Aluminum-plastic membrane used for packaging lithium battery

An aluminum-plastic film and lithium battery technology, which is applied in the field of packaging aluminum-plastic film, can solve the problems of poor bonding layer toughness and heat-sealing bonding strength, and achieve the effect of high chemical resistance, packaging adhesion and explosion-proof effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

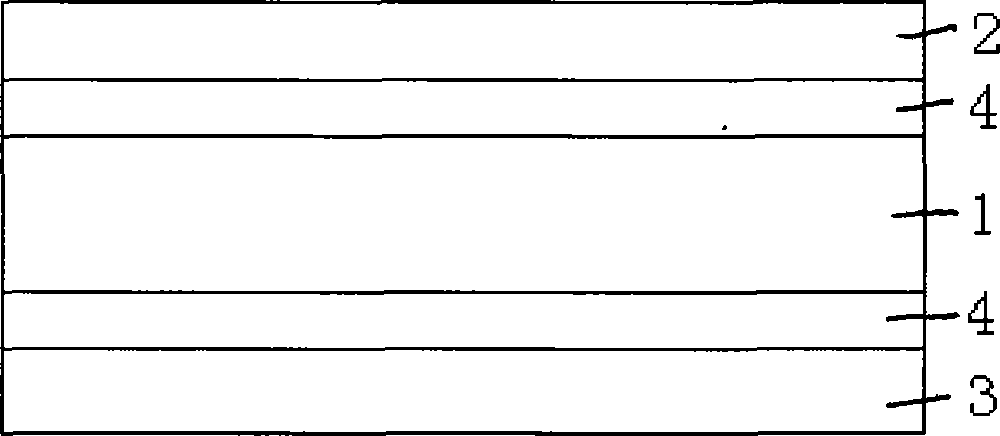

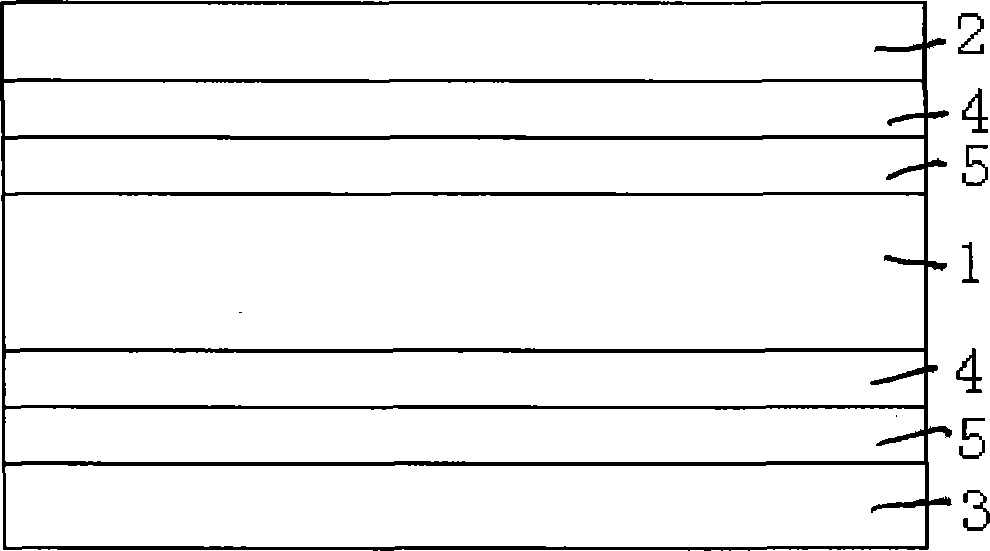

[0032] Using a 40 μm thick high-toughness aluminum foil 1, the surface of the aluminum foil is grafted with a plasma gas with a volume ratio of oxygen and nitrogen of 4:6, and then a thermosetting adhesive is applied to the treated surface of the aluminum foil. On the surface, bake at 40-100°C for 1-5 minutes to make a thermosetting adhesive layer 4 with a thickness of 3-10 μm, and then perform surface grafting treatment with plasma gas with argon and nitrogen volume ratio of 3:7 to achieve high wear resistance. The tough polyamide film is compound coated on the treated surface of the aluminum foil with a temperature of 40-100°C and a pressure of 0.2-1kgf to form an outer protective layer 2; then the aluminum foil is treated with a plasma gas with a volume ratio of oxygen and nitrogen of 4:6 the other surface, and apply a thermosetting adhesive on the other treated surface of the aluminum foil, and bake at 40-100°C for 1-5 minutes to form another thermosetting adhesive layer 4 ...

Embodiment 2

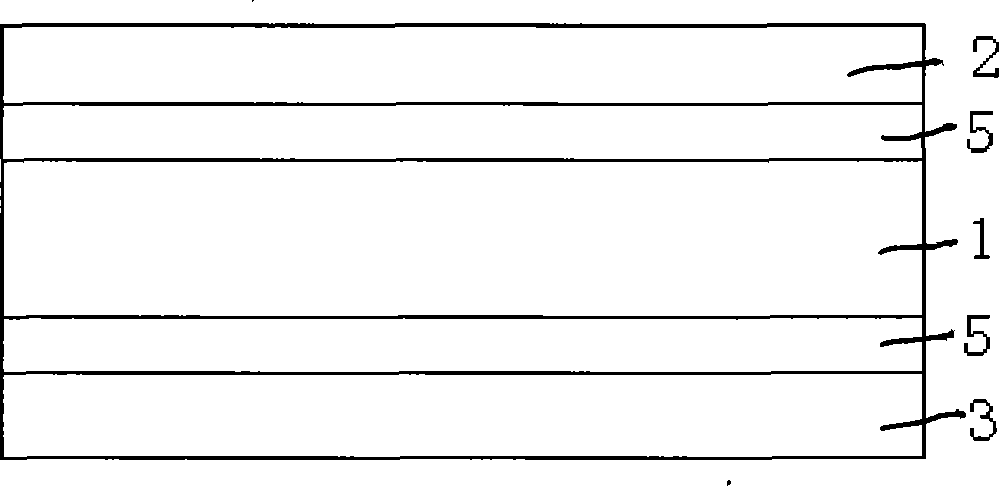

[0034] Adopt the high tenacity aluminum foil 1 of 40 μ m thickness, be that the volume ratio of oxygen and nitrogen is 4: 6 plasma gas carries out surface grafting to one surface of aluminum foil; The plasma gas with a nitrogen volume ratio of 3:7 is used for surface grafting treatment. Blend low-density polyethylene and ethylene-vinyl acetate copolymer at a mass fraction of 1:1 and extrude a coating film 10-20 μm thick on the treated surface of the aluminum foil to form a thermoplastic buffer adhesive layer 5, and then treat the polyamide film One surface of the aluminum foil is attached to the extruded film, and the protective layer 2 is compounded at a temperature of 100-160°C and a pressure of 0.5-1.5kgf; then the other surface of the aluminum foil is treated with a plasma gas with a volume ratio of oxygen and nitrogen of 4:6, and the Low-density polyethylene and ethylene-vinyl acetate copolymer are blended and extruded with a mass fraction of 1:1 to form a coating film 10...

Embodiment 3

[0036] A 25 μm thick polyamide film with high wear resistance and toughness is used as the protective layer 2, and the surface of the film is grafted with a plasma gas with a volume ratio of argon and nitrogen of 3:7, and then the thermosetting adhesive is coated. Apply it on the treated surface of the polyamide film, and bake it at 40-100°C for 1-5min to form a thermosetting adhesive layer 4 with a thickness of 3-10μm; use a 50μm-thick unsaturated anhydride-modified polypropylene film as the thermal Sealing layer 3, the surface of the polypropylene film is grafted with a plasma gas with a volume ratio of argon and nitrogen of 3:7, and then a thermosetting adhesive is applied to the treated surface of the polypropylene film , bake at 40-100°C for 1-5min to make another thermosetting adhesive layer 4 with a thickness of 3-10μm; use a high-toughness aluminum foil 1 with a thickness of 40μm, and use a plasma gas with a volume ratio of oxygen and nitrogen of 4:6 to The two surface...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com