Surface polymer brush modified hydrogel material as well as preparation method and application thereof

A technology of polymer brushes and hydrogels, applied in instruments, glasses/goggles, optics, etc., can solve the problems of unsatisfactory hydrophilicity and decreased mechanical properties of hydrogels, and achieve improved protein adsorption resistance, surface The effect of uniform performance and good hydrophilicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

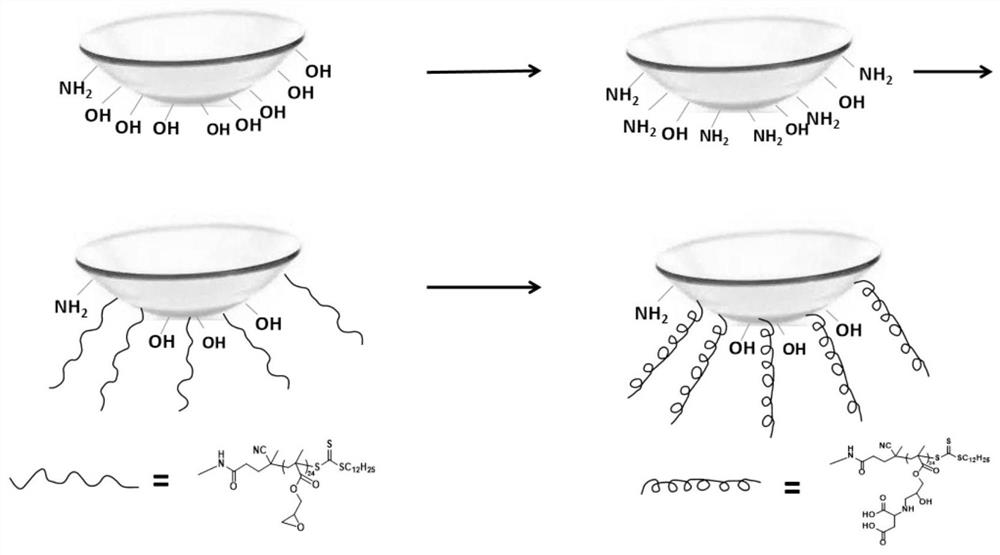

[0034] The preparation of surface aspartic acid modified corneal contact lens, the experimental flow chart is as follows figure 1 shown.

[0035] step 1:

[0036] Put HEMA (1 mL), methacrylic acid (MAA) (8.5 μL), crosslinker ethylene glycol dimethacrylate (EGDMA) (15 μL), and photoinitiator 1299 (9.5 μL) into contact lens preparation The mold was reacted in an ultraviolet curing reactor for 30 min, and then placed in a mixed solution of ethanol and water to release the mold to obtain a contact lens.

[0037] Step 2:

[0038] Place the contact lens prepared in step 1 and 3-aminopropyltriethoxysilane in an acetone solution, stir and react at room temperature for 8 h, wash the contact lens twice with ethanol and water after the reaction is completed, and soak in 24 h in distilled water, changing the water every 8 h.

[0039] Step 3:

[0040] Using glycidyl methacrylate (GMA) as monomer (0.71 g, 5 mmol), RAFT chain transfer agent (61 mg, 0.167 mmol), AIBN (2.7 mg, 0.0167 mmol)...

Embodiment 2

[0046] Preparation of Surface Serine Modified Corneal Contact Lens

[0047] Step 1: Mix HEMA (1 mL), N-vinylpyrrolidone (NVP) (12.0 μL), crosslinker ethylene glycol dimethacrylate (EGDMA) (12 μL), and thermal initiator AIBN (20 mg) Put it into a contact lens preparation mold, react in a 70-degree constant temperature oven for 8 h, and place it in a mixed solution of ethanol and water to demould to obtain a contact lens.

[0048] Step 2, step 3 and step 4 are the same as the steps in embodiment 1.

[0049] Step 5: Add a certain amount of serine to the ethanol / water (1:4, v / v) mixed solution to prepare a 0.1 mol / L amino acid aqueous solution, and adjust the pH value to 10~12. Put the corneal contact lens prepared in step 4 into the amino acid aqueous solution, then place it in a constant temperature shaking box, and react at 50 °C for 24 h. After the reaction is finished, the corneal contact lens is taken out, and the pH value of the solution is washed to 7 with distilled wate...

Embodiment 3

[0051] Preparation of corneal contact lens modified with lactobionic acid

[0052] The experimental flow chart is as Figure 5 shown. Step 1 and step 2 are the same as those in Example 1.

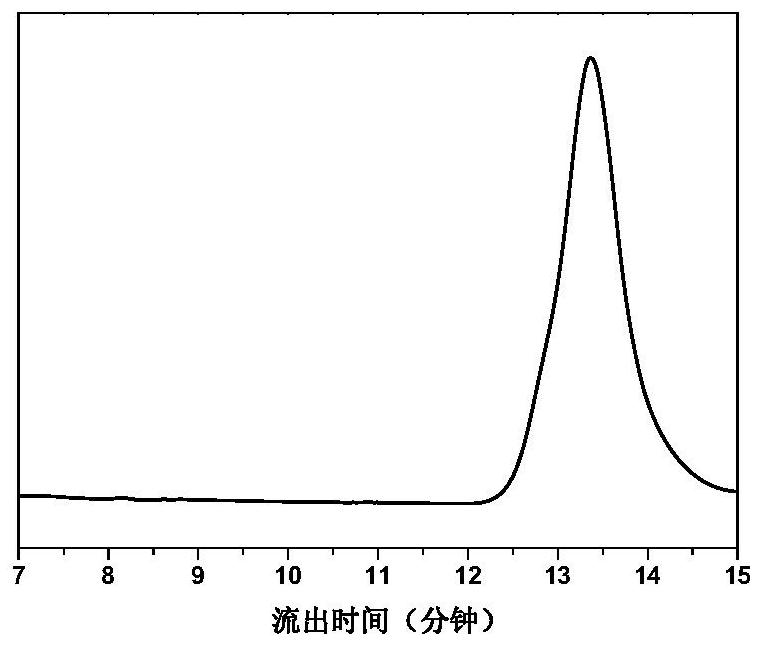

[0053] Step 3: Using glycidyl methacrylate (GMA) as monomer (0.71 g, 5 mmol), add RAFT chain transfer agent (36.5 mg, 0.1 mmol), AIBN (2.7 mg, 0.0167 mmol), the oxygen in the reaction tube was removed through three cycles of liquid nitrogen freezing-vacuumizing-thawing and nitrogen gas circulation. Add 8 mL of tetrahydrofuran. It was placed in an oil bath at 70°C for 8 h, and after the reaction was completed, the atmosphere was vented and the reaction was quenched in an ice bath. The reaction solution was dropped into n-hexane for precipitation. After the polymer was purified by two dissolution-precipitation methods, it was dried to obtain polyglycidyl methacrylate (PGMA). The conversion rate of monomer is about 78%, and the degree of polymerization is 39.

[0054] Step 4: PGMA (50 m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com