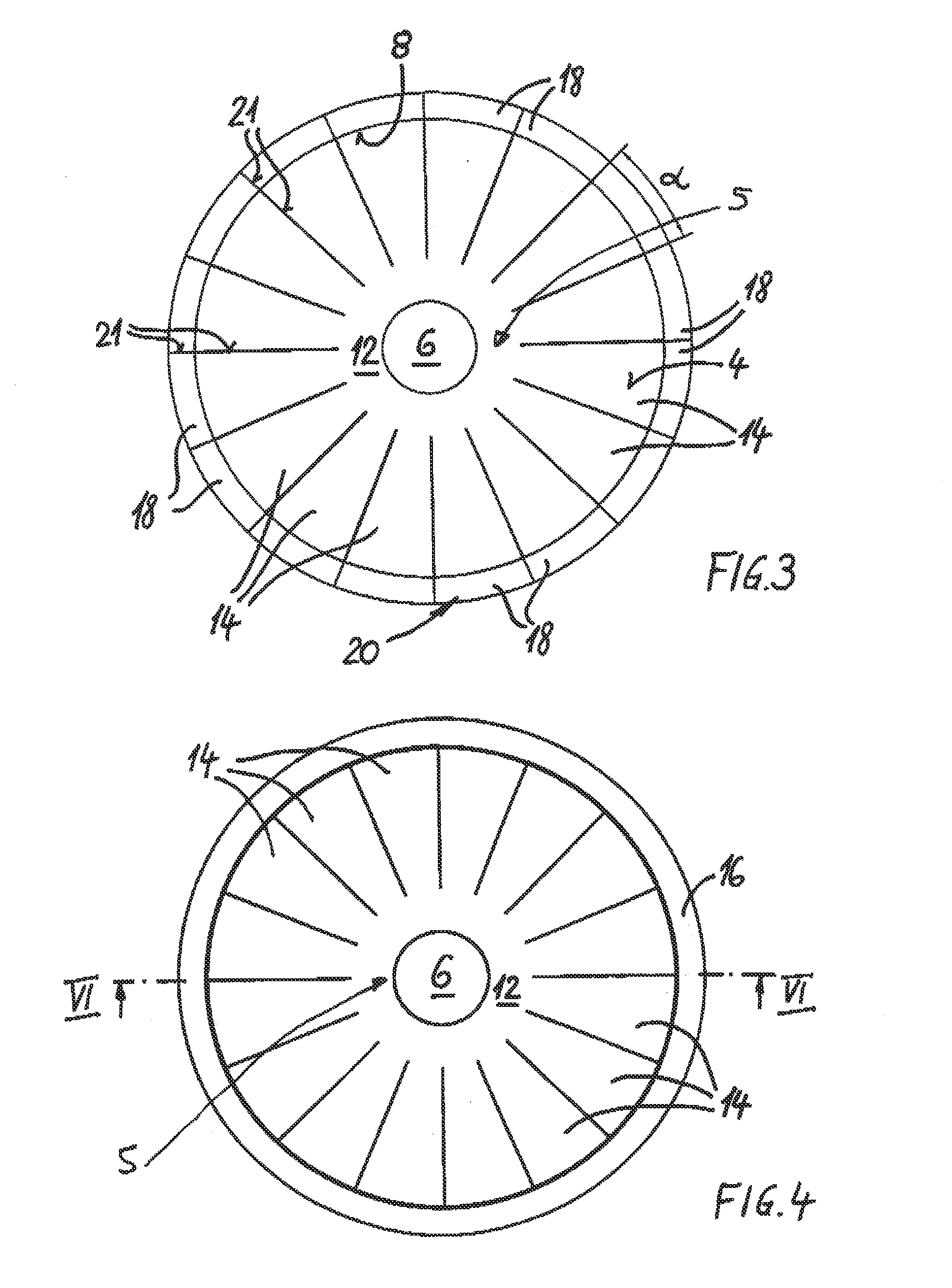

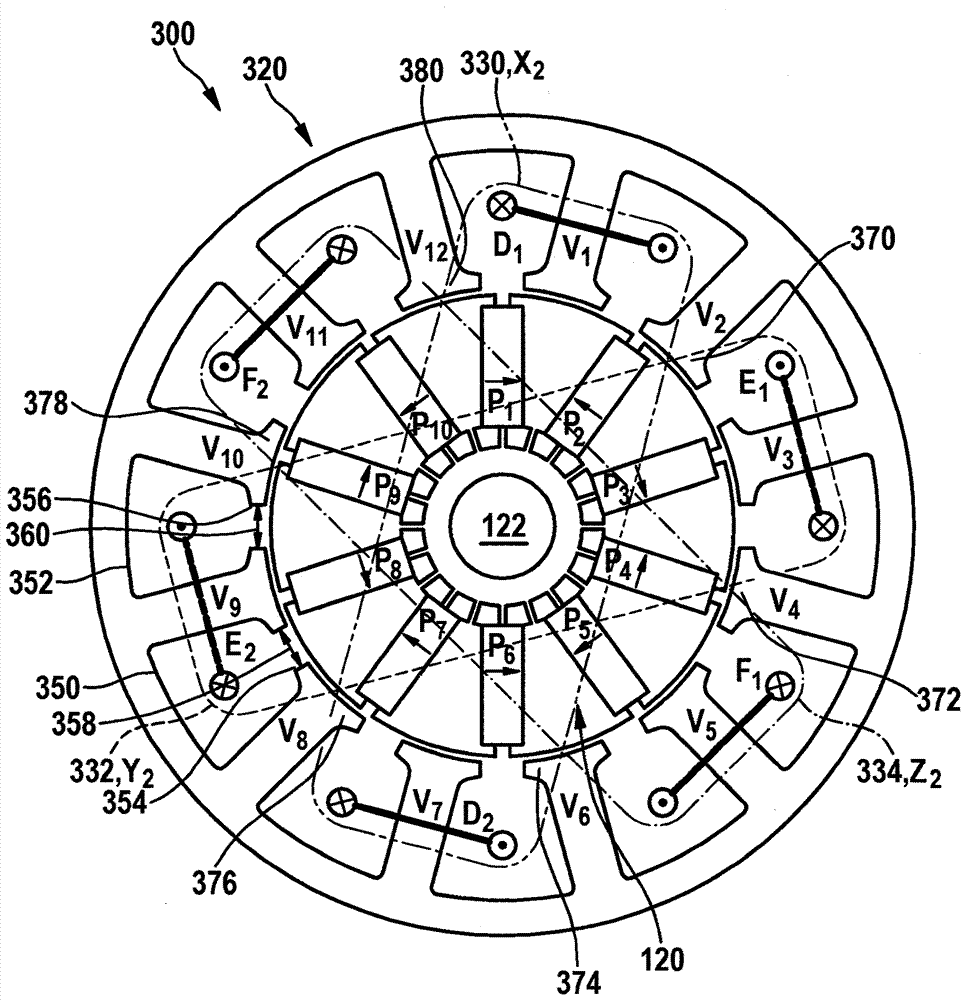

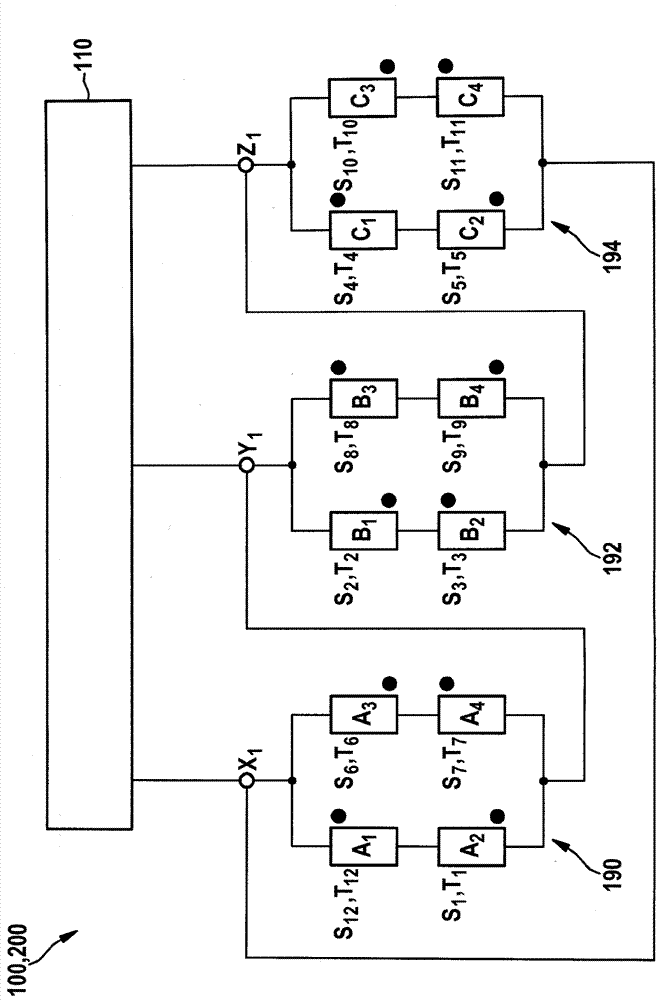

An electric motor for driving an ABB system

InactiveCN107887988AImprove efficiencySmall magnetic detent torqueMagnetic circuit rotating partsMagnetic circuit stationary partsMagnetic fluxSpoke

The invention relates to an electric motor (100) for driving an ABB system in a motor vehicle. The electric motor comprises a permanently-excited inner rotor (120) and an outer stator (150). The outerstator (150) has at least twelve stator teeth (S1-12). The inner rotor (12) has poles (P1-10) with a preset number, which are spaced from one another uniformly on the circumferential side. The numberof the poles is corresponding to a number obtained by subtracting integer multiples of two from the number of the stator teeth (S1-12) and the poles (P1-10) which are spaced from one another uniformly on the circumferential side are constructed like spokes for concentrating corresponding magnetic flux.

Owner:ROBERT BOSCH GMBH

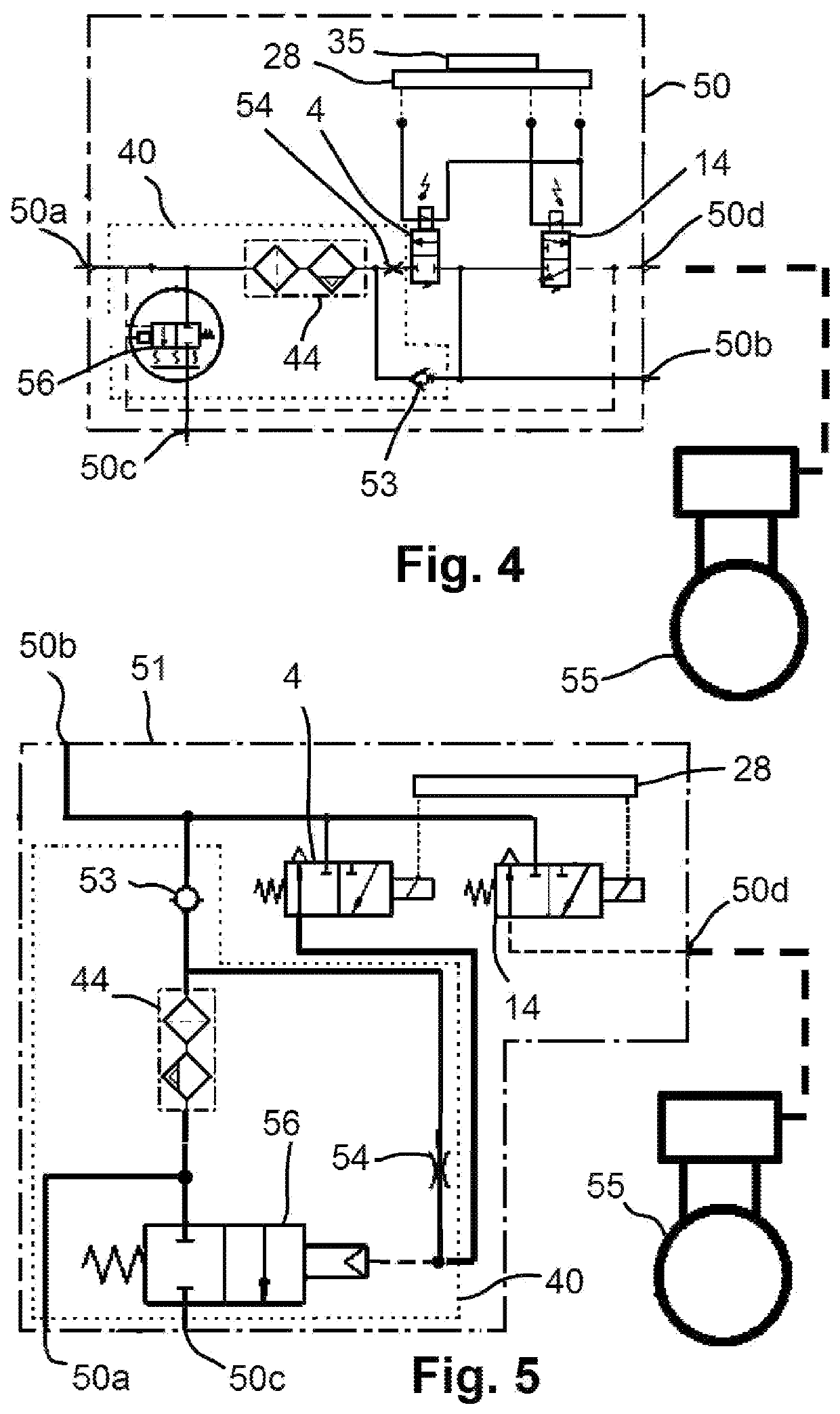

Control module of an air treatment system of a utility vehicle

PendingUS20210323529A1Undesired leakageReliable preventionServomotor componentsServometer circuitsPlastic materialsAir treatment

A control module for an air treatment system of a utility vehicle comprises the following: a first and second pneumatic magnetic valve having a first or second coil, connecting pins, and armatures accommodated in the coils, a circuit carrier, and a module housing that is cast from a plastic material, into which housing the coils are cast. The connecting pins project from a first side of the module housing and are electrically connected to the circuit carrier. A plug-in connection for receiving a connection plug is formed in the module housing, wherein the plug-in connection has plug-in pins, which extend through the module housing and are electrically connected to the circuit carrier. The module housing has a mounting surface having pneumatic connections for installation on an air dryer housing of an air dryer.

Owner:WABCO GMBH

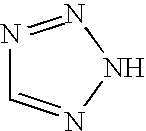

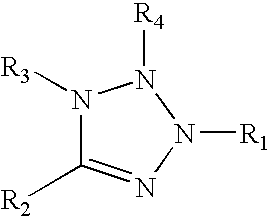

Class of charge-actuated chromogenic structures based on the oxidation and reduction of optical switchable materials in a thin-film electrochemical cell

InactiveUS20040084661A1Easy to manufactureLow costNon-linear opticsOptical elementsElectrical batteryChromogenic

An electrochemically-activated optical switch is provided, comprising a molecular system configured between a pair of electrodes. The molecular system includes a moiety that is oxidizable or reducible in the presence of an electric current.

Owner:HEWLETT PACKARD DEV CO LP

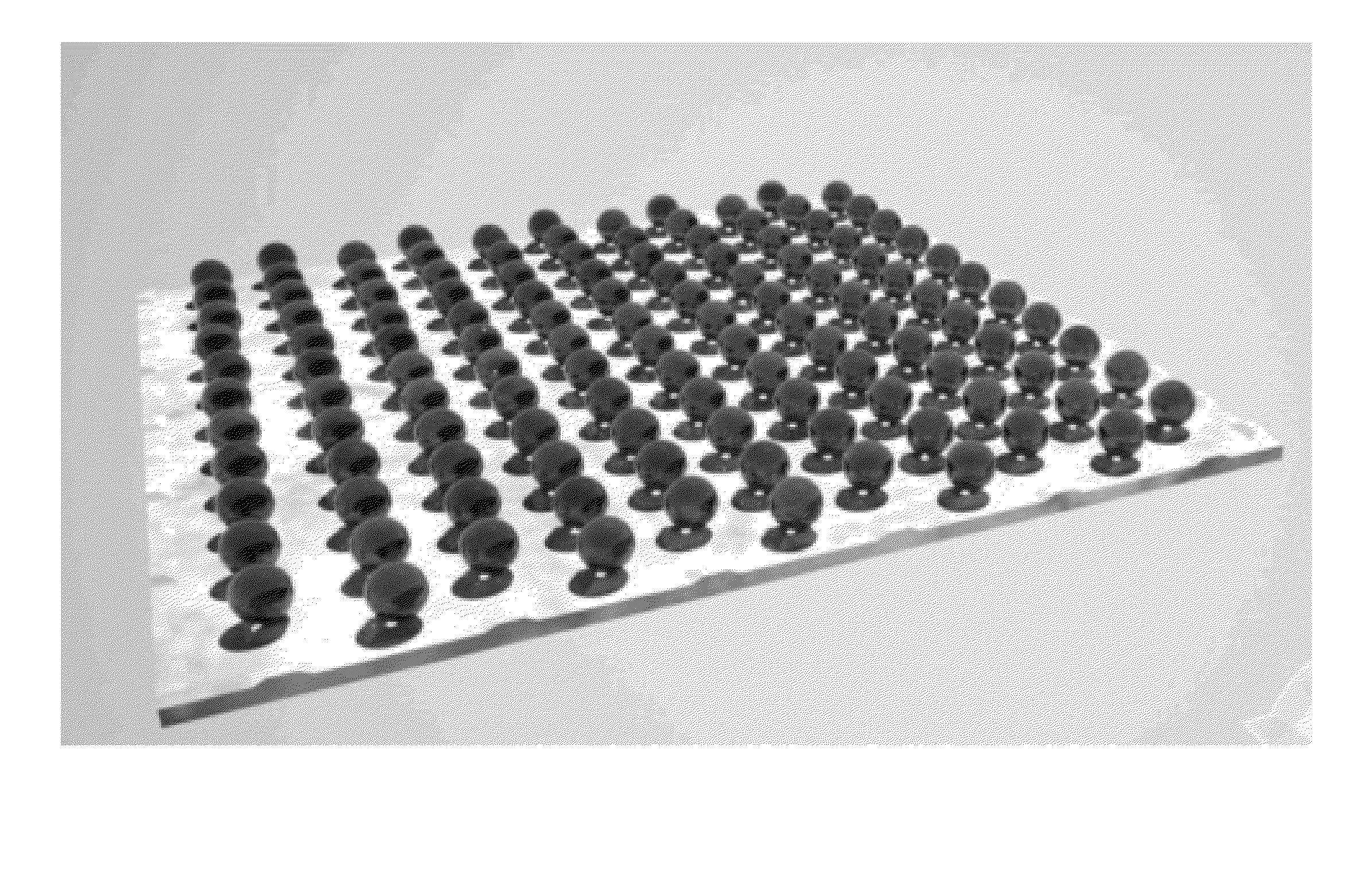

Photodetector focal plane array systems and methods

ActiveUS20160190194A1Improve efficiencyHigh frequency responseSolid-state devicesSemiconductor/solid-state device manufacturingPhotovoltaic detectorsSemiconductor materials

A photodetector focal plane array system, comprising: a substrate comprising a plurality of photosensitive regions; and a microcomponent disposed adjacent to each of the plurality of photosensitive regions operable for receiving incident radiation and directing a photonic nanojet into the associated photosensitive region. Optionally, each of the microcomponents comprises one of a microsphere and a microcylinder. Each of the microcomponents has a diameter of between ˜λ and ˜100λ, where λ is the wavelength of the incident radiation. Each of the microcomponents is manufactured from a dielectric or semiconductor material. Each of the microcomponents has an index of refraction of between ˜1.4 and ˜3.5. Optionally, high-index components can be embedded in a lower index material. The microcomponents form an array of microcomponents disposed adjacent to the substrate.

Owner:THE UNIV OF NORTH CAROLINA AT CHAPEL HILL +1

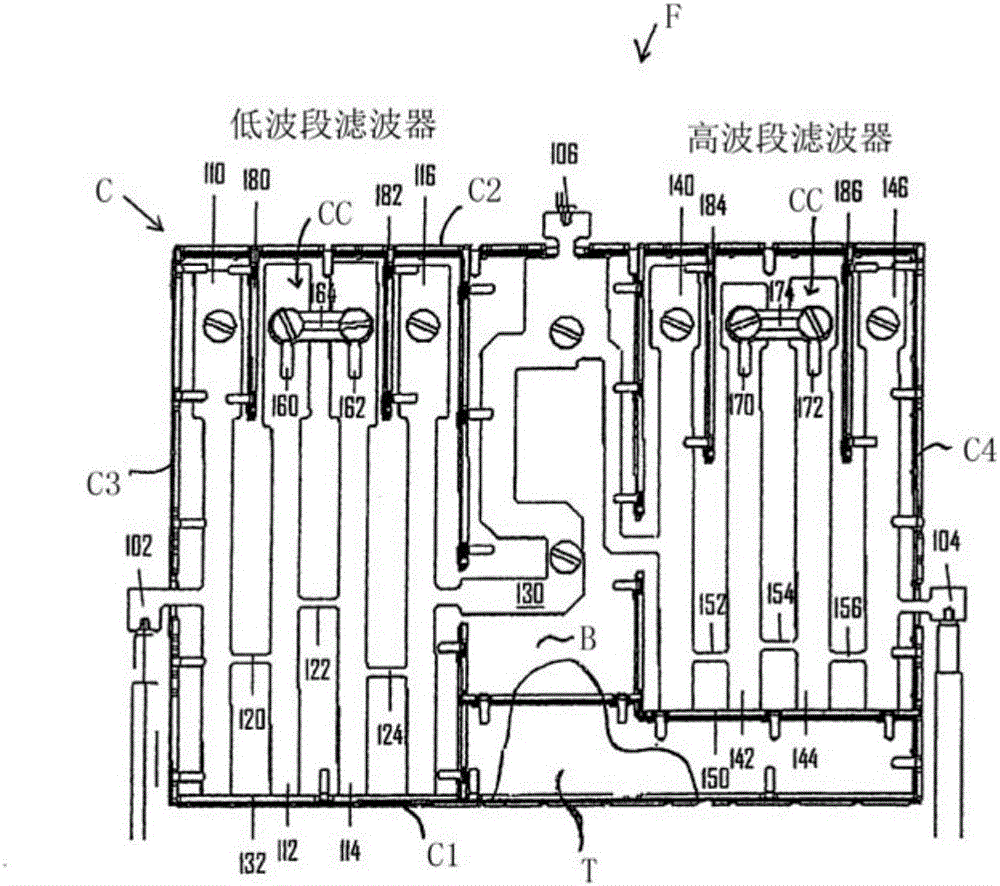

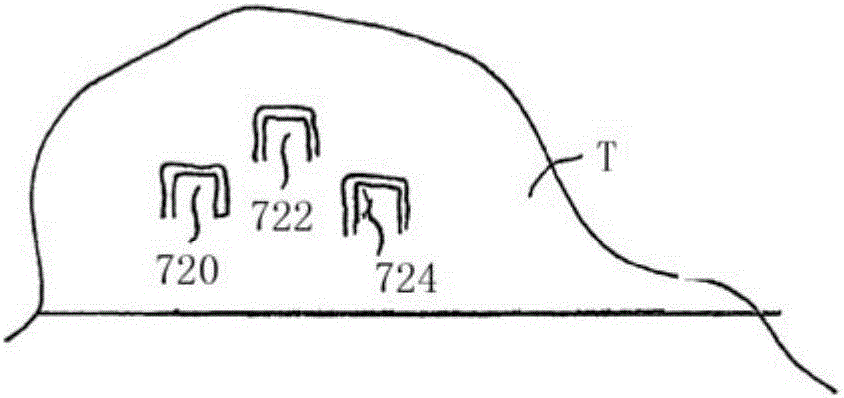

RF filter

ActiveCN106463806AFirmly connectedHigh degree of integrationResonatorsWaveguidesEngineeringRf filters

The invention relates to an RF filter, particularly a stripline type RF filter, comprising a casing (C) and two or more strip-conductor-type resonators (110, 112, 114, 1 16 and 140, 142, 144, 146) in the casing. At a distance from the ends of the resonator, between the resonator sides, there are one or more coupling lines (120, 122, 124 and 152, 154, 156) forming an integral piece with the resonators.

Owner:PRISM MICROWAVE

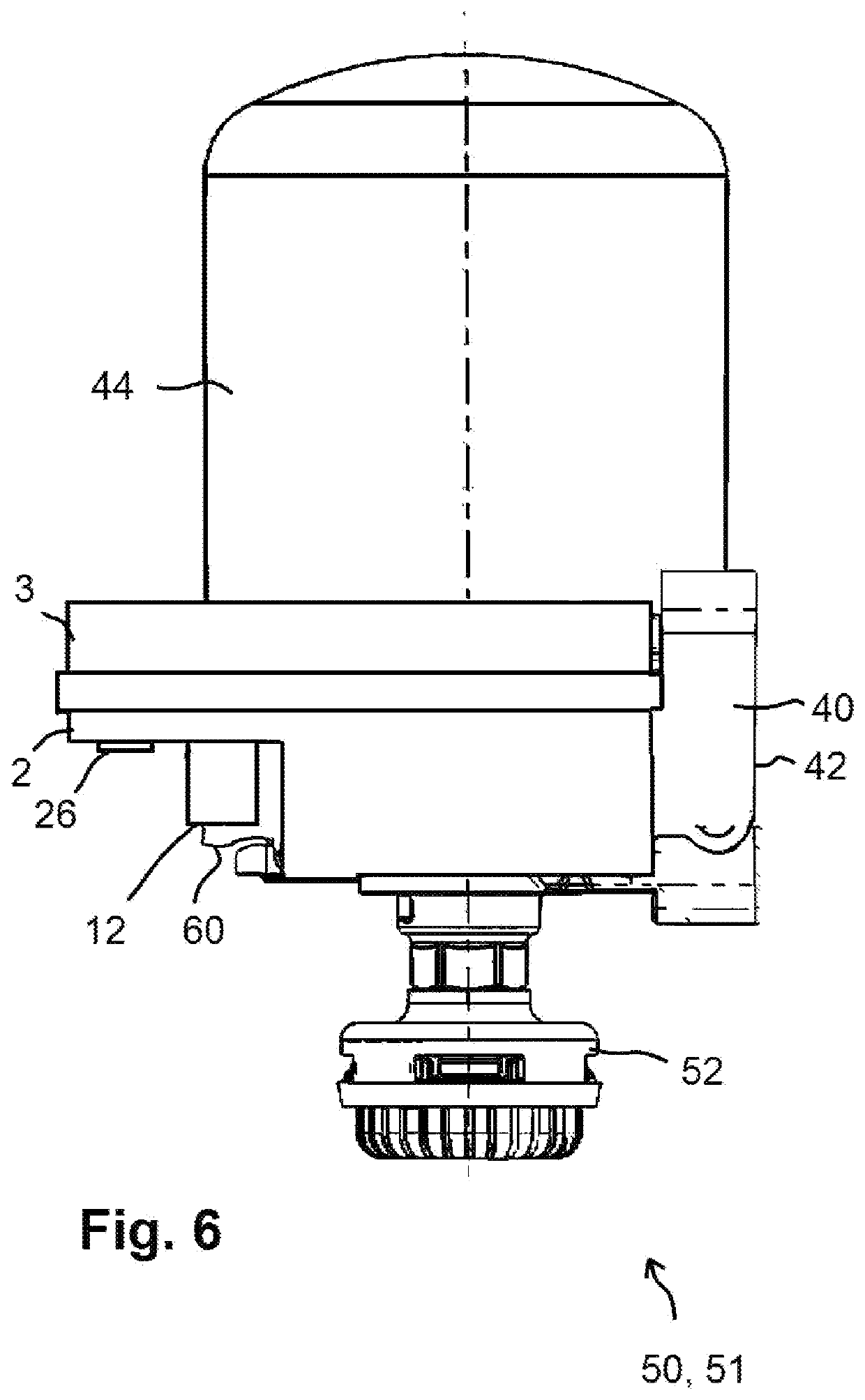

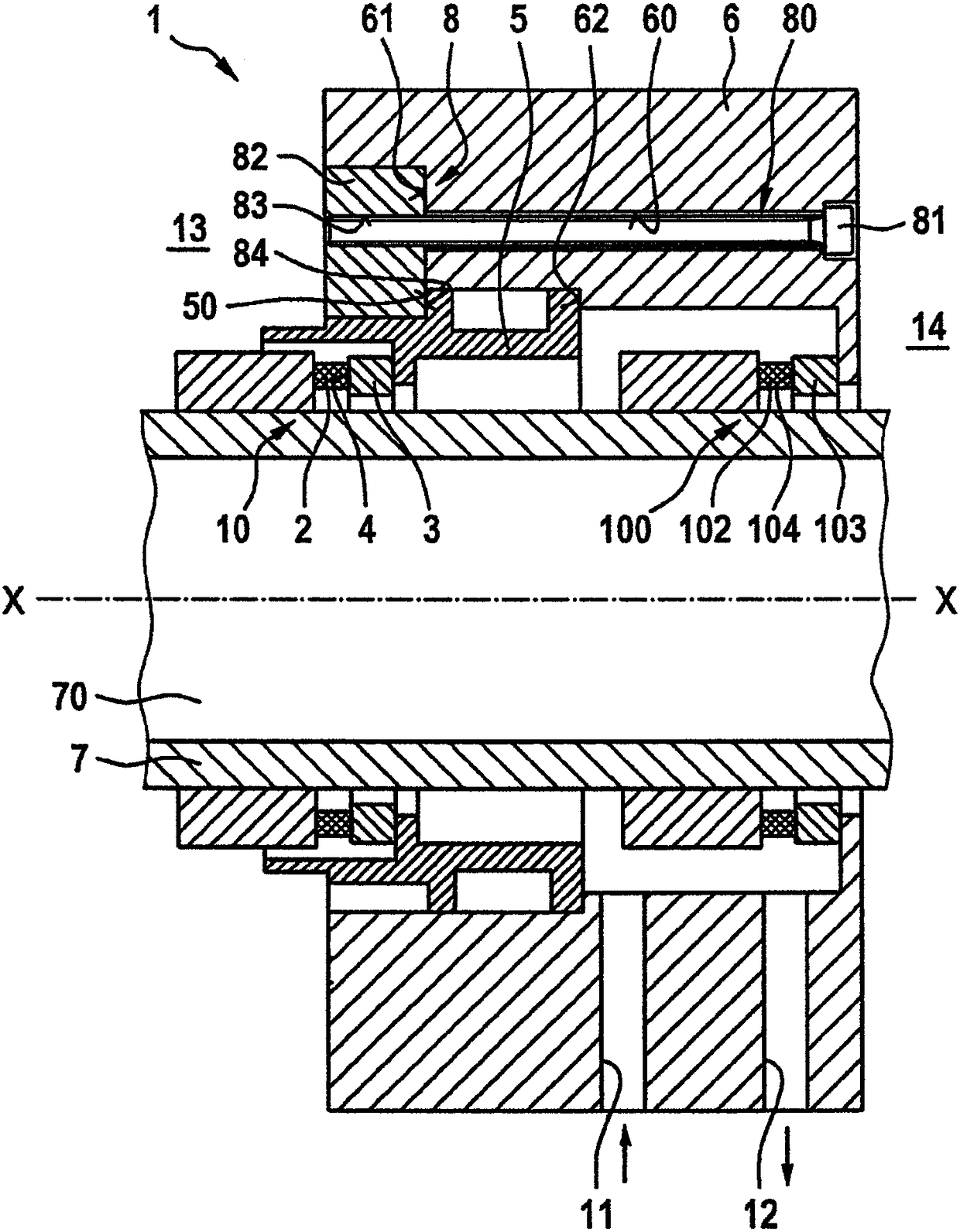

Mechanical sealing arrangement with a simplified structure

The invention relates to a slip ring sealing arrangement (1) comprising a rotating slip ring (2) and a stationary slip ring (3) which define a sealing gap (4) thereinbetween, a holding ring (5) for holding the stationary slip ring (3), a housing (6) with one side oriented towards a product side (13) and one side oriented towards an atmosphere side (14), and a clamping device (8), wherein a clamping connection is embodied between the housing (6) and the holding ring (5) by means of the clamping device (8), and the housing (6) has at least one through-opening (60) which connects the side of thehousing oriented towards the product side (13) to the side of the housing oriented towards the atmosphere side (14), the clamping device (8) comprising a screwed bolt (80) and a clamping element (82),the screwed bolt (80) being arranged in the through-opening (60) of the housing (6), and the clamping element (82) comprising a threaded opening (83) in which the screwed bolt (80) is screwed, and wherein the clamping element (82) has a gripping surface (84) applied to the holding ring (5) in order to form the clamping connection.

Owner:EAGLEBURGMANN GERMANY GMBH &CO KG

Bayonet connection for connecting a connector to a tubular body, bayonet ring, and tubular body

ActiveUS20190203864A1Easy manufacturabilitySmooth rotationExhaust apparatusSilencing apparatusEngineering

Owner:VOLKSWAGEN AG

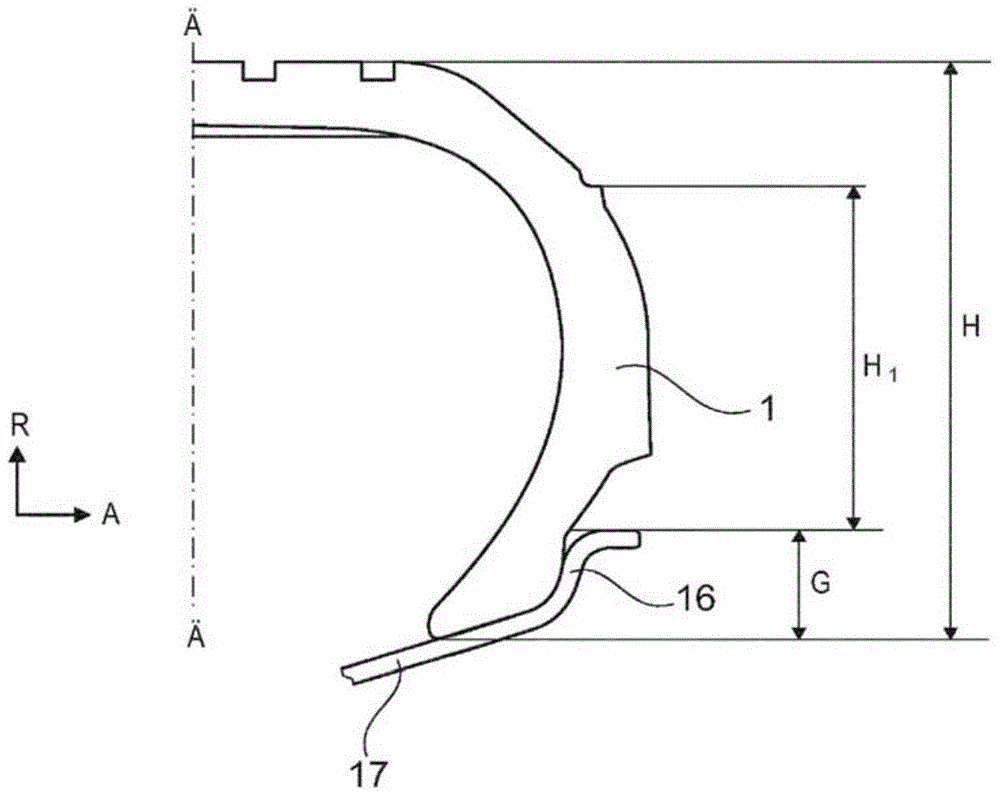

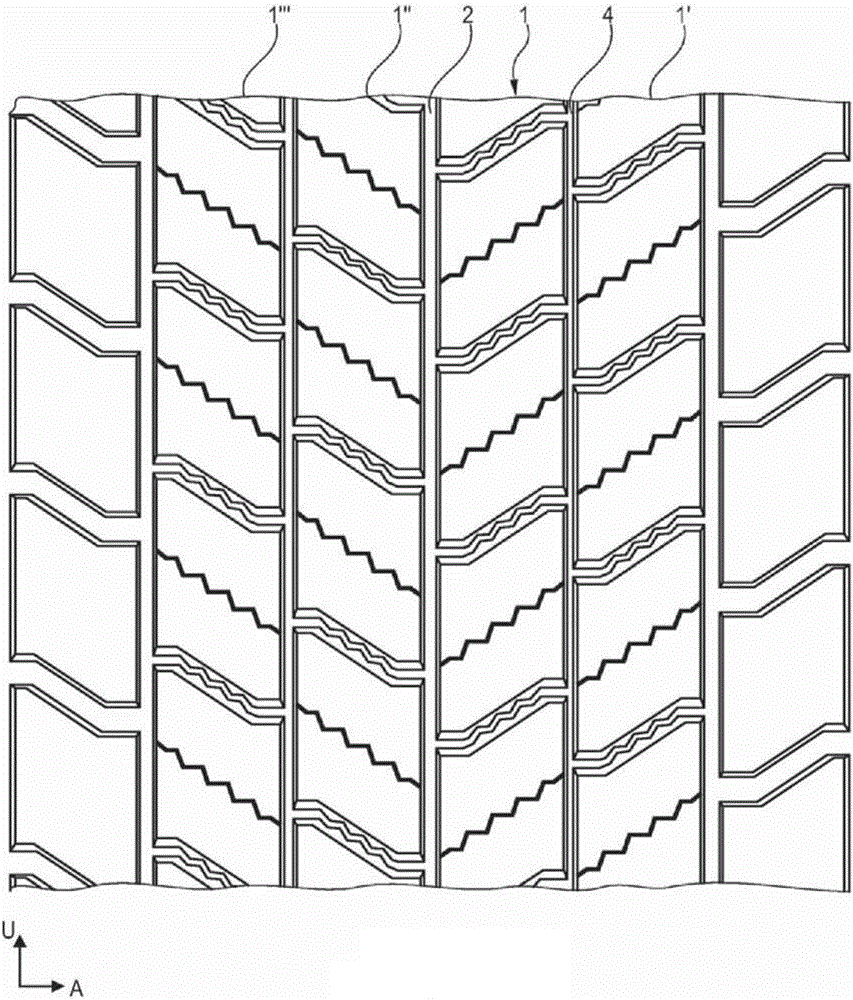

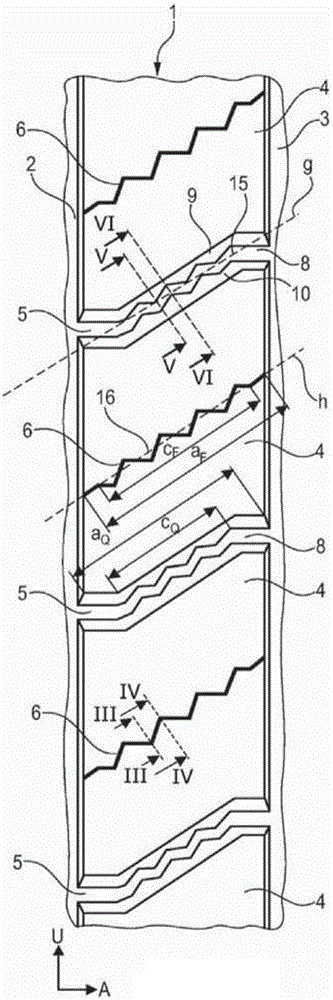

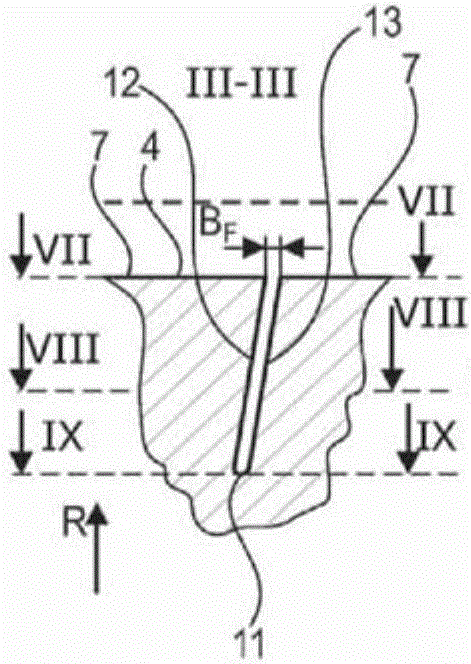

Pneumatic vehicle tire

ActiveCN106132730AGuaranteed gripReduce the risk of formationTyre tread bands/patternsGround contactTransverse groove

Tread profile of a pneumatic vehicle tire comprising at least one profile block sequence (1), which is delimited in the axial direction A of the tire by two circumferential grooves (2, 3) and is configured in the circumferential direction U of the tire from profile block elements (4) spaced apart from one another by transverse grooves (5), wherein the profile block elements (4) are delimited in the radial direction R by a radially outer surface (7) forming a ground contacting surface, wherein one profile element (4) is arranged between two transverse grooves (5) adjacent in the circumferential direction U, wherein a fine incision (6) is configured running transversely in the radial outer surface (7) of the profile block element (4), characterized in that both transverse grooves (5) have a zig-zag shape or an undulating shape from circumferential groove (2) to circumferential groove (3), at least in one section (CQ) of their extension, along their primary extension direction, wherein the amplitude AQ of the zig-zag or undulating shape has its maximum in the groove bottom (8) and, starting from the groove bottom (8) constantly decreases along the radial extension R towards the outside, and that at least one transversely running fine incision (6) of the profile block element (4) has a zig-zag shape or an undulating shape from circumferential groove (2) to circumferential groove (3) in at least one section (CF) of its extension along its primary extension direction, wherein the amplitude AF of the zig-zag or undulating shape has its maximum in the radial outer surface (7) and, starting from the radially outer surface (7), constantly decreases along the radial extension R towards the inside.

Owner:CONTINENTAL REIFEN DEUTSCHLAND GMBH

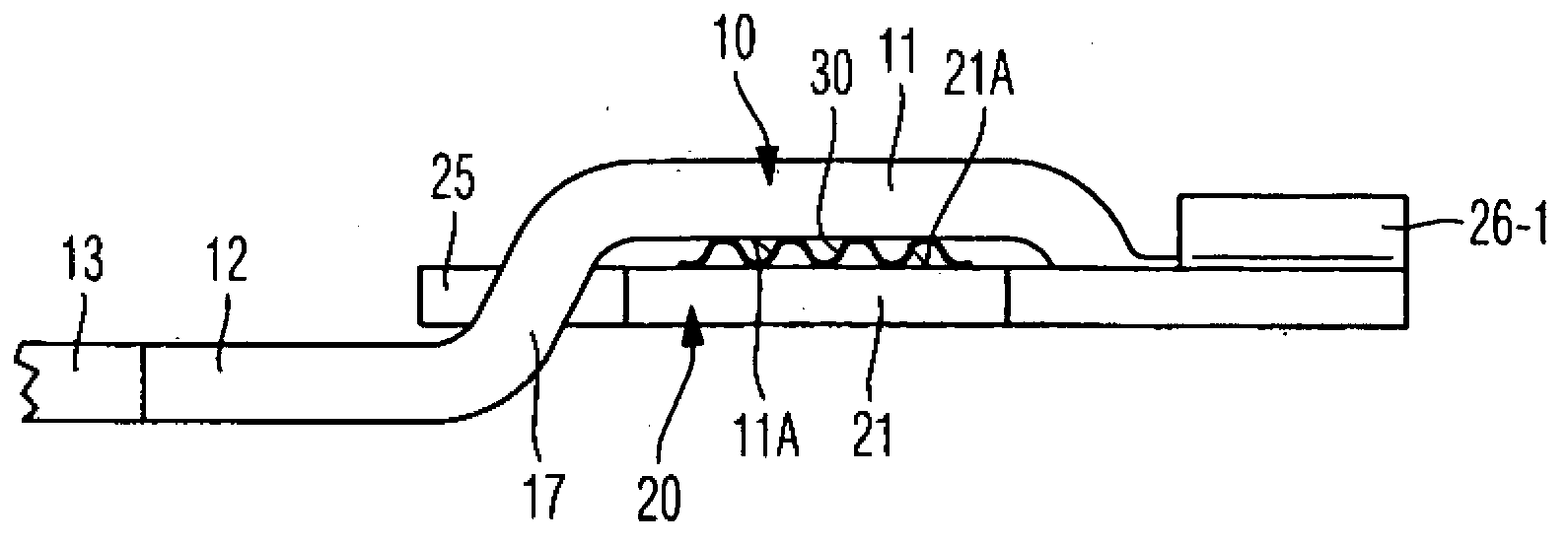

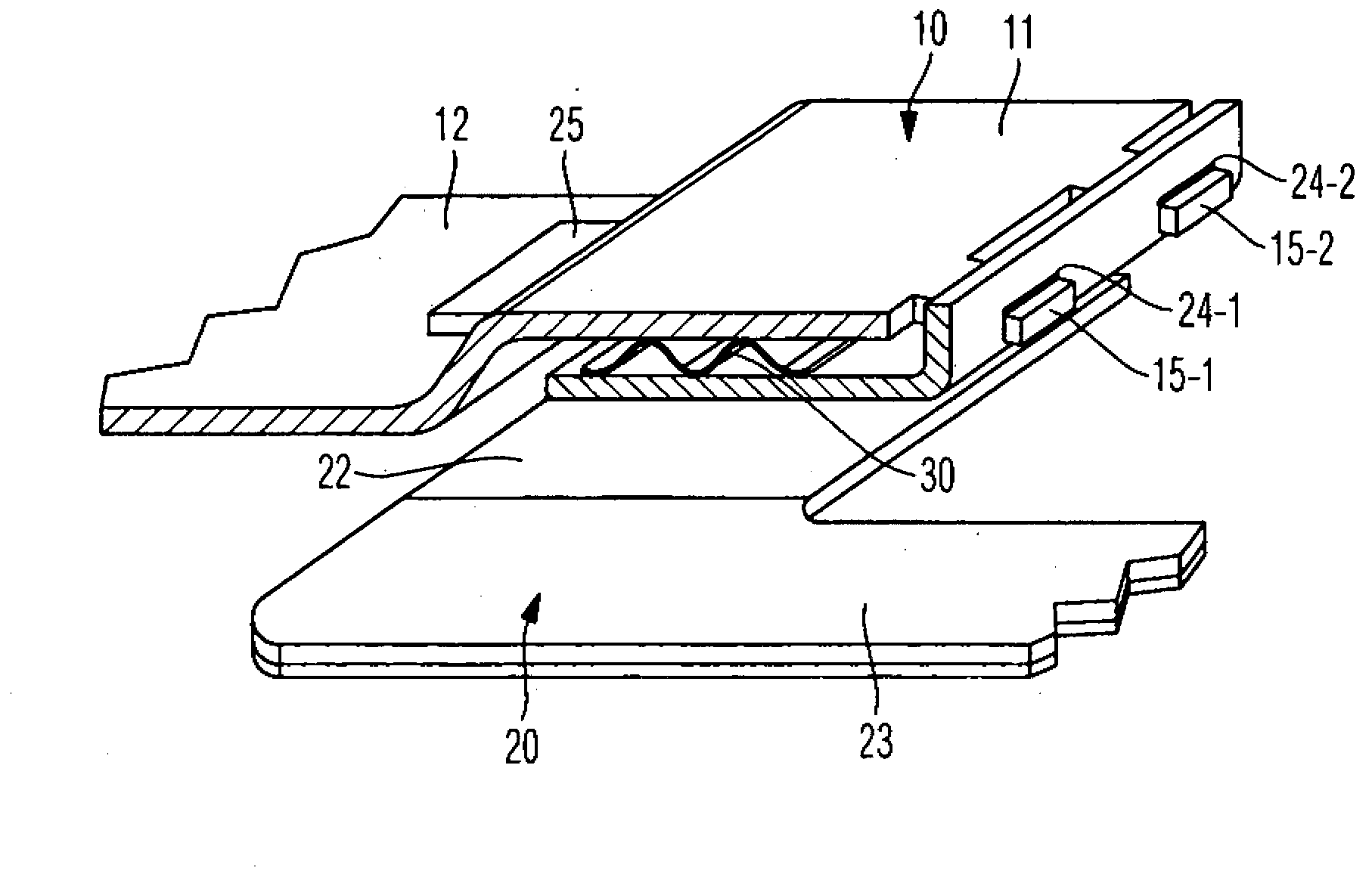

High-current plug connector

ActiveCN103181032ASave installation spaceReduce contact surfaceCoupling contact membersElectrical conductorElectrical connection

The invention describes a high-current plug connector for currents of more than 100 A, in particular more than 200 A. The high-current plug connector of the invention comprises a first connection element (10) which comprises a first contact section (11) and a first connection section (12), and also a second connection element (20) which comprises a second contact section (21) and a second connection section (22). The high-current plug connector also has a spring element (30), which is arranged between the first and the second contact section (11, 21), for establishing an electrical connection between the first and the second connection element (10, 20), wherein the first and the second connection section are each connected to an electrical conductor (13, 23). The first and the second contact section (11, 21) are each in the form of flat pieces. A first, planar contact area (11 A) is formed on a front face of the first contact section, and a second, planar contact area (21 A) is formed on a front face of the second contact section (21), wherein the spring element (30) is clamped exclusively between the first and the second contact areas (11A, 21A) in order to electrically connect the first and the second contact section (11, 21).

Owner:BAYERISCHE MOTOREN WERKE AG

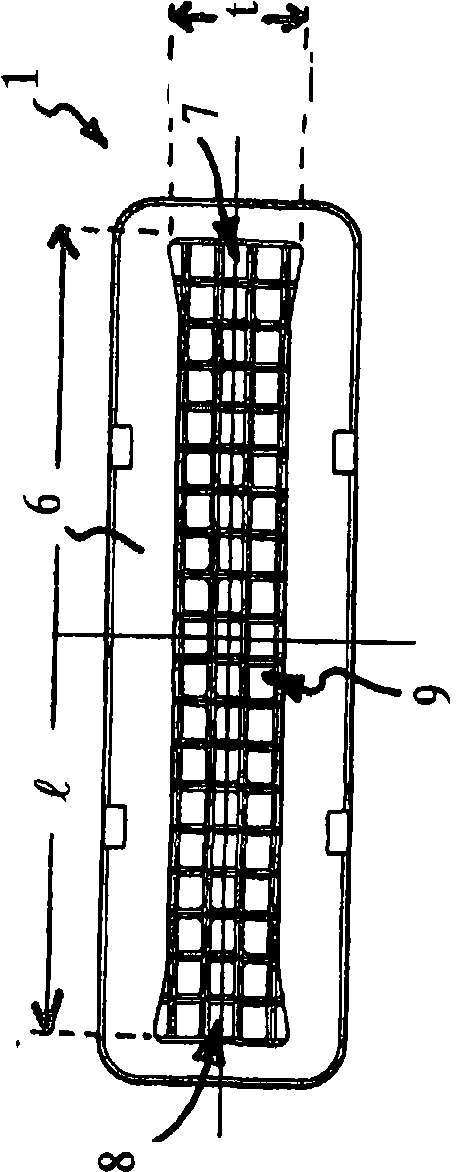

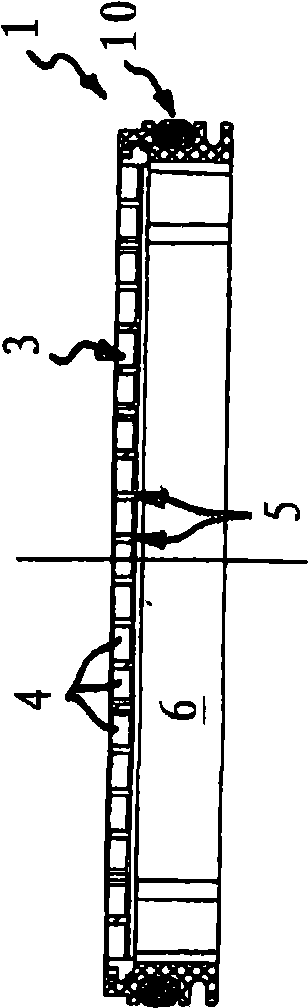

Jet former

The former (1) has a homogenizing device with a set of passage holes that are limited by a flow guiding wall, where the former has a larger stream width compared to stream depth (t) for producing a flat water flow volume. A flow guide (6) is provided upstream or downstream and narrows in a partial area in a flow direction. The flow guide has edge areas (7, 8) with a larger flow cross section relative to a longitudinal middle area (9), where the edge areas extend in both sides of the guide in a longitudinally extending manner.

Owner:NEOPERL

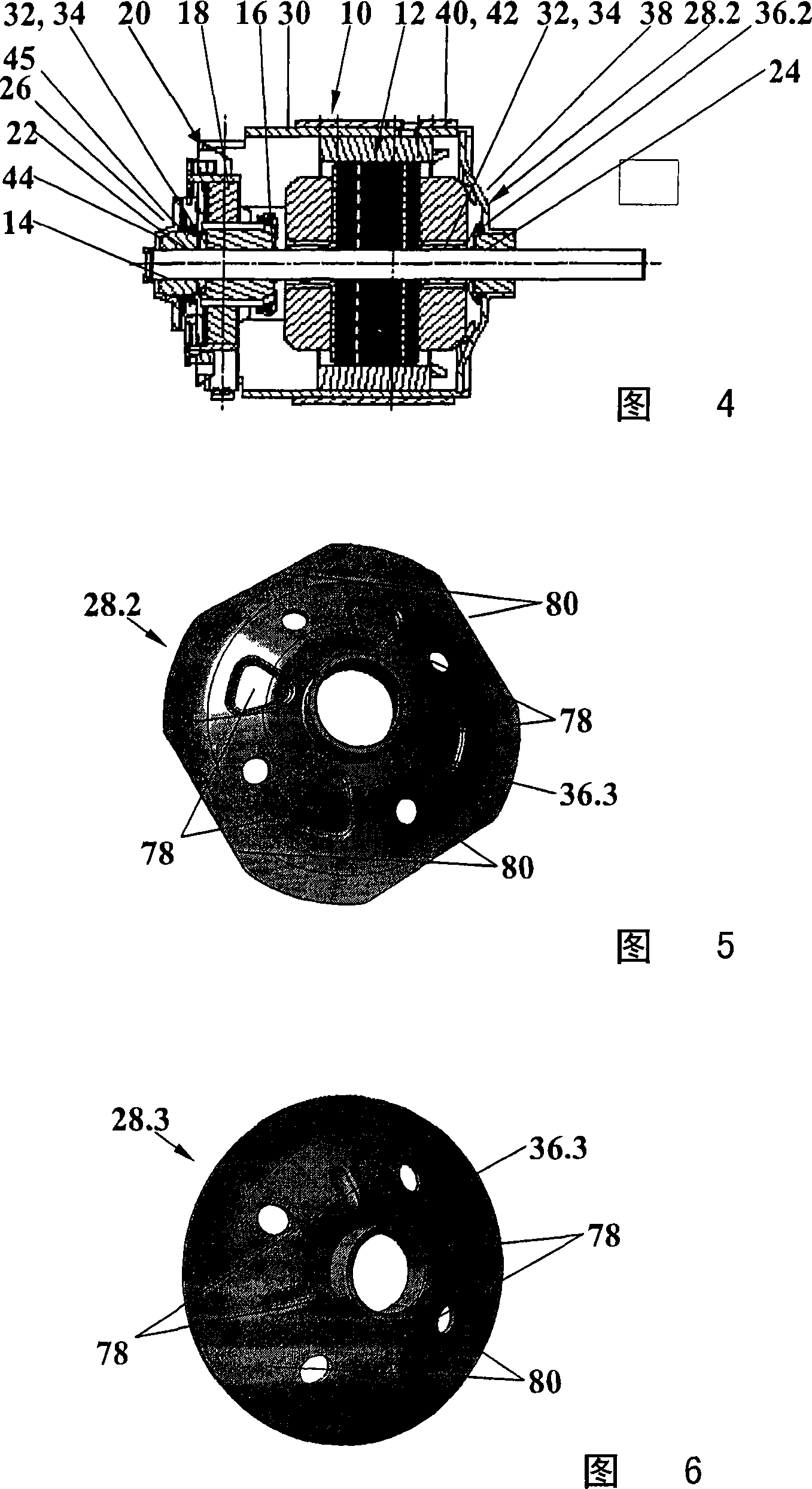

Electric machine

InactiveCN101023571AHigh strengthEasy manufacturabilityCentering/balancing rotorsSupports/enclosures/casingsElectric machineryEngineering

The invention relates to an electric machine (10), preferably a blower drive for a motor vehicle, comprising a shaft (14) which is mounted in at least two bearings having specific axial play. At least one bearing is secured in a bearing seat of an end shield (28.1, 28.2, 28.3) and is placed directly in the bearing seat. The at least one bearing is a cylinder bearing (24) having a cylindrical outer periphery and the bearing seat is a sleeve (36.1, 36.2) having a cylindrical internal diameter wherein the cylinder bearing (24) is secured to the outer periphery by means of a press seat and is maintained in an axial manner in the bearing seat by the thus obtained friction engagement. The advantage of said configuration is that a more precise adjustment of the anchor longitudinal play is possible. Also, no additional components, for example, retaining springs, are required.

Owner:ROBERT BOSCH GMBH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com