Wedge-shaped tension clamp

A tension-resistant clamp and wedge-shaped technology, which is applied in the direction of adjusting/maintaining mechanical tension and cable suspension devices, can solve problems such as unreliable pressure, hydraulic tension clamp cracks, threats to safe operation of power transmission, etc., and achieves simple structure, Guaranteed grip effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to clearly illustrate the design concept of the present invention, the present invention will be described below in conjunction with examples.

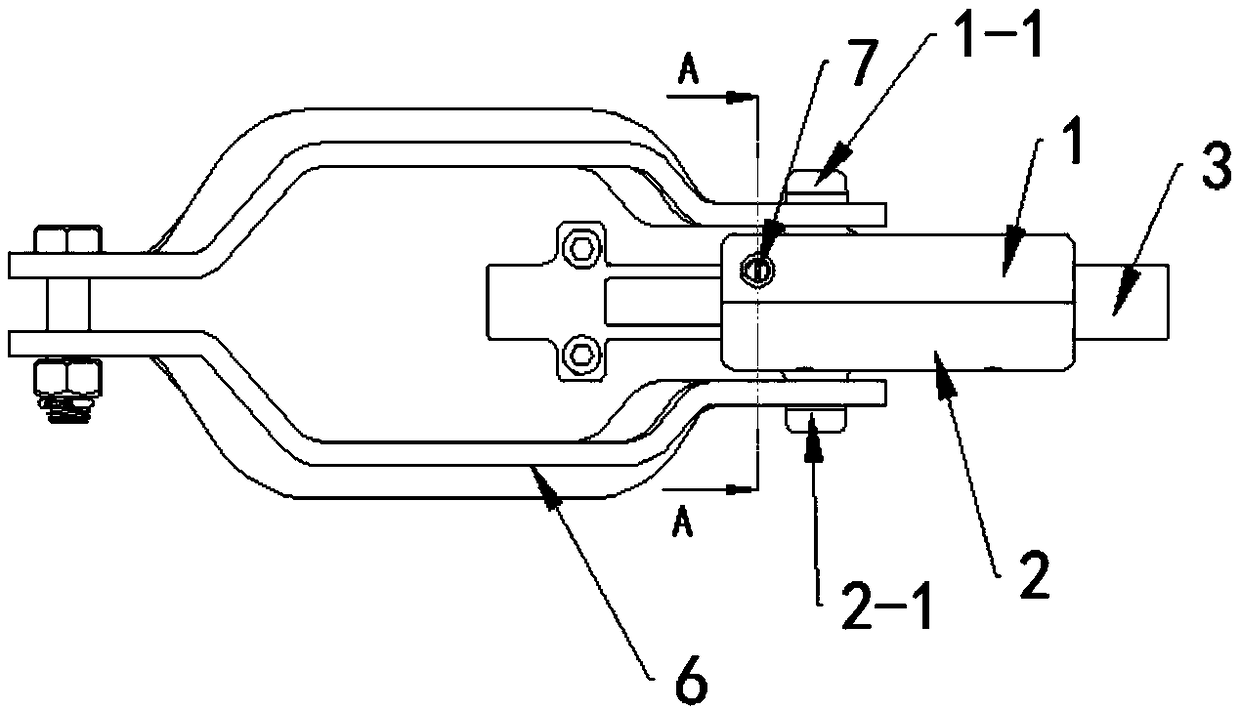

[0027] Such as Figure 1-3 In the example shown, the wedge-shaped strain clamp of the present invention includes: a positioning sheath 1, a sheath 2, an upper splint 3, a lower splint 4, a connecting plate 6 and a set of anti-off devices 7; wherein, the positioning sheath 1 and the mounting plane of the sheath 2 are connected by four screws 5 to form a wedge-shaped sheath with a wedge-shaped hole, the rectangular area of the front cross-section of the wedge-shaped hole is larger than the rectangular area of the rear cross-section; the upper splint 3 and the lower splint 4 are set through In the wedge-shaped hole, the corresponding surfaces of the upper splint 3 and the lower splint 4 are parallel, and the upper surface of the upper splint 3 and the lower surface of the lower splint 4 are respectively attached to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com