Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

45results about How to "Adjust surface properties" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Surface modification method for polytetrafluoroethylene separation membrane

ActiveCN102773026AImprove performanceHigh retention rateSemi-permeable membranesThin oxidePlasma technology

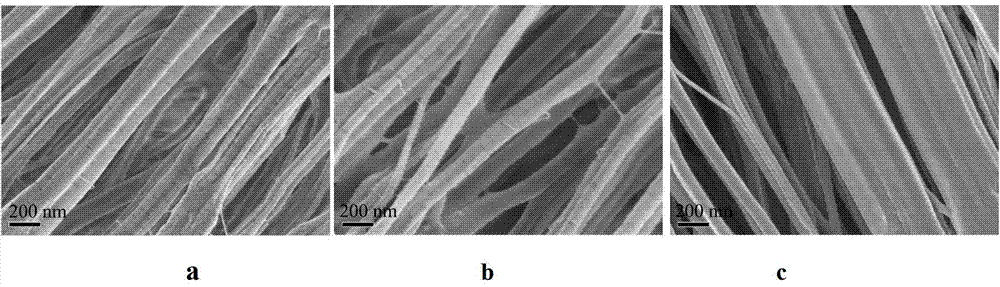

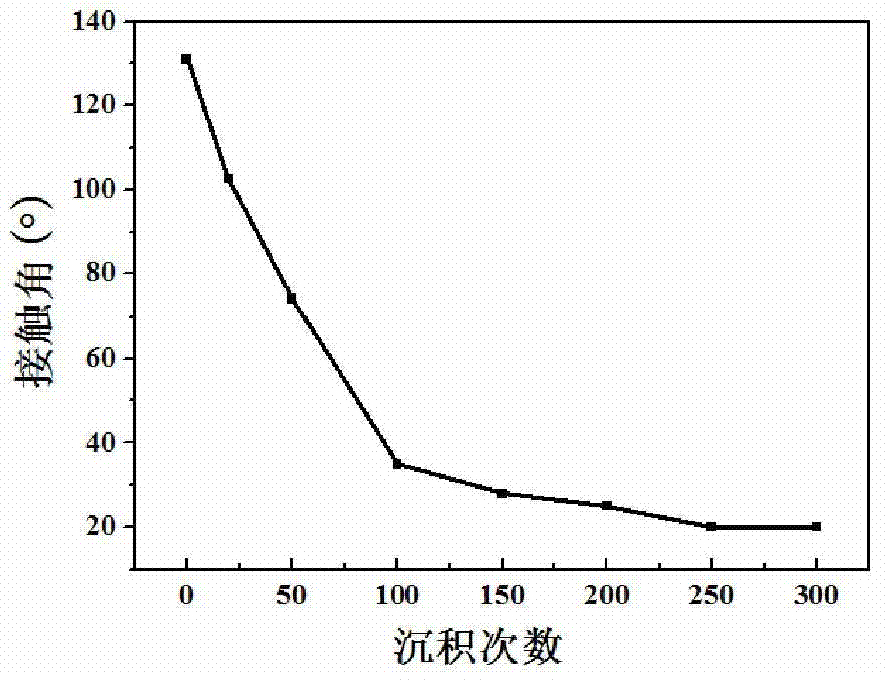

The invention relates to a surface modification method for a polytetrafluoroethylene separation membrane. The method comprises the following steps of: activating the surface of the PTFE (polytetrafluoroethylene) membrane by virtue of a plasma technology, and then continuously depositing thin oxide layers on the surfaces of pore channels of the separation membrane by virtue of an atomic layer deposition technology to realize precise adjustment and control on pore diameter and surface properties of the separation membrane. According to the method, the plasma technology is used for pretreating, and then the atomic layer deposition is carried out, so that the growth mechanism of a deposition layer on the surface of the PTFE membrane is changed, the island type growthof the deposition layer is changed to conformal growth, the deposition layer is uniform and smooth, and the hydrophily, the pure water flux, the separating property and the anti-pollution capacity of the separation membrane are all obviously improved.

Owner:NANJING UNIV OF TECH

Method for preparing carbon-contained catalyst carrier

ActiveCN101722051AAdjust surface propertiesEasy to useCatalyst carriersMetal/metal-oxides/metal-hydroxide catalystsRefractoryFree carrier

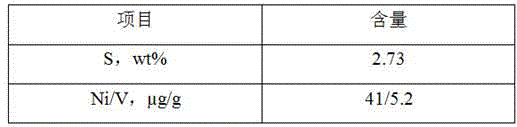

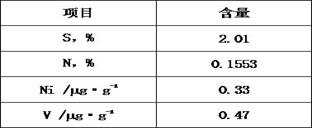

The invention discloses a method for preparing a carbon-contained catalyst carrier, which comprises the following steps of: preparing a carbon-free porous inorganic refractory oxide carrier; soaking a precursor of carbon on the carbon-free inorganic refractory oxide carrier; introducing a metal auxiliary agent when preparing the carbon-free carrier and / or soaking the precursor of the carbon; then carrying out heat treatment on the porous inorganic refractory oxide carrier loaded with the precursor of the carbon and the metal auxiliary agent; decomposing the precursor of the carbon into carbon to obtain the carbon-contained catalyst carrier. In the preparation process of the catalyst carrier, by the promoting function of a few of metal auxiliary agents, the precursor of the carbon is decomposed, and the strict processing condition is prevented; the surface of the catalyst carrier is covered, the surface property of the catalyst carrier is adjusted, and the aim of improving the use performance of catalyst is achieved. Compared with a method for adding the precursor of the carbon in the molding process of the carrier, the method has the advantages of carrier strength improvement and utilization ratio improvement of carbon in the carrier, and greatly improves the hydrogenation processing activity of heavy mass distillate oil.

Owner:CHINA PETROLEUM & CHEM CORP +1

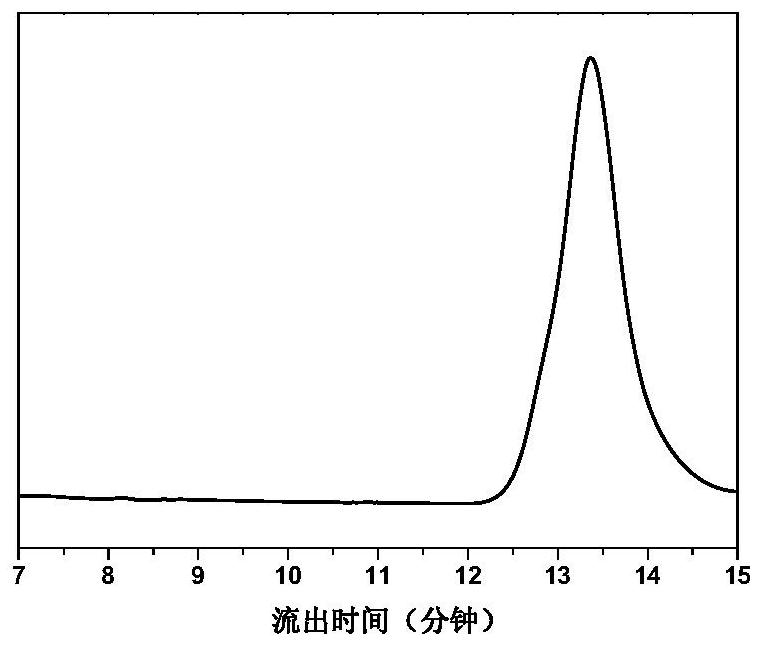

Method for preparing heavy oil hydrotreating catalyst

ActiveCN106140182AHigh catalytic activityIncrease contentMetal/metal-oxides/metal-hydroxide catalystsRefining to eliminate hetero atomsActive componentHydrodesulfurization

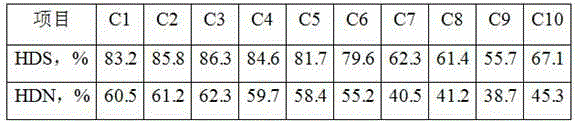

The invention discloses a method for preparing a heavy oil hydrotreating catalyst. The method comprises the following steps: (1) a physical pore expanding agent I is impregnated with a hydrogenation active component impregnation solution I and a titanium-containing solution I respectively, a physical pore expanding agent II is impregnated with a hydrogenation active component impregnation solution II and a titanium-containing solution II respectively, and the impregnated physical pore expanding agent I and physical pore expanding agent II are dried for standby application; (2) the physical pore expanding agent I and the physical pore expanding agent II obtained in the step (1) are mixed with pseudo boehmite dried gel powder, a chemical pore expanding agent, an extruding promotor and a peptizing agent, the mixture is kneaded into a plastomer, extruding, drying and roasting are performed, and a modified alumina carrier is prepared; (3) the modified alumina carrier obtained in the step (2) is impregnated with a hydrogenation active component impregnation solution III and is dried and roasted, and the heavy oil hydrotreating catalyst is prepared. The catalyst prepared with the method has higher content of active metal in large pores and smaller content of active metal in small pores, multiple active components are distributed at the large pores, the utilization ratio of the large pores is increased remarkably, and the heavy oil hydrotreating catalyst has better hydro-desulfurization and hydro-denitrification activity.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for preparing carbon-containing catalyst

ActiveCN101940957AAdjust surface propertiesEasy to useCatalyst carriersCatalyst activation/preparationRefractoryThermal treatment

The invention discloses a method for preparing a carbon-containing catalyst, which comprises the following steps of: (1) preparing a porous inorganic refractory oxide carrier; (2) soaking a carbon precursor in the inorganic refractory oxide carrier; (3) introducing a metal aid into the step (1) or the step (2); (4) performing thermal treatment, namely thermally treating the porous inorganic refractory oxide carrier carrying the carbon precursor and the metal aid, and decomposing the carbon precursor into carbon so as to obtain a carbon-containing catalyst carrier; and (5) loading an active metal component to obtain the catalyst. The carbon-containing carrier is prepared by pre-soaking the carbon precursor, and then the active metal is loaded to prepare the carbon-containing catalyst so as to simplify the preparation process of the carbon-containing catalyst carrier and improve the physical and chemical properties and the use property of the carbon-containing catalyst.

Owner:CHINA PETROLEUM & CHEM CORP +1

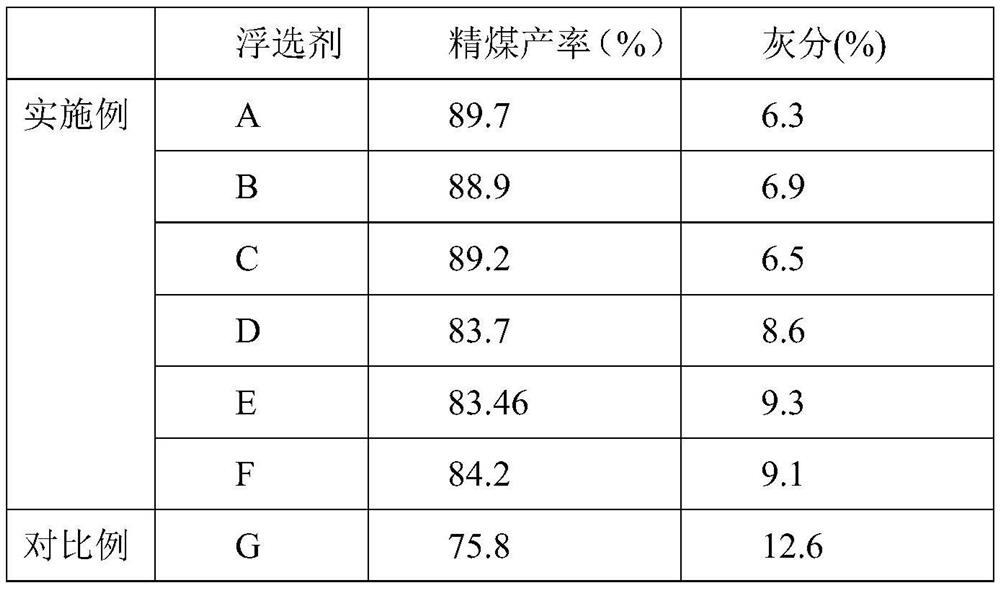

Floatation process for oxidized coal slime

InactiveCN104014431AAdjust surface propertiesImprove hydrophobicityFlotationFoaming agentProcess engineering

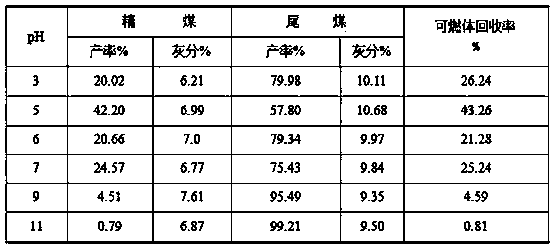

The invention discloses a floatation process for oxidized coal slime and belongs to the technical field of coal washing and dressing. According to the method, the coal slime is reduced through organic reducing agents, then collecting agents and foaming agents are sequentially added to the coal slime and stirred, and finally clean coal and tailing products are floated. According to the method, as the organic reducing agents are added, the surface property of the coal slime is adjusted, the hydrophobic property of the coal slime is improved, and the floatation effect is improved; by the adoption of the floatation scheme, the floatation effect of the oxidized coal sling can be improved remarkably.

Owner:TAIYUAN UNIV OF TECH

Silver catalyst for high selectivity oxidation of ethylene to prepare ethylene oxide, and use method thereof

ActiveCN105233824AExtend your lifeHigh selectivityOrganic chemistryMetal/metal-oxides/metal-hydroxide catalystsWater vaporNitrogen gas

The invention discloses a silver catalyst for high selectivity oxidation of ethylene to prepare ethylene oxide. The silver catalyst is composed of a main active component, an assistant and a carrier, wherein the main active component is silver, and the content is 1-30wt%; the assistant is one or more of Na, Cs, Ce, Re and Zr, and the content of the oxide of the assistant is 0.001-10wt%; and the sum of the content of above three components is 100%. The specific surface area of the catalyst is 1-10m<2> / g, and the pore volume of the catalyst is 0.1-1ml / g. The invention also provides a method for improving the stability of the catalyst in oxidation of ethylene to prepare ethylene oxide. The method is characterized in that an adjustment gas for promoting the activity stability of the catalyst is introduced to a reaction system with reaction raw materials in the reaction process; and the adjustment gas is formed by an adjustment component and a dilution component, the adjustment component is a gas of one or more of sulfur, phosphorus and VII A family elements, and the dilution gas is one or more of water vapor, air, nitrogen, methane and ethane. The method can improve the stability of the catalyst, reduces catalyst inactivation and prolongs the life of the catalyst.

Owner:CHINA NAT OFFSHORE OIL CORP +3

Method for preparing zirconium-containing hydrodemetallization catalyst

ActiveCN106140183AIncrease contentImprove uniformityMetal/metal-oxides/metal-hydroxide catalystsRefining to eliminate hetero atomsAir atmospherePlasticizer

The invention discloses a method for preparing a zirconium-containing hydrodemetallization catalyst. The method comprises the steps of 1, impregnating a physical pore-enlarging agent I in hydrogenation activity component impregnation liquid I and zirconium-containing solution I respectively, impregnating a physical pore-enlarging agent II in hydrogenation activity component impregnation liquid II and zirconium-containing solution II respectively, and drying the impregnated physical pore-enlarging agent I and physical pore-enlarging agent II for use; 2, conducting mix-kneading on the physical pore-enlarging agent I and physical pore-enlarging agent II obtained from step 1 and pseudo-boehmite dry gelatine powder, chemical pore-enlarging agent, extrusion aid and peptizing agent to form a plasticizer, conducting band extrusion and drying, roasting dried materials in the nitrogen atmosphere, and then conducting roasting in the air to obtain a modified alumina supporter; 3, impregnating the modified alumina supporter obtained in step 2 in hydrogenation activity component impregnation liquid III, and conducting drying and roasting to obtain the zirconium-containing hydrodemetallization catalyst. The content of active metal in the catalyst prepared with the method is relatively high at the positions of large pores and is relatively low at the positions of small pores, and the utilization rate of large pores is increased remarkably. The hydrodemetallization catalyst has high activity and long-term operation stability.

Owner:CHINA PETROLEUM & CHEM CORP +1

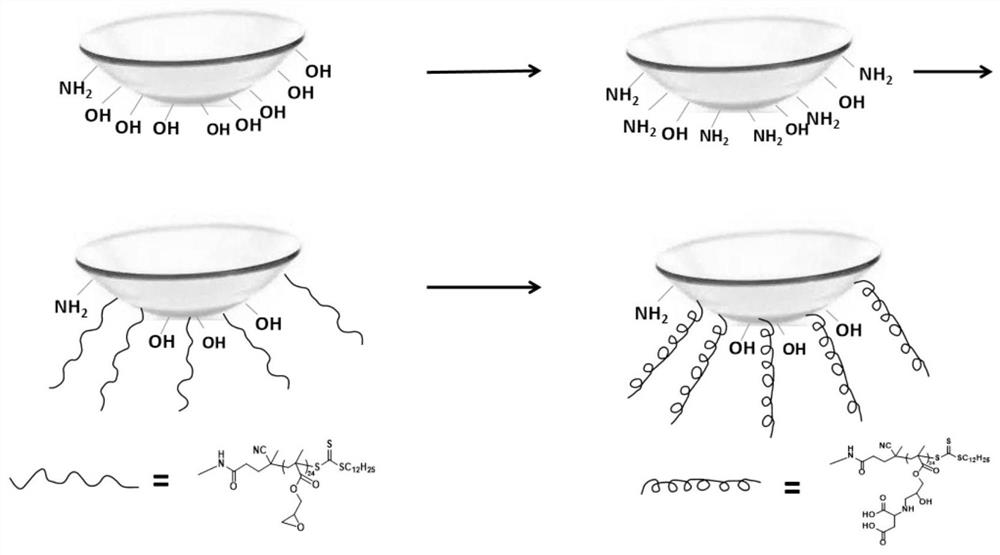

Surface polymer brush modified hydrogel material as well as preparation method and application thereof

ActiveCN112625253AIncrease moisture contentImprove hydrophilicityOptical partsPolymer science(Hydroxyethyl)methacrylate

The invention discloses a preparation method of a surface polymer brush modified hydrogel material. Beta-hydroxyethyl methacrylate (HEMA) is used as a main monomer to prepare cross-linked hydrogel, and the physical and chemical properties of the hydrogel are changed by adding a third component. Then, hydroxyl on the surface of the hydrogel is activated into amino, the amino is coupled to carboxyl at the tail end of polyglycidyl methacrylate (PGMA) prepared through reversible addition-fragmentation chain transfer (RAFT) free radical polymerization, and a polymer chain is grafted to the surface of the hydrogel. Further, the surface of the hydrogel is modified with functional molecules through the reaction of small molecules with amino groups and epoxy groups in the PGMA. Through a post-modification method, the surface of the hydrogel is modified with a layer of functional polymer brush, and the length of the polymer brush can be adjusted through the RAFT polymerization reaction feeding ratio. On the basis of keeping the water content and mechanical properties of the hydrogel, the surface properties of the hydrogel are changed, and the protein adsorption resistance is improved.

Owner:NANJING 3H MEDICAL PROD CO LTD

Modified four-feet needle-shaped zinc oxide crystal whisker and preparation method thereof

InactiveCN101260567AGood dispersionGood compatibilityPolycrystalline material growthAfter-treatment detailsEthyl acetateSilicon dioxide

The invention discloses a modified tetragonal needle zinc oxide crystal whisker and a preparation method thereof, wherein, the preparation method comprises the following steps of: dispersing the tetragonal needle zinc oxide crystal whisker into deionized water, adding sodium silicate hydrate, stirring at 40 to 80 DEG C to enable the solution to be uniformly dispersed, adding ethyl acetate, stirring for 1 to 10h, then filtering a product, washing, and drying to the constant weight; mixing and stirring the received product with 95 percent ethanol, adding organic siloxane, stirring at 30 to 60 DEG C for 0.5 to 3h, filtering, washing, and drying to the constant weight. The invention has the surface of the tetragonal needle zinc oxide crystal whisker covered by nano silicon dioxide so as to improve the interface bonding between the crystal whisker and polymers, and generates the nano silicon dioxide on the surface of the crystal whisker to realize the evenness of the degree of supersaturation and acquire a comparative complete coverage. The modified tetragonal needle zinc oxide crystal whisker has the advantages of simple technology, moderate condition and easy execution.

Owner:SOUTH CHINA UNIV OF TECH

Preparation method of boron-containing hydrogenation and demetalization catalyst

ActiveCN106140122AHigh catalytic activityImprove catalytic stabilityMetal/metal-oxides/metal-hydroxide catalystsRefining to eliminate hetero atomsBoehmiteUrea

The invention discloses a preparation method of a boron-containing hydrogenation and demetalization catalyst. The preparation method comprises steps as follows: (1) hydrogenation active components, namely, an impregnation liquid I and a boron-containing solution I are used for impregnating a physical pore expanding agent I respectively, hydrogenation active components, namely, an impregnation liquid II and a boron-containing solution II are used for impregnating a physical pore expanding agent II respectively, and the impregnated physical pore expanding agent I and the impregnated physical pore expanding agent II are dried and soaked with a urea solution respectively for standby use; (2) the physical pore expanding agent I and the physical pore expanding agent I obtained in the step (1) are mixed with pseudo-boehmite dry gelatine powder, a chemical pore expanding agent, an extrusion aid and a peptizing agent, the mixture is kneaded to form a plastic body, the plastic body is extruded to form strips, formed products are put in a sealing device for heat treatment, a treated material is dried and calcined, and a modified alumina support is prepared; (3) a hydrogenation active component, namely, an impregnation liquid III is used for impregnating the modified alumina support, the catalyst is dried and calcined after impregnation, and the boron-containing hydrogenation and demetalization catalyst is prepared. According to the catalyst prepared with the method, the content of active metal is relatively high at large pores and relatively low at small pores, the utilization rate of the large pores is remarkably increased, and the hydrogenation and demetalization catalyst has high activity and long-period operation stability.

Owner:CHINA PETROLEUM & CHEM CORP +1

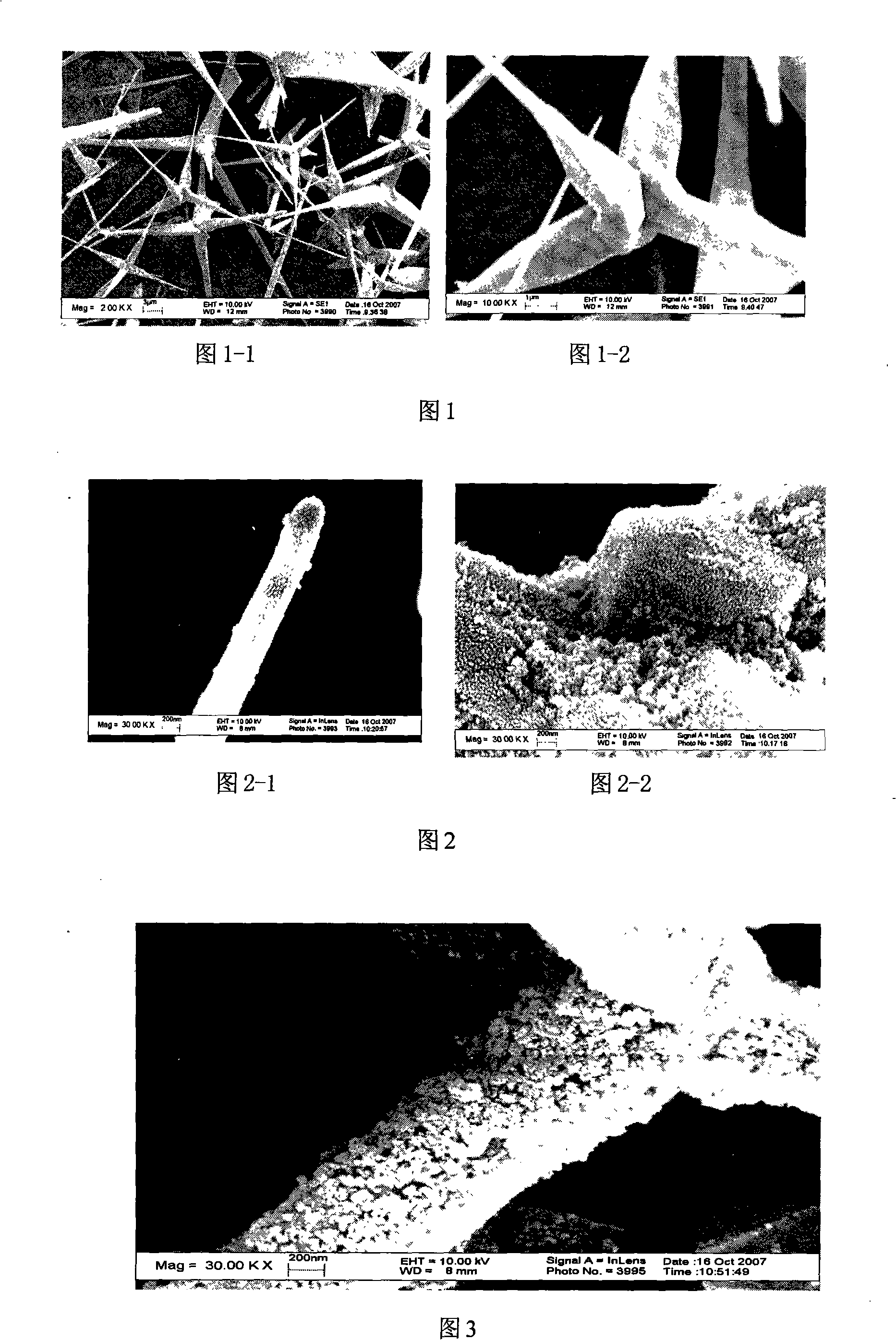

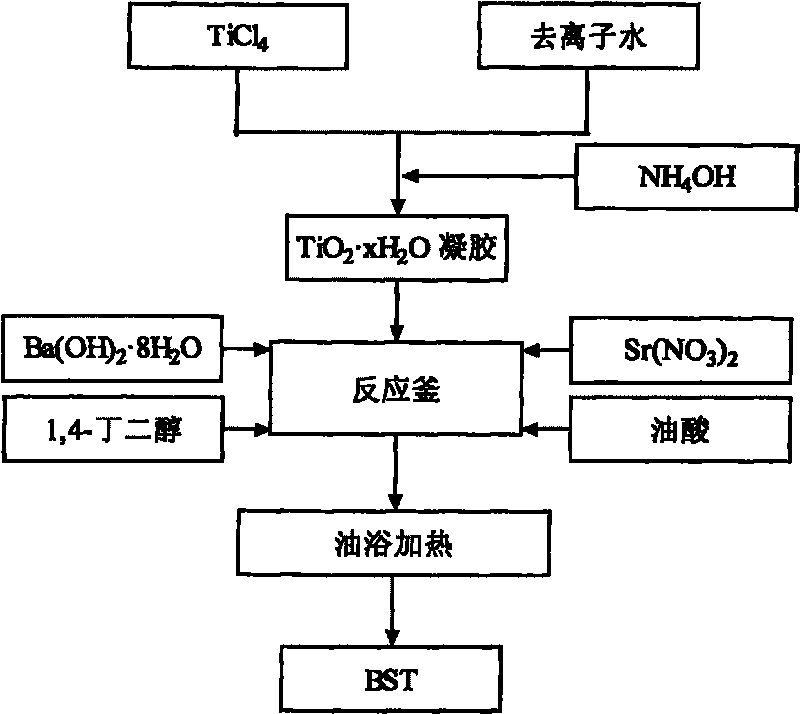

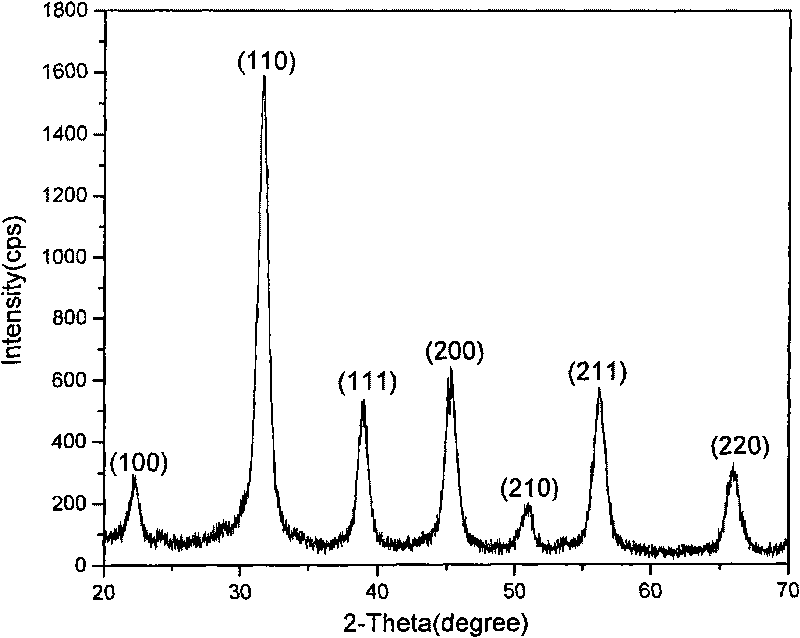

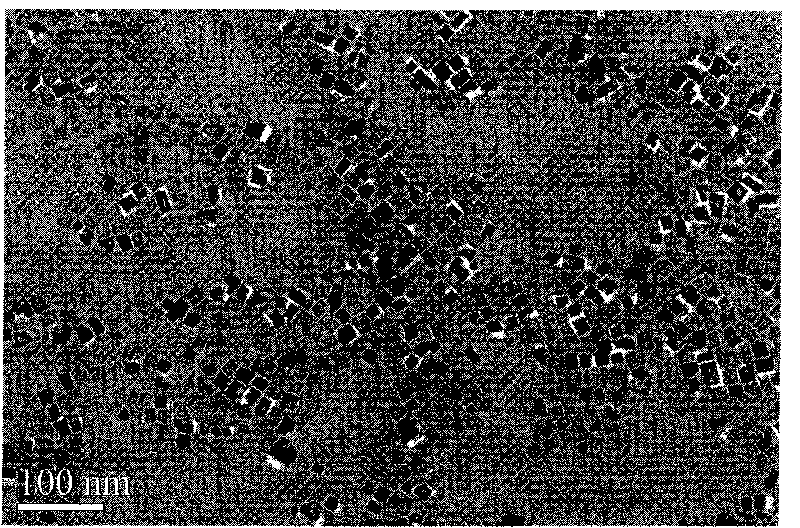

Barium strontium titanate ferroelectric nano single crystal particle and preparation method thereof

InactiveCN101705519AEasy to controlSuitable for large-scale preparationPolycrystalline material growthSingle crystal growth detailsDispersion stabilityBarium strontium titanate

The invention relates to a barium strontium titanate ferroelectric nano single crystal particle and a preparation method thereof. Pure Sr(NO3)2, Ba(OH)2.8H2O and TiCl4 serve as raw materials, de-ionized water and 1,4-butanediol serve as reaction medium and oleic acid serves as surfactant; at the absence of mineralizer, the nucleation-growth process is controlled by alcohol heat action in an autoclave to synthesize and obtain barium strontium titanate ferroelectric nano single crystal particles. The barium strontium titanate ferroelectric nano single crystal particle prepared by the invention has the characteristics of accurate chemical composition, regular cubic appearance, near single dimension, favourable dispersion stability and the like. The ferroelectric nano single crystal material can be used for self-assembly aiming to the nanometer ordered array structure of super high density ferroelectric memory, and the microstructural characteristics of the invention have not been reported publicly so far.

Owner:NANJING UNIV OF TECH

Organic/inorganic gradient diffusion interface layer-based organic photovoltaic cell and preparation method thereof

ActiveCN109873081AImproved interface contactReduce interface barriers and defectsSolid-state devicesSemiconductor/solid-state device manufacturingOxideOrganic semiconductor

The invention discloses an organic / inorganic gradient diffusion interface layer-based organic photovoltaic cell and a preparation method thereof. The organic photovoltaic cell sequentially comprises atransparent substrate layer, a metal negative electrode layer, a gradient diffusion composite interface layer, an organic active layer, a hole transmission layer and a metal positive electrode layerfrom bottom to top, wherein the material in the gradient diffusion composite interface comprises an inorganic metal oxide and an organic semiconductor molecule, and the corresponding layer is sequentially fabricated on each layer during fabrication. Compared with a traditionally metal oxide and organic / inorganic dual interface layers, the organic photovoltaic cell has the advantages that photoelectric conversion efficiency is remarkably improved; on one hand, the surface defect of an inorganic interface material can be passivated, and the charge recombination probability caused by physical defect is reduced; and on the other hand, the problem of charge interface transmission caused by energy level difference between an active layer and the interface layer can be reduced by building the organic-inorganic composite interface layer with a gradient diffusion structure.

Owner:NANJING UNIV OF POSTS & TELECOMM

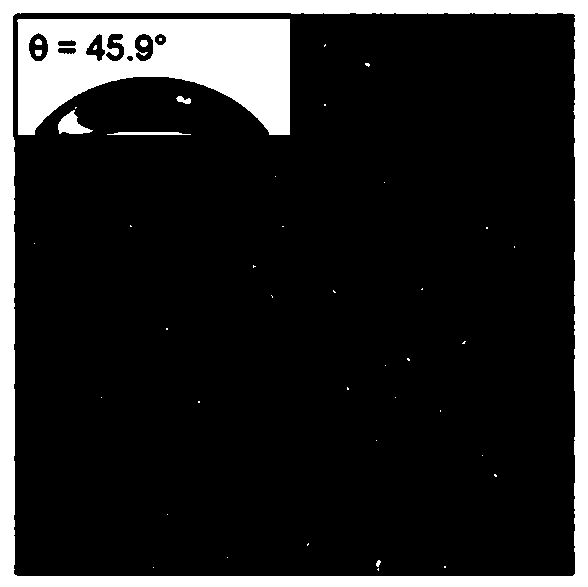

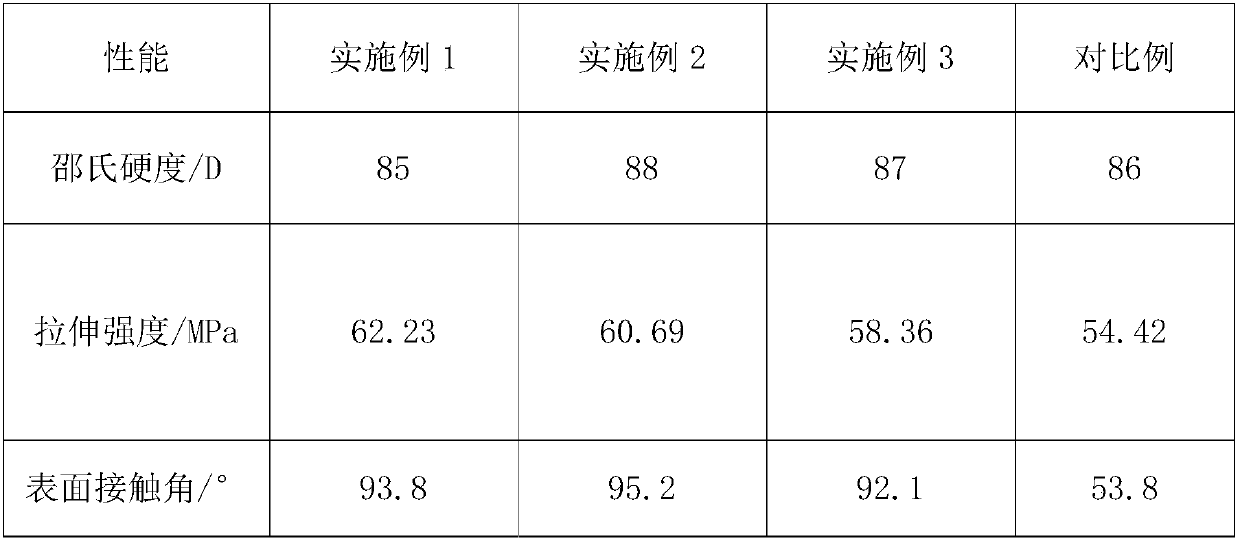

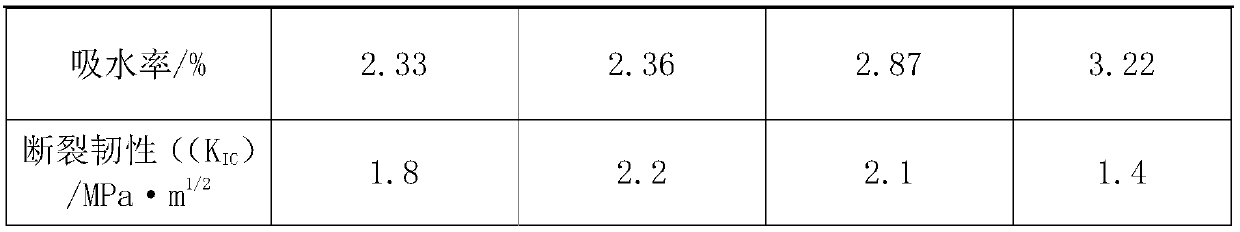

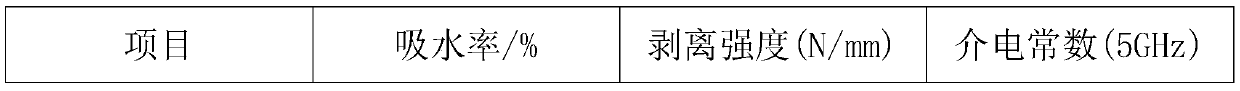

Preparation method of polyurethane modified phenolic resin composition for semiconductor packaging

ActiveCN109679046ALower dielectric constant and water absorptionImprove surface propertiesEpoxy resin adhesivesChemistryChemical Linkage

The invention provides a preparation method of polyurethane modified phenolic resin. The obtained polyurethane modified phenolic resin is suitable for semiconductor packaging. According to the methodprovided by the invention, an organic fluorine group and a polyurethane group are bonded in a phenolic resin compound through chemical bonds by controlling a ratio of the organic fluorine group to thepolyurethane group in the phenolic resin, thereby realizing effective dispersion of the organic fluorine group and the polyurethane group in phenolic resin, and the mechanical properties and surfaceproperties of a polyurethane modified phenolic resin material can be effectively adjusted. By applying the polyurethane modified phenolic resin as a curing agent to modification of an epoxy resin composition, the modulus of the epoxy resin composition can be greatly reduced, and meanwhile, the processability and solder resistance of the epoxy resin composition in the semiconductor packaging can beimproved. The polyurethane modified phenolic resin for semiconductor packaging provided by the invention also has necessary fluidity, filling property and flame retardancy.

Owner:NINGBO DUNHE TECH CO LTD

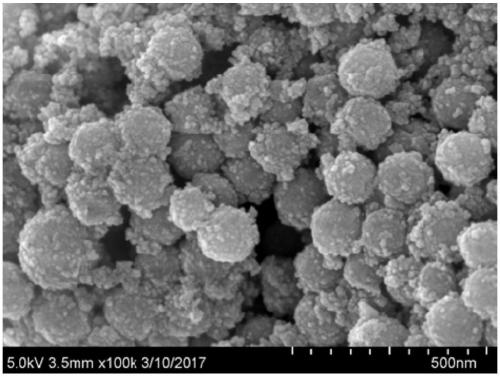

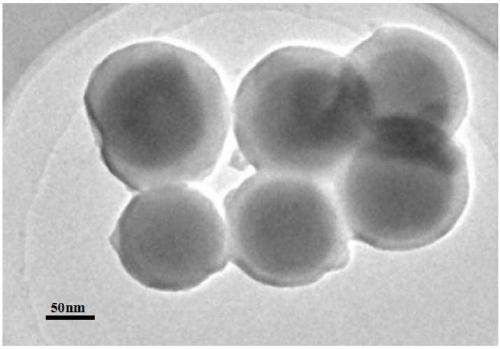

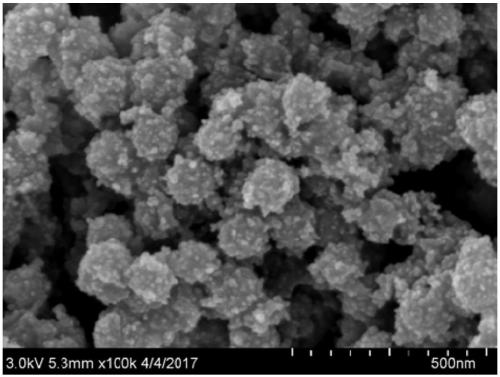

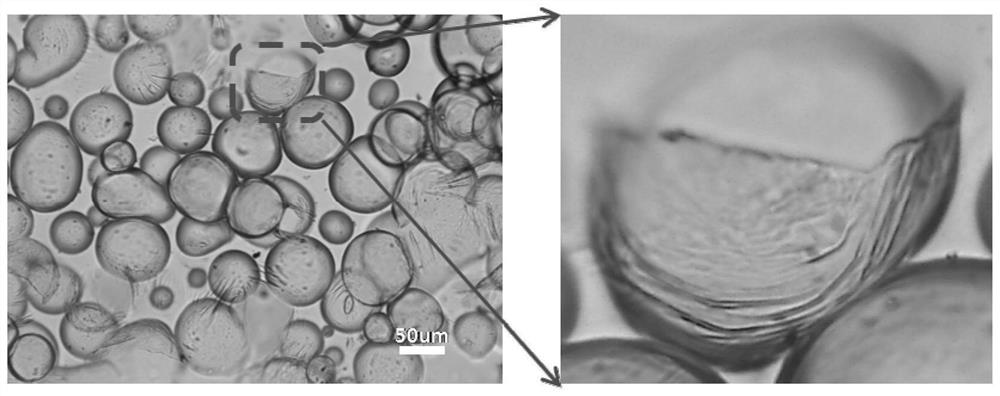

Phase change material nano capsule and preparation method thereof

ActiveCN109554167AGood dispersionImprove bindingHeat-exchange elementsSilicon dioxidePhase-change material

The invention discloses a phase change material nano capsule and a preparation method thereof. The phase change material nano capsule takes silica as a shell layer and fatty acids as a core material,is spherical, and has a D50 of 100 nm to 200 nm, a particle diameter distribution coefficient K of 0.3-0.7, and a shell thickness of 20-40 nm. The phase change material nano capsule can maintain gooddispersing performance when the particle diameter is less than 200 nm, and reduces the agglomeration phenomenon among particle diameters.

Owner:UNIV OF SCI & TECH BEIJING

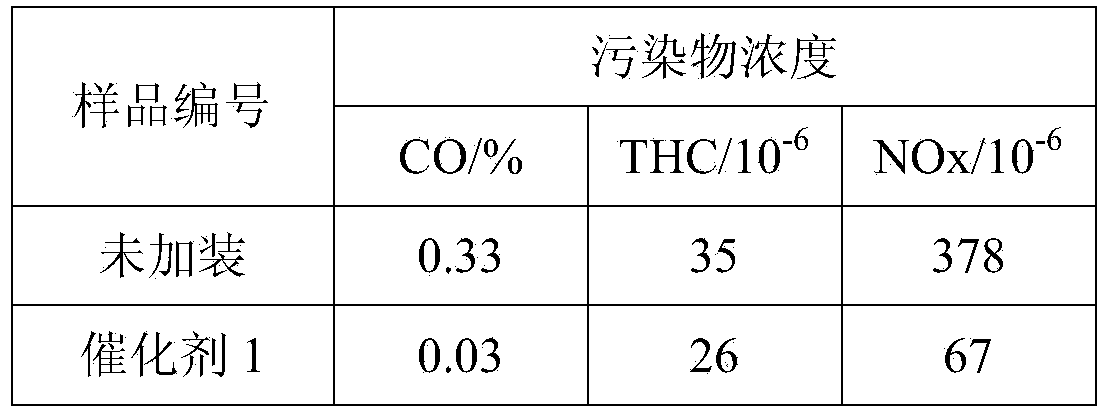

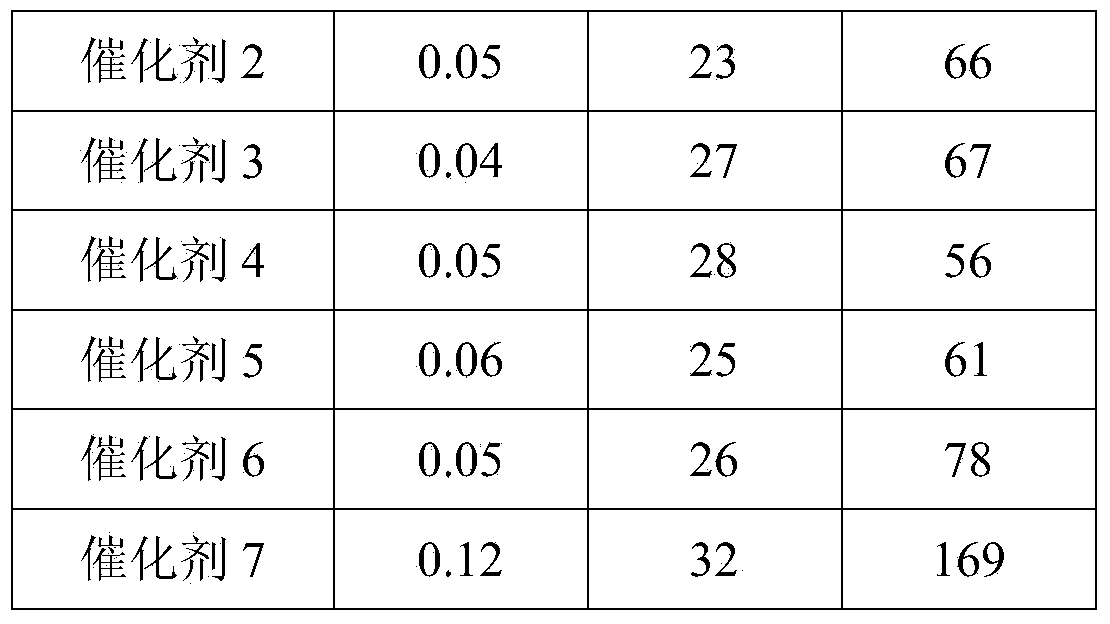

Tail gas purification catalyst with soft metal wire carrier substrate

ActiveCN103801328AEasy to installEfficient purificationDispersed particle separationCatalyst activation/preparationCeriumAcid washing

The invention provides a tail gas purification catalyst with a soft metal wire carrier substrate. The tail gas purification catalyst comprises the soft metal wire carrier substrate and a high-performance coating material, wherein the surface of the soft metal wire carrier substrate carrying noble metal is coated with the high-performance coating material; the soft metal wire carrier substrate is a pretreated soft FeCrAl metal wire carrier. A pretreatment process for the soft FeCrAl metal wire carrier comprises the following steps of performing ketone / alcohol washing on the soft metal wire carrier, then performing acid washing, alkali washing and water washing, and calcining the soft metal wire carrier under the conditions of high temperature and rich oxygen in a muffle furnace. Every 100 grams of the high-performance coating material is prepared from 10 to 40 grams of aluminum-alkaline earth composite oxide, 10 to 20 grams of a cerium-zirconium composite oxide, 5 to 15 grams of auxiliaries and the balance being water, and the pH value of the material is 3 to 6. The invention also provides a preparation method for the tail gas purification catalyst with the metal wire soft carrier substrate. According to the catalyst, the soft metal wire carrier with a variable shape and an adjustable geometric volume is introduced, and is coated with the coating material after being pretreated, so that a convenient-to-mount, high-purification-efficiency and low-cost solution is provided for the treatment of tail gas of motor vehicles.

Owner:JHM HI TECH NANJING

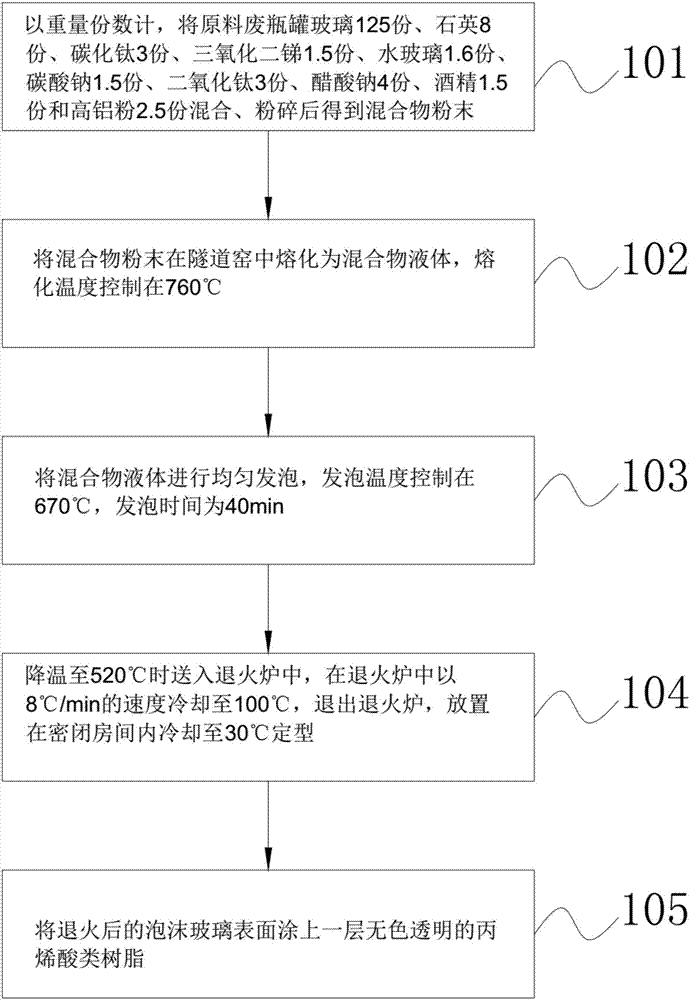

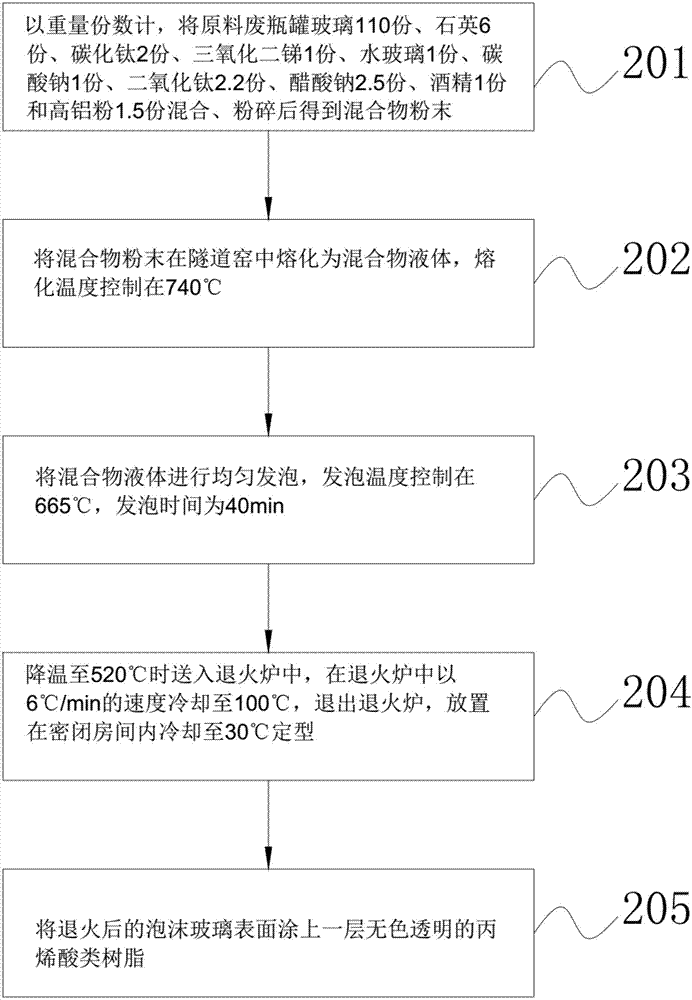

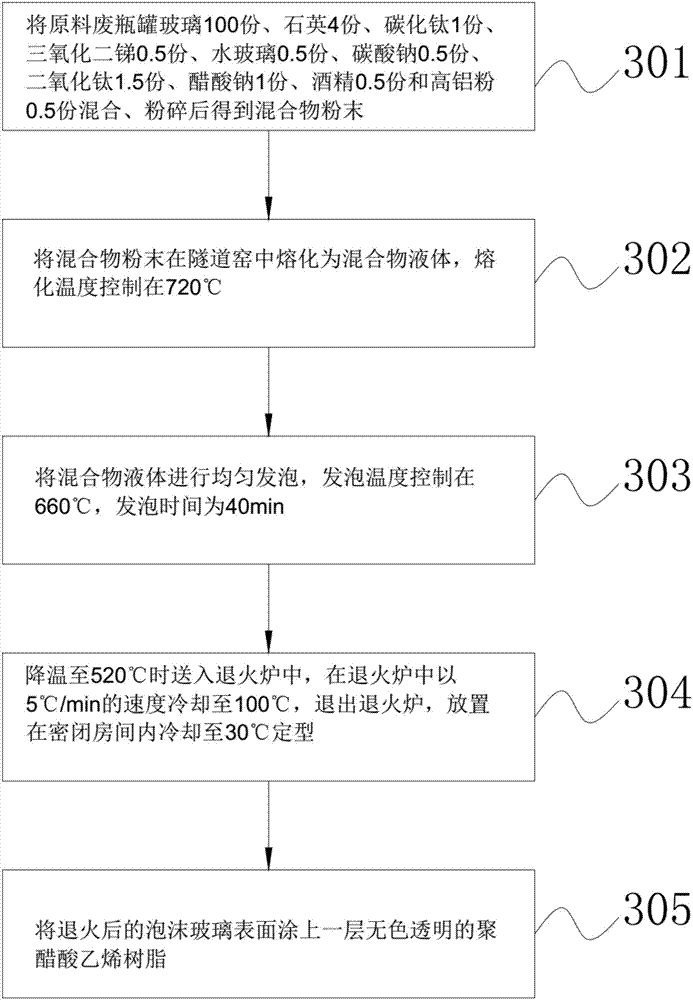

Manufacturing technique for sound-insulating foam glass

InactiveCN106957150ASolve thermal conductivitySolve the sound insulationGlass shaping apparatusCoatingsTunnel kilnAdhesive

The invention provides a manufacturing technique for a sound-insulating foam glass and relates to the technical field of glass production. The manufacturing technique comprises the following steps: (1) mixing and crushing the following raw materials in parts by weight: 100-125 parts of waste bottle glass, 4-8 parts of quartz, 1-3 parts of titanium carbide, 0.5-1.5 parts of antimonous oxide, 0.5-1.6 parts of adhesives, 1-4 parts of acetate, 0.5-1.5 parts of surface active agent and 0.5-2.5 parts of release agent, thereby acquiring mixture powder; (2) melting the mixture powder in a tunnel kiln under the melting temperature at 720-760 DEG C, thereby acquiring a liquid mixture; (3) uniformly foaming the liquid mixture for 30-40min under the foaming temperature of 660-670 DEG C; (4) while reducing the temperature to 500-520 DEG C, feeding into an annealing furnace, reducing to 100 DEG C in the annealing furnace at the rate of 5-8 DEG C / min, exiting from the annealing furnace, placing into an air-tight room, cooling to 30 DEG C and forming; (5) coating a layer of transparent organic protecting film on the surface of the annealed foam glass. The manufacturing technique has the advantages of low heat conductivity coefficient, excellent sound insulation, high strength, completeness and high heat stability.

Owner:合肥协耀玻璃制品有限公司

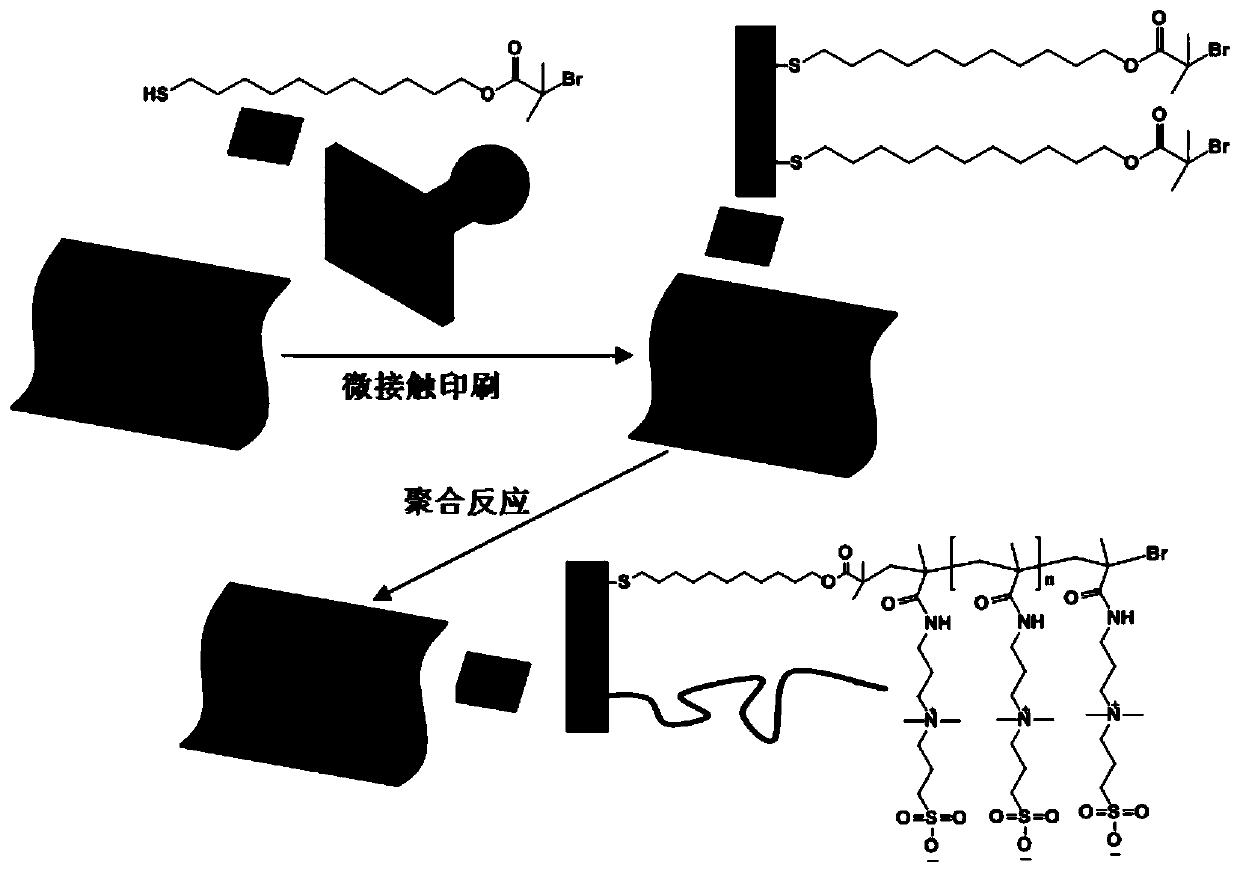

Preparation method of zwitterionic polymer pattern on surface of solid substrate

PendingCN111333759AChange adsorption behaviorAdjust surface propertiesPolymer sciencePolymer modified

The invention provides a preparation method of a zwitterionic polymer pattern on the surface of a solid substrate. The preparation method mainly comprises the following steps: cleaning the substrate,grafting an initiator to the substrate, and grafting a zwitterionic polymer to the surface of the substrate through an atom transfer radical polymerization method to obtain a solid surface with a zwitterionic polymer micro-nano pattern. The zwitterionic polymer layer obtained by the method is a zwitterionic polymer modified solid surface prepared by adopting an atom transfer radical polymerizationprinciple; the zwitterionic polymer layer has the advantage of good homogeneity, has organic pollution resistance and biological pollution resistance, and can be used for preventing biological pollution and resisting biological corrosion on the surface of a material.

Owner:QINGDAO UNIV OF SCI & TECH

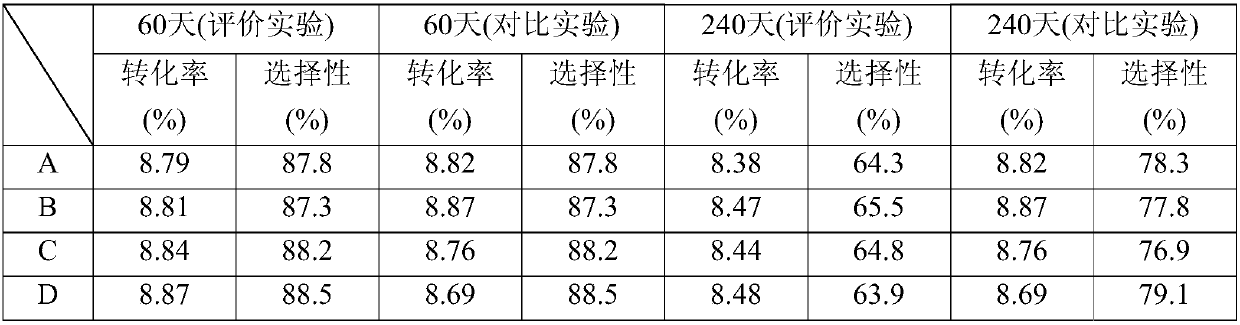

A silver catalyst for producing ethylene oxide by highly selective ethylene oxidation and its application method

ActiveCN105233824BExtend your lifeHigh selectivityOrganic chemistryMetal/metal-oxides/metal-hydroxide catalystsAdjuvantWater vapor

The invention discloses a high-selectivity ethylene oxide silver catalyst for producing ethylene oxide, which consists of three parts: main active component, auxiliary agent and carrier, the main active component is silver, and the content is 1-30wt%; the auxiliary agent is One or more of Na, Cs, Ce, Re, Zr, the oxide content of the additive is 0.001-10wt%; the rest is carrier; the specific surface area of the catalyst is 1-10m2 / g, and the pore volume is 0.1-1ml / g. The present invention also provides a method for improving the stability of the catalyst in the epoxidation of ethylene oxide to ethylene oxide. In the reaction process, a kind of regulating gas that promotes the stability of the catalyst activity is introduced into the reaction system along with the reaction raw materials; the regulating gas It is composed of adjusting component and diluting component, the adjusting component is the gas of one or more elements in sulfur, phosphorus, group VIIA elements, and the diluting gas is the gas of water vapor, air, nitrogen, methane and ethane one or more. The method of the invention can improve the stability of the catalyst, slow down the deactivation of the catalyst and prolong the life of the catalyst.

Owner:CHINA NAT OFFSHORE OIL CORP +3

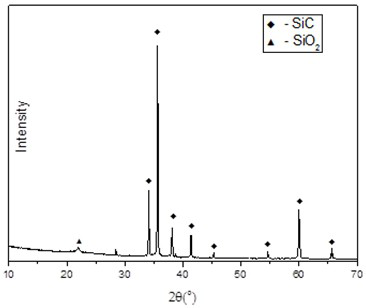

Catalyst carrier for cracking of biological tar, catalyst and preparation method

ActiveCN113117716AImprove high temperature strengthImprove high temperature stabilityCatalyst carriersCatalyst activation/preparationPtru catalystSilicon oxide

The invention discloses a catalyst carrier for biological tar cracking, a catalyst and a preparation method. The catalyst carrier for biological tar cracking takes a silicon carbide-silicon nitride composite material as a matrix, silicon oxide is distributed on the matrix, and the preparation method comprises the following steps: firstly, preparing the silicon carbide-silicon nitride composite material; then making the composite material contact with oxygen-containing gas for treatment, and conducting cooling to obtain a carrier intermediate A; and conducting mixing with an alkaline solution or a hydrofluoric acid solution, conducting washing, carrying out low-temperature heat treatment, and carrying out high-temperature heat treatment to obtain the biological tar cracking catalyst carrier. The invention also provides the catalyst adopting the carrier. The catalyst for biological tar cracking is good in wear resistance, high in activity, high in microwave absorption rate, good in thermal shock resistance and high in water resistance at high temperature, and the preparation method is simple, low in cost, resistant to sintering and carbon deposition and capable of being recycled for a long time.

Owner:CHINA PETROLEUM & CHEM CORP +1

Phosphorus-doped alumina-loaded palladium catalyst and preparation method thereof

PendingCN111437844AAdjust surface propertiesImprove performanceCatalyst activation/preparationIncinerator apparatusChemistryAluminium oxides

The invention provides a phosphorus-doped alumina-loaded palladium catalyst and a preparation method thereof. The preparation method comprises the following steps: preparing a phosphorus-modified aluminum oxide carrier: dissolving P123 in absolute ethyl alcohol, sequentially adding water, ammonia water and a phosphorus precursor, uniformly mixing to obtain a mixed solution, dissolving an aluminumsource in absolute ethyl alcohol, adding the mixed solution, stirring, aging, drying and roasting to obtain phosphorus-modified aluminum oxide; and loading palladium metal: adding the phosphorus-modified alumina carrier into the impregnation liquid for isopyknic impregnation, drying and roasting to obtain the catalyst. According to the technical scheme, a one-step precipitation method is adopted in the preparation step of the phosphorus-modified aluminum oxide carrier so that the phosphorus element generates strong interaction with the aluminum oxide carrier in a high-dispersion form, the surface property of the aluminum oxide is effectively adjusted, and the palladium-based catalyst prepared by taking the aluminum oxide as the carrier through a charge-enhanced isovolumetric impregnation method is excellent in performance.

Owner:FUJIAN NORMAL UNIV

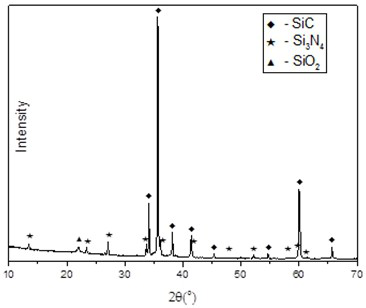

Catalyst carrier for biomass pyrolysis, catalyst and preparation method of catalyst carrier

PendingCN113117710AUniform particle sizeGood thermal stabilityCatalyst carriersCatalyst activation/preparationCarbide siliconTemperature treatment

The invention discloses a preparation method of a catalyst carrier for biomass pyrolysis, and the preparation method comprises the following steps: firstly preparing a green body, then carrying out molding, drying and roasting treatment on the obtained green body, adding the green body into a hydrofluoric acid solution for soaking treatment, and conducting washing to obtain a silicon carbide carrier; performing high-temperature treatment on the silicon carbide carrier in the presence of oxygen-containing gas; and finally, conducting mixing with an alkaline solution or a hydrofluoric acid solution for treatment, and then conducting washing, drying and roasting to obtain the carrier. The invention also provides a biomass pyrolysis catalyst adopting the carrier. The biomass pyrolysis catalyst has the advantages of high strength and wear resistance, can be applied to a fixed bed, a moving bed or a fluidized bed, especially has stable performance in a high-temperature environment of a biomass pyrolysis reaction, and has relatively high catalyst activity and relatively long catalyst life.

Owner:CHINA PETROLEUM & CHEM CORP +1

A kind of method adopting emulsion template to control dinitramide ammonium particle size

ActiveCN110627590BAdjust surface propertiesBarrier particle sizeExplosive working-up apparatusPressure gas generationOil emulsionMoisture absorption

The invention discloses a method for controlling the particle size of ammonium dinitramide by using an emulsion template, which can simultaneously solve the problems of controlling the particle size of ammonium dinitramide in moisture absorption and spheroidization. In the method, deionized water is used as ammonium dinitramide solvent, functional filler is used as a template agent, and a solvent insoluble in ammonium dinitramide is used as a dispersion medium for template agent, and a water-in-oil emulsion system is prepared through the action of a high-speed homogenizer at normal temperature. The solvent is removed by vacuum drying, so as to obtain the ammonium dinitramide composite powder coated with the template agent. By adjusting the oil / water volume ratio, the concentration of ammonium dinitramide aqueous solution, the concentration of template agent dispersion, the mass ratio of template agent / ammonium dinitramide and other parameters to control the droplet size of ammonium dinitramide aqueous phase, and finally realize the spherical dinitramide Control of particle size of ammonium amide powder. The emulsion template method strategy provided by the invention can simultaneously adjust the particle size and hygroscopicity of ammonium dinitramide. The object of the emulsion template method is ammonium dinitramide aqueous solution, and the experimental operation is simple and safe.

Owner:XIAN MODERN CHEM RES INST

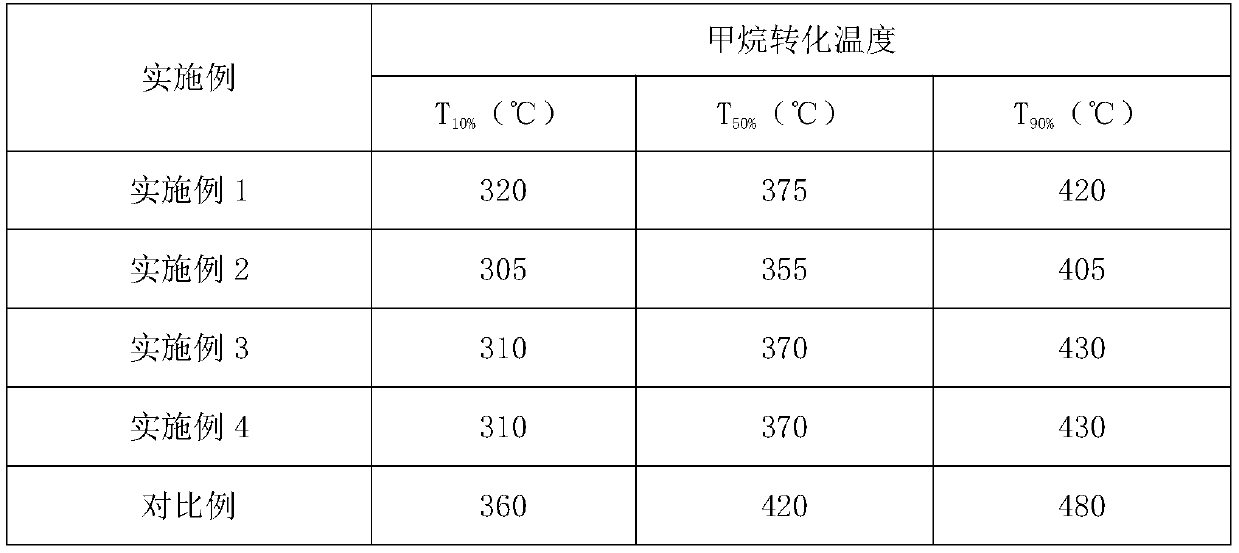

A kind of Pt-based dehydrogenation catalyst with adjustable performance and method for improving its stability

ActiveCN105435782BStable surface propertiesTuned surface properties that stabilize catalyst activityHydrocarbonsMetal/metal-oxides/metal-hydroxide catalystsAlkaneActive component

The present invention discloses a performance adjustable Pt-based dehydrogenation catalyst. The catalyst comprises the following components and contents: 0.1-1.0 wt% of Pt oxide serving as a main active component; one or more of Na, K, Ca, Zr, Sn, La and Ce as an aid agent, wherein the content of an oxide of an element of the aid agent is 0.01-10 wt%; and the balance of a carrier. The present invention also provides a method for improving activity and stability of the catalyst in a reaction process of light alkane dehydrogenation. According to the change for catalytic activity, in the method, an adjustment gas for stabilizing the catalytic activity is added into a reaction system; the adjustment gas consists of adjustment components and dilution components, wherein the adjustment components are gases of one or more elements in the VIIA element, and the content of the adjustment components is 0.001-1 v%; the dilution components are one or more gases of water vapor, air, nitrogen, methane or ethane gas. According to the method provided by the present invention, in the reaction process, the active component Pt can be dispersed, the catalyst deactivation is slowed down, and the service life of the catalyst is prolonged.

Owner:CHINA NAT OFFSHORE OIL CORP +3

Method for controlling the particle size of dinitramide ammonium by adopting emulsion template

ActiveCN110627590AAdjust surface propertiesBarrier particle sizeExplosive working-up apparatusPressure gas generationMass ratioMoisture absorption

The invention discloses a method for controlling the particle size of dinitramide ammonium by adopting an emulsion template, and can simultaneously solve the problems of moisture absorption and spherical particle size control of dinitramide ammonium. According to the method, deionized water is used as a solvent of dinitramide ammonium, a functional filler is used as a template agent, a solvent which does not dissolve dinitramide ammonium is used as a template agent dispersion medium, a water-in-oil emulsion system is prepared through action of a high-speed homogenizer at normal temperature, and the solvent is removed through vacuum drying, so that dinitramide ammonium composite powder coated with the template agent is obtained. The droplet size of the water phase of ammonium dinitramide iscontrolled through adjustment of parameters such as the volume ratio of oil to water, the concentration of an ammonium dinitramide water solution, the concentration of a template agent dispersion liquid and the mass ratio of the template agent to ammonium dinitramide, and finally regulation and control of the particle size of spherical ammonium dinitramide powder are realized. The emulsion template method strategy provided by the invention can simultaneously adjust the particle size and moisture absorption performance of ammonium dinitramide. The operation object of the emulsion template method is the ammonium dinitramide water solution, and experimental operation is simple and safe.

Owner:XIAN MODERN CHEM RES INST

Method for preparing carbon-containing catalyst

ActiveCN101940957BAdjust surface propertiesEasy to useCatalyst carriersCatalyst activation/preparationRefractoryThermal treatment

The invention discloses a method for preparing a carbon-containing catalyst, which comprises the following steps of: (1) preparing a porous inorganic refractory oxide carrier; (2) soaking a carbon precursor in the inorganic refractory oxide carrier; (3) introducing a metal aid into the step (1) or the step (2); (4) performing thermal treatment, namely thermally treating the porous inorganic refractory oxide carrier carrying the carbon precursor and the metal aid, and decomposing the carbon precursor into carbon so as to obtain a carbon-containing catalyst carrier; and (5) loading an active metal component to obtain the catalyst. The carbon-containing carrier is prepared by pre-soaking the carbon precursor, and then the active metal is loaded to prepare the carbon-containing catalyst so asto simplify the preparation process of the carbon-containing catalyst carrier and improve the physical and chemical properties and the use property of the carbon-containing catalyst.

Owner:CHINA PETROLEUM & CHEM CORP +1

Boron-containing catalyst as well as preparation method and application thereof

PendingCN112717947AImprove diffusion efficiencyReduced activityHeterogenous catalyst chemical elementsCatalyst activation/preparationPtru catalystHydrogen treatment

The invention discloses a boron-containing catalyst as well as a preparation method and application thereof. The method comprises the following steps: (1) dissolving yeast in an aqueous solution, and mixing the solution with starch to form a mixed material; (2) mixing a boron-containing solution with the mixed material obtained in the step (1) to prepare a pre-impregnation solution, and introducing the pre-impregnation solution into a physical pore-enlarging agent for later use; (3) mixing pseudo-boehmite powder with the standby material obtained in the step (2), and molding, drying and roasting the mixture to obtain an aluminum oxide carrier; and (4) impregnating the alumina carrier with the hydrogenation active component impregnation liquid, and drying and roasting the alumina carrier to obtain the boron-containing catalyst. The activity stability of the hydrotreating catalyst prepared by the method is remarkably improved.

Owner:CHINA PETROLEUM & CHEM CORP +1

A kind of slime flotation agent and preparation method thereof

ActiveCN114011583BEasy to spreadIncrease the surface contact angleFlotationPolyvinyl alcoholGlycol synthesis

The invention provides a slime flotation agent, which is composed of natural oil, kerosene, ethylene glycol, long-chain alkyl organic amine, dimethyl sulfate, hydrophobically modified polyvinyl alcohol, lye and sulfosalicylic Hydrophobically modified polyvinyl alcohol is especially added, which can increase the surface contact angle between coal particles and reagents and improve the hydrophobicity of the surface of coal particles; the added organic amine and dimethyl sulfate form a quaternary Ammonium salt cation can improve the cationicity of the flotation agent, adjust the surface properties of the solution, make the kerosene evenly dispersed in the water, increase the coverage area of the kerosene on the surface of the coal particles, and enhance the flotation efficiency.

Owner:CHINA UNIV OF MINING & TECH (BEIJING) +1

A combination method of fluorine-containing resin prepreg for high-frequency copper-clad laminates

ActiveCN109760398BLow hygroscopicityLow dielectric constantLamination ancillary operationsLaminationGlass fiberPolymer science

The invention discloses a high-frequency copper-clad plate and fluorine-containing resin prepreg combination mode. The high-frequency copper-clad plate and fluorine-containing resin prepreg combination mode comprises the steps of baking of glass fiber cloth, preparing of fluorine-containing resin impregnation liquid, dipping of the glass fiber cloth into the fluorine-containing resin impregnationliquid, plasma activation, pressing and the like, the problems that when light and thin copper foil is adopted for pressing, a copper-clad plate manufactured through an existing fluorine-containing resin copper-clad plate manufacturing technology is high in hygroscopicity, high in dielectric constant and high in transmission loss, a product is high in peel strength and poor in adhesiveness, and the phenomenon of falling off of a copper sheet is prone to being caused are solved, meanwhile, after being pressed, prepreg and the copper foil enter protective liquid to be impregnated, and the adhesion degree between the prepreg and the copper foil is enhanced again; and a protective liquid system is reasonable in component, compatibility among all the components is good, an interpenetrating network is formed advantageously under the cooperation action of various molecules, the use strength of the copper-clad plate is ensured, the structure is simple, and the water absorption rate is low.

Owner:久耀电子科技(江苏)有限公司

A kind of preparation method of carbon-containing catalyst carrier

ActiveCN101722051BAdjust surface propertiesEasy to useCatalyst carriersMetal/metal-oxides/metal-hydroxide catalystsDecompositionRefractory

The invention discloses a method for preparing a carbon-containing catalyst carrier. Firstly, a carbon-free porous inorganic refractory oxide carrier is prepared, and carbon precursors are impregnated on the carbon-free inorganic refractory oxide carrier. After preparing the carbon-free carrier and / or When impregnating the carbon precursor, the metal additive is introduced, and then the porous inorganic refractory oxide carrier loaded with the carbon precursor and the metal additive is heat-treated, and the carbon precursor is decomposed into carbon to obtain a carbon-containing catalyst carrier. In the preparation process of the catalyst carrier of the present invention, the carbon precursor is decomposed through the promotion of a small amount of metal additives, avoiding harsh treatment conditions, forming a covering on the surface of the catalyst carrier, adjusting the surface properties of the catalyst carrier, and achieving the purpose of improving the performance of the catalyst . Compared with the precursor in which carbon is added during the forming process of the carrier, the method of the invention has the advantages of improving the strength of the carrier and the utilization rate of carbon in the carrier, and greatly improves the activity of hydroprocessing of heavy distillate oil.

Owner:CHINA PETROLEUM & CHEM CORP +1

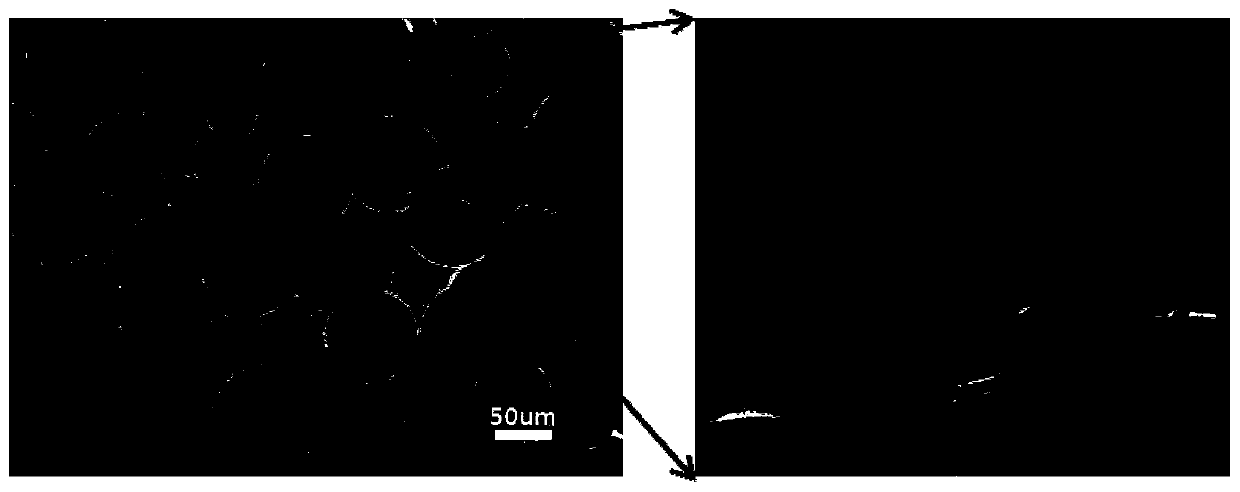

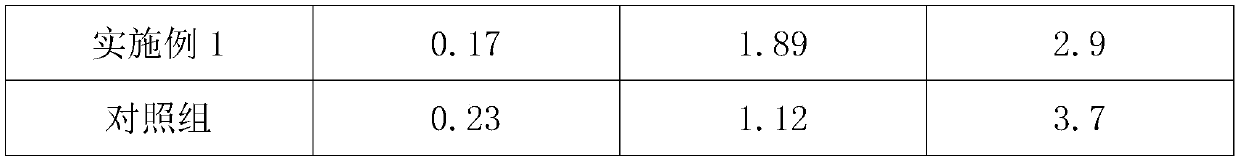

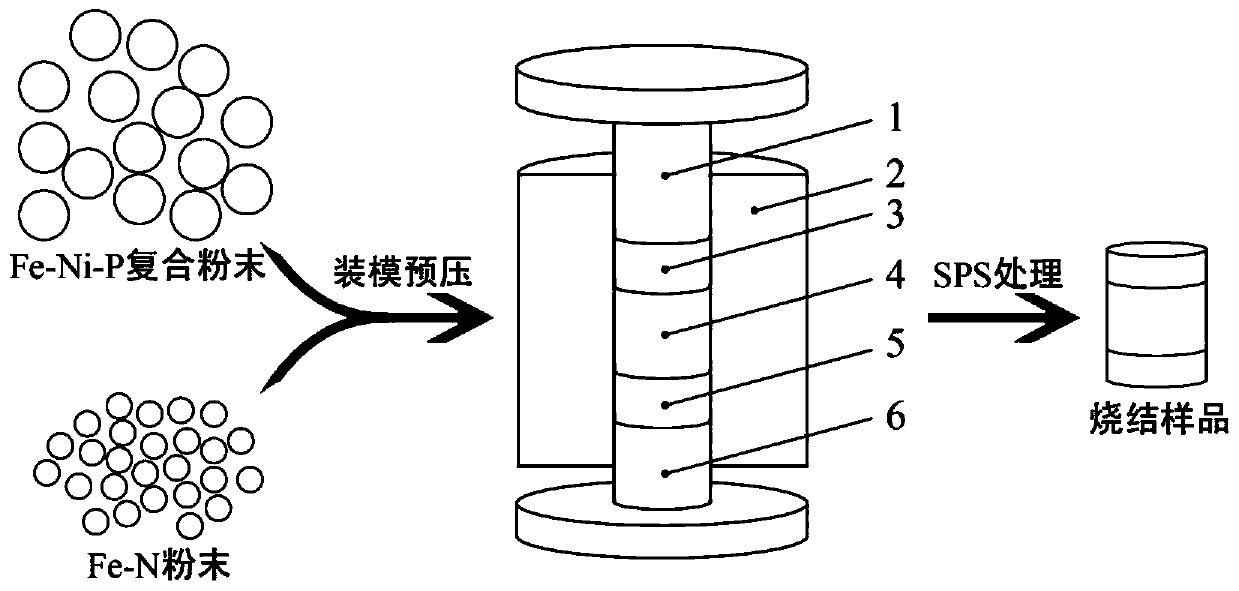

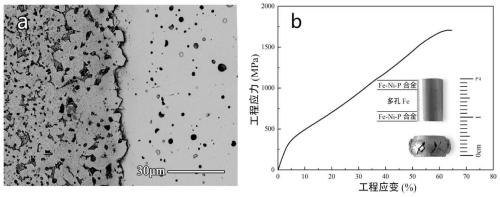

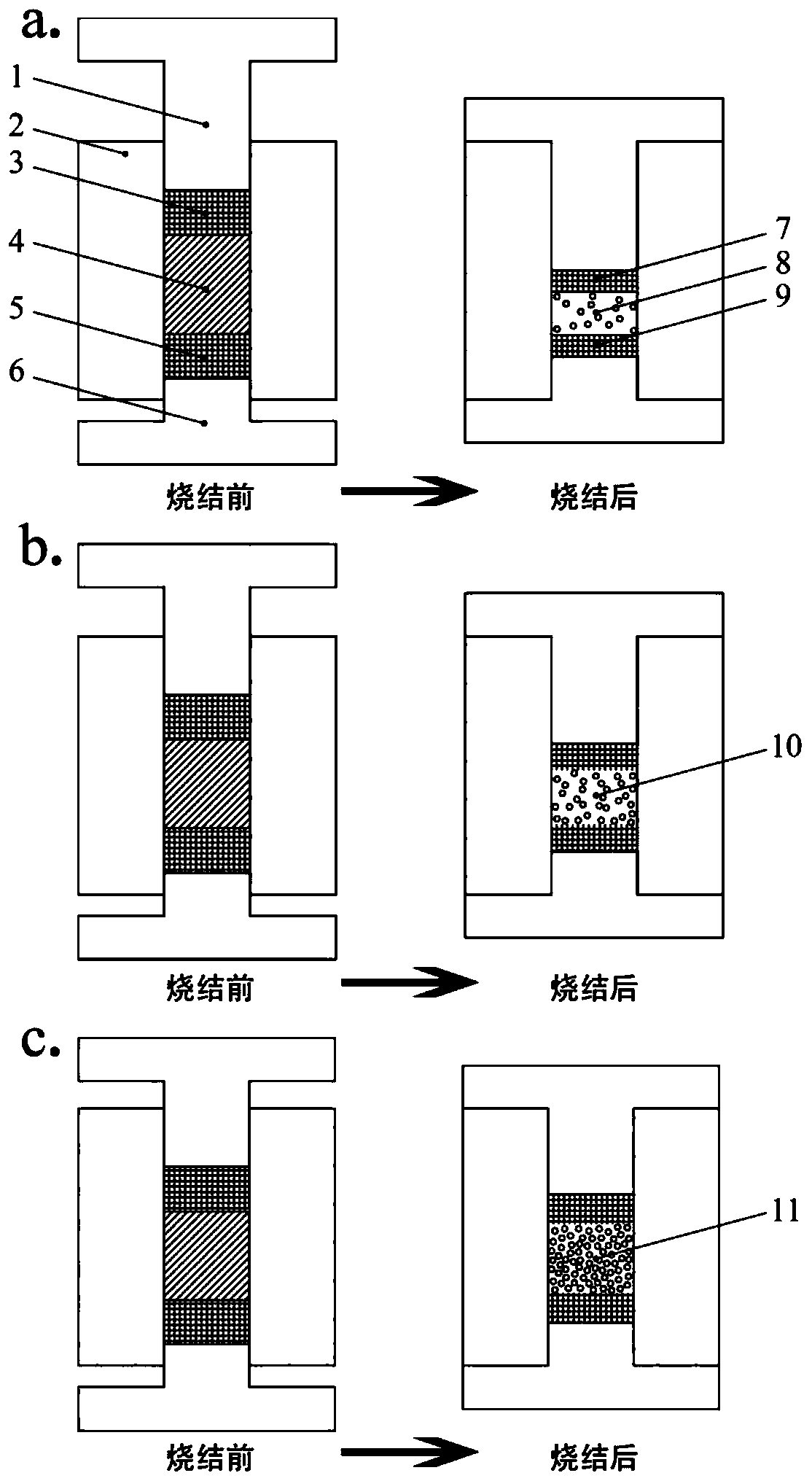

Preparation method of iron-based composite material

The invention provides a preparation method of an iron-based composite material, and relates to the technical field of metal matrix composite materials and advanced manufacturing. Fe-Ni-P composite powder with the particle size being 1-2 microns and Fe-N powder with the particle size being 100-250 nm are used as raw materials; and the size and the axial displacement of a graphite die pressing headare controlled to achieve control over the porous iron porosity, and the Fe-Ni-P alloy / porous Fe / Fe-Ni-P alloy composite material with the porosity being 14% to 39% is prepared. The weight of the Fe-Ni-P alloy is reduced, and meanwhile, the good shock absorption and damping properties are obtained. On the other hand, subsequent cryogenic treatment of a shaped sample can induce conversion from themetastable state gamma phase in a surface layer Fe-Ni-P alloy to the alpha phase, the hardness strength is remarkably improved accordingly, the phase change degree can be controlled by changing the cryogenic treatment temperature and holding time, and the adjustment of the surface layer properties is further achieved.

Owner:SOUTHWEST JIAOTONG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com