Device for collecting and drying grains

A technology of grain and mounting holes, which is applied in the field of agricultural machinery, can solve the problems of high cost of electric drive, dust pollution, noise pollution, etc., and achieve the effect of reducing maintenance risk, high degree of mechanization, and improving service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

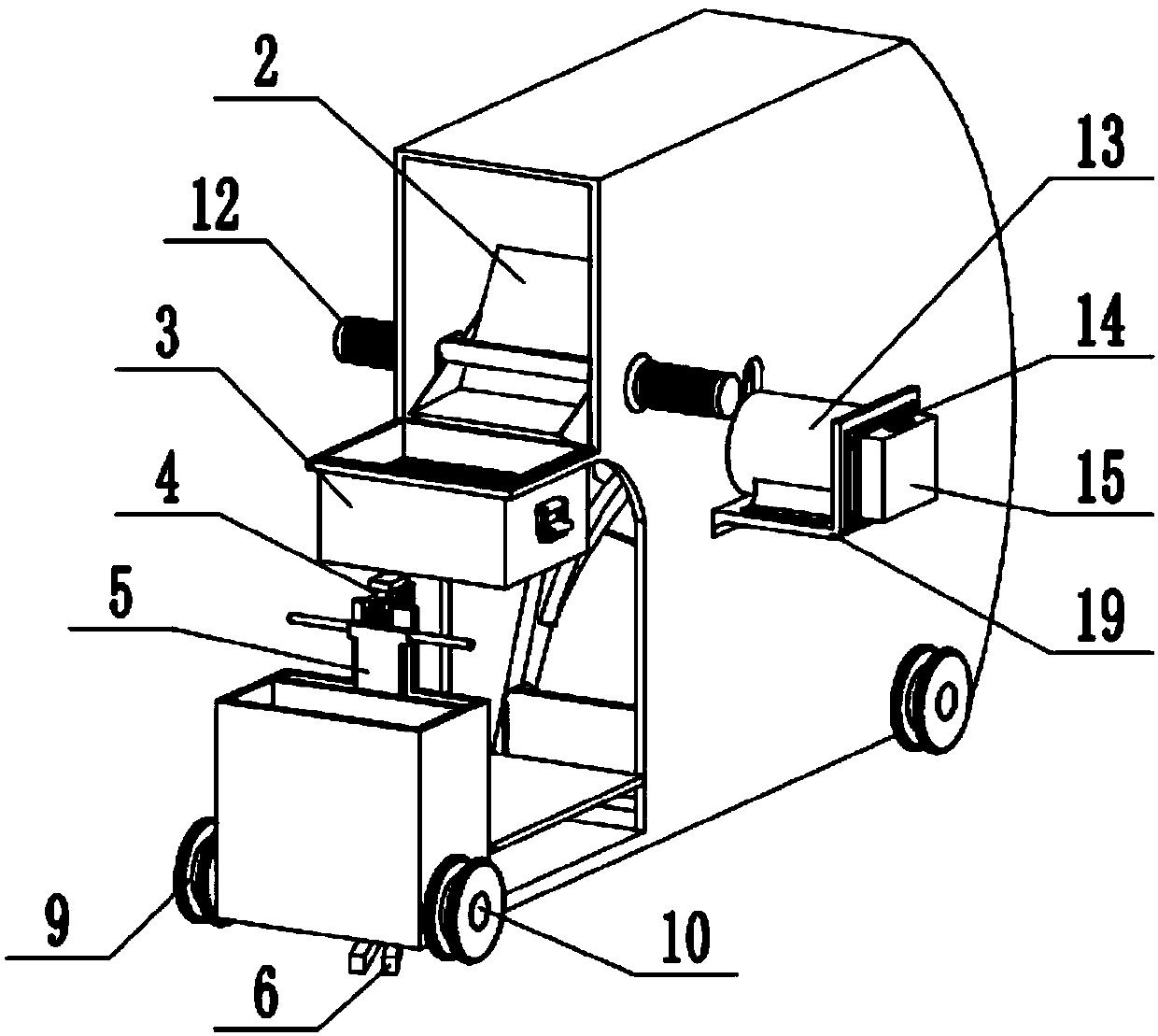

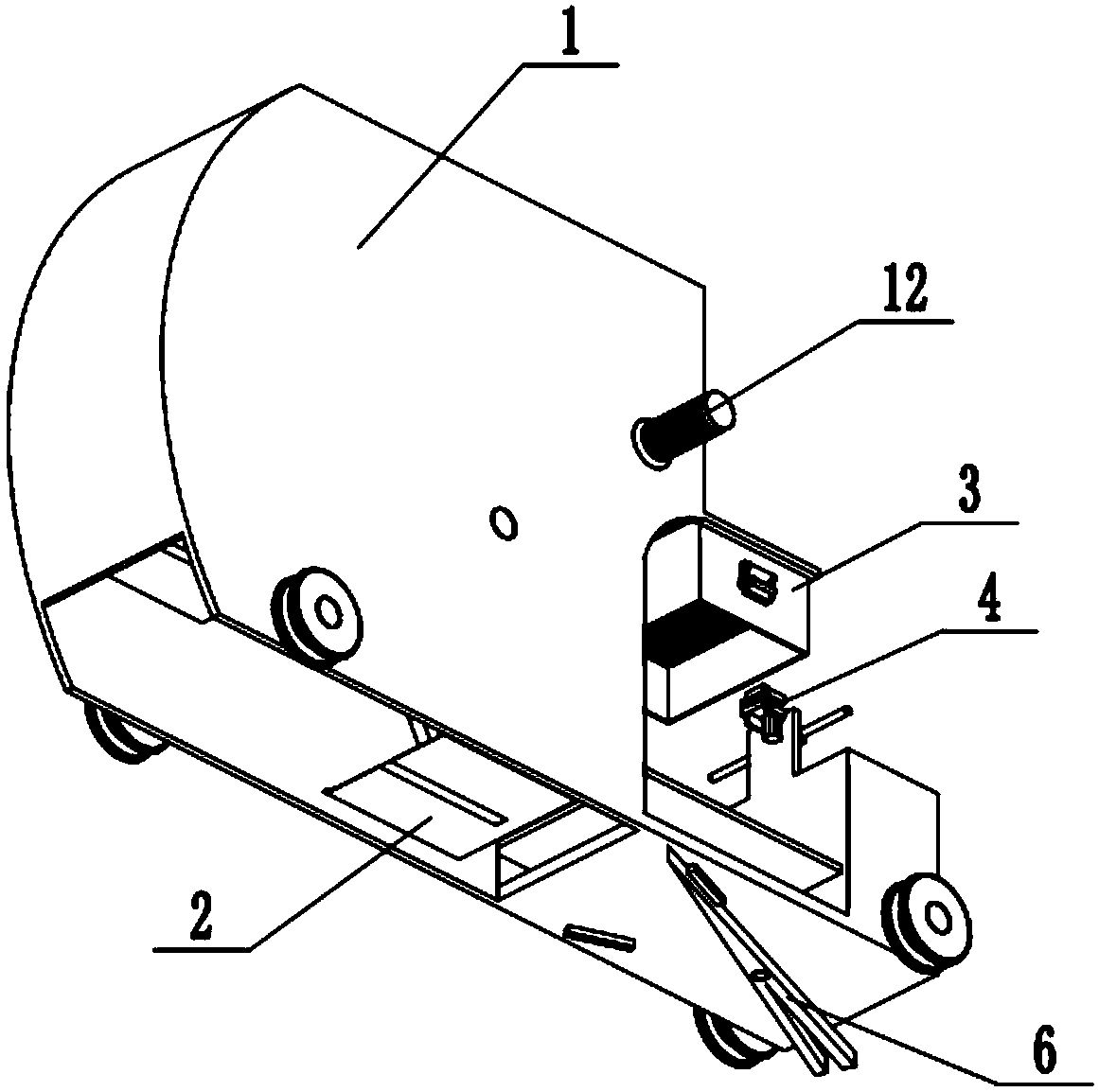

[0020]A method for collecting and drying grain, which cleverly uses the linkage effect of the upper turntable 7 and the lower turntable 8 to cooperate with the bucket assembly 2, so that the bottom of the bucket assembly 2 is always kept flush with the ground, which is convenient for the bucket assembly 2 to carry grain The collection work; through the synchronous periodic rotation of the upper turntable 7 and the lower turntable 8, the lifting plate 703 of the upper turntable 7 and the reversing plate 202 of the bucket assembly 2 are used to realize the work of mechanized reversing the grain, and the grain loaded in the bucket assembly The grain on 2 is poured into the bagging device 3; the sealing device 4 is designed with a separate control structure, and the electric push rod 406 and the heating block 407 can be used to seal the bagged grain. The device designed by this method is made of Case 1, bucket assembly 2, bagger 3, sealer 4, support plate 5, partition 6, upper turn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com