A high-conductivity copper alloy containing tellurium-nickel and its preparation method

A copper alloy and high-conductivity technology, applied in the field of high-conductivity copper alloy and its preparation, can solve the problems of high alloy strength and low plasticity, and achieve the effects of high purity, high raw material stability and high strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

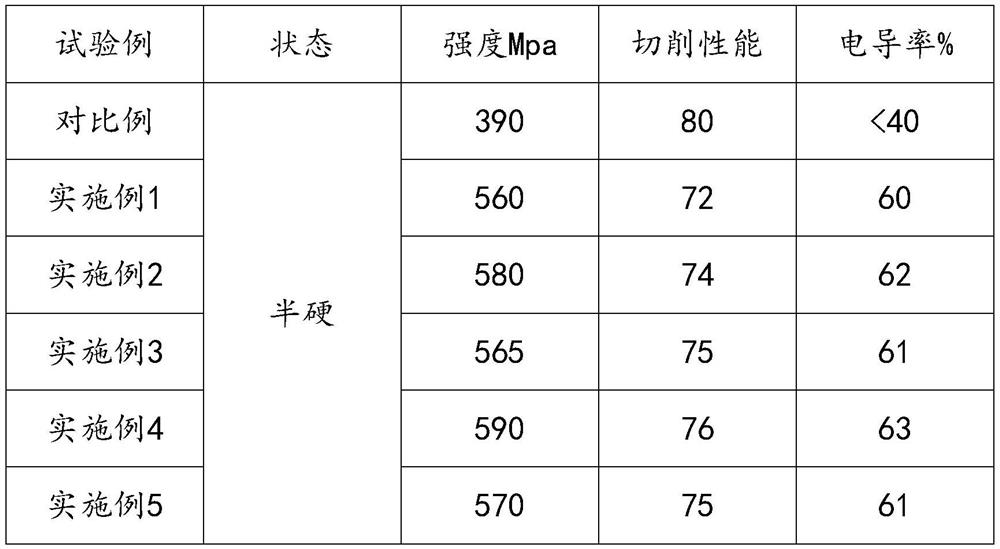

Examples

Embodiment 1

[0043] A preparation method of a tellurium-nickel-containing high-conductivity copper alloy, comprising the following steps:

[0044] S1, according to the composition of the raw material, take by weighing each component according to weight percentage, standby;

[0045] S2, preheating the furnace, adding the weighed pure copper into the furnace and covering the graphite flakes, heating up and melting to a liquid state;

[0046] S3. After all the pure copper is melted, add metallic nickel to the copper liquid, and continue to stir slowly;

[0047] S4. After the metal nickel is completely melted, add phosphorous copper alloy and high-purity iron in turn, and continue to stir slowly, the phosphorus in the phosphorous copper alloy accounts for 0.4% of the weight of the copper solution;

[0048] S5. After the high-purity iron is completely melted by slowly heating up, pure hoof is added, and stirring is continued slowly. After the pure hoof is completely melted, the copper alloy liqu...

Embodiment 2

[0062] A preparation method of a tellurium-nickel-containing high-conductivity copper alloy, comprising the following steps:

[0063] Weigh 97% of copper, 0.7% of tellurium, 2% of nickel, and 0.29% of iron in weight percentages, respectively, and place them for later use; preheat the furnace to 500° C., add the weighed pure copper into the furnace and add its weight. The 1% graphite flakes are evenly covered with the copper layer, and the temperature is raised to 1100°C at a heating rate of 50°C / min. After the pure copper is completely melted into the copper liquid, the weighed metal nickel is added to the copper liquid, and the stirring is continued for 2min. Then, stop stirring and wait until the metal nickel is completely melted, add elemental phosphorus, which accounts for 0.1% of the weight of the copper solution, and add high-purity iron for about 30 minutes, then add high-purity iron, and continue to stir slowly for 2 minutes again; slowly heat up to 1100 ° C, and wait f...

Embodiment 3

[0065] Different from Example 1, the content of each component in this example is calculated as: copper 97.98%; tellurium 0.5%; nickel 1%; iron 0.5%; unavoidable impurities 0.02%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com