Textile printing and dyeing ink and preparation method thereof

A technology for textiles and inks, applied in the field of preparation of textile printing and dyeing inks, can solve the problems of printing and dyeing inks that are immature and uncirculated, and achieve the effects of high color fastness, good fluidity and rich colors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

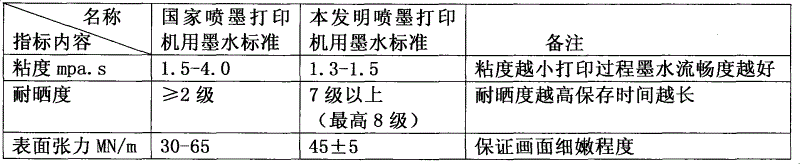

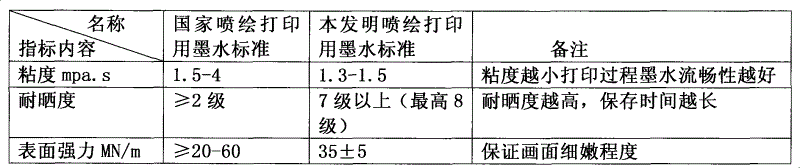

Method used

Image

Examples

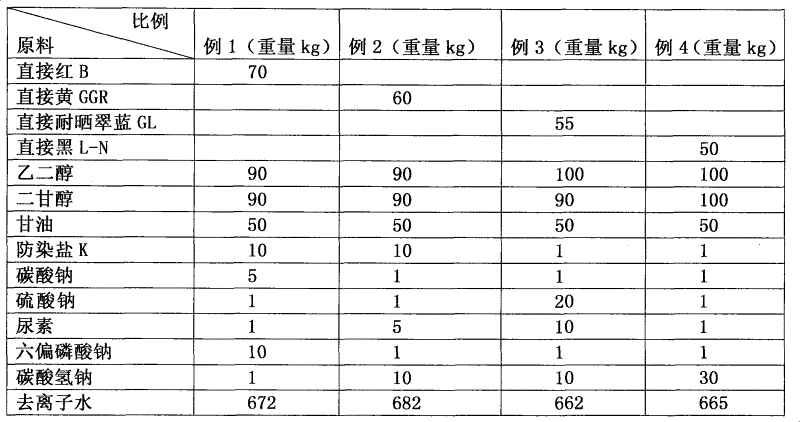

Embodiment 1

[0068] Method for preparing 1000kg of red printing and dyeing ink for textile printing and dyeing ink at one time:

[0069] Direct red B dye 70kg, ethylene glycol 90kg, diethylene glycol 90kg, glycerin 50kg, resist salt K10kg, sodium carbonate 5kg, sodium sulfate 1kg, urea 1kg, sodium bicarbonate 1kg, sodium hexametaphosphate 10kg and deionized water 672 kg were weighed separately, then placed in a mixing container at room temperature and stirred for 1 hour, allowed to stand for 12 hours, filtered by a filter, packaged, and the finished red printing and dyeing ink of textile printing and dyeing ink was obtained.

Embodiment 2

[0071] Method for preparing 1000kg of yellow printing and dyeing ink for textile printing and dyeing ink at one time:

[0072] Direct yellow GGR dye 60kg, ethylene glycol 90kg, diethylene glycol 90kg, glycerin 50kg, resist salt K10kg, sodium carbonate 1kg, sodium sulfate 1kg, urea 5kg, sodium bicarbonate 10kg, sodium hexametaphosphate 1kg and deionized water 682 kg were weighed separately, then placed in a stirring container at room temperature and stirred for 50 minutes, left to stand for 16 hours, filtered with a filter, packaged, and the finished product of yellow printing and dyeing ink of textile printing and dyeing ink was obtained.

Embodiment 3

[0074] The method of preparing 1000kg blue printing and dyeing ink of textile printing and dyeing ink at one time:

[0075] Direct lightfast turquoise blue GL dye 55kg, ethylene glycol 100kg, diethylene glycol 90kg, glycerin 50kg, resist salt K1kg, sodium carbonate 1kg, sodium sulfate 20kg, urea 10kg, sodium bicarbonate 10kg, sodium hexametaphosphate 1kg and 662 kg of deionized water were weighed separately, then placed in a stirring container at room temperature, stirred and mixed for 1 hour, left to stand for 24 hours, filtered with a filter, packaged, and the finished product of blue printing and dyeing ink of textile printing and dyeing ink was obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface tension | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com