Jet former

A technology of former and jet, which can be used in indoor sanitary pipe installations, water supply installations, buildings, etc., and can solve problems such as high noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

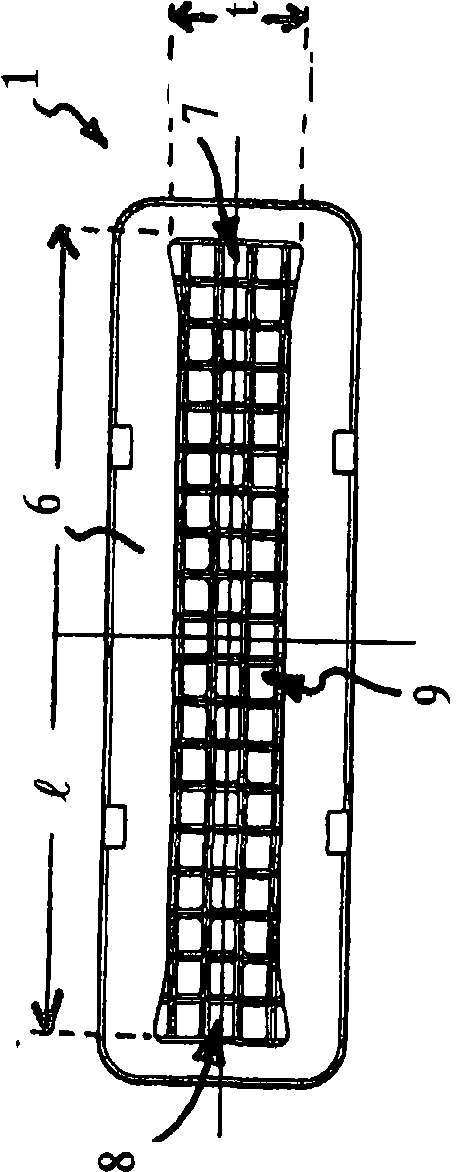

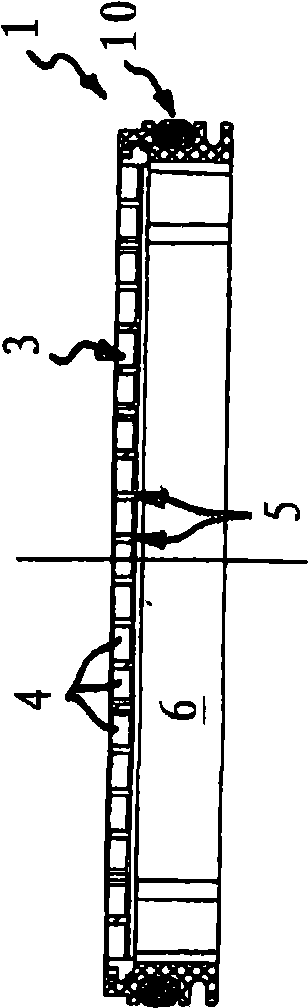

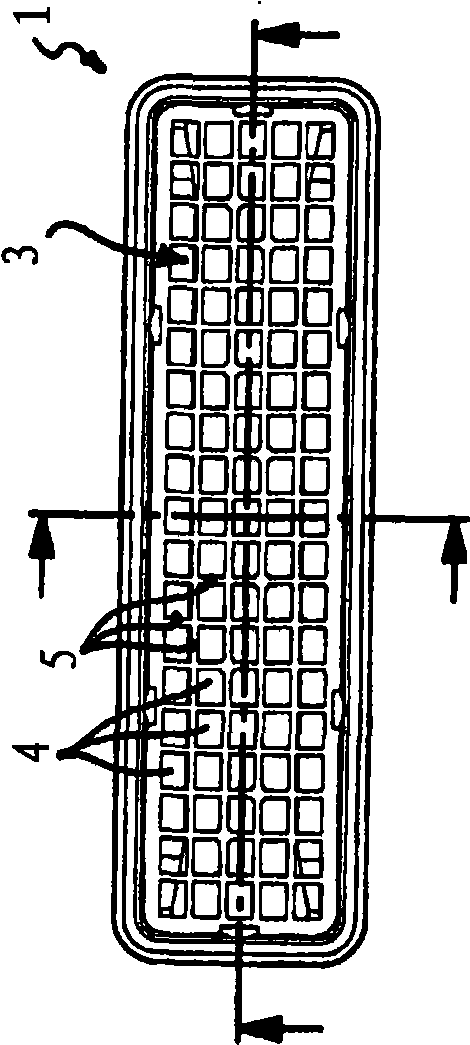

[0023] exist Figures 1 to 7 A jet former 1 is shown in a different view. From Figure 7 It can be clearly seen in the transverse sectional view of , that the jet shaper 1 can be installed in the water outlet 2 of the sanitary water valve. The jet former 1 has a homogenizer 3 which forms the inflow-side end face of the jet former 1 . The homogenizer 3 has a plurality of throughflow openings 4 which are each surrounded and delimited by a fluid-guiding wall 5 . From figure 1 , 3 And it can be clearly seen from 5 to 7 that the fluid-guiding wall 5 is formed as a grid-like structure.

[0024] exist figure 1 As can be seen in , the jet former 1 has a jet width l greater than the jet depth t in order to generate a smooth water jet strip. From Figure 4 and 7 It can be seen in the transverse sectional view of the homogenizer 3 that a fluid guide 6 is connected downstream of the homogenizer 3, which tapers nozzle-like at least in some regions in the flow direction. On both s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com