Pneumatic vehicle tire

A technology for pneumatic tires and vehicles, which is applied to vehicle parts, tire parts, tire treads/tread patterns, etc., can solve the problems of reducing the traction effect, reducing the effective grip edge, etc., to achieve high grip efficiency and high Traction effect, effect that increases the risk of crack formation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

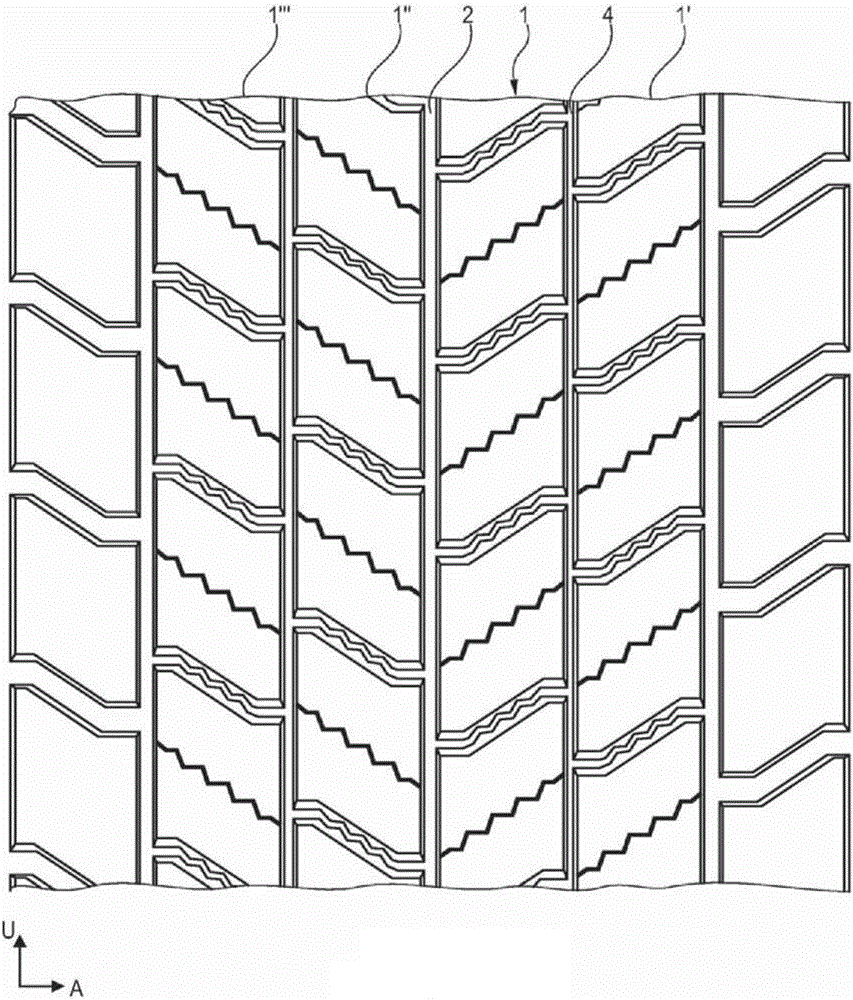

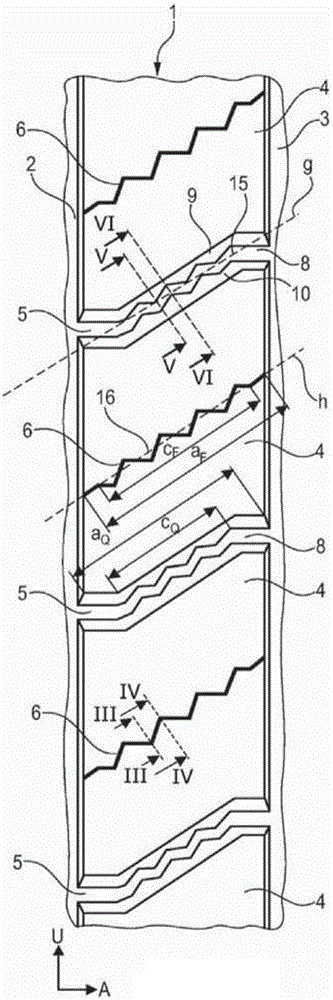

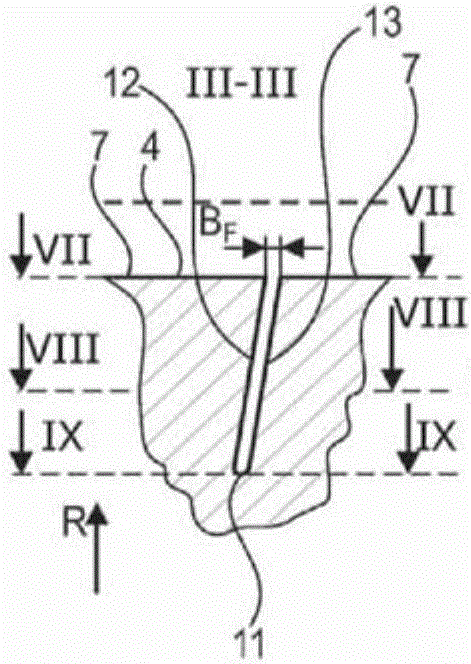

[0029] These Figures 2 to 9 Shown is a block row 1 of a commercial vehicle tire formed to be oriented in the circumferential direction U of the vehicle pneumatic tire and extending over the entire circumference of the vehicle pneumatic tire. The block row 1 is bounded towards one side in the axial direction A of the vehicle pneumatic tire by a circumferential groove 2 of known type extending over the entire circumference of the vehicle pneumatic tire and in the circumferential direction U up orientation. The block row 1 is bounded towards the other side in the axial direction A of the vehicle pneumatic tire by a circumferential groove 3 extending over the entire circumference of the vehicle pneumatic tire and oriented in the circumferential direction U . The block row 1 is formed in a known manner from a plurality of block units 4 of known type arranged one behind the other in the circumferential direction U of the pneumatic vehicle tire and correspondingly passing through ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com