Paint composition and method for forming multilayered coating

一种多层涂膜、组合物的技术,应用在涂层、聚醚涂料、环氧树脂涂料等方向,能够解决多层涂膜不足成品外观等问题,达到优异平滑度和鲜映性、提高遮盖、改进热流动性的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

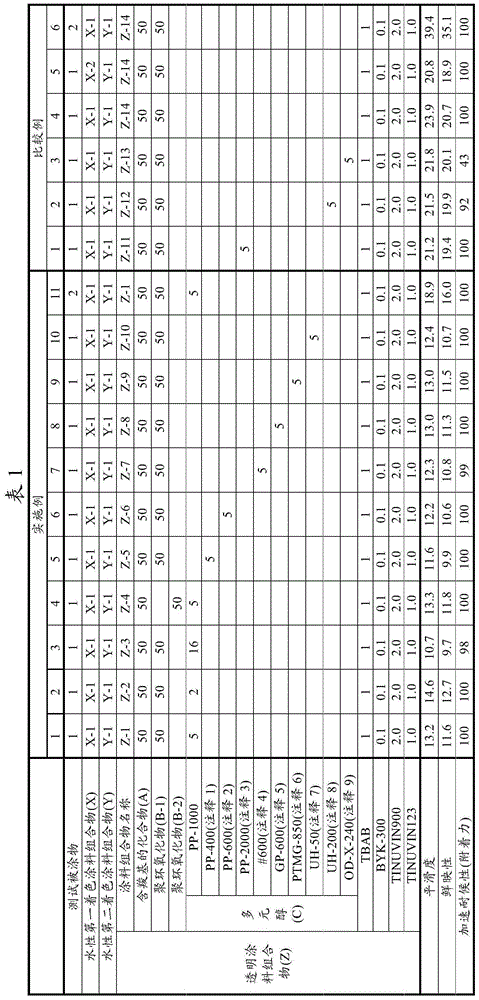

Examples

preparation example 1

[0181] 70.7 parts of deionized water and 0.52 parts of "Aqualon KH-10" (trade name, produced by Dai-ichi Kogyo Seiyaku Co., Ltd., emulsifier, active ingredient: 97%) were placed in a device equipped with a thermometer, a thermostat, Stirrer, reflux condenser, and dropping funnel in a reactor, and mixed by stirring in a nitrogen stream, and the mixture was heated to 80°C. Subsequently, 1% of the total amount of the monomer emulsion described below and 5 parts of a 6% ammonium persulfate aqueous solution were introduced into the reactor, and maintained at 80° C. for 15 minutes. The remaining monomer emulsion was then added dropwise to the reactor over 3 hours while maintaining the temperature of the reactor. After the dropwise addition was completed, the mixture was aged for 1 hour. Then, while gradually adding 40 parts of 5% 2-(dimethylamino)ethanol aqueous solution to the reactor, the mixture was cooled to 30° C., and filtered through 100-mesh nylon cloth to obtain 45% solid ...

preparation example 2

[0184] 130 parts of deionized water and 0.52 parts of "Aqualon KH-10" were placed in a reactor equipped with a thermometer, thermostat, stirrer, reflux condenser, and dropping funnel, and mixed by stirring in a nitrogen stream, and The mixture was heated to 80°C. Subsequently, 1% of the total amount of the monomer emulsion (1) described below and 5.3 parts of a 6% ammonium persulfate aqueous solution were introduced into the reactor, and maintained at 80° C. for 15 minutes. The remaining monomer emulsion (1) was then added dropwise to the reactor over 3 hours while maintaining the temperature of the reactor. After the dropwise addition was completed, the mixture was aged for 1 hour. Then the monomer emulsion (2) described below was added dropwise over 1 hour, and the mixture was aged for 1 hour, after which, while 40 parts of 5% dimethylethanolamine aqueous solution was gradually added to the reactor, the mixture was cooled to 30° C., and filtered through 100-mesh nylon clot...

preparation example 3

[0189] Put 174 parts of trimethylolpropane, 327 parts of neopentyl glycol, 352 parts of adipic acid, 109 parts of isophthalic acid and 101 parts of 1,2-cyclohexanedicarboxylic anhydride into a device equipped with a thermometer, a thermostat, Stirrer, reflux condenser and water separator in the reactor, and the mixture was heated from 160°C to 230°C over 3 hours. The obtained condensation water was distilled off by a water separator, and the reaction was performed while maintaining the temperature at 230° C. until an acid value of 3 mg KOH / g or less was obtained. 59 parts of trimellitic anhydride was added to the reaction product, and an addition reaction was performed at 170° C. for 30 minutes. The resulting product was then cooled to below 50°C and neutralized according to the acid groups by an equal amount of 2-(dimethylamino)ethanol. Subsequently, deionized water was gradually added to obtain a hydroxyl-containing polyester resin solution (I-2-1) having a solid concentrat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com