Manufacturing technique for sound-insulating foam glass

A production process and sound-insulating foam technology, which is applied in the coating and other directions, can solve the problems of insufficient thermal conductivity, poor thermal stability, and poor sound insulation performance, and achieve the effect of increasing viscosity, good thermal stability, and stabilizing the bubble structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

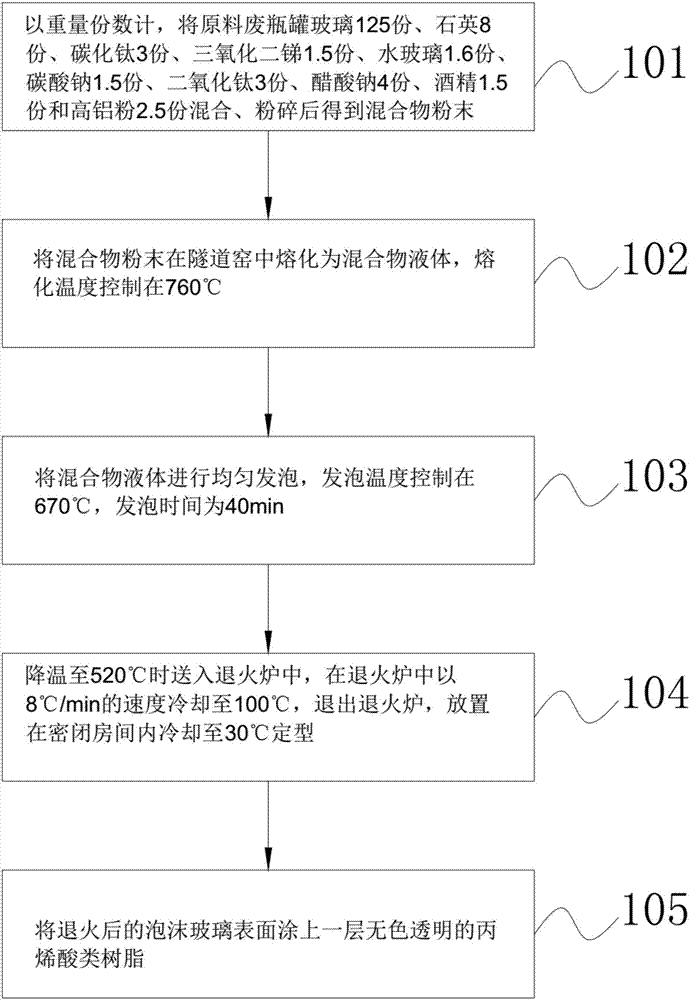

Embodiment 1

[0035] Such as figure 1 As shown, a production process of sound insulation foam glass includes the following steps:

[0036] 101. In parts by weight, combine 125 parts of raw material waste glass, 8 parts of quartz, 3 parts of titanium carbide, 1.5 parts of antimony trioxide, 1.6 parts of water glass, 1.5 parts of sodium carbonate, 3 parts of titanium dioxide, and 4 parts of sodium acetate. 1 part, 1.5 parts alcohol and 2.5 parts high-alumina powder are mixed and crushed to obtain a mixture powder;

[0037] 102. Melt the mixed powder into a mixed liquid in a tunnel kiln, and control the melting temperature at 760°C;

[0038] 103. Perform uniform foaming of the mixture liquid, the foaming temperature is controlled at 670℃, and the foaming time is 40min;

[0039] 104. When the temperature is lowered to 520℃, it will be sent to the annealing furnace, cooled to 100℃ at a rate of 8℃ / min in the annealing furnace, exit the annealing furnace, and placed in a closed room to cool to 30℃ for fin...

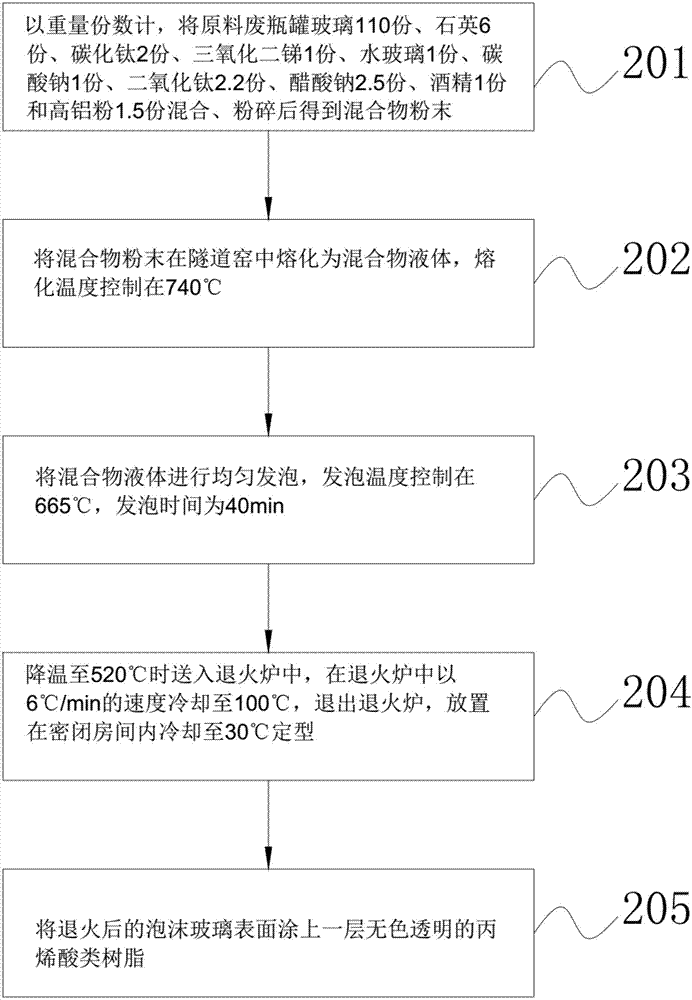

Embodiment 2

[0053] Such as figure 2 As shown, a production process of sound insulation foam glass includes the following steps:

[0054] 201. In terms of parts by weight, take 110 parts of raw material waste glass, 6 parts of quartz, 2 parts of titanium carbide, 1 part of antimony trioxide, 1 part of water glass, 1 part of sodium carbonate, 2.2 parts of titanium dioxide, 2.5 parts of sodium acetate. 1 part, 1 part of alcohol and 1.5 parts of high alumina powder are mixed and crushed to obtain the mixture powder;

[0055] 202. Melt the mixed powder into a mixed liquid in a tunnel kiln, and control the melting temperature at 740°C;

[0056] 203. Perform uniform foaming of the mixture liquid, the foaming temperature is controlled at 665°C, and the foaming time is 40 minutes;

[0057] 204. When the temperature is lowered to 520℃, it will be sent to the annealing furnace, cooled to 100℃ at a rate of 6℃ / min in the annealing furnace, exit the annealing furnace, and placed in a closed room to cool to 30...

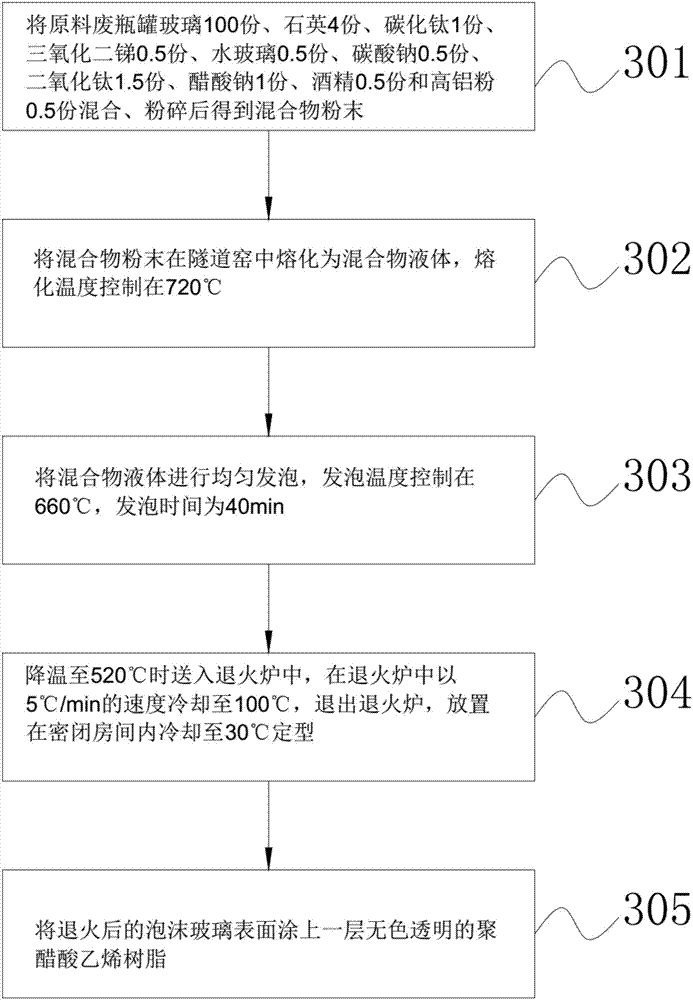

Embodiment 3

[0071] Such as image 3 As shown, a production process of sound insulation foam glass includes the following steps:

[0072] 301. In terms of parts by weight, combine 100 parts of waste glass bottles, 4 parts of quartz, 1 part of titanium carbide, 0.5 parts of antimony trioxide, 0.5 parts of water glass, 0.5 parts of sodium carbonate, 1.5 parts of titanium dioxide, and 1 part of sodium acetate. 1 part, 0.5 part of alcohol and 0.5 part of high alumina powder are mixed and crushed to obtain the mixture powder;

[0073] 302. Melt the mixed powder into a mixed liquid in a tunnel kiln, and control the melting temperature at 720°C;

[0074] 303. Perform uniform foaming of the mixture liquid, the foaming temperature is controlled at 660°C, and the foaming time is 40 minutes;

[0075] 304. When the temperature is lowered to 520℃, it will be sent to the annealing furnace, cooled in the annealing furnace at a rate of 5℃ / min to 100℃, exit the annealing furnace, and placed in a closed room to co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com