Floatation process for oxidized coal slime

A technology for coal slime and clean coal, applied in flotation, solid separation and other directions, can solve the problems of large consumption of chemicals, low efficiency, poor floatability, etc., and achieve the effect of improving the effect of flotation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Embodiment 1: Carry out flotation test with Vc as reducing agent, kerosene as collector, and 2-octanol as foaming agent.

[0033] The flotation process of the present embodiment comprises the following steps:

[0034] Use Vc to test the dosage of reducing agent on oxidized coal slime. The specific operation steps are as follows: After the slurry level reaches the marking line, weigh a certain amount of Vc and add it to the flotation tank to adjust the slurry. After 2 minutes, add kerosene, continue to adjust the slurry for 1 minute, and then add Second-octanol, after stirring for 10s, start to scrape the bubbles, and the scraping time is 3min. The obtained product is filtered, dried, weighed and assayed.

[0035] In this example, the dosage of Vc is 1.25~10kg / t oxidized coal slime; the dosage of collector kerosene is 1000g / t; the dosage of foaming agent 2-octanol is 100g / t.

[0036] Present embodiment has chosen different Vc consumptions, and gained flotation test res...

Embodiment 2

[0040] Embodiment 2: Carry out flotation test with Vc as reducing agent, kerosene as collector, and 2-octanol as foaming agent.

[0041] In this embodiment, flotation tests were carried out for different pH values of the ore slurry, and the pH values were respectively selected as 3, 5, 6, 7, 9, and 11.

[0042] The flotation process of the present embodiment comprises the following steps:

[0043] (1) Add reducing agent Vc to the pulp, the dosage is 10000g / t, and mix the pulp and stir for 2min;

[0044] (2) Add collector kerosene, the dosage is 1000g / t, stir for 1min;

[0045] (3) Add the foaming agent 2-octanol, the dosage is 100g / t, and stir for 10s;

[0046] (4) Start to count and scrape bubbles for 3 minutes;

[0047] (5) The obtained product is filtered, dried, weighed and tested.

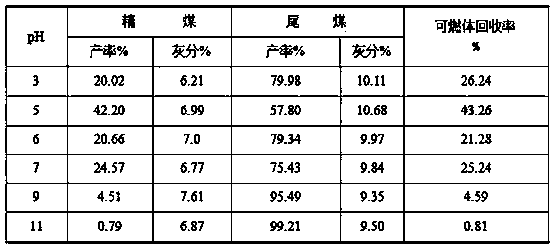

[0048] This embodiment carries out flotation test for the different pH values of ore pulp, and the flotation test result of gained is shown in Table 3:

[0049] Table 3 Test results...

Embodiment 3

[0052] Example 3: The flotation test was carried out with Vc as reducing agent, span80 and kerosene compounded as collector, and 2-octanol as foaming agent.

[0053] The flotation process of the present embodiment comprises the following steps:

[0054] (1) Adjust the pulp to be neutral: adjust pH=7;

[0055] (2) Add the reducing agent ascorbic acid (Vc), the dosage is 1250g / t, and the slurry is stirred for 2 minutes;

[0056] (3) Add collector, the dosage is 1000g / t, stir for 1min;

[0057] The collector is compounded by span80 and kerosene, and the ratio of choosing Span80 and kerosene is: 20%: 80%;

[0058] (4) Add the foaming agent 2-octanol, the dosage is 100g / t, and stir for 10s;

[0059] (5) Start to count and scrape bubbles for 3 minutes;

[0060] (6) The obtained product is filtered, dried, weighed and tested.

[0061] The flotation test results under different reagent combinations are shown in Table 4:

[0062] Table 4 Flotation test results of oxidized coal sl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com