Phase change material nano capsule and preparation method thereof

A technology of nanocapsules and phase change materials, applied in the direction of heat exchange materials, chemical instruments and methods, etc., can solve the problems of difficult micron capsule phase change material slurry, capsule rupture, etc., to achieve reduced shell thickness, better Combining ability, improving the effect of phase change energy storage performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

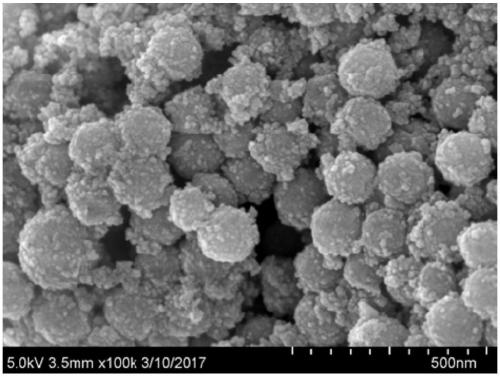

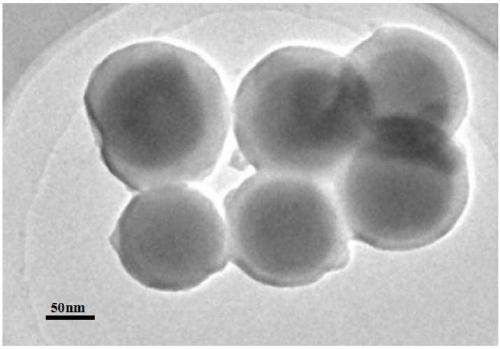

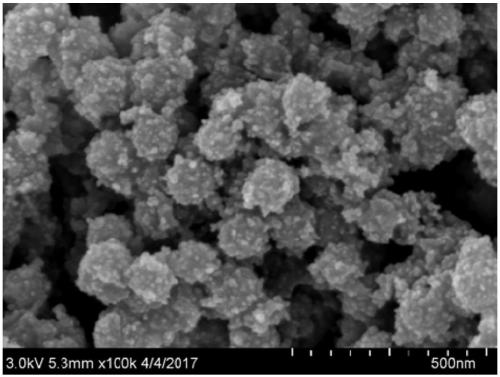

Image

Examples

Embodiment 1

[0027] A nanocapsule of phase change material, comprising the following steps of preparation:

[0028] (1) Weigh lauric acid, sodium lauryl sulfate, n-butanol, and deionized water in a ratio of 1:0.01:0.5:100 by weight, and weigh the fatty acid, anionic surfactant, and deionized water After the water is mixed, stir and melt in a 60°C water bath. After it is completely melted, add the additive dropwise, and stir well. The stirring speed is 900r / min, and the stirring time is 50min, and the lauric acid emulsion is obtained;

[0029] (2) Mix ethyl orthosilicate, absolute ethanol and deionized water in a volume ratio of 1:6:4, and stir evenly, then add ammonia water and continue stirring for 15 minutes. The amount of ammonia water added is the same as that of ethyl orthosilicate The volume ratio is 0.2:1, and the silica sol can be obtained by stirring evenly;

[0030] (3) Add the lauric acid emulsion prepared in step (1) dropwise to the silica sol prepared in step (2), keep the wa...

Embodiment 2

[0033] A nanocapsule of phase change material, comprising the following steps of preparation:

[0034] (1) Stearic acid and sodium lauryl sulfate, n-butanol and deionized water are weighed in a ratio of 1:0.01:0.5:100 by weight, and the weighed fatty acid and anionic surfactant, deionized water After the ionic water is mixed, it is stirred and melted in a 60°C water bath, and after it is completely melted, the additive is added dropwise, fully stirred evenly, the stirring speed is 900r / min, and the stirring time is 50min, and the stearic acid emulsion is obtained;

[0035] (2) Mix ethyl orthosilicate, absolute ethanol and deionized water in a volume ratio of 1:6:4, and stir evenly, then add ammonia water and continue stirring for 15 minutes. The amount of ammonia water added is the same as that of ethyl orthosilicate The volume ratio is 0.2:1, and the silica sol can be obtained by stirring evenly;

[0036] (3) Add the stearic acid emulsion prepared by step (1) dropwise into t...

Embodiment 3

[0039] A nanocapsule of phase change material, comprising the following steps of preparation:

[0040] (1) Weigh palmitic acid, sodium lauryl sulfate, n-butanol and deionized water in a ratio of 1:0.01:0.5:100 by weight, and weigh the fatty acid and anionic surfactant, deionized After the water is mixed, stir and melt in a 75°C water bath. After it is completely melted, add the additive dropwise, and stir well. The stirring speed is 900r / min, and the stirring time is 50min, and the palmitic acid emulsion is obtained;

[0041](2) Mix ethyl orthosilicate, absolute ethanol and deionized water in a volume ratio of 1:6:4, and stir evenly, then add ammonia water and continue stirring for 15 minutes. The amount of ammonia water added is the same as that of ethyl orthosilicate The volume ratio is 0.2:1, and the silica sol can be obtained by stirring evenly;

[0042] (3) Add the palmitic acid emulsion prepared in step (1) dropwise to the silica sol prepared in step (2), keep the water...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com