Surface modification method for polytetrafluoroethylene separation membrane

A polytetrafluoroethylene, surface modification technology, applied in the direction of semi-permeable membrane separation, chemical instruments and methods, membrane technology, etc., can solve the problems of poor hydrophilicity of PTFE separation membrane, complex modification process, etc., to achieve pore size and surface properties Continuous, easy mass production, and the effect of improving anti-pollution ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

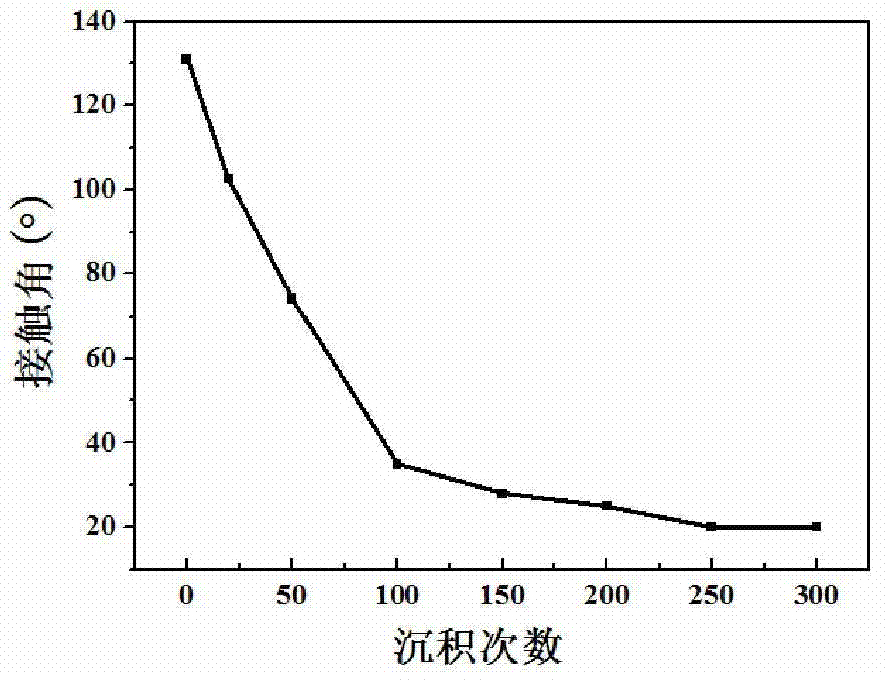

[0025] Example 1: First, put the PTFE separation membrane into the plasma chamber, vacuumize, adjust the plasma power to 22W, and treat the front and back sides for 5 minutes. Titanium isopropoxide (TIP) was used as the first precursor, deionized water (H 2 O) is the second precursor, high-purity nitrogen (N 2 ) as carrier and sweep gas. The pulse time of the two precursors was 0.2s and 0.015s respectively, the exposure time of the precursor was 5s, and the cleaning time was 20s. Heat the temperature of the reaction chamber to 150°C, keep the membrane at the set temperature of the reaction chamber for 2 minutes, and prepare modified membranes with 20, 50, 100, 150, 200, 250, and 300 cycles respectively.

[0026] Table 1 shows the composition of surface elements before and after plasma treatment of PTFE membrane. (measured by XPS)

[0027]

[0028] It can be seen from Table 1 that after the plasma treatment of the PTFE membrane, 1.06 (at.%) of oxygen and 0.31 (at.%) of n...

Embodiment 2

[0033] Example 2: First, put the PTFE separation membrane into the plasma chamber, vacuumize, adjust the plasma power to 10W, and treat the front and back sides for 10 minutes. The first precursor of trimethylaluminum (TMA), deionized water (H 2 O) is the second precursor, and argon (Ar) is used as the carrier gas and sweep gas. The pulse times of the two precursors were 0.015s and 0.5s, respectively, the exposure times of the precursors were 10s and 50s, and the cleaning times were 30s and 60s, respectively. Heat the temperature of the reaction chamber to 70°C, keep the membrane at the set temperature of the reaction chamber for 5 minutes, and prepare modified membranes with 20, 50, 80, and 100 cycles respectively.

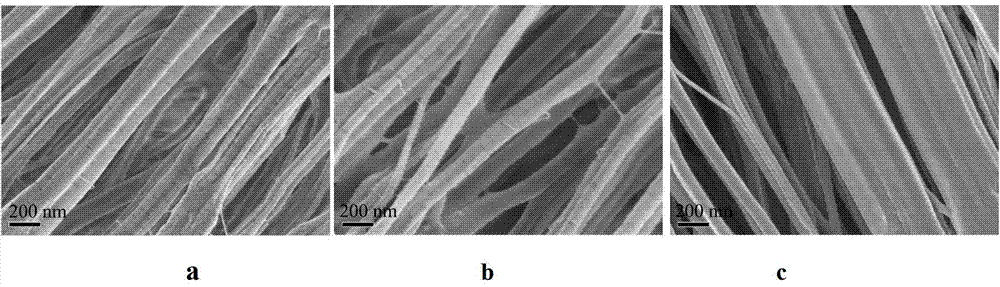

[0034] The surface-modified membrane in this example was observed and analyzed by scanning electron microscope. The membrane pore size decreased with the increase of deposition times, and the hydrophilic angle changed from the original 131° to 70±4°, 35±5°, 15±...

Embodiment 3

[0035] Example 3: First, put the PTFE separation membrane into the plasma chamber, vacuumize, adjust the plasma power to 300W, and treat the front and back sides for 1 minute. Titanium tetrachloride (TiCl 4 ) as the first precursor, ozone (O 3 ) is the second precursor, and argon (Ar) is used as the carrier gas and sweep gas. The pulse time of the two precursors was 0.015 s and 1 s, the exposure time of the precursor was 0 s, and the cleaning time was 10 s and 5 s, respectively. Heat the temperature of the reaction chamber to 200° C., keep the membrane at the set temperature of the reaction chamber for 1 min, and prepare a modified membrane with 500 cycles.

[0036] The static water contact angle of the modified membrane was characterized as 28±5°, the flux of pure water increased by 19%, and the rejection rate of silica microspheres increased by 64%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com