Preparation method of blocked isocyanate for improving film-forming performance of cathodic electrophoretic coating

A technology for blocking isocyanate and cathodic electrophoretic coatings, applied in electrophoretic coatings, epoxy resin coatings, coatings, etc., can solve the problems of high heating loss, narrow deblocking range, low crosslinking density, etc. The effect of easy reaction process and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0058] The preparation method of the blocked isocyanate that improves the film-forming performance of cathodic electrophoretic coating of the present embodiment comprises the following specific steps:

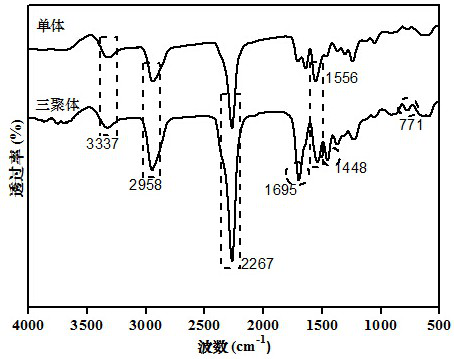

[0059] (1) Preparation of isocyanate trimer: Add 100g of isophorone diisocyanate to a 500mL four-neck flask equipped with a condensing reflux tube, agitator, dropping funnel, thermometer, and nitrogen protection device, and add 0.4g of organic bismuth DY -20 and 44.98g methyl ethyl ketone, react at a constant temperature of 105°C, measure the -NCO group content regularly, until the -NCO content drops to a predetermined value (the "theoretical value" is half of the -NCO reacted), then lower the reaction temperature to room temperature , to prepare a mixed isocyanate with isocyanate trimer and monomer structure;

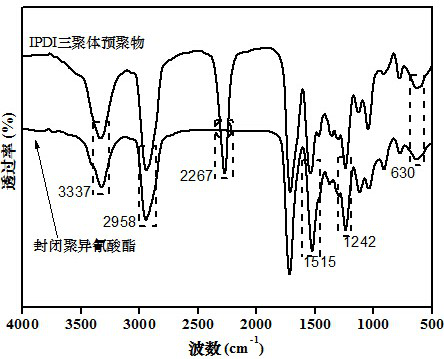

[0060] (2) Preparation of branched polyisocyanate crosslinking agent: control the R value of the prepolymerization reaction to 2.05, dissolve 20.20 g of trihydroxypropa...

Embodiment 2

[0065] The preparation method of the blocked isocyanate that is used to improve the film-forming performance of cathodic electrophoretic coating of the present embodiment comprises the following concrete steps:

[0066] (1) Preparation of isocyanate trimer: Add 100g of 4,4-diphenylmethane diisocyanate into a 500mL four-necked flask equipped with a condensing reflux tube, stirrer, dropping funnel, thermometer, and nitrogen protection device, and add 0.4 g of organic bismuth DY-20 and 44.98g of methyl ethyl ketone were reacted at a constant temperature of 105°C, and the -NCO group content was measured regularly until the -NCO content dropped to a predetermined value. Mixed isocyanates of monomer structure;

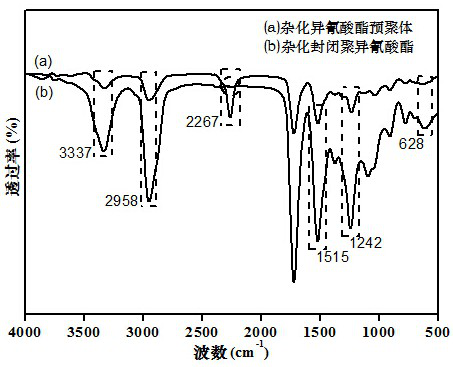

[0067] (2) Preparation of branched polyisocyanate crosslinking agent: control the R value of the prepolymerization reaction to 2.05, dissolve 20.20 g of trihydroxypropane in methyl ethyl ketone, and add it dropwise to the system obtained in step (1) within 1 hour Then heat ...

Embodiment 3

[0072] The preparation method of the blocked isocyanate that is used to improve the film-forming performance of cathodic electrophoretic coating of the present embodiment comprises the following specific steps:

[0073] (1) Preparation of isocyanate trimer: Add 100g of isophorone diisocyanate to a 500mL four-neck flask equipped with a condensing reflux tube, agitator, dropping funnel, thermometer, and nitrogen protection device, and add 0.4g of organic bismuth DY -20 and 44.98g methyl ethyl ketone, 105 ℃ constant temperature stirring reaction, regularly measure -NCO group content, until the -NCO content drops to a predetermined value, the reaction temperature is lowered to room temperature, and the isocyanate trimer and monomer structure are prepared. Mixed isocyanates;

[0074] (2) Preparation of branched polyisocyanate crosslinking agent: control the R value of the prepolymerization reaction to 2.05, dissolve 20.20 g of trihydroxypropane in methyl ethyl ketone, and add it dr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| corrosion potential | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com