Preparation method of graphene foams

A graphene foam and graphene technology, applied in the field of electrochemical energy storage devices, can solve problems such as large energy consumption and difficult mass production, and achieve the effects of easy operation and simple equipment requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

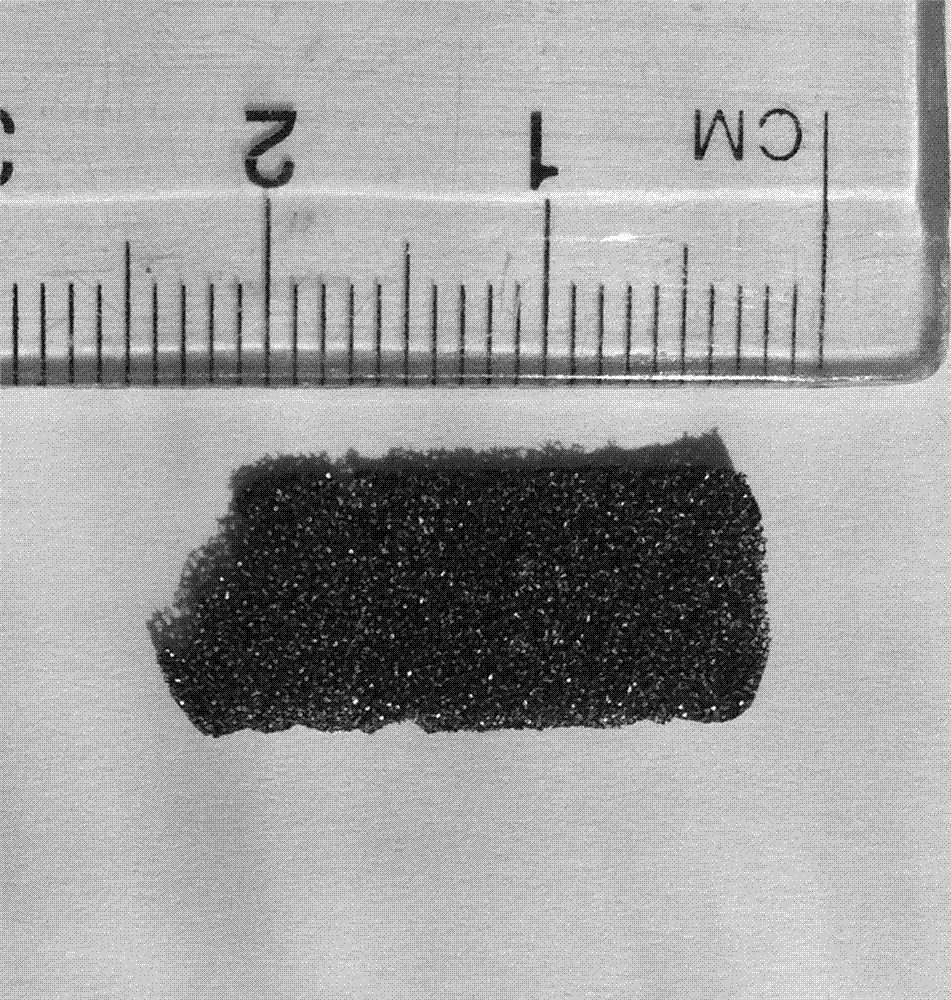

Image

Examples

Embodiment 1

[0023] (1) Plasma treatment is carried out to nickel foam, and soaked in 6.0 mg / ml graphene oxide solution;

[0024] (2) In the ascorbic acid solution containing 10.0 mg / ml, the graphene oxide coated on the nickel foam is reduced, the reduction temperature is 60 ° C, and the time is 12 hours;

[0025] (3) Place the nickel foam coated with graphene in an aqueous solution containing 6 M hydrochloric acid, take it out after 6 hours, and wash it repeatedly with absolute ethanol and water to obtain a graphene foam.

Embodiment 2

[0027] (1) Plasma treatment is carried out to nickel foam, and soaked in 8.0 mg / ml graphene oxide solution;

[0028] (2) in hydroiodic acid, the graphene oxide coated on the nickel foam is reduced, and the time is 30 minutes;

[0029] (3) Place the nickel foam coated with graphene in an aqueous solution containing 0.5 M ferric nitrate at 80°C, take it out after 20 hours, and wash it repeatedly with absolute ethanol and water to obtain a graphene foam.

Embodiment 3

[0031] (1) Plasma treatment is carried out to nickel foam, and soaked in 10.0 mg / ml graphene oxide solution;

[0032] (2) The graphene oxide coated on the nickel foam is reduced in a hydrazine hydrate solution, the reduction temperature is 95° C., and the time is 1 hour;

[0033] (3) Place the nickel foam coated with graphene in an aqueous solution containing 3 M hydrochloric acid at 80°C, take it out after 6 hours, and wash it repeatedly with absolute ethanol and water to obtain a graphene foam.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com