Modified four-feet needle-shaped zinc oxide crystal whisker and preparation method thereof

A zinc oxide whisker and needle-like technology, which is applied in the field of modified four-legged needle-like zinc oxide whiskers and its preparation, can solve the problems of incomplete coating of nano-silica, weak bond between the whiskers and polymer matrix, and unsatisfactory properties. See reports on zinc oxide treatment, etc., to achieve the effects of mild conditions, improved interface bonding, and easy implementation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

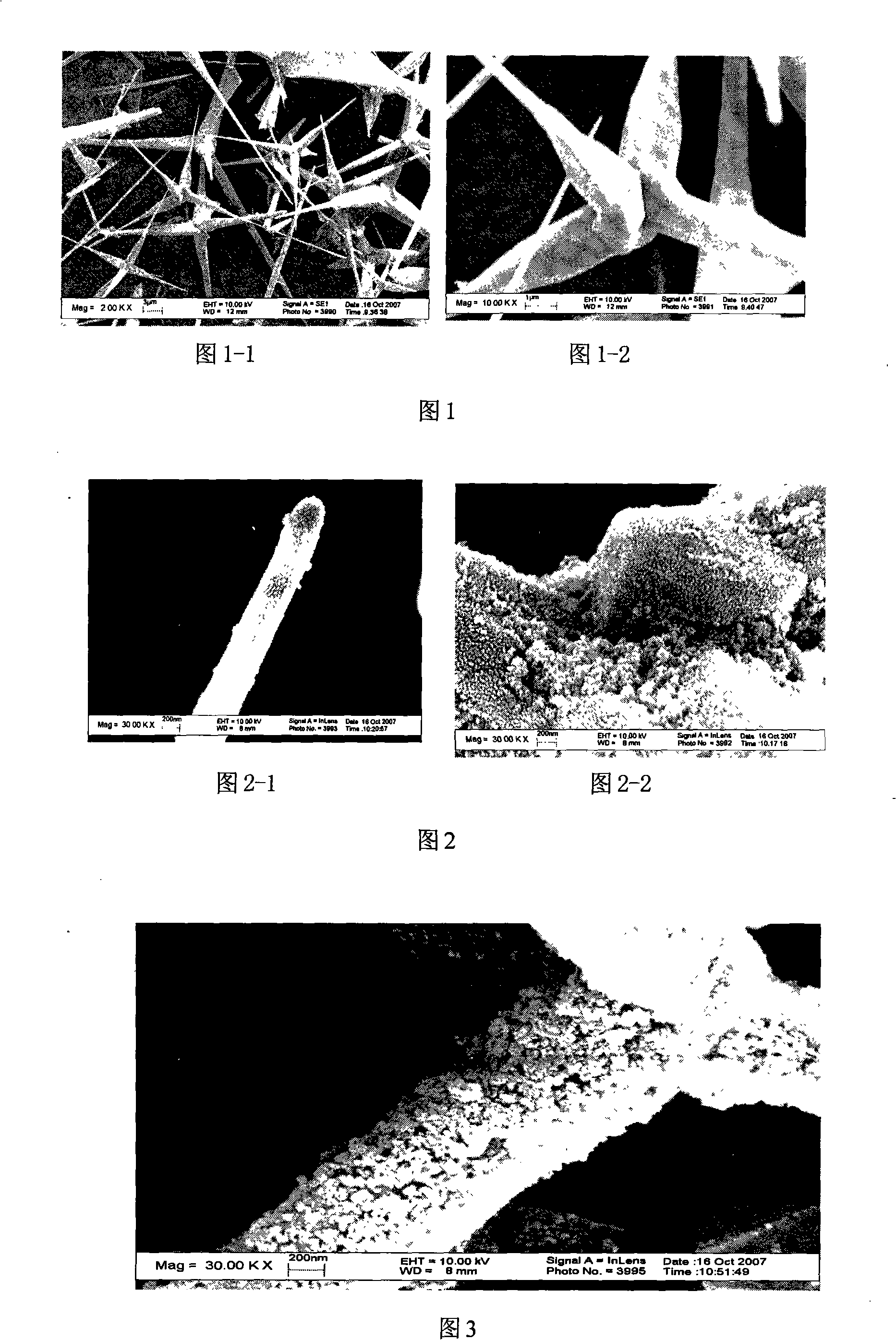

Image

Examples

Embodiment 1

[0032] Example 1: Table 1 is the raw material formula for preparing the modified four-legged acicular zinc oxide whiskers in this example.

[0033] Table 1

[0034] Raw materials (parts by weight)

1#

2#

3#

4#

5#

Four-legged needle-shaped zinc oxide crystal

must

100

100

100

100

100

1

23.66

47.32

70.98

100

1

17.6

35.2

52.8

100

water

100

600

800

1000

1200

[0035] Disperse the four-legged needle-shaped zinc oxide whiskers in deionized water, add hydrated sodium silicate, stir at 60 °C to make it evenly dispersed, then add ethyl acetate, and stir in a water bath at 60 °C for 4 hours, the product is filtered, washed, and dried to At constant weight, four-legged needle-shaped zinc oxide whiskers coated with a certain amount of nano-silica...

Embodiment 2

[0041] Example 2: Table 3 is the raw material formula of the modified four-legged needle-shaped zinc oxide whiskers prepared in this example.

[0042] table 3

[0043] raw material (weight

amount)

1#

2#

3#

4#

5#

6#

7#

8#

9#

10#

11#

12#

four pin

oxidation

Zinc whiskers

100

100

100

100

100

100

100

100

100

100

100

100

Hydrated silicon

9.46

23.6

6

47.3

2

70.9

8

94.6

4

9.46

9.46

9.46

9.46

9.46

9.46

9.46

[0044] Ethyl acetate

Ester

7.04

17.6

35.2

52.8

70.4

35.2

35.24

35.2

...

Embodiment 3

[0054] In order to investigate the effect of the amount of organosiloxane added on the amount of nano-silica coated on zinc oxide whiskers, Table 5 lists the raw material formulations of modified four-legged needle-shaped zinc oxide whiskers with different amounts of KH570 and KH560.

[0055] table 5

[0056] Raw materials (parts by weight)

[0057] Disperse the four-legged needle-shaped zinc oxide whiskers in deionized water, add hydrated sodium silicate, stir at 40°C to make it evenly dispersed, then add ethyl acetate, and after stirring for 10 hours, the product is filtered and washed; Mix and stir with 95% ethanol, add organosiloxane, stir at 40°C for 2 hours, filter, wash, and dry to constant weight to prepare four-legged acicular oxide coated silica with different coupling agent contents. For zinc whiskers, a certain amount of four-legged acicular zinc oxide whiskers coated with silica that have been prepared by coupling agent were calcined in a muffle furnace ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com