Method for treating hazardous waste incineration bottom ash by using plasma technology

A hazardous waste and technical treatment technology, applied in the field of ion technology to treat hazardous waste incineration slag, can solve the problems of inability to directly comprehensively utilize, high construction cost, strong regional monopoly, etc., to meet ultra-low leaching toxicity, meet technical requirements, The effect of broad promotion space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] Get medical waste incineration slag as raw material slag A, with 400 kg / h of raw material slag weight (which contains 100 kg of fly ash after washing treatment), put into continuous plasma furnace for plasma heating treatment. During the treatment process, add 40 kg of sodium-calcium ordinary glass frit, 5 kg of alumina, and 8 kg of calcium carbonate. The plasma heating treatment temperature is 1300 ° C. After 10 minutes of treatment, the material is continuously discharged, cooled with flowing water, and the water temperature is 20 degrees. . The produced vitrified slag was sampled and passed the waste toxicity leaching test.

Embodiment 2

[0051] Take medical waste incineration slag as raw material slag B, add 700 kg / h raw material slag weight (which contains 200 kg of washed fly ash) into continuous plasma furnace for plasma heating treatment. During the treatment process, add 140 kg of sodium-calcium ordinary glass frit, 10 kg of alumina, and 35 kg of calcium carbonate. Considering that the vitreous (glassy substance) is mixed with stainless steel substances (stainless steel substances include metal tweezers and other appliances in medical waste) , mixed into the glass body through the slag), the plasma heating treatment temperature is 1600 ° C, the treatment time is 19 minutes, and the material is continuously discharged, cooled with flowing water, and the water temperature is 20 ° C. Since the stainless steel substances mixed in the glass body are pure metal substances, they are separated from the vitrified slag after water cooling and can be sorted out later. The produced vitrified slag was sampled and pass...

Embodiment 3

[0053] Get medical waste incineration slag as raw material slag C, put into continuous plasma furnace and carry out plasma heat treatment with 500 kg / h raw material slag weight (which contains 100 kg of fly ash after washing treatment). During the treatment process, 7 kg of alumina was added, 15 kg of calcium carbonate was added, the plasma heating temperature was 1200°C, and the material was discharged continuously after 12 minutes of processing time, and cooled with flowing water at a water temperature of 20°C. The produced vitrified slag was sampled and passed the waste toxicity leaching test.

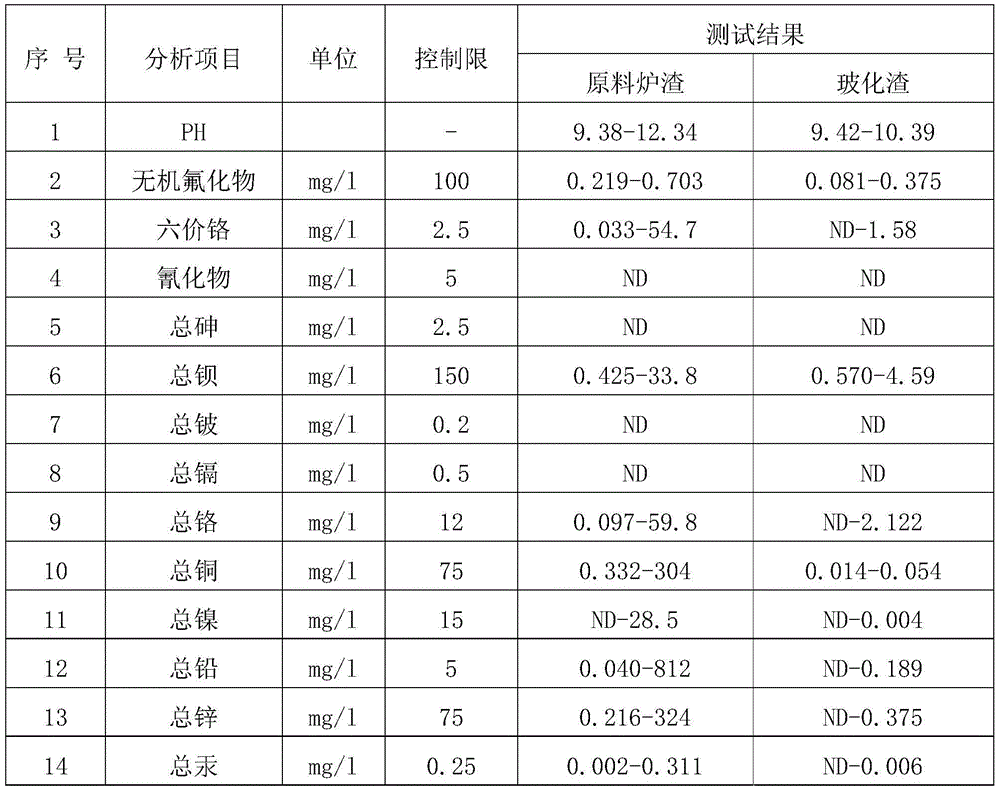

[0054] In summary, the present invention decomposes and destroys toxic organic substances including dioxins remaining in the slag by using high temperature generated by plasma, and the effectiveness can reach more than 99%, and forms a closed structure through heating and cooling Vitrified slag with high hardness and high strength can solidify the heavy metal ions contained in the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com