Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

46results about How to "Speed up heat flow" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

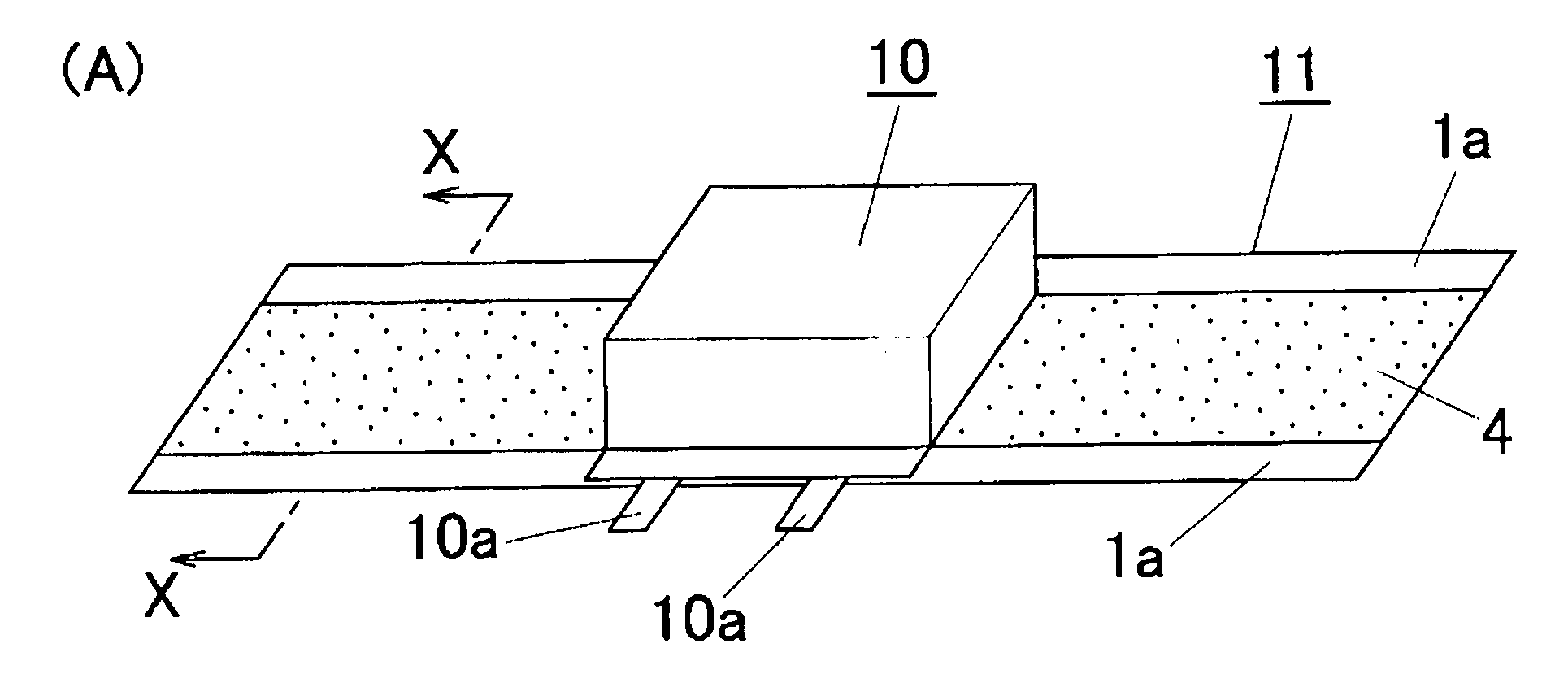

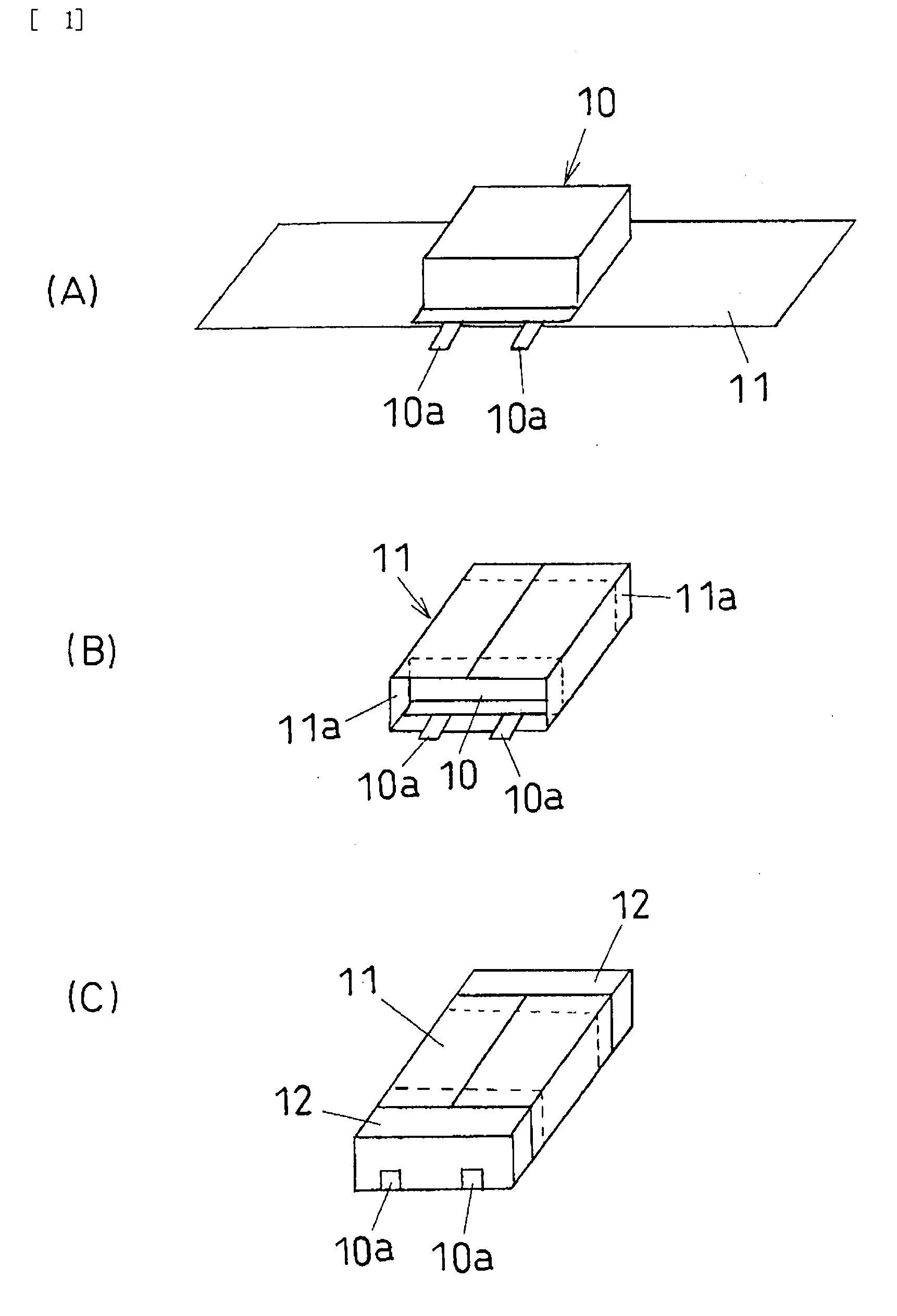

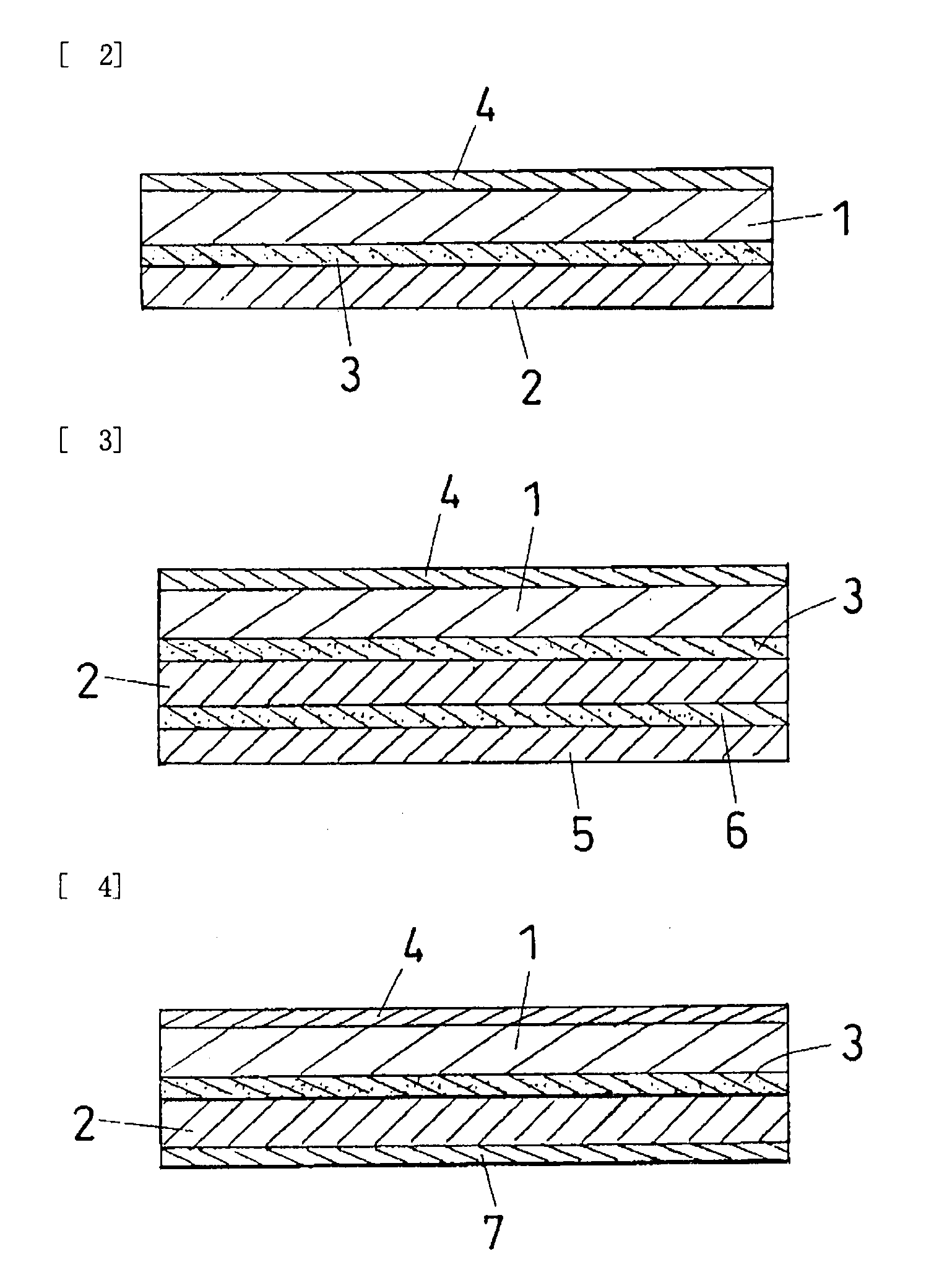

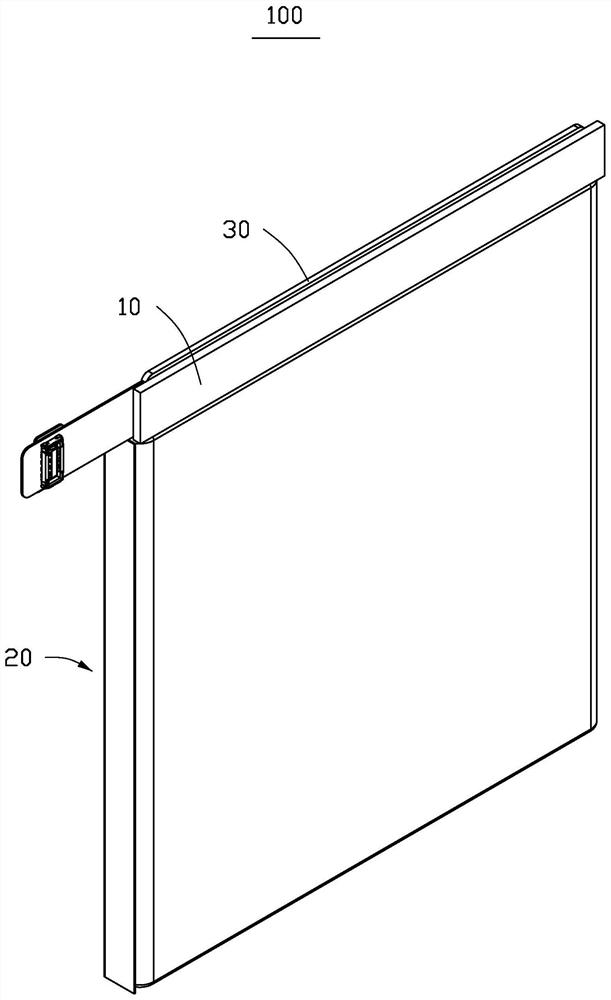

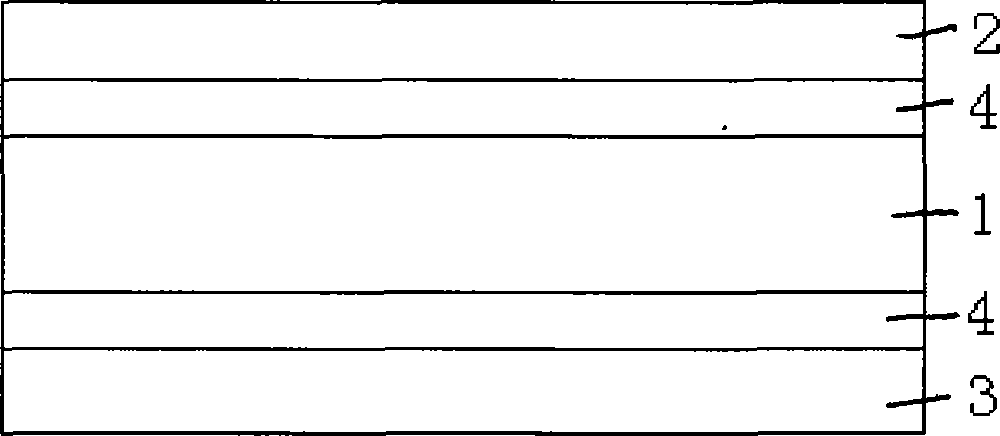

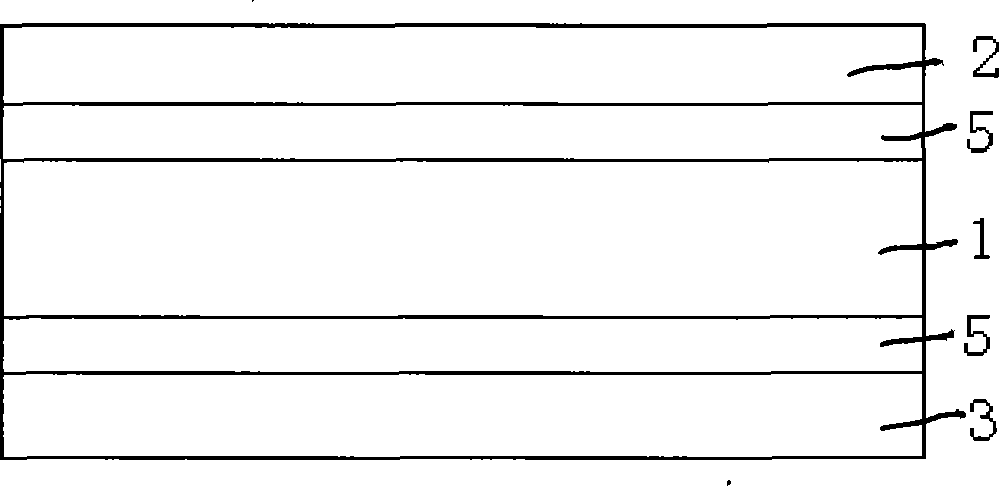

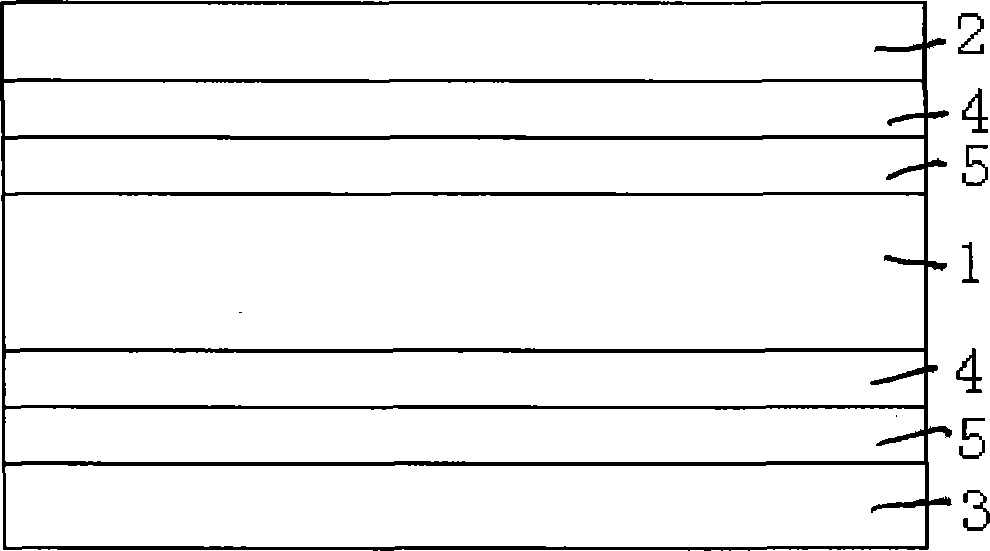

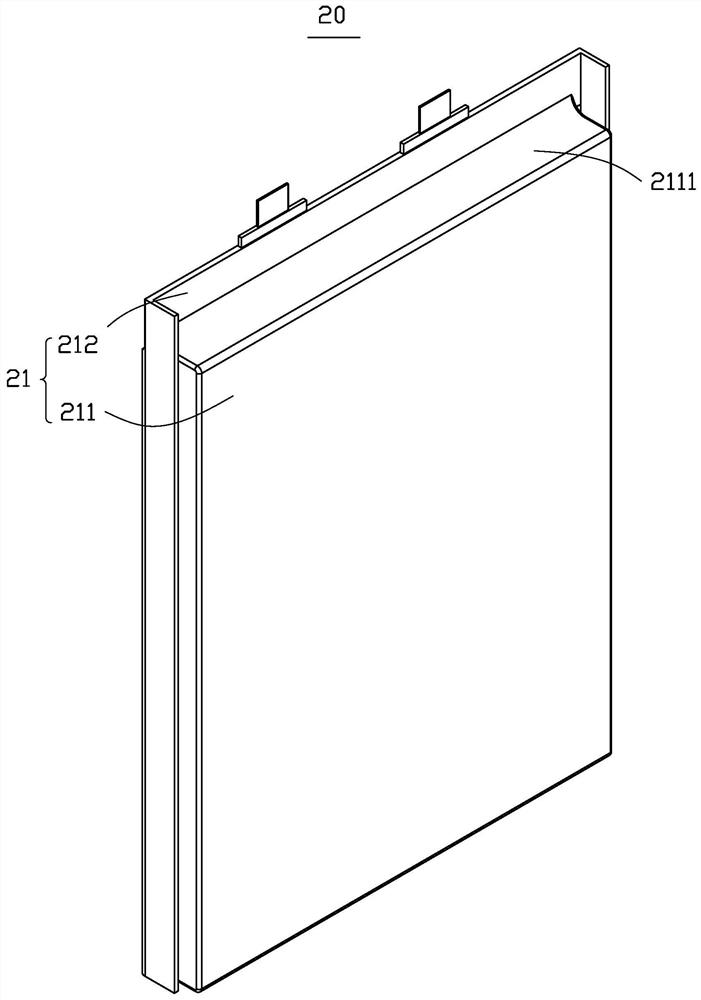

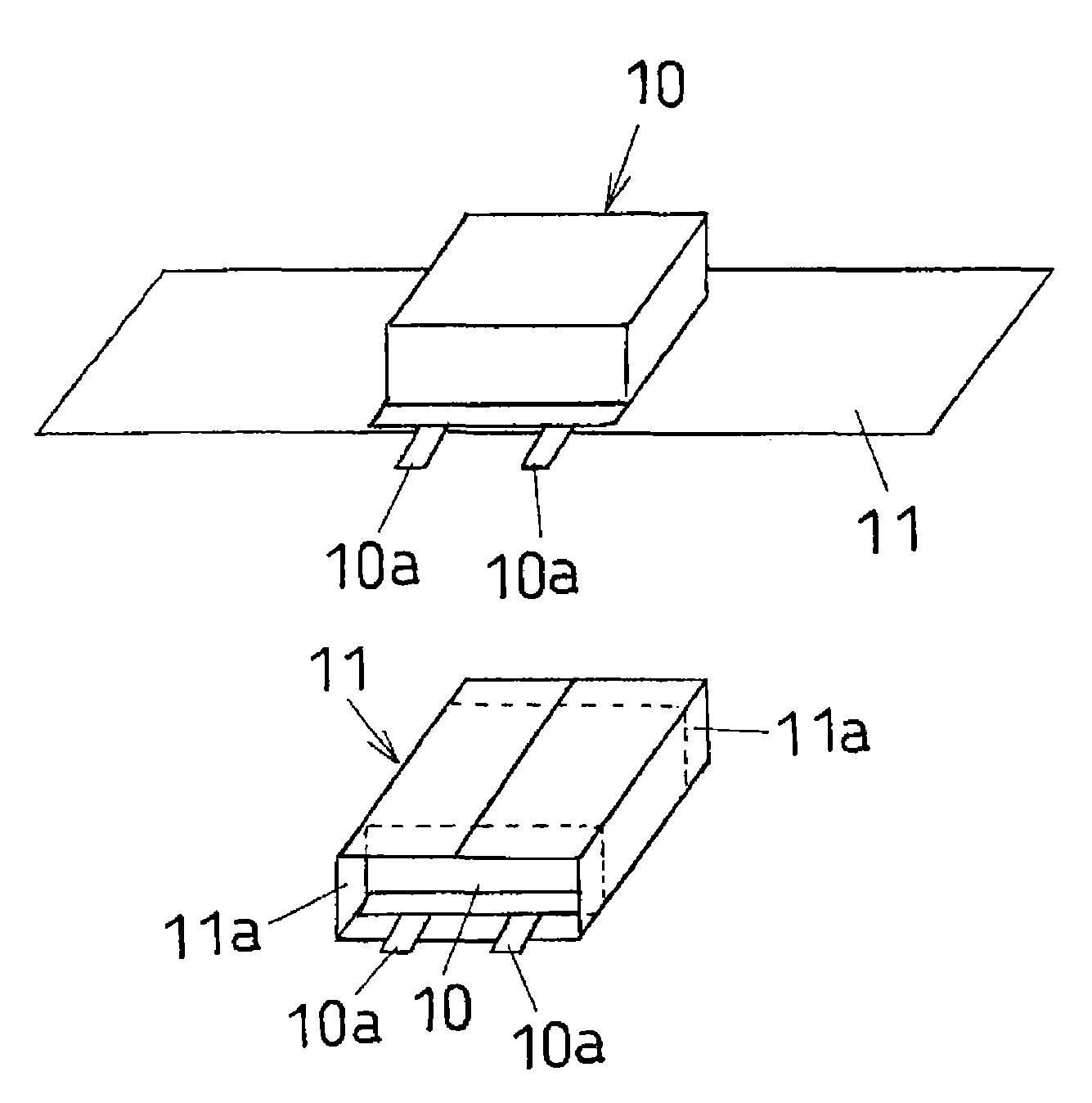

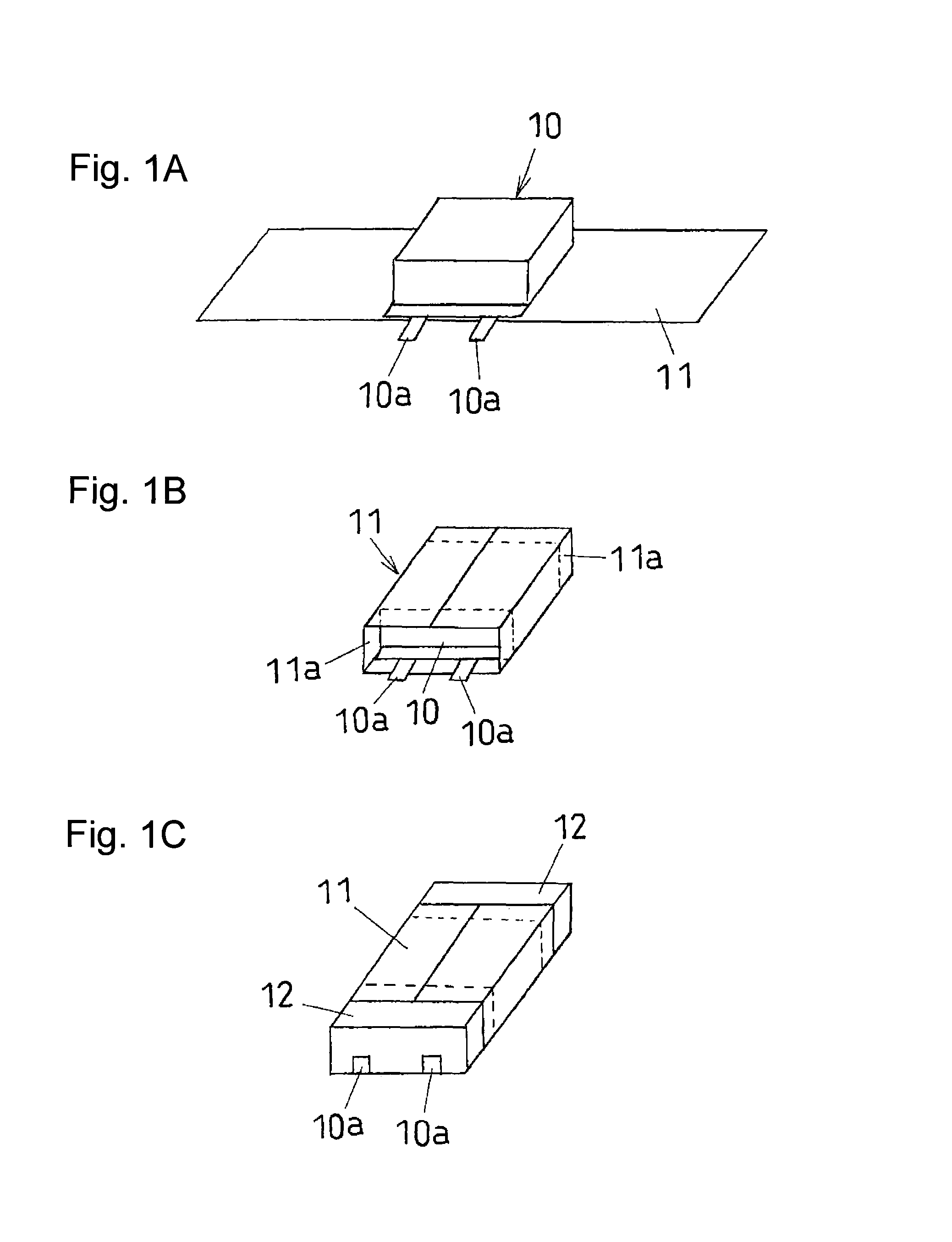

Laminate packing material for battery and laminate battery

ActiveUS20100040942A1Reduce in quantitySimplification of battery production lineSynthetic resin layered productsJackets/cases materialsMetallic foilThermal adhesive

In a laminated external packaging material for a battery according to the present invention, a metallic foil 2 is adhered to one surface side of a base film 1, and a coated film layer 4 of thermal adhesive resin having a softening point of 160° C. or below and capable of thermally bonding to a surface film of a battery main body is formed on the other surface side of the base film 1. With this laminated external packaging material for a battery, without using an adhesive tape or a hot-melt adhesive, this packaging material can be easily and assuredly bonded to the battery main body and also can be bonded firmly to an end portion reinforcing plastic component.

Owner:RESONAC PACKAGING CORP

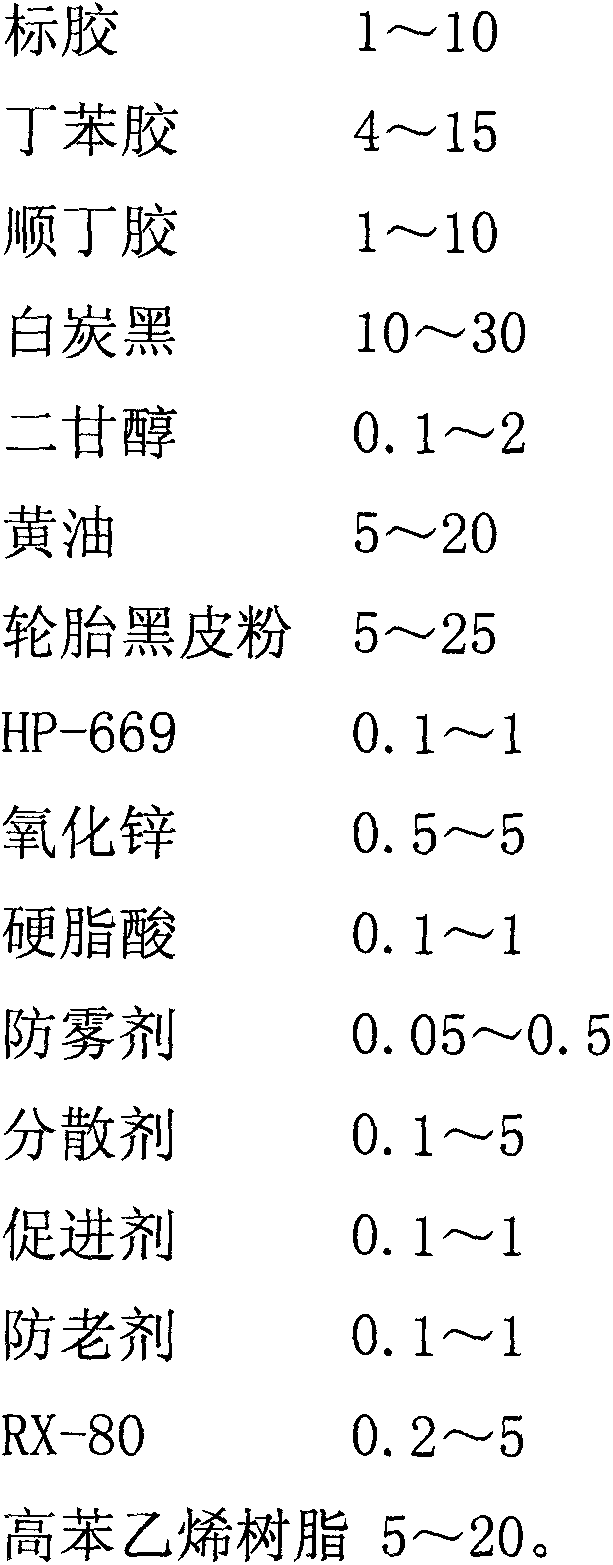

Wear-resistant sole material and preparation method thereof

InactiveCN103159999AAvoid thickening and lifting the moldReduce flash weightSolesRubber materialCrack resistance

The invention discloses a wear-resistant sole material which is prepared from standard rubber, styrene-butadiene rubber, cis-1,4-polybutadiene rubber, white carbon black, diethylene glycol, butter, tire black powder, HP-669, zinc oxide, stearic acid, antifogging agent, dispersing agent, accelerator, anti-aging agent, RX-80 and high styrene resin. The preparation method of the wear-resistant sole material comprises the following steps: evenly mixing the materials, adding into a Banbury mixer, banburying, adding the banburying mixture into a screw extruder, carrying out melt blending, granulating, mixing the granules in an open mill, and carrying out mold pressing to obtain the wear-resistant sole material. The wear-resistant sole material disclosed by the invention enhances the heat flowability of the rubber material in the die; and the wear-resistant sole material avoids rising the mold due to thickening, and reduces the burr weight of the product, thereby saving the cost and enhancing the yield of the product. The product prepared from the wear-resistant sole material disclosed by the invention has the advantages of favorable wear resistance, favorable resilience and excellent flex crack resistance.

Owner:叶建华

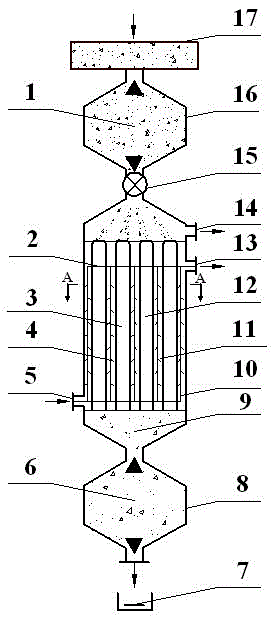

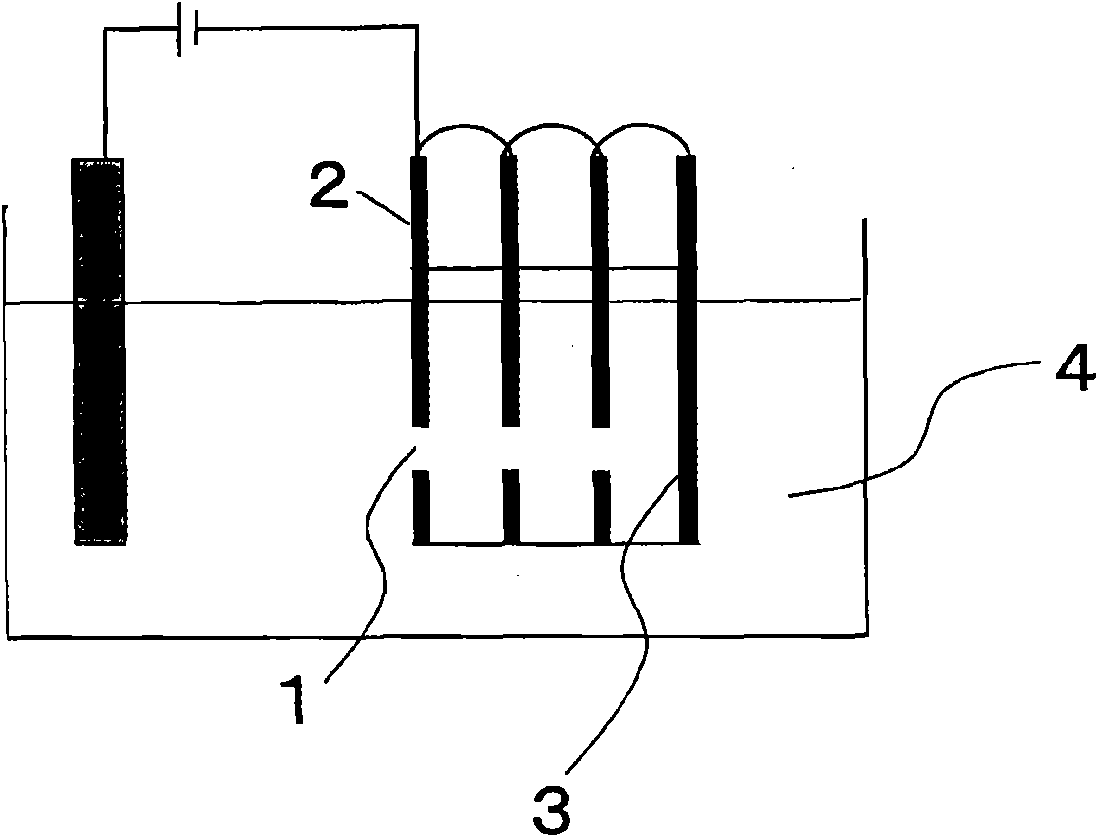

Coal thermolysis device for heat-carrying gas

InactiveCN102911677AHigh thermal conductivityLarge heat transfer temperature differenceHydrocarbon from carbon oxidesGaseous fuelsHeat transmissionProcess engineering

The invention provides a coal thermolysis device for heat-carrying gas. The coal thermolysis device is formed by correspondingly fastening two metal plates in which a plurality of semicircular concave grooves are arranged according to the concave grooves, wherein the plurality of semicircular concave grooves are combined to form a plurality of heat-carrying gas heat transmission pipes; the heat transmission pipes are sequentially communicated with a small vertical pipe, a transverse pipe, a main pipe, a heat-carrying gas inlet and a heat-carrying gas outlet, so as to form a heat-carrying gas heat transmission system. According to the coal thermolysis device, the heat-carrying can be used for directly drying the coal in a destructive distillation chamber through a metal heat intromission pipe, so as to achieve normal-pressure or destructive distillation; and the coal thermolysis device has the characteristics of being fast in transmission rate, high in heat utilization rate, simple in structure and low in cost.

Owner:TAIYUAN UNIV OF TECH

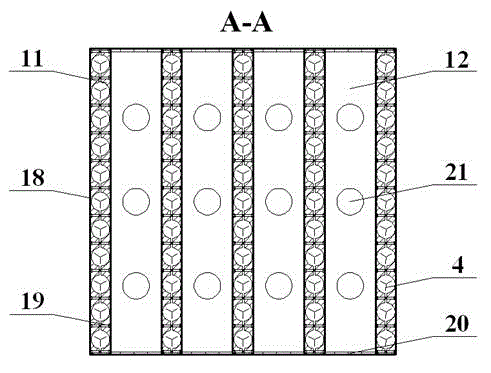

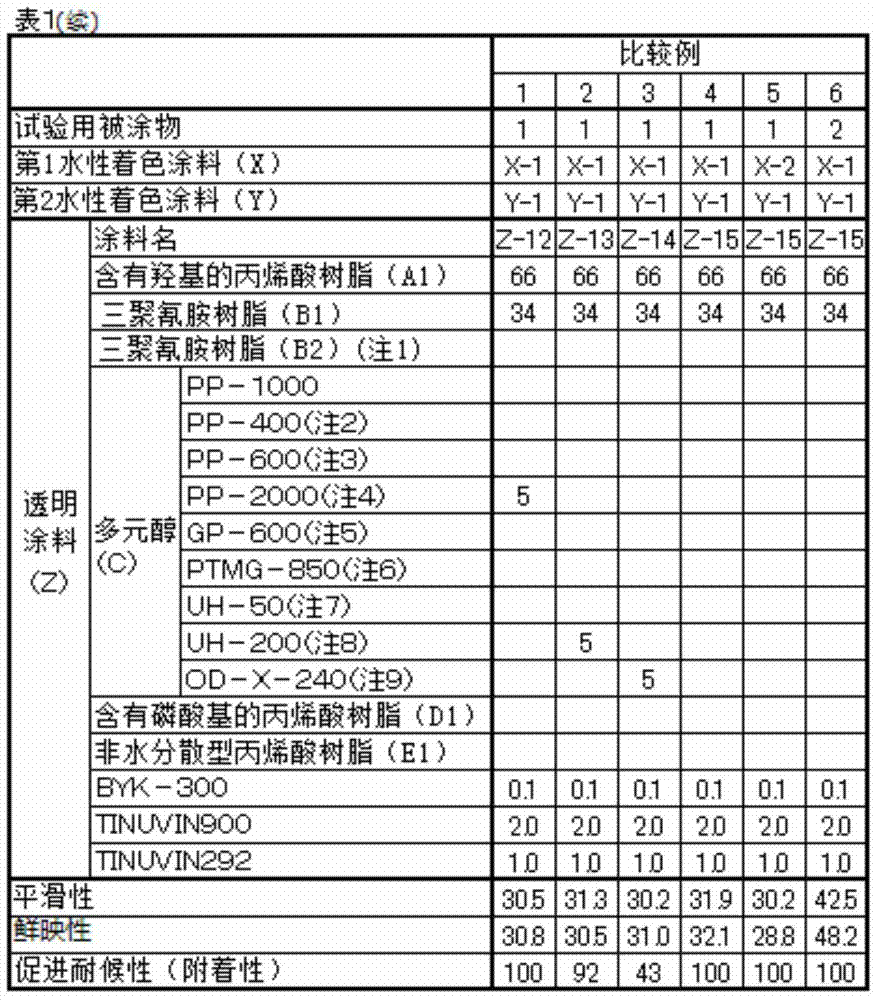

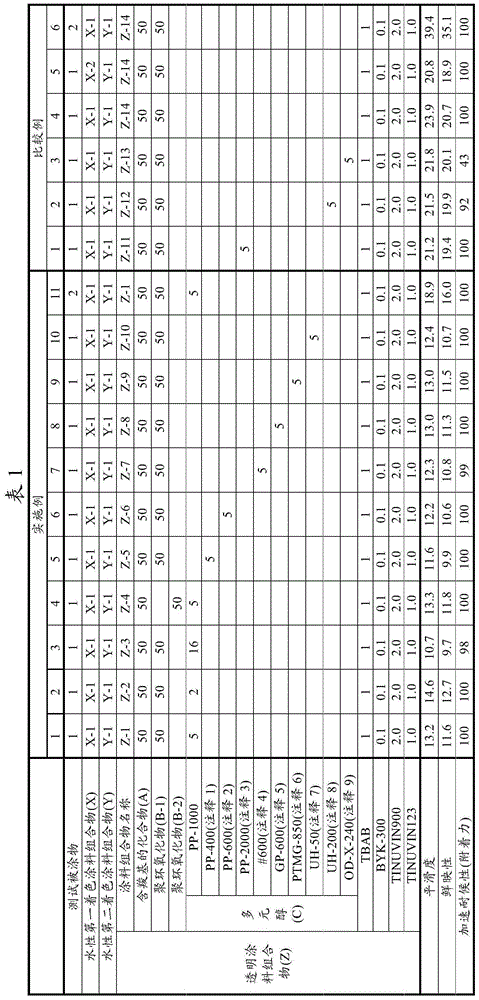

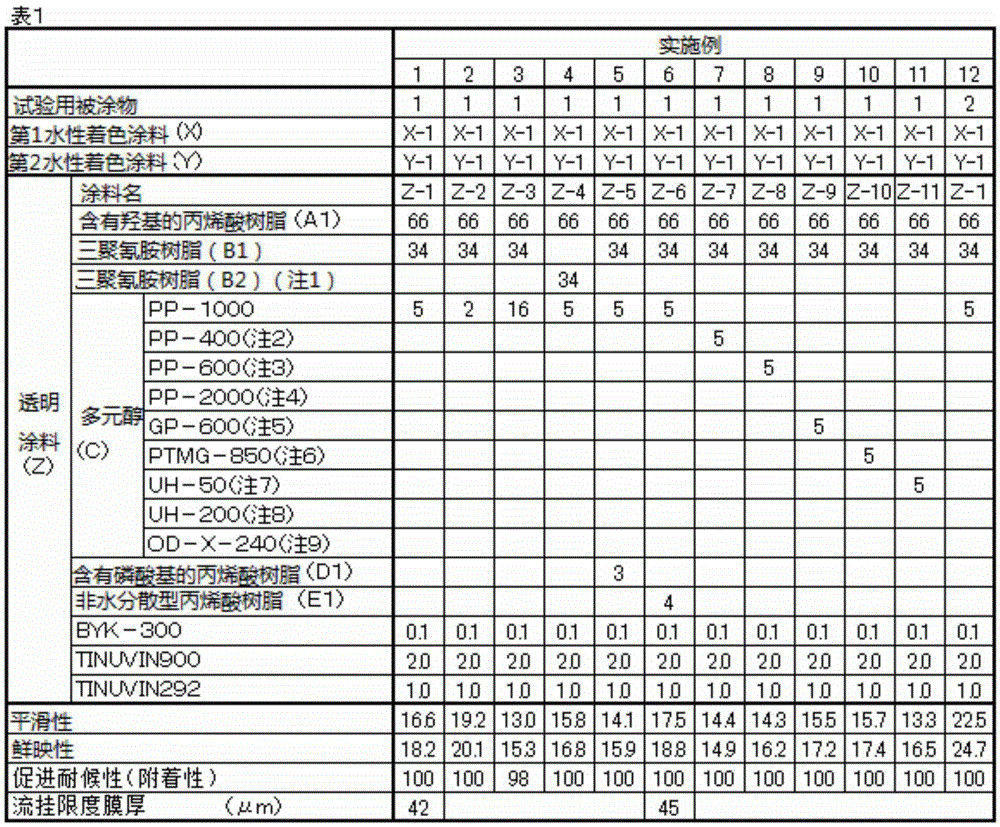

Paint composition and multi-layer coating forming method

ActiveCN103894332AIncreased concealmentGood concealmentCoatingsSpecial surfacesMolar massMelamine resin

The invention provides a transparent paint composition of a multilayer coating film, which is not easy to be affected by the roughness of the surface of the bottom material, the flatness and the DOI performance are excellent, when the coated object is sequentially coated by a first water coloration paint, a second water coloration paint, and a transparent coating, and then is solidified together to form the multi-layer coating film, and the multi-layer coating forming method. The paint composition comprises the acrylic resin (A) containing the hydroxyl, the melamine resin (B), and the polyhydric alcohols (C) having the special number-average molar mass in a range from 300-1500. The paint composition can be used as the transparent paint, and the coated object is sequentially coated by the first water coloration paint, the second water coloration paint, and the transparent coating, which are heated and solidified together to form the multi-layer coating.

Owner:KANSAI PAINT CO LTD

Bagasse polypropylene bioplastics and preparation method thereof

The invention relates to the field of bioplastics, and provides bagasse polypropylene bioplastics and a preparation method thereof. The bioplastics are obtained by mixing and processing bagasse, polypropylene, an inorganic nanometer reinforcing agent, a coupling agent, a plasticizer, a heat stabilizer, a lubricant, a dispersant, and the like, and the bioplastics comprise 20-40% of bagasse, 20-40% of polypropylene, and 10-30% of inorganic nanometer reinforcing agents; the preparation of the bioplastics comprises the steps of bagasse pretreatment, stepwise mixing and combination of the materials, and plastic particle preparation; the bioplastics of the invention have low manufacturing cost, high physical and mechanical strength, good surface finish, water resistance and chemical corrosion resistance, are green, environment-friendly, and new products, and are applicable to injection molding for the preparation of high-performance products for daily use.

Owner:NINGBO HOMELINK ECO ITECH CO LTD +1

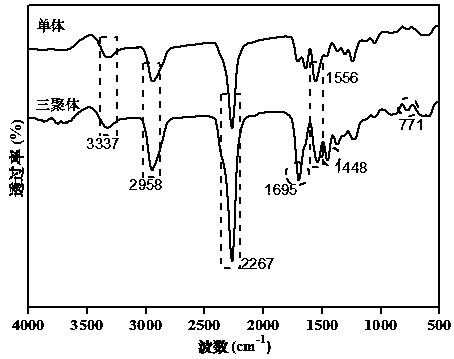

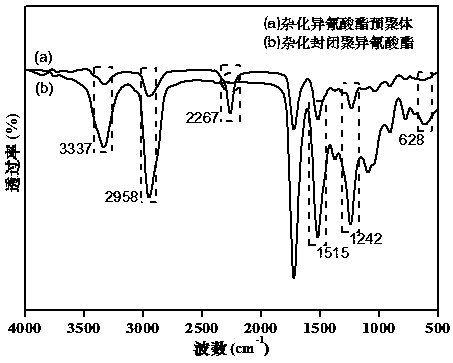

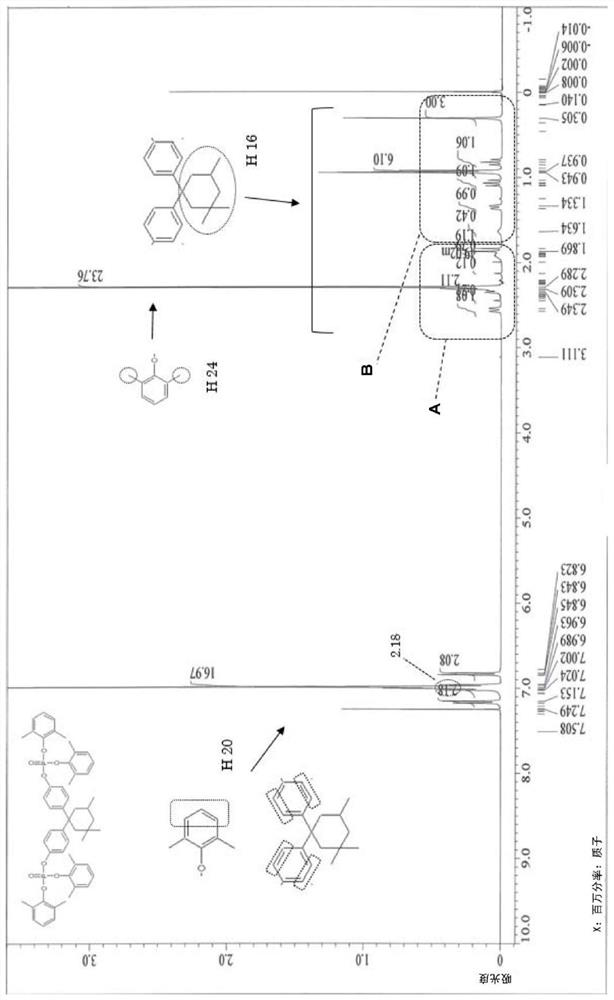

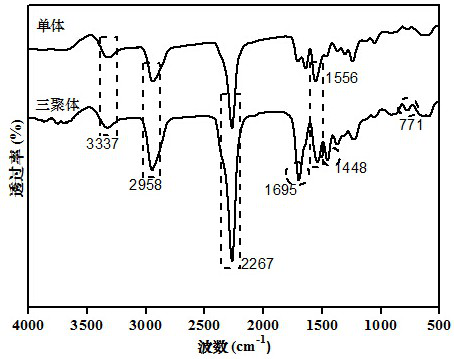

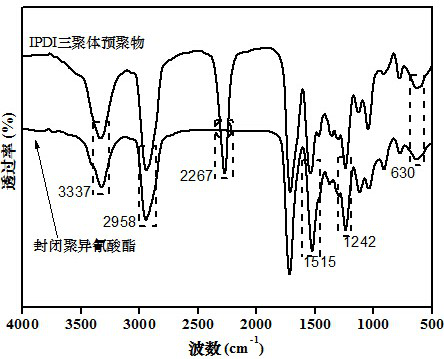

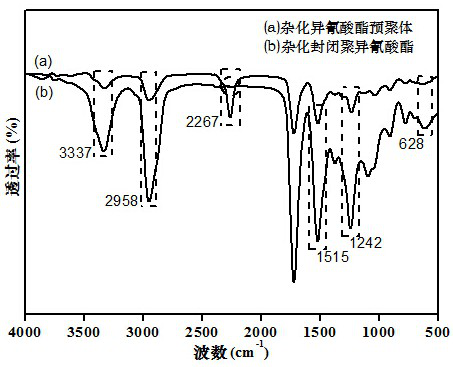

Preparation method of blocked isocyanate used for improving film forming performance of cathode electrophoresis coating

ActiveCN108929427AIncrease crosslink densityHigh Threshing PowerPaints for electrolytic applicationsEpoxy resin coatingsPolyesterCross-link

The invention discloses a preparation method of blocked isocyanate used for improving film forming performance of a cathode electrophoresis coating. The method comprises the following steps: (1) preparing an isocyanate tripolymer by using an organic compound as a catalyst under protection of a nitrogen gas; (2) performing chain extension by a polyhydroxy monomer to prepare an isocyanate-terminatedpolyisocyanate prepolymer, and blocking the prepolymer by using a composite blocking agent to prepare a branched polyisocyanate cross-linking agent; and (3) in the branching system, adding diisocyanate, performing chain extension by a polyester polyol to prepare an isocyanate-terminated diisocyanate prepolymer, performing hydrophilic modification on the isocyanate-terminated diisocyanate prepolymer by an alkynol surfactant, and blocking the prepolymer by using a composite blocking agent to obtain the blocked polyisocyanate cross-linking agent. The preparation method for the blocked isocyanatedisclosed by the invention is simple, the reaction process is easy to control, the blocked isocyanate has low deblocking temperature as a curing agent, and the prepared electrophoresis coating film has low heating loss, good thermal fluidity, high flatness, a high crosslinking density, and excellent corrosion resistance.

Owner:HUNAN UNIV +1

Polystyrene modified plastic and preparation method thereof

The invention discloses a polystyrene modified plastic which comprises the following components in percentage by weight: 70-78% of polystyrene, 7-12% of polycarbonate, 10-12% of inorganic nanoparticle, 0.7-1.5% of coupling agent, 0.7-1.5% of antioxidant, 0.7-1.5% of filler, 0.7-1.5% of lubricant and 0-1% of color master batch, totaling 100%. The polystyrene modified plastic has reasonable formula design. The produced modified polystyrene has the advantages of high impact resistance, favorable heat resistance and frictional resistance.

Owner:SUZHOU RONGCHANG COMPOUND MATERIAL

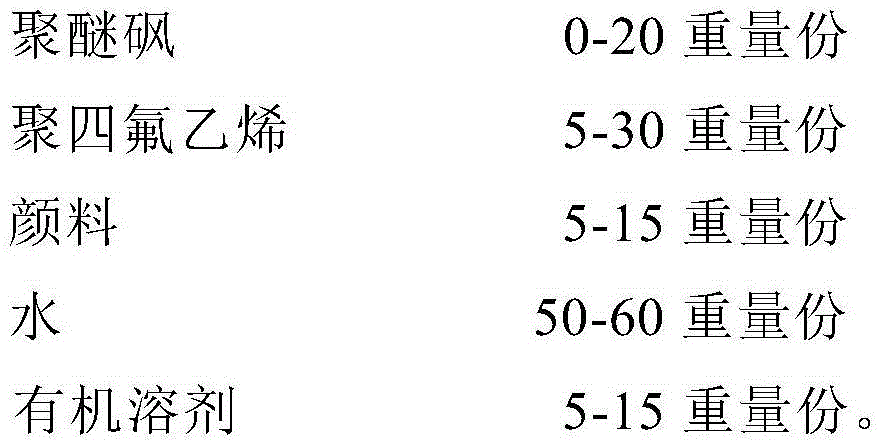

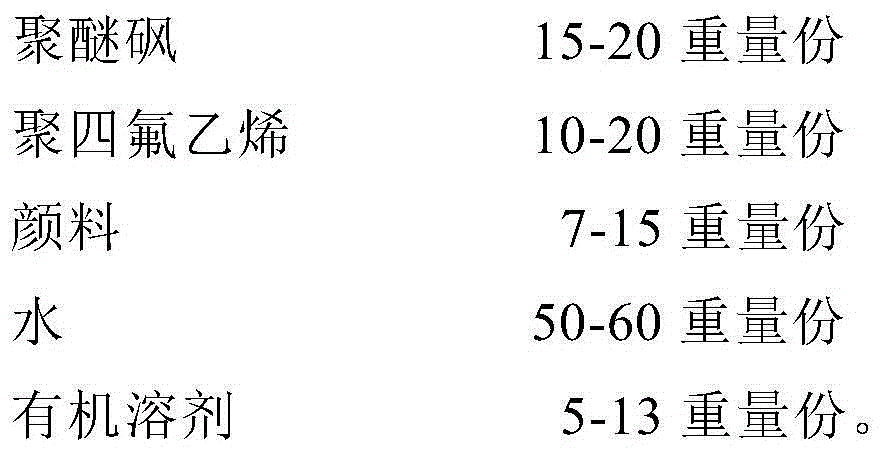

Aqueous anti-adhesion coating for iron substrate

The invention relates to an aqueous anti-adhesion coating. The coating contains polyethersulfone (PES), polytetrafluoroethylene, a pigment, water and a solvent. The aqueous anti-adhesion coating solves the problem of shedding of a film, and makes aqueous coatings be especially suitable for an iron substrate. The coating can be individually used to form the coating layer of an article, and also can be used to form any layer of a multilayer non-adhesion coating.

Owner:曾志玲

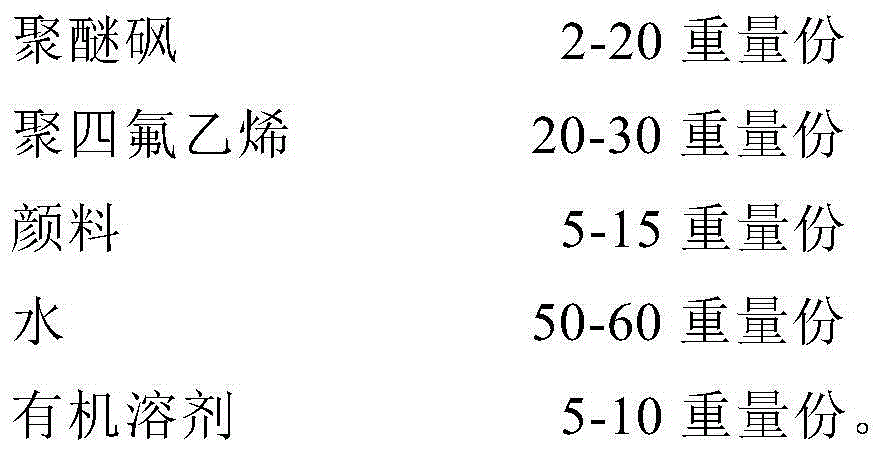

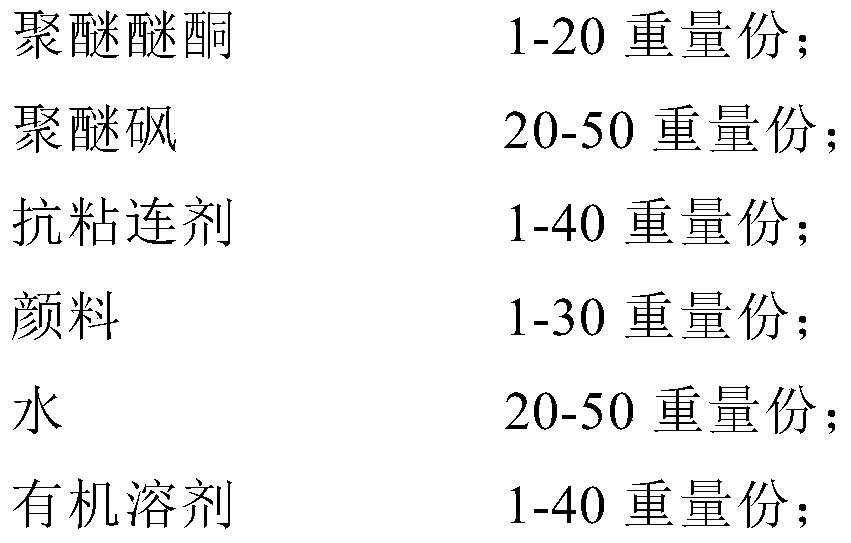

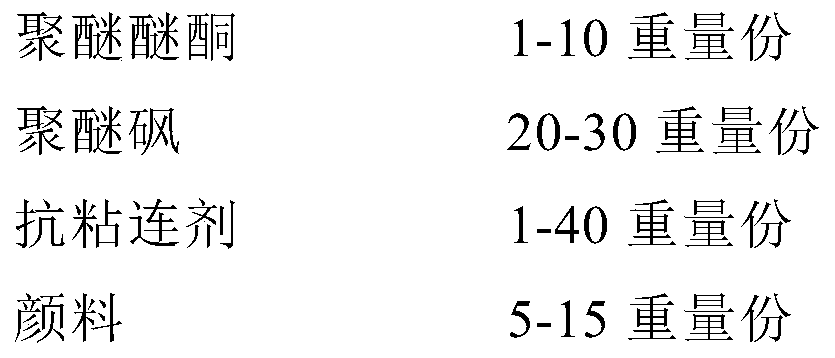

Anti-adhesion paint and product coated by the anti-adhesion paint

InactiveCN105482685ALower glass transition temperatureGood weather resistanceLayered productsAnti-corrosive paintsPoly ether ether ketoneAnti-Adhesion Agent

The invention relates to an anti-adhesion paint and a product coated by the anti-adhesion paint. The purpose of the anti-adhesion paint is to solve the problems of relatively bad leveling performance and bad post-film-formation flatness of poly-(ether-ether-ketone). According to the invention, polyether sulphone is added into the poly-(ether-ether-ketone) paint and the proportions of the ingredients are adjusted, so that an anti-adhesion paint of good leveling performance, excellent high-temperature resistance, excellent corrosion resistance and excellent weather resistance is obtained. The anti-adhesion paint disclosed by the invention comprises the following ingredients in parts by weight: 1-20 parts of poly-(ether-ether-ketone), 20-50 parts of polyether sulphone, 1-40 parts of anti-adhesion agent, 1-30 parts of pigment, 20-50 parts of water and 1-40 parts of organic solvent. The anti-adhesion paint disclosed by the invention can be used for products with anti-adhesion requirements and especially for outdoor products or kitchenware products with relatively high weather-resisting and scratch-resisting requirements.

Owner:曾志玲

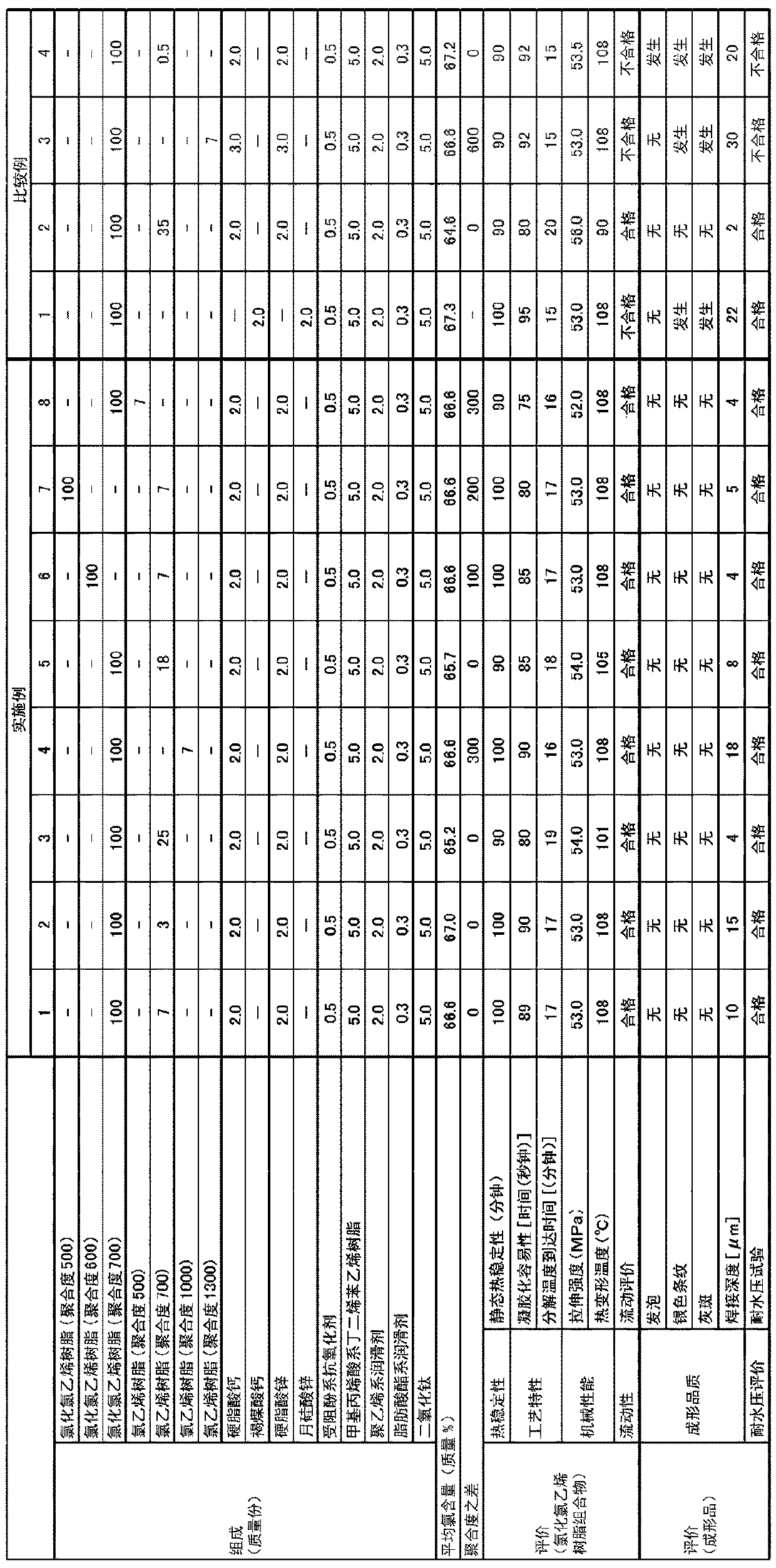

Resin composition for injection molding

Owner:SEKISUI CHEM CO LTD +1

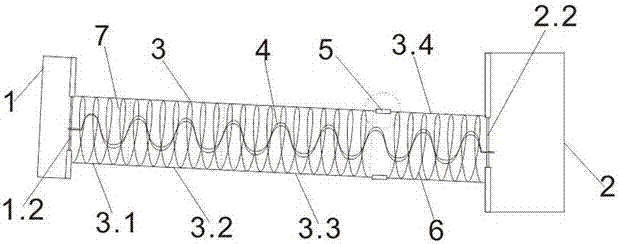

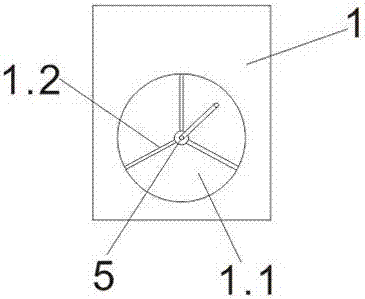

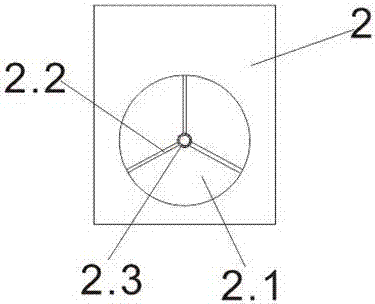

Phosphogypsum crushing and drying powder production line

The invention discloses a phosphogypsum crushing and drying powder production line. The phosphogypsum crushing and drying powder production line comprises a rotary kiln (3), a crusher, a frying furnace and a ball mill. A phosphogypsum wet base is dried and dehydrated in the rotary kiln (3), sent to the crusher (3) to be crushed, and then calcinated and grinded through the frying furnace and the ball mill correspondingly to prepare the finished gypsum powder, the rotary kiln (3) is installed between a kiln hood (1) and a kiln tail smoke chamber (2), the rotary kiln (3) is a anti-blocking material phosphogypsum high temperature rotary kiln, and the frying furnace is a blast type phosphogypsum powder frying furnace. An anti-blocking screw for avoiding blocking is arranged in the rotary kiln, a flow deflector which can improve the conveying speed is arranged in the baking section of the rotary kiln, a cooling belt is provided with a water cooling structure for cooling the material by replacing a cooler, the structure of the frying furnace is improved to increase the processing phosphogypsum efficiency of the production line, production cost is reduced, and the enthusiasm of enterprises to use the phosphogypsum is improved.

Owner:四川省高宇新型建材有限公司

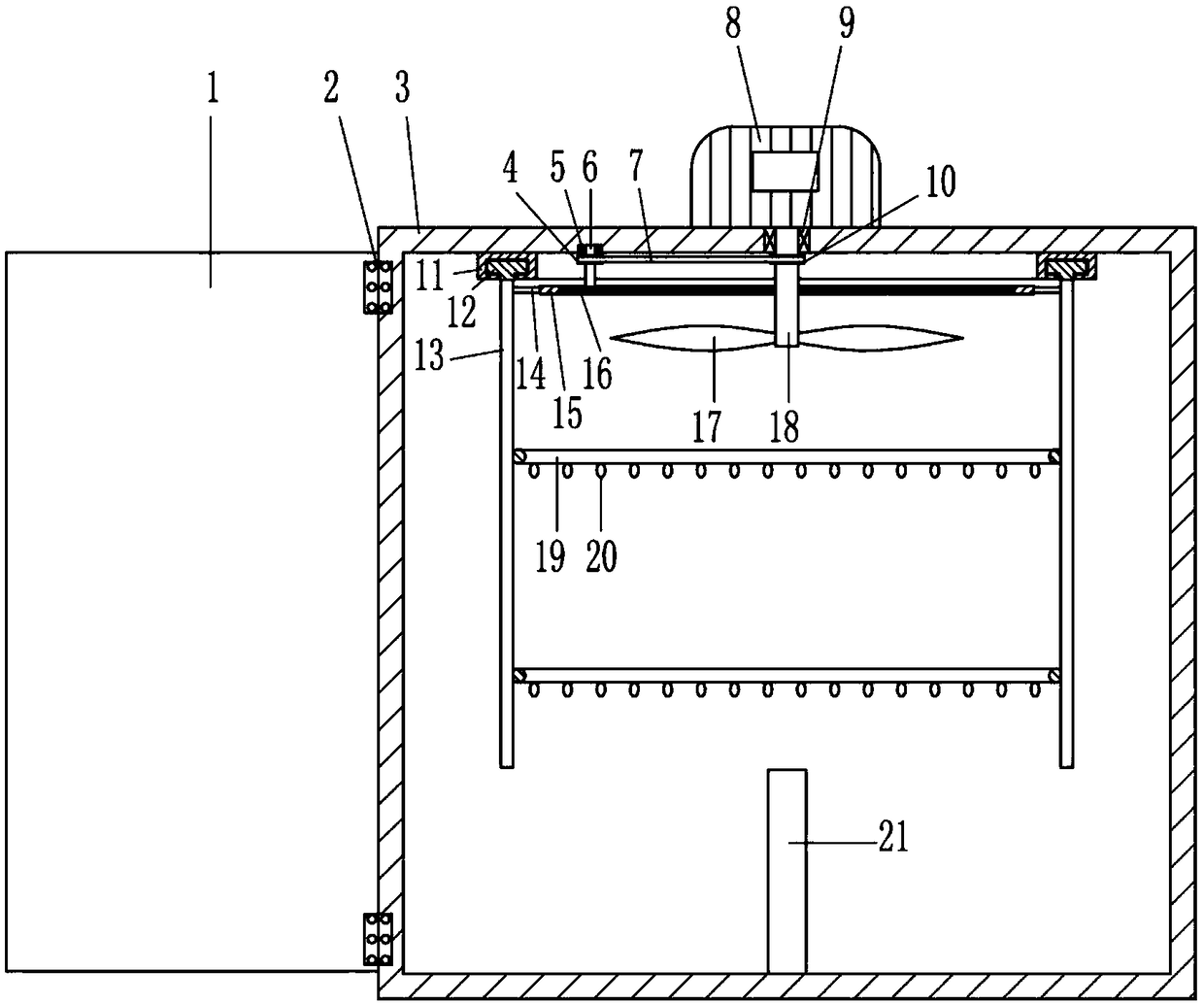

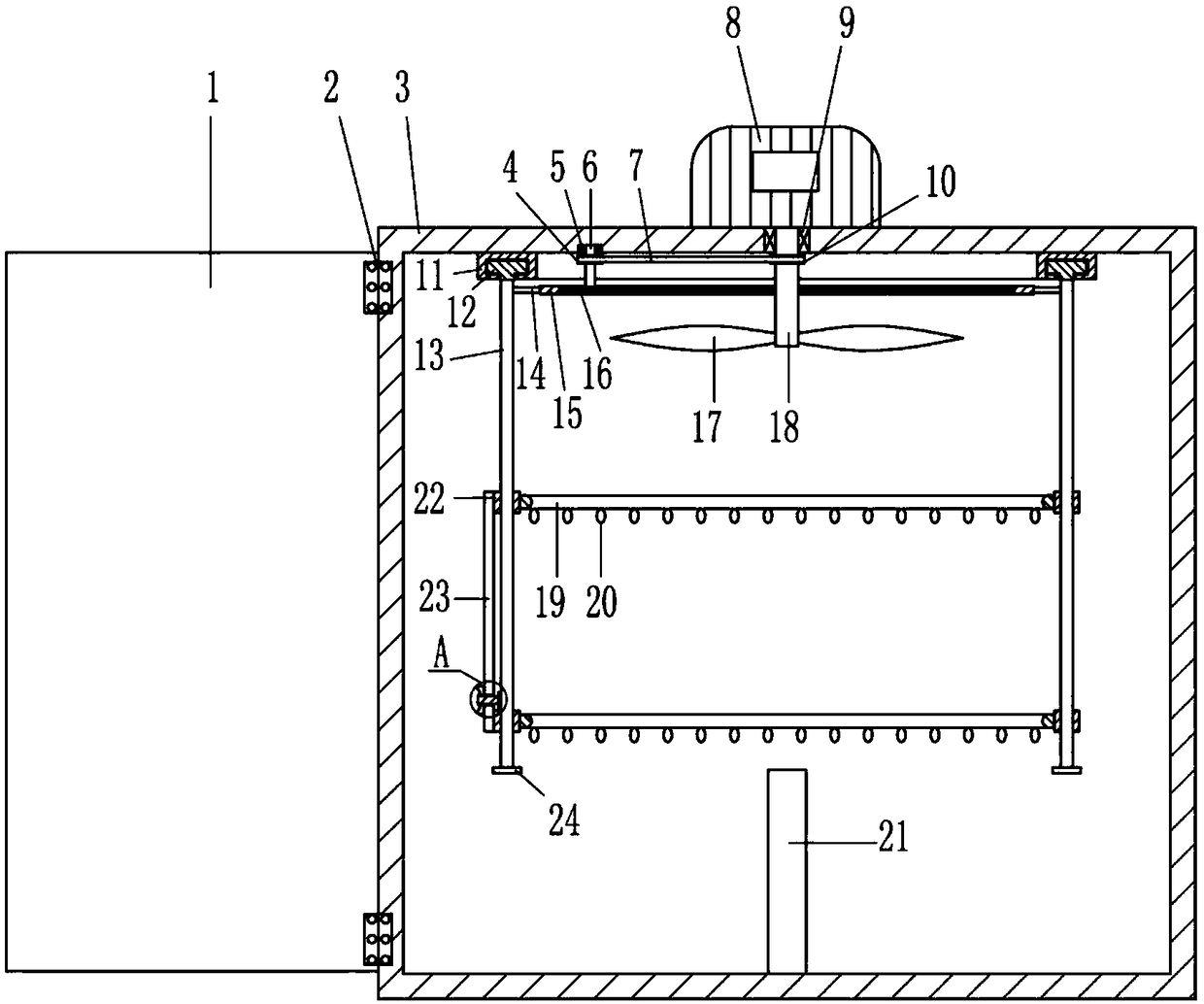

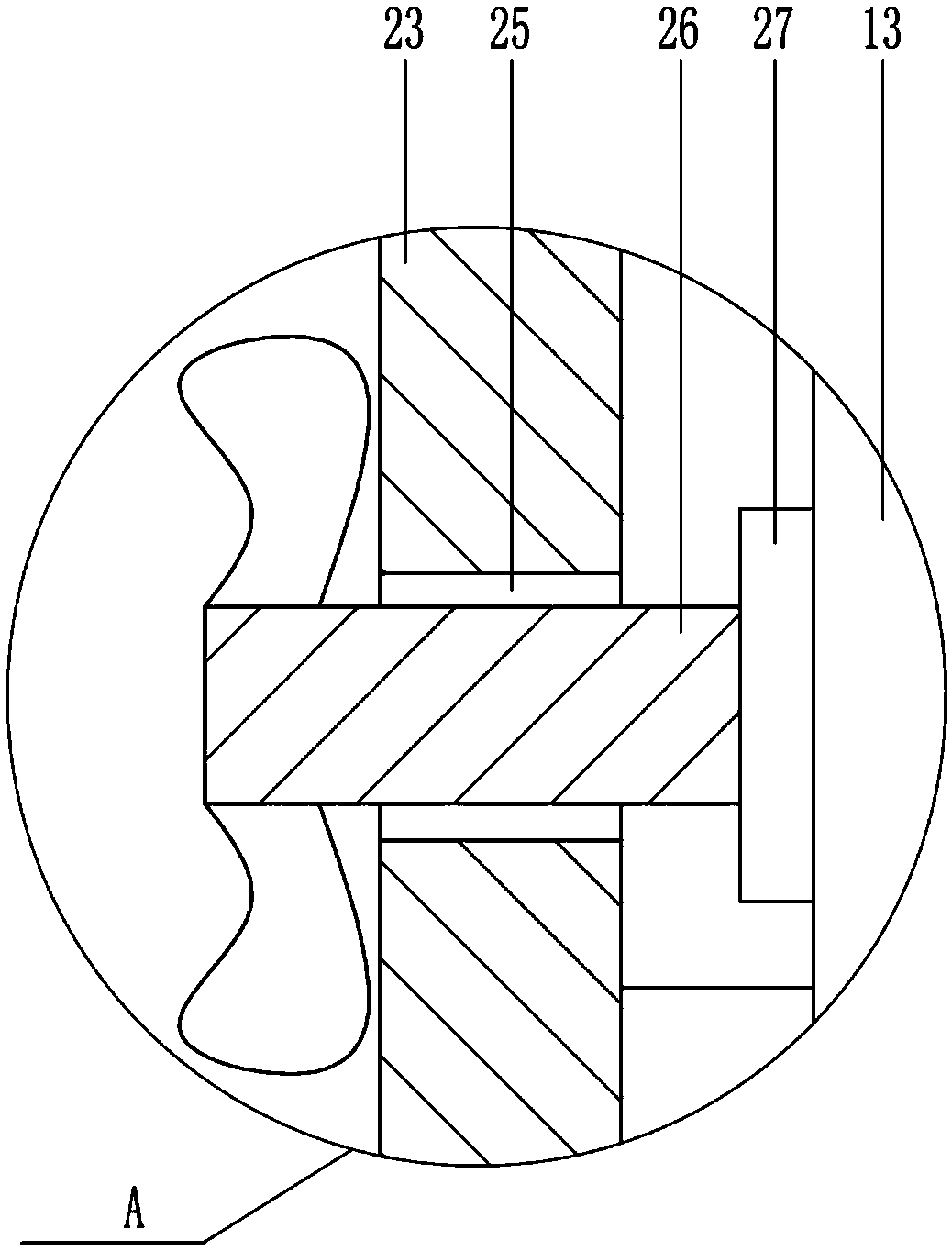

Preserved meat drying box for food processing

ActiveCN108935623AReduce labor burdenSpeed up heat flowMeat/fish preservation by dryingHinge angleEngineering

The present invention belongs to the field of food processing and particularly relates to a preserved meat drying box for food processing. A technical problem to be solved is to provide the preservedmeat drying box for the food processing, which can improve baking efficiency of preserved meat and ensure that the preserved meat can be evenly baked. The preserved meat drying box for the food processing comprises a door panel, two hinges, an oven, a first belt pulley, a first bearing seat, a first rotating shaft, a first flat belt, a motor, a second bearing seat, a second belt pulley, a circularsliding rail, a first sliding block, fixed rods, a first connecting rod, an inner gear ring, a cylindrical gear, fan blades, a second rotating shaft, annular hanging rods, hanging rings and a heatingplate; the door panel is hinged with the oven through the hinges; the motor is fixedly connected with the top part of the oven; and the second bearing seat is embedded in the top part of the oven. The preserved meat drying box for the food processing achieves effects of rapidly baking the preserved meat and ensuring the baking process of the preserved meat to be even.

Owner:SICHUAN RUNYU FOOD

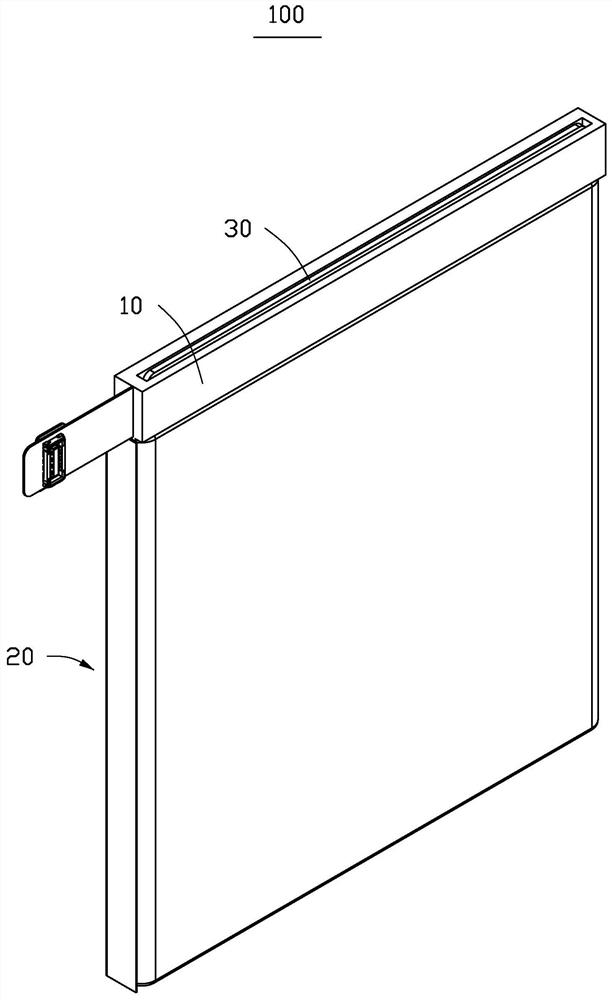

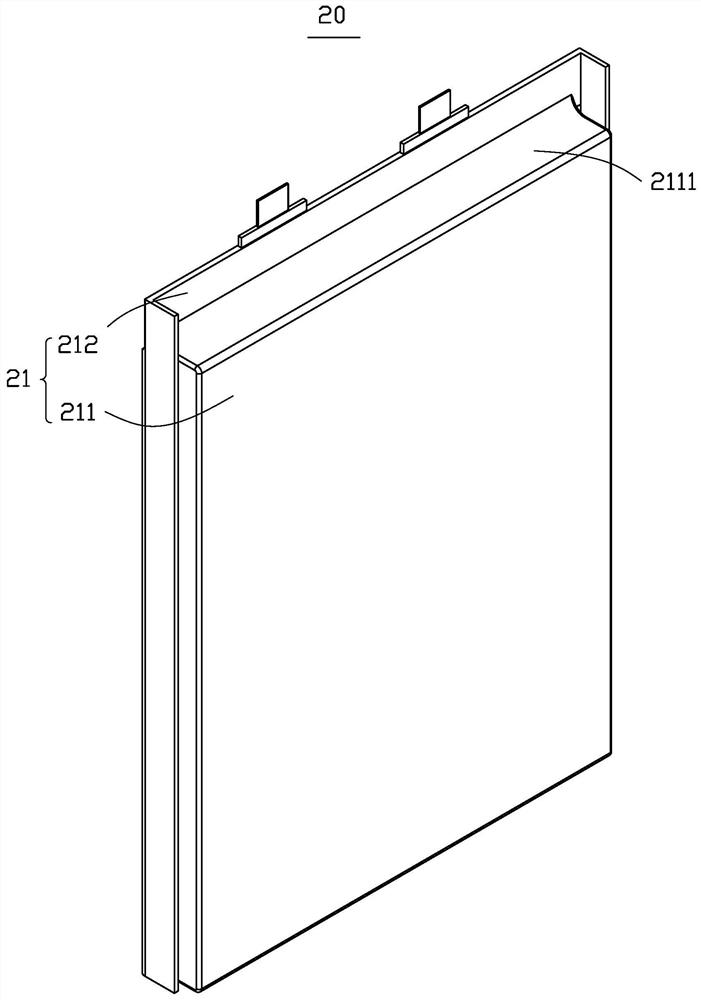

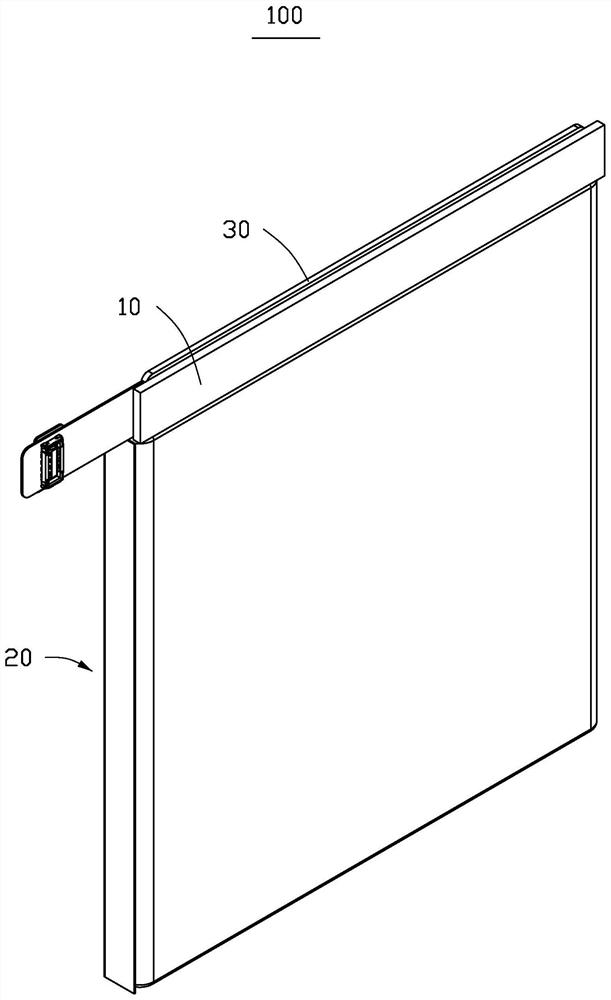

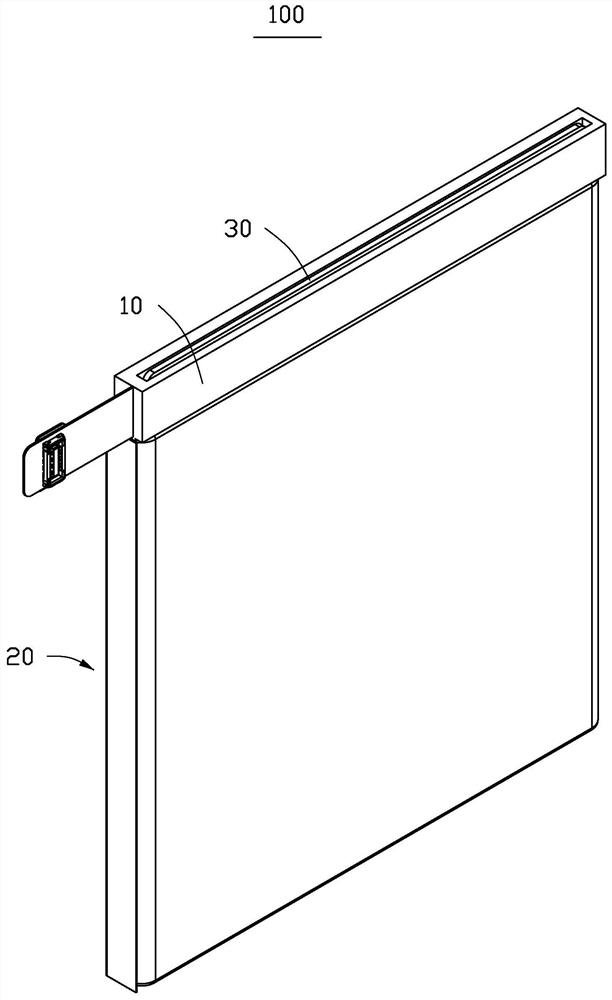

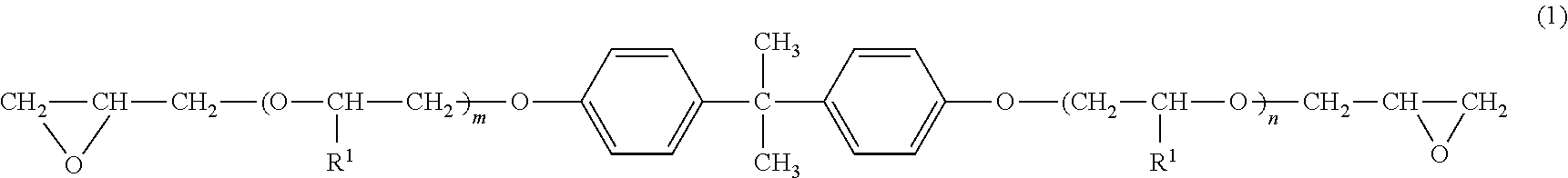

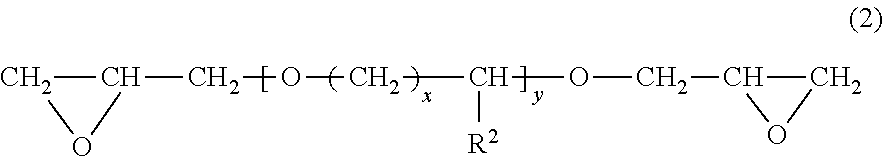

Composite phase change material, application method thereof, and battery

ActiveCN111793471ASpeed up heat flowReduce manufacturing costCircuit thermal detailsSecondary cellsPhoto irradiationAdhesive

The invention provides a composite phase change material. The composite phase change material comprises, by weight, 65-80 parts of a phase change material and 20-35 parts of an adhesive. The adhesivecomprises an acrylate monomer with the molecular weight of 50-300, an acrylate polymer with the molecular weight of 500-2000 and an initiator. The invention also provides an application method of thecomposite phase change material, and a battery applying the composite phase change material. The initiator in the composite phase change material can generate free radicals under the condition of ultraviolet irradiation to initiate polymerization reaction among components in the composite phase change material, so that the composite phase change material is cured, and the curing and forming speedof the composite phase change material is greatly reduced. In addition, the cured composite phase change material does not flow after being heated, and the reliability is good.

Owner:DONGGUAN NVT TECH

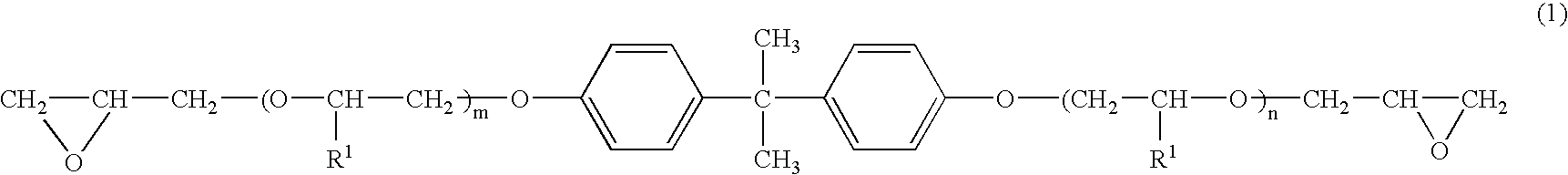

Cationic Electrodeposition paint compositions

ActiveUS20080287612A1Excels in film thicknessImprove corrosion resistanceSynthetic resin layered productsCoatingsEpoxyXylene

This invention discloses a cationic electrodeposition paint composition containing an amino group-containing modified epoxy resin which is obtained through reaction of specific modified epoxy resin with xylene formaldehyde resin having phenolic hydroxyl groups and amino group-containing compound. The cationic electrodeposition paint composition excels in film thickness retention, finished appearance of coating film and electrocoatability of galvanized alloy steel sheet and can form coating film having good corrosion resistance, even when its content of volatile organic compound (VOC) is reduced.

Owner:KANSAI PAINT CO LTD

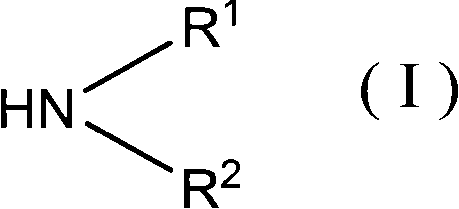

Cationic electrodeposition coating composition

InactiveCN101870843AConvenient finishingEasy to processPolyurea/polyurethane coatingsPaints for electrolytic applicationsFirming agentBis epoxide

An object of the present invention is to provide a coating composition that has excellent throwing power and electrodeposition coating applicability onto hot dip galvanized steel sheets, and that provides a cationic electrodeposition coating film having a superior finish and excellent anti-corrosion properties, and a multilayer coating film with a superior finish formed on the cationic electrodeposition coating film by a 3C1B process. The present invention provides a cationic electrodeposition coating composition having amino group-containing epoxy resin (A) obtained by reacting epoxy resin (A1) having an epoxy equivalent of 500 to 2,500 with amine compound (A2); and blocked polyisocyanate curing agent (B).

Owner:KANSAI PAINT CO LTD

Paint composition and method for forming multilayered coating

ActiveCN104870581ASmall molecular weightSpeed up heat flowLiquid surface applicatorsEster polymer adhesivesSingle processPolyol

Owner:KANSAI PAINT CO LTD

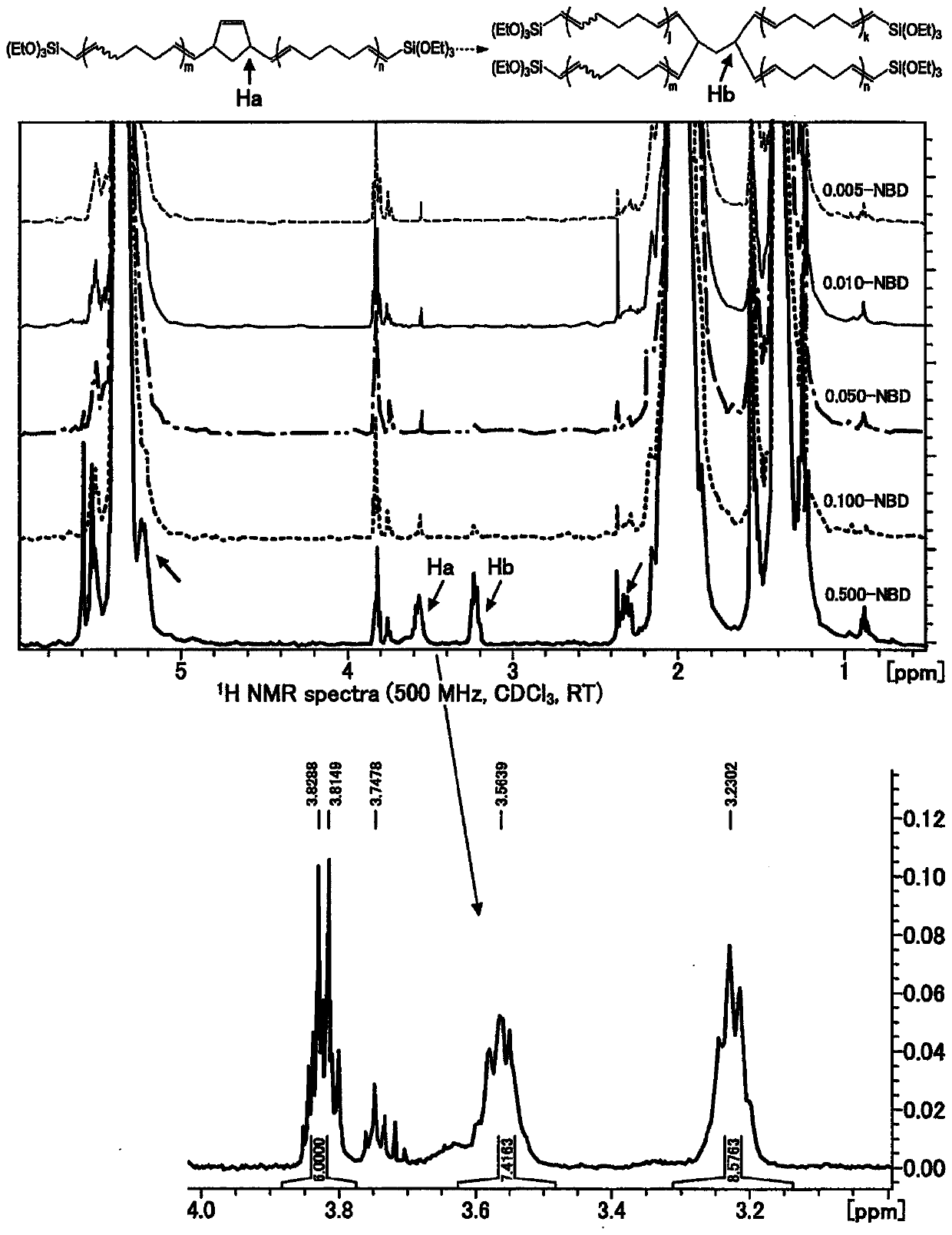

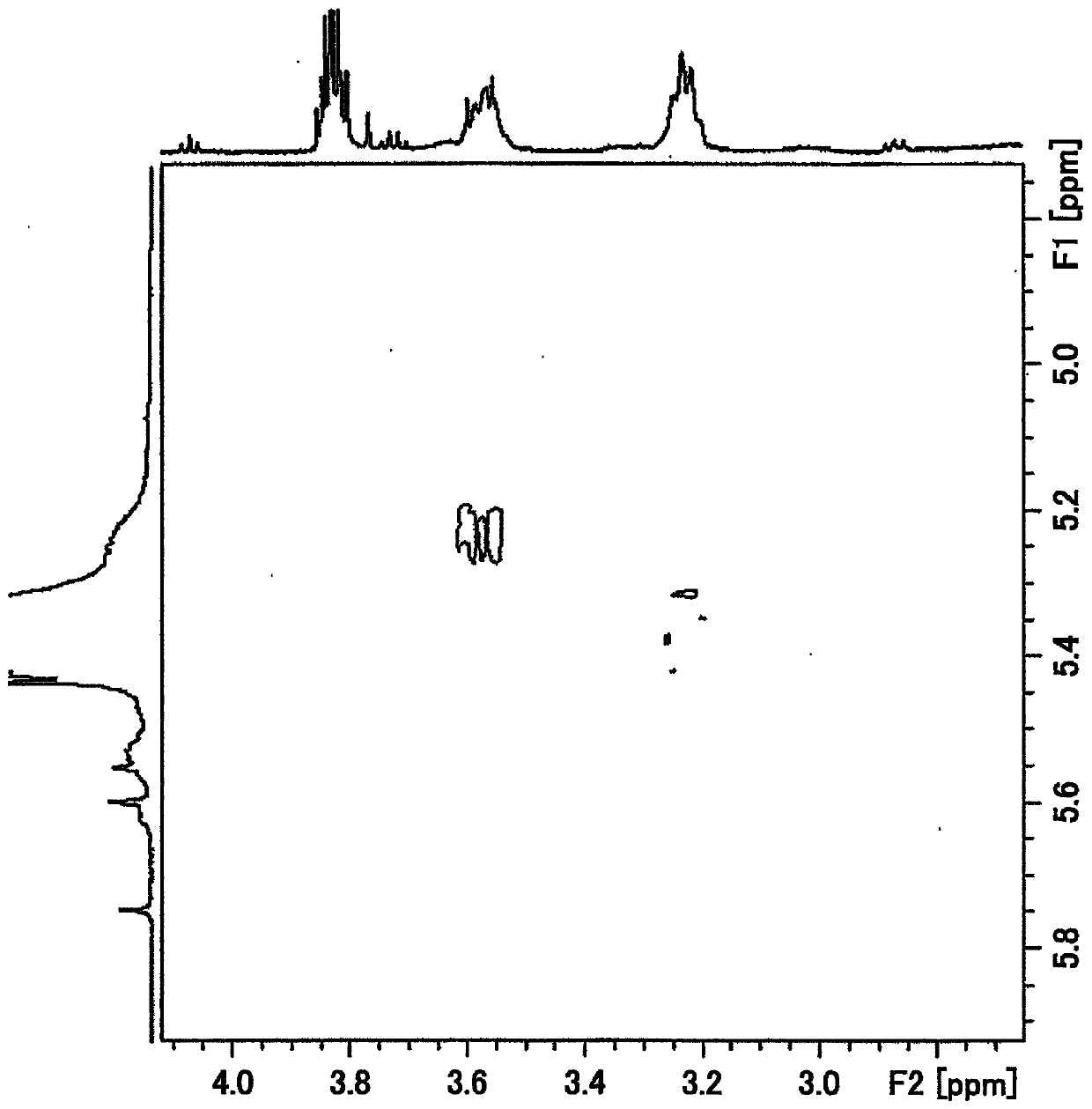

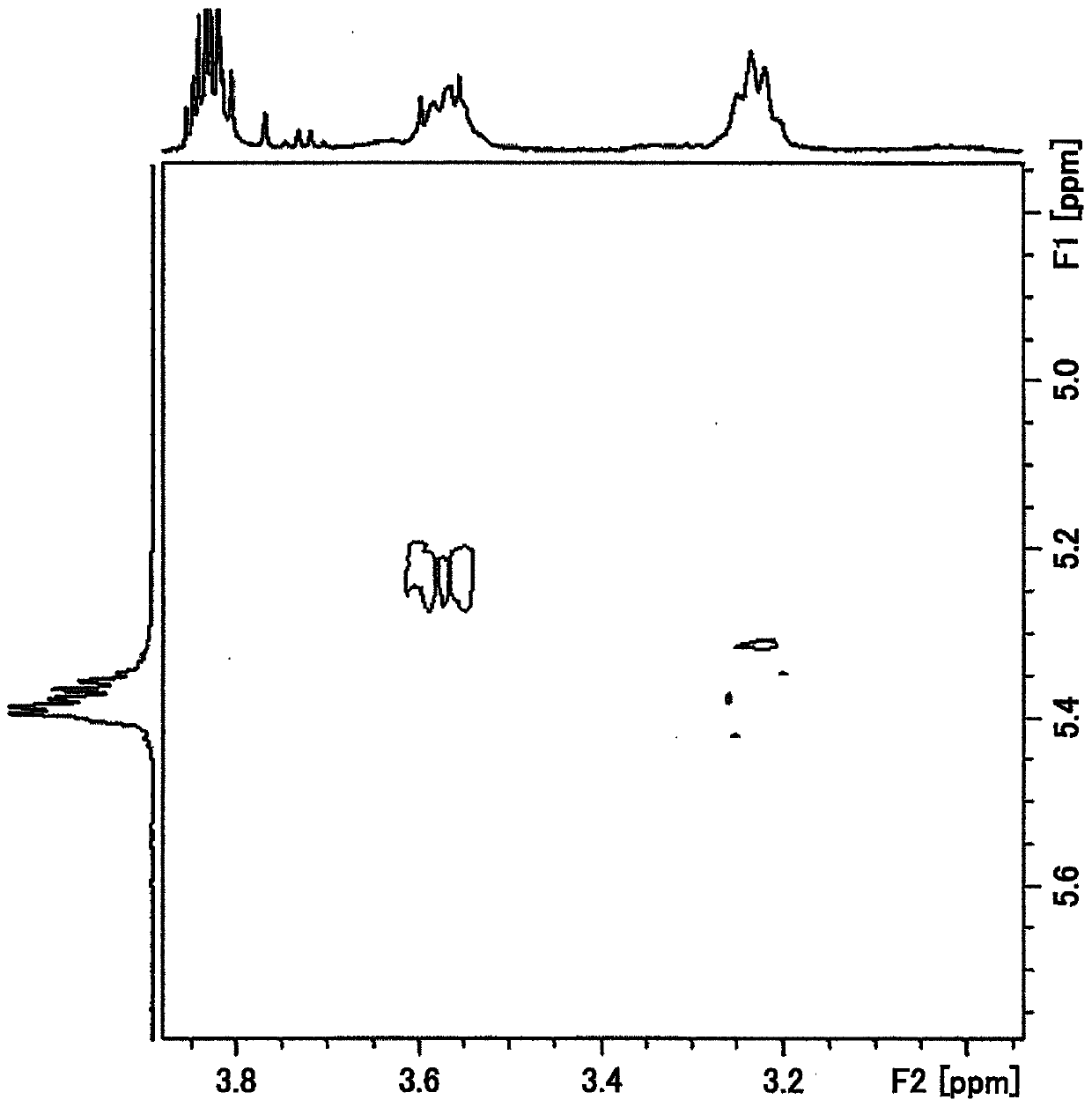

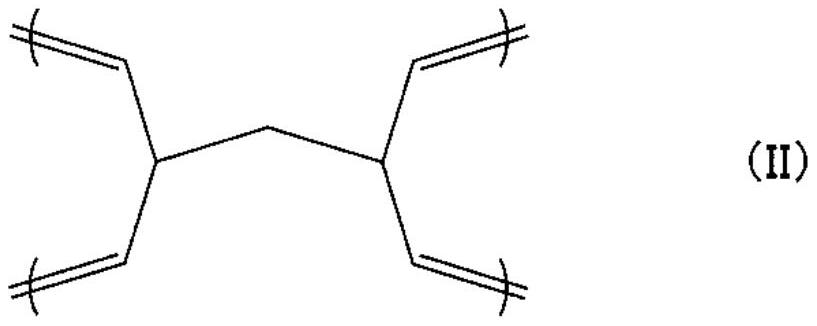

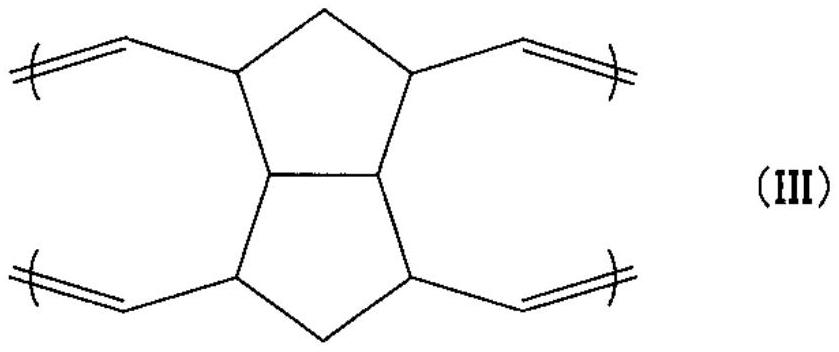

Cyclopentene ring-opening copolymer and method for producing same

ActiveCN110312749AReduce the heating effectSpeed up heat flowSpecial tyresCyclopentenePolymer science

A cyclopentene ring-opening copolymer having a branched structure, wherein the cyclopentene ring-opening copolymer includes a structure in which at least four cyclopentene ring-opening polymer chainsare connected via branched-structure monomers, and at least some of the cyclopentene ring-opening polymer chains are end-modified.

Owner:ZEON CORP

Molded epoxy resin sheet and its preparation process

InactiveCN100556682CExcellent mechanical propertiesImprove liquiditySynthetic resin layered productsLaminationFiberUnsaturated polyester

The invention discloses an epoxy sheet molding compound, wherein the middle core material is composed of fibers impregnated with epoxy resin paste, and the upper and lower surfaces are covered with PE films. In parts by weight, the epoxy sheet molding compound is made of the following raw materials: 100 parts of epoxy resin, 4-20 parts of diluent, 15-80 parts of curing agent, 9-16 parts of thickener, 6 parts of organic acid ~18 parts, 1~4 parts of internal release agent, 80~180 parts of filler, 50~150 parts of fiber. The preparation steps of the epoxy sheet molding compound include the preparation of epoxy resin paste, the preparation of the epoxy sheet molding compound and the curing of the epoxy sheet molding compound. The epoxy sheet molding compound has the advantages of good thermal fluidity, short curing time, long storage time and the like, and the preparation process is simple. Higher-strength epoxy composite structural parts can be prepared by hot-press curing. Compared with unsaturated polyester SMC products, the strength is greatly improved, and the corrosion resistance and insulation properties are enhanced.

Owner:WUHAN UNIV OF TECH

Method for preparing epoxy sheet mould plastic

Owner:SHANGHAI MANSDA INDAL

Aluminum-plastic membrane used for packaging lithium battery

ActiveCN101992570BImprove heat resistanceImprove wear resistanceCell component detailsMetal layered productsPlasma technologyAluminum foil

The invention discloses an aluminum-plastic membrane used for packaging the lithium battery. The aluminum-plastic membrane mainly comprises a protective layer, an aluminum foil layer and a heat sealing layer, wherein the protective layer is bound and combined with the aluminum foil layer through a glue layer, the heat sealing layer is bound and combined with the aluminum foil layer through a glue layer; before the binding and combining, the plasma technology is adopted to perform surface grafting treatment to the surfaces of the protective layer, the aluminum foil layer and the heat sealing layer; and then the protective layer and the aluminum foil layer are separately combined with the both sides of one glue layer through hot-pressing, and the aluminum foil layer and the heat sealing layer are are separately combined with the both sides of one glue layer through hot-pressing. The aluminum-plastic membrane has higher chemical resistance, moisture-proof property, oxygen-isolating property and packaging-binding property, also has explosion-proof property and is suitable for the soft package lithium battery.

Owner:MING CROWN ADVANCED MATERIAL CO LTD

Composite phase change material, application method and battery of the composite phase change material

ActiveCN111793471BSpeed up heat flowReduce manufacturing costCircuit thermal detailsSecondary cellsLight irradiationAdhesive

The present application provides a composite phase change material, which comprises 65-80 parts of a phase change material and 20-35 parts of a binder in parts by weight. The adhesive comprises an acrylate monomer with a molecular weight of 50-300, an acrylate polymer with a molecular weight of 500-2000 and an initiator. The application also provides an application method of the composite phase change material and a battery using the composite phase change material. The initiator in the composite phase change material can generate free radicals under ultraviolet light irradiation conditions to initiate polymerization between the components in the composite phase change material, so that the composite phase change material is cured, so as to greatly shorten the composite phase change The speed at which the material solidifies into shape. In addition, after curing, the composite phase change material will not flow when heated, and has good reliability.

Owner:DONGGUAN NVT TECH

Reaction product of epoxy resins, bisphenol, xylene-formaldehyde and amine in cationic electrodeposition paint

InactiveUS7994263B2Reduce contentImprove corrosion resistanceSynthetic resin layered productsCoatingsXylylenePolymer science

This invention discloses a cationic electrodeposition paint composition containing an amino group-containing modified epoxy resin which is obtained through reaction of specific modified epoxy resin with xylene formaldehyde resin having phenolic hydroxyl groups and amino group-containing compound. The cationic electrodeposition paint composition excels in film thickness retention, finished appearance of coating film and electrocoatability of galvanized alloy steel sheet and can form coating film having good corrosion resistance, even when its content of volatile organic compound (VOC) is reduced.

Owner:KANSAI PAINT CO LTD

Laminate packing material for battery and laminate battery

ActiveUS8323827B2Reduce in quantitySimple processSynthetic resin layered productsJackets/cases materialsMetallic foilEngineering

In a laminated external packaging material for a battery according to the present invention, a metallic foil 2 is adhered to one surface side of a base film 1, and a coated film layer 4 of thermal adhesive resin having a softening point of 160° C. or below and capable of thermally bonding to a surface film of a battery main body is formed on the other surface side of the base film 1. With this laminated external packaging material for a battery, without using an adhesive tape or a hot-melt adhesive, this packaging material can be easily and assuredly bonded to the battery main body and also can be bonded firmly to an end portion reinforcing plastic component.

Owner:RESONAC PACKAGING CORP

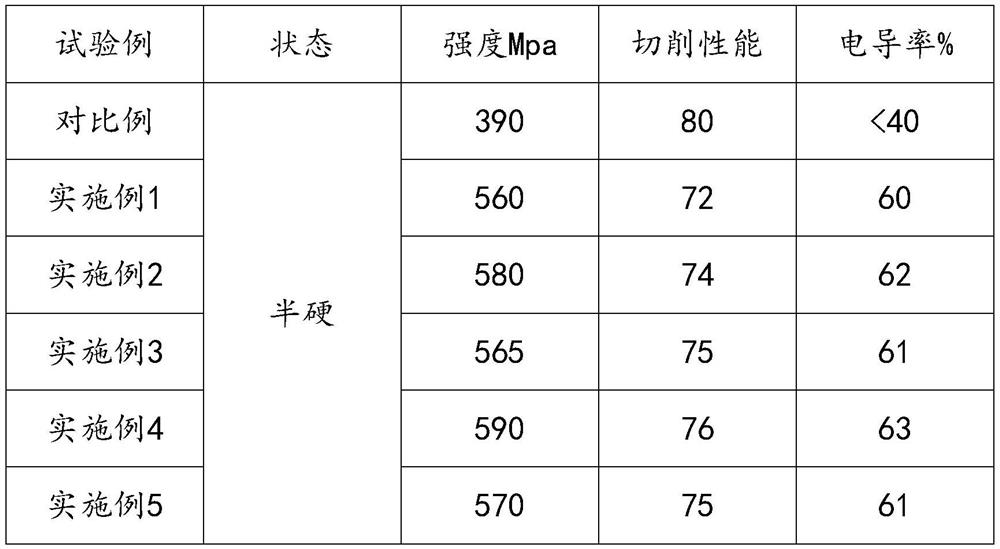

A high-conductivity copper alloy containing tellurium-nickel and its preparation method

The invention discloses a high-conductivity copper alloy containing tellurium-nickel and a preparation method thereof. A quaternary alloy is formed by adding nickel-iron-tellurium to pure copper, graphite flakes are used as a covering agent, and phosphor-copper alloy is used as a deoxidizer. According to the melting point and high suction, the materials are added sequentially for melting, and the high-conductivity copper alloy is prepared through the melting and casting process. Nickel, iron elements, solid solution of nickel and iron expands the plasticity of iron in the alloy, and at the same time increases the strength of pure copper, overcoming the shortcomings of high strength but low plasticity of copper-iron alloys in traditional technology, and the tellurium element improves the cutting performance of the alloy and pure copper A high-performance copper alloy that not only maintains the mechanical properties of the copper alloy, but also has high electrical conductivity, high strength and good cutting performance coexists.

Owner:四川科派新材料有限公司

Coating composition and multilayer coating film forming method

ActiveCN103894332BSpeed up heat flowExcellent finishing appearanceSpecial surfacesCoatingsPolymer sciencePolyol

The invention provides a transparent paint composition of a multilayer coating film, which is not easy to be affected by the roughness of the surface of the bottom material, the flatness and the DOI performance are excellent, when the coated object is sequentially coated by a first water coloration paint, a second water coloration paint, and a transparent coating, and then is solidified together to form the multi-layer coating film, and the multi-layer coating forming method. The paint composition comprises the acrylic resin (A) containing the hydroxyl, the melamine resin (B), and the polyhydric alcohols (C) having the special number-average molar mass in a range from 300-1500. The paint composition can be used as the transparent paint, and the coated object is sequentially coated by the first water coloration paint, the second water coloration paint, and the transparent coating, which are heated and solidified together to form the multi-layer coating.

Owner:KANSAI PAINT CO LTD

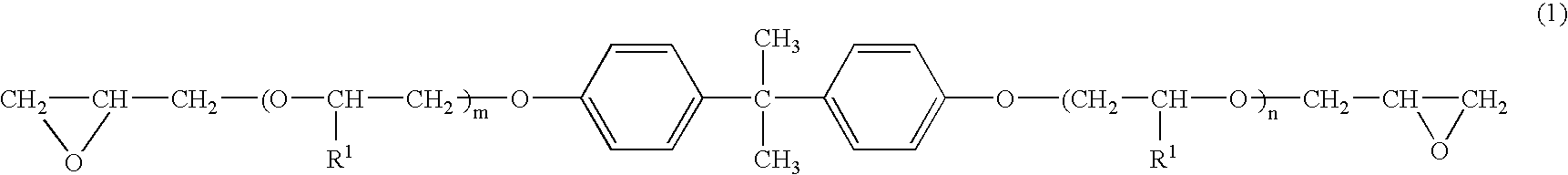

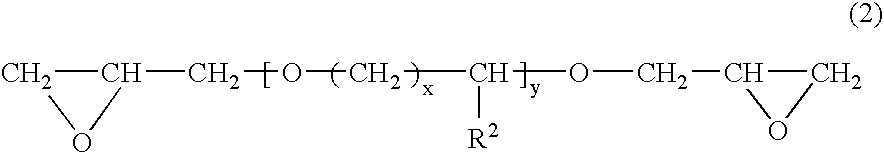

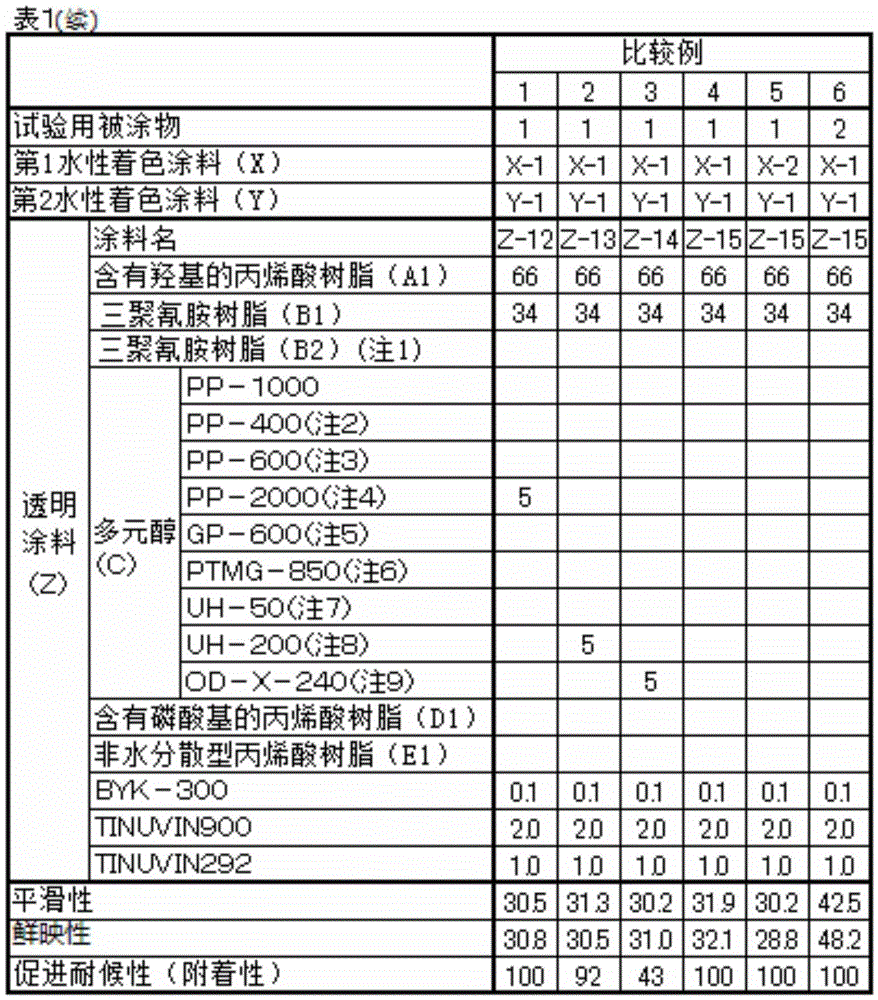

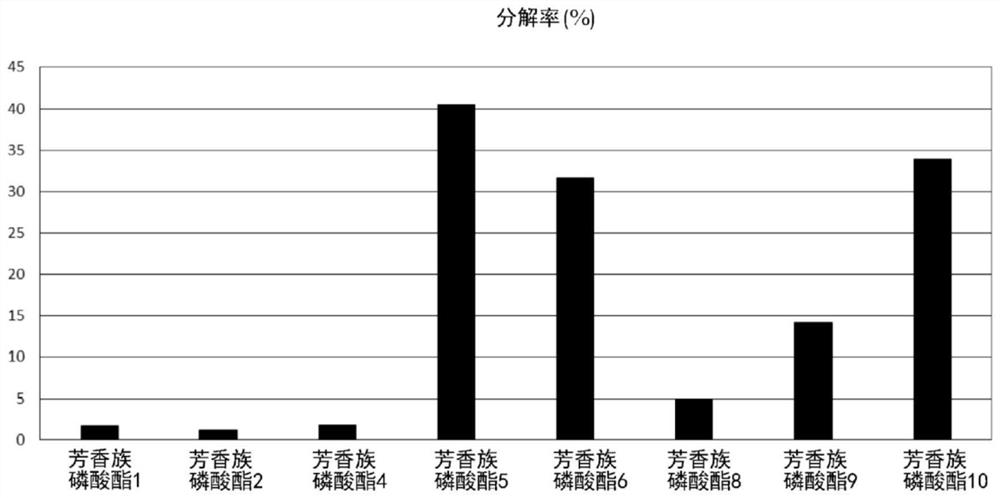

Flame retardant containing aromatic phosphoric acid ester, and thermoplastic resin composition containing same

PendingCN111788281ASpeed up heat flowImprove heat resistanceFireproof paintsPhosphoric Acid EstersPolymer science

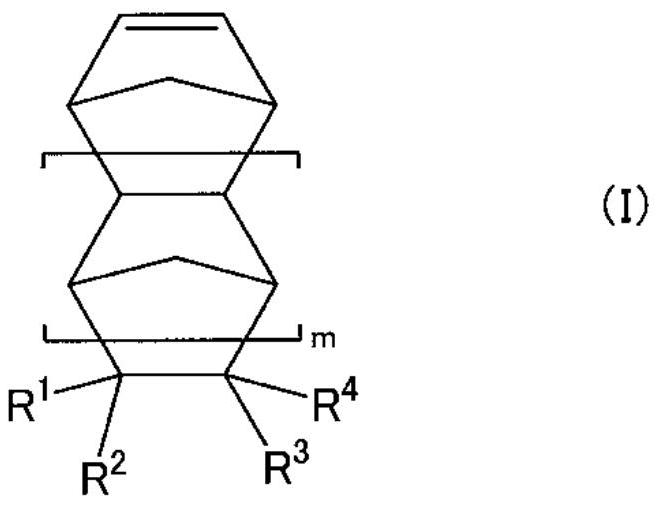

A flame retardant contains an aromatic phosphoric acid ester represented by general formula (I). In the formula, R1-R4, R7, and R8 each independently represent a C1-4 alkyl group or a C1-4 alkoxy group, R5, R6, and R9 each independently represent a C1-10 alkyl group or a C1-10 alkoxy group, n is an integer of 1-10, n1 and n2 each independently are an integer of 0-3, m1 and m2 each independently are an integer of 0-4, p is an integer of 0-26, k is an integer of 1-12, and when p is 2 or higher, any two R9 may connect to form another ring together with the carbon atoms of the ring to which R9 isbonded.

Owner:DIAHACHI CHEMICAL INDUSTRY CO LTD

Preparation method of blocked isocyanate for improving film-forming performance of cathodic electrophoretic coating

ActiveCN108929427BIncrease crosslink densityHigh Threshing PowerPaints for electrolytic applicationsEpoxy resin coatingsPolyesterPolymer science

The invention discloses a preparation method of blocked isocyanate used for improving film forming performance of a cathode electrophoresis coating. The method comprises the following steps: (1) preparing an isocyanate tripolymer by using an organic compound as a catalyst under protection of a nitrogen gas; (2) performing chain extension by a polyhydroxy monomer to prepare an isocyanate-terminatedpolyisocyanate prepolymer, and blocking the prepolymer by using a composite blocking agent to prepare a branched polyisocyanate cross-linking agent; and (3) in the branching system, adding diisocyanate, performing chain extension by a polyester polyol to prepare an isocyanate-terminated diisocyanate prepolymer, performing hydrophilic modification on the isocyanate-terminated diisocyanate prepolymer by an alkynol surfactant, and blocking the prepolymer by using a composite blocking agent to obtain the blocked polyisocyanate cross-linking agent. The preparation method for the blocked isocyanatedisclosed by the invention is simple, the reaction process is easy to control, the blocked isocyanate has low deblocking temperature as a curing agent, and the prepared electrophoresis coating film has low heating loss, good thermal fluidity, high flatness, a high crosslinking density, and excellent corrosion resistance.

Owner:HUNAN UNIV +1

Ring-opening copolymers

Provided is a ring-opening copolymer containing a structural unit derived from a norbornene compound represented by general formula (I), a structural unit derived from a monocyclic cyclic olefin, and a branched structural unit, the content ratio of the branched structural unit being 0.005-0.08 mol% of the total repeating structural units in the ring-opening copolymer. (In general formula (I), each of R1-R4 independently represents a hydrogen atom, a chain saturated hydrocarbon group having 1-20 carbon atoms, or a substituent group containing a halogen atom, a silicon atom, an oxygen atom, or a nitrogen atom, and m is 0 or 1. )

Owner:ZEON CORP

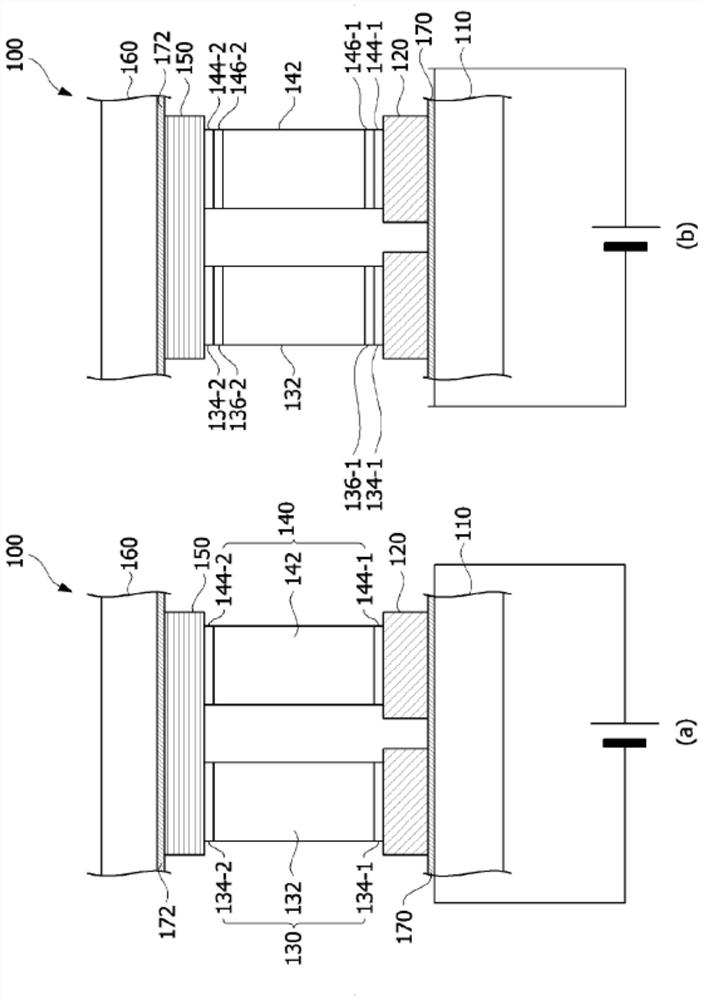

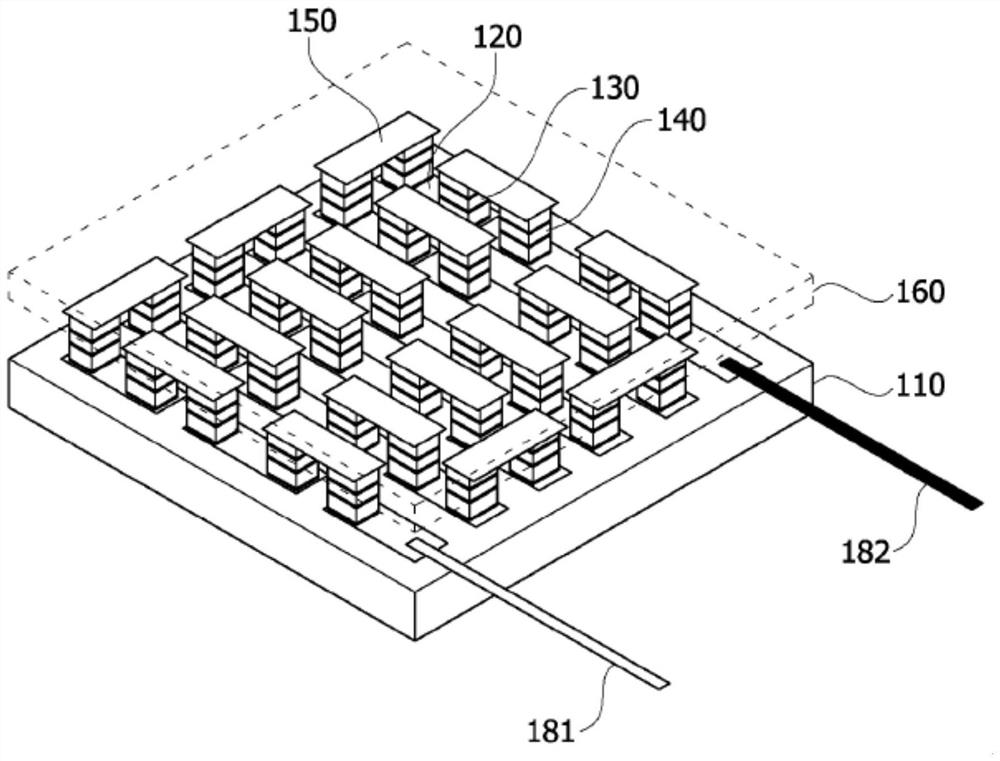

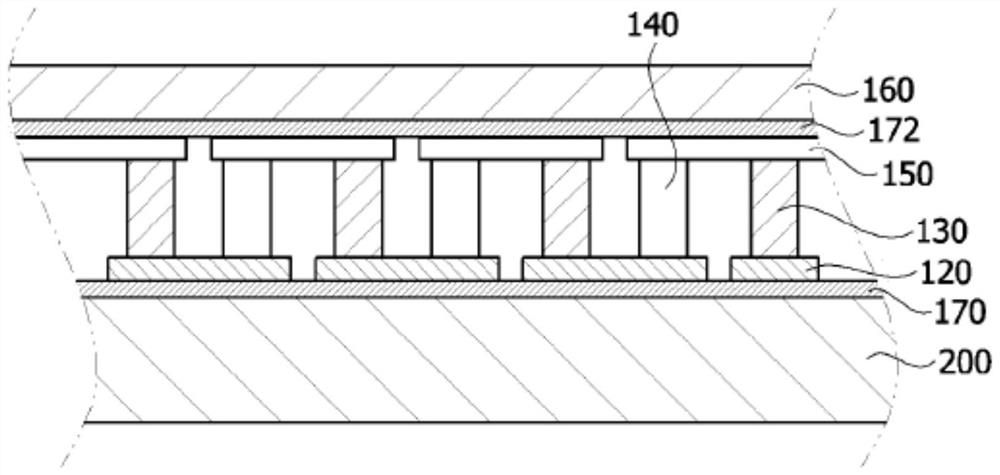

Thermoelectric device

PendingCN114207853AReduce thermal resistanceImprove performanceThermoelectric device with peltier/seeback effectThermoelectric device detailsSemiconductor structureEngineering physics

A thermoelectric device according to one exemplary embodiment of the present invention comprises: a heat dissipation member in which a groove is formed; the first electrode is arranged in the groove; a semiconductor structure disposed on the first electrode; a second electrode disposed on the semiconductor structure; a substrate disposed on the second electrode; and a sealing member disposed between the substrate and a sidewall of the recess.

Owner:LG INNOTEK CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com