Cyclopentene ring-opening copolymer and method for producing same

A manufacturing method and technology of cyclopentene, applied in tire parts, transportation and packaging, special tires, etc., can solve problems such as poor productivity and poor thermal fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0129] Hereinafter, the present invention will be further described based on detailed examples, but the present invention is not limited to these examples. In addition, in the following, "part" is a weight standard unless otherwise indicated. In addition, tests and evaluations were performed as follows.

[0130] [Molecular weight of cyclopentene ring-opened copolymer]

[0131] The weight-average molecular weight (Mw) and the molecular weight distribution (Mw / Mn) were obtained based on a polystyrene-equivalent molecular weight graph by gel permeation chromatography (GPC), and were determined based on the graph. In addition, the specific measurement conditions of the gel permeation chromatography are as follows.

[0132] Measuring device: HLC-8320EcoSCE (manufactured by Tosoh Corporation)

[0133] Column: Two pieces of GMH-HR-H (manufactured by Tosoh Corporation) were connected in series.

[0134] Detector: Differential refractometer RI-8320 (manufactured by Tosoh Corporatio...

preparation example 1

[0150] Preparation of diisobutyl monomethoxide aluminum / toluene solution (2.5% by weight)

[0151] In a nitrogen atmosphere, 61 parts of toluene and 7.8 parts of a 25.4% by weight triisobutylaluminum / n-hexane solution (manufactured by Tosoh Finechem Co., Ltd.) were added to a glass container containing a stirring bar. Next, the container was cooled to -45°C, vigorously stirred, and 0.32 parts (equal molar amount with respect to triisobutylaluminum) of methanol were slowly added dropwise. Thereafter, it was left to stand at room temperature while stirring, and a diisobutylmonomethoxide / toluene solution (2.5% by weight) was prepared.

Synthetic example 1

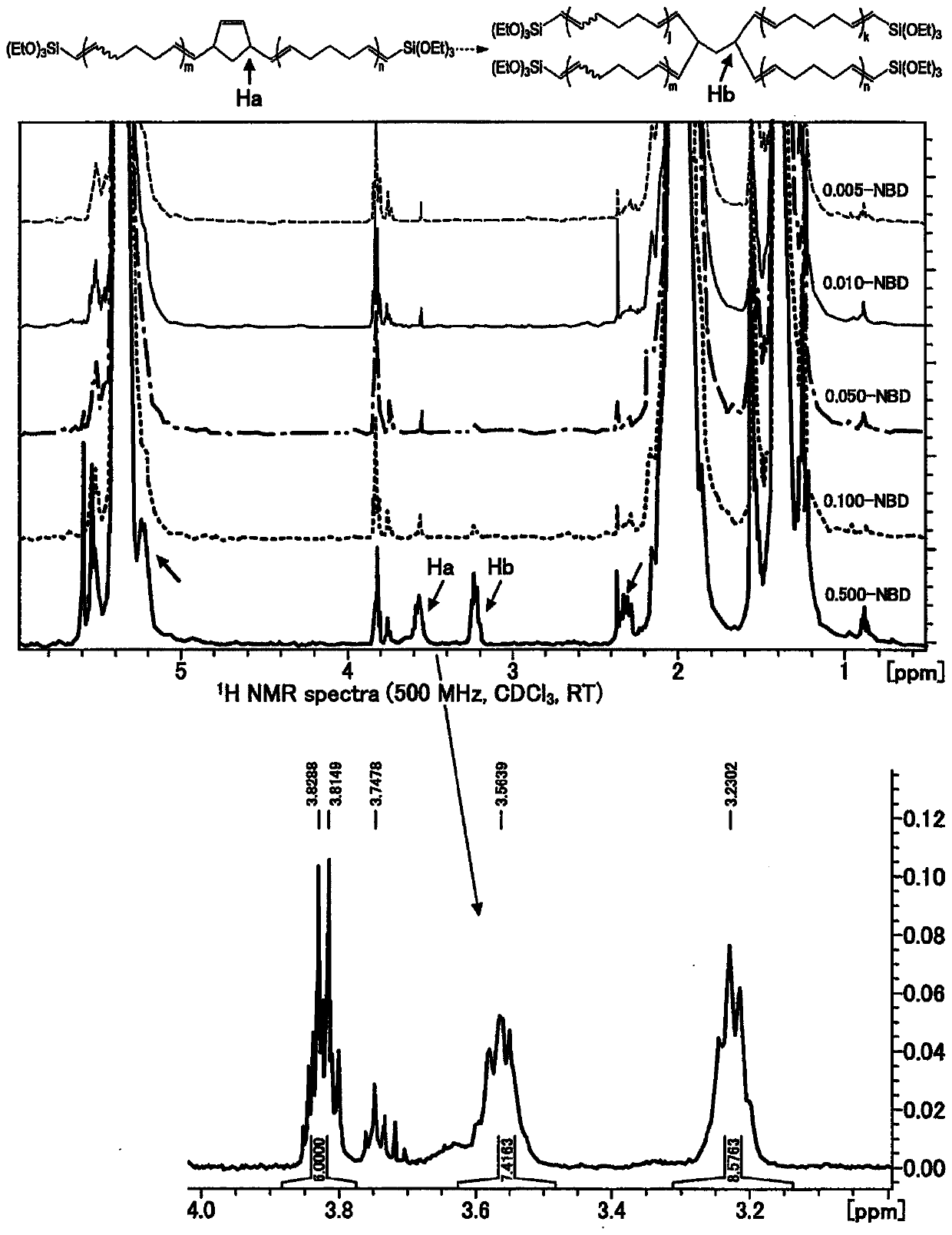

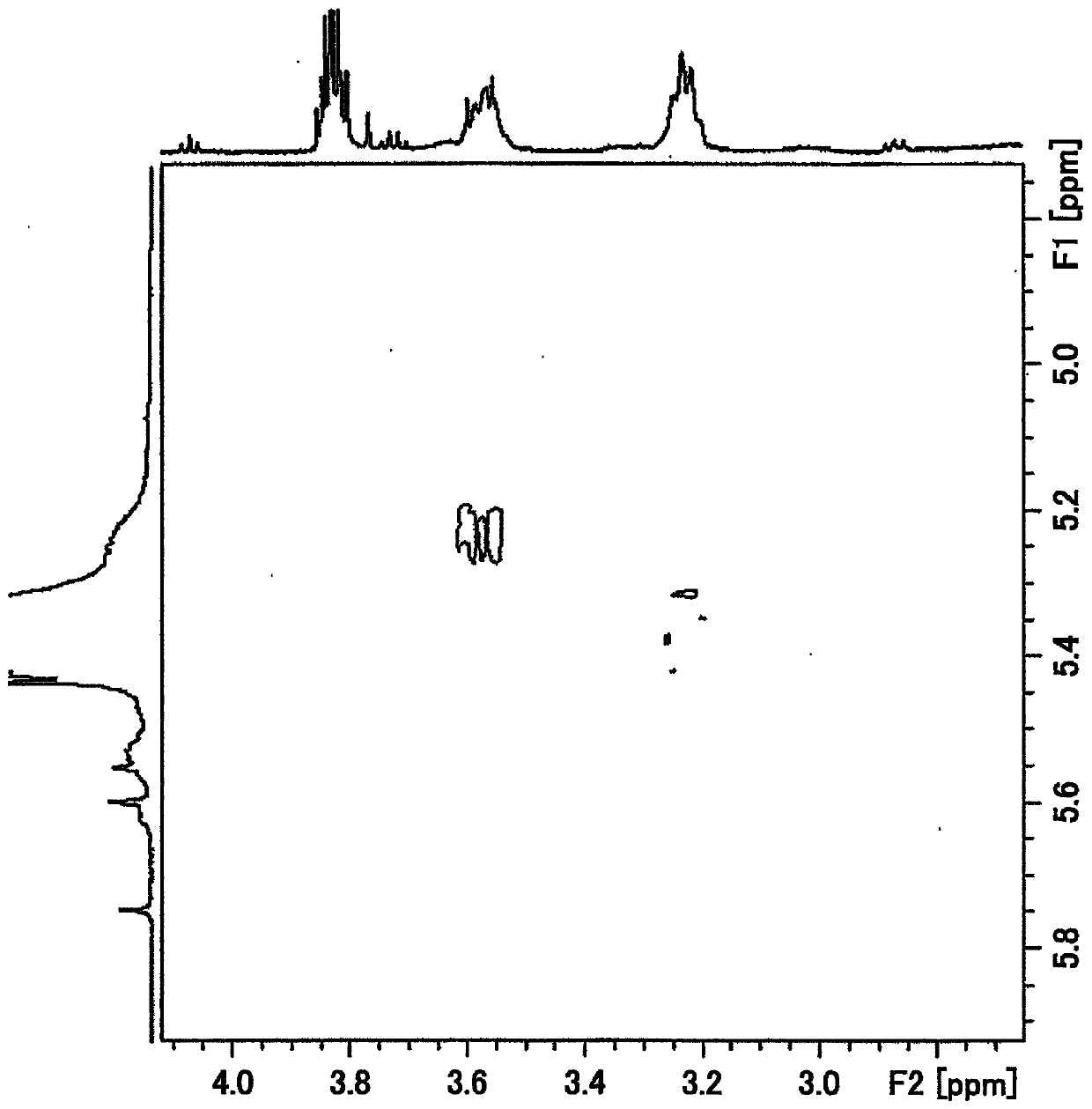

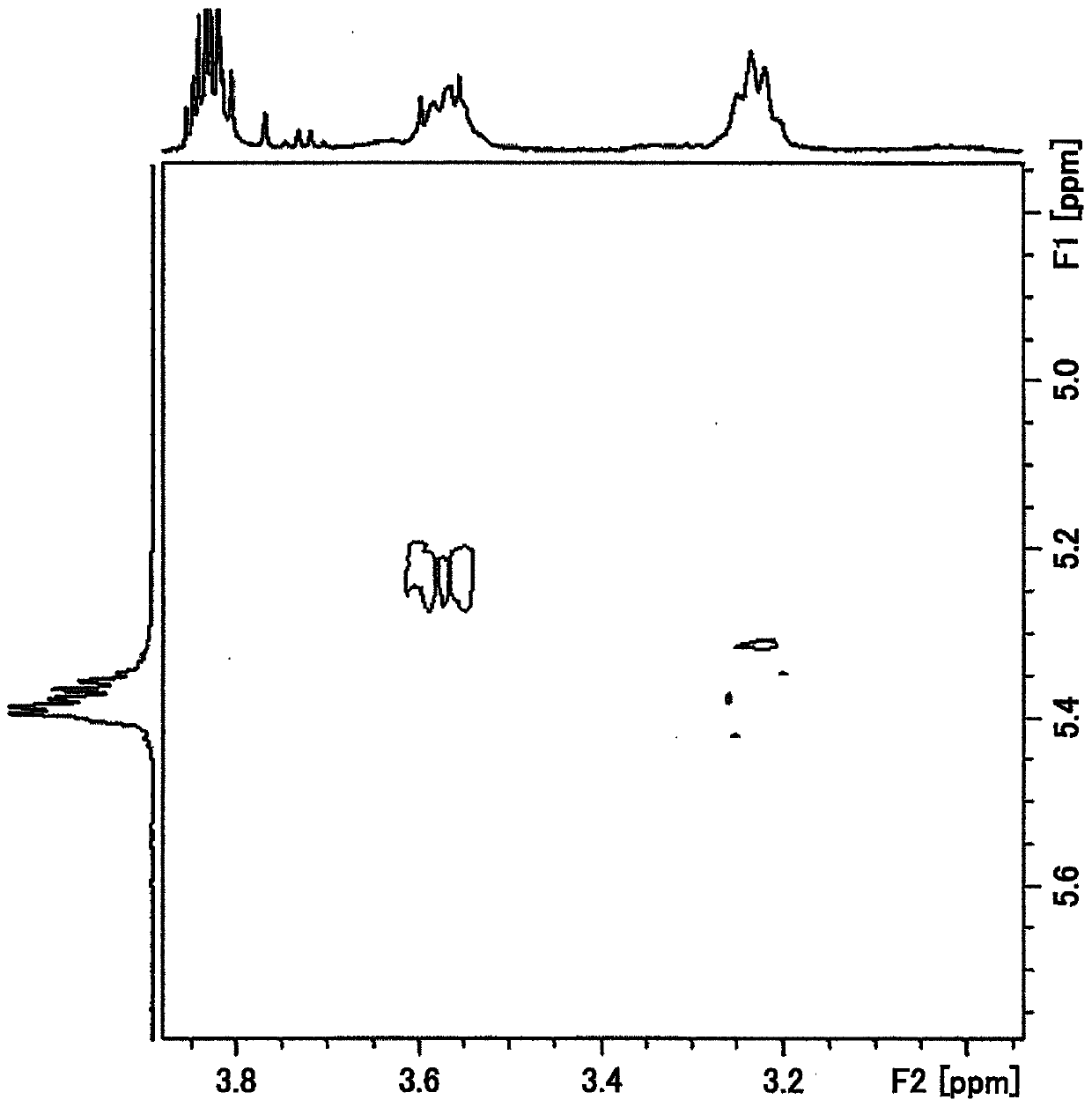

[0153] Under nitrogen, in a pressure-resistant glass reaction vessel with a stirrer, add 500 parts of cyclopentene, 0.34 parts of norbornadiene (NBD), 1.42 parts of 1,2-bis(triethoxysilyl) Ethylene and 10 parts of the 2.5% by weight diisobutylaluminum monomethoxide / toluene solution prepared in Preparation Example 1 were heated to 50°C. To this was added 29 parts of 1.0 wt% WCl 6 / toluene solution, and carry out the polymerization reaction at 50° C. for 4 hours. After 4 hours of polymerization, an excess of ethanol was added to the pressure-resistant glass reaction vessel to terminate the polymerization. After that, the solution in the pressure-resistant glass reaction vessel was injected into extreme excess of ethanol. Next, the precipitated polymer was recovered, washed with ethanol, and vacuum-dried at 40° C. for 3 days to obtain 210 parts of a cyclopentene / norbornadiene ring-opened copolymer. pass 1 H-NMR spectrum measurement and various two-dimensional NMR spectrum mea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com