Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

824results about How to "Avoid high pressure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

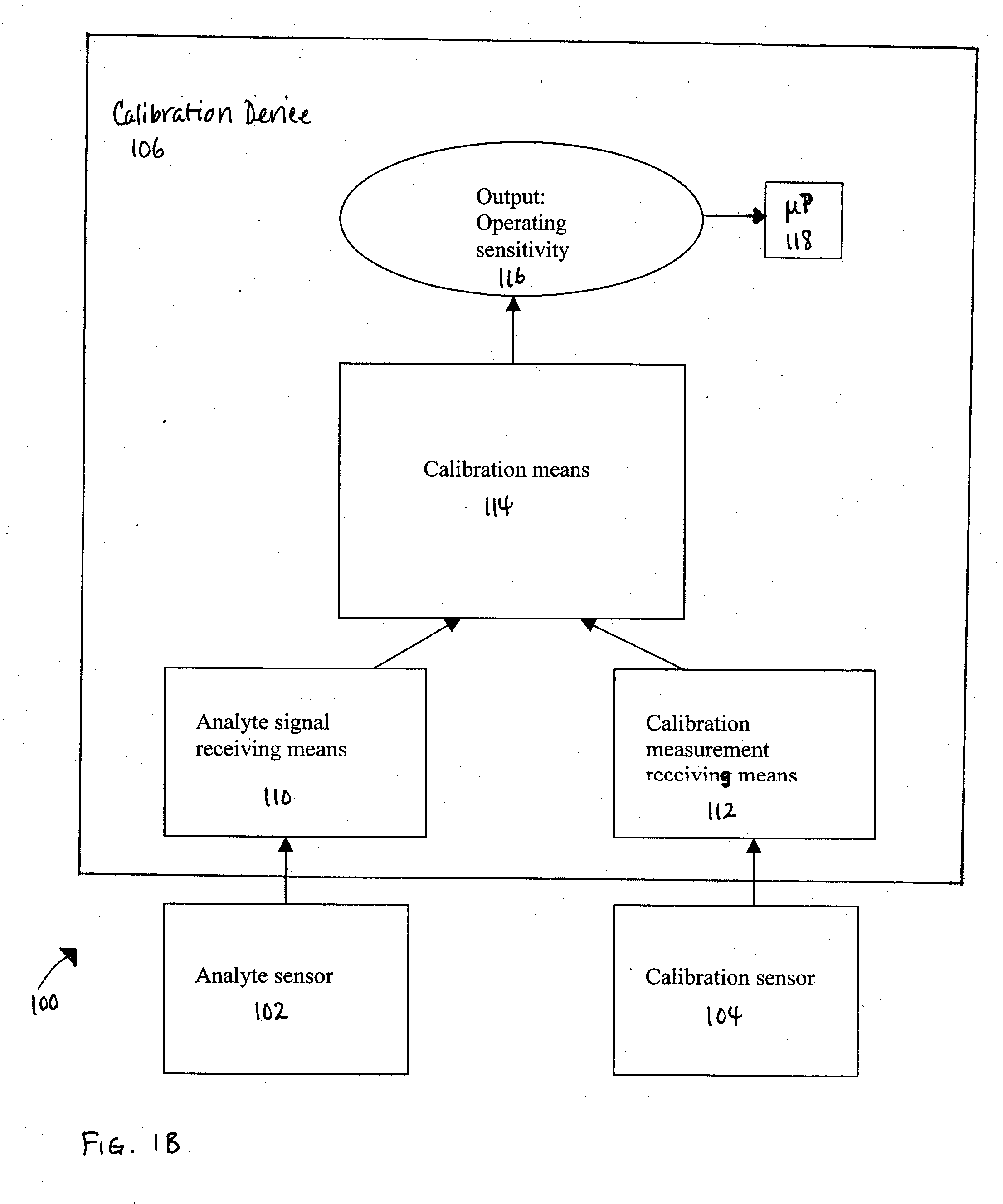

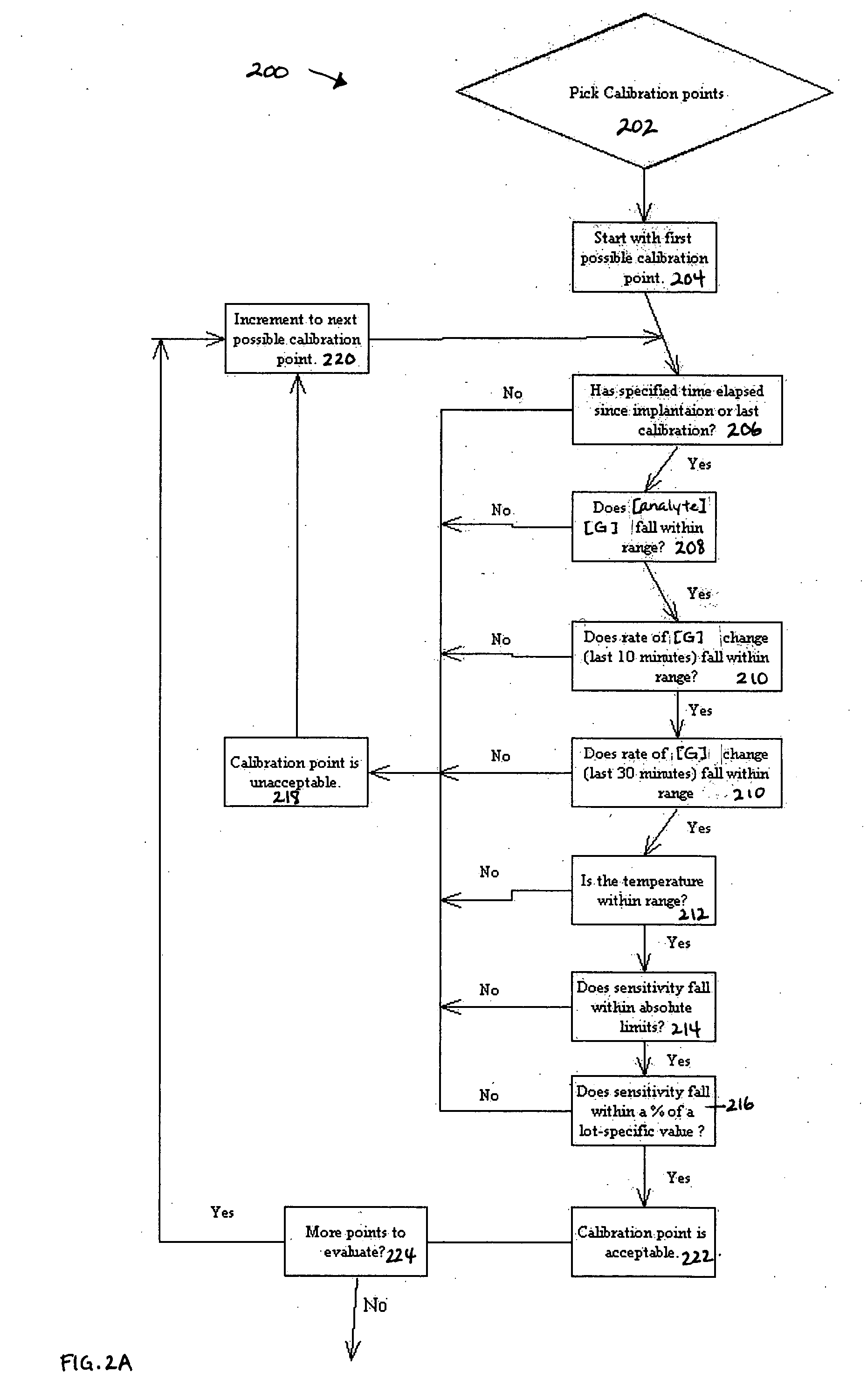

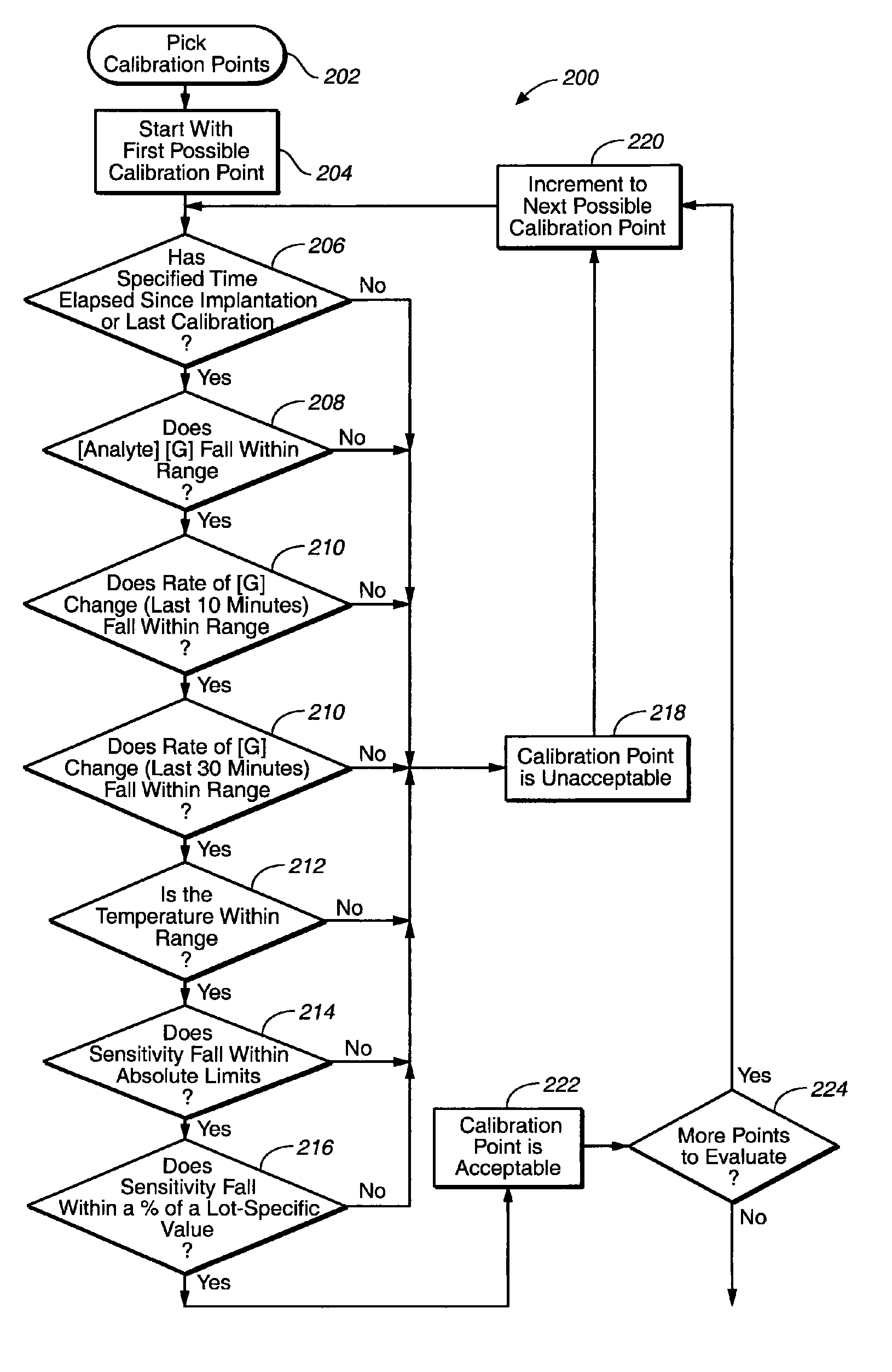

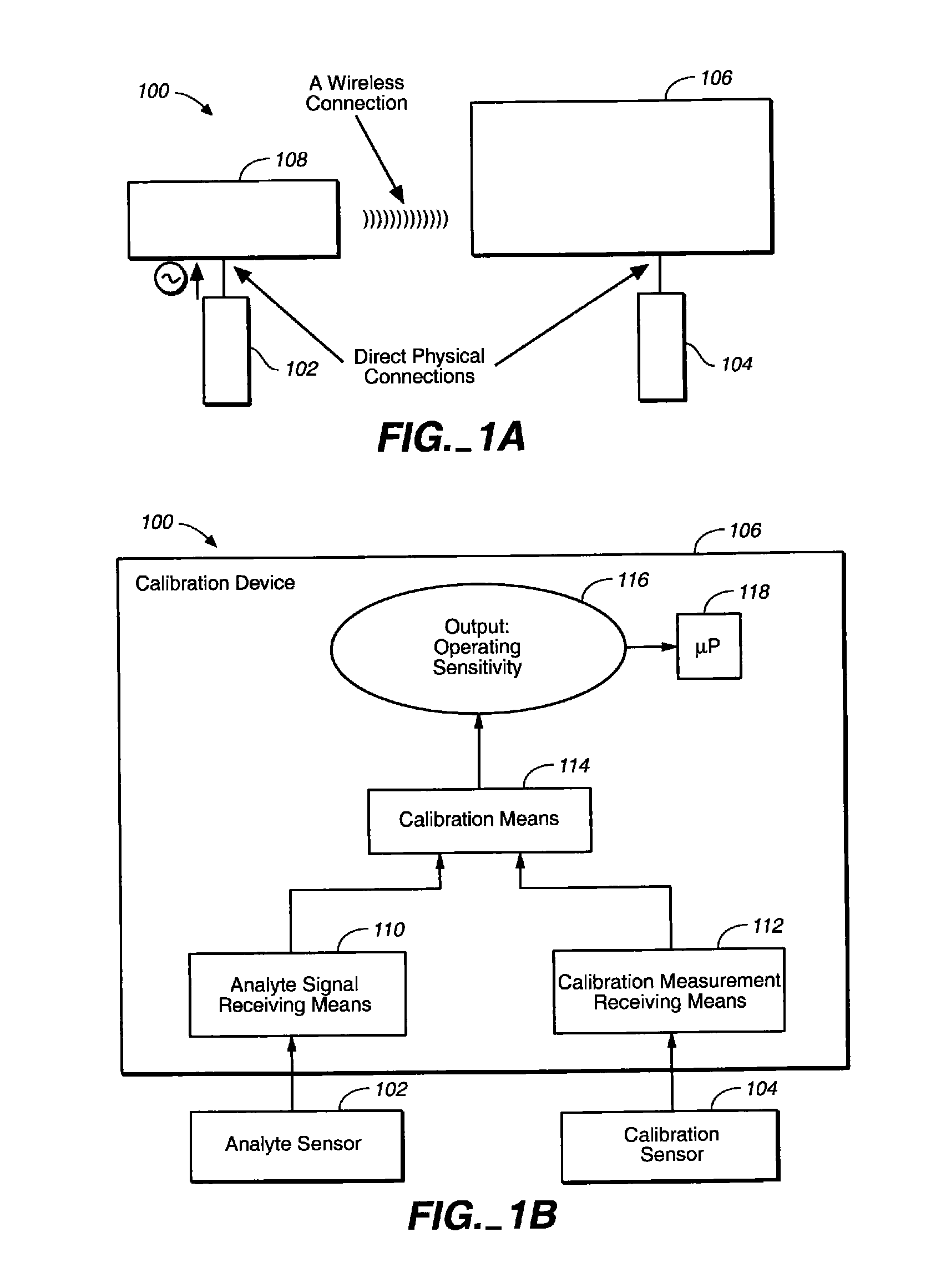

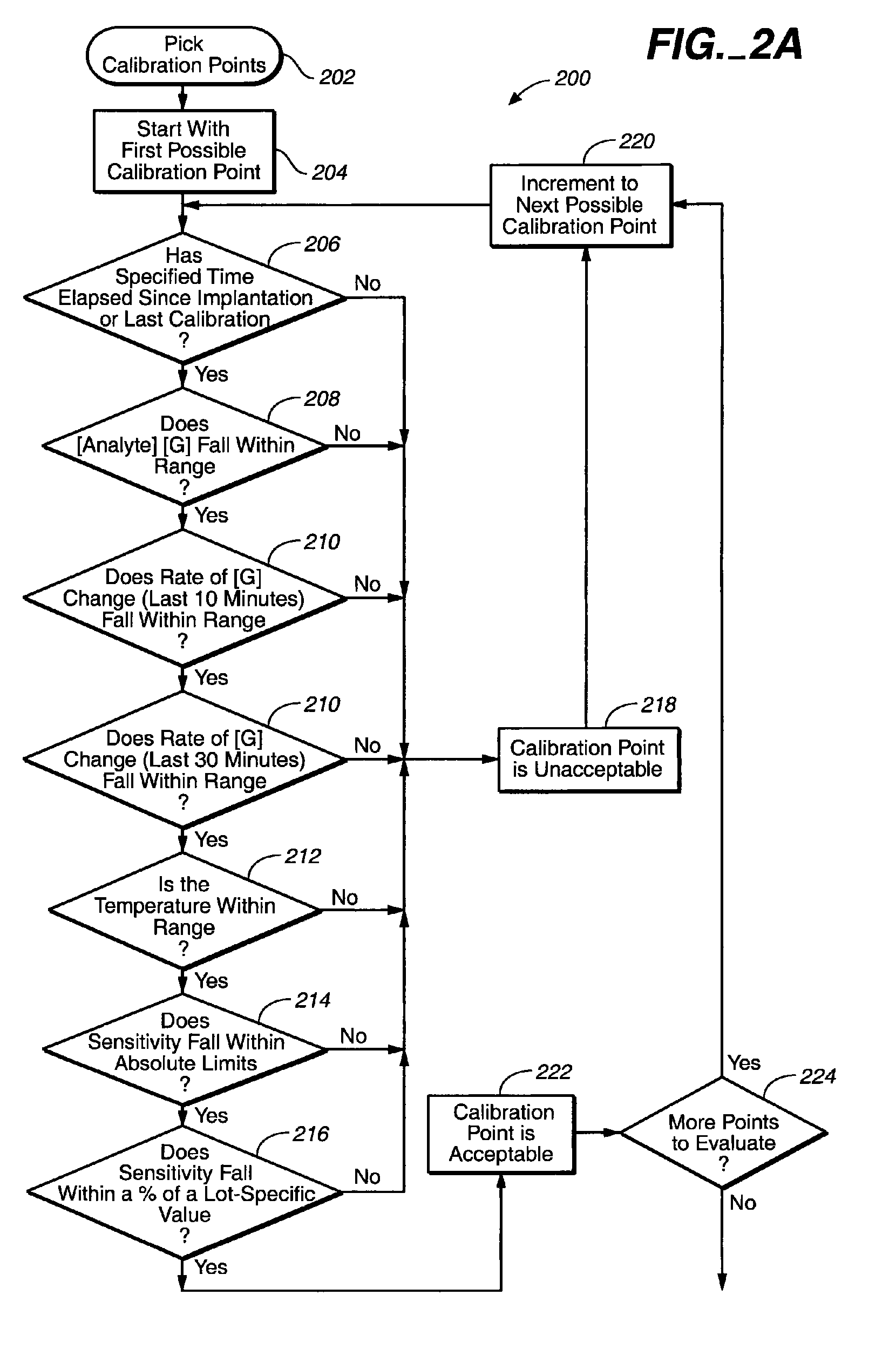

Method of calibrating an analyte-measurement device, and associated methods, devices and systems

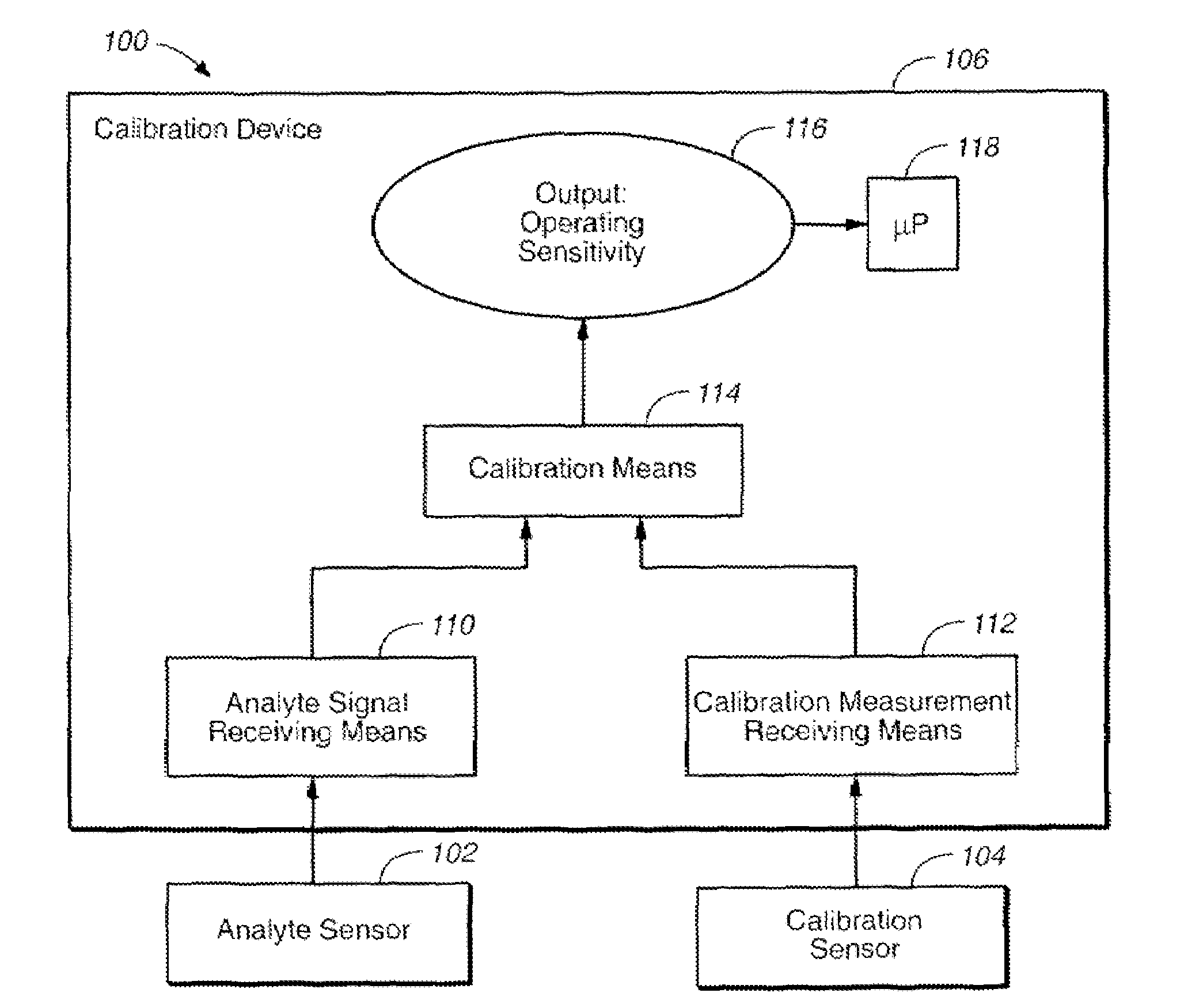

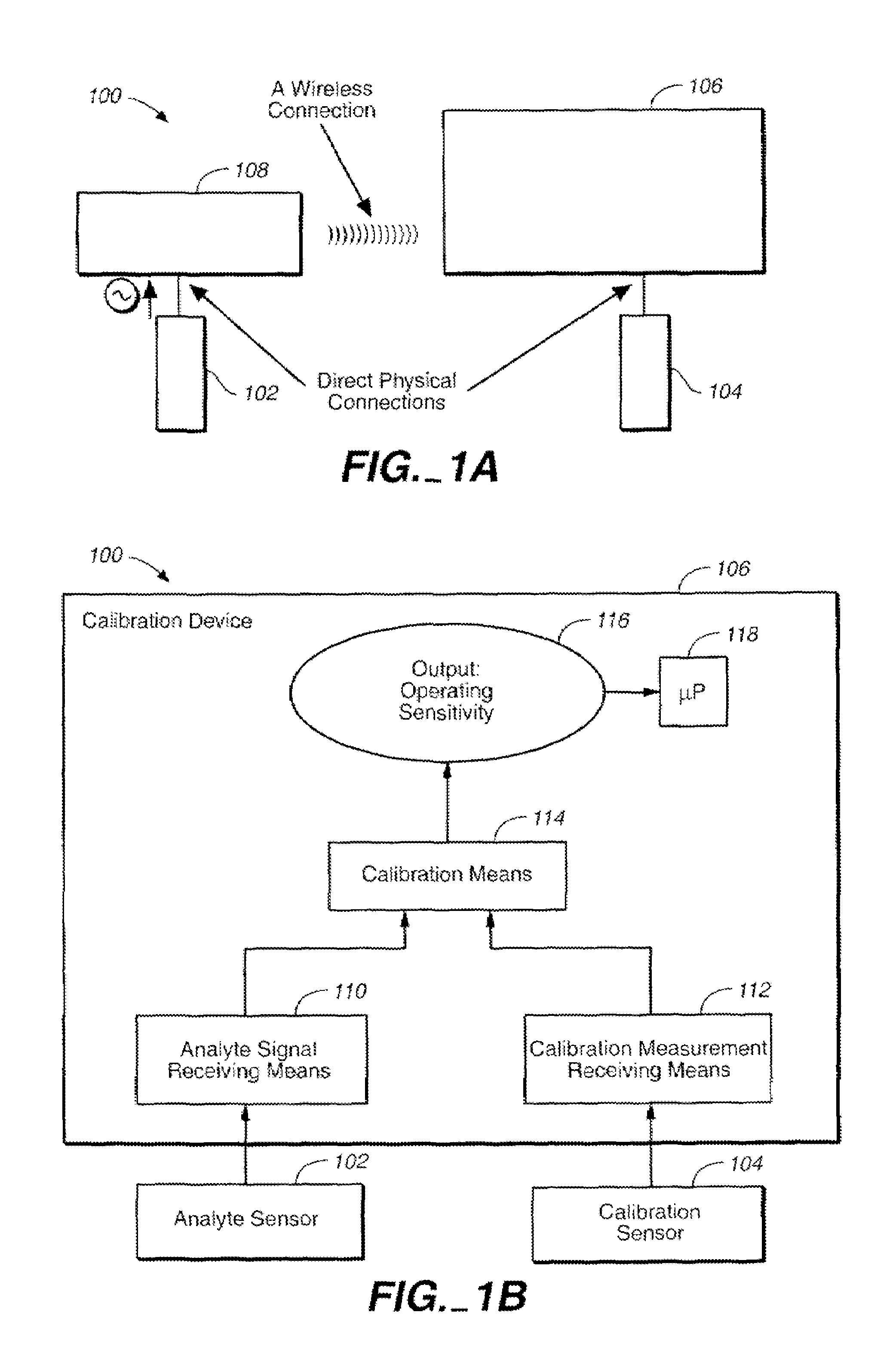

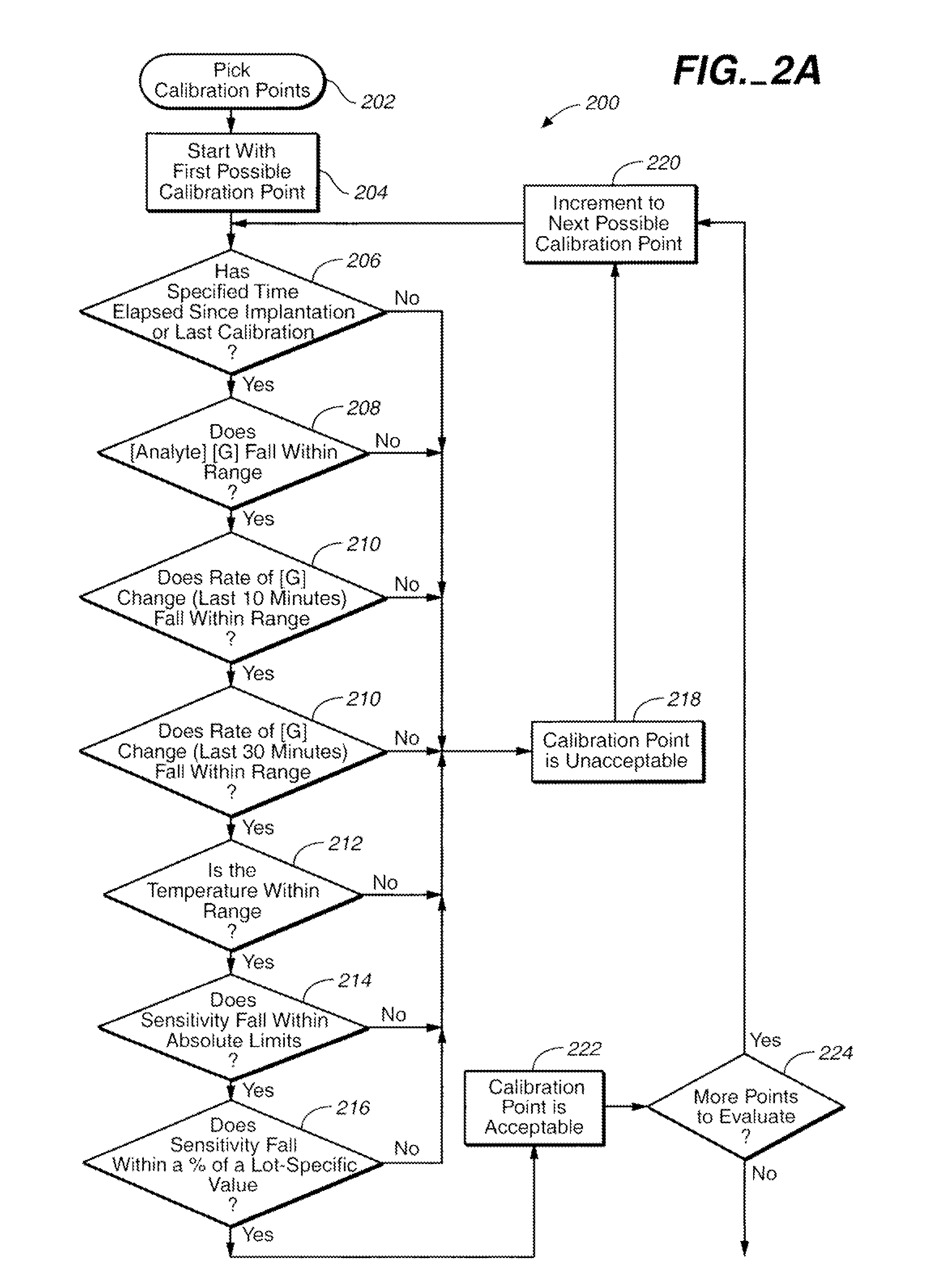

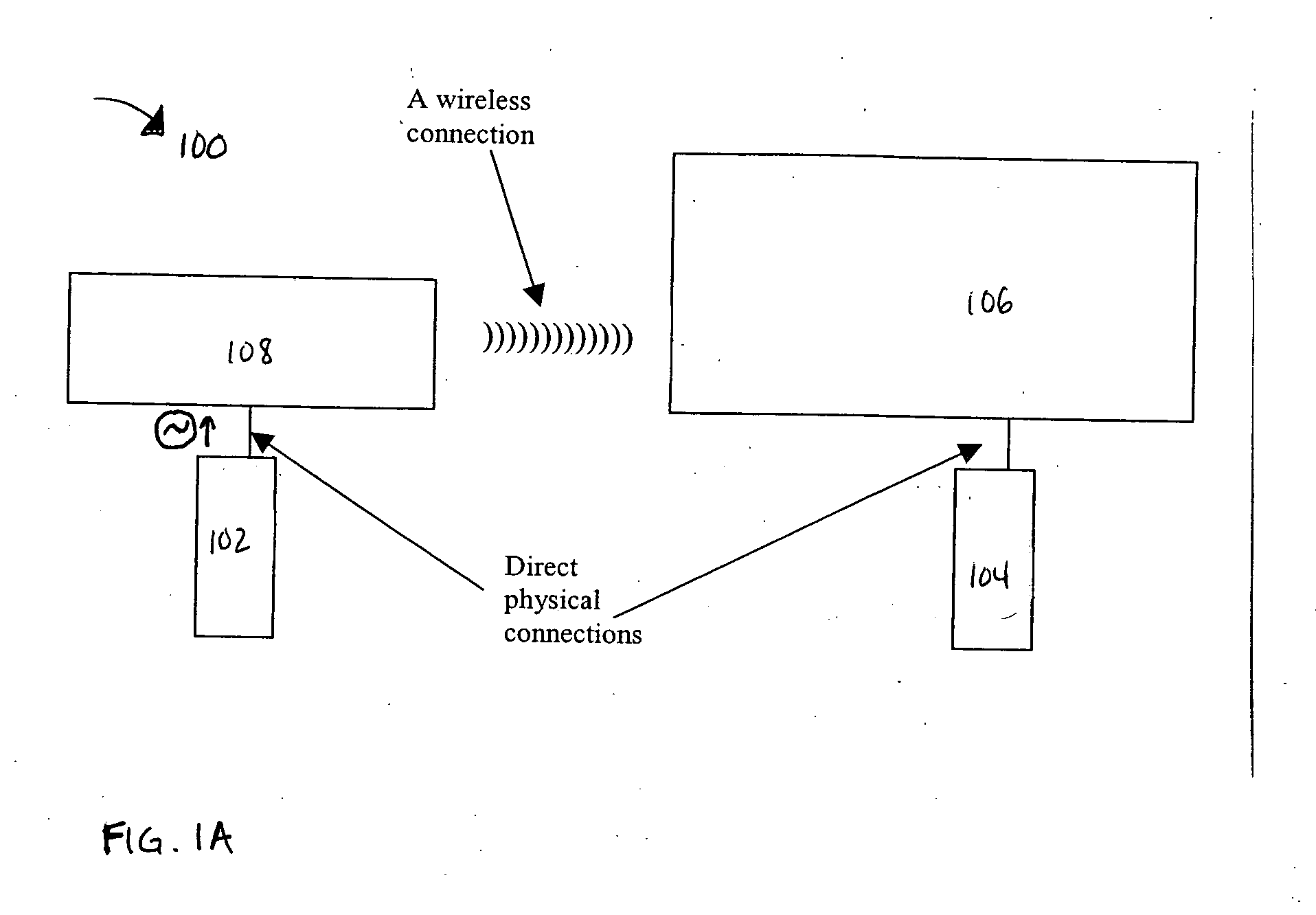

ActiveUS7299082B2Improve mobilityAvoid high pressureMicrobiological testing/measurementCatheterMeasurement deviceAnalyte

Owner:ABBOTT DIABETES CARE INC

A method of calibrating an analyte-measurement device, and associated methods, devices and systems

ActiveUS20050239154A1Improve mobilityAvoid high pressureMicrobiological testing/measurementCatheterMeasurement deviceAnalyte

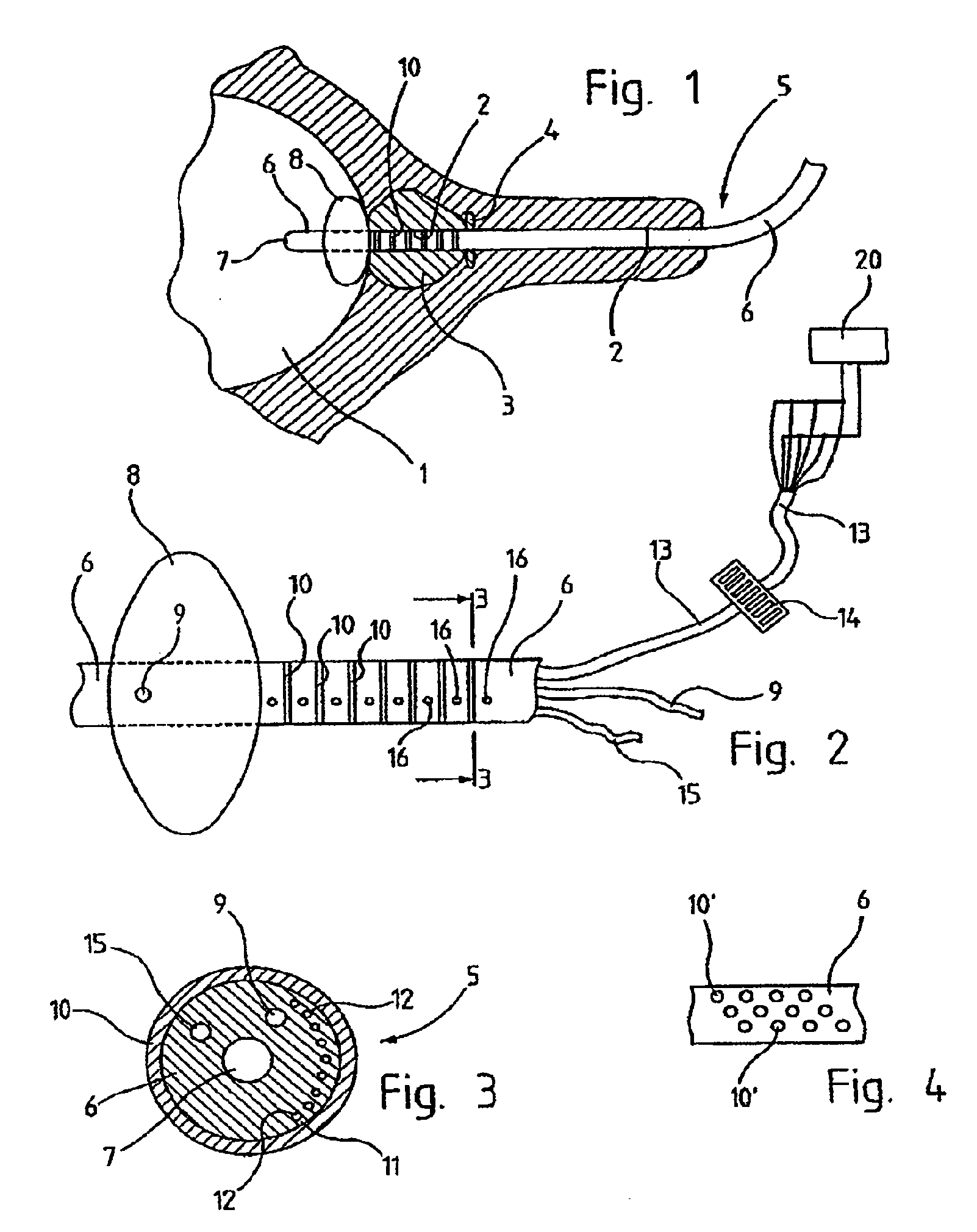

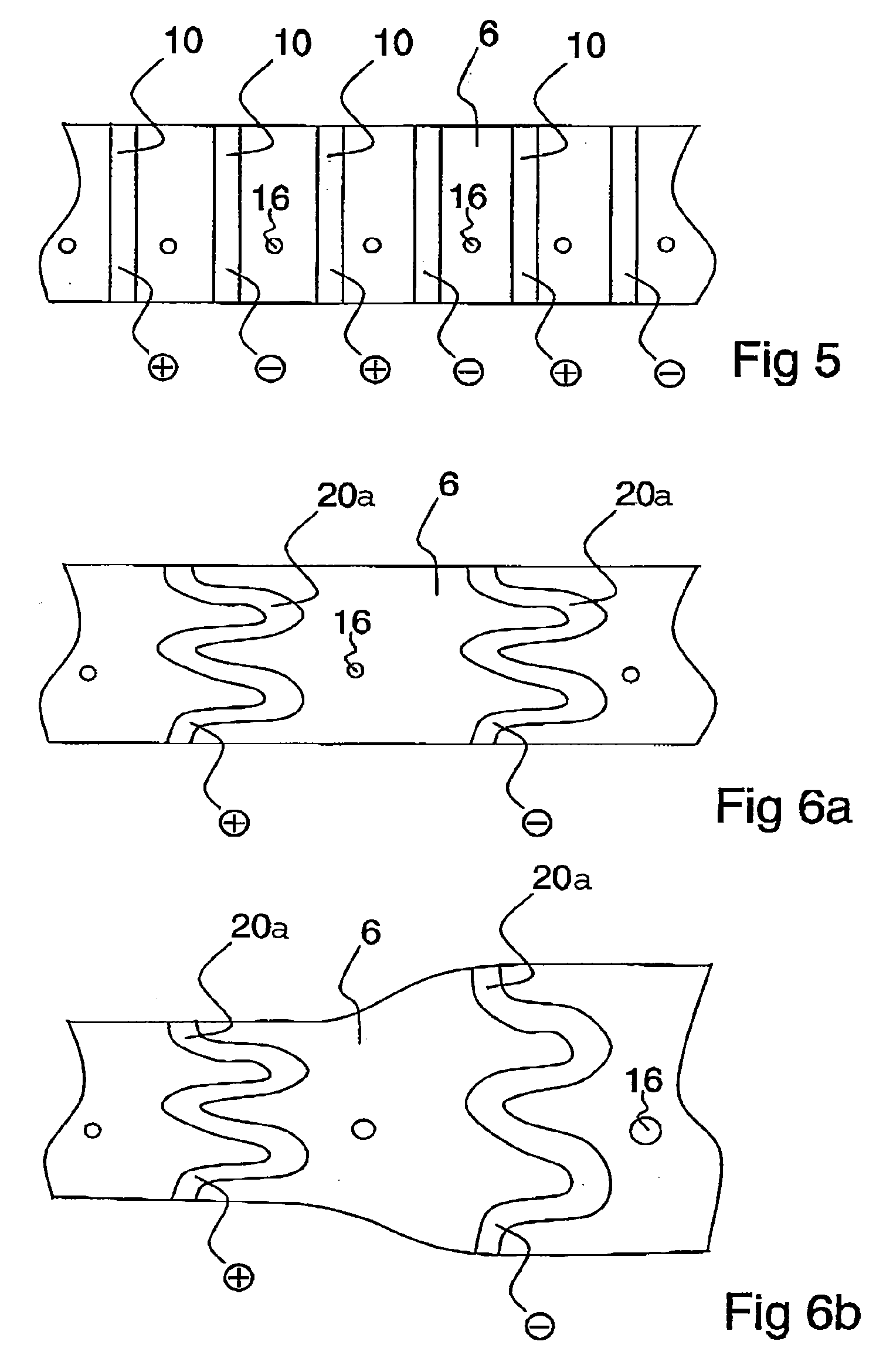

The invention relates to a method for calibrating an analyte-measurement device that is used to evaluate a concentration of analyte in bodily fluid at or from a measurement site in a body. The method involves measuring a concentration, or calibration concentration, of an analyte in blood from an “off-finger” calibration site, and calibrating the analyte-measurement device based on that calibration concentration. The invention also relates to a device, system, or kit for measuring a concentration of an analyte in a body, which employs a calibration device for adjusting analyte concentration measured in bodily fluid based on an analyte concentration measured in blood from an “off-finger” calibration site.

Owner:ABBOTT DIABETES CARE INC

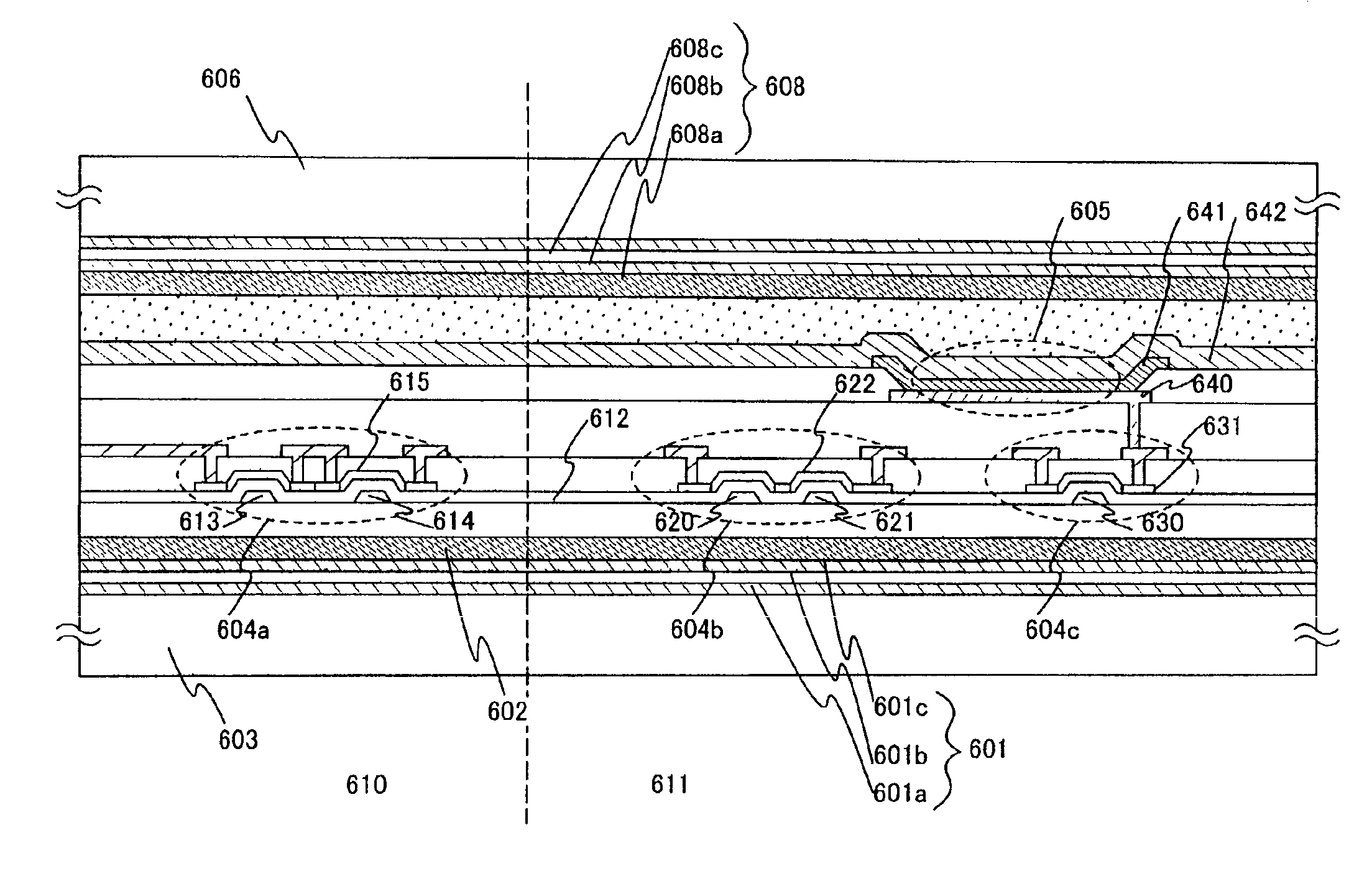

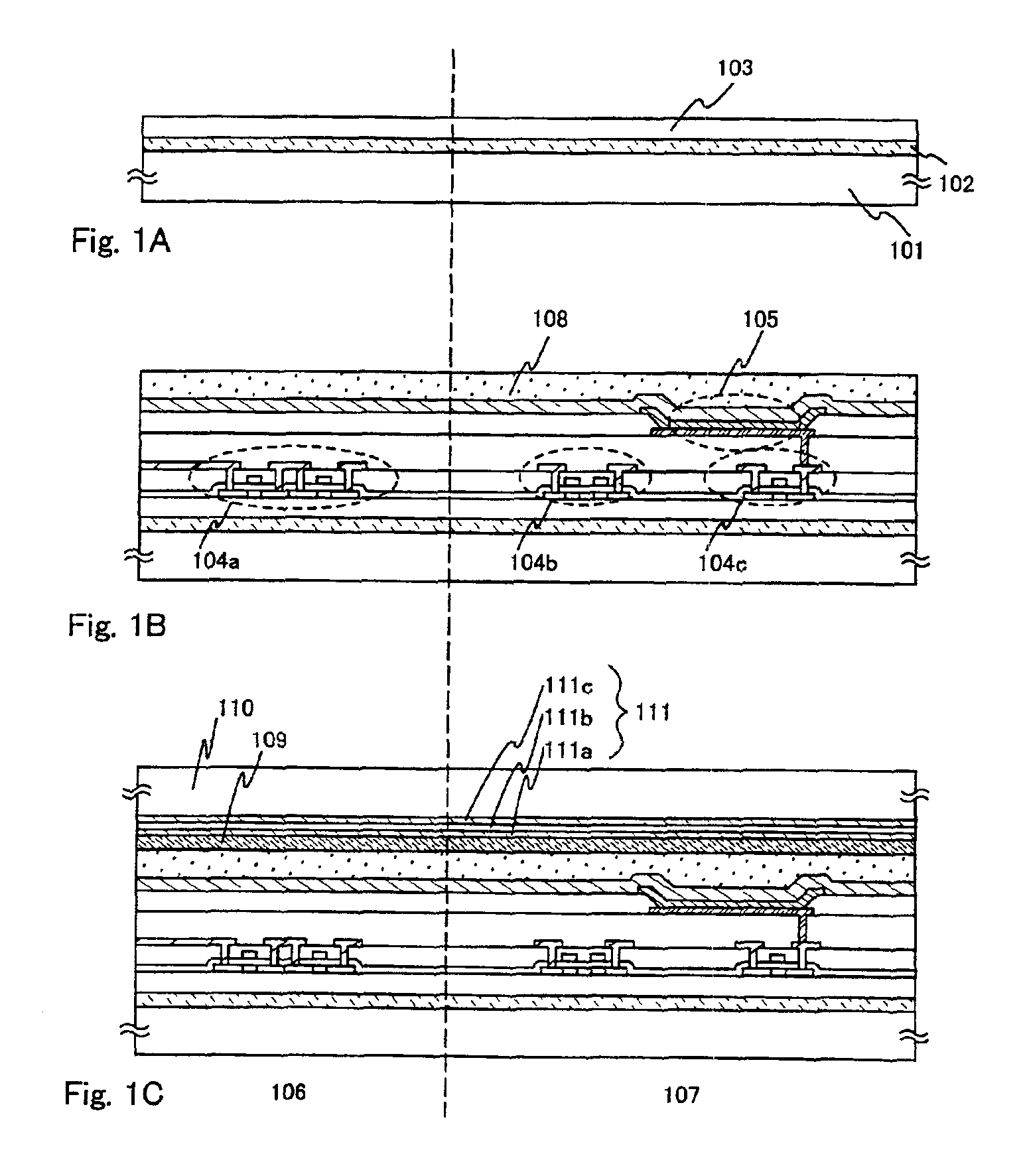

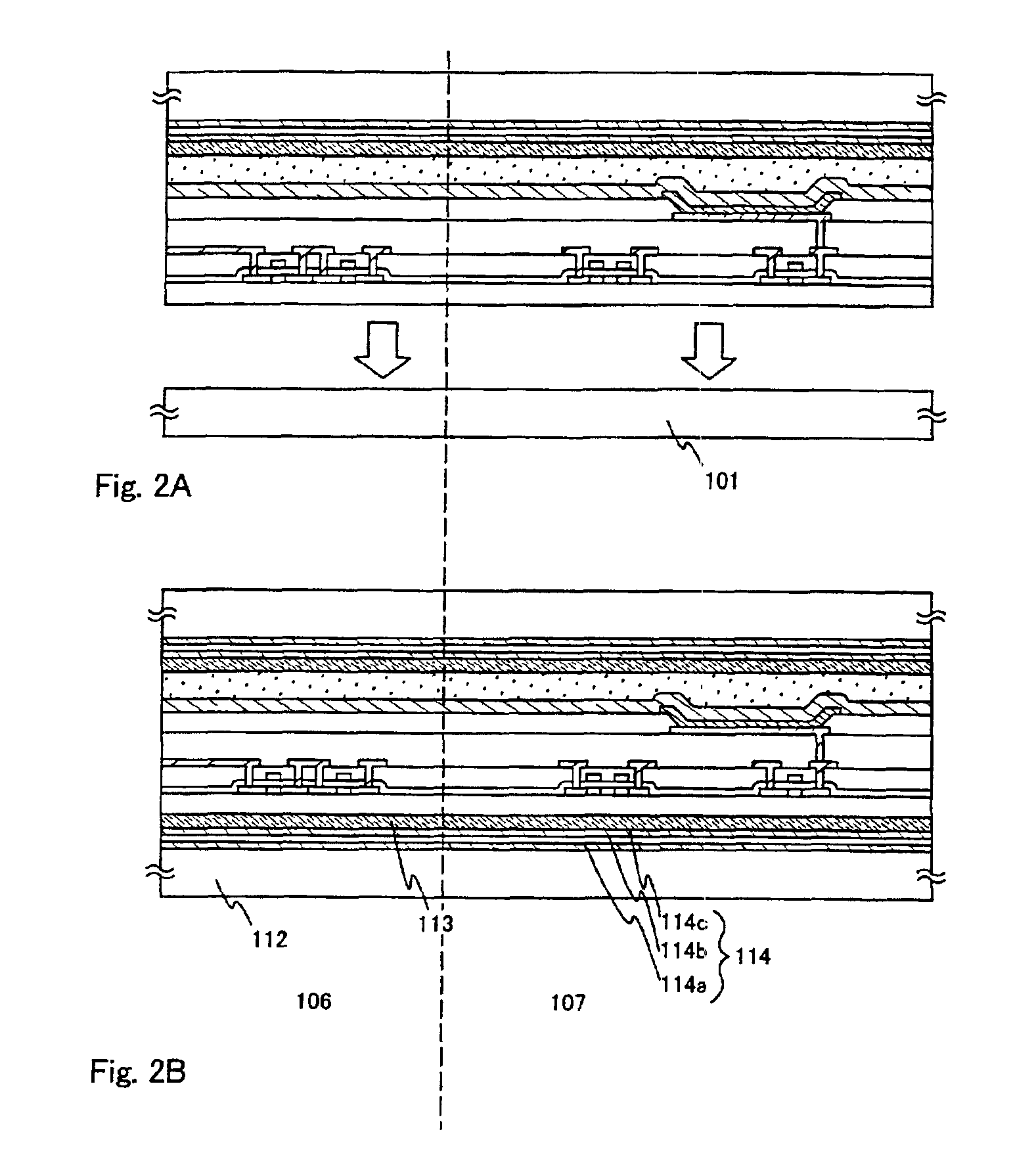

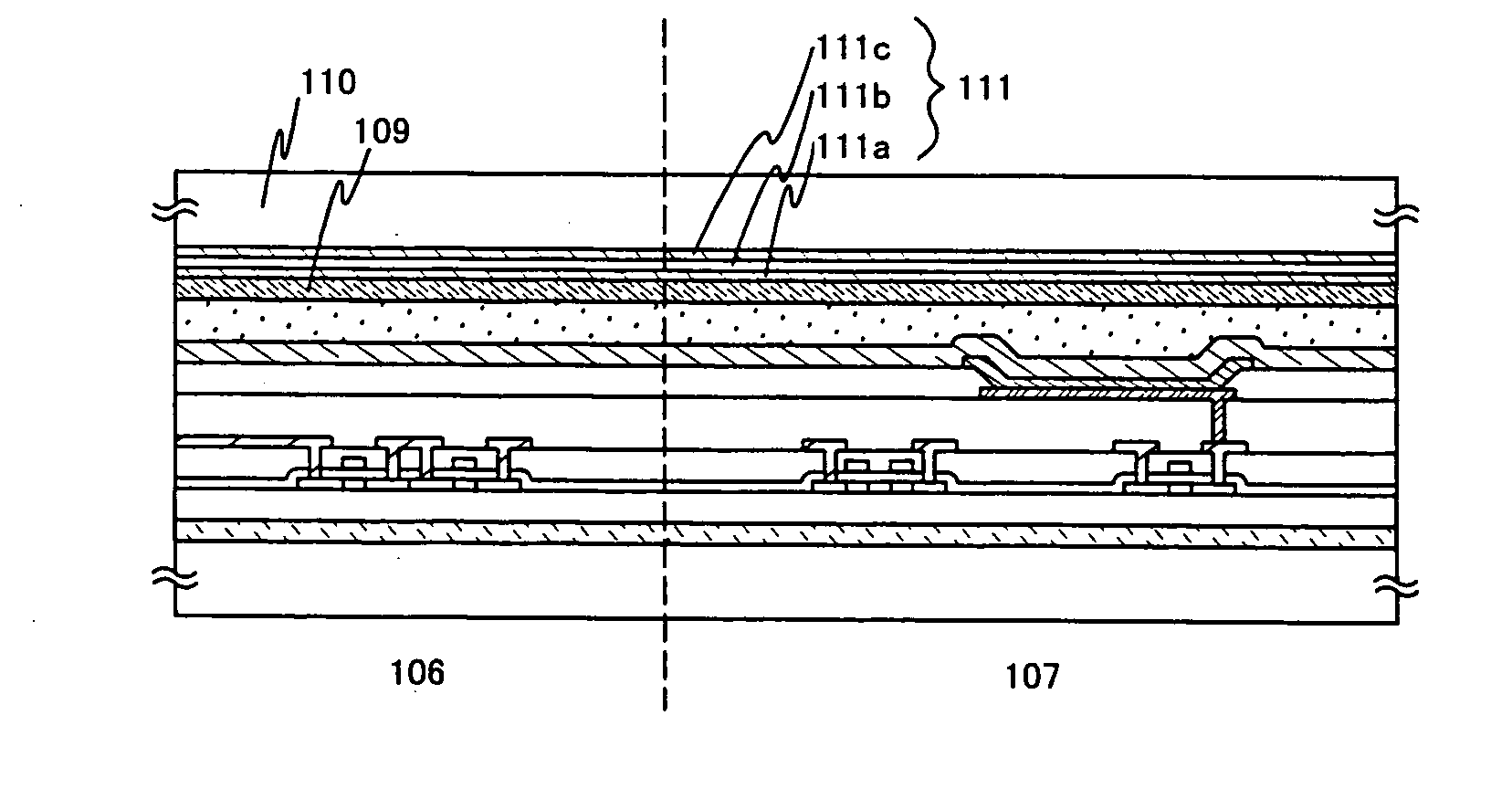

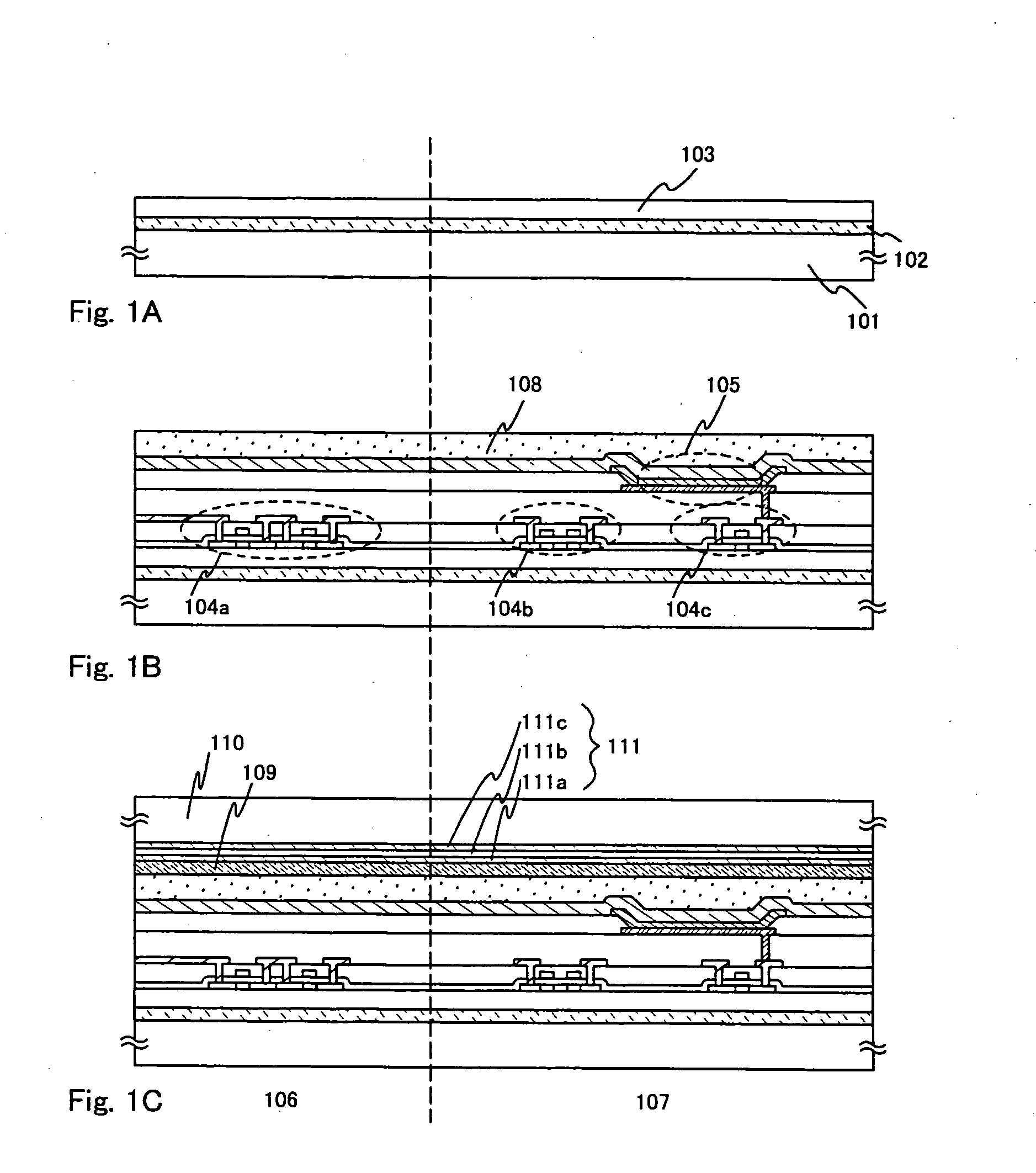

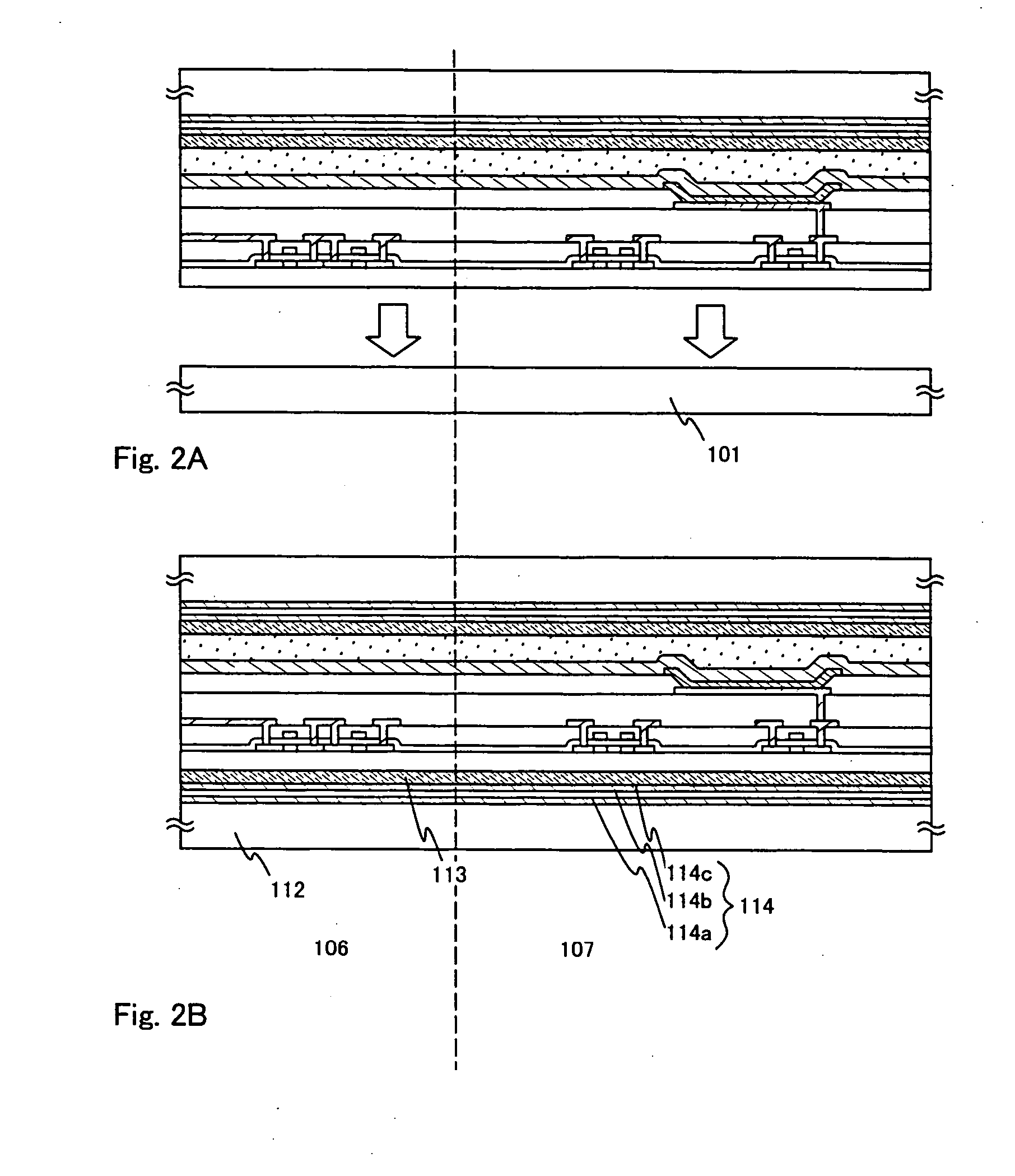

Light emitting device and method of manufacturing the same

InactiveUS6849877B2Prevent degradationPrevent penetrationFinal product manufactureSemiconductor/solid-state device detailsStress relaxationOxygen

The present invention has an object of providing a light emitting device including an OLED formed on a plastic substrate, which can prevent the degradation due to penetration of moisture or oxygen. On a plastic substrate, a plurality of films for preventing oxygen or moisture from penetrating into an organic light emitting layer in the OLED (hereinafter, referred to as barrier films) and a film having a smaller stress than that of the barrier films (hereinafter, referred to as a stress relaxing film), the film being interposed between the barrier films, are provided. Owing to a laminate structure of a plurality of barrier films, even if a crack occurs in one of the barrier films, the other barrier film(s) can effectively prevent moisture or oxygen from penetrating into the organic light emitting layer. Moreover, the stress relaxing film, which has a smaller stress than that of the barrier films, is interposed between the barrier films, thereby making it possible to reduce a stress of the entire sealing film. As a result, a crack due to stress hardly occurs.

Owner:SEMICON ENERGY LAB CO LTD

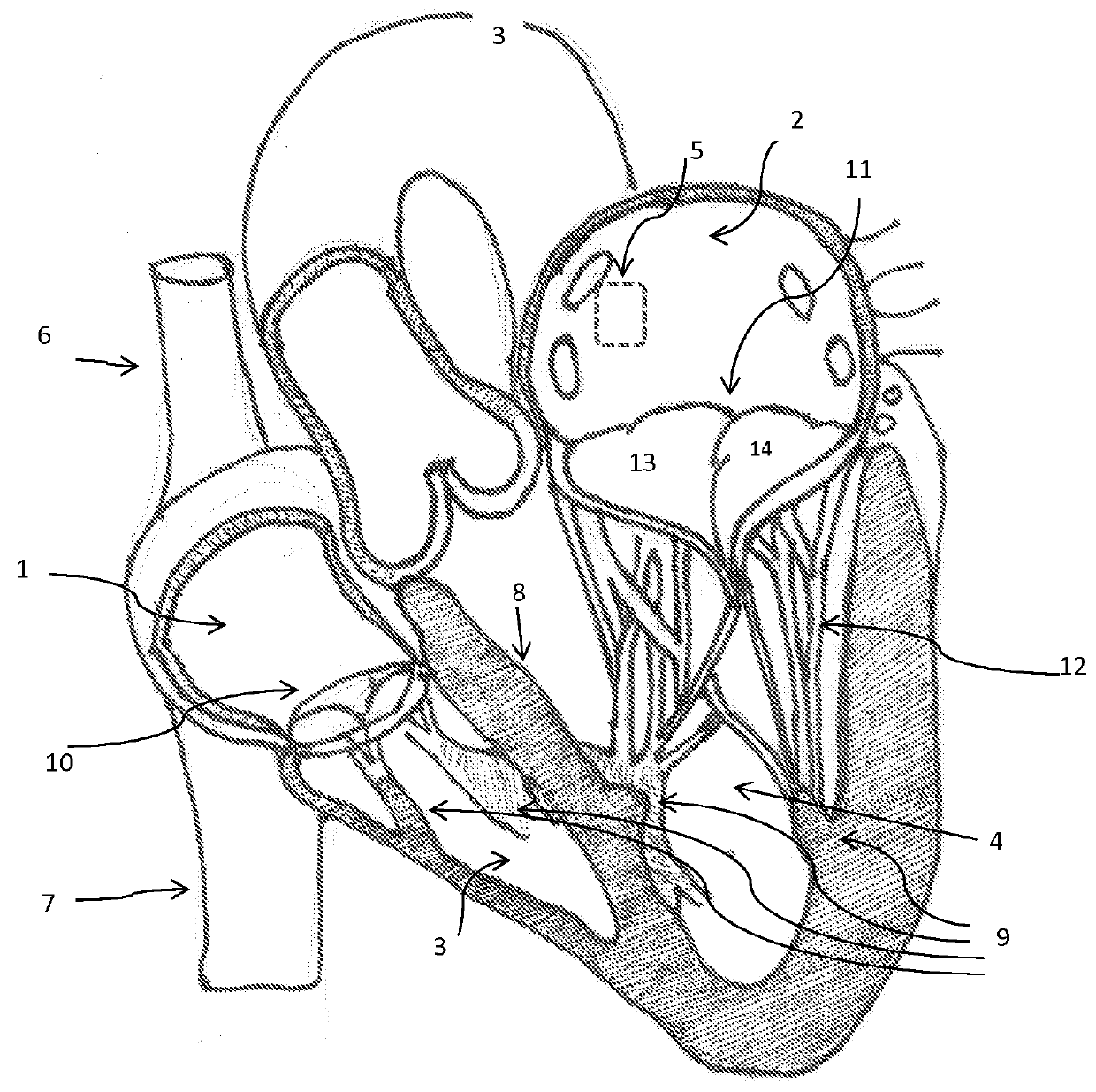

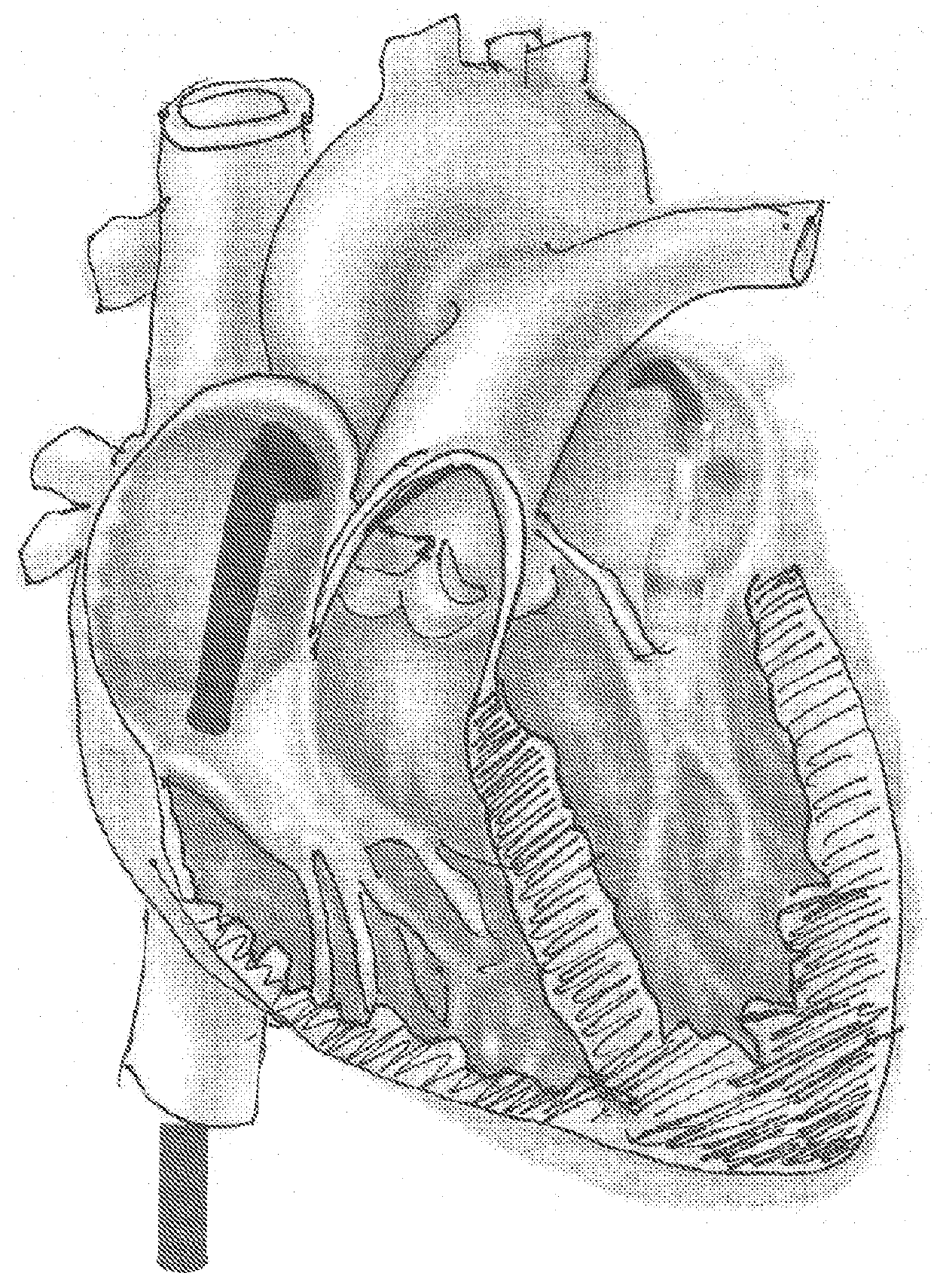

Catheter-guided replacement valves apparatus and methods

ActiveUS20160030171A1Reduced overall height dimensionMinimize intrusionStentsHeart valvesStructure and functionCatheter

The present invention is a replacement mitral valve suitable for catheter-based deployment. The replacement mitral valve has structure and dimensions that are uniquely suited to engage the annulus surrounding the native mitral valve and to restore normal function to a diseased valve. The invention describes the structures and functions of a replacement mitral valve and methods that are adapted for minimally invasive, catheter-based deployment of the valve.

Owner:NAVIGATE CARDIAC STRUCTURES

Correlation of alternative site blood and interstitial fluid glucose concentrations to venous glucose concentration

InactiveUS8216138B1Improve mobilityEnhance mobility of fluidImmobilised enzymesBioreactor/fermenter combinationsMeasurement deviceAnalyte

The invention relates to a method for calibrating an analyte-measurement device that is used to evaluate a concentration of analyte in bodily fluid at or from a measurement site in a body. The method involves measuring a concentration, or calibration concentration, of an analyte in blood from an “off-finger” calibration site, and calibrating the analyte-measurement device based on that calibration concentration. The invention also relates to a device, system, or kit for measuring a concentration of an analyte in a body, which employs a calibration device for adjusting analyte concentration measured in bodily fluid based on an analyte concentration measured in blood from an “off-finger” calibration site.

Owner:ABBOTT DIABETES CARE INC

Method of calibrating of an analyte-measurement device, and associated methods, devices and systems

ActiveUS20080081969A1Improve mobilityAvoid high pressureImmobilised enzymesBioreactor/fermenter combinationsAnalyteMeasurement device

The invention relates to a method for calibrating an analyte-measurement device that is used to evaluate a concentration of analyte in bodily fluid at or from a measurement site in a body. The method involves measuring a concentration, or calibration concentration, of an analyte in blood from an “off-finger” calibration site, and calibrating the analyte-measurement device based on that calibration concentration. The invention also relates to a device, system, or kit for measuring a concentration of an analyte in a body, which employs a calibration device for adjusting analyte concentration measured in bodily fluid based on an analyte concentration measured in blood from an “off-finger” calibration site.

Owner:ABBOTT DIABETES CARE INC

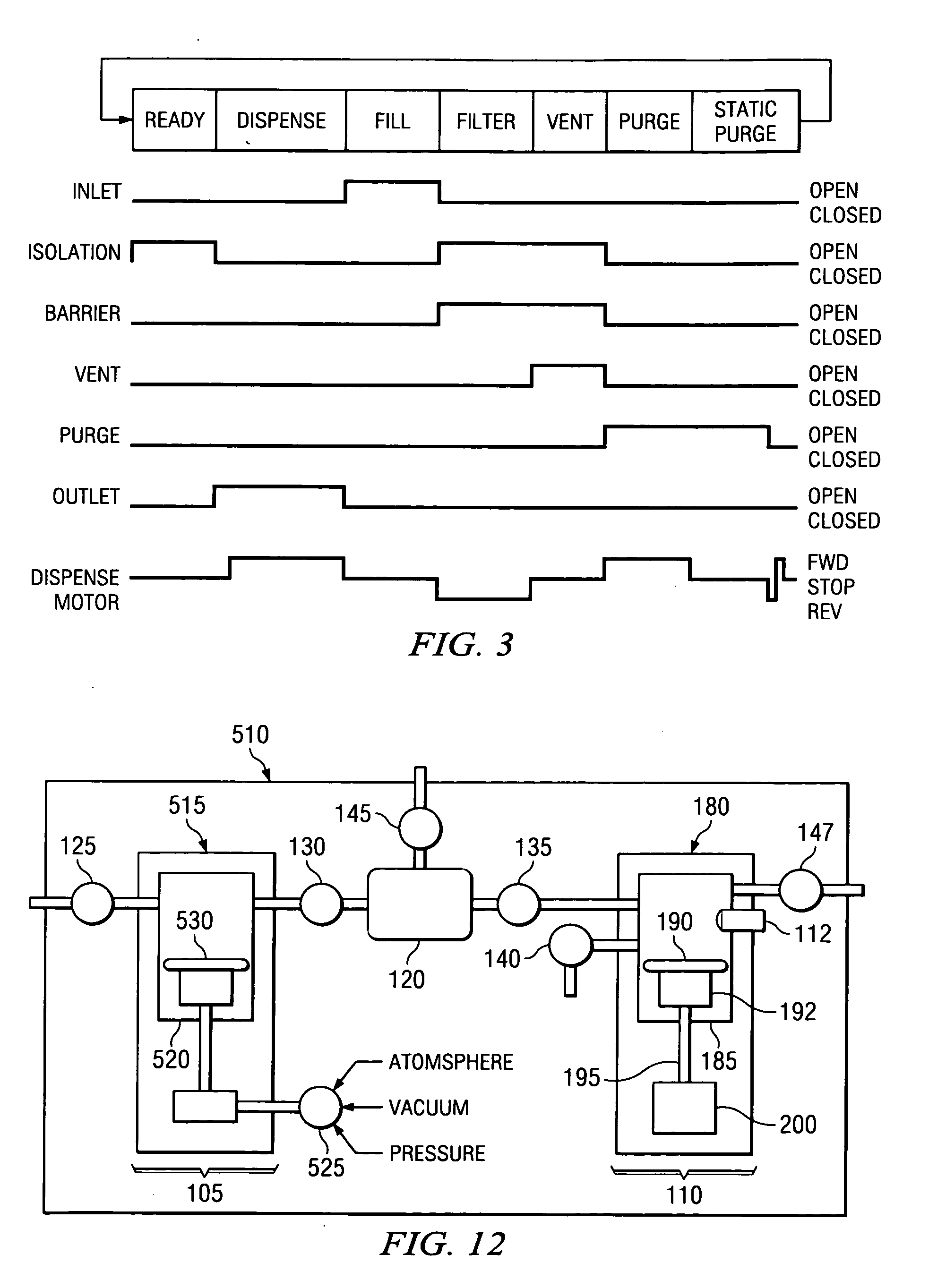

System and method for control of fluid pressure

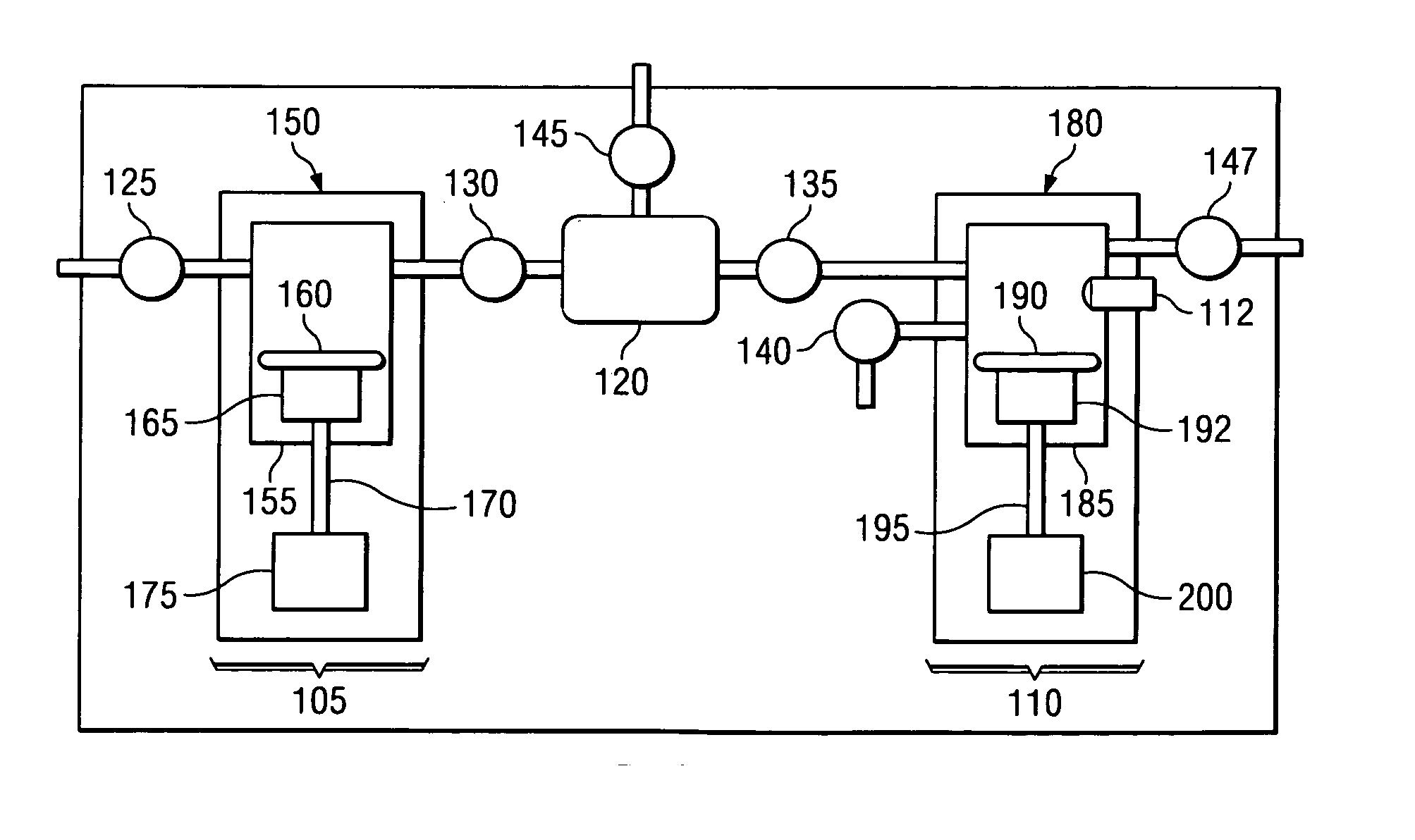

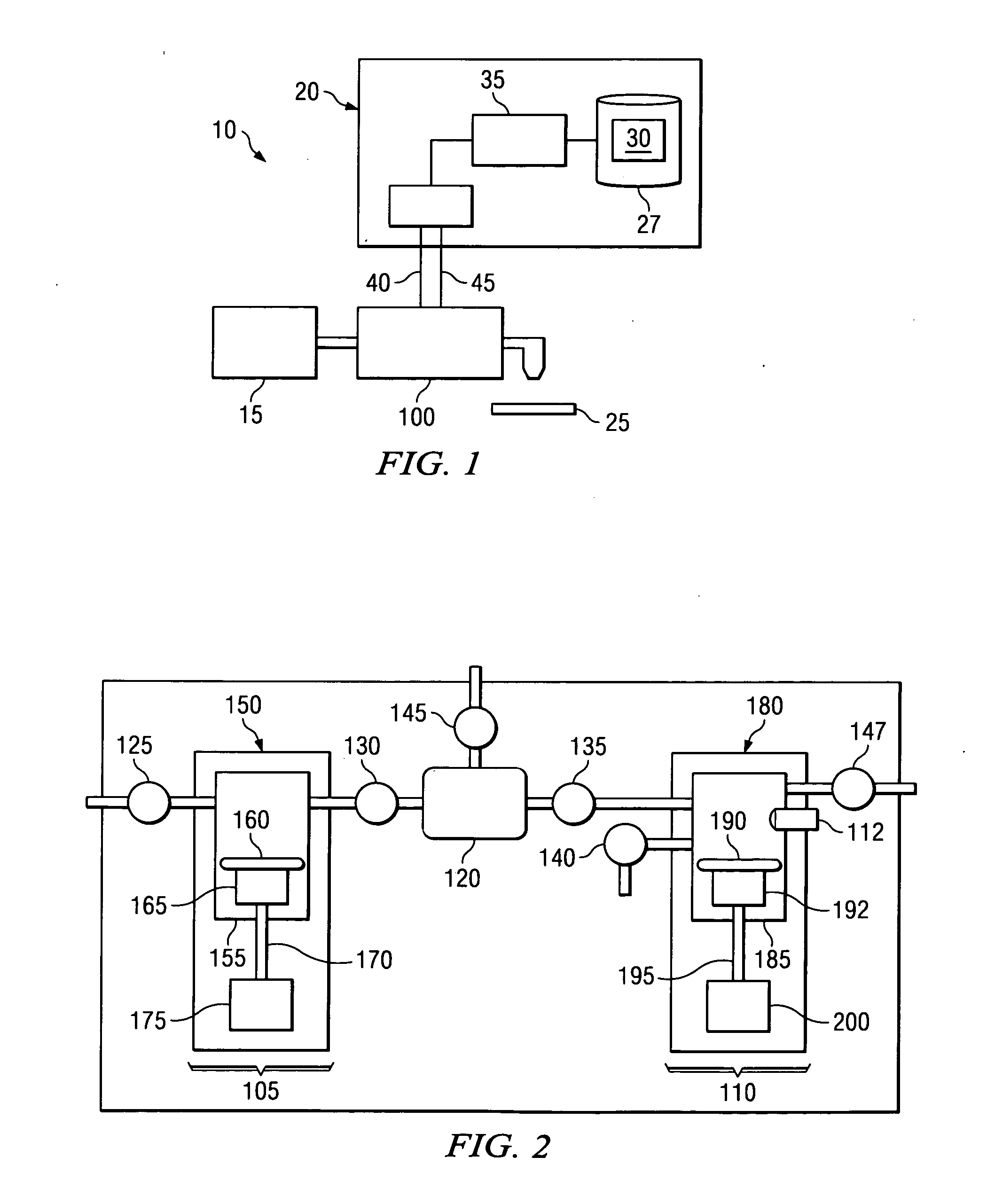

ActiveUS20070128046A1Gentler handlingEliminates and reduces disadvantageFluid parameterFlexible member pumpsPressure decreaseEngineering

Embodiments of the present invention are related to a pumping system that accurately dispenses fluid using a multiple stage (“multi-stage”) pump. More particularly, embodiments of the present invention provide for control of a feed stage pump to regulate fluid pressure at a downstream dispense stage pump. According to one embodiment of the present invention, a pressure sensor at the dispense stage pump determines the pressure in a dispense chamber. When the pressure reaches a predefined threshold, the dispense stage pump can begin to increase the available volume of the dispense chamber, thereby causing the pressure in the dispense chamber to drop. As the pressure decreases / increases at the downstream pump, the pressure applied by the upstream pump can bed increased / decreased.

Owner:ENTEGRIS INC

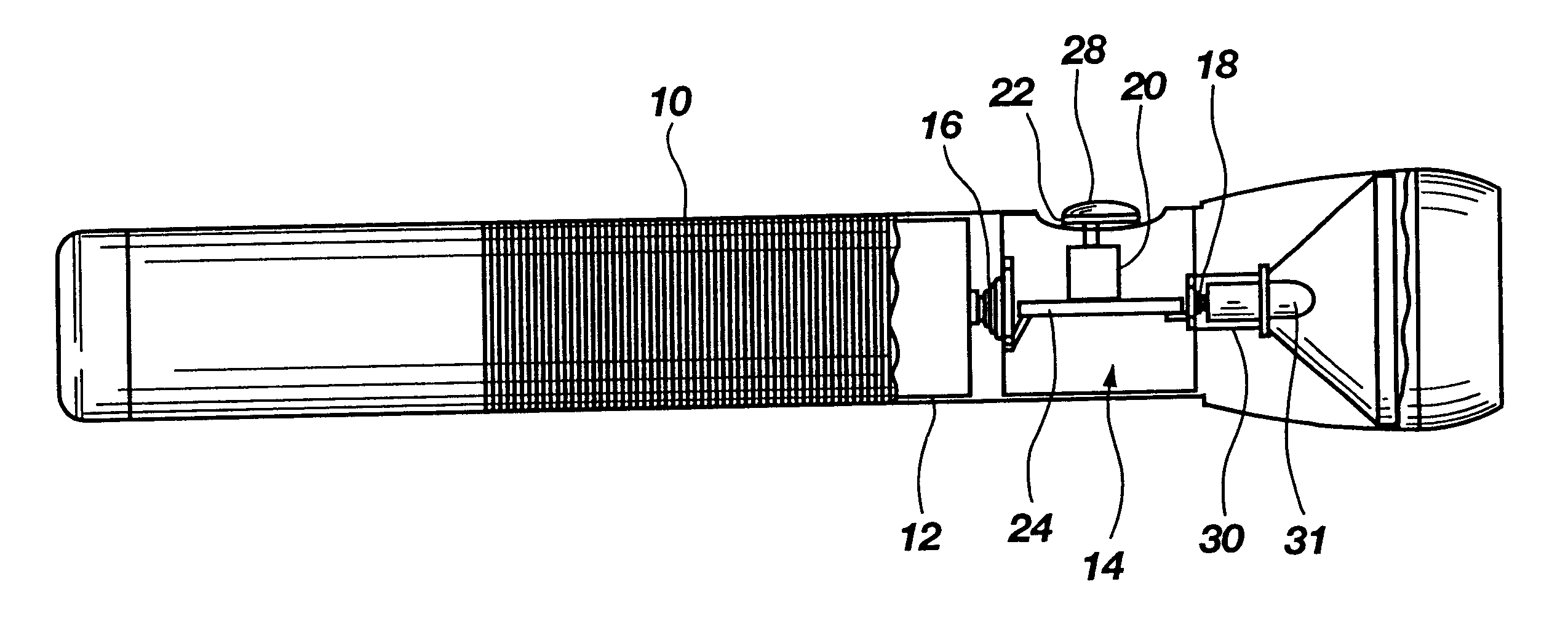

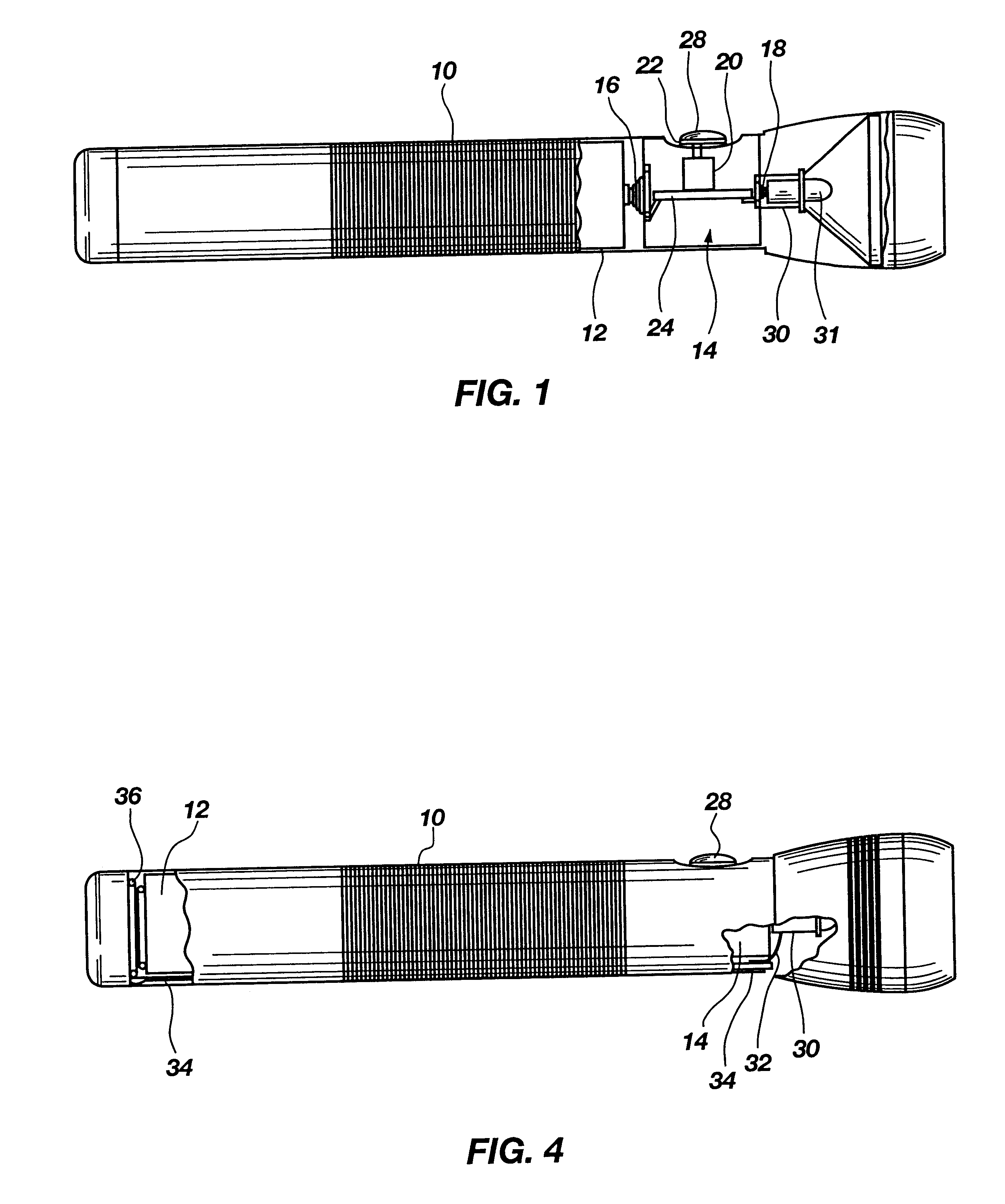

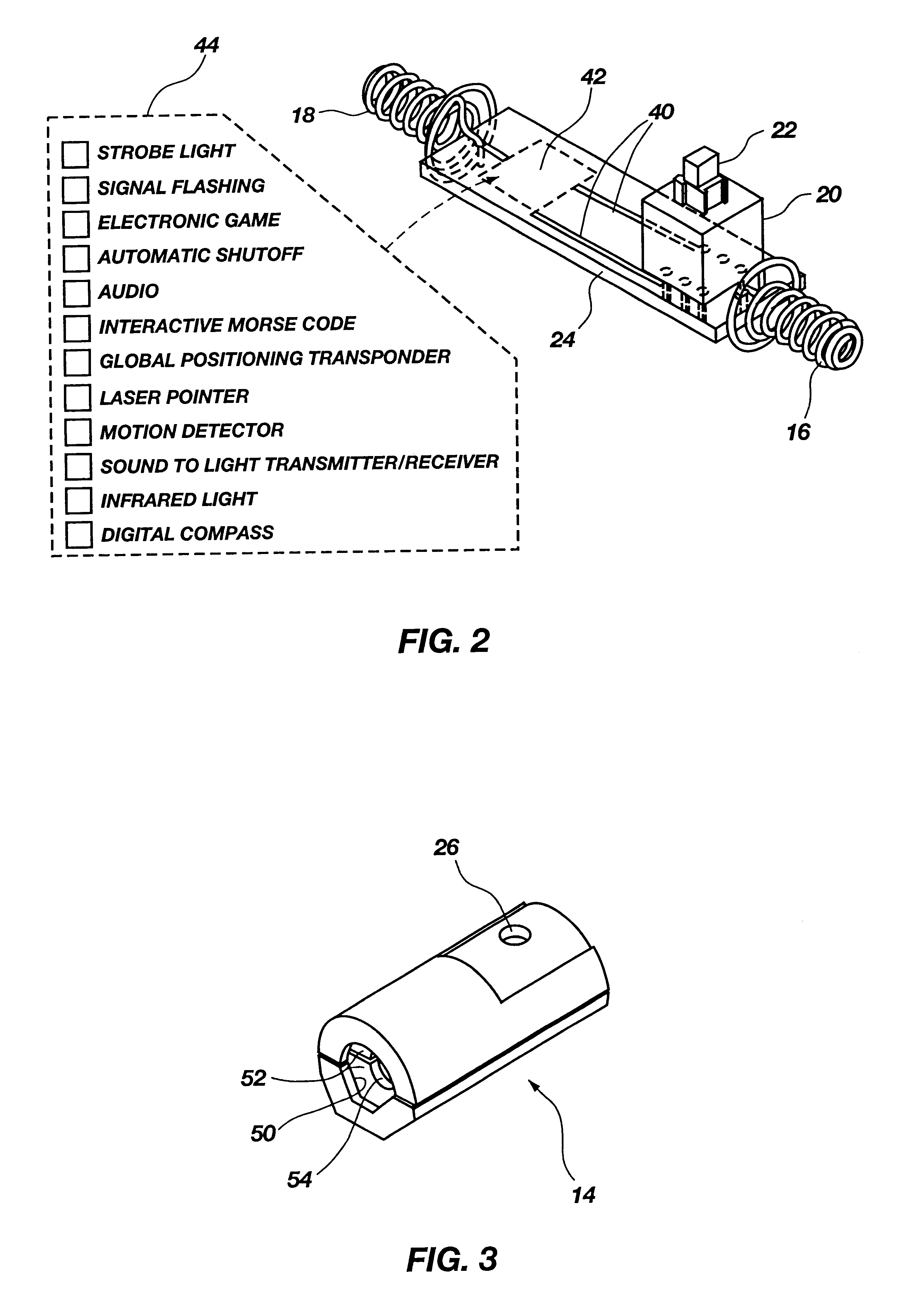

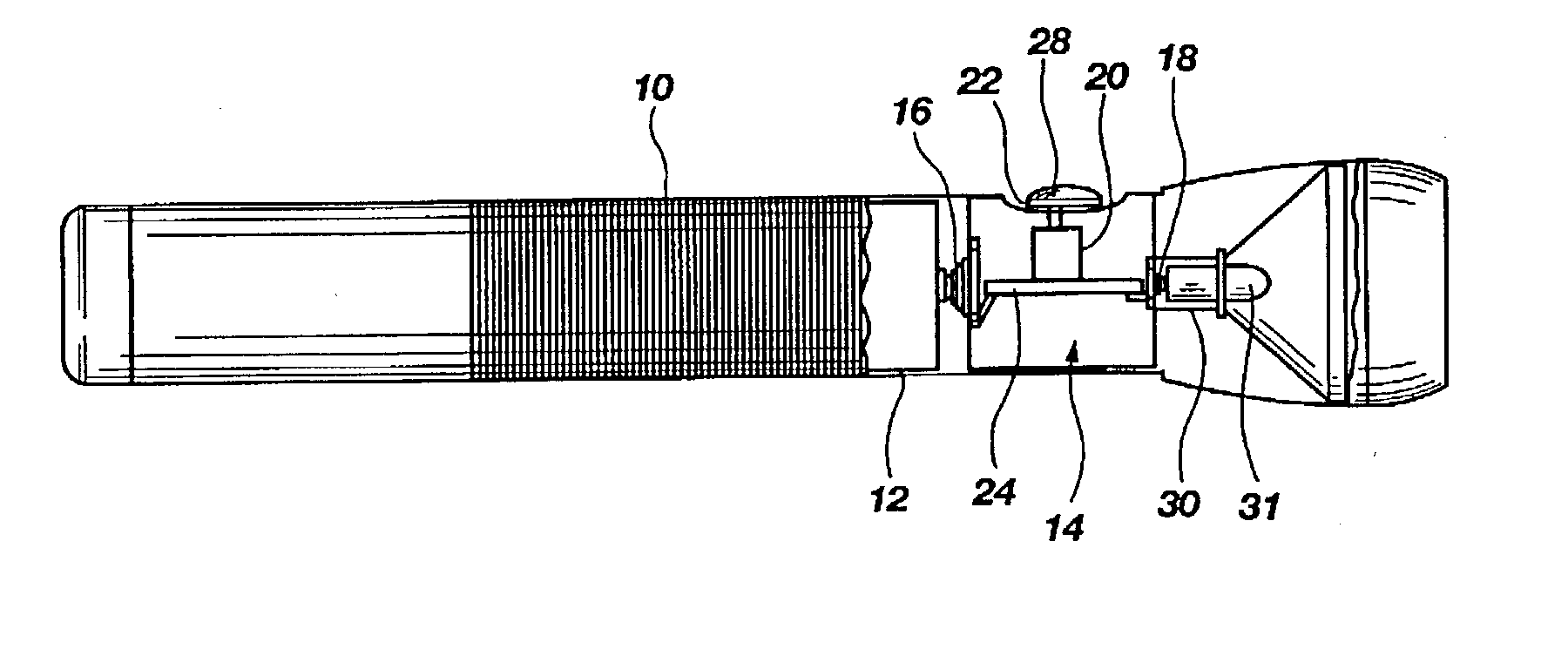

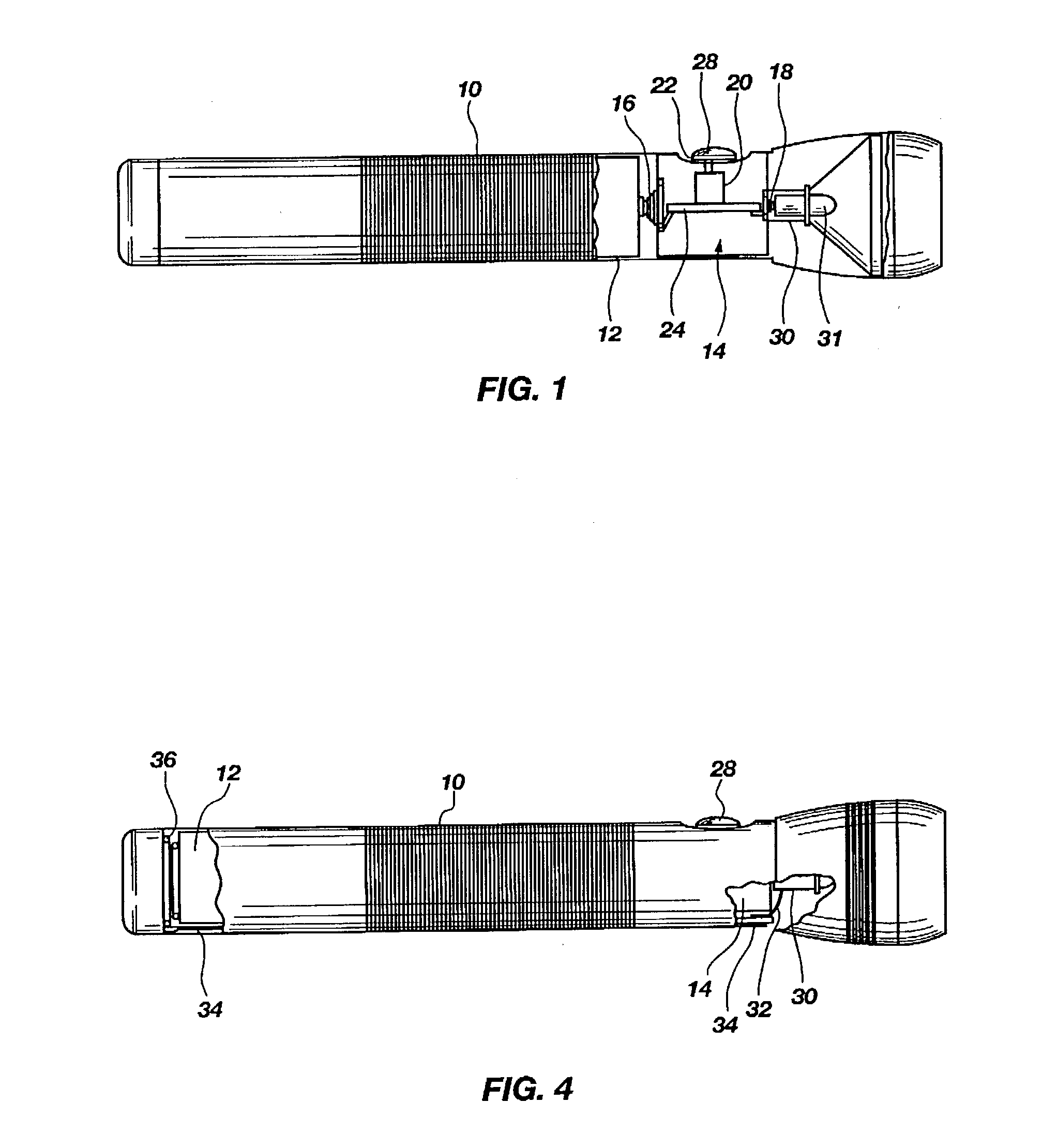

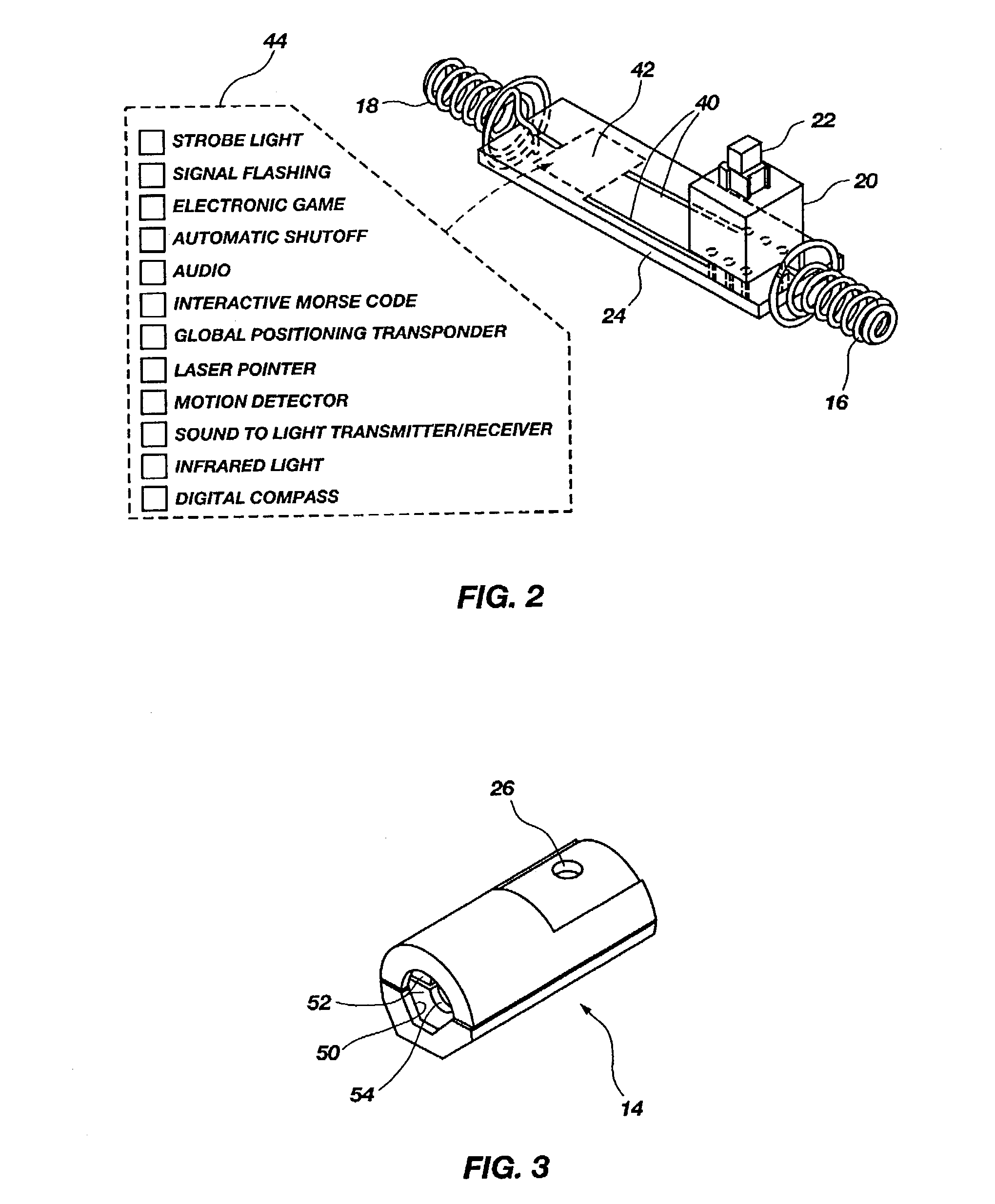

Flashlight and flashlight electrical connectors

InactiveUS6585391B1Easy to useAvoid high pressureContact surface shape/structurePoint-like light sourceElectricityElectrical resistance and conductance

A flashlight with unique flashlight electrical connections, including a switch structure featuring a switch requiring a small amount of force, and a short stroke distance to actuate, attached to a member on which a circuit adding additional functions to the flashlight may be located. The member has conductive springs attached to either end that are used to complete the electrical circuit with the battery and the lamp, while their compressive force is absorbed by a housing protecting the switch structure. A conductive strip is used to improve the conductivity of the circuit in a metal flashlight which has been provided with an electrically resistive protective coating.

Owner:MAG INSTR INC

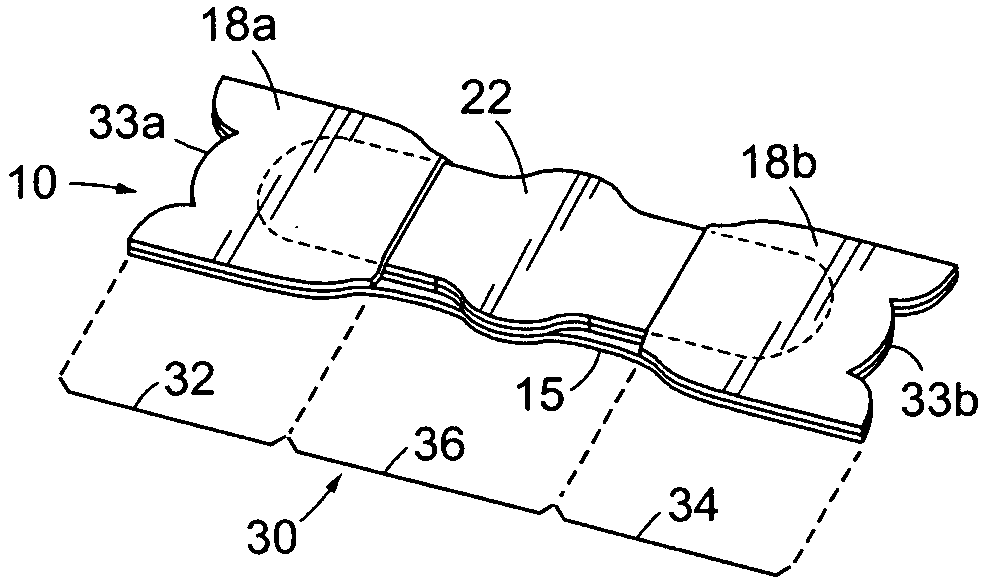

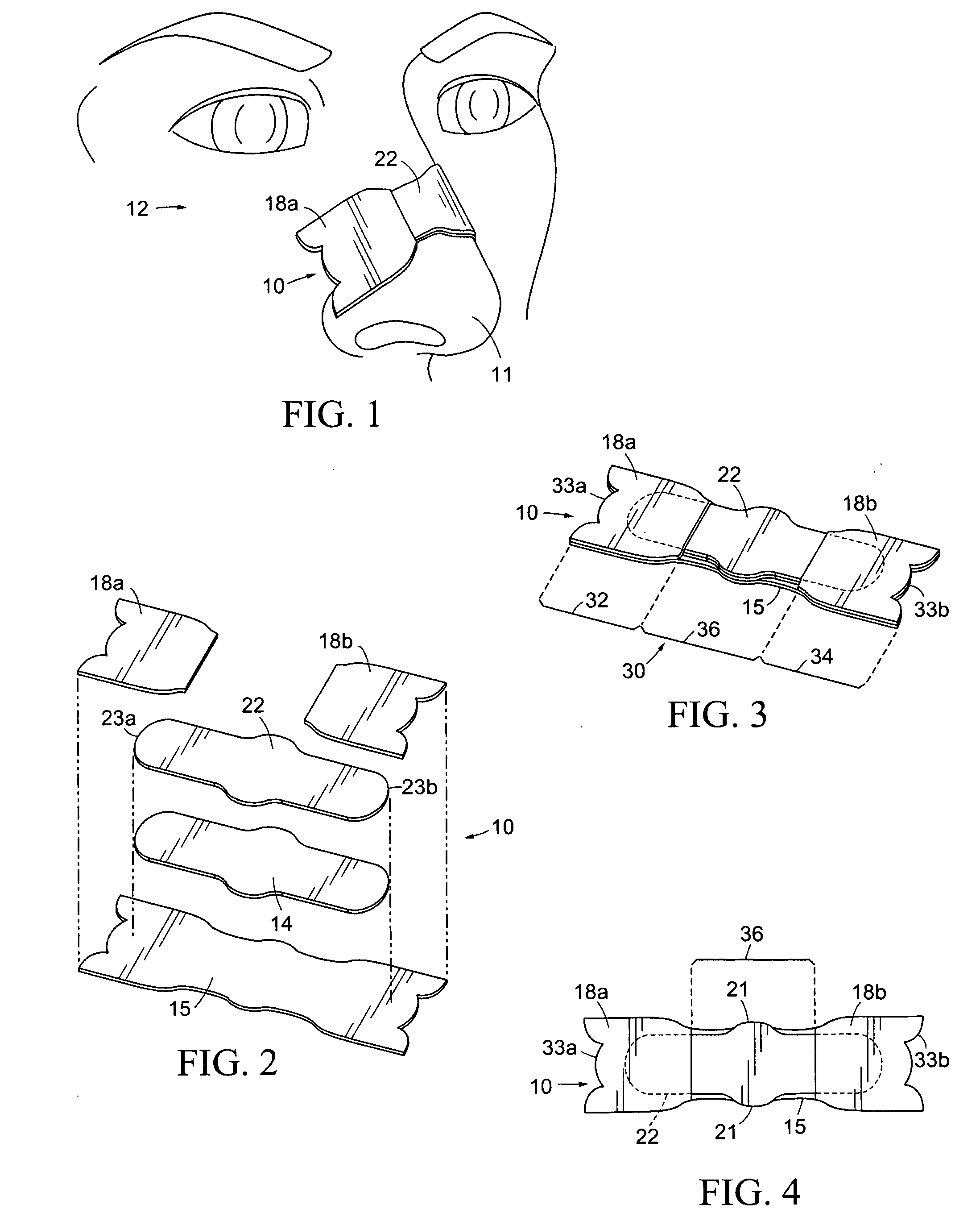

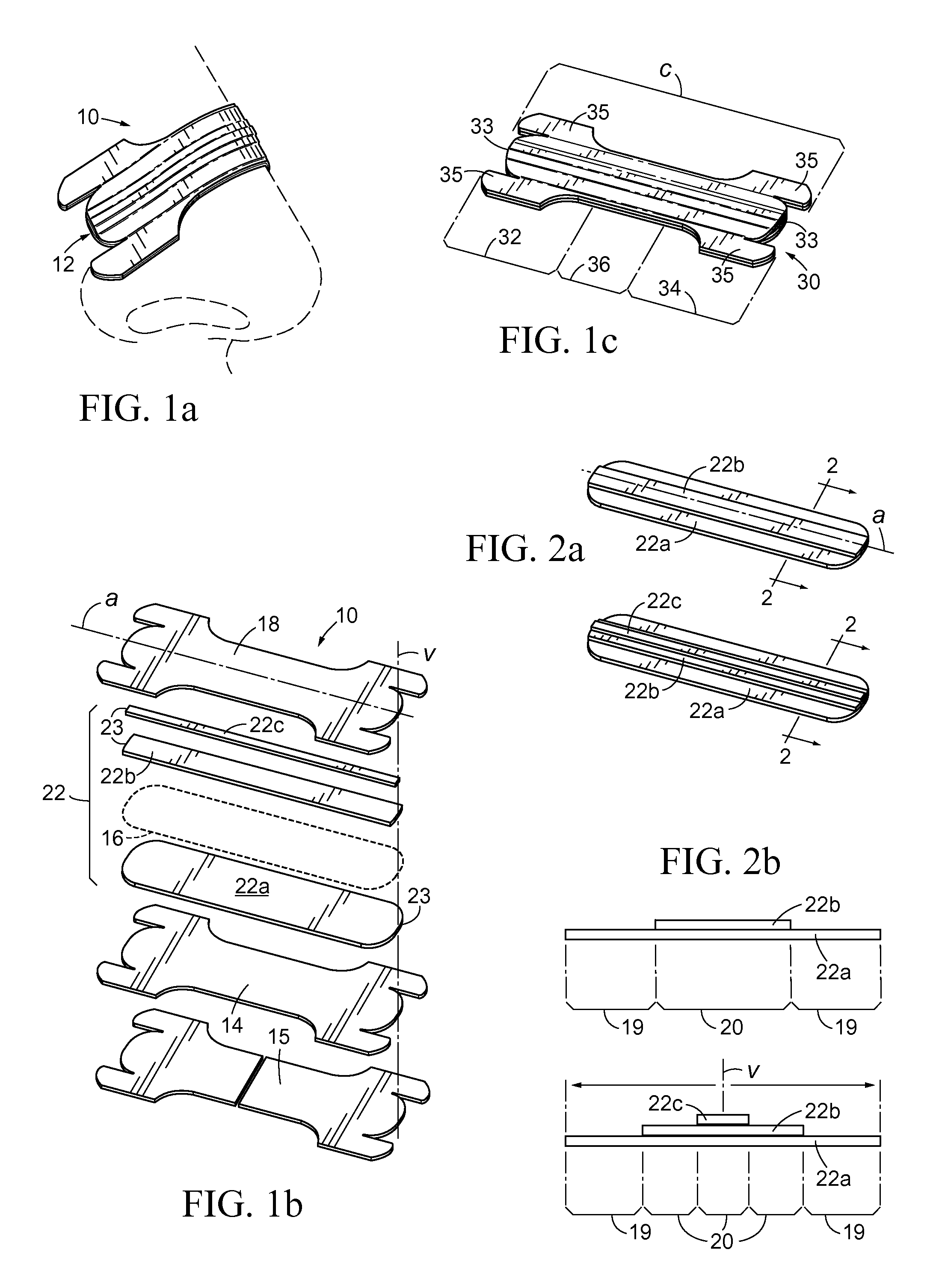

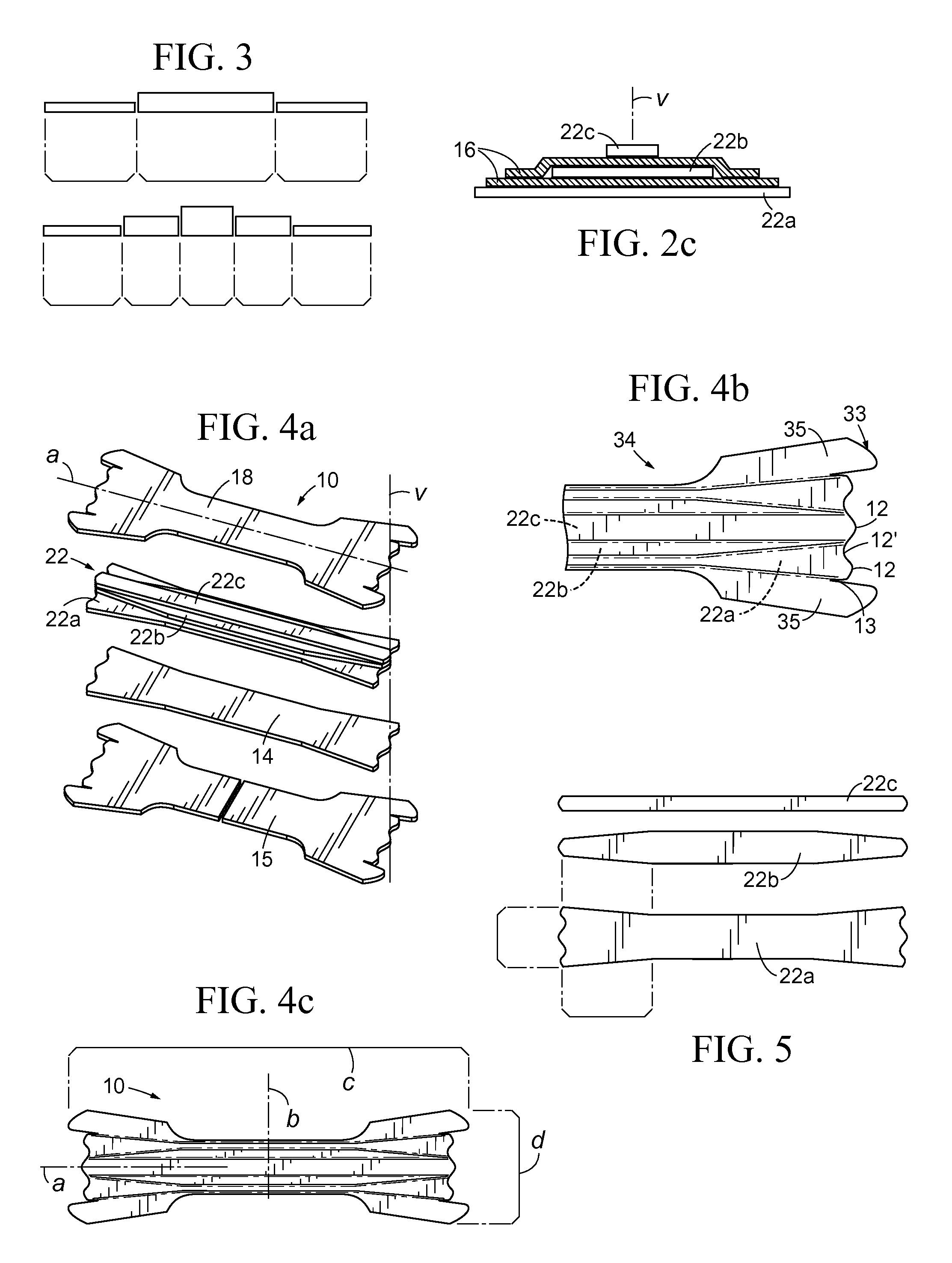

Nasal Dilator and Method of Manufacture

ActiveUS20090234383A1Efficient preparationEqual efficiencyLamination ancillary operationsSurgeryNasal passageNasal passages

A nasal dilator comprises a laminate of vertically stacked layers forming a unitary, or single body, truss where each layer includes at least one member. The truss features horizontal regions adapted to engage outer wall tissues of first and second nasal passages and to traverse the bridge of a nose therebetween. When in use the dilator acts to stabilize and / or expand the nasal outer wall tissues and prevent said tissues from drawing inward during breathing. Manufacturing methods produce dilator layers and / or finished nasal dilator devices efficiently at the same or lower cost as traditional methods by fabricating dilator elements in whole or part along common lines or edges. Said common lines define peripheral dimensions and form spaced apart relationships between dilator layers, members and finished dilator devices without sacrificing usable material to do so. Manufacturing steps include cutting through a fabrication laminate along lines defining at least portions of one or more layers, members, and the truss's peripheral edges. Manufacturing methods further maximize material usage by incorporating waste material into a subsequent fabrication process. Dilator embodiments further include means for providing disparate dilating force to opposing nasal passages, and means for incorporating promotional printing into the dilator fabrication process.

Owner:HORIZON IP TECH LLC

Light emitting device and method of manufacturing the same

InactiveUS20050127371A1Prevent degradationPrevent penetrationFinal product manufactureElectroluminescent light sourcesStress relaxationOxygen

The present invention has an object of providing a light emitting device including an OLED formed on a plastic substrate, which can prevent the degradation due to penetration of moisture or oxygen. On a plastic substrate, a plurality of films for preventing oxygen or moisture from penetrating into an organic light emitting layer in the OLED (hereinafter, referred to as barrier films) and a film having a smaller stress than that of the barrier films (hereinafter, referred to as a stress relaxing film), the film being interposed between the barrier films, are provided. Owing to a laminate structure of a plurality of barrier films, even if a crack occurs in one of the barrier films, the other barrier film(s) can effectively prevent moisture or oxygen from penetrating into the organic light emitting layer. Moreover, the stress relaxing film, which has a smaller stress than that of the barrier films, is interposed between the barrier films, thereby making it possible to reduce a stress of the entire sealing film. As a result, a crack due to stress hardly occurs.

Owner:SEMICON ENERGY LAB CO LTD

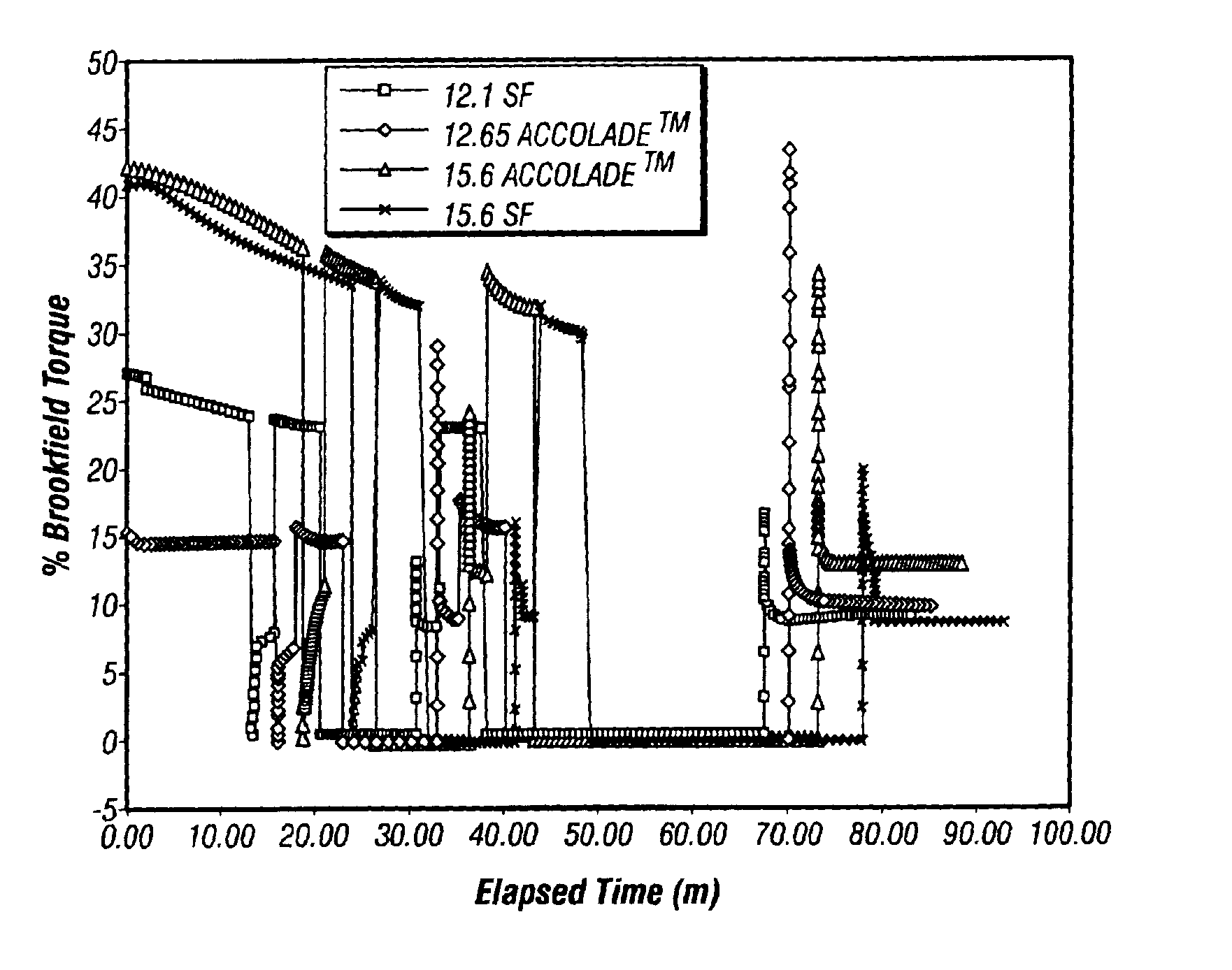

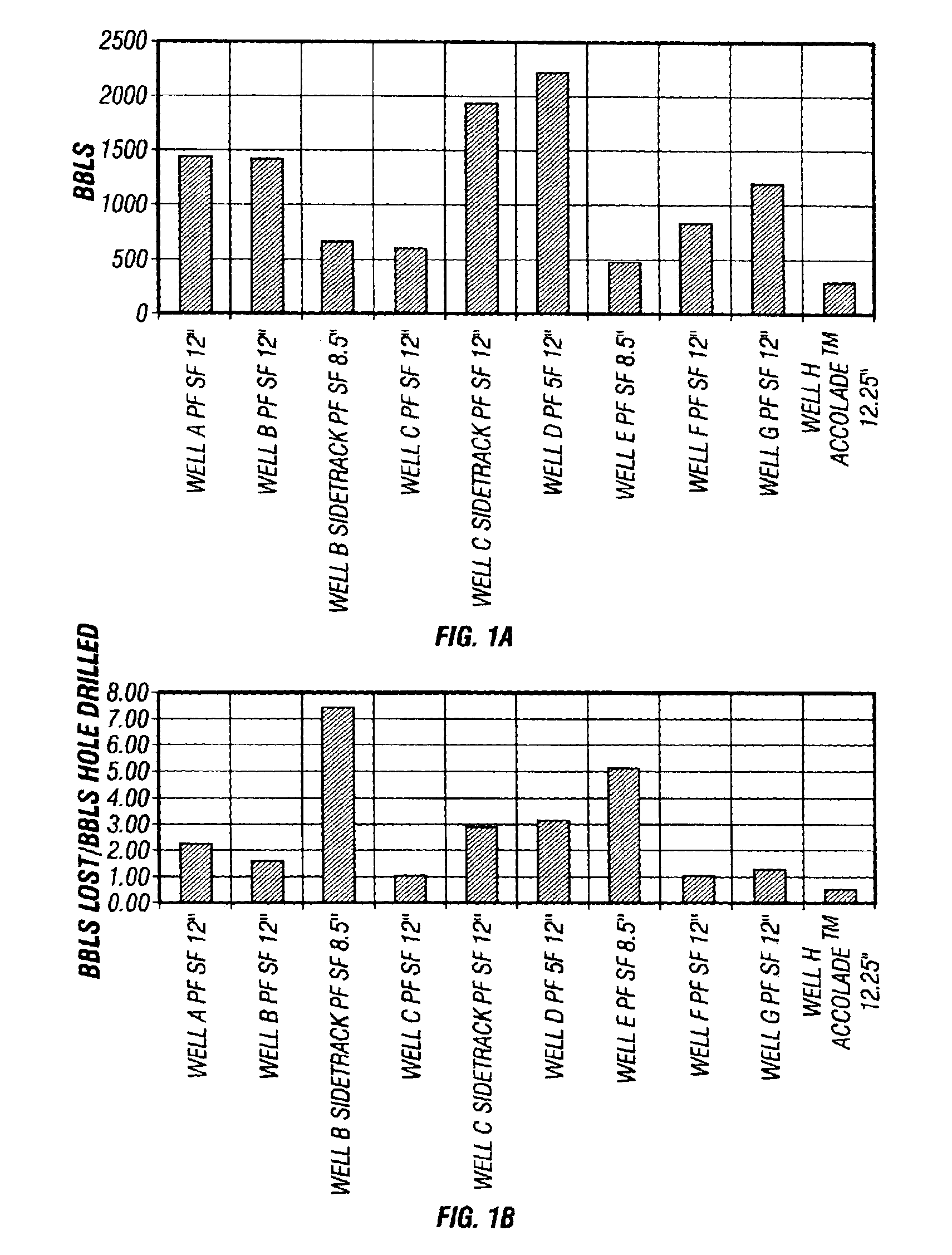

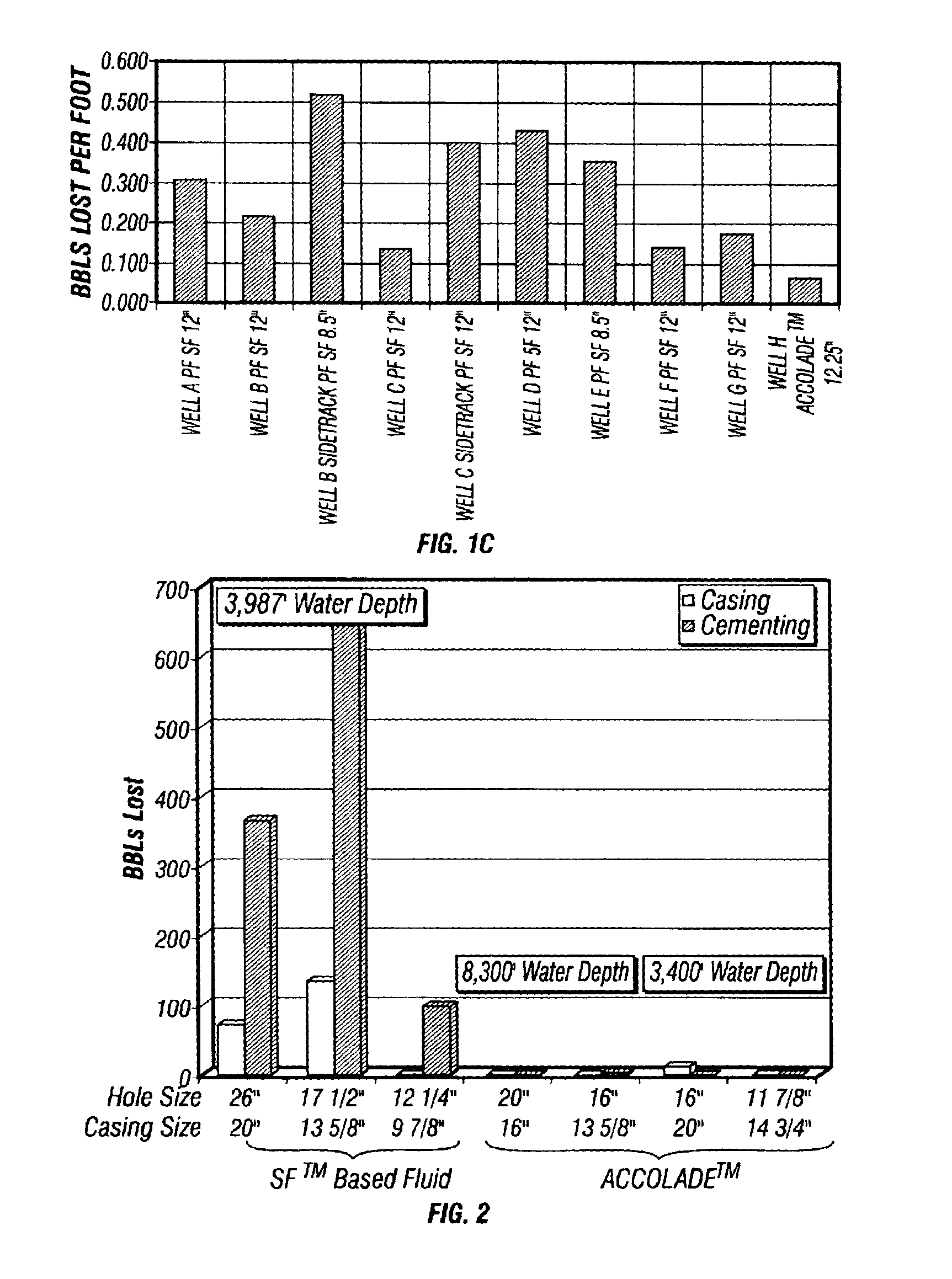

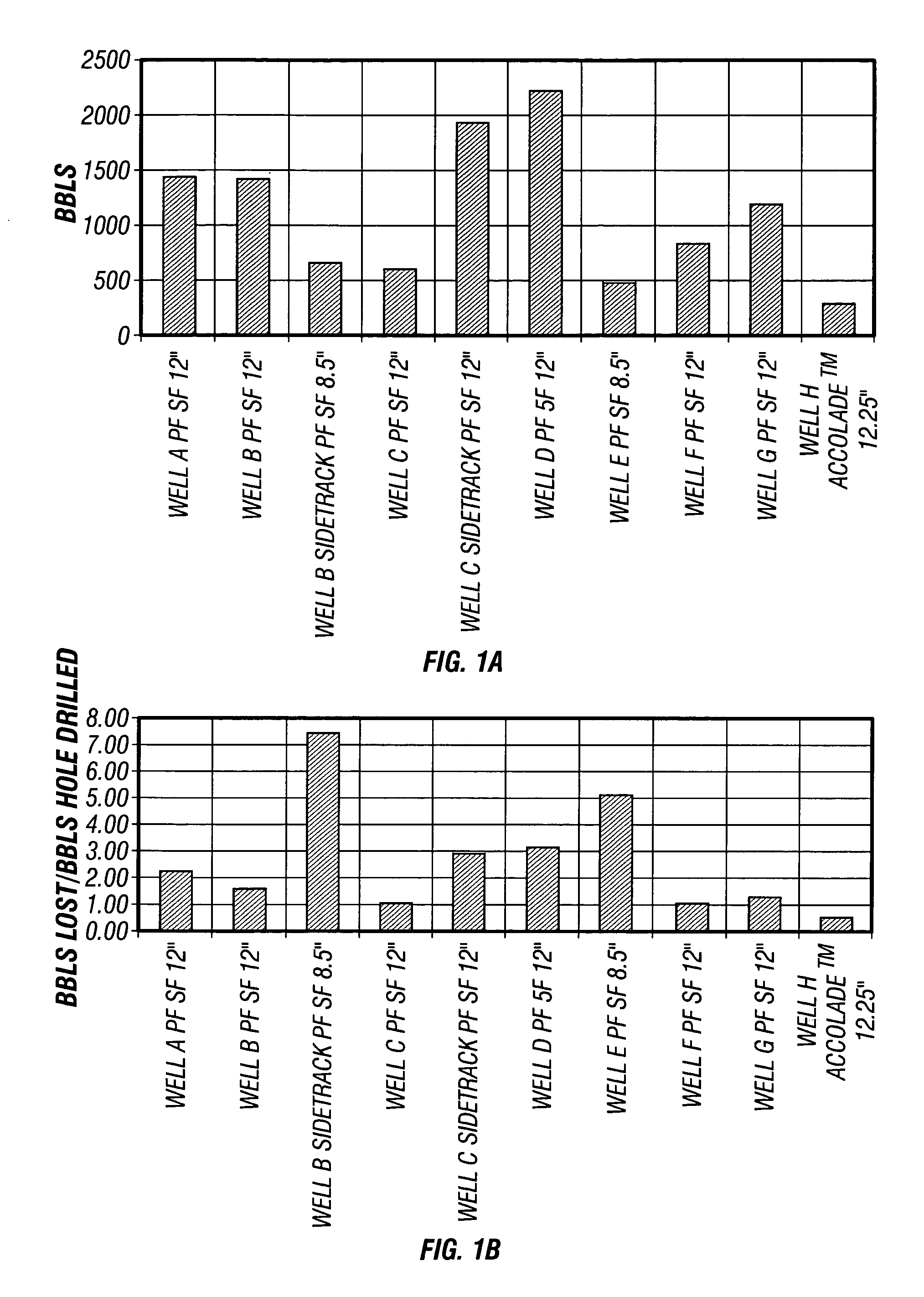

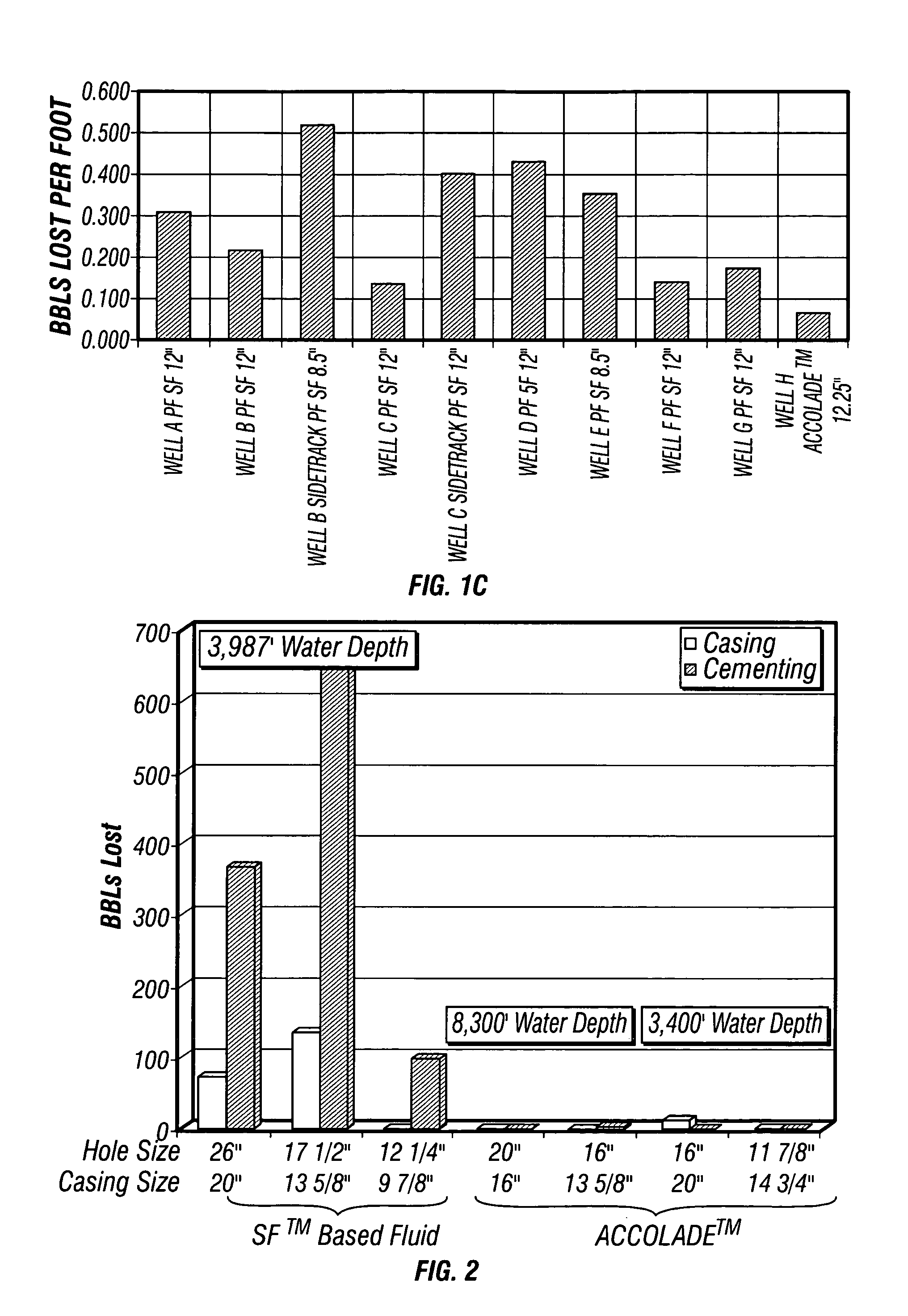

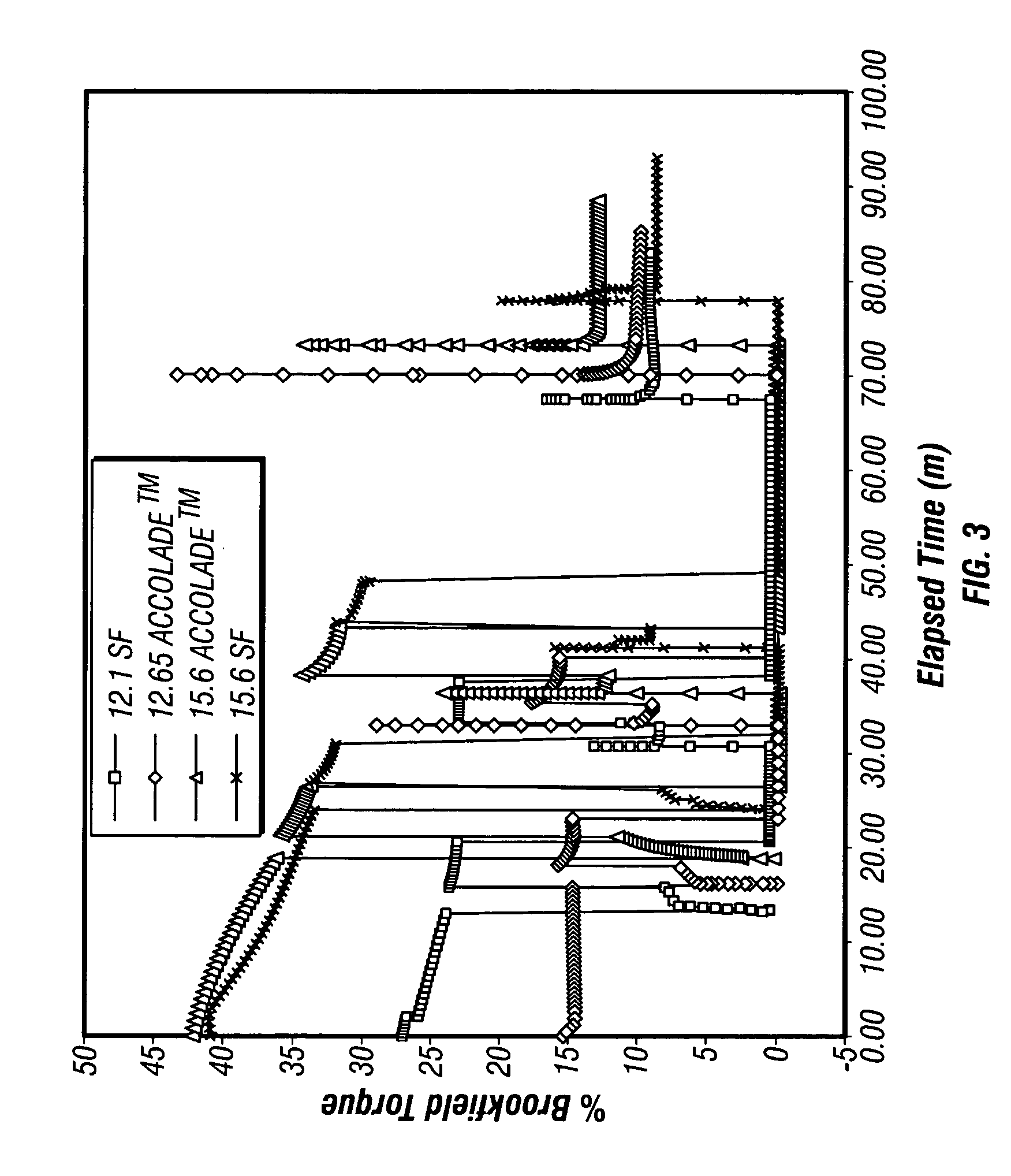

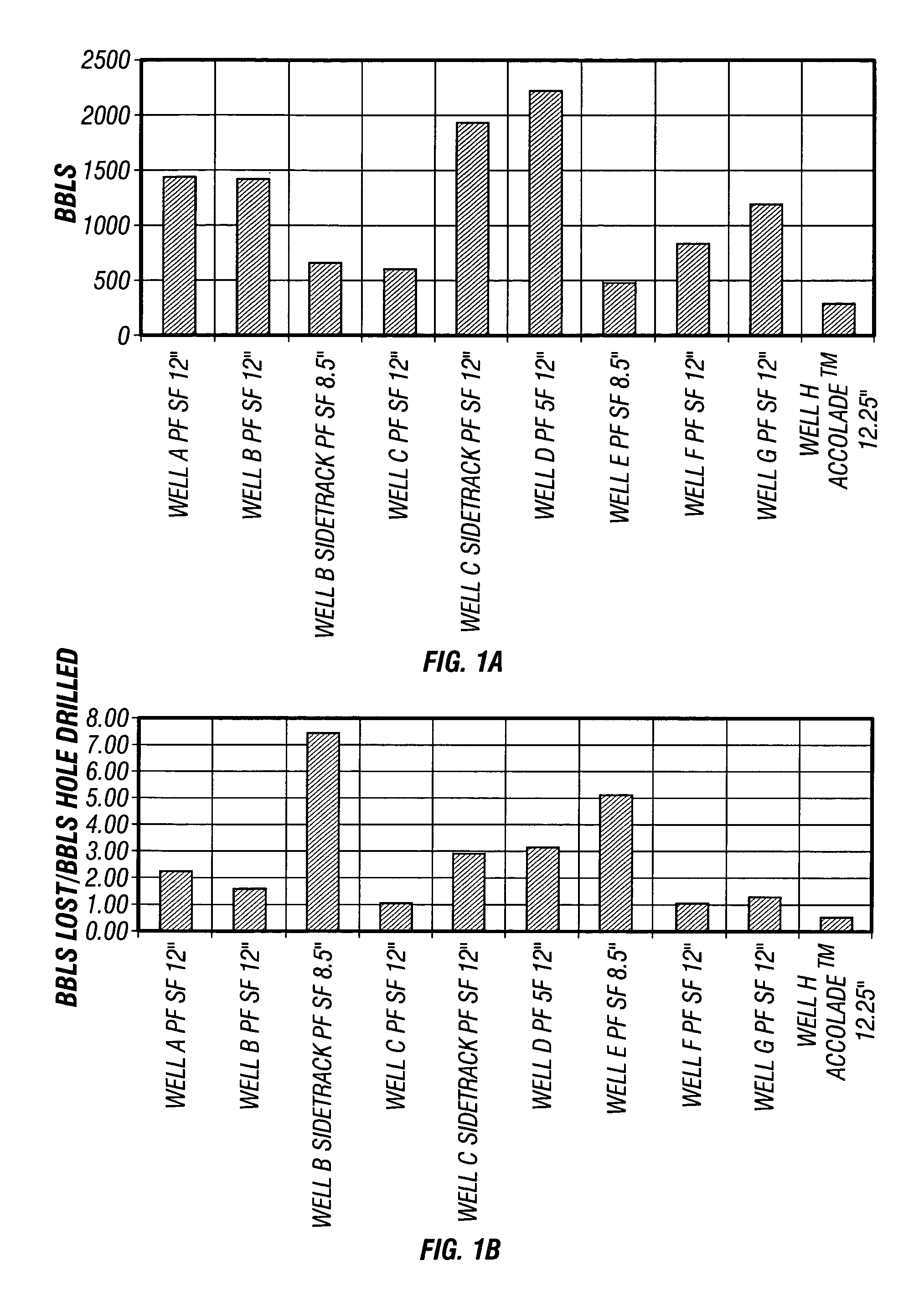

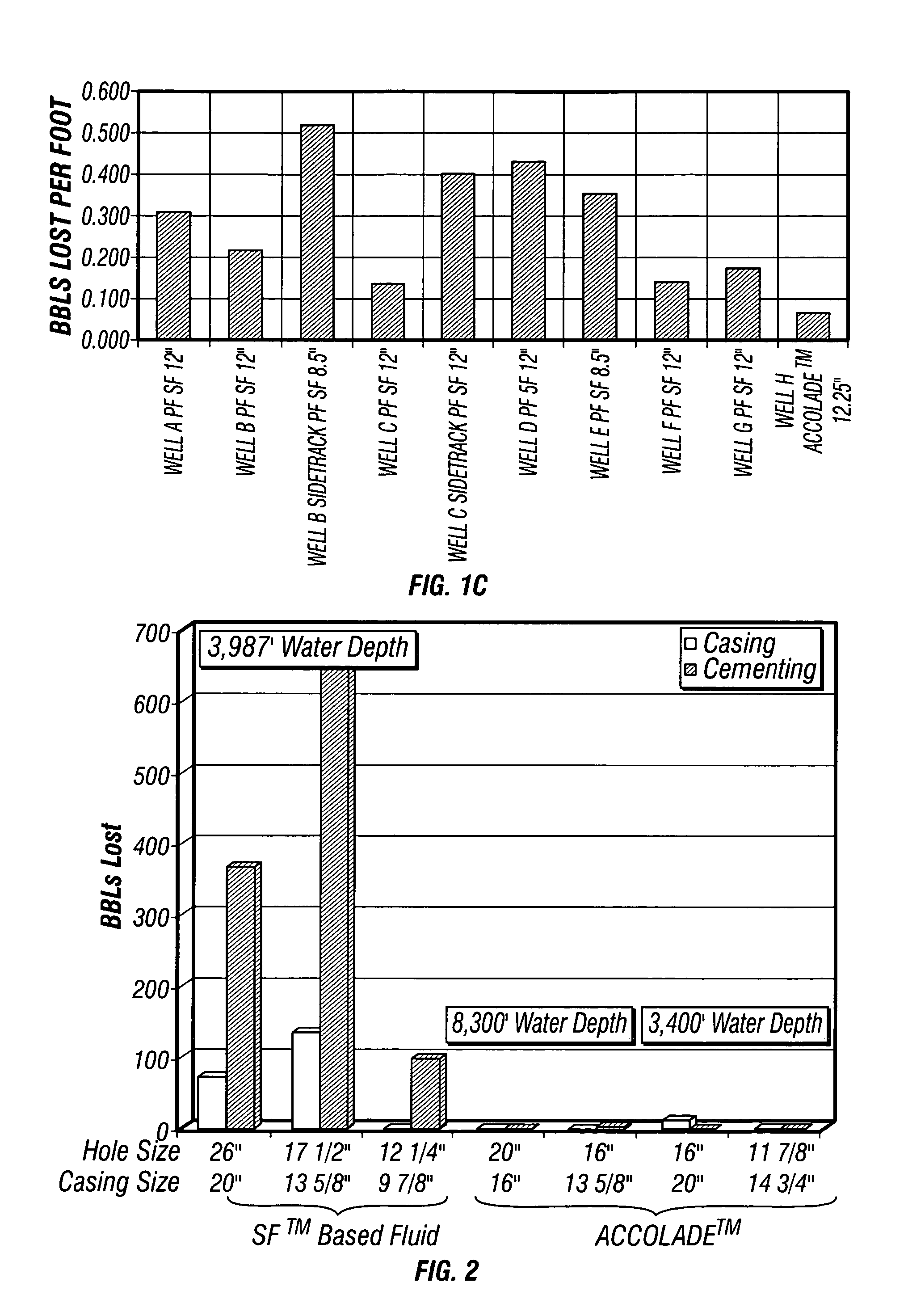

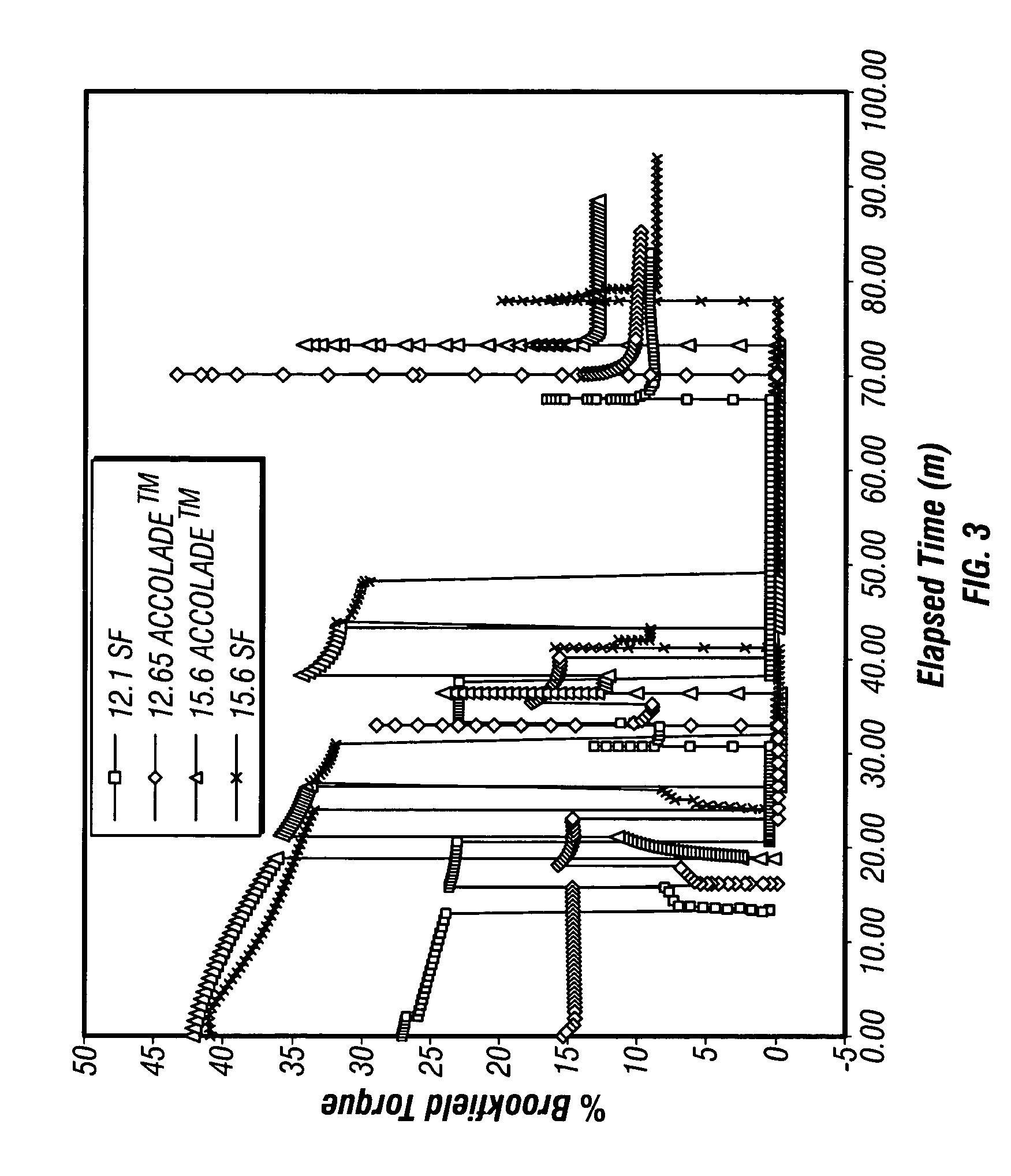

Method of formulating and using a drilling mud with fragile gels

A method for drilling, running casing in, and / or cementing a borehole in a subterranean formation without significant loss of drilling fluid is disclosed, as well as compositions for use in such method. The method employs a drilling fluid comprising a fragile gel or having fragile gel behavior and providing superior oil mud rheology and overall performance. The fluid is especially advantageous for use in deep water wells because the fluid exhibits minimal difference between downhole equivalent circulating density and surface density notwithstanding differences in drilling or penetration rates. When an ester and isomerized olefin blend is used for the base of the fluid, the fluid makes an environmentally acceptable and regulatory compliant invert emulsion drilling fluid. The fluid preferably contains no organophilic clays.

Owner:HALLIBURTON ENERGY SERVICES INC

Fin-type field effect transistor

ActiveUS7348642B2Reduce resistanceReduce capacitanceTransistorSolid-state devicesDriving currentCapacitance

Owner:AURIGA INNOVATIONS INC

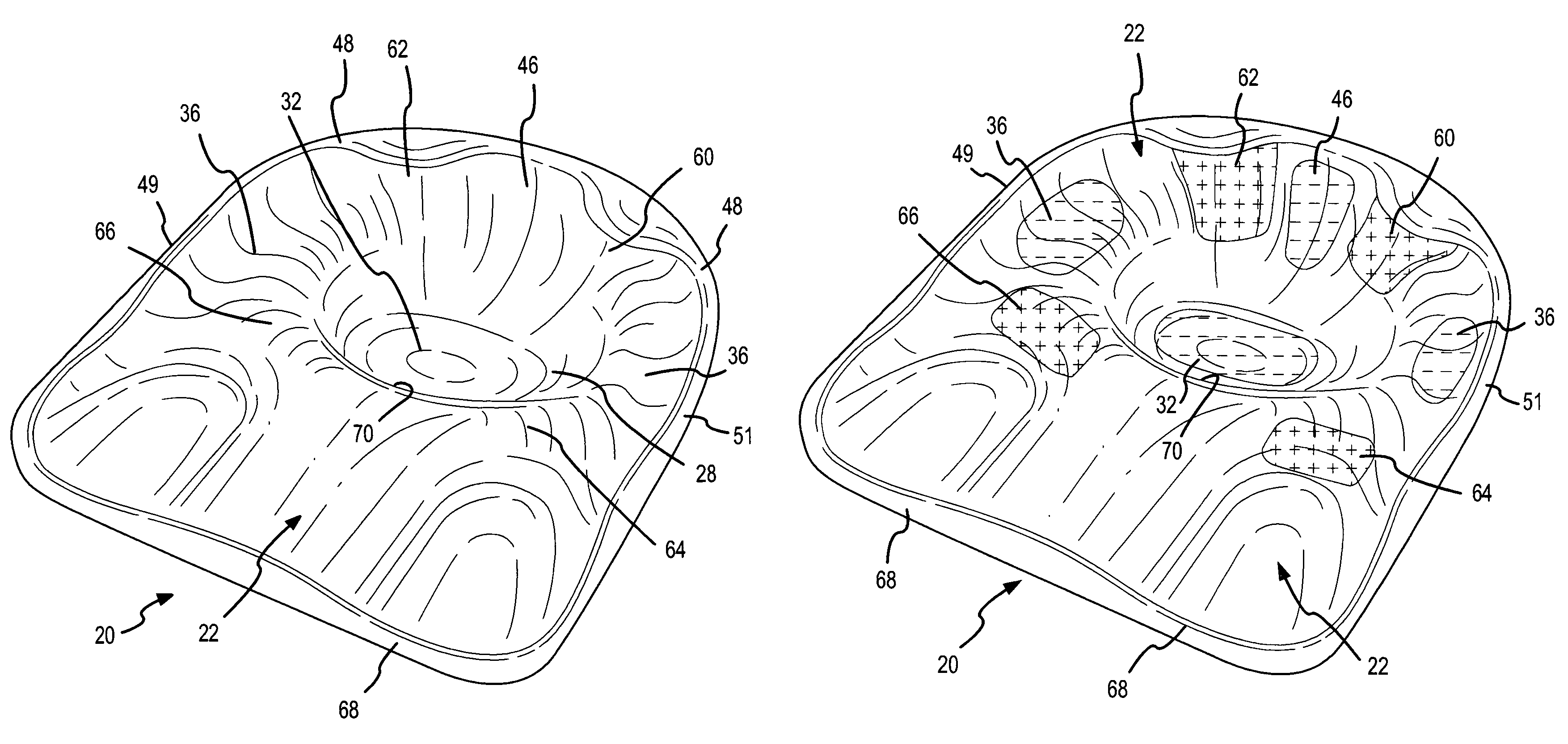

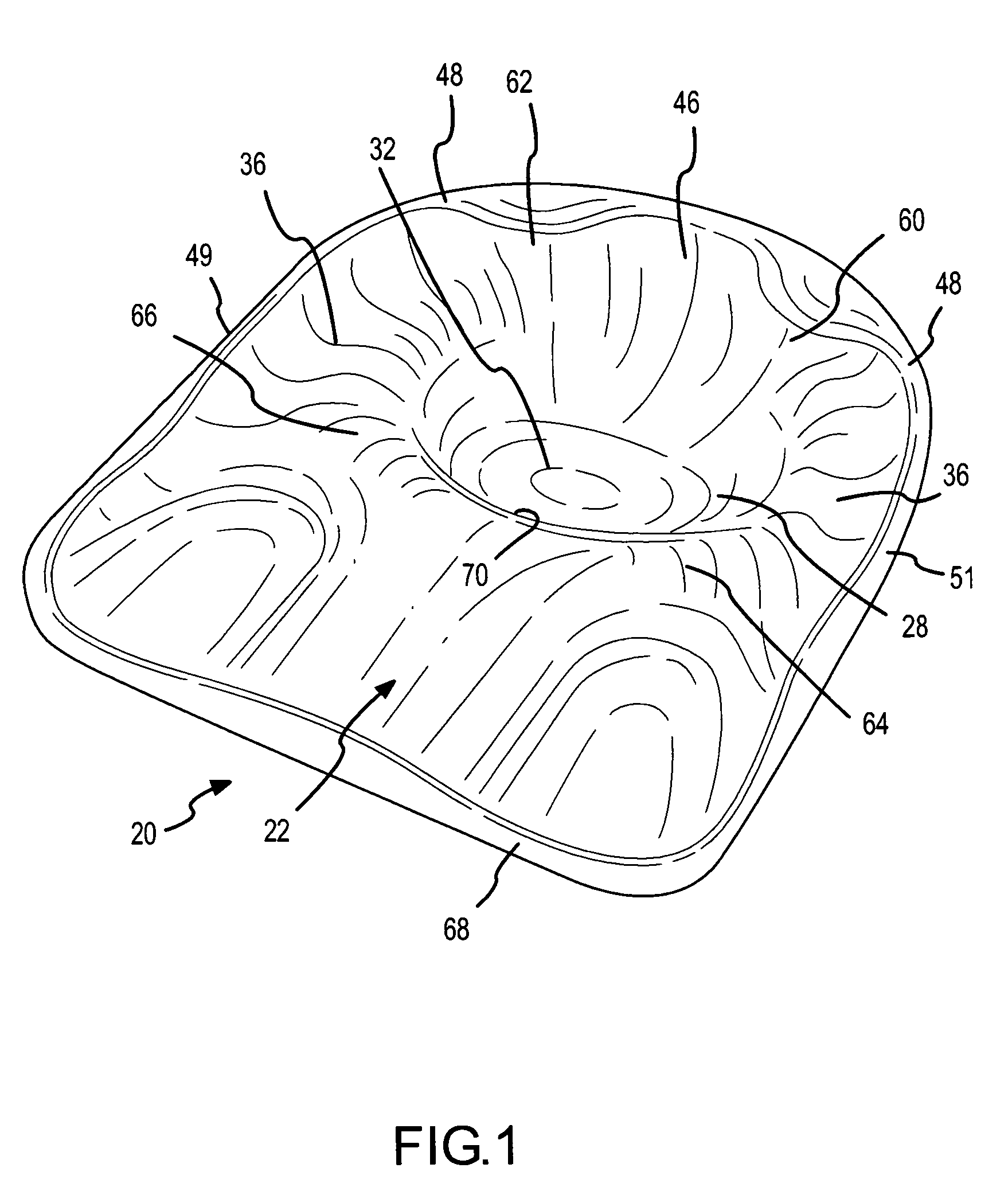

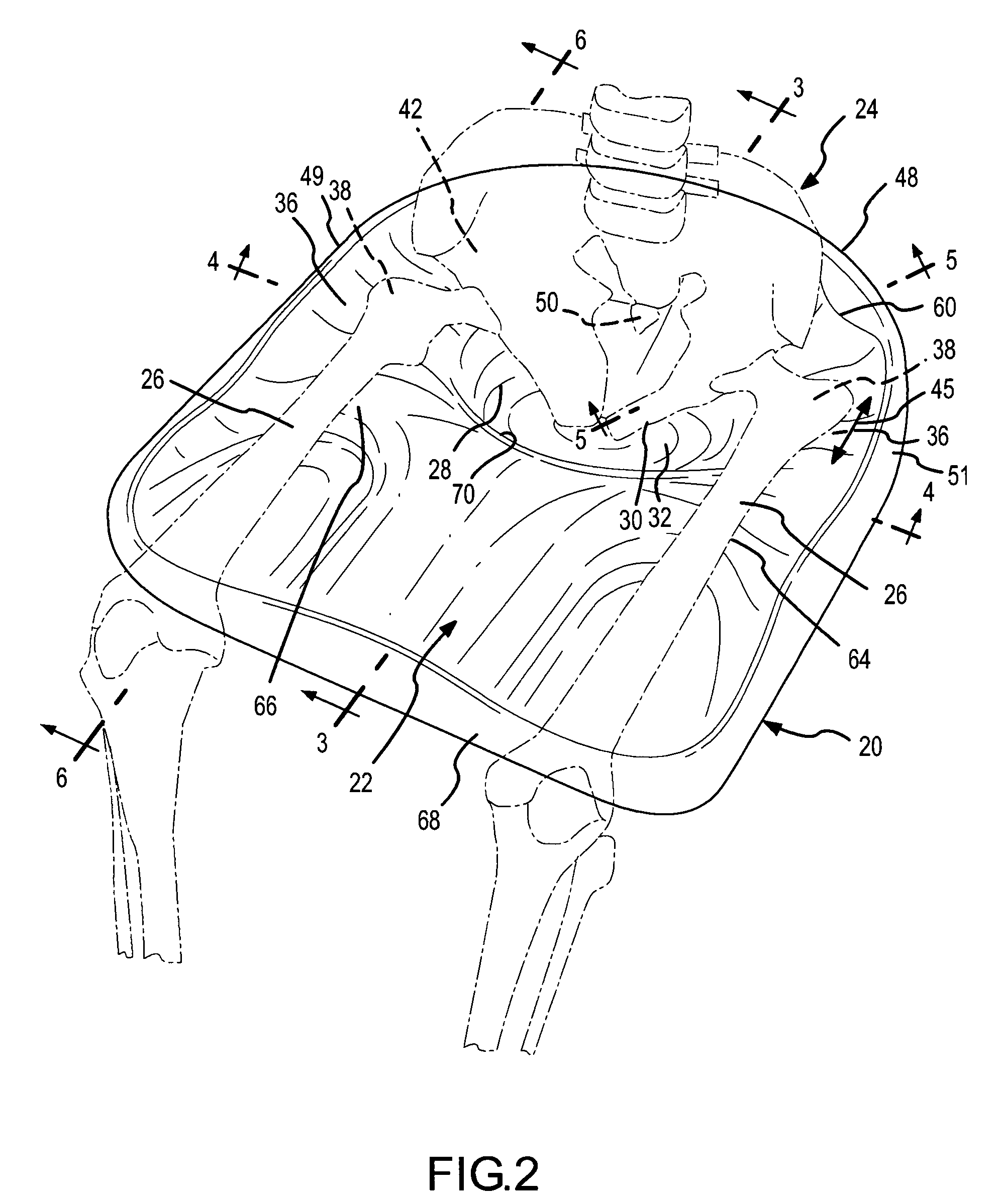

Contoured seat cushion and method for offloading pressure from skeletal bone prominences and encouraging proper postural alignment

InactiveUS7216388B2Reduce riskIncreased riskSofasWheelchairs/patient conveyanceSkin breakdownButtocks

A support contour of a cushion, such as a wheelchair cushion, defines relief areas at locations adjacent to skin covering the ischial tuberosities, the greater trochanters and the coccyx and sacrum of a person sitting on the support contour. Support areas of the support contour transfer force into the pelvic area adjacent to skin covering tissue masses on opposite lateral sides of the posterior buttocks and beneath the proximal thighs of the person. Greater clearance is also provided in the perineal area. Risks of pressure ulcers from pressure and shear forces on bony prominences is reduced while providing support at the broader areas without bony prominences in such a manner to encourage postural alignment. The risks of skin breakdown perineal are diminished.

Owner:ASPEN SEATING

Pressure-sensitive adhesive for optical films

ActiveUS20090305068A1High viscosityEasy to operateFilm/foil adhesivesSynthetic resin layered productsPolymer scienceHeat resistance

Pressure-sensitive adhesives for optical films exhibit high cohesion, excellent re-workability, adhesion properties, heat resistance and durability without chemical crosslinking.A pressure-sensitive adhesive contains an acrylic triblock copolymer (I) at not less than 60% by mass based on the total mass of all solids contained in the pressure-sensitive adhesive, the acrylic triblock copolymer being represented by the formula A1-B-A2 wherein: A1 and A2 are each independently an alkyl methacrylate polymer block having Tg of not less than 100° C. and B is an acryl acrylate polymer block having Tg of not more than −20° C.; the content of the polymer block B is 50 to 95% by mass; Mw is in the range of 50,000 to 300,000; and the molecular weight distribution is in the range of 1.0 to 1.5. In a preferred embodiment, the acrylic triblock copolymer (I) is a combination of an acrylic triblock copolymer (Ia) having Mw of 50,000 to less than 100,000 and an acrylic triblock copolymer (Ib) having Mw of 100,000 to 300,000, in a mass ratio (Ia):(Ib) of 45:55 to 75:25.

Owner:KURARAY CO LTD

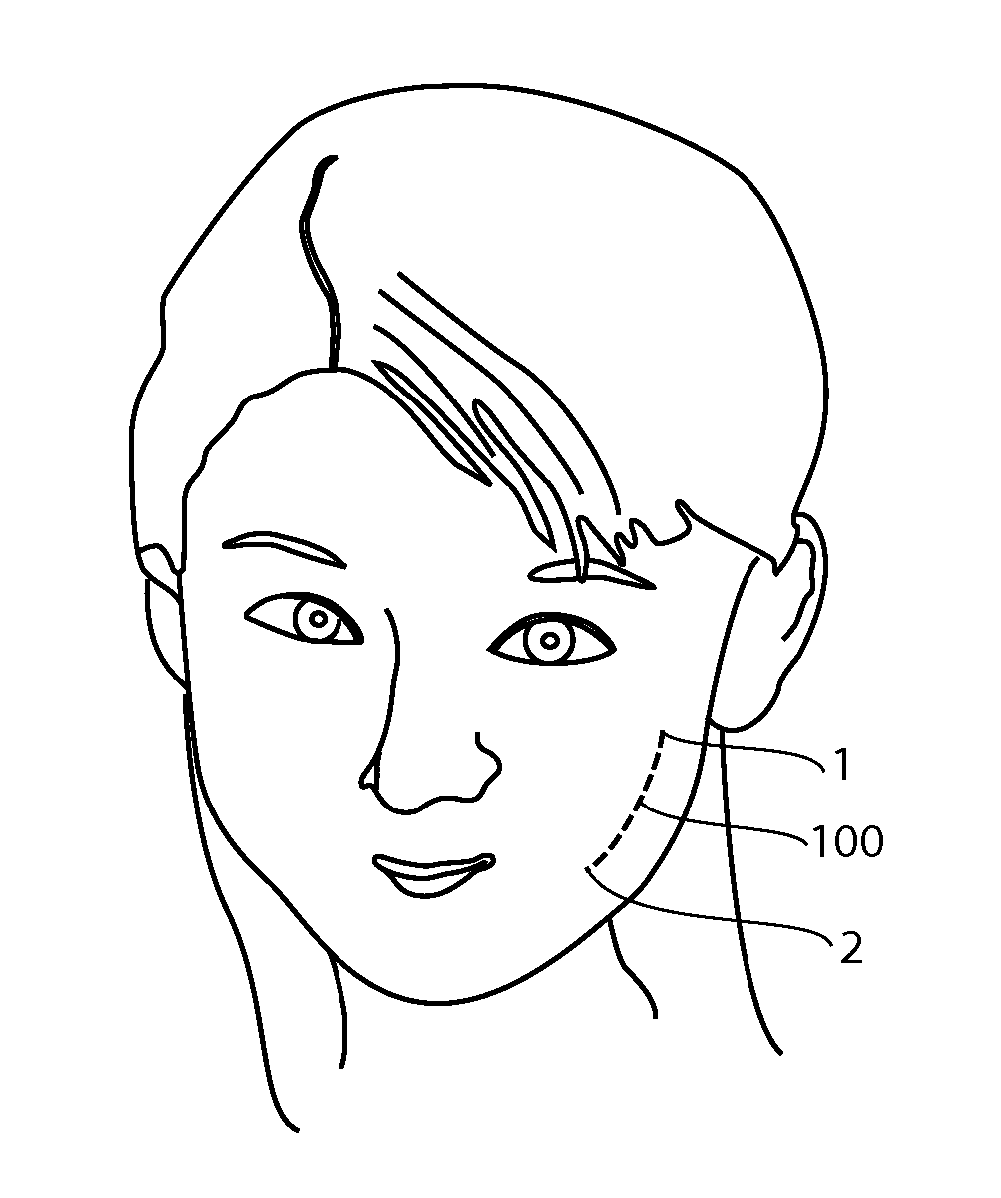

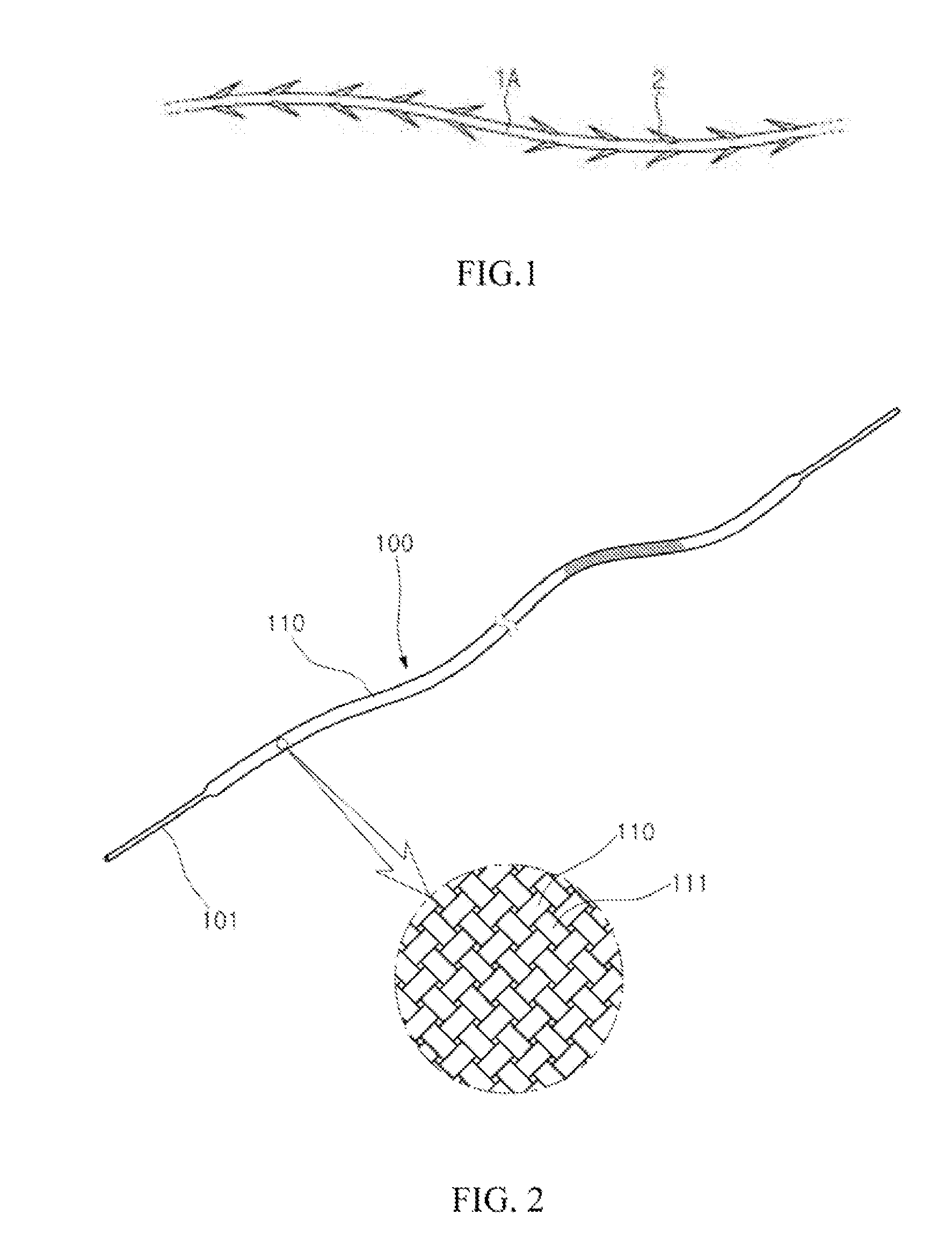

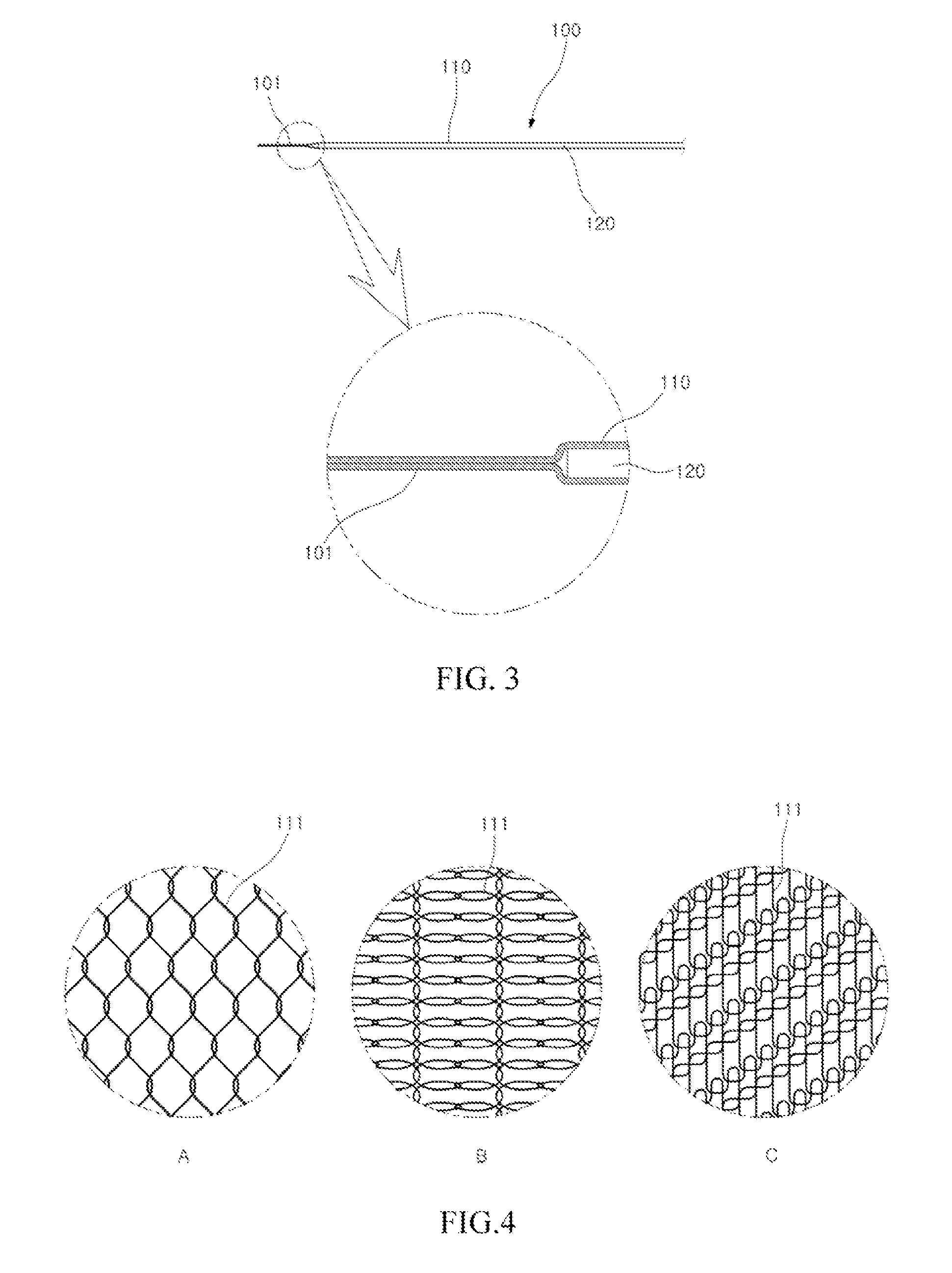

Linear tension material for plastic surgery

InactiveUS20080046094A1High strengthAvoid fatigueSuture equipmentsCosmetic implantsWrinkle skinFiber

The present invention relates to a linear tension material for surgery used to pull skin tissue. An object of the present invention is to provide a linear tension material for plastic surgery which prevents permanent deformation due to excessive elongation and fatigue and of which a portion besides united portions is uniformly and properly united with body tissue. According to an aspect of the present invention, there is provided a linear tension material for plastic surgery which is provided to pull a predetermined site inside skin tissue of the body in a state of tensile load so as to smooth out wrinkles and pull the tissue to tighten a saggy portion, the linear tension material including: a core material in a code shape, which is made of a flexible resin including polyorganosiloxane; and a covering material which covers an outside of the core material to be united with the core material, shrinks together with the core material, and has a fiber textile structure formed by weaving a number of fiber threads.

Owner:HAN KWANG HEE +1

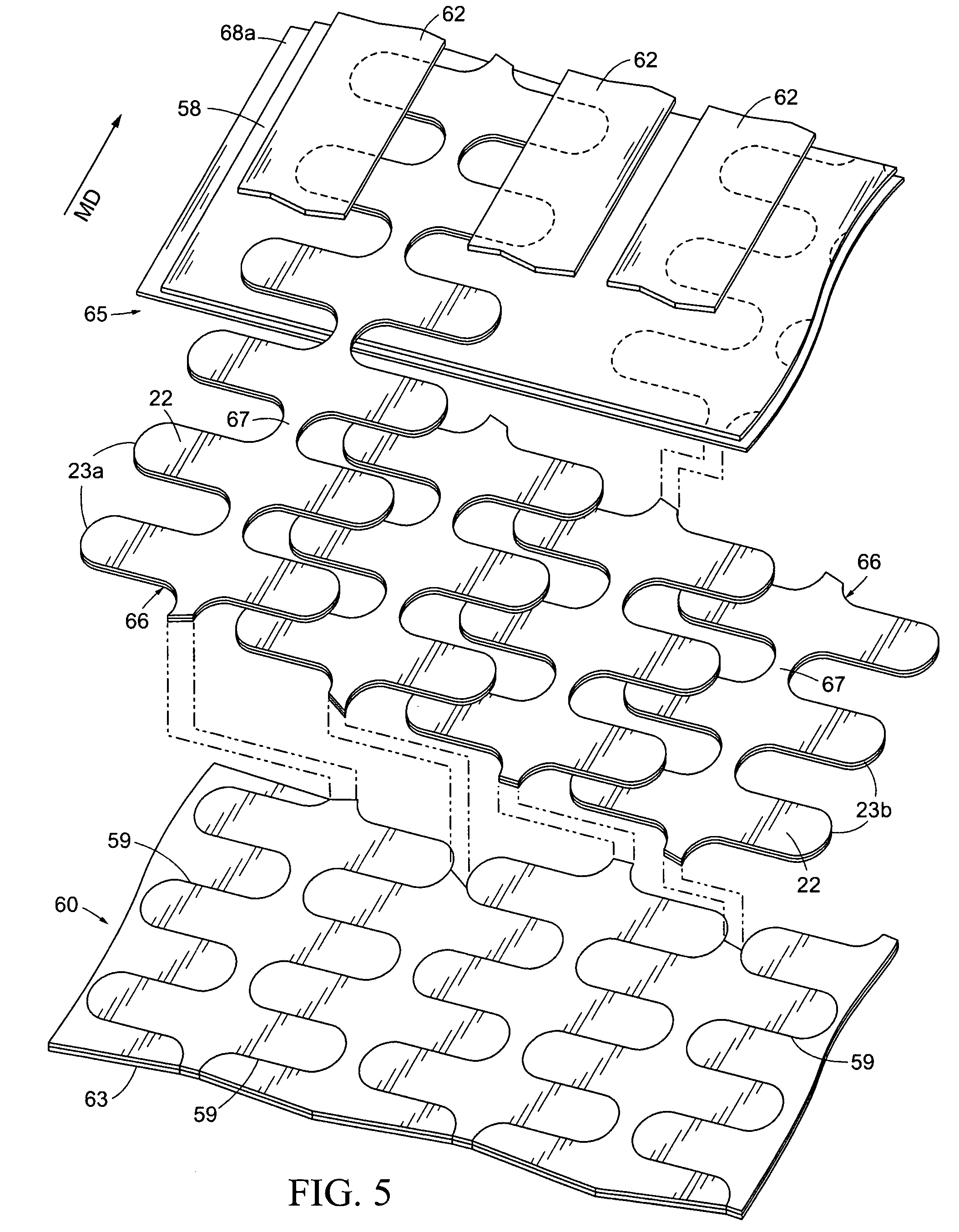

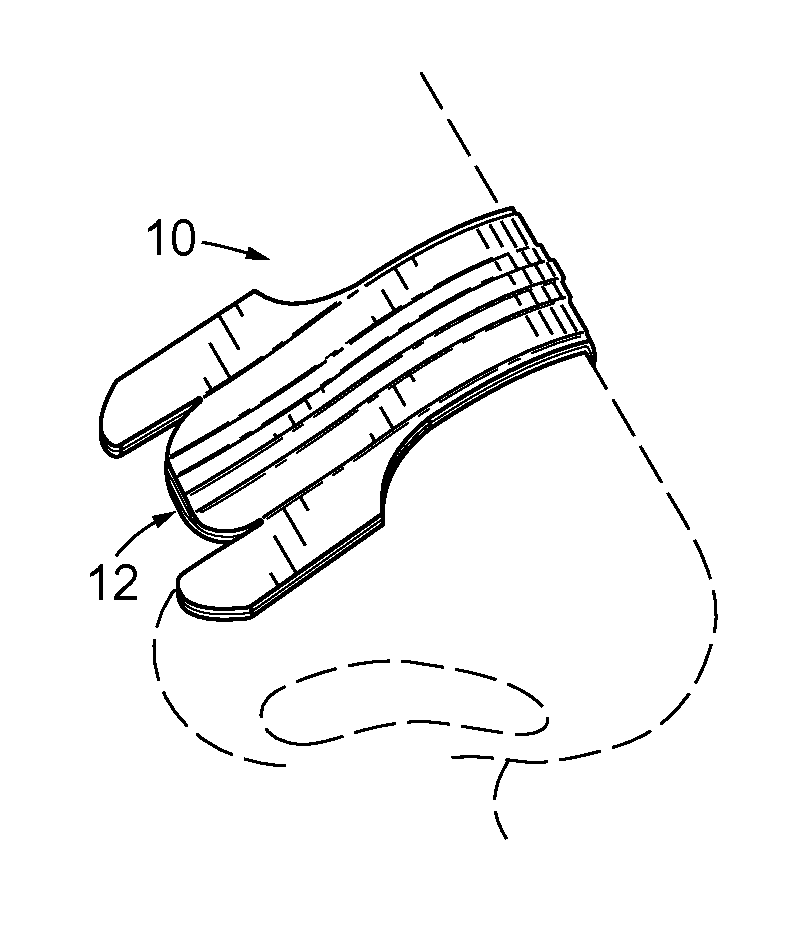

Overlapping Resilient Member Structures in Nasal Dilator Devices

ActiveUS20130104882A1Easy to removeLittle and no stressRespiratorsBreathing masksNasal dilatorsStructural engineering

A nasal dilator is constructed as a single body truss having a resilient member structure comprising a plurality of overlaid, island-placed, or overlapping resilient members. Methods of mass producing dilator devices, individual resilient members, and overlapped, overlaid, and island-placed resilient member structures are also disclosed.

Owner:HORIZON IP TECH LLC

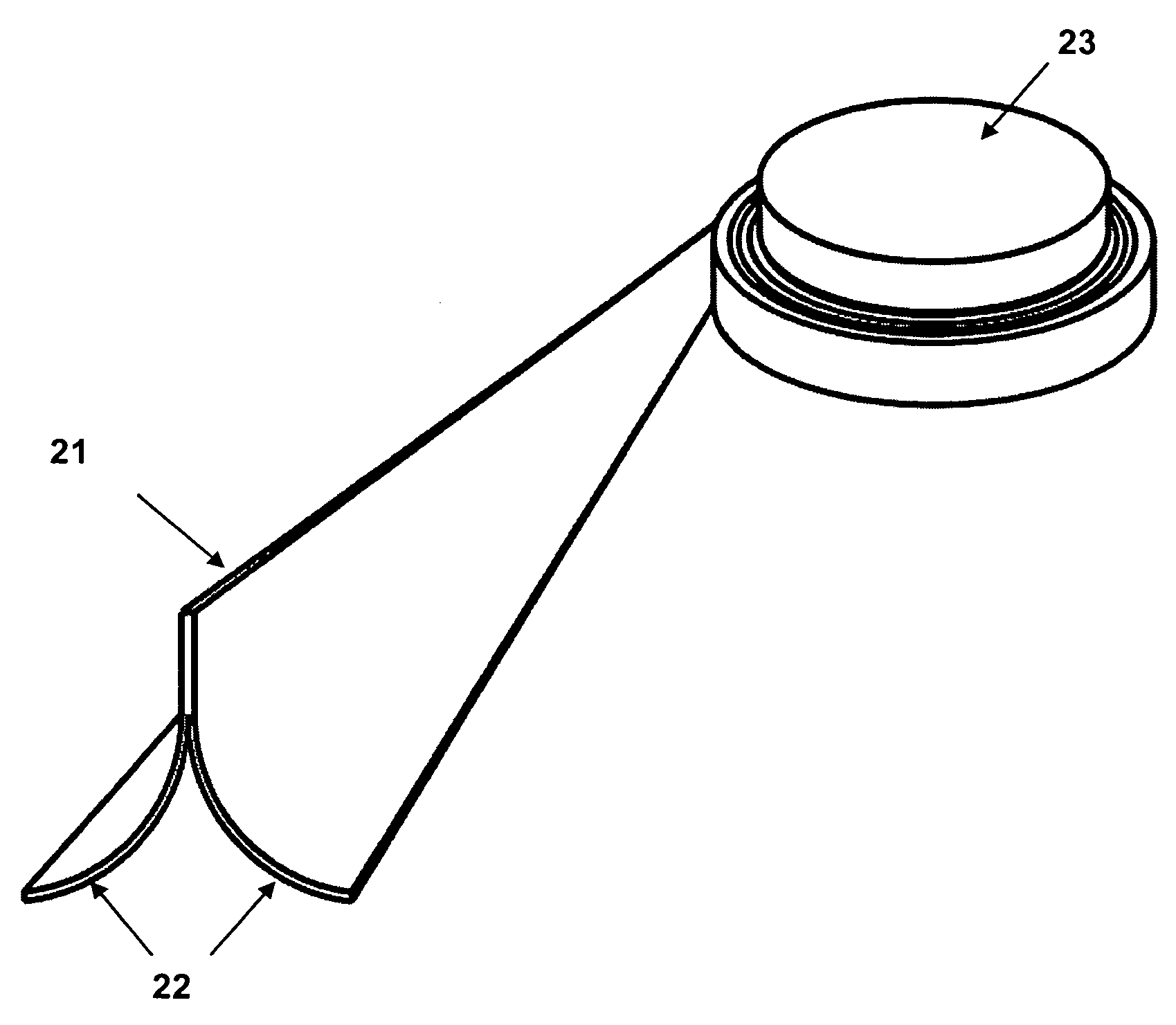

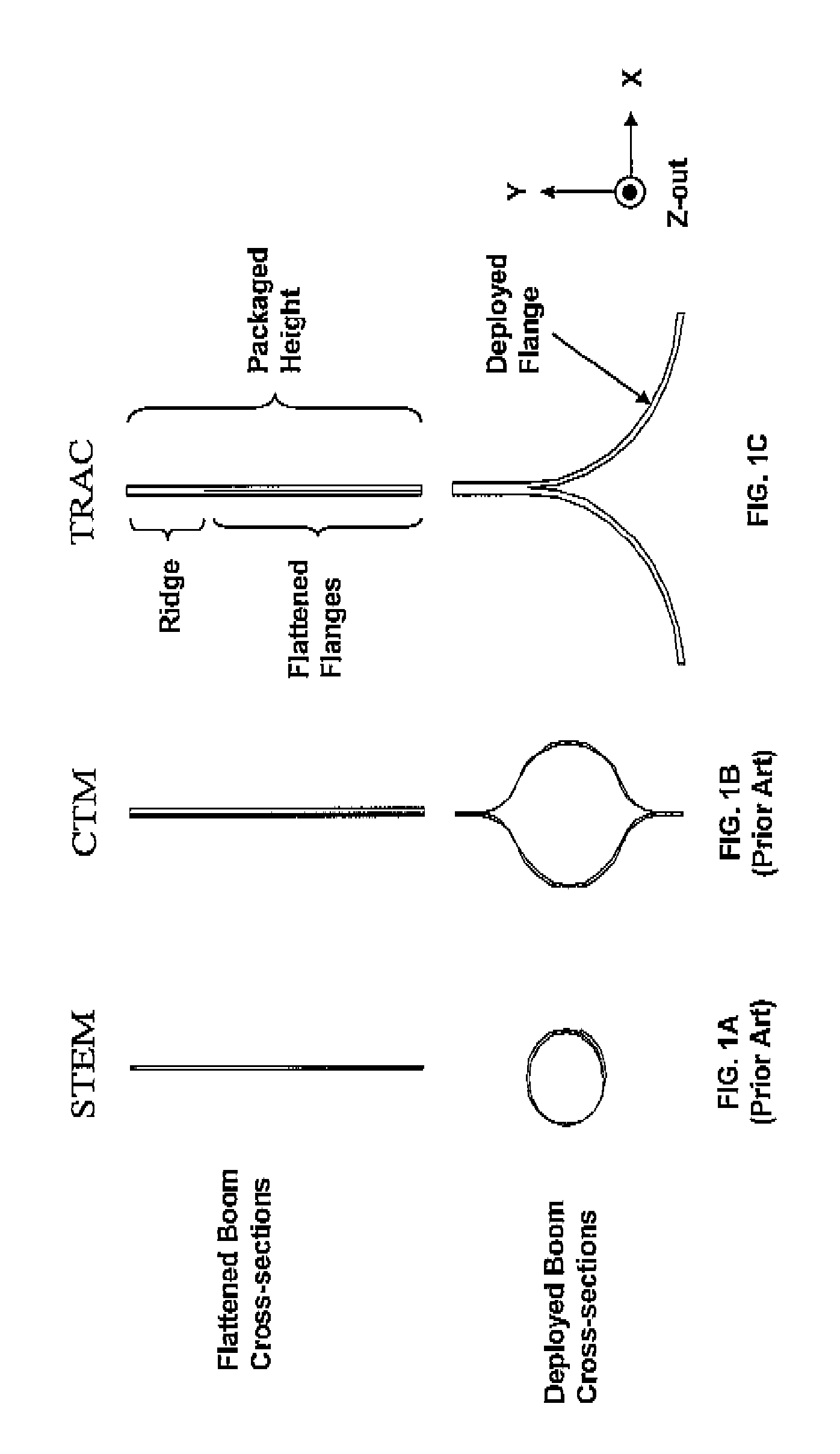

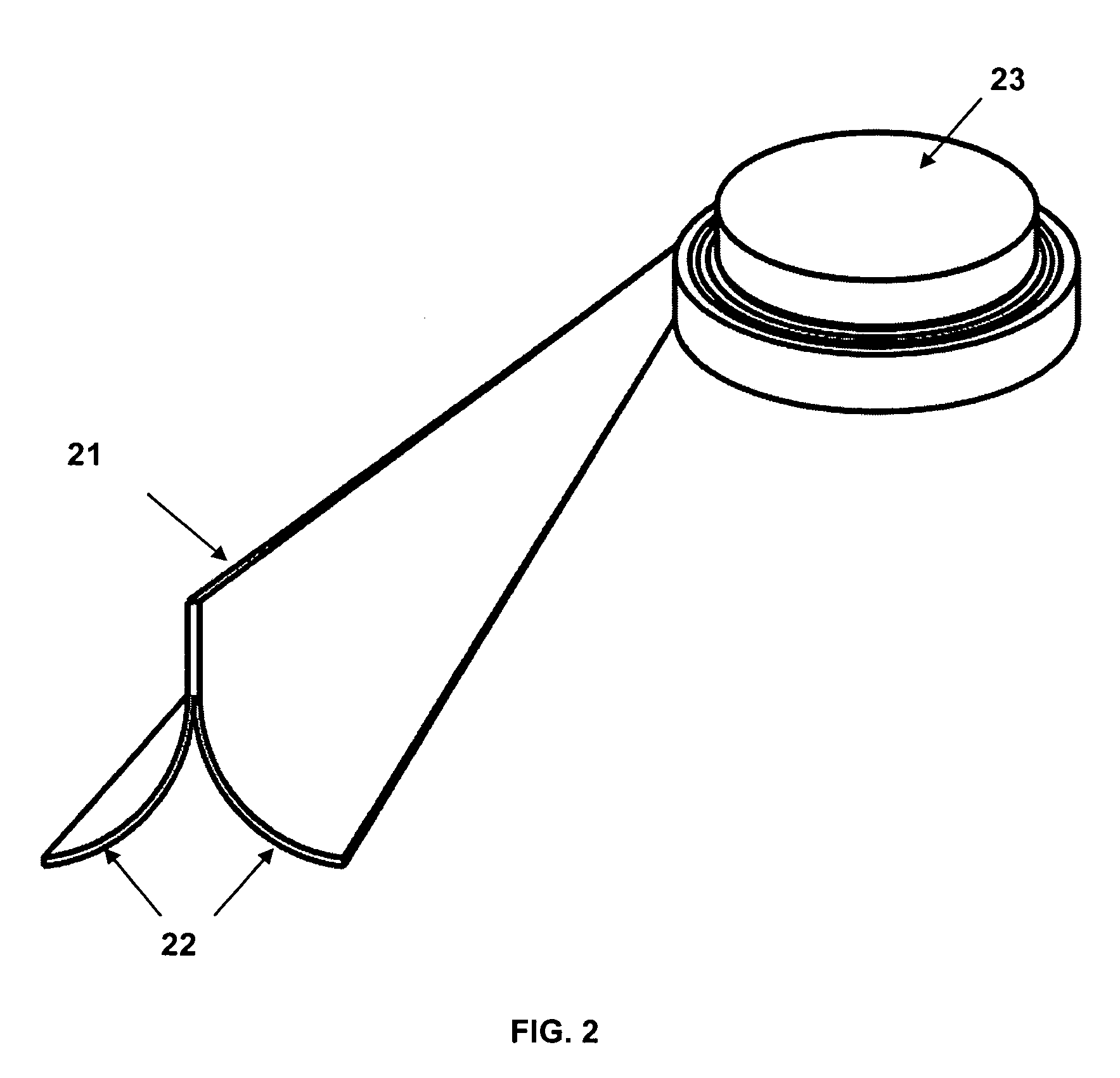

Triangular rollable and collapsible boom

ActiveUS7895795B1Reduced torsional stiffnessIncreased bending stiffnessCosmonautic vehiclesCosmonautic partsFiberCarbon fibers

An elastic space-deployable boom of carbon fiber reinforced plastic or other resilient material having an open substantially triangular cross-section when deployed and stowed with a flattened cross-section about a circular hub.

Owner:THE GOVERNMENT OF THE UNITED STATES AS REPSESENTED BY THE SEC OF THE AIR FORCE

Method of formulating and using a drilling mud with fragile gels

A method for drilling, running casing in, and / or cementing a borehole in a subterranean formation without significant loss of drilling fluid is disclosed, as well as compositions for use in such method. The method employs a drilling fluid comprising a fragile gel or having fragile gel behavior and providing superior oil mud rheology and overall performance. The fluid is especially advantageous for use in deep water wells because the fluid exhibits minimal difference between downhole equivalent circulating density and surface density notwithstanding differences in drilling or penetration rates. When an ester and isomerized olefin blend is used for the base of the fluid, the fluid makes an environmentally acceptable and regulatory compliant invert emulsion drilling fluid. The fluid preferably contains no organophilic clays.

Owner:HALLIBURTON ENERGY SERVICES INC

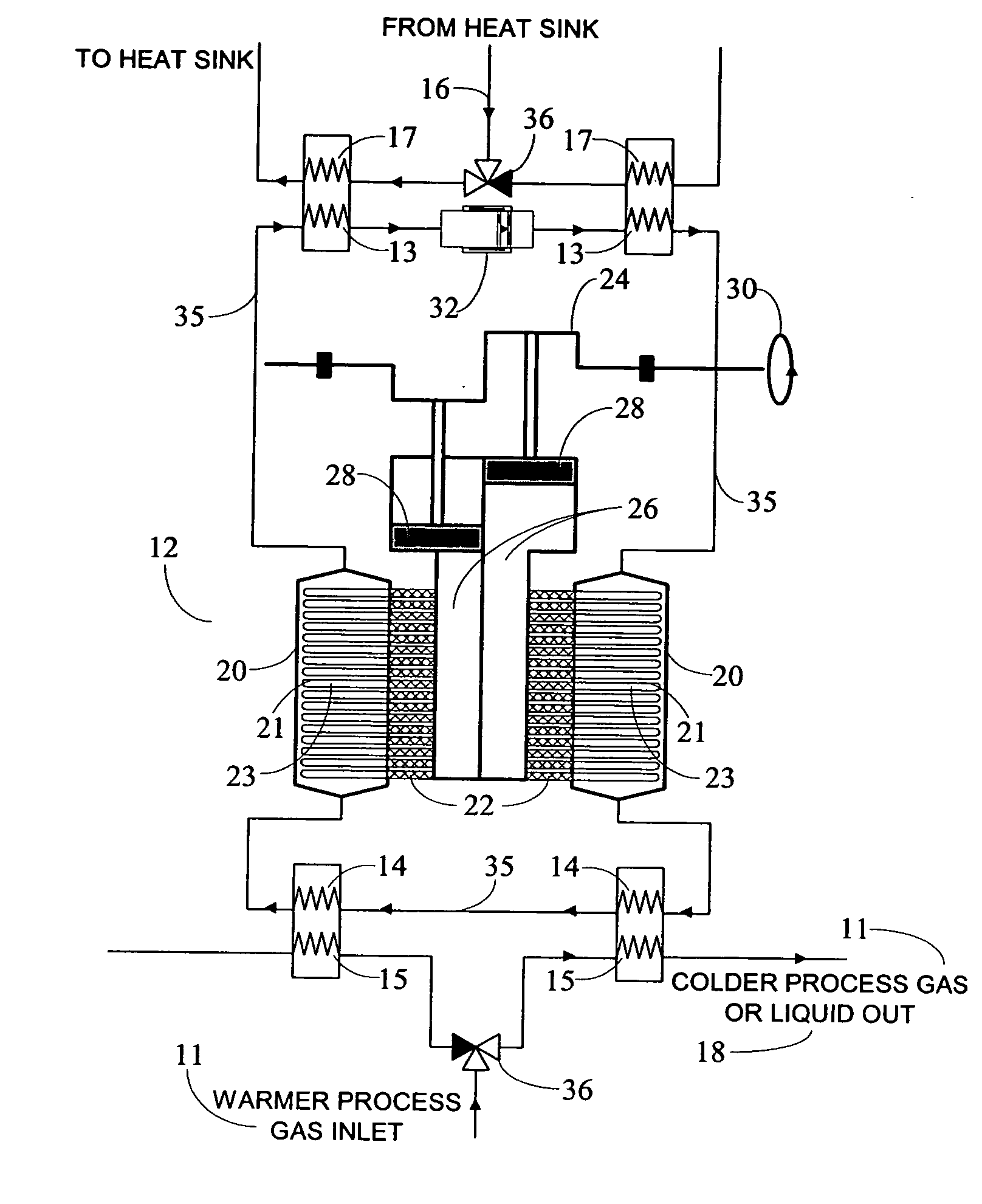

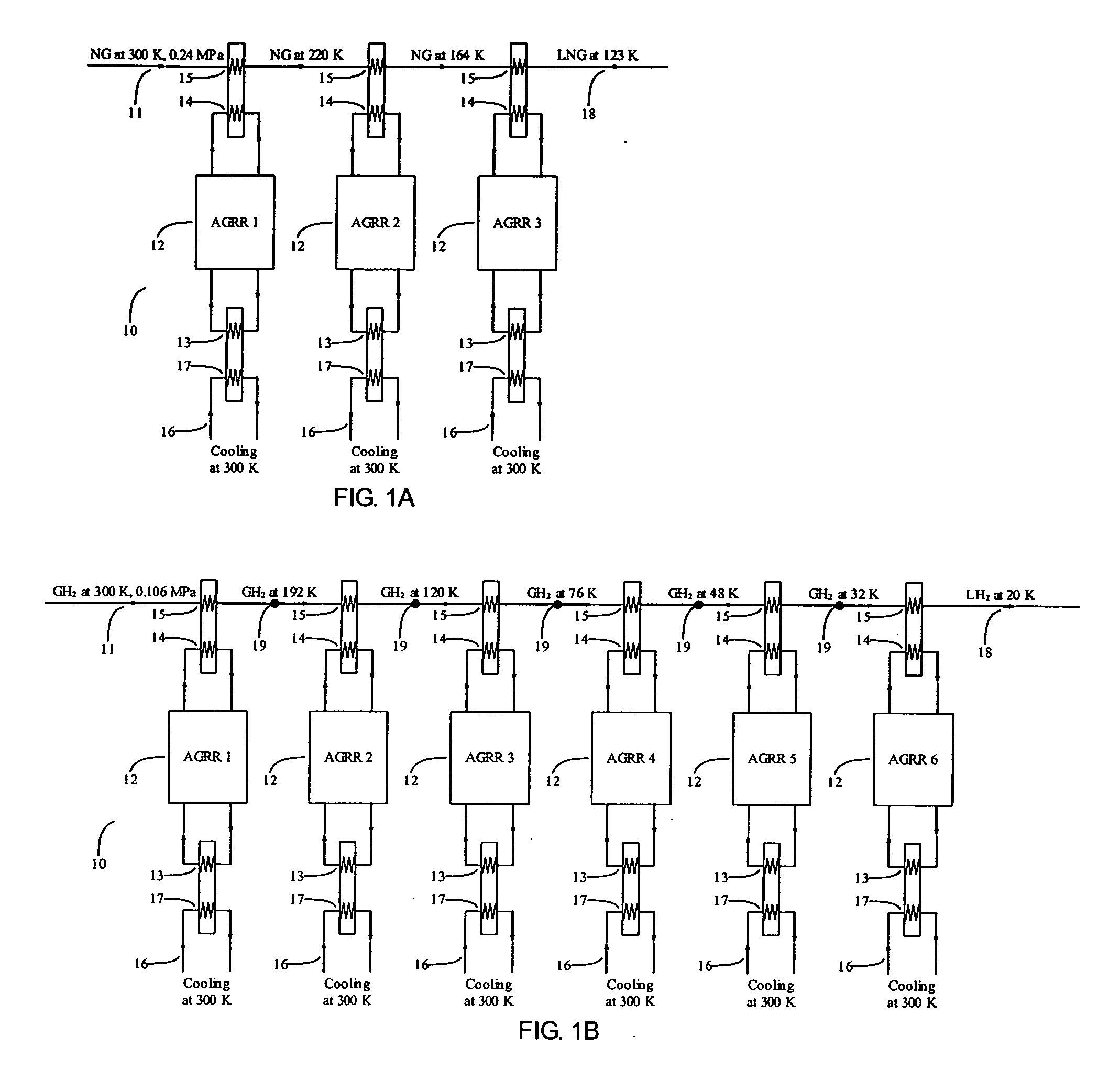

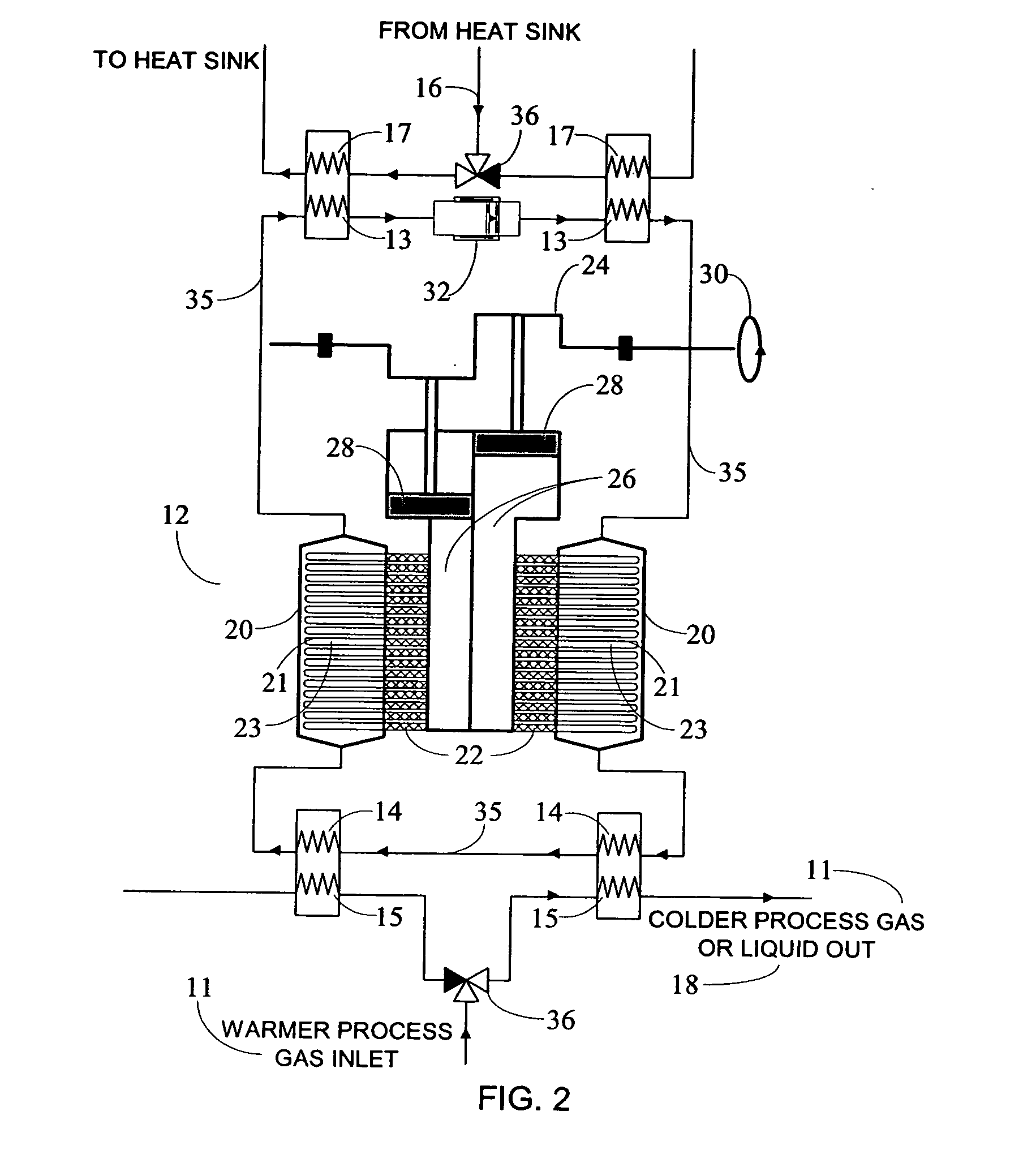

Active gas regenerative liquefier system and method

InactiveUS20080016907A1Improve efficiencyMinimize irreversible entropy creationSolidificationLiquefactionHydrogenProduct gas

The present invention provides an active gas regenerative liquefier (AGRL) for efficiently cooling and liquefying a process stream based on the combination of several active gas regenerative refrigerator (AGRR) stages configured to sequentially cool and liquefy the process stream, e.g. natural gas or hydrogen. In specific embodiments, the individual AGRR stages include heat exchangers, dual active regenerators, and a compressor / expander assembly, configured to recover a portion of the work of compression of a refrigerant by simultaneously expanding a refrigerant in one portion of the device while compressing the refrigerant in another portion to effect cooling of a heat transfer fluid, and ultimately the process stream.

Owner:PROMETHEUS TECH

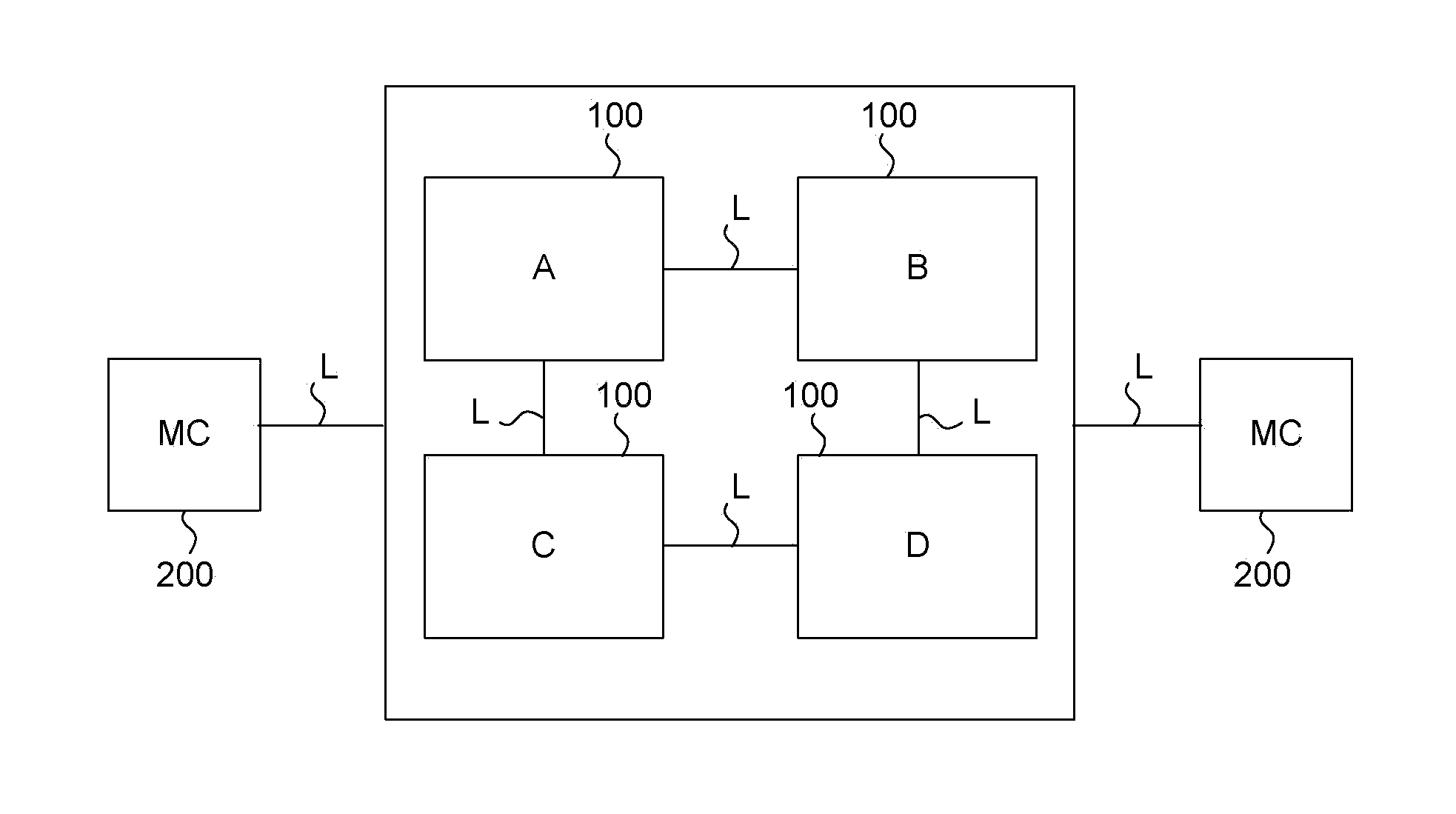

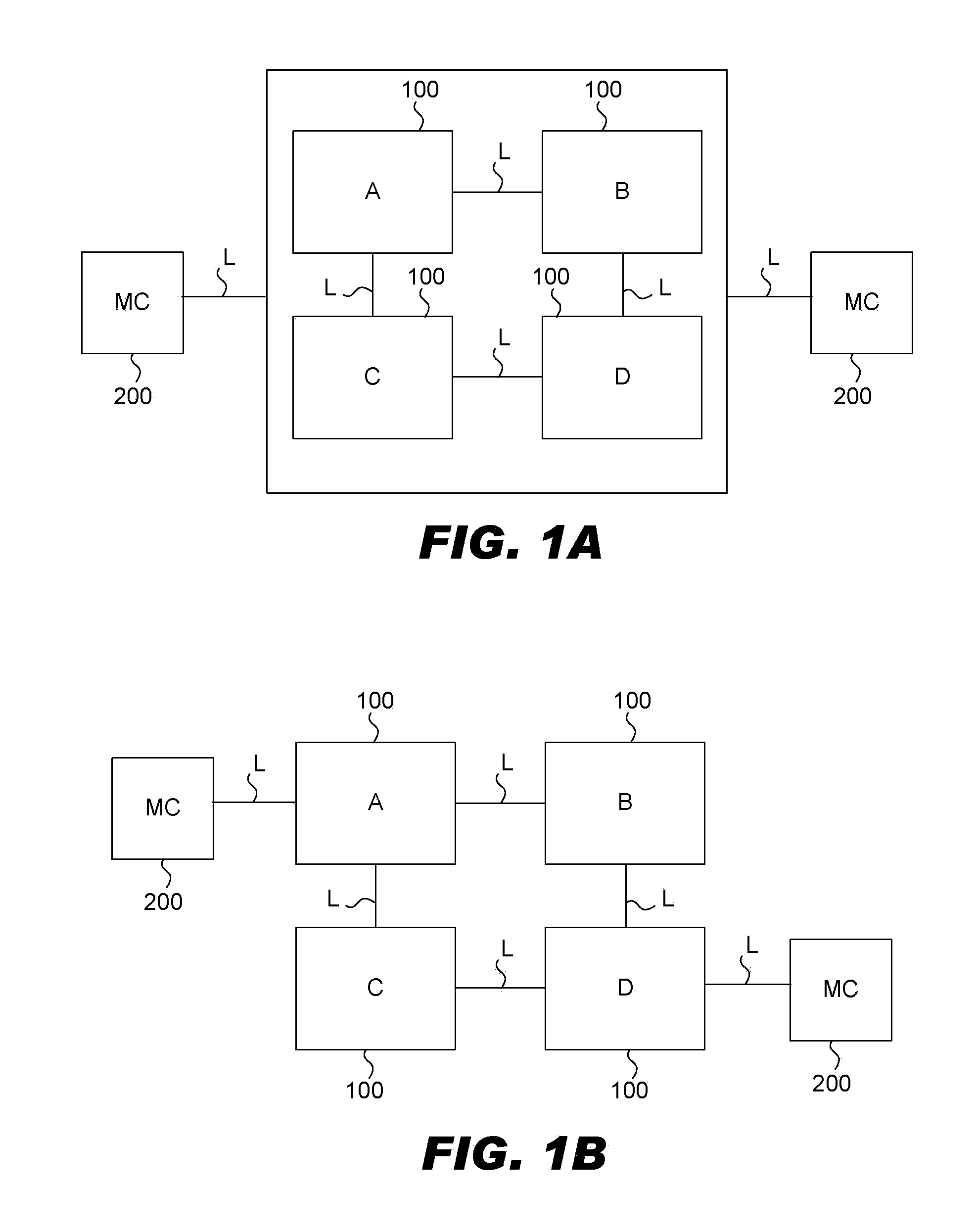

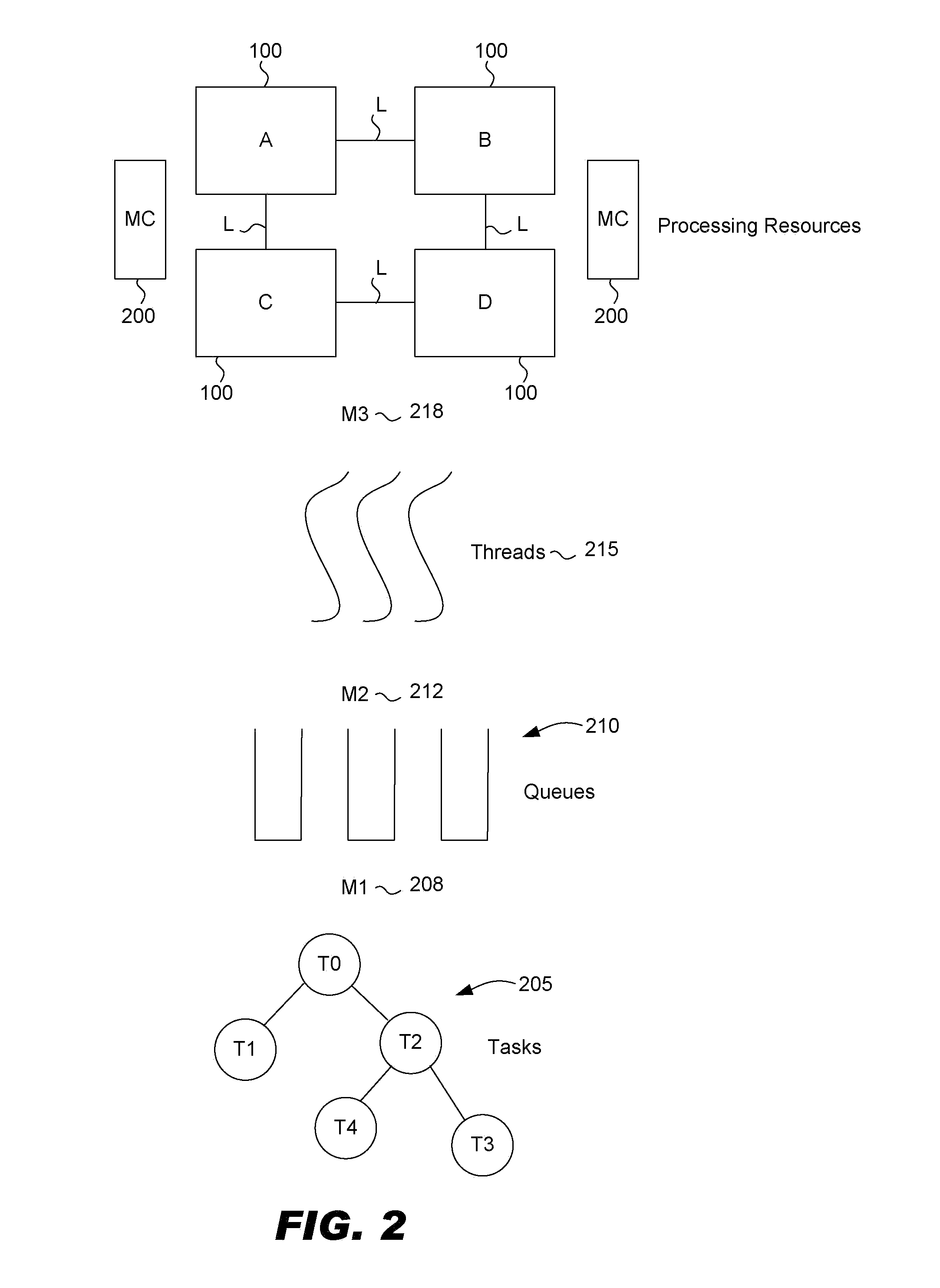

Adaptive queuing methodology for system task management

InactiveUS20120102501A1Reduce contentionIncrease pressureResource allocationMemory systemsGranularityHigh pressure

A task management methodology for system having multiple processors and task queues adapts a queuing topology by monitoring a queue pressure and adjusting the queue topology from a selection of at least two different queue topologies. The queue pressure may be periodically monitored and queues with different granularities selected. The methodology reduced contention when there is high pressure on the queues while also reducing overhead to manage queues when there is less pressure on the queues.

Owner:SAMSUNG ELECTRONICS CO LTD

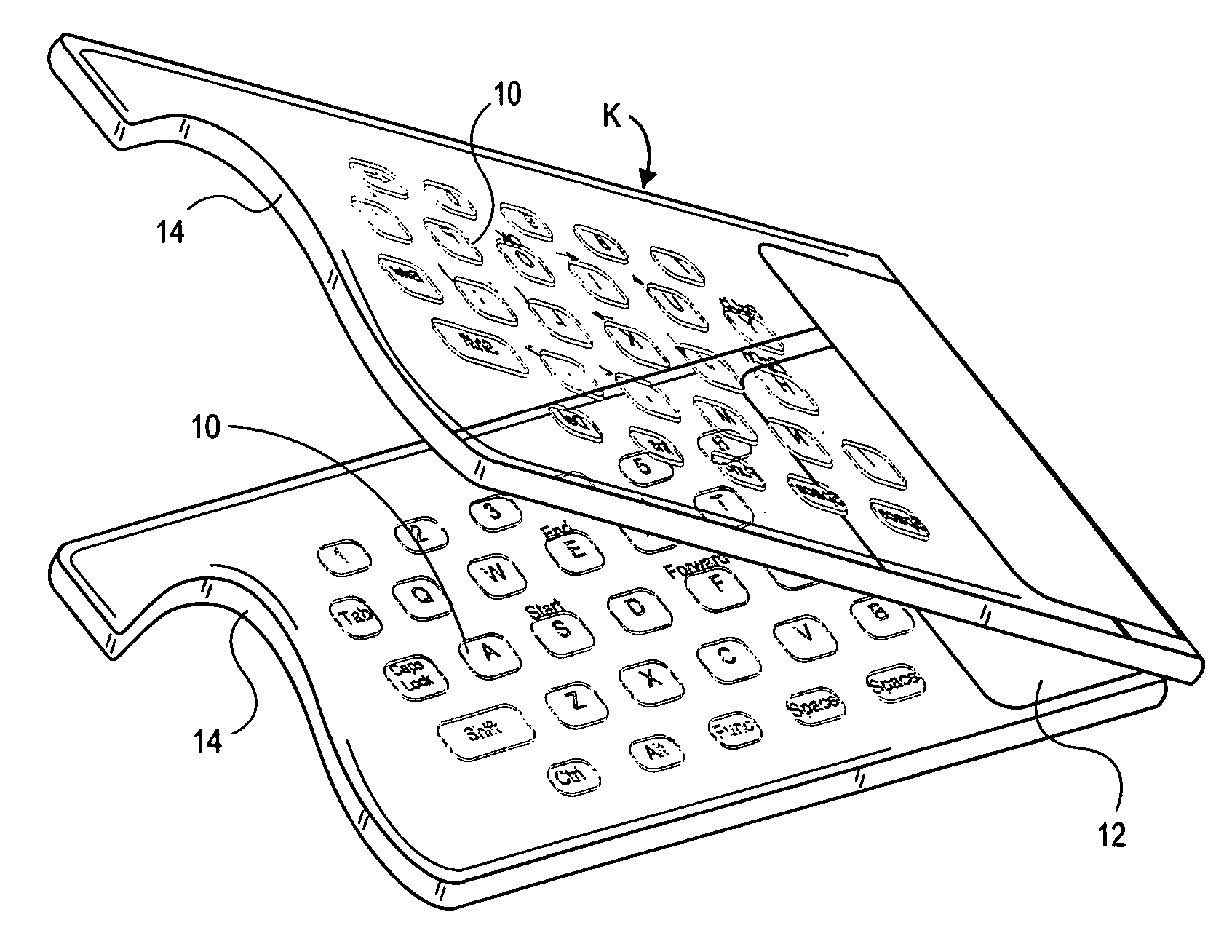

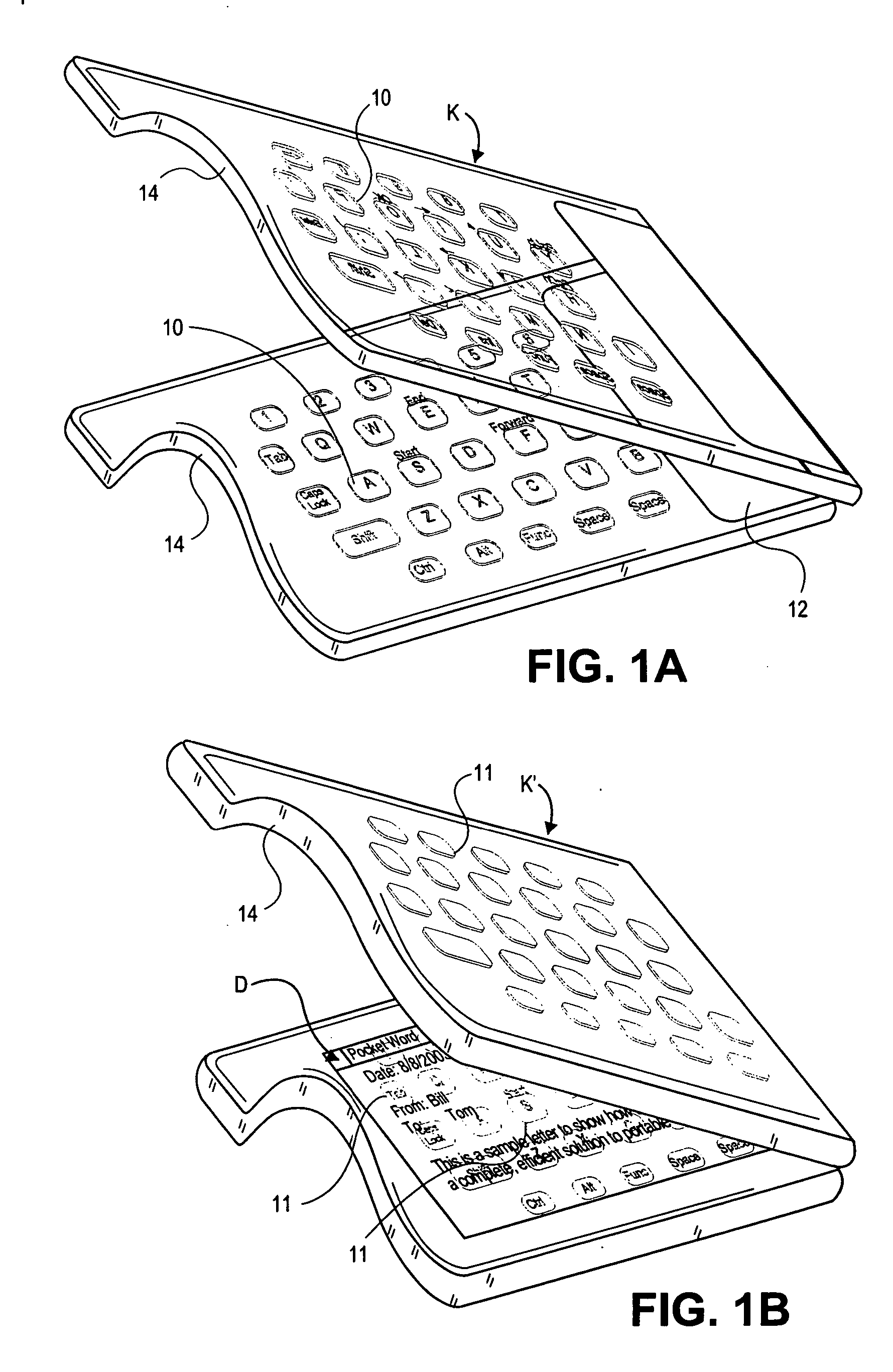

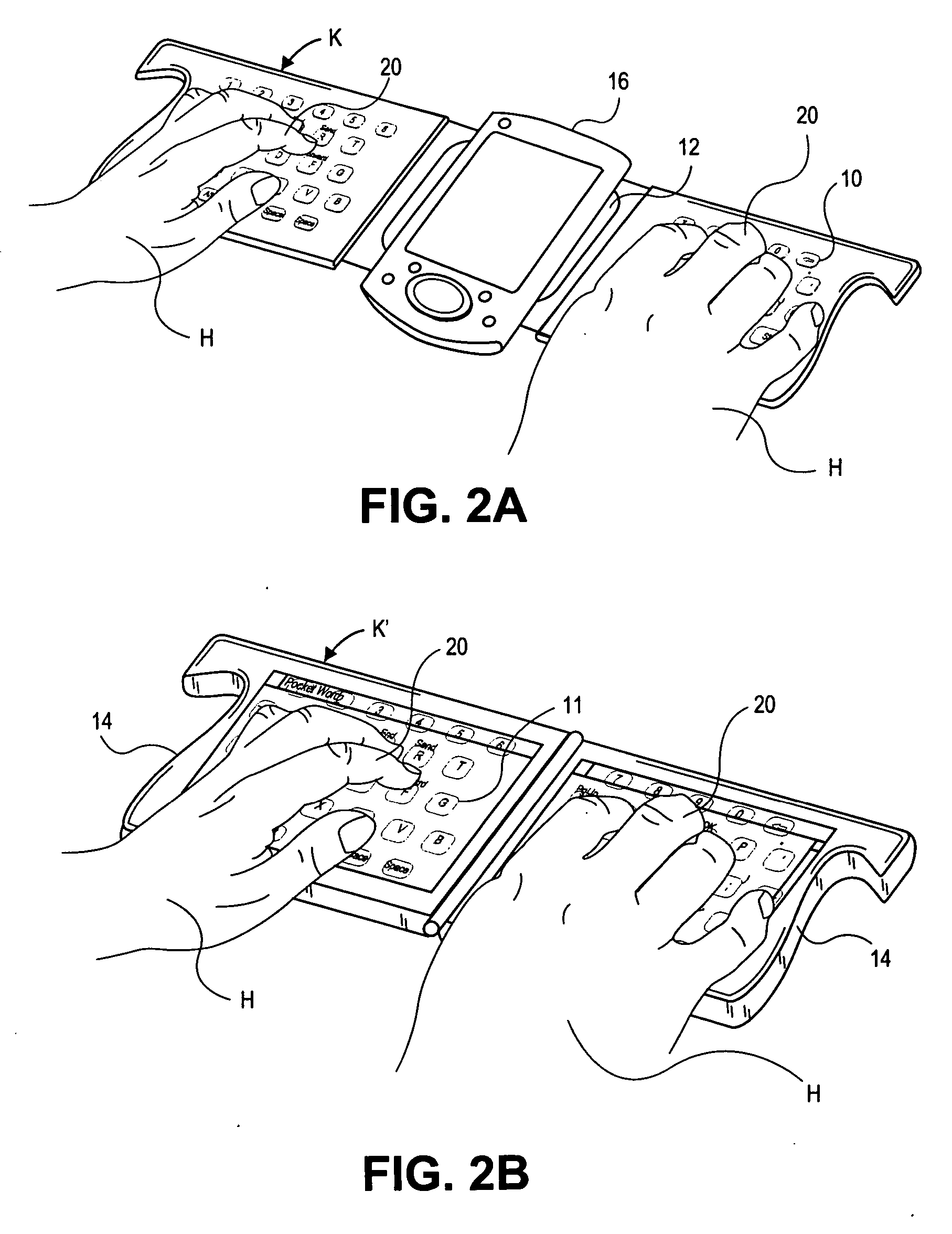

Double side transparent keyboard for miniaturized electronic appliances

InactiveUS20050104855A1Easy to controlSimple data entryInput/output for user-computer interactionEmergency casingsMiniaturizationEngineering

An optically or electronically transparent keyboard is disclosed having a key support, a display area, and keyboard transparency enabling keyboard operation from the front or rear. A keyboard, preferably of the QWERTY variety, is provided with transparent keyboard sections overlying one another. The keyboard sections when open dispose keyboard halves. QWERTY alignment is the same on the front and backside of the keyboard so that data entry is intuitive. Operation of the folding transparent keyboard can occur conventionally on a support surface or be enabled by support of the keyboard and miniaturized device in the palms of the user. In the palms of the user, the backside keyboard can be used with transparent viewing of the finger input. The sides of the keyboard are ergonomically shaped to position the hands properly, give better control of the keyboard while also making it easier to enter data.

Owner:PARADIGM RES TECH

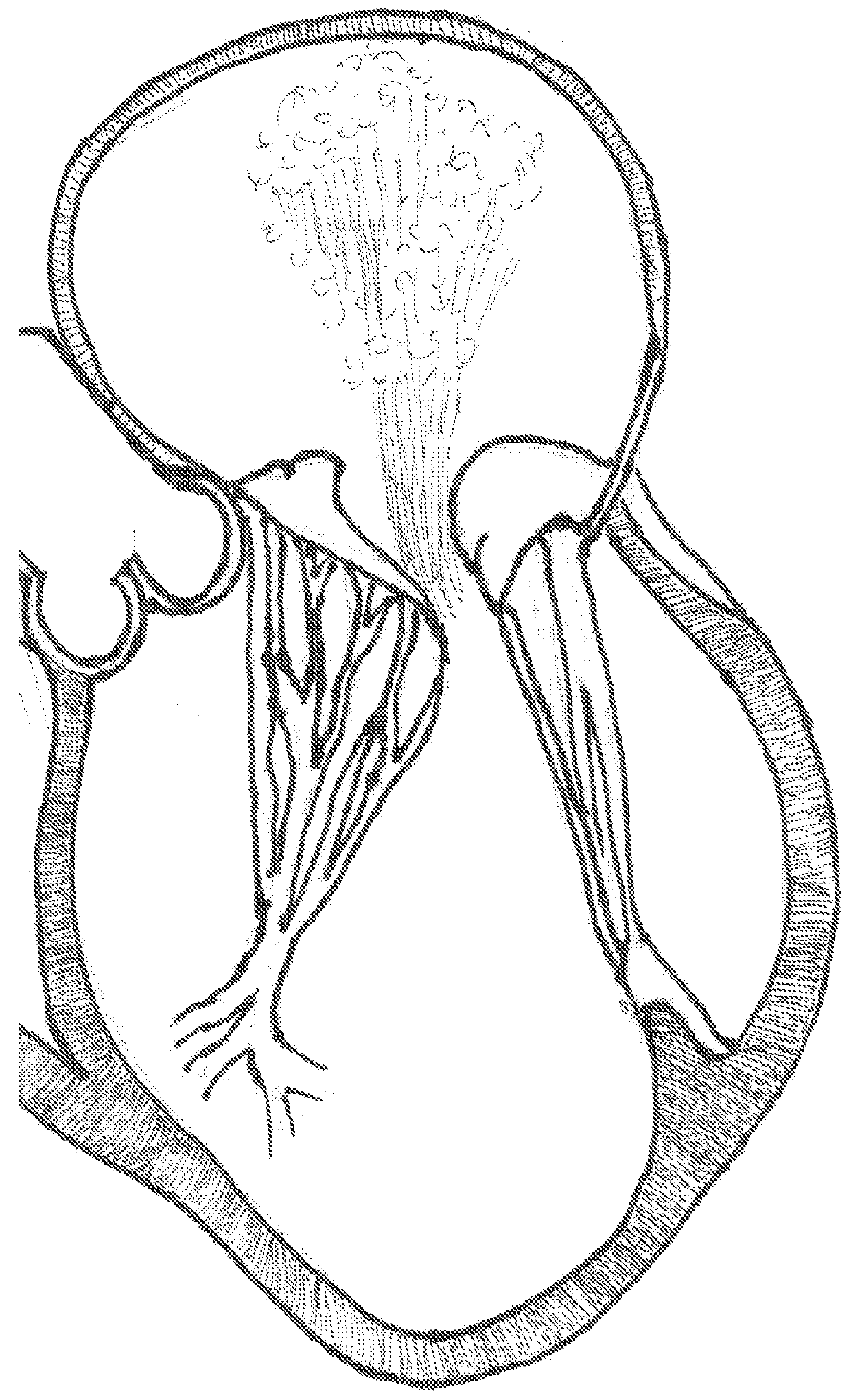

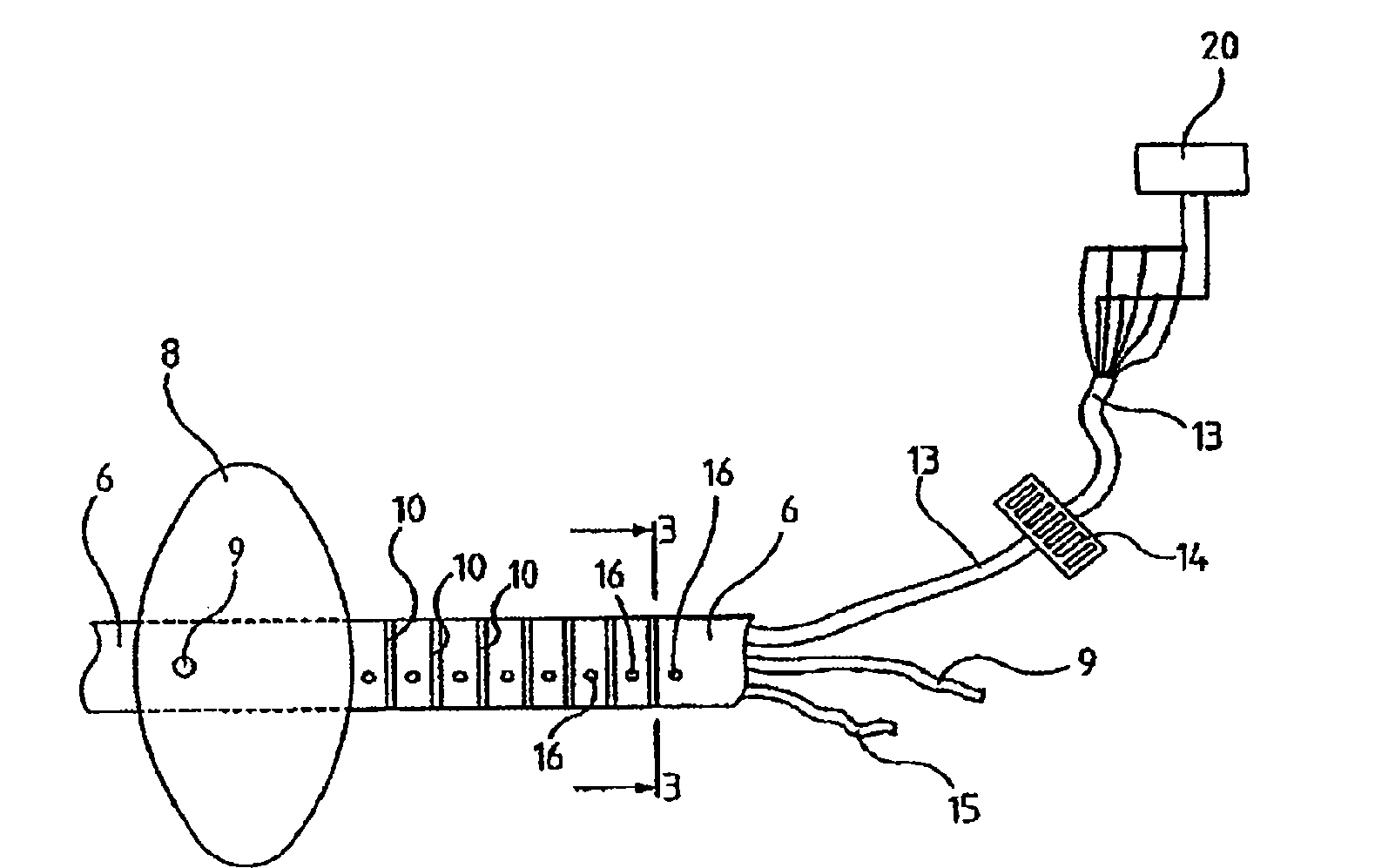

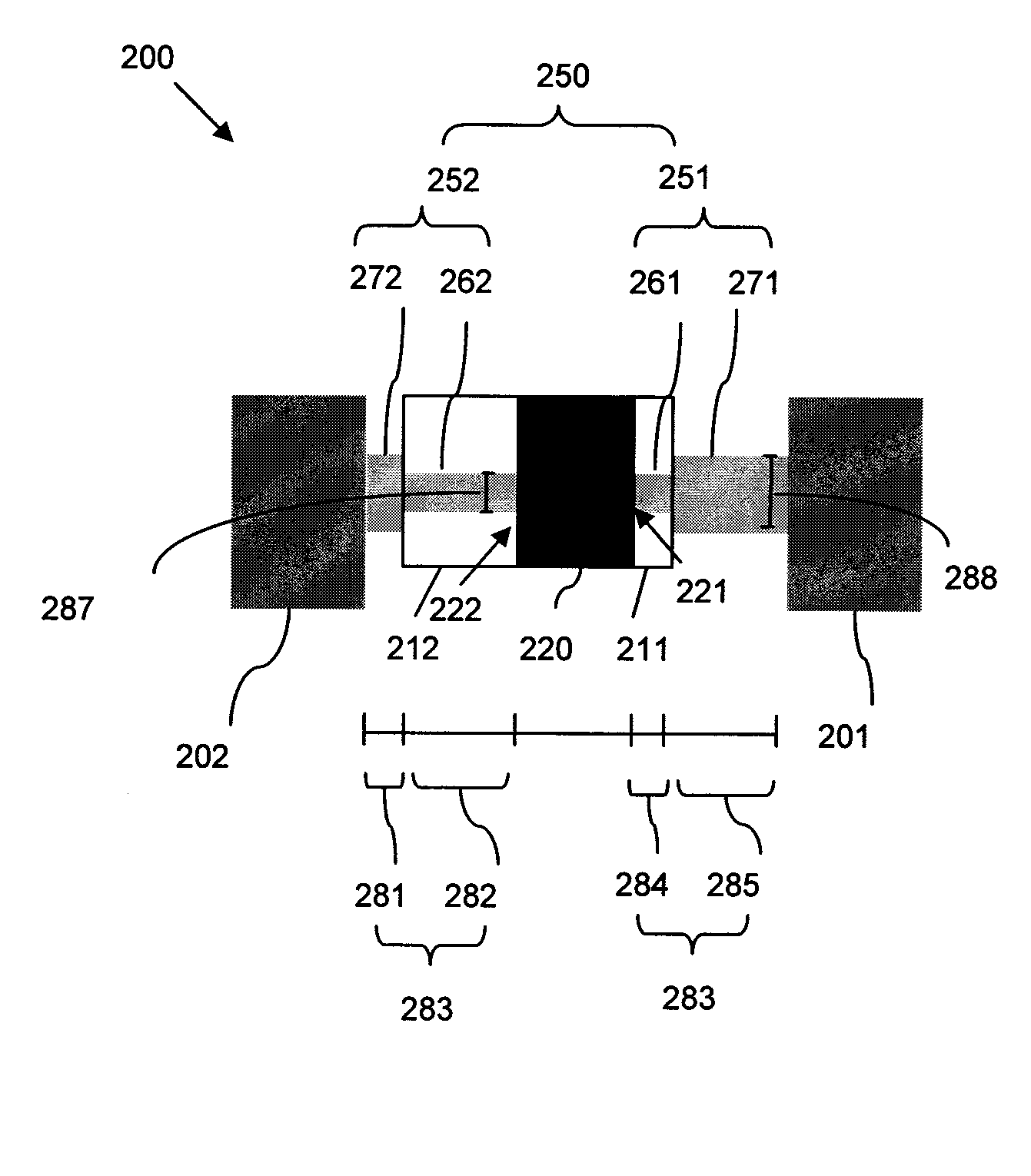

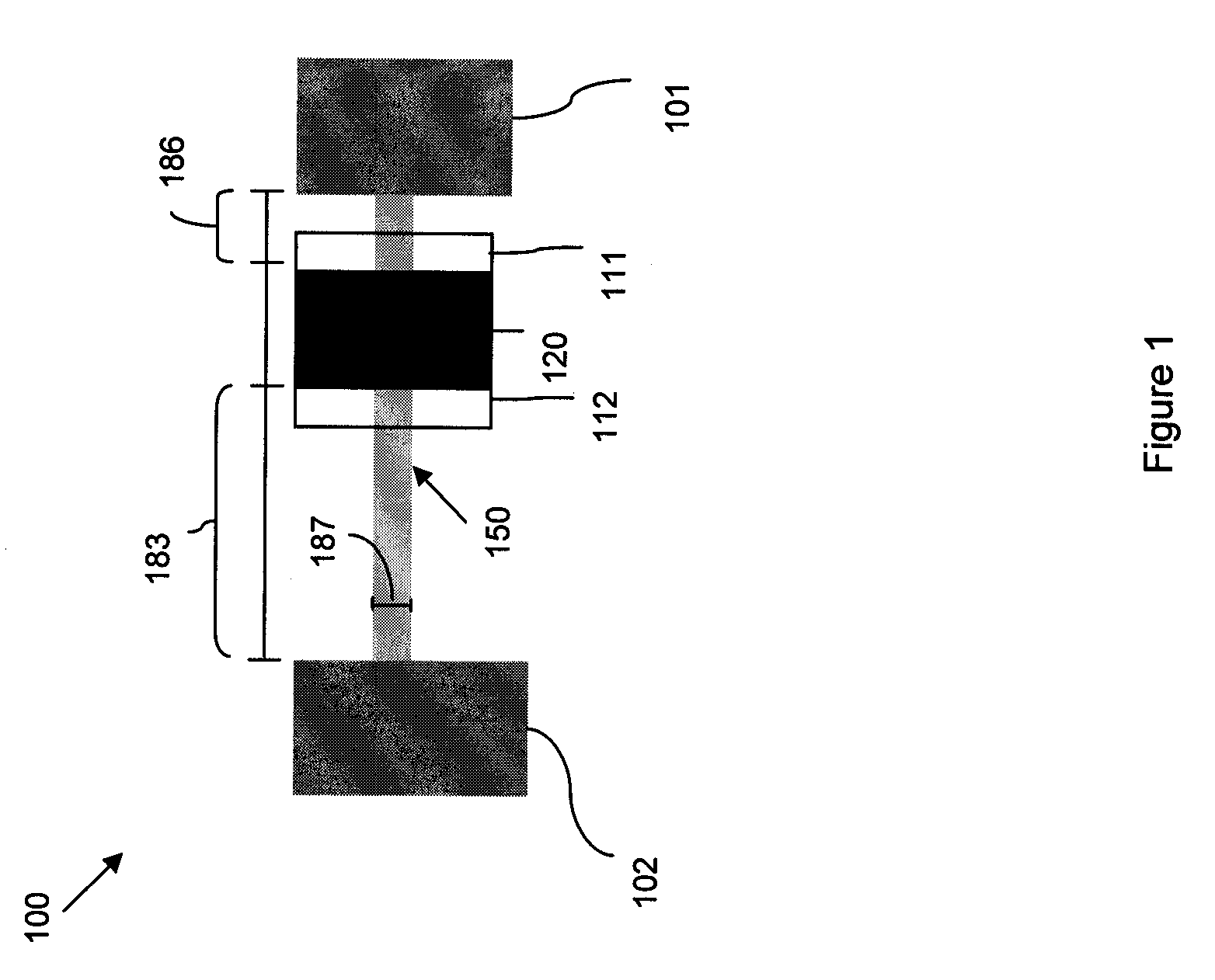

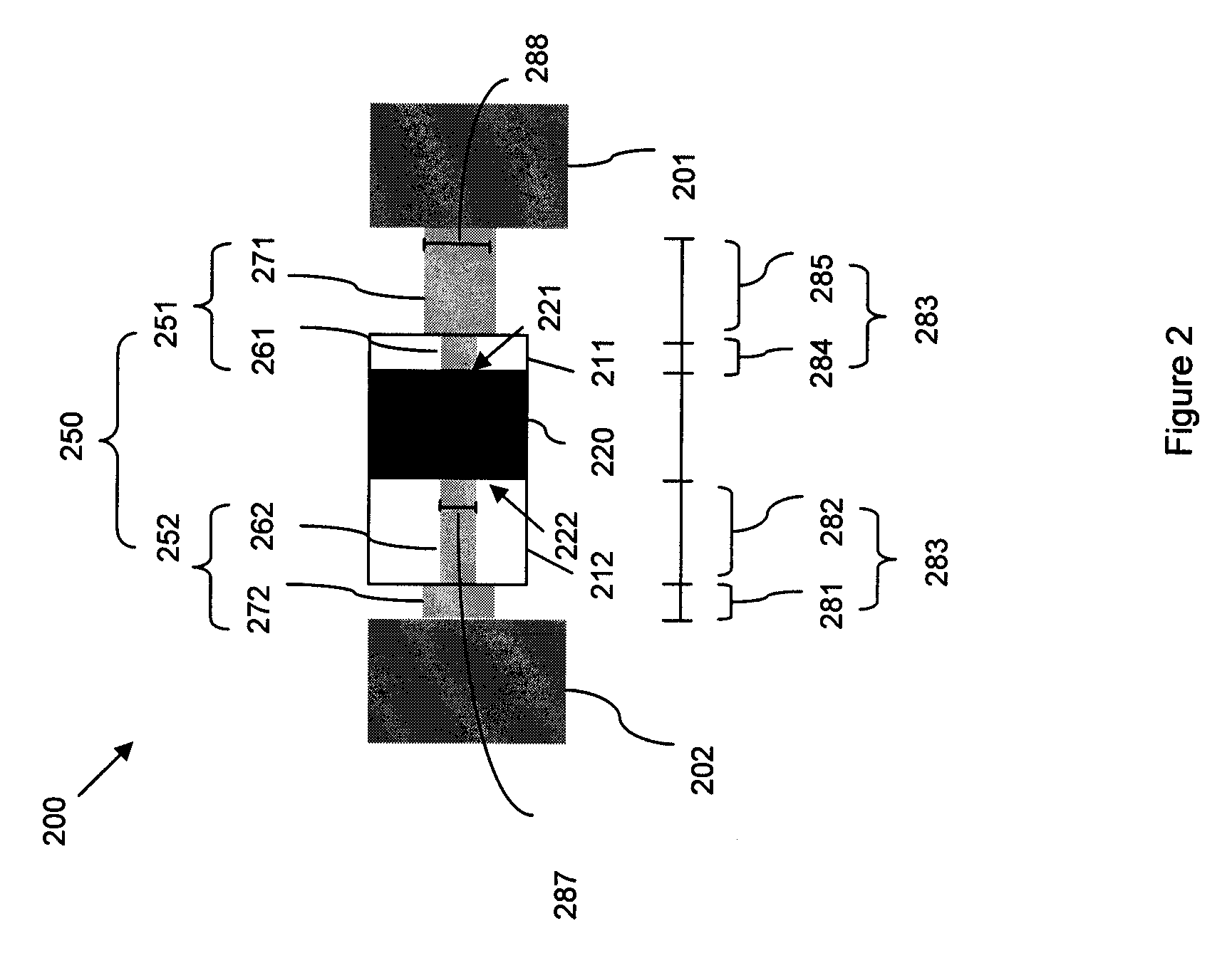

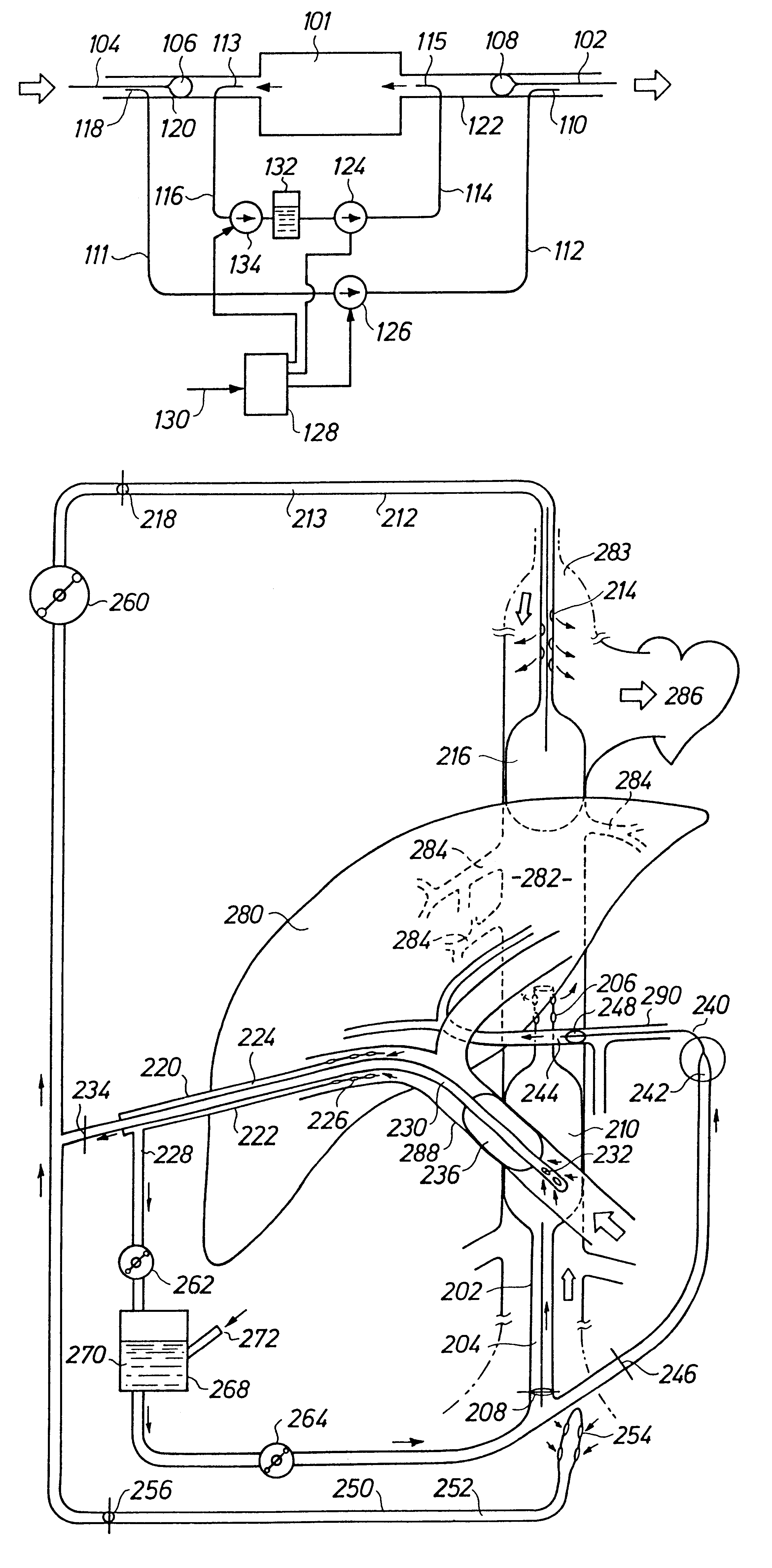

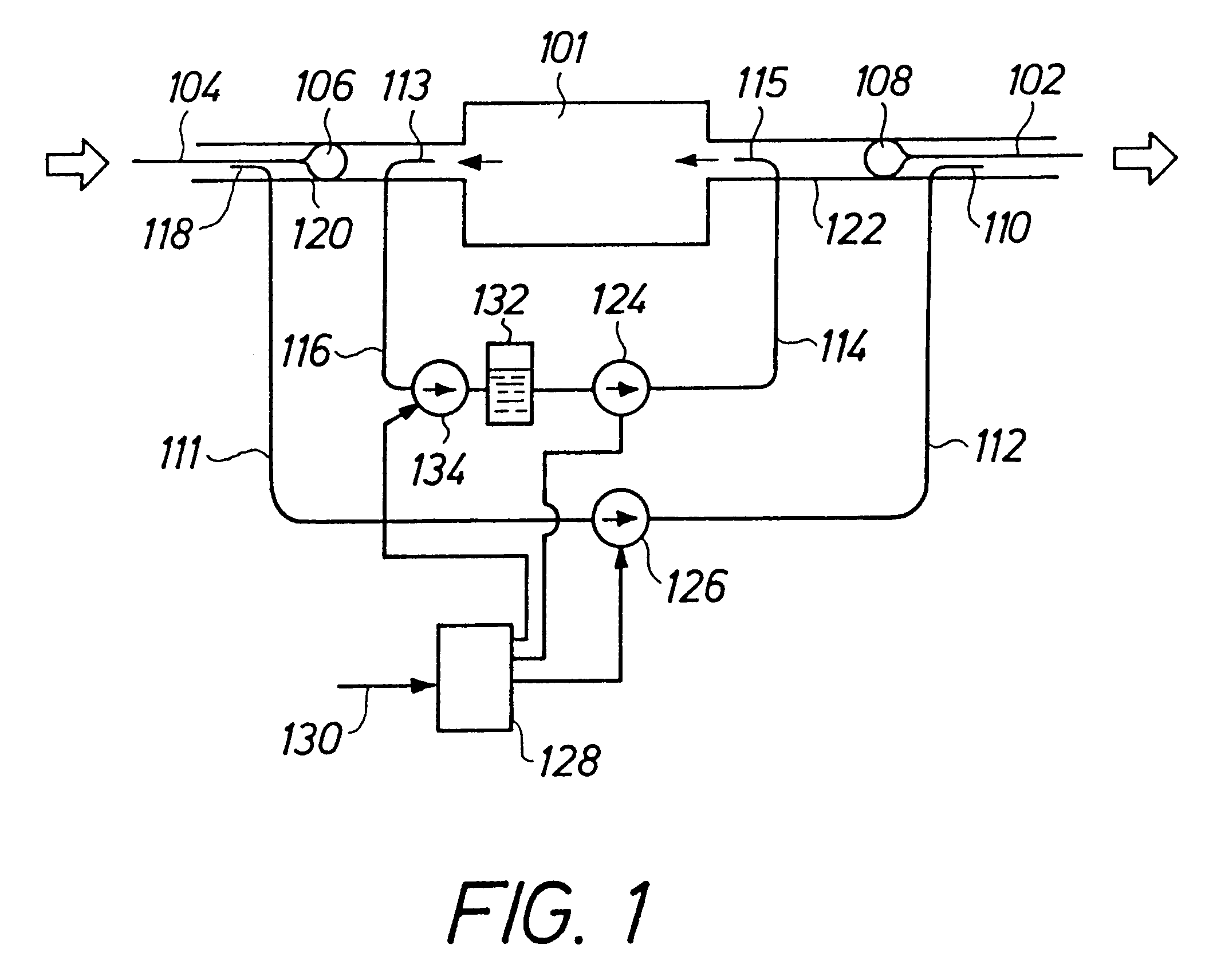

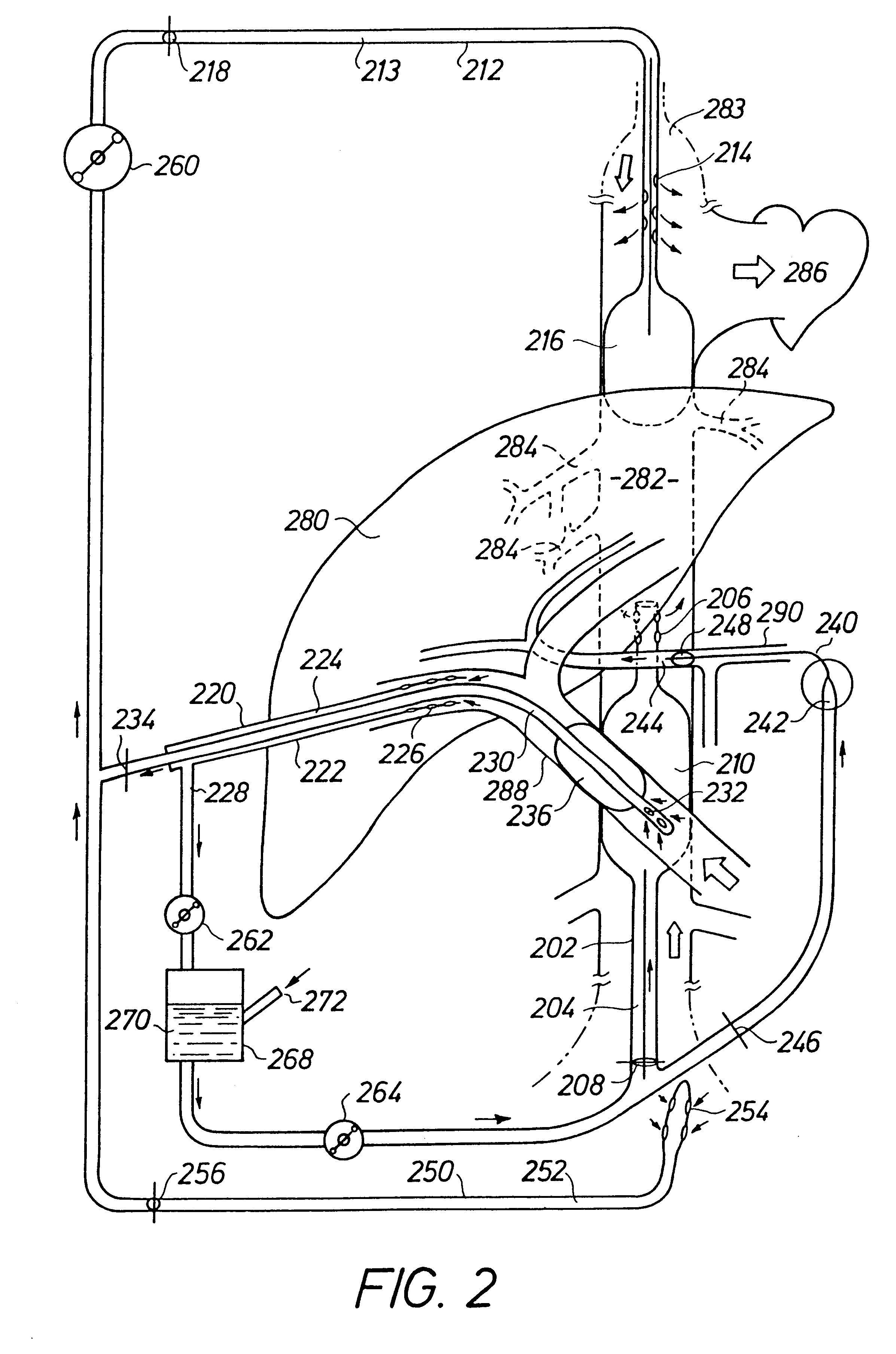

Perfusion system

InactiveUS6287273B1Prolonged and increased therapeutic effectReduce risk of leakageStentsBalloon catheterBlood streamPerfusion fluid

A perfusion system for non-surgically isolating and perfusing an organ, particularly the liver (101), in a patient, and including; by-pass cathether apparatus having inlet and outlet lumens (111, 112) introducible into the blood vessels of the organ percutaneously and devised so as to by-pass the blood flow past the organ in a by-pass circuit; perfusion catheter apparatus having inlet and outlet lumens (114, 116) introducible into the blood vessels percutaneously and being devised so as to lead the flow of perfusion fluid in a perfusion circuit through the organ; occlusive seals (106, 108) for isolating the organ from the systemic blood flow; pump apparatus including a by-pass pump (261), a perfusion fluid pump (124) and a suction pump (134) for establishing a negative relative pressure at the perfusion outlet from the organ; and control apparatus (128) coupled to the pumps (124, 126, 134) so as to control the operation thereof such that the outflow of fluid from the organ exceeds the inflow of fluid into the organ in the perfusion circuit due to a net volume contribution of blood from the systemic circulation entering the isolated organ.

Owner:ARGMED +1

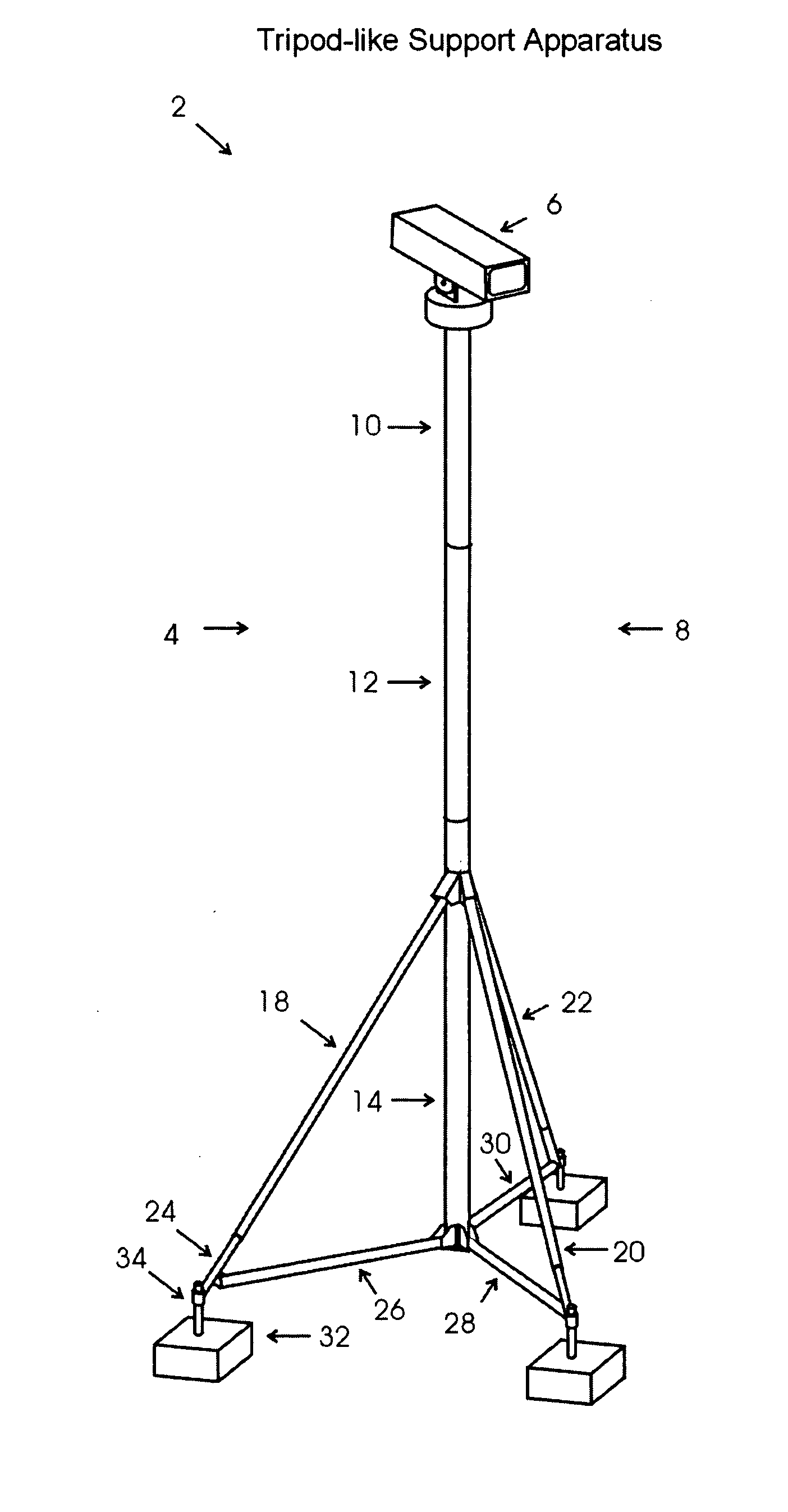

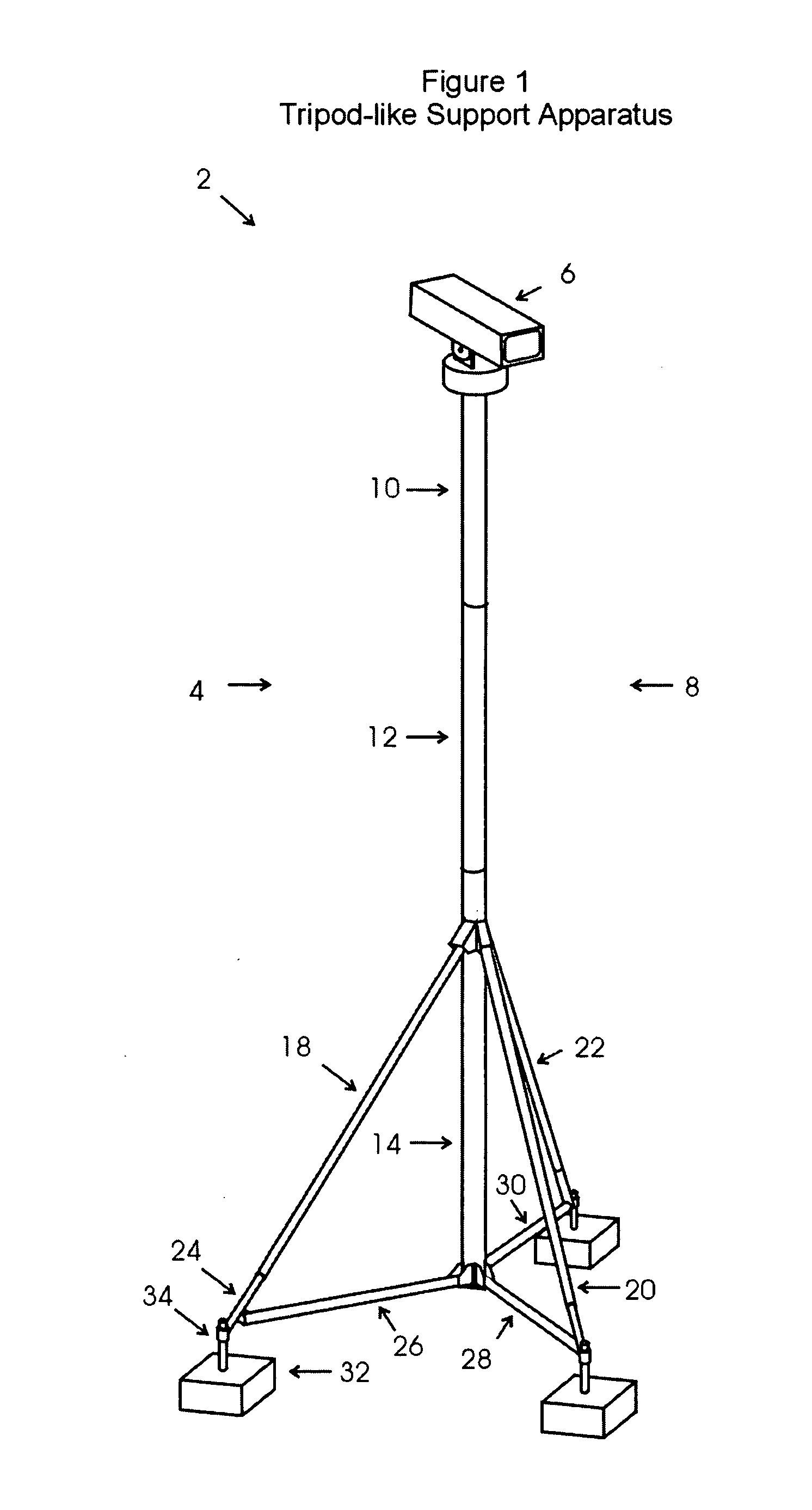

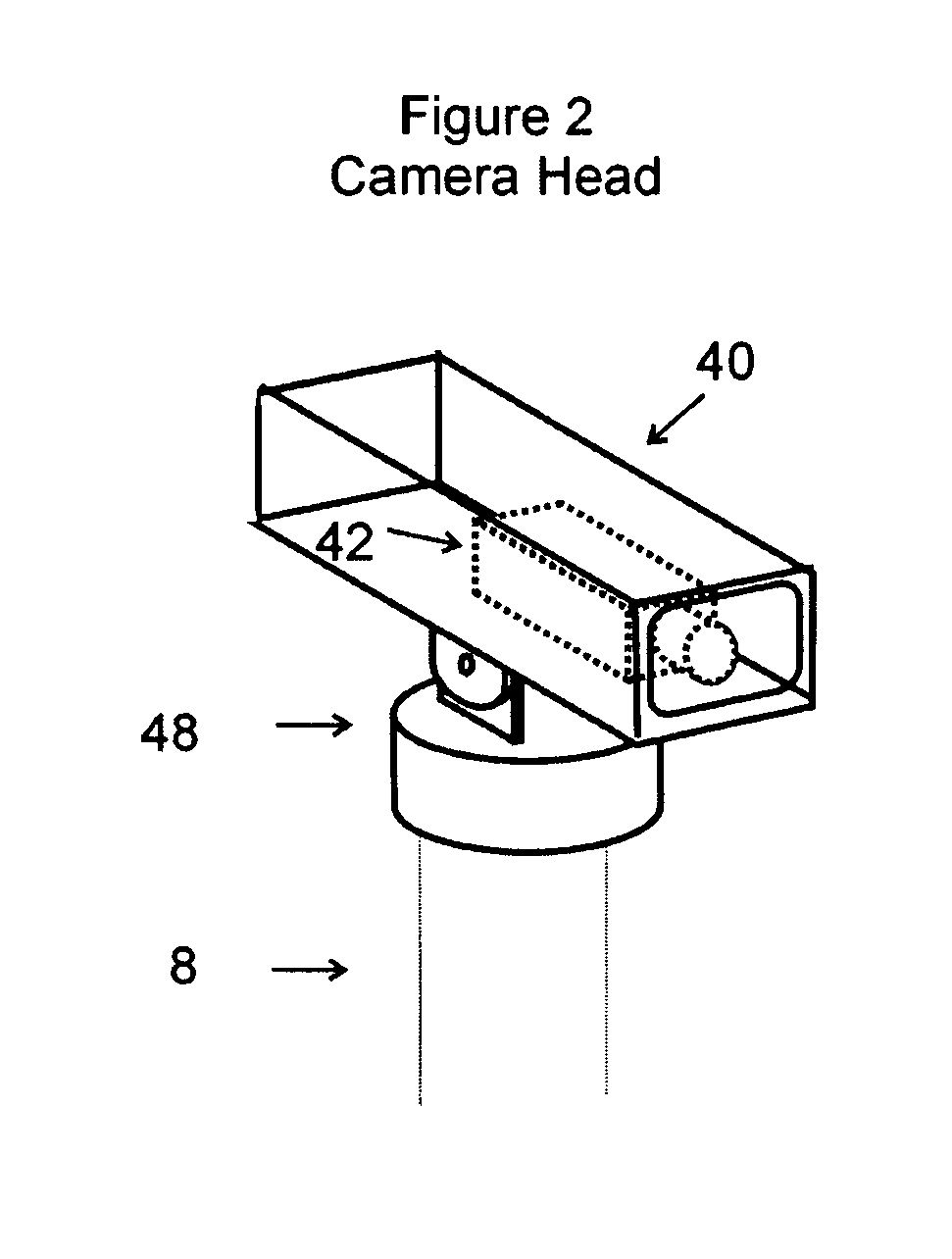

Traffic surveillance method and system

InactiveUS20050151846A1Set upGood dataTelevision system detailsColor television detailsTamper resistanceSurveillance Methods

The invention relates generally to a method and system for monitoring traffic events at a predetermined location, using a temporary video camera set up to record traffic movements through an intersection or other location along a road. The method preferably comprises taking a video recording of the location, and then sending the recording to a foreign country where the recording can be reviewed manually at a reduced cost. To facilitate an accurate and consistent review of the recording, the invention preferably uses “event lines” that can be superimposed on the video monitor, wherein the event lines help determine when a vehicle has passed through an intersection, i.e., when a recordable traffic event occurs. The system also preferably uses a computer-operated program adapted to assist the operator in reviewing, verifying and summarizing the recorded information, wherein a particular key or keys can be pressed depending on the type of event to be indicated. The system is also able to identify the exact frame number of a recordable event that corresponds to an exact moment in real time, i.e., when the event actually occurred. A tripod-like apparatus for temporarily setting up a video camera in locations where no existing pole or structure is available, as well as a tamper-proof housing in which the video recording device can be temporarily mounted, can also be provided.

Owner:THORNHILL WILLIAM

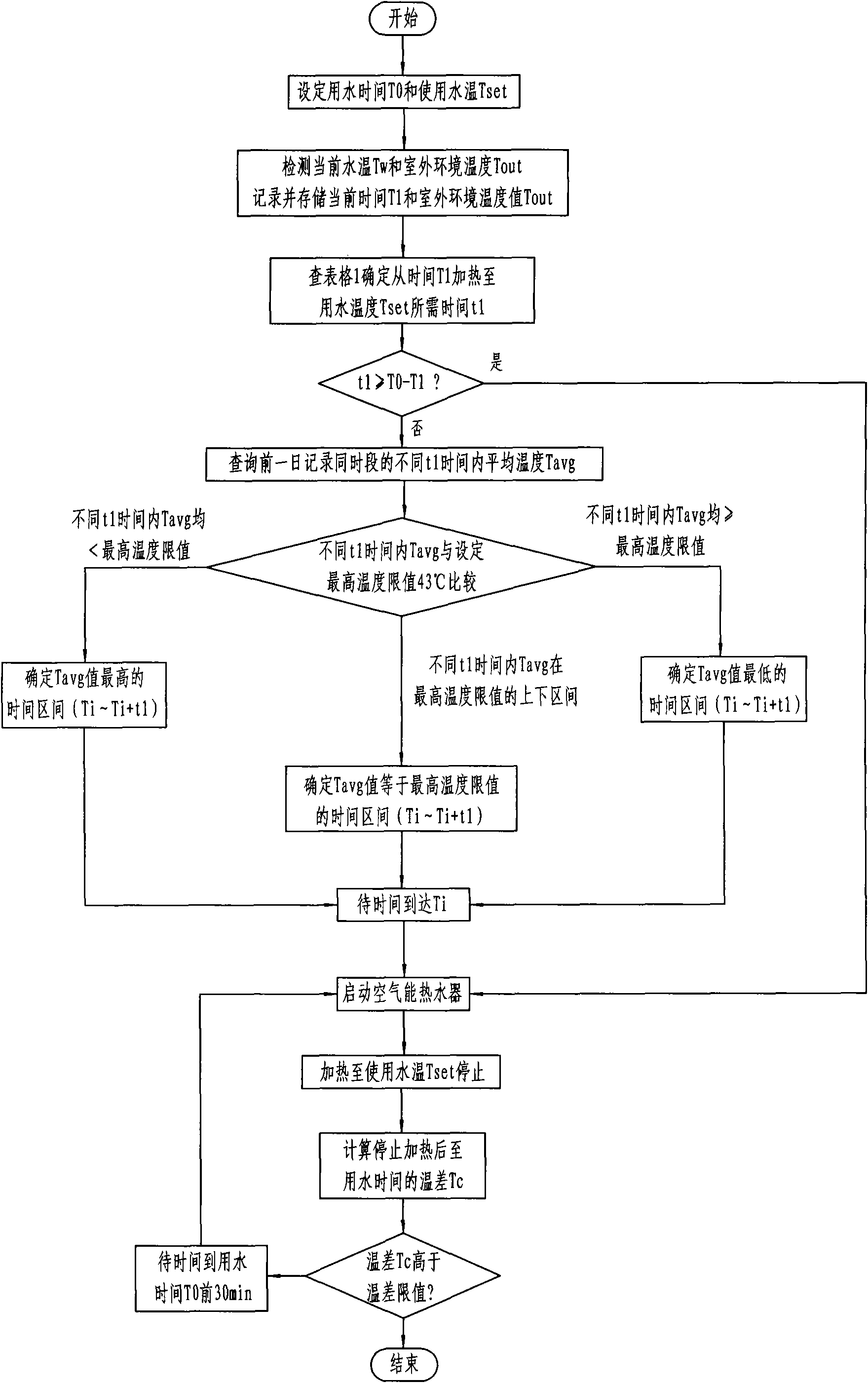

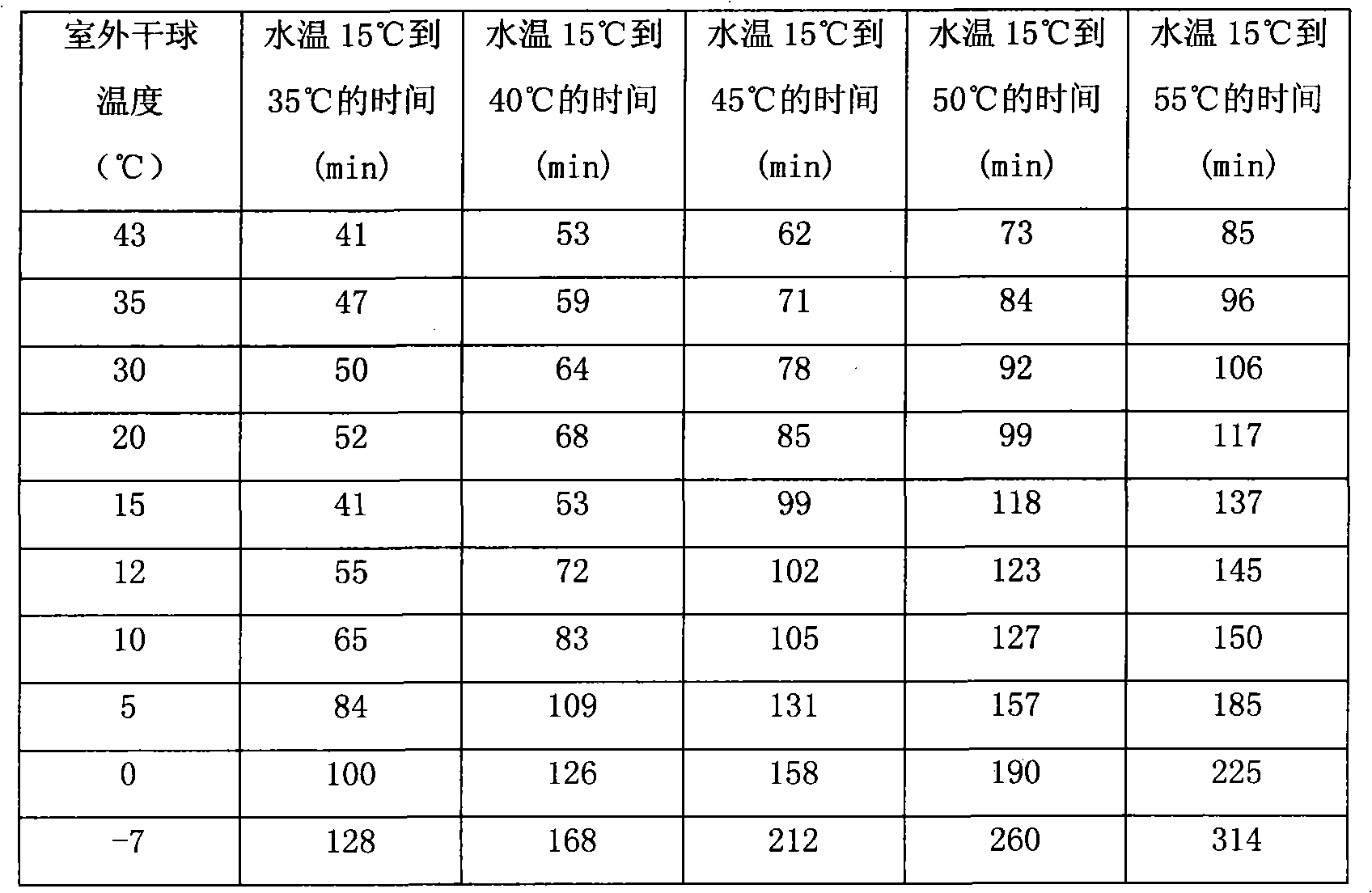

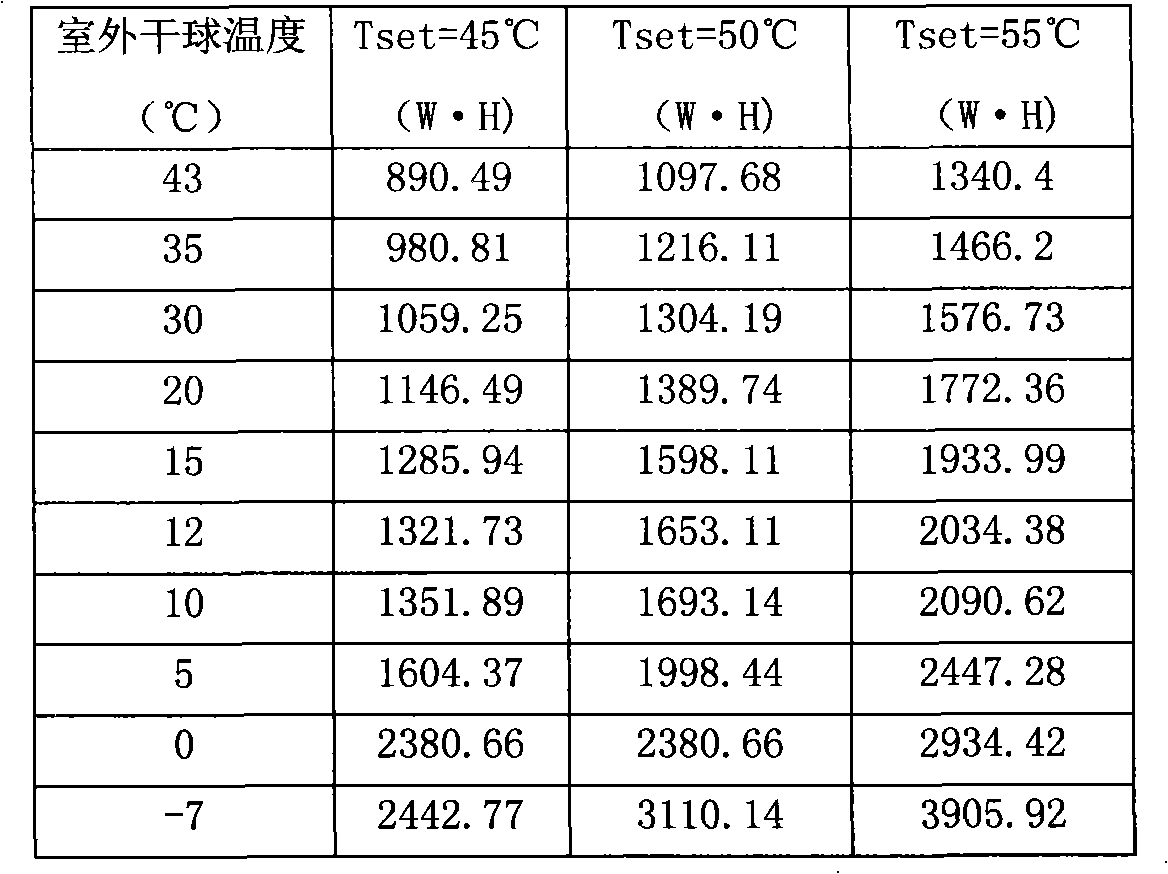

Controlling method of air-source water heater

The invention discloses a controlling method of an air-source water heater. The control of the air-source water heater is realized based on a timing water consumption mode, and a timing switch is utilized to automatically regulate the opening / stopping time of the water heater according to the outdoor environmental temperature daily range; in use, a user directly sets the time and the temperature of water consumption, and the air-source water heater selects to start the water heater for heating at the higher outdoor environmental temperature. The invention has the following advantages that: firstly, the time and the temperature of the water consumption are directly set, which is more human-friendly and is convenient for the user to operate and use; secondly, the air-source water heater selects to work at the higher outdoor environmental temperature by utilizing the outdoor environmental temperature daily range so as to improve the heating effect of the air-source water heater as large as possible and realize the energy saving operation of the air-source water heater.

Owner:AUX AIR CONDITIONING LTD BY SHARE LTD

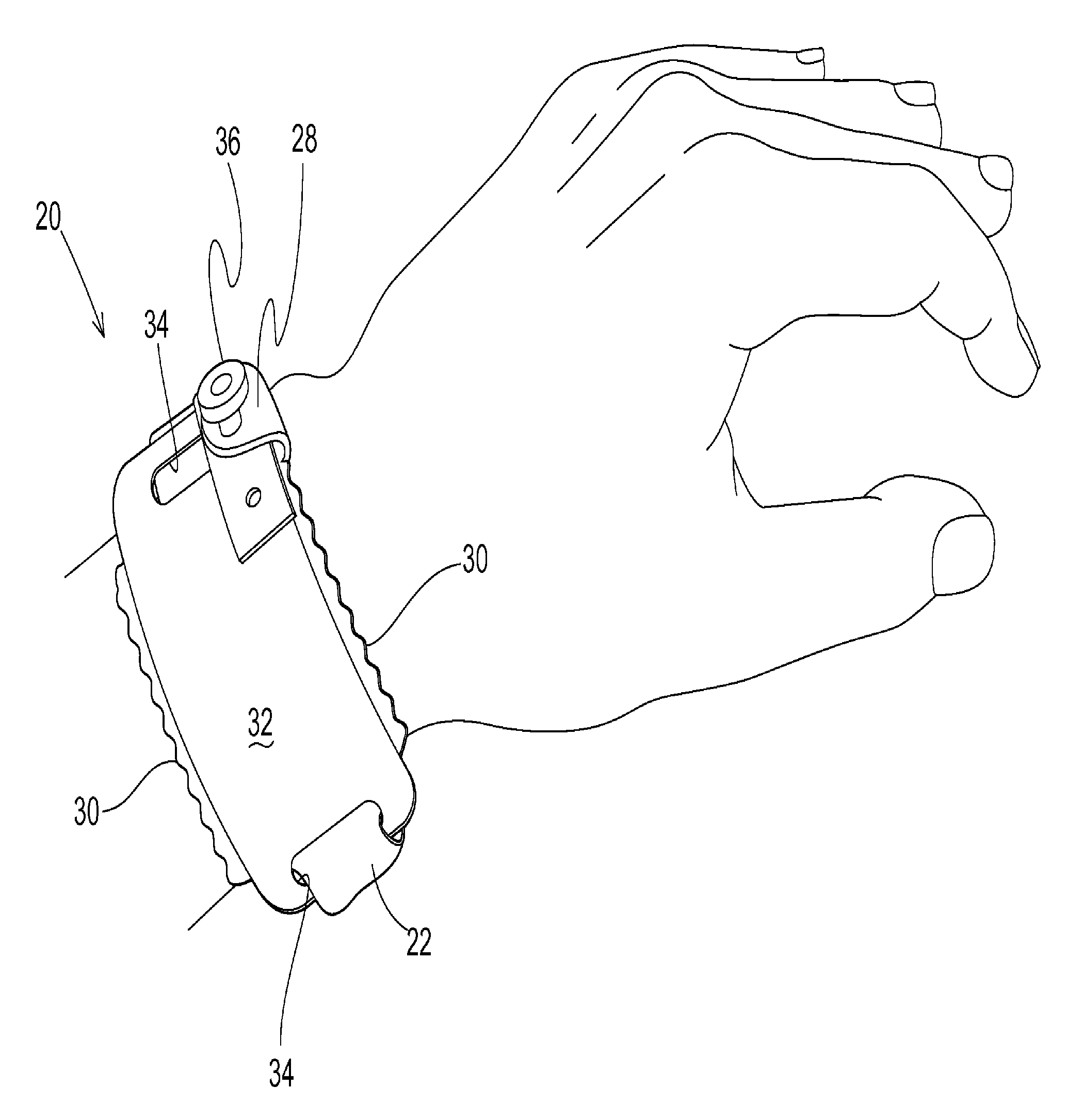

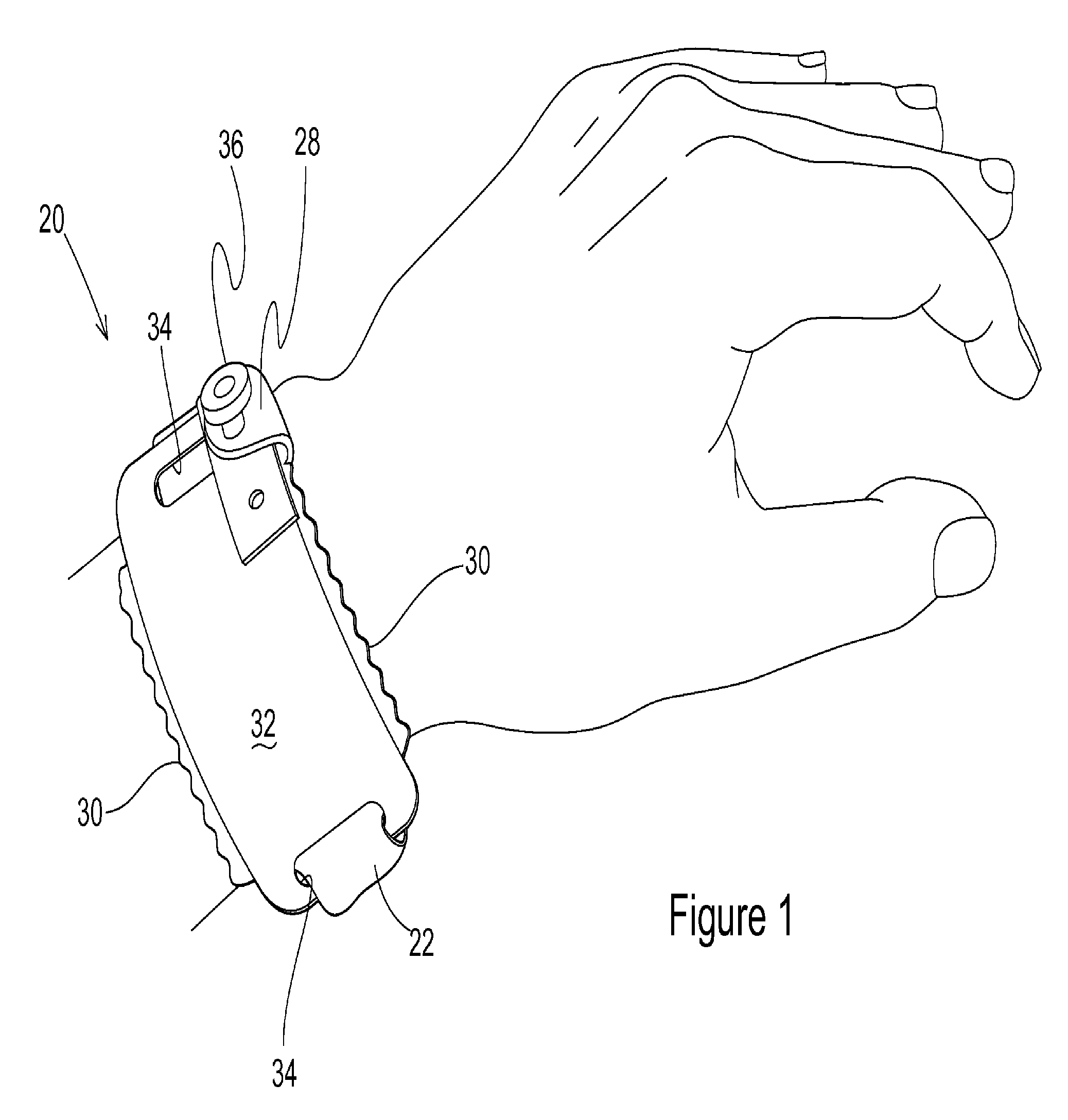

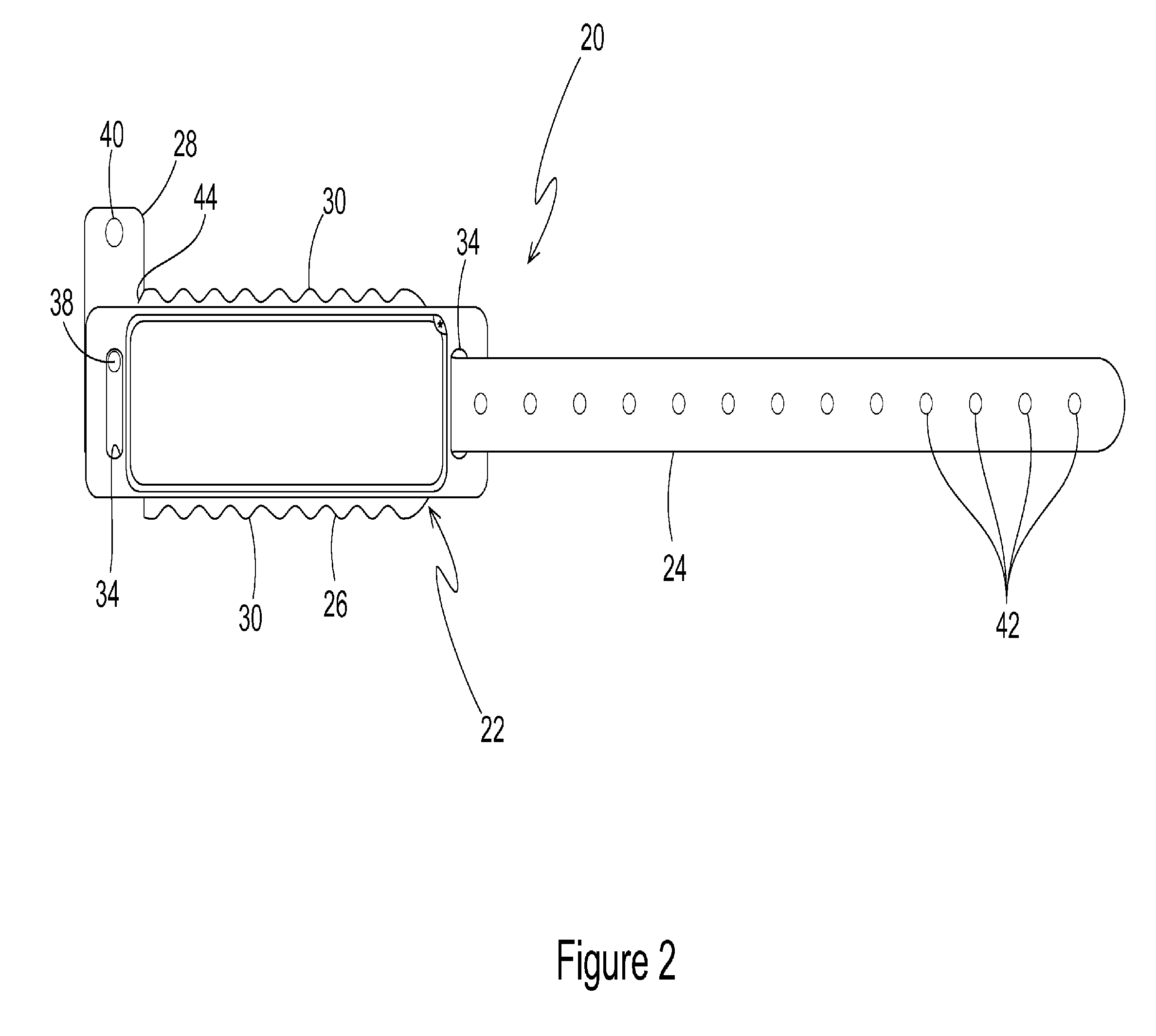

Business Form With Wristband Carriers

ActiveUS20090282717A1Great commercial successSimple designStampsPerson identificationFace sheetBusiness forms

Owner:ZEBRA TECH CORP

Flashlight and flashlight electrical connectors

InactiveUS20040095759A1Easy to useAvoid high pressurePoint-like light sourceElectric circuit arrangementsElectricityElectrical resistance and conductance

A flashlight with unique flashlight electrical connections, including a switch structure featuring a switch requiring a small amount of force, and a short stroke distance to actuate, attached to a member on which a circuit adding additional functions to the flashlight may be located. The member has conductive springs attached to either end that are used to complete the electrical circuit with the battery and the lamp, while their compressive force is absorbed by a housing protecting the switch structure. A conductive strip is used to improve the conductivity of the circuit in a metal flashlight which has been provided with an electrically resistive protective coating.

Owner:MAG INSTR INC

Method of formulating and using a drilling mud with fragile gels

A method for drilling, running casing in, and / or cementing a borehole in a subterranean formation without significant loss of drilling fluid is disclosed, as well as compositions for use in such method. The method employs a drilling fluid comprising a fragile gel or having fragile gel behavior and providing superior oil mud rheology and overall performance. The fluid is especially advantageous for use in deep water wells because the fluid exhibits minimal difference between downhole equivalent circulating density and surface density notwithstanding differences in drilling or penetration rates. When an ester and isomerized olefin blend is used for the base of the fluid, the fluid makes an environmentally acceptable and regulatory compliant invert emulsion drilling fluid. The fluid preferably contains no organophilic clays.

Owner:HALLIBURTON ENERGY SERVICES INC

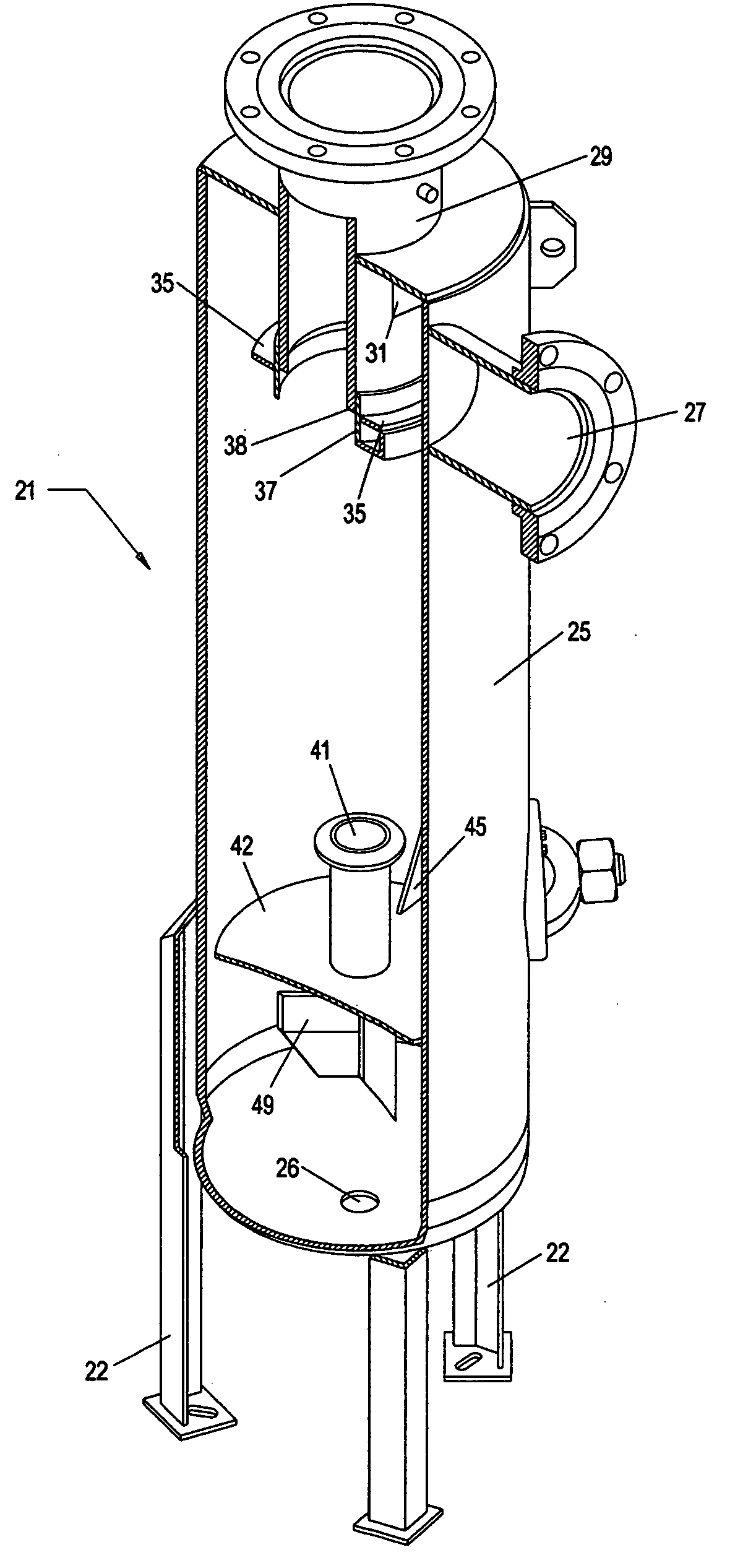

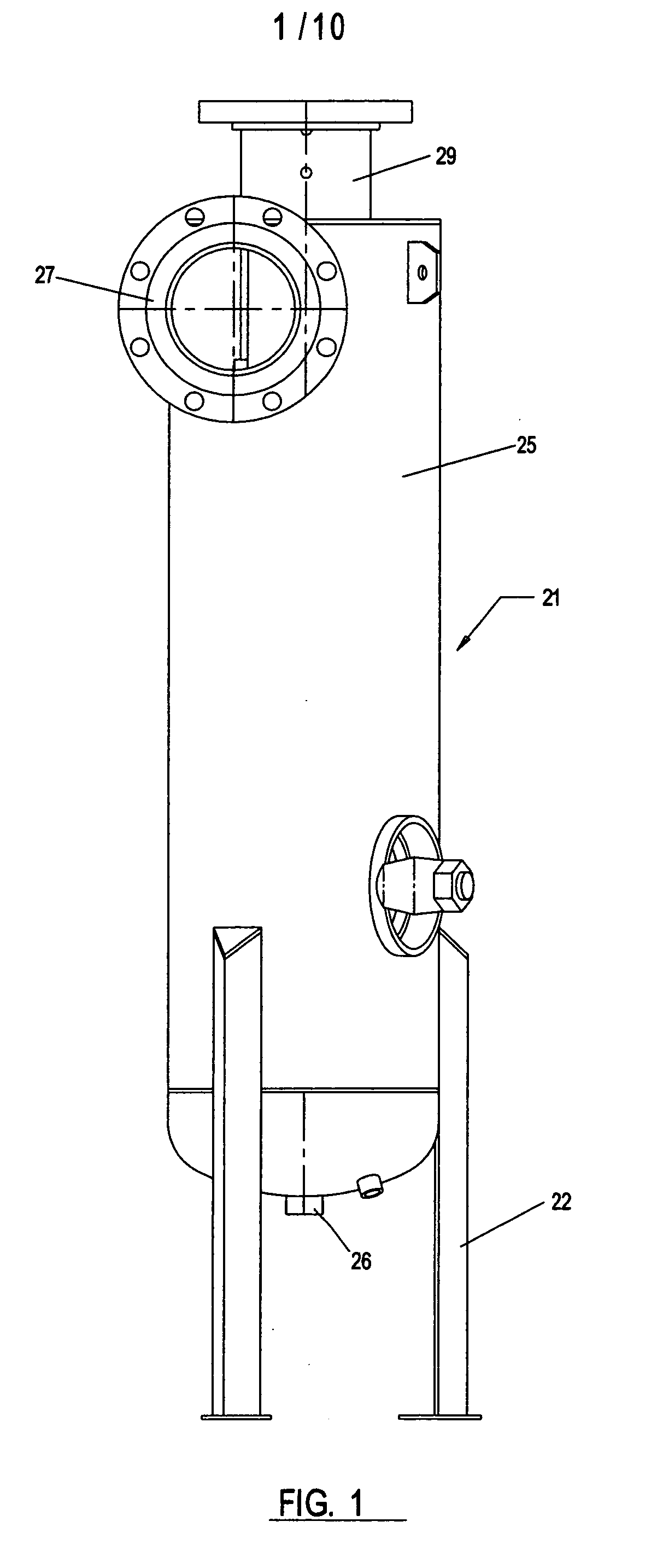

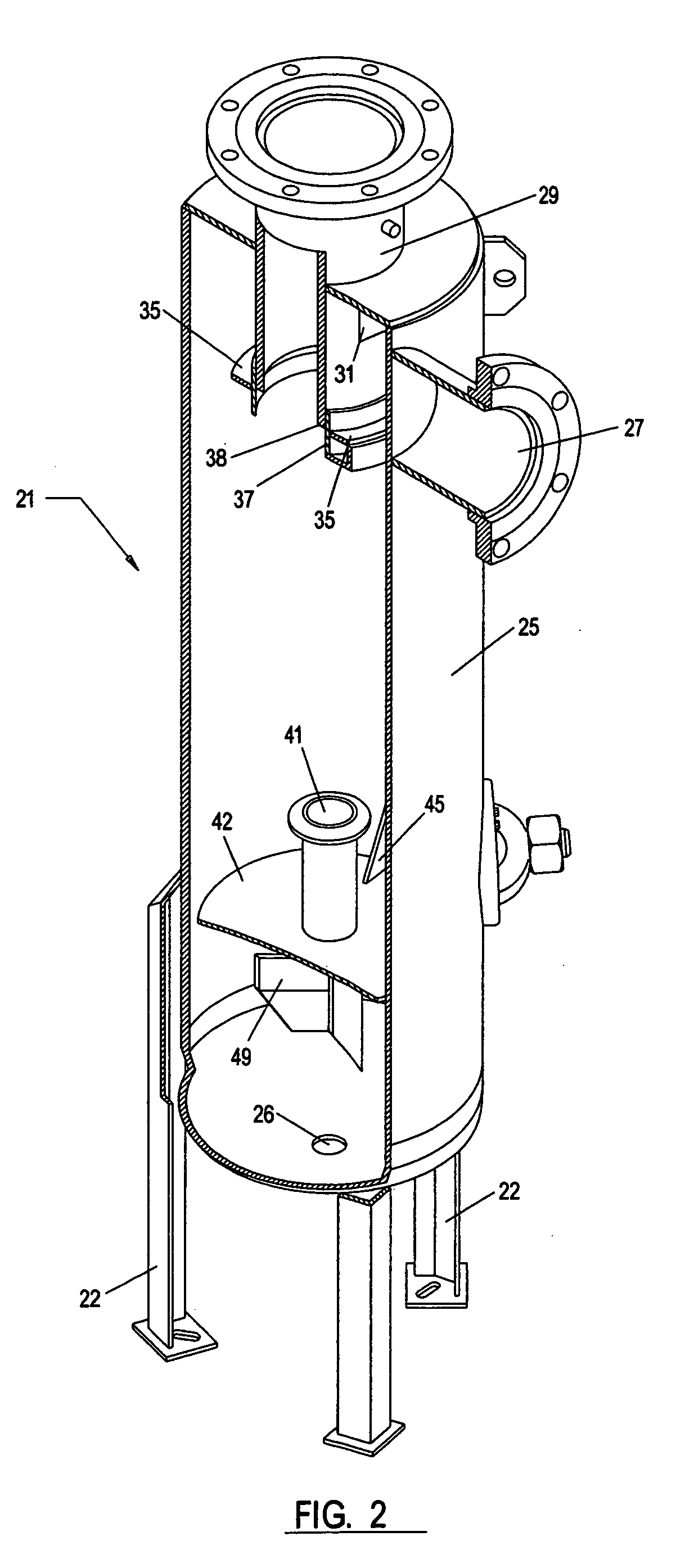

Dual stage centrifugal liquid-solids separator

InactiveUS7025890B2Reduce cavitationEasy to disassembleWater/sewage treatment by centrifugal separationLiquid degasificationDual stageSpins

Disclosed is a vortex-based centrifugal separator for removing solids from a liquid / solids fluid stream in two stages. A fluid stream under pressure is introduced at the top of the cylindrical separator at a tangential angle forming helical downward flow. The first stage uses a centrally-located spin plate for reversing the cleaner interior flow of the vortex back upward, while the heavier solids settle at the bottom of the chamber for periodic removal. In the second stage, a plurality of louvered slots in an upper discharge pipe remove finer solids from the exiting upward fluid flow prior to discharge.

Owner:GRISWOLD CONTROLS LLC

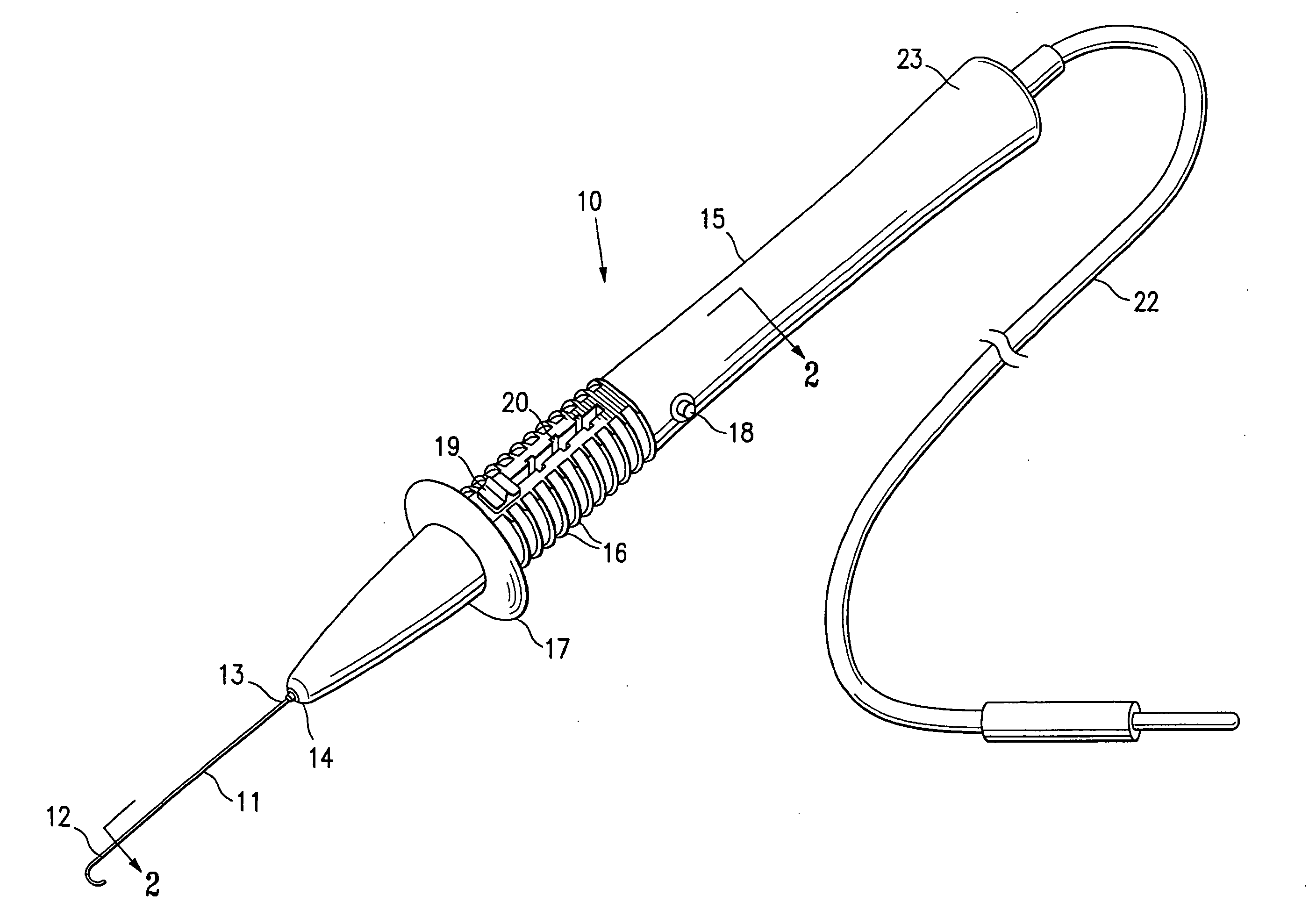

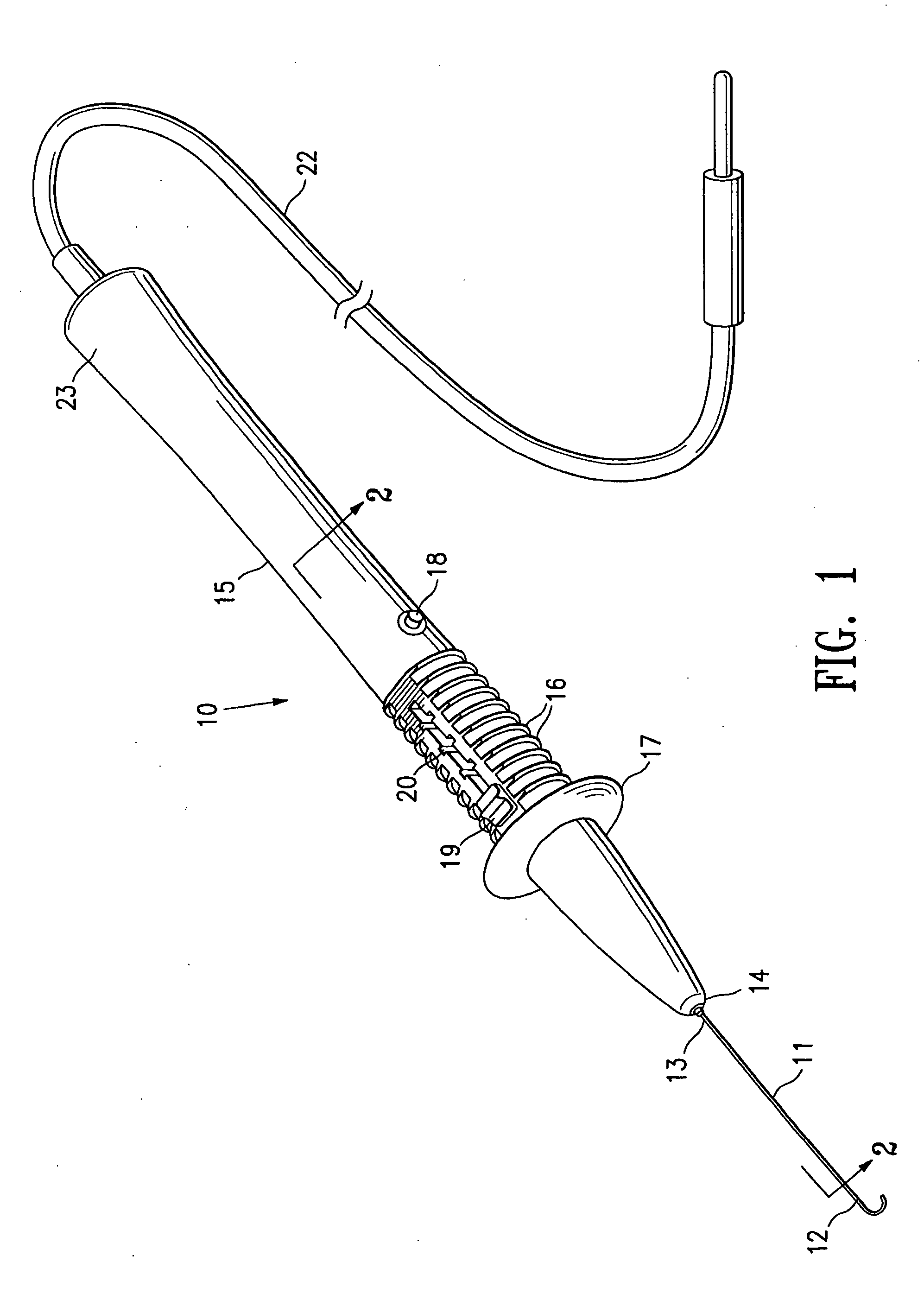

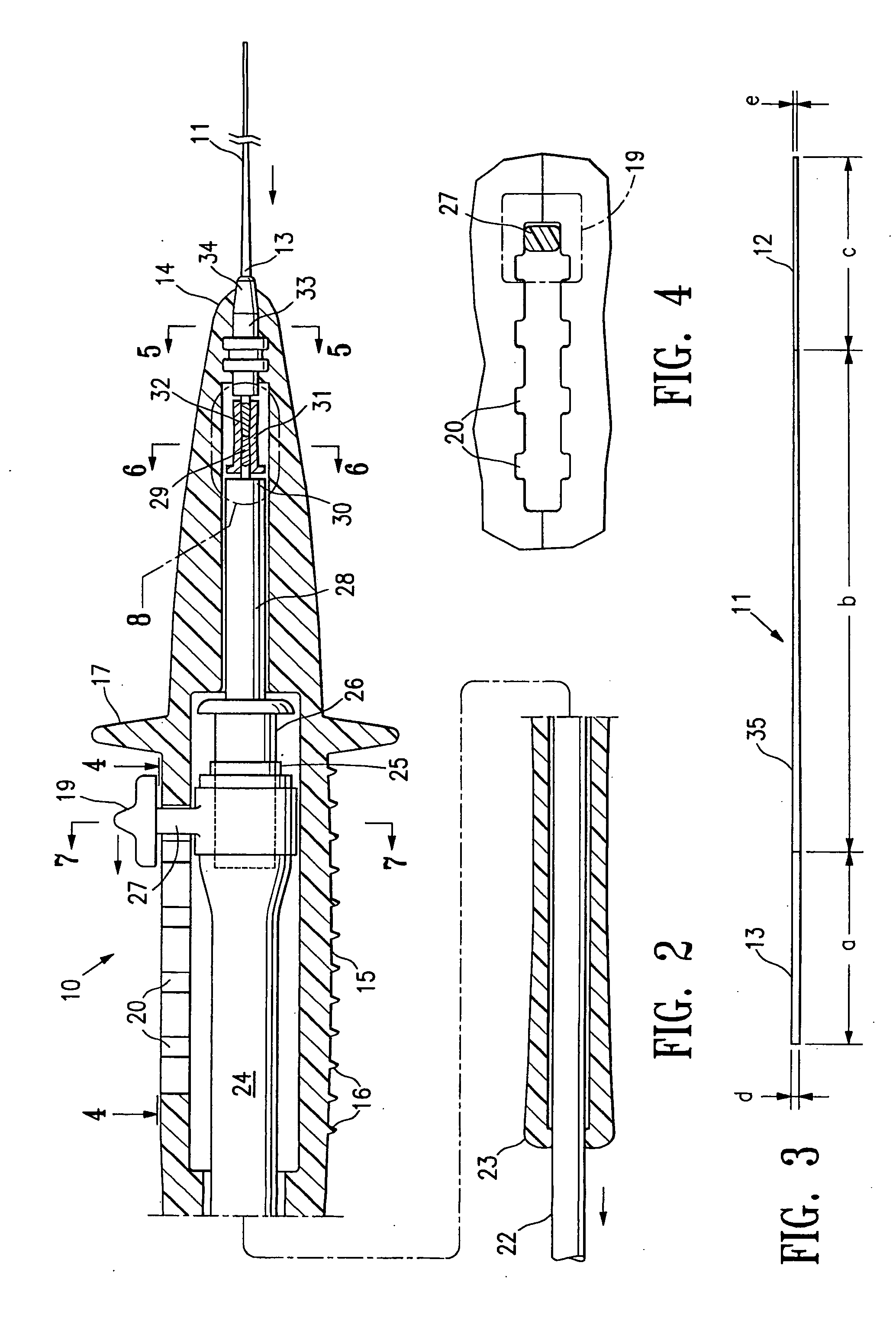

Shapeable electrosurgical scalpel

InactiveUS20090082763A1Less traumaSmoother marginSurgical needlesVaccination/ovulation diagnosticsElectrosurgeryConnective tissue

Owner:SENORX

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com