Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

110results about How to "Conducive to direct contact" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Barium-strontium-calcium descaling and blockage removing agent for near-well area and preparing method of barium-strontium-calcium descaling and blockage removing agent

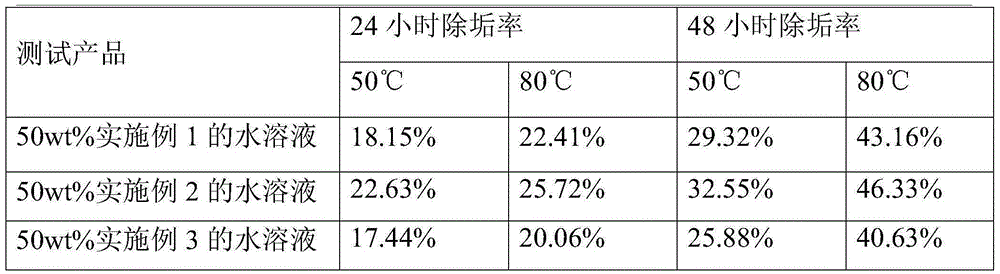

ActiveCN105112036APrevents accumulation of scaleReduce secondary damageDrilling compositionCarboxylic saltChloroacetic acids

The invention discloses a barium-strontium-calcium descaling and blockage removing agent for a near-well area and a preparing method of the barium-strontium-calcium descaling and blockage removing agent. The barium-strontium-calcium descaling and blockage removing agent comprises a polyamine carboxylate solution, nonionic surfactant accounting for 3%-10% of the total mass of the polyamine carboxylate solution and an emulsion breaker accounting for 2%-8% of the total mass of the polyamine carboxylate solution. The polyamine carboxylate solution is prepared from polyamine midbody and chloroacetic acid salt through a reaction, wherein the polyamine midbody is prepared through organic amine and epoxy chloropropane with the mole ratio of 1.05-1.5:1 through a reaction, and the chloroacetic acid salt is prepared from chloroacetic acid and alkali with the same mole ratio through a reaction. The barium-strontium-calcium descaling and blockage removing agent for the near-well area has a good removing effect on indissolvable salt such as barium sulfate, strontium sulfate and calcium sulfate, and the descaling rate is higher than 40%. Meanwhile, the barium-strontium-calcium descaling and blockage removing agent has the expansion preventing and inhibiting performance, the clay expansion reducing rate is higher than 80%, corrosion to equipment is slight, and water locking can be avoided. Blockage removing can be effectively achieved on a reservoir stratum near a well, the permeability of the reservoir stratum is improved, and thus the recovery ratio of oil and gas resources is increased.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Technique for manufacturing high-power light emitting diode (LED) lamp

InactiveCN101876406AImprove cooling effectAnti agingPoint-like light sourceElectric circuit arrangementsFluorescenceEngineering

The invention relates to the technical field of techniques for manufacturing light emitting diode (LED) lamps, in particular to a technique for manufacturing a high-power LED lamp. The technique comprises the following steps: die-bonding with fulmargin, welding the wires, sealing the primer, coating a fluorescent powder glue film, sealing finish, and the like, wherein the colloid in each step is dried in a sectional baking mode. After using the technical scheme, a LED chips is fixed with fulmargin, so that the LED chip can emit heat easily; before coating the fluorescent powder glue film, a layer of primer is sealed so as to tile and cover the fluorescent powder glue film on the LED chip, thereby avoiding the wires are damaged when the fluorescent powder is spotted, and isolating the fluorescent powder layer from the LED chip to avoid direct contact and be beneficial to deferring senility; and in addition, the primer, fluorescent powder glue film and finish are baked in a sectional mode, so that all the layers are uniform and can be well combined.

Owner:东莞市光宇新能源科技有限公司

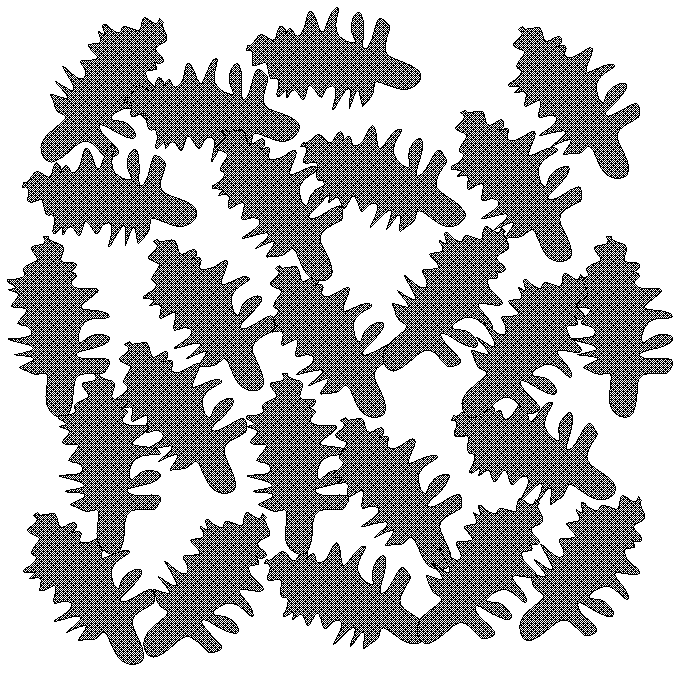

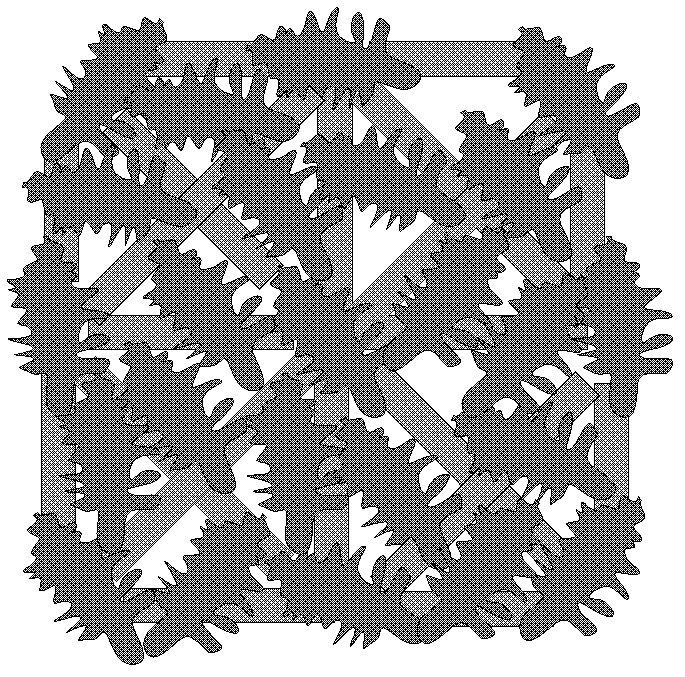

Single-component extrusion molding conductive rubber for electromagnetic shielding and preparation method of single-component extrusion molding conductive rubber

InactiveCN102220012ALarge specific surface areaConducive to direct contactCross-linkElectromagnetic shielding

The invention discloses a single-component extrusion molding conductive rubber for electromagnetic shielding and a preparation method of the single-component extrusion molding conductive rubber, belonging to the technical field of electromagnetic shielding materials. The single-component extrusion molding conductive rubber is composed of dendritic silver coated copper powder, silvered glass fiber, polydimethylsiloxane containing vinyl by rubber base body, reinforcing agent gaseous phase white carbon black, alkynol inhibitor, metal platinum catalyst, and cross-linking agent methylhydropolyorganosiloxane. The preparation method comprises the following steps: pretreatment is carried out to the dendritic silver coated copper powder and the silvered glass fiber through amido coupling agent methyl organodisilane according to the formula, the rubber base body and the gaseous phase white carbon black are added in a vacuum kneading machine, are mixed uniformly and are added in a double-planet mixing plant, and then the alkynol inhibitor, the metal platinum catalyst and the treated electric conduction powder are mixed uniformly to form a component 1; the treated electric conduction powder is added in a cross-linking agent and is mixed uniformly to form a component 2; and two components in the double planets are mixed to form the single-component on-site forming electromagnetic shielding silicon rubber. The rubber has good shielding performance and good mechanical property.

Owner:BEIJING UNIV OF TECH

Plant source extraction deodorant and preparation method thereof

InactiveCN102240409ANo pollution in the processConducive to direct contactDeodrantsDeodorantPlant Sources

The technology (a plant source extraction deodorant and a preparation method thereof) is a pure plant essence extraction process. The deodorant is named as an offensive odor removal agent. The technical field belongs to environmental protection or medicinal preparation class. A technical problem to be solved is that how to prolong effective duration of the product. A key point to solve the problem is that further increasing concentration of the product and adding citric acid with 0.5g / kg in a finished product stock solution. A main purpose of this product is processing bathrooms, landfill sites, and non-current sewage. An aim of the invention is to achieve effects of environmental protection, green, non-toxic and harmless and virtuous recycling.

Owner:胡镜 +1

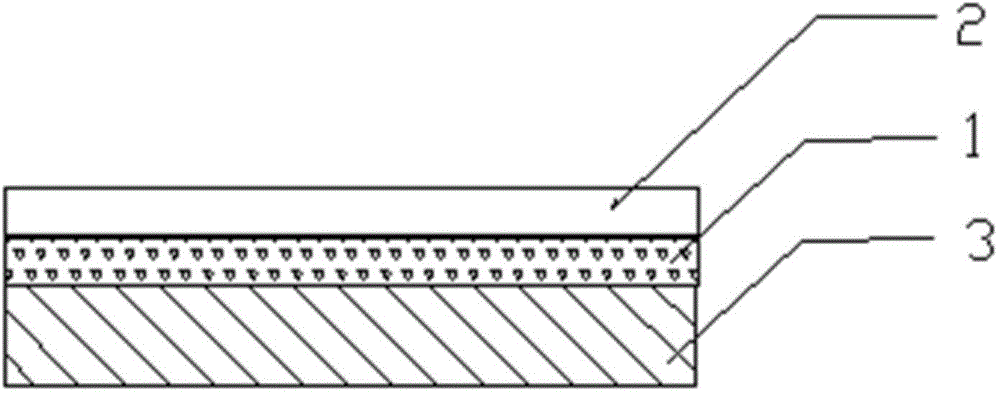

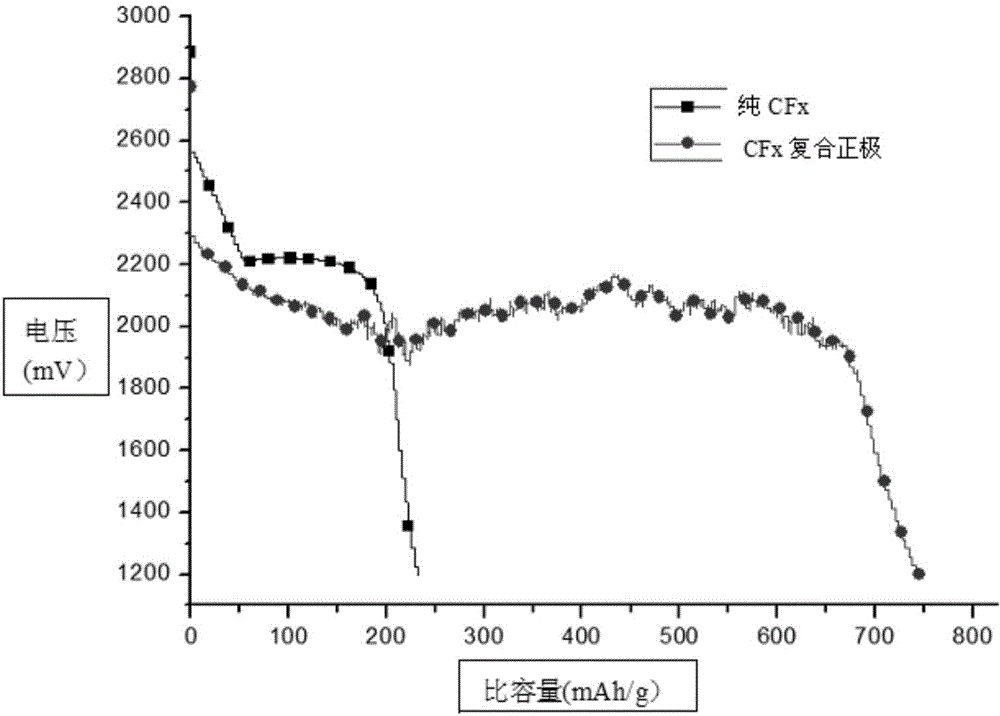

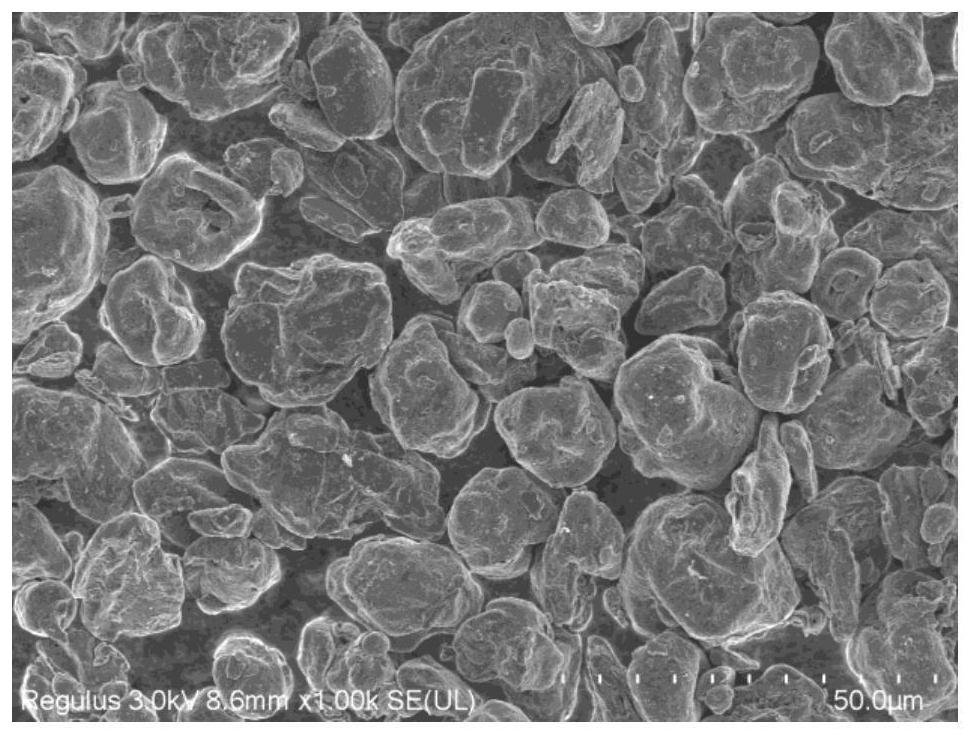

Carbon fluoride composite positive electrode and preparation method thereof

InactiveCN104466107AReduce polarizationStable structureNon-aqueous electrolyte cellsPrimary cell electrodesAdhesiveSlurry

The invention discloses a carbon fluoride composite positive electrode and a preparation method of the carbon fluoride composite positive electrode. According to the carbon fluoride composite positive electrode, an aluminum foil is used as a substrate, and the surface of the substrate sequentially comprises a composite coating containing carbon fluoride, carbon conductive and adhesives and a nickel-containing plating layer from bottom to top. The preparation method comprises the following steps: adding carbon fluoride, carbon conductive and adhesives into organic solvents for stirring uniformly to obtain mixed slurries; coating the surface of the aluminum foil by the obtained mixed slurries; drying and forming the compound coating on the surface of the aluminum foil; plating the nickel-containing plating layer on the surface of the composite coating by means of chemical nickel plating; performing thermal treatment and rolling; cutting into electrode positive electrodes. The preparation method is easy to operate, mild in process conditions and low in cost; the prepared composite positive electrode is stable in structure and high in conductivity and can be used for preparing a lithium carbon fluoride battery with high specific capacity and high current efficiency.

Owner:XIANGTAN UNIV

Method for manufacturing insole with jute fiber

ActiveCN101167606AEfficient removalWeaken joint forceInsolesFibre treatment to obtain bast fibreFiberPectinase

A method for manufacturing insoles by jute fibers comprises treating jute fibers with the complex enzyme de-gelatinizing, wherein, the complex enzyme de-gelatinizing treatment uses complex enzyme aqueous solution which is formulated by pectase and laccase to provide the de-gelatinizing treatment to jutes, adjusting the pH value of the complex enzyme aqueous solution to be more than or equal to 4.0 but less than 5.0 when the complex enzyme de-gelatinizing treatment is carried out, elevating the temperature to 35 DEG C to 65 DEG C for 20-120 minutes, and then adjusting the pH value of the solution to be 7.5 to 9.5, keeping the temperature under 40 DEG C to 70 DEG C for 20-120 minutes, enzyme-devitalizating the jutes which are treated by the complex enzyme, mixing the de-gelatinized jute fibers with the chemical fibers, carding, net-spreading, and needling the mixed fibers, hot-pressing the needled mixed fibers and molding. The insole manufactured by the method of the invention is very comfortable when in use, and is not urticant in feeling when in use, good in bacteria repellency, not easily wormy, and strong in air permeability, hygroscopicity, and moisture character.

Owner:SUZHOU MOWEI NATURAL FIBER MATERIAL

Method for degumming jute by using complex enzyme

InactiveCN101130887AReduce usageImprove spinnabilityBiochemical fibre treatmentVegetable materialPectinaseLacquer

The present invention relates to a method for degumming jute by utilizing composite enzyme. The described composite enzyme includes pectase and laccase, and said method includes the following steps: utilizing pectase and laccase to make them into composite enzyme aqueous solution, and impregnating jute with said composite enzyme aqueous solution, the weight ratio of the described composite enzyme aqueous solution and jute is 15:1, and the weight ratio of described composite enzyme and jute is greater than or equal to 0.5:100 and less than 1:100: regulating pH value of said composite enzyme aqueous solution to 5.0-5.5, heating to 55deg.C-60deg.C, retaining for 25-50min, then regulating pH value of said solution to 7.5-8.0, and retaining for 25-50min at 60deg.C-70deg.C, finally, making the jute after which is treated by composite enzyme undergo the process of enzyme deactivation treatment.

Owner:JIANGSU REDBUD DYEING TECH CO LTD

Flame-retardant cable insulating material containing NCNFS/ZIF-90 and application

InactiveCN105837907AImprove loss on ignition indexImprove flame retardant performancePlastic/resin/waxes insulatorsHeat resistancePhysical chemistry

The invention relates to a flame-retardant cable insulating material containing NCNFS / ZIF-90. The material comprises a NCNFS / ZIF-90 polyene material, namely NCNFS / ZIF / LDPE / PS, can improve the heat resistance and strength of the material, reduce the ageing time of the insulating material, keep being not degraded for a long time under high temperature effect, and keep good flame-retardant effect, and greatly improves the LOI (Loss On Ignition) index.

Owner:WENZHOU HONGCHENGXIANG TECH

Method for manufacturing seat cushion with jute fibre

ActiveCN101172571AGood puffing effectImprove acupuncture effectUpholstery fillingFibre treatment to obtain bast fibrePectinaseAntibiosis

The invention relates to a manufacturing method of a seat cushion made of jute fiber. The method comprises the following steps: firstly, the soaking is performed to jute in compound enzyme water solution prepared by pectase and laccase, and the weight ratio of the compound enzyme water solution and the jute is 12 : 1 to 40 : 1; the pH value of the compound enzyme water solution is firstly adjusted into 4.0 to 6.5, and the compound enzyme water solution is warmed up to 35 to 65 DEG C, and the temperature is kept for 20 to 120 minutes; and then pH value of the compound enzyme water solution is adjusted to more than 8.0 and less than and equal to 9.5, and the compound enzyme water solution is kept for 20 to 120 minutes at 14 to 70 DEG C; then the enzyme inactivation process is performed to the jute processed through the compound enzyme; secondly, jute fiber after being degumed is mixed with chemical fiber, and carding, mesh placement and needling are performed to the chemical fiber; thirdly, the mixed fiber after being needled is thermally pressed and molded; fourthly, a sleeve body is coated. The seat cushion manufacuted by the invention is soft and comfortable, has no urtication feeling when being used by people, and has good antibiosis and anti-acarine performance.

Owner:SUZHOU MOWEI NATURAL FIBER MATERIAL

Method for increasing denitrification rate in wastewater treatment through goethite

ActiveCN104692526ALarge specific surface areaImprove adsorption capacityTreatment with anaerobic digestion processesGoethiteWastewater disposal

The invention discloses a method for increasing denitrification rate in wastewater treatment through goethite. The method is characterized in that nanometer goethite is fed in a certain ratio according to carbon-nitrogen ratio into an anaerobic tank of a sewage treatment plant to be uniformly mixed; or granular goethite can fill as fillers a reaction column, a film is covered, sewage is poured into the reaction column from bottom to top after startup, and the hydraulic retention time is controlled to be 0.5 to 12h so that the sewage can be fully in contact with goethite; goethite promotes the microorganism to reduce nitrate in sewage into NO or N2O or N2 through organic matters in the sewage, so as to achieve the denitrification effect. With the adoption of the method, the denitrification rate can be increased, and the damage of accumulated nitrite to microorganism can be avoided; in addition, the quantity of fed external carbon sources can be decreased while the denitrification rate is increased, and thus the cost is effectively reduced.

Owner:HEFEI UNIV OF TECH

Silicon-carbon composite material, preparation method thereof, lithium battery negative electrode material and lithium battery

The invention provides a silicon-carbon composite material, a preparation method thereof, a lithium battery negative electrode material and a lithium battery. The preparation method comprises the following steps: S1, mixing nano silicon, a carbon source, an etching agent, a binder and a solvent to obtain a mixture; S2, performing primary carbonization treatment on the mixture to obtain a graphene-like carbon film coated silicon material; S3, mixing the graphene-like carbon film coated silicon material, a carbon series conductive agent and a polymer conductive agent, and carrying out compactionmolding to obtain a molded material blank; and S4, carrying out secondary carbonization treatment on the molded material blank to obtain the silicon-carbon composite material; wherein the etching agent is an alkali metal salt. Through the synergistic effect of the primary carbonization treatment and the secondary carbonization treatment, the silicon-carbon composite material with longer cycle life and better rate capability is obtained.

Owner:YINLONG ENERGY CO LTD

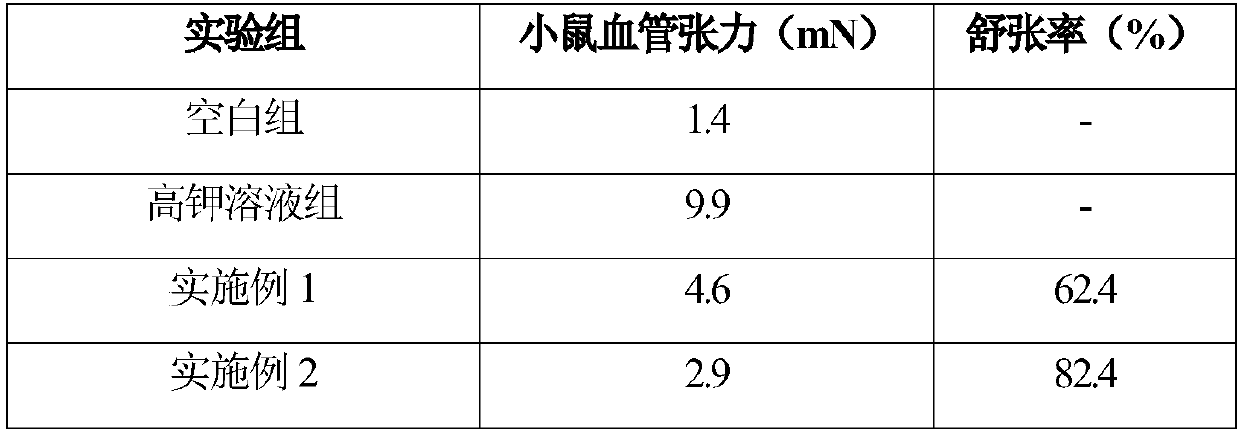

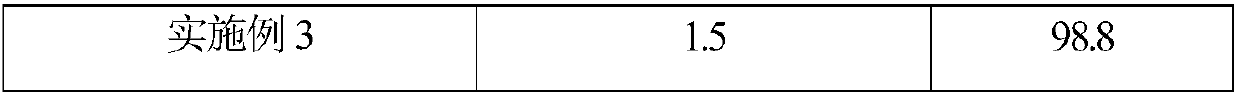

Preparation method and application of atropa belladonna extract

InactiveCN107582729AAvoid enteringPromote leachingCardiovascular disorderPlant ingredientsWarm waterCell wall

The invention discloses a preparation method and an application of an atropa belladonna extract. The preparation method comprises processes as follows: soaking in warm water, ethanol extraction, percolation and the like. According to the medicine preparation method, the inside of a percolator is covered with multiple layers of cellulase membranes, cell walls consisting of cellulose in atropa belladonna are broken with cellulase, leaching of effective components in cells is accelerated, and the utilization rate of raw materials is greatly increased; the atropa belladonna extract prepared with the method can be taken as a novel vascular smooth muscle relaxing medicine and used for preparing medicines for treating hypertension, and a new scheme can be provided for clinical treatment of hypertension.

Owner:SOUTH CENTRAL UNIVERSITY FOR NATIONALITIES

Battery temperature sensor

PendingCN107677391AEasy to installReduce volumeThermometers using physical/chemical changesThermodynamicsEngineering

The invention relates to a battery temperature sensor. The battery temperature sensor includes a ring-shaped fiber which is provided with a fiber grating thereon. The ring-shaped fiber is fixed to thesurface of a battery monomer through a soft fixing assembly. The battery temperature sensor herein also includes a temperature measurement apparatus. The ring-shaped fiber and the temperature measurement apparatus are connected. The technical solution has the following beneficial advantages: the ring-shaped fiber is provided with a fiber grating thereon, and the fiber grating is fixed to the surface of the battery monomer through the soft fixing assembly, which reduces the size of an apparatus and makes packaging much simpler. In addition, the battery temperature sensors can be easily installed in respective battery monomers inside a battery box, can independently monitor the temperature of respective battery monomers, and can monitor the temperature of respective batteries inside the battery box in a differentiated manner.

Owner:SHENZHEN YIXUN TECH CO LTD

Metal product polishing liquid and preparation method thereof

The invention discloses metal product polishing liquid. The polishing liquid is prepared from, by weight, 20-30 parts of citric acid, 50-100 parts of glacial acetic acid, 2-10 parts of 2-ethylimidazole, 5-12 parts of salicylic acid, 10-20 parts of glycolic acid, 8-15 parts of 1H-benzotriazole, 20-80 parts of polyethylene glycol 8000, 100-150 parts of tetrahydrofurfuryl alcohol, 50-150 parts of ethyl alcohol, 80-100 parts of butyl acetate, 5-12 parts of oleic alcohol polyoxyethylene ether, 5-12 parts of ethylenediamine, 4-6 parts of nano-silicon dioxide, 3-9 parts of nano-zinc oxide and 30-80 parts of auxiliaries. The metal product polishing liquid contains the auxiliaries, the auxiliaries contain rice bran and mango skin, an oxide layer on the surface of a metal product can be effectively removed by means of extraction, tea seed powder can remove blots on the surface of the metal product, effective substances in a polishing agent can easily make direct contact with the oxide layer on the surface of the metal product, the efficiency is improved when the polishing agent removes the oxide layer, and after being modified through iron powder, latex powder and natural resin can form a layer of compact protective film on the surface layer of the metal product after being polished.

Owner:广西钱隆投资管理有限公司

Method for degumming jute by using complex enzyme

ActiveCN101130890AImprove spinnabilityHigh strengthBiochemical fibre treatmentVegetable materialPectinaseLacquer

The present invention relates to a method for degumming jute by using composite enzyme. The described composite enzyme includes pectase and laccase, and said method includes the following steps: making the pectase and laccase into composite enzyme aqueous solution, impregnating jute with said composite enzyme aqueous solution, the weight ratio of the described composite enzyme aqueous solution and jute is 12:1-40:1, regulating pH value of the described composite enzyme aqueous solution to 5.0-5.5, heating to 55deg.C-60deg.C, retaining for 25-50min, then regulating pH value of said solution to 7.5-8.0, retaining for 15-24min at 60deg.C-70deg.C, finally, making the jute after which is treated by composite enzyme undergo the process of enzyme deactivation treatment.

Owner:JIANGSU REDBUD DYEING TECH CO LTD

Method for degumming jute by using complex enzyme

ActiveCN101130892AImprove spinnabilityHigh strengthBiochemical fibre treatmentVegetable materialPectinaseLacquer

The present invention relates to a method for degumming jute by using composite enzyme. The described composite enzyme includes pectase and laccase, and said method includes the following steps: impregnating jute with composite enzyme aqueous solution prepared by using pectase and laccase, the weight ratio of the described composite enzyme aqueous solution and jute is 12:1-40:1; regulating pH value of the described composite enzyme aqueous solution to make it be greater than 5.5 and less than or equal to 6.5, heating to 35deg.C-65deg.C, retaining for 20-120min, then regulating pH value of aid solution to 7.5-9.5, retaining for 20-120min at 40deg.C-70deg.C, finally, making the jute after which is treated by composite enzyme undergo the process of enzyme deactivation treatment.

Owner:JIANGSU REDBUD DYEING TECH CO LTD

Method for degumming jute by using complex enzyme

ActiveCN101135065AImprove spinnabilityHigh strengthBiochemical fibre treatmentVegetable materialPectinaseLacquer

The process of degumming jute with composite enzyme comprising pectase and laccase includes the following steps: dipping jute in composite enzyme aqua compounded with pectase and laccase in 12-40 times weight of jute; regulating the pH value of composite enzyme aqua to 5.0-5.5, heating to 55-60 deg.c and maintaining for 20-120 min; regulating the pH value of composite enzyme aqua to 7.5-8.0 and maintaining at 40-59 deg.c for 50-120 min; and deactivating enzyme of treated jute. The process is simple and has high lignin eliminating effect.

Owner:JIANGSU REDBUD DYEING TECH CO LTD

Method for degumming jute by using complex enzyme

InactiveCN101130889AImprove spinnabilityHigh strengthBiochemical fibre treatmentVegetable materialPectinaseLacquer

The present invention relates to a method for degumming jute by using composite enzyme. The described composite enzyme includes pectase and laccase, and said method includes the following steps: making pectase and laccase into composite enzyme aqueous solution, impregnating jute with said composite enzyme aqueous solution, the weight ratio of the described composite enzyme aqueous solution and jute is 12:1-40:1, regulating pH value of said composite enzyme aqueous solution to 5.0-5.5, heating to 55deg.C-60deg.C, retaining for 15-24min, then regulating pH value of said solution to 7.5-8.0, retaining for 20-120min at 60deg.C-70deg.C, finally, making the jute after which is treated by composite enzyme undergo the process of enzyme deactivation treatment.

Owner:JIANGSU REDBUD DYEING TECH CO LTD

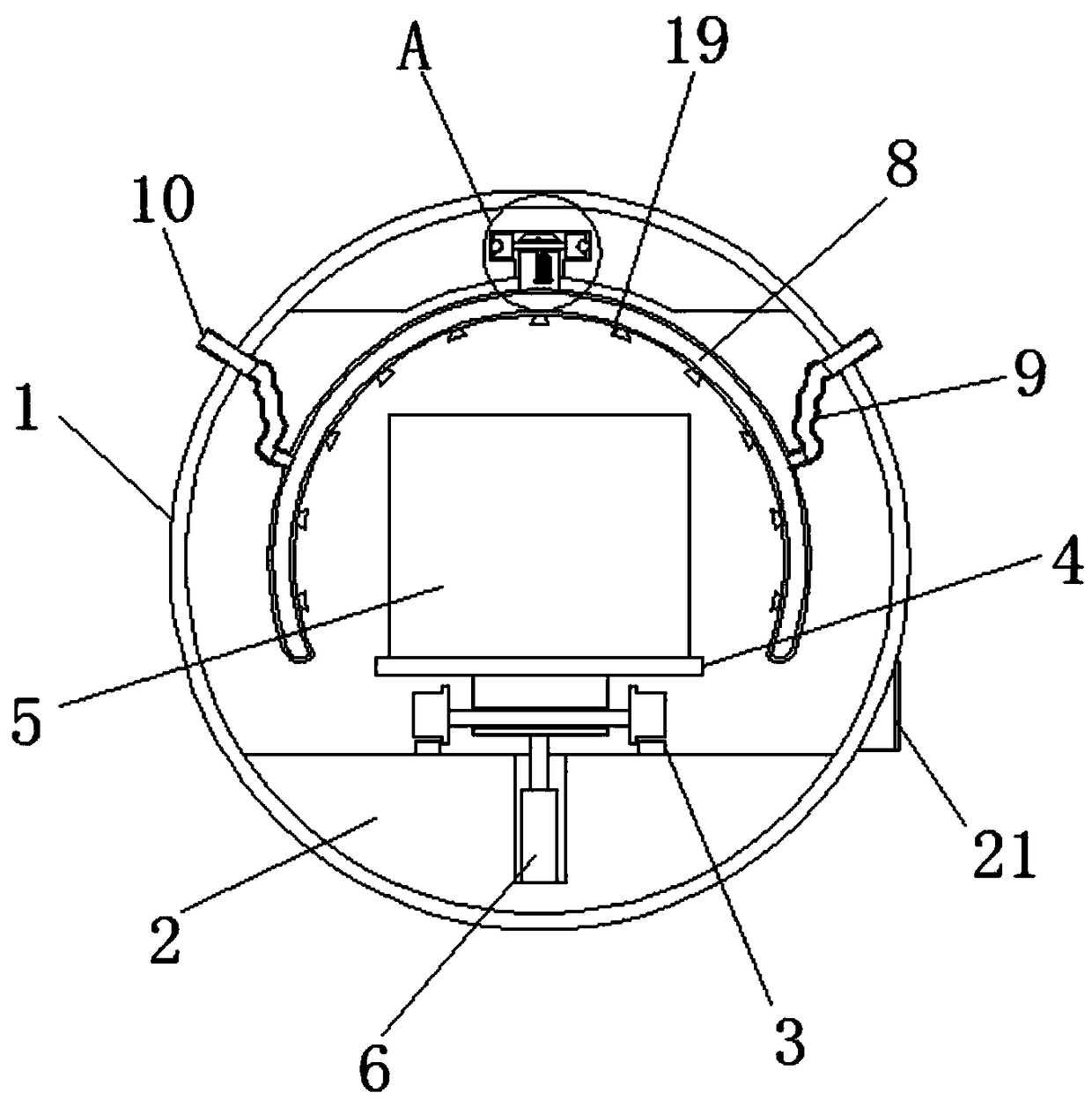

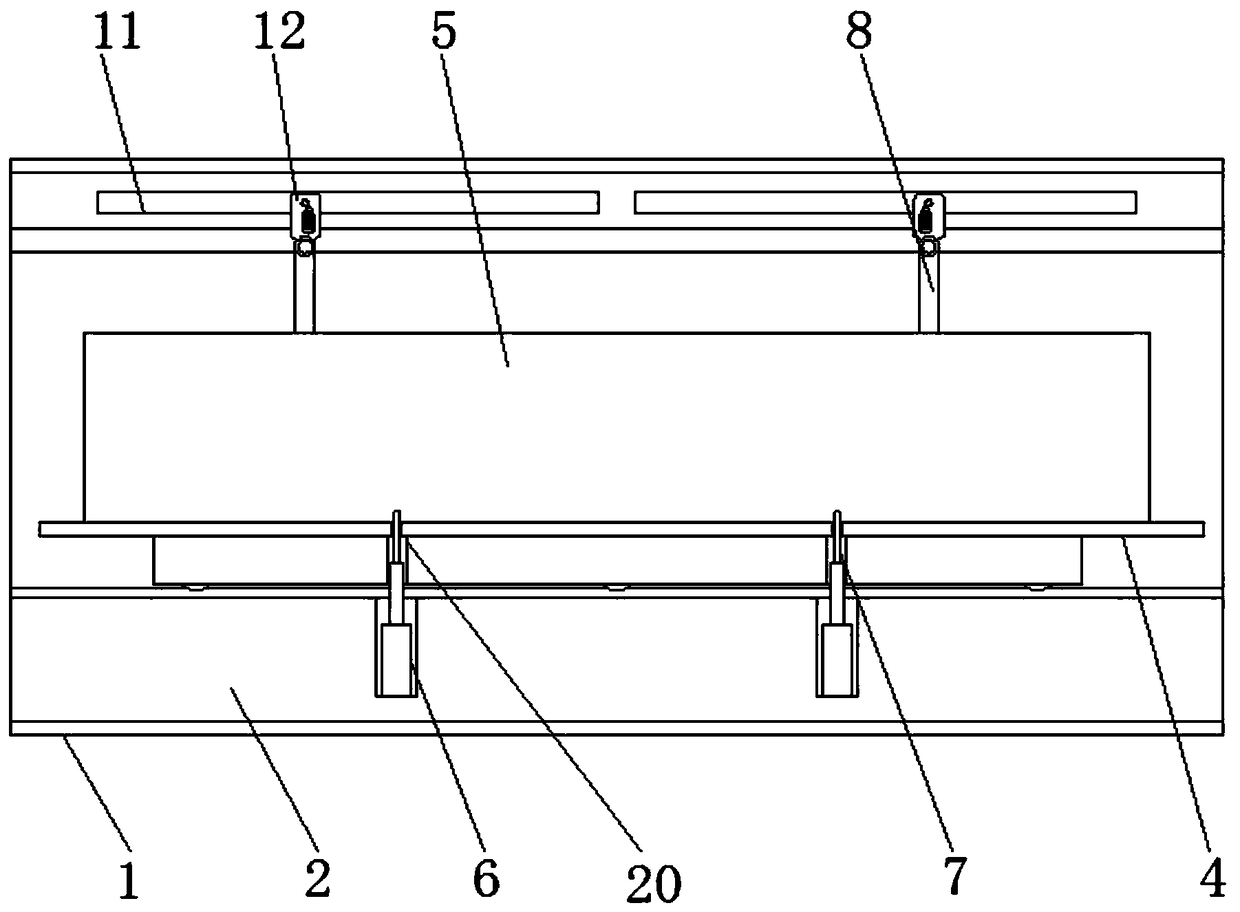

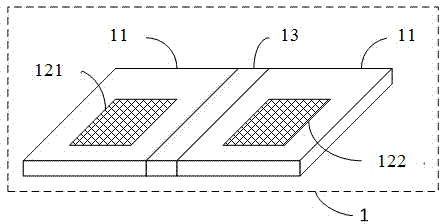

Autoclaved aerated concrete block water content control device

ActiveCN108972856AJet evenlyConducive to direct contactCeramic shaping apparatusGear wheelEngineering

The invention discloses an autoclaved aerated concrete block water content control device which comprises an autoclaving bin. A base is arranged at the lower portion of the interior of the autoclavingbin, and a steel rail is installed above the base. By means of the autoclaved aerated concrete block water content control device, a first bevel gear is driven through a rotating motor to rotate so as to drive a second bevel gear to rotate, in addition, the second bevel gear drives a rotating shaft to rotate so that wheels can roll in wheel rails, then a guide pipe can swing and move along the wheel rails and are matched with spraying heads which are evenly distributed in the ring-shaped guide pipe to spray gas to concrete blocks, autoclaving and aerating are evenly conducted on the concreteblocks conveniently, and pits which are likely to happen in the surfaces of the concrete blocks due to gas sprayed by the spraying gas are avoided. In addition, an electric push rod is used for pushing a humidity sensor to enter a through hole and be inserted into the concrete blocks to conduct humidity detection, and therefore the humidity sensor can directly make contact with the concrete blocksconveniently, and water content detection can be accurately conducted on the concrete blocks conveniently.

Owner:HENGYANG HENGYU LIGHTWEIGHT INSULATION MATERIAL CO LTD

Method for degumming jute by using complex enzyme

ActiveCN101135064AImprove degumming effectImprove spinnabilityBiochemical fibre treatmentVegetable materialPectinaseLacquer

The process of degumming jute with composite enzyme comprising pectase and laccase includes the following steps: dipping jute in composite enzyme aqua compounded with pectase and laccase in 12-40 times weight of jute; regulating the pH value of composite enzyme aqua to 5.0-5.5, heating to 55-60 deg.c and maintaining for 25-50 min; regulating the pH value of composite enzyme aqua to 7.5-8.0, heating to 60-70 deg.c and maintaining for 50-120 min; and deactivating enzyme of treated jute. The process is simple and has high lignin eliminating effect.

Owner:JIANGSU REDBUD DYEING TECH CO LTD

Method for degumming jute by using complex enzyme

ActiveCN101130896AImprove spinnabilityHigh strengthBiochemical fibre treatmentVegetable materialPectinaseLacquer

The present invention relates to a method for degumming jute by using composite enzyme. The described composite enzyme includes pectase and laccase, and said method includes the following steps: impregnating jute with the composite enzyme aqueous solution prepared by using pactase and laccase, the weight ratio of the described composite enzyme aqueous solution and jute is greater than 15:1 and less than or equal to 40:1, regulating pH value of the described composite enzyme aqueous solution to 5.0-5.5, heating to 55deg.C-60deg.C, retaining for 25-50min, then regulating pH value of said solution to 7.5-8.0, retaining for 25-50min at 60deg.C-70degC, finally, making the jute after which is treated by composite enzyme undergo the process of enzyme deactivation treatment.

Owner:JIANGSU REDBUD DYEING TECH CO LTD

Method for degumming jute by using complex enzyme

ActiveCN101130893AImprove spinnabilityHigh strengthBiochemical fibre treatmentVegetable materialPectinaseLacquer

The present invention relates to a method for degumming jute by using composite enzyme. The described composite enzyme includes pectase and laccase, and said method includes the following steps: impregnating jute with composite enzyme aqueous solution prepared by using pectase and laccase, the height ratio of the described composite enzyme aqueous solution and jute is 12:1-40:1, regulating pH value of the described composite enzyme aqueous solution to make it be greater than 5.5 and less than or equal to 6.5, heating to 35deg.C-65deg.C, retaining for 20-120min, then regulating pH value of said solution to 7.5-9.5, retaining for 20-120min at 40deg.C-70deg.C, finally making the jute after which is treated by composite enzyme undergo the process of enzyme deactivation treatment.

Owner:JIANGSU REDBUD DYEING TECH CO LTD

LASO-coated octahedral structural lithium nickel manganate composite material and preparation method thereof

ActiveCN108807920AShorten the migration pathFacilitated DiffusionMaterial nanotechnologyCell electrodesSolid state electrolyteManganate

The invention discloses a LASO-coated octahedral structural lithium nickel manganate composite material and a preparation method thereof. A matrix is a regularly octahedral structural lithium nickel manganate positive electrode material and is subjected to layer-by-layer coating modification by a Li-Al-Si-O inorganic solid electrolyte, the capacity is improved, the cycling performance is improved,and especially, the electrochemical high temperature performance is improved significantly.

Owner:淮安新能源材料技术研究院

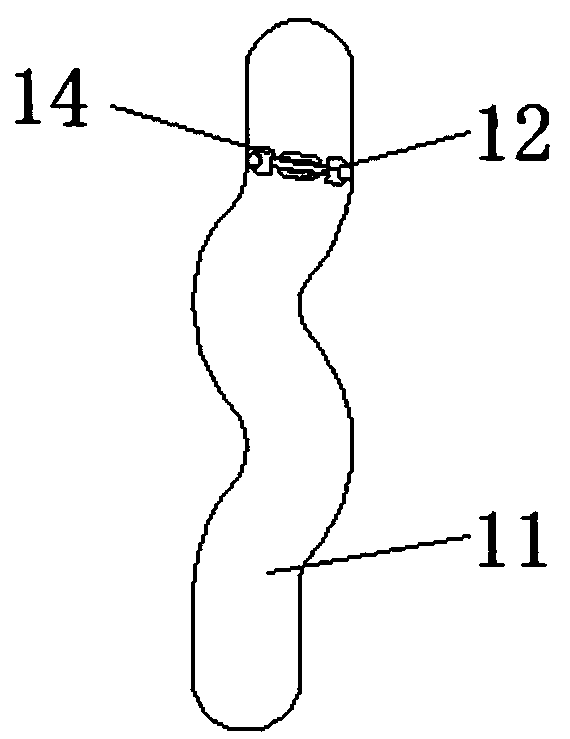

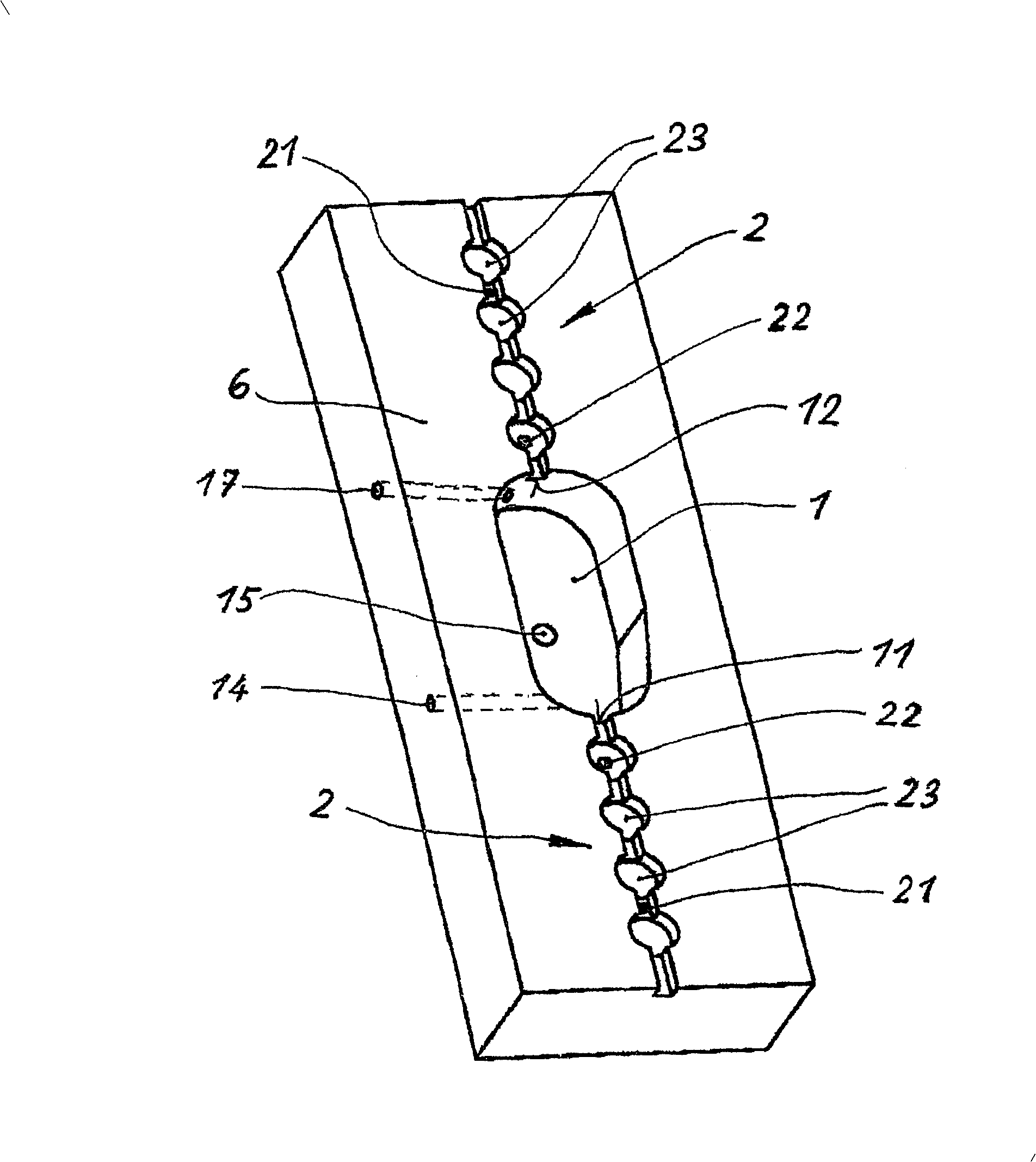

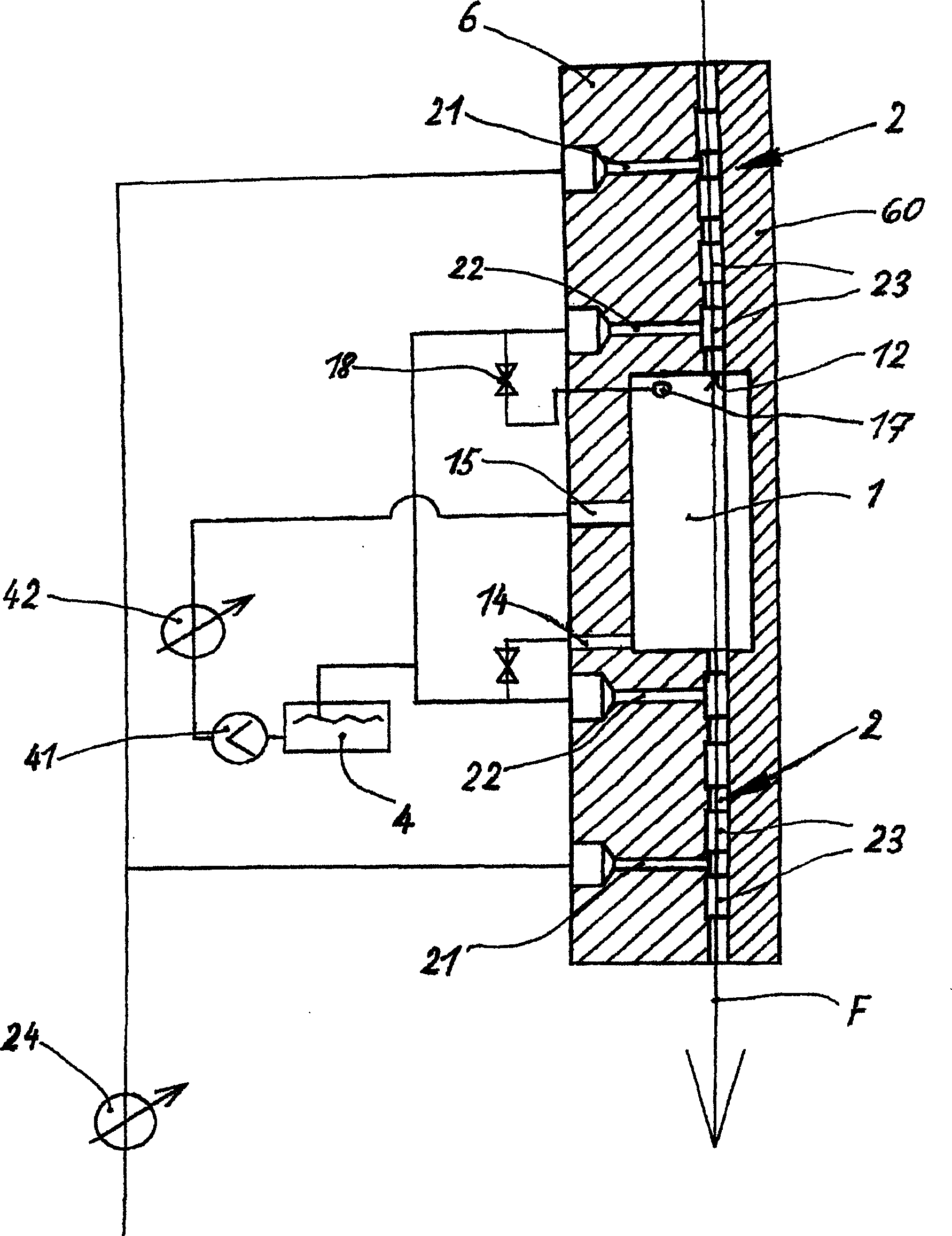

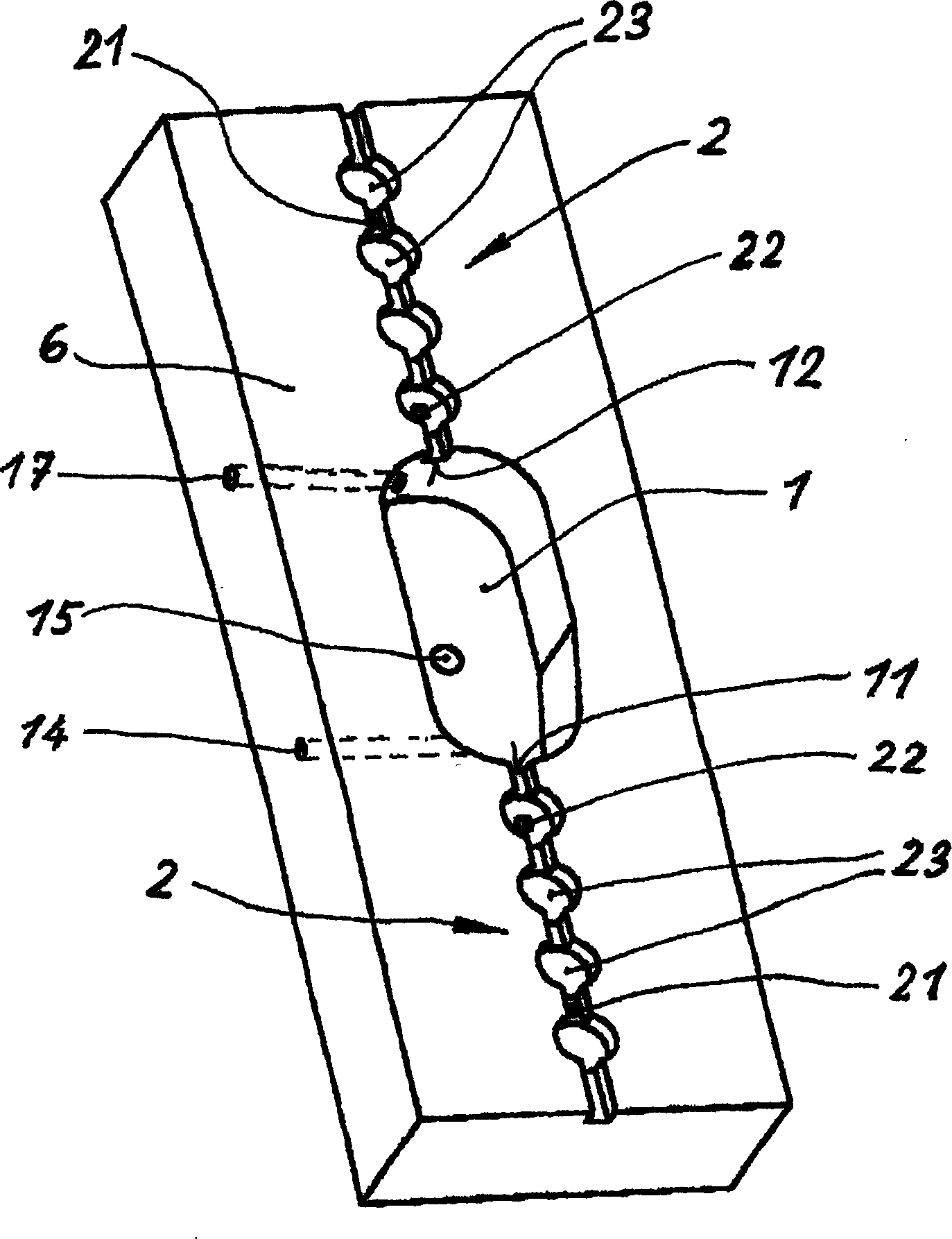

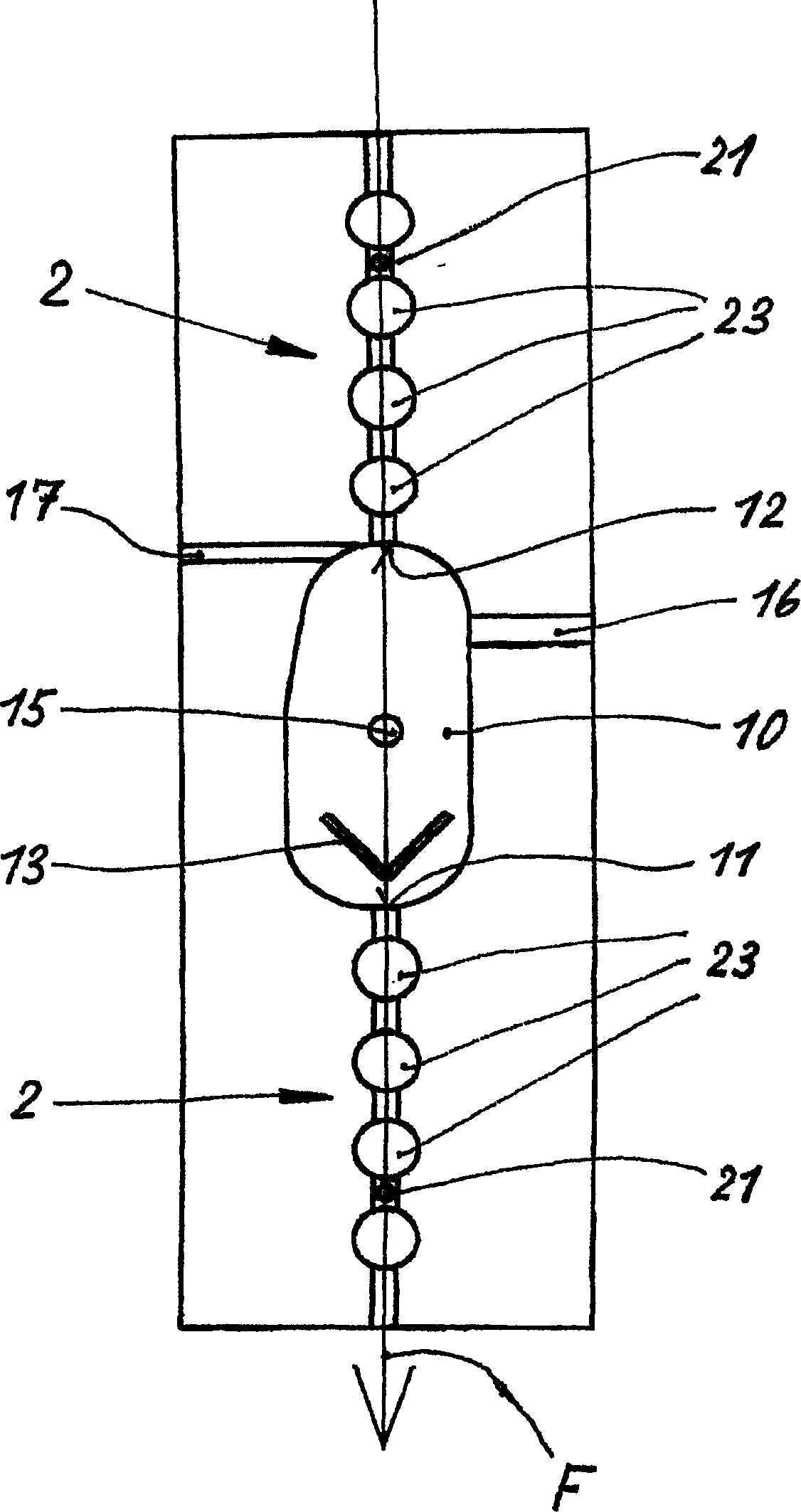

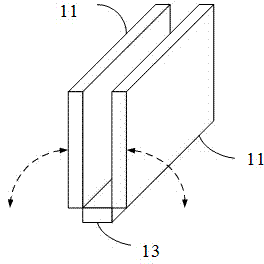

Method and device for continuously treating synthetic fibers in heat exchange chamber

InactiveCN100453720CAvoid enteringAvoid mixingTextile treatment containersLiquid/gas/vapor yarns/filaments treatmentEngineeringSynthetic fiber

The invention relates to a method and device for continuously treating synthetic fibers in a heat exchange chamber, in which the fiber to be treated comes into direct contact with the heat exchange medium. A sealing device, which is subjected to the action of a sealing medium, is provided at the fiber exit opening and at the fiber entry opening with a supply line for the sealing medium, which is arranged in the proximity of the fiber exit opening or the fiber entry opening. The sealing medium is kept away from the fiber passing through the heat exchange chamber. This is achieved by removing the sealing medium before the heat exchange chamber or also by removing the heat exchange medium together with the sealing medium. A removal line for the sealing medium is arranged in the proximity of the heat exchange chamber. In addition, the heat exchanger is provided in a separable manner so that the fiber can inserted by removing one part.

Owner:天科纺织机械部件有限公司

Method and device for continuously treating synthetic fibers in heat exchange chamber

InactiveCN1441864AAvoid enteringAvoid mixingTextile treatment containersLiquid/gas/vapor yarns/filaments treatmentSynthetic fiberCooling medium

The invention relates to a method and device for continuously treating synthetic fibers in a heat exchange chamber, in which the fiber to be treated comes into direct contact with the heat exchange medium. A sealing device, which is subjected to the action of a sealing medium, is provided at the fiber exit opening and at the fiber entry opening with a supply line for the sealing medium, which is arranged in the proximity of the fiber exit opening or the fiber entry opening. The sealing medium is kept away from the fiber passing through the heat exchange chamber. This is achieved by removing the sealing medium before the heat exchange chamber or also by removing a cooling medium together with the sealing medium. In addition, the heat exchanger is provided in a separable manner so that the fiber can be inserted by removing one part.

Owner:天科纺织机械部件有限公司

Electric rotorcraft charging system

ActiveCN104734294AConducive to direct contactSmall footprintBatteries circuit arrangementsElectric powerAirplaneElectric energy

The invention provides an electric rotorcraft charging system. The electric rotorcraft charging system comprises a charging part and an airborne part, wherein the charging part comprises a charging platform and a windbreaker, and the airborne part comprises an electric energy receiving device and an airborne battery. The electric rotorcraft charging system is suitable for charging batteries of various electric rotorcrafts capable of vertical take-off and landing. A conductive contact surface with good electrical conductivity arranged on the charging platform is convenient for the electric rotorcraft to make direct contact with the contact surface through an electric conductor to achieve conduction-type charging. Moreover, the arrangement of the charging platform capable of being folded enables the occupied space of the charging platform to be smaller, the protection of the front side or the back side of the conductive contact surface is facilitated, and the use of a heating resistor capable of heating further enables the charging platform to avoid the problem of a charging obstacle caused by ice or accumulated snow. When the electric rotorcraft charging system is used to charge, the charging of the airborne battery can be directly performed after the electric rotorcraft lands at the charging platform, and the use is very convenient.

Owner:深圳市多翼创新科技有限公司

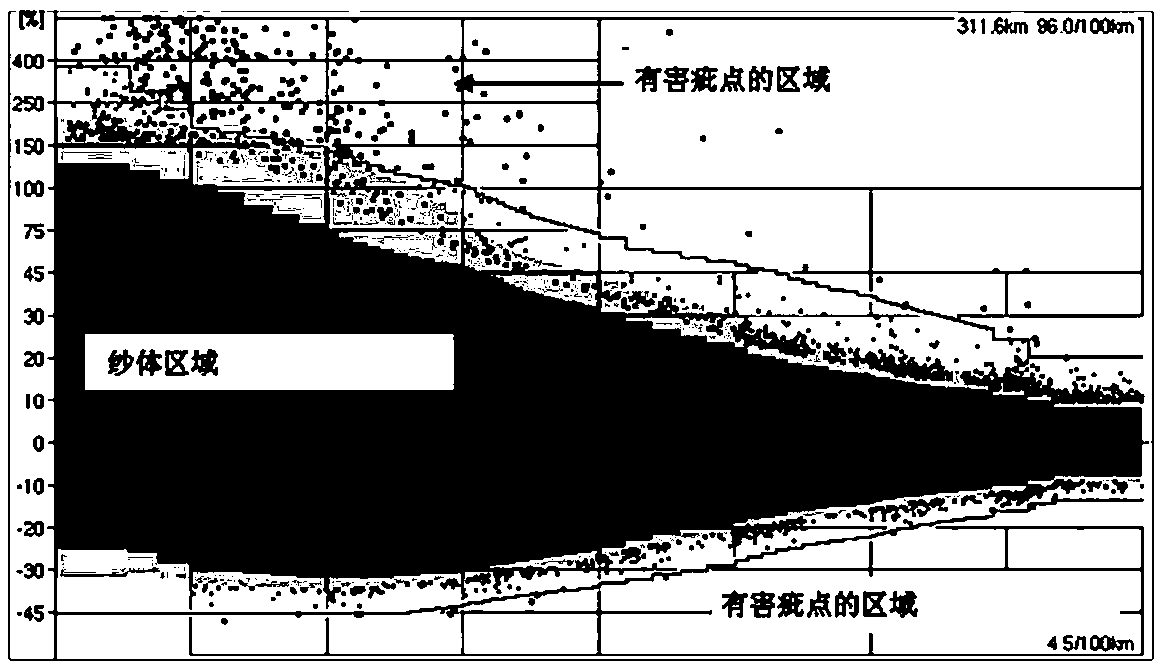

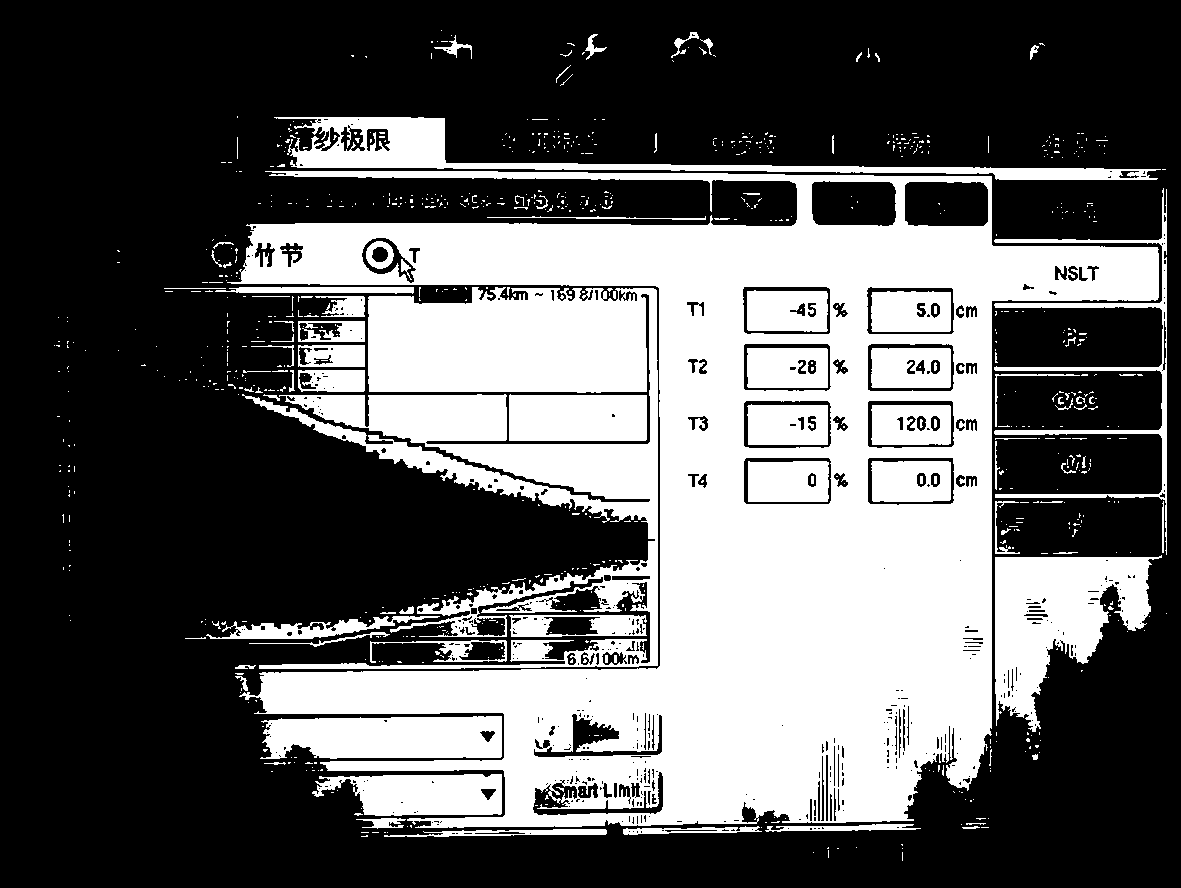

Preparation method of rose modified regenerated fiber anti-ultraviolet skin care yarn

The invention belongs to the technical field of textile materials, and discloses a preparation method of a rose modified regenerated fiber anti-ultraviolet skin care yarn. According to a blowing process, a plucker is directly transited to an opener and a single beater scutcher. According to a drawing process, slivers are uniformed by an automatic evener in a drafting manner. According to a rovingprocess, a lower axial winding density is selected, breaking of rough yarns caused by sticking is avoided in the spinning process, and tube leakage of the rough yarns is avoided. According to a spinning process, Siro compact spinning is implemented by the aid of a spiral airflow device, and less computer use is ensured without hardheads by a jaw. According to a spooling process, yarns are identified by a yarn cleaner, matrix coordinate graphs are drawn by a device, processes are set according to requirements of clients and yarn indexes, and harmful defects can be effectively removed in a cut manner. According to the rose modified regenerated cellulose fibers or fabrics prepared by textile technologies, indexes are excellent, hairiness is less, fabric hand feeling is better, fabric surfacesare smooth, and anti-ultraviolet and skin care effects are obvious.

Owner:德州悦丰纺织科技有限公司

Device for collecting and drying grains

PendingCN109607227AIngenious structural designHigh degree of mechanizationWrapper twisting/gatheringSolid materialEngineeringAgricultural machinery

The invention discloses a device for collecting and drying grains, and belongs to the technical field of agricultural machinery. The device for collecting and drying the grains is composed of a machine shell, a bucket assembly, a bag packer, a sealing device, a supporting plate, a separating plate, an upper rotating disc, a lower rotating disc, wheels, a first shaft, a second shaft, an armrest, adirect current motor, a switch, a storage battery, a third shaft and a motor mounting bracket. According to the device for collecting and drying the grains, a high degree of mechanization is realized,and no other electrical equipment is used in the whole process of grain collection except the direct current motor for controlling the rotation of the upper rotating disc, and the automation level ofthe grain collection is improved, the risk of equipment maintenance is reduced, the service life of the device is prolonged, and the cost is reduced greatly; and the combined action of the upper rotating disc, the lower rotating disc and the bucket assembly is used ingeniously, and a direct position relationship between the upper rotating disc and the lower rotating disc is controlled accurately,and a position relationship between an upper rotating disc mounting hole and a lower rotating disc mounting hole which are positioned at the bucket assembly is controlled accurately, and thus the accurate control over the movement of the bucket assembly always keeping level to the floor is ensured.

Owner:祝凯旋

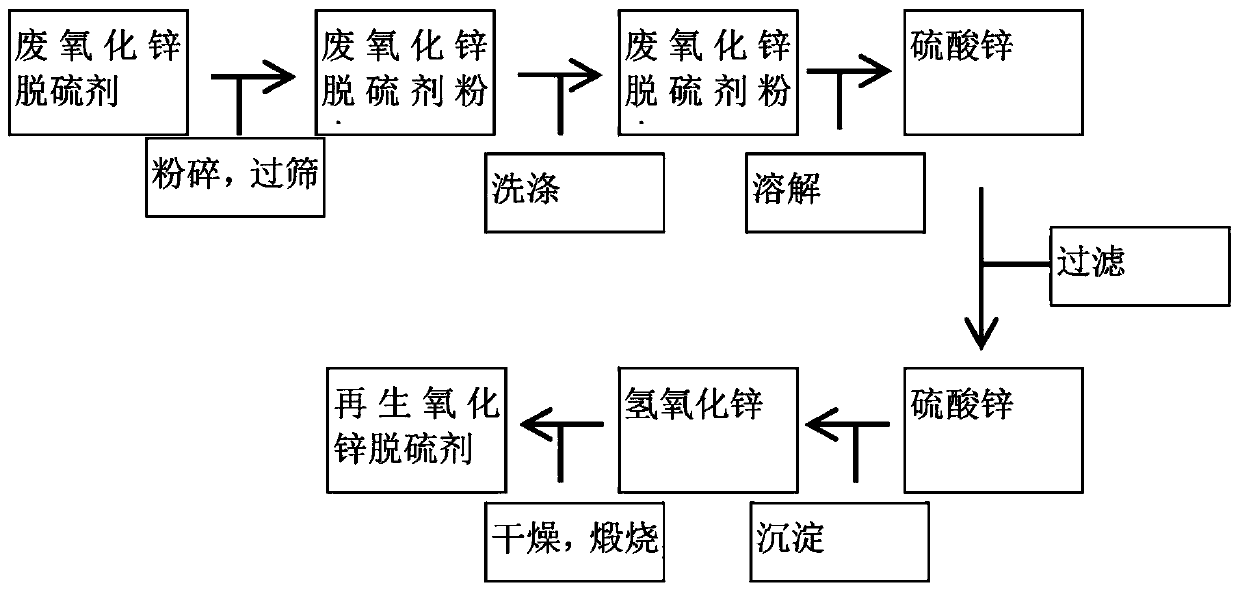

Regeneration method of zinc oxide desulfurizer

ActiveCN110917876AAvoid decompositionMeet environmental protection requirementsDispersed particle separationEthylene diamine tetra aceticEthylene diamine

The invention relates to a regeneration method of a zinc oxide desulfurizer. The method comprises the following steps of pulverizing a zinc oxide desulfurizer to be regenerated to obtain waste desulfurizer powder; washing the waste desulfurizer powder with a mixed aqueous solution of povidone and sodium carbonate, washing with water, mixing the washed waste desulfurizer powder with a sulfuric acidsolution, hydrogen peroxide, a potassium permanganate solution and ethylene diamine tetraacetic acid (EDTA-2Na), reacting for 2-5 hours, and filtering to obtain a filtrate and filter residues; mixingthe filtrate with ammonia water, controlling the pH value to be 7.8-9, stirring for 0.5-3 hours, and filtering to obtain a precipitate; and cleaning, drying and calcining the precipitate to obtain the regenerated zinc oxide desulfurizer. The regeneration method of the zinc oxide desulfurizer is simple and easy to operate, the operation cost is low, the method is free of toxic gas emission and capable of better meeting the environmental protection requirement, the method has wide application range and is suitable for regeneration of the waste zinc oxide desulfurizer, and the regeneration sulfur capacity is high.

Owner:HUNAN HUANDA ENVIRONMENTAL PROTECTION

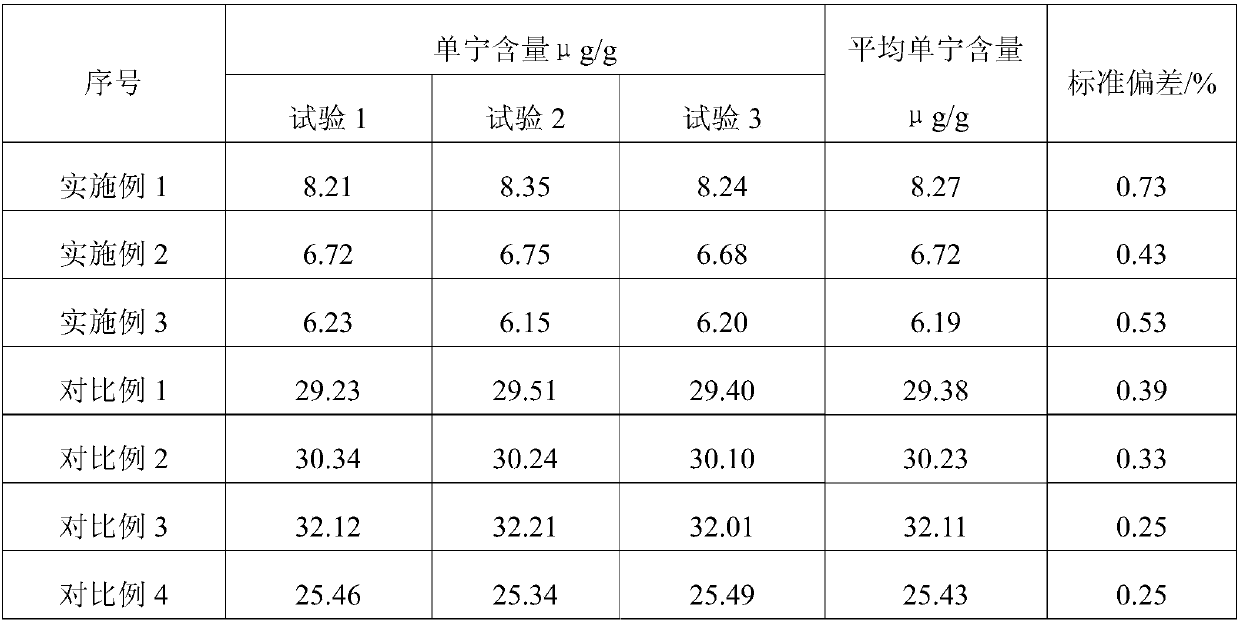

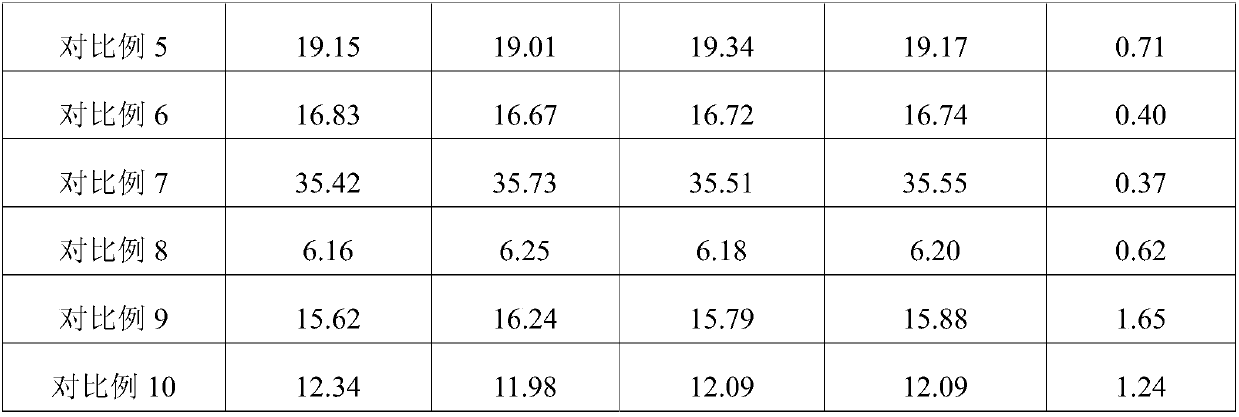

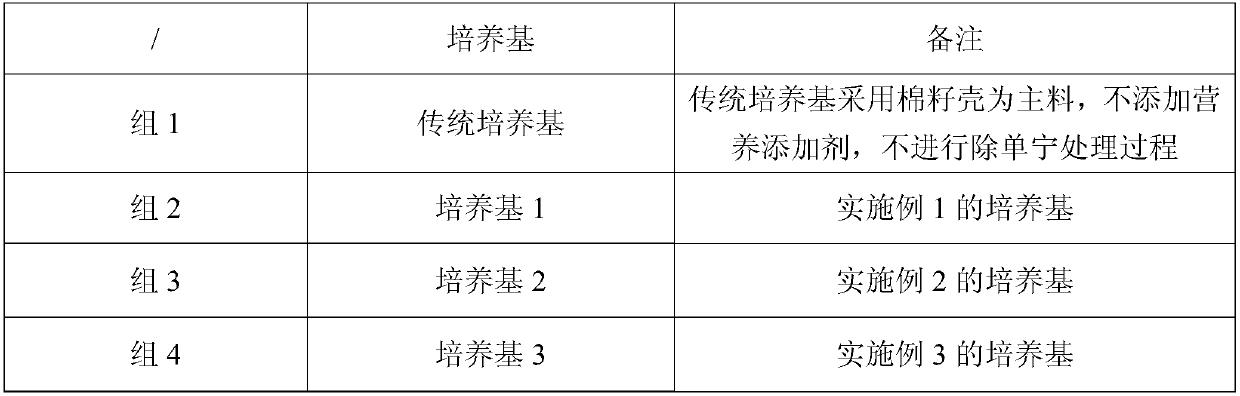

Low-tannin content agrocybe cylindracea culture medium and preparation method thereof

InactiveCN107721589APromote decompositionRealize secondary useCalcareous fertilisersAnimal corpse fertilisersVitamin CNutrition

The invention belongs to the technical field of edible mushroom production and cultivation and discloses a low-tannin content agrocybe cylindracea culture medium which comprises the following raw materials in parts by weight: 50-80 parts of wood bits, 10-20 parts of agrocybe cylindracea residues, 20-30 parts of waste cotton, 20-35 parts of cottonseed hull, 10-25 parts of corncobs, 5-15 parts of wheat bran, 5-15 parts of rice bran, 20-30 parts of a nutrient additive, 3-8 parts of quick lime, 0.2-0.8 part of vitamin B1, 0.2-0.8 part of vitamin C, 0.5-5 parts of citric acid and a proper amount ofpurified water. As the culture medium is prepared with a special treatment liquid, the content of tannin in the wood bits is greatly reduced. The culture medium disclosed by the invention is low in tannin, rich in nutrition, high in biological utilization rate, applicable to growth of agrocybe cylindracea and high in feasibility, and the agrocybe cylindracea cultivation cost is greatly reduced.

Owner:GUANGXI ZHEYUAN AGRI SCI & TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com