Method for preparing high-purity superfine zirconium boride powder by high-frequency plasma

A high-frequency plasma and plasma technology is applied in the field of preparing high-purity ultrafine zirconium boride powder, which can solve the problems of low activity, low cost of raw materials, and high process cost, and achieve good particle dispersibility, strong adaptability of raw materials, and high preparation technology. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

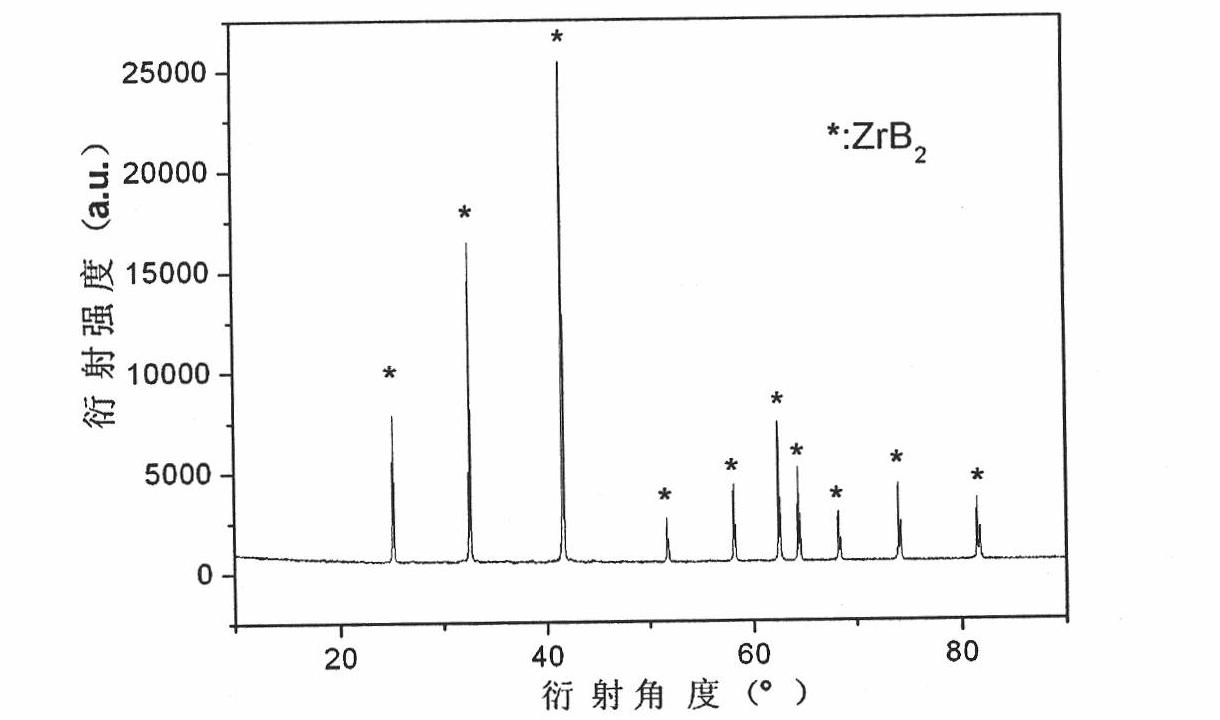

[0035] Using boron trichloride and zirconium tetrachloride as raw materials, superfine zirconium boride powder is prepared by high-frequency plasma hydrogenation synthesis. The chemical reaction is shown in the following formula.

[0036] 2BCl 3 +ZrCl 4 +5H 2 →ZrB 2 +10HCl

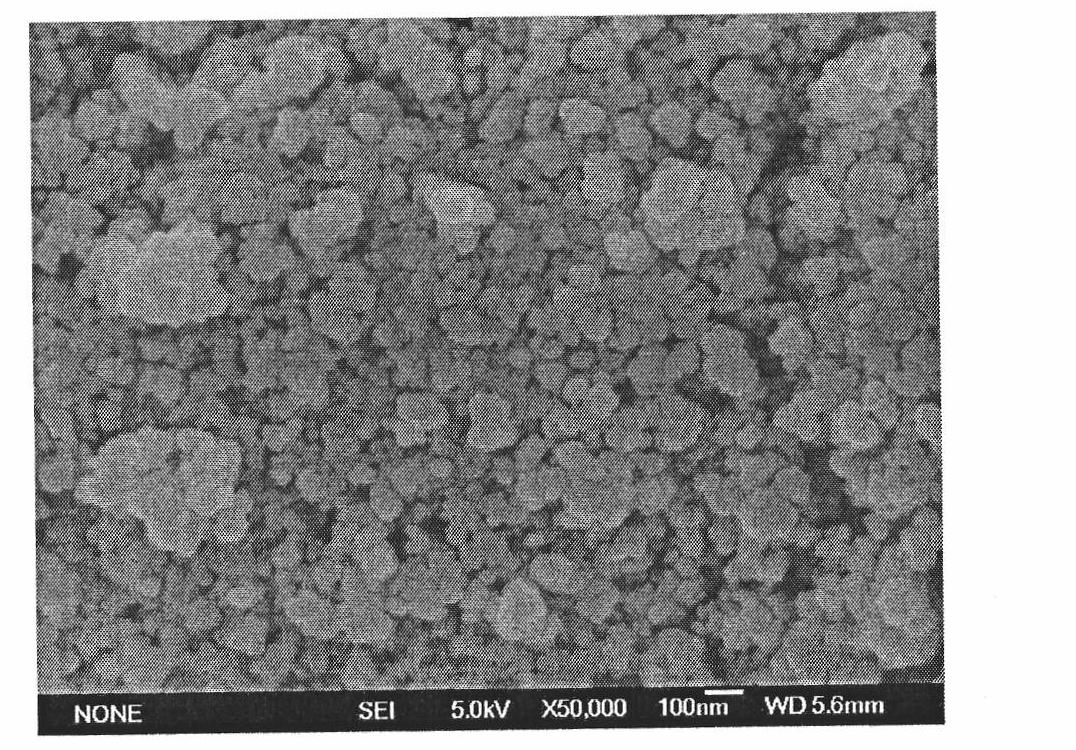

[0037] With hydrogen as the carrier gas, gaseous boron trichloride and gaseous zirconium tetrachloride are added into the plasma reactor, wherein the ratio of boron trichloride and zirconium tetrachloride is added in a ratio of 2:1 according to the ratio of the amount of substances . During the experiment, the vacuum degree in the system was maintained at 200Pa. The tail gas is discharged after being absorbed by sodium hydroxide solution. The synthesized product is washed and dried to obtain superfine zirconium boride with a particle size of 30-60nm.

Embodiment 2

[0039] Using boric acid and zirconia as raw materials, superfine zirconium boride powder is prepared by high-frequency plasma hydrogenation synthesis. The chemical reaction is shown in the following formula.

[0040] 2H 3 BO 3 +ZrO 2 +5H 2 →ZrB 2 +8H 2 o

[0041] Using hydrogen as a carrier gas, boric acid and zirconia are added into the plasma reactor, wherein the proportion of boric acid and zirconia is added in a ratio of 2:1 according to the ratio of the amount of substances. During the experiment, a cooling gas was introduced at the tail flame of the plasma arc to maintain a vacuum of 1kPa in the system. The synthesized product is washed and dried to obtain superfine zirconium boride with a particle size of 10-40nm.

Embodiment 3

[0043] Using diboron trioxide and zirconium dioxide as raw materials, superfine zirconium boride powder is prepared by high-frequency plasma hydrogenation synthesis. The chemical reaction is shown in the following formula.

[0044] B 2 o 3 +ZrO 2 +5H 2 →ZrB 2 +5H 2 o

[0045] Firstly, boron trioxide and zirconium dioxide are ball-milled and mixed at a ratio of 1:1, and a mixed gas of hydrogen and argon is used as a carrier gas, and solid raw materials are added to the plasma arc region. The reactor wall is provided with an insulation device. The synthesized product is washed and dried to obtain superfine zirconium boride with a particle size of 50-100nm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com