Natural rubber masterbatch and method for production thereof

A technology of natural rubber latex and natural rubber, which is applied in the direction of transportation and packaging, special tires, tire parts, etc., can solve the problems of high heat generation, deterioration of carbon black dispersion, lack of wear resistance, etc., and achieve improvement Effect of abrasion resistance and low heat generation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

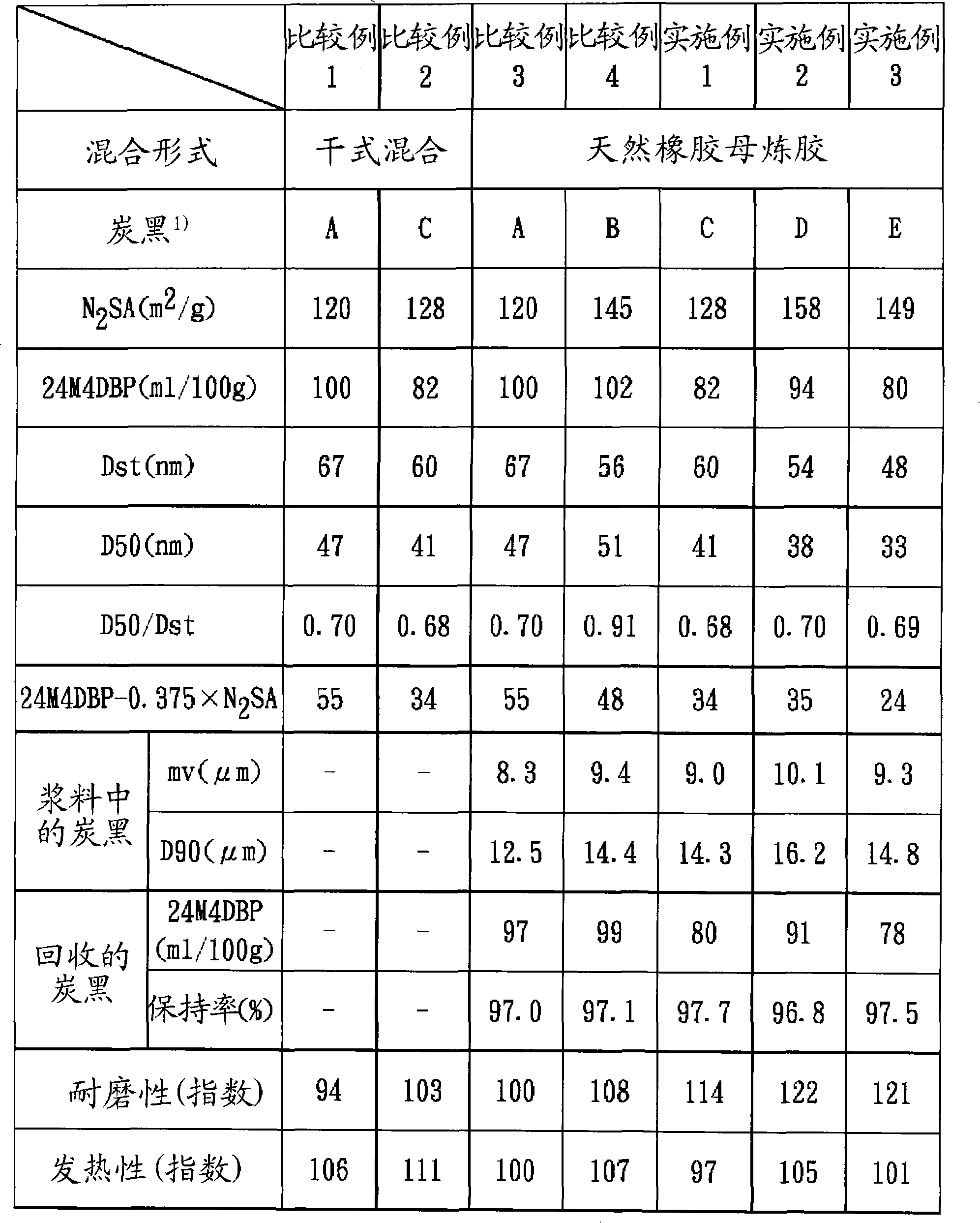

[0069] Hereinafter, the present invention will be described based on examples.

[0070] Various measurements of the respective Examples and Comparative Examples were performed as follows.

[0071] (1) Wear resistance test

[0072] Each test rubber composition was used for a tire tread, and various tires of size 1000R2014PR were manufactured, and the tires were driven for 6000 km in rough road conditions.

[0073] Abrasion resistance index=(running distance / wear amount of the test tire for the test) / (running distance / wear amount of the tire of Comparative Example 3)

[0074] The larger the value, the better the abrasion resistance.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com