Composite phase change material, application method and battery of the composite phase change material

A composite phase-change material and phase-change material technology, applied in the direction of secondary batteries, heat exchange materials, chemical instruments and methods, etc., can solve problems affecting battery performance and safety, overall battery temperature rise, and mobile terminal performance degradation, etc. , to achieve the effect of reducing preparation cost, shortening speed and improving heat dissipation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0056] The present application also provides a method for preparing the above-mentioned composite phase change material, which comprises the following steps:

[0057] The phase change material and the adhesive are uniformly mixed under the condition of 80° C. to 120° C. according to a certain weight portion.

[0058] Specifically, in this embodiment, the phase change material and the binder may be mixed in certain parts by weight at a temperature of 80° C. to 120° C. for 30 minutes to 50 minutes through an open mill until they are evenly mixed.

[0059] The homogeneously mixed phase change material and the binder are extruded from an extruder at a temperature of 80° C. to 120° C. to form the composite phase change material. Wherein, the extruder is a twin-screw extruder.

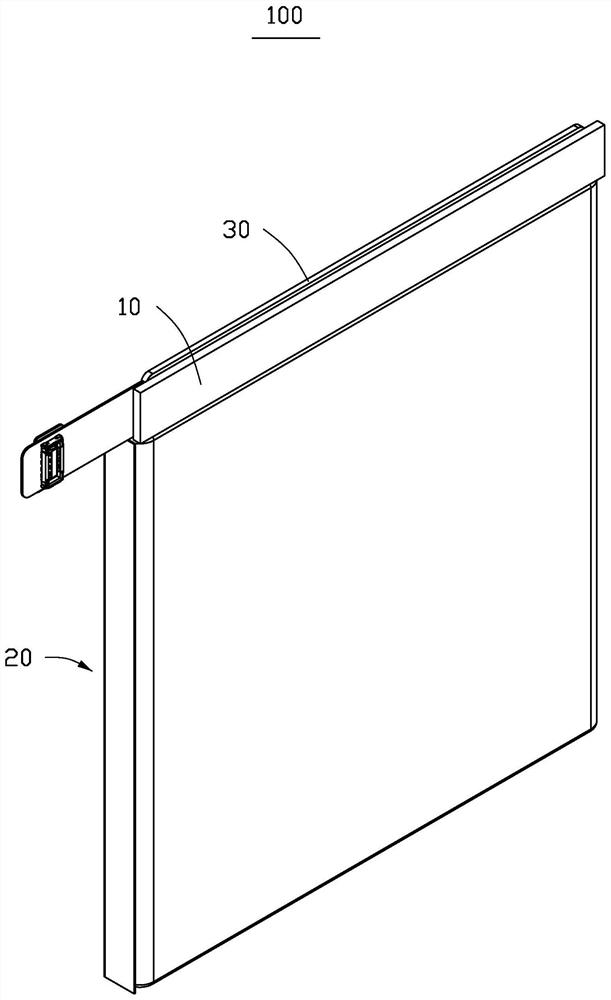

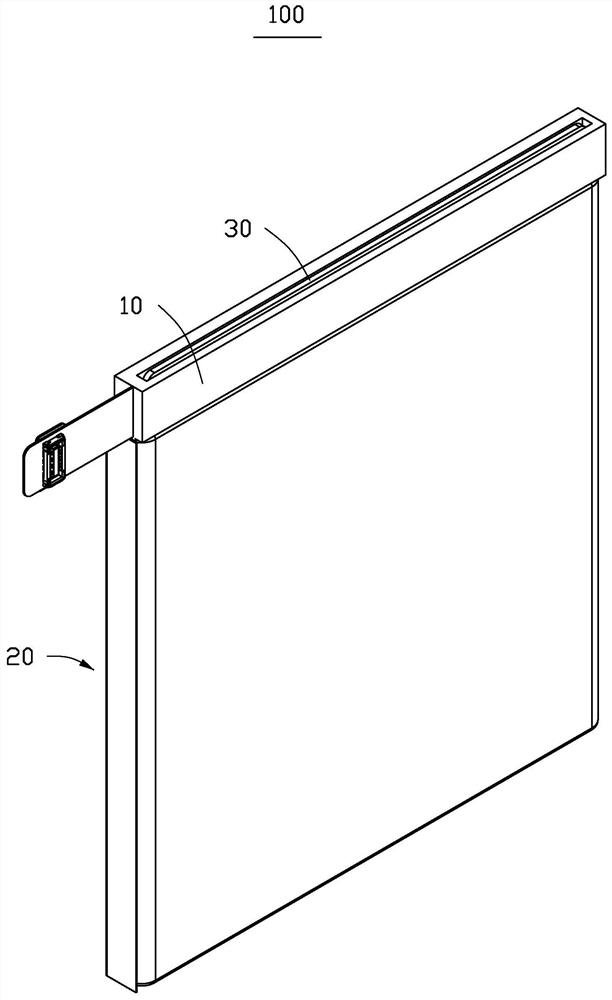

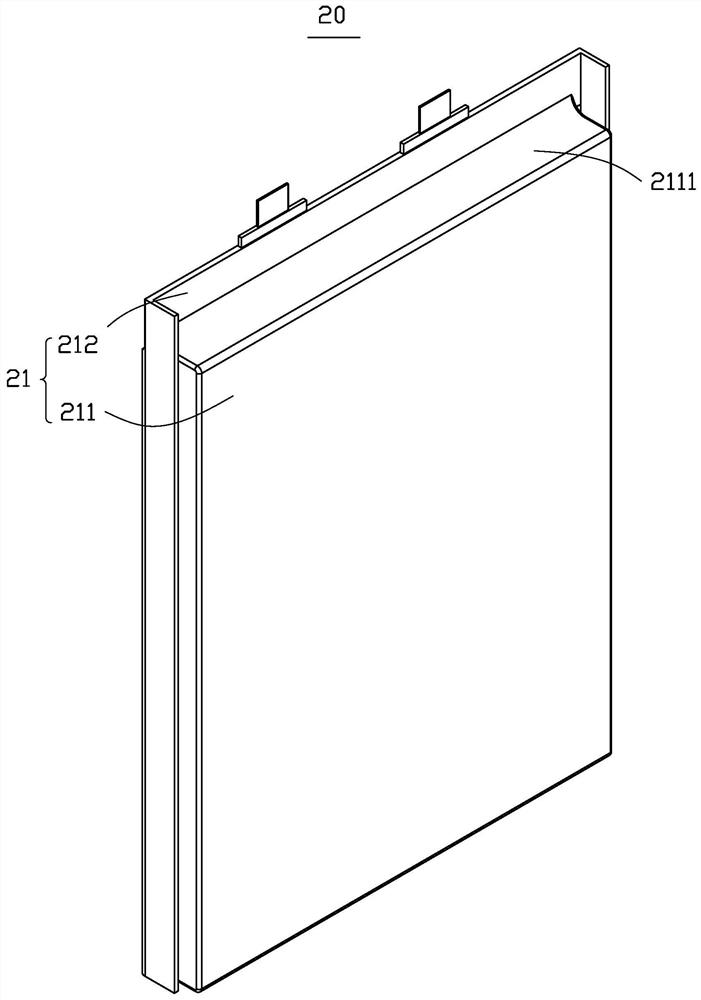

[0060] In some embodiments, the composite phase change material may be in the form of a sheet. At this time, the preparation method of the composite phase change material further includes the step of: comp...

Embodiment 1

[0077] A composite phase change material comprises 70 parts of phase change material and 30 parts of adhesive in parts by weight.

[0078] In Example 1, the above composite phase change material can be prepared by the following method.

[0079] Preparation of phase change materials: heat-melt unmodified paraffin, then add long-chain alkylamine, silane coupling agent and surfactant to the unmodified paraffin after heat-melting, mix them in water bath or oil bath Keep warm for 2 hours. Wherein, the weight of the long-chain alkylamine that adds is 8% of the weight of unmodified paraffin wax, the weight of the silane coupling agent that adds is 0.5% of the weight of unmodified paraffin wax, the weight of the surfactant that adds 0.3% by weight of unmodified paraffin. The long-chain alkylamine is n-dodecylamine, the silane coupling agent is vinyltrimethoxysilane, and the surfactant is palmitic acid. Then successively add the polyphenol oxygen resin and Clariant PEG-6000 (molecul...

Embodiment 2

[0083] A composite phase-change material comprises 75 parts of phase-change material and 25 parts of adhesive in parts by weight.

[0084]In Example 2, the above composite phase change material can be prepared by the following method.

[0085] Preparation of phase change materials: heat-melt unmodified paraffin, then add long-chain alkylamine, silane coupling agent and surfactant to the unmodified paraffin after heat-melting, mix them in water bath or oil bath Keep warm for 2 hours. Wherein, the weight of the long-chain alkylamine that adds is 27% of the weight of unmodified paraffin wax, the weight of the silane coupling agent that adds is 0.5% of the weight of unmodified paraffin wax, the weight of the surfactant that adds 0.3% by weight of unmodified paraffin. The long-chain alkylamine is n-hexadecylamine, the silane coupling agent is propyltrimethoxysilane, and the surfactant is hexamethylene glycol monohexadecyl ether. Then add the polyphenol oxygen resin and Clariant ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com