Method for preparing conductive carbon black and hydrogen by plasma technology

A technology of conductive carbon black and plasma, applied in chemical instruments and methods, hydrogen, chemical/physical/physical-chemical processes of applied energy, etc., can solve problems such as failure, achieve convenient shutdown and load regulation, and be beneficial to the environment Protective, wide-ranging effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

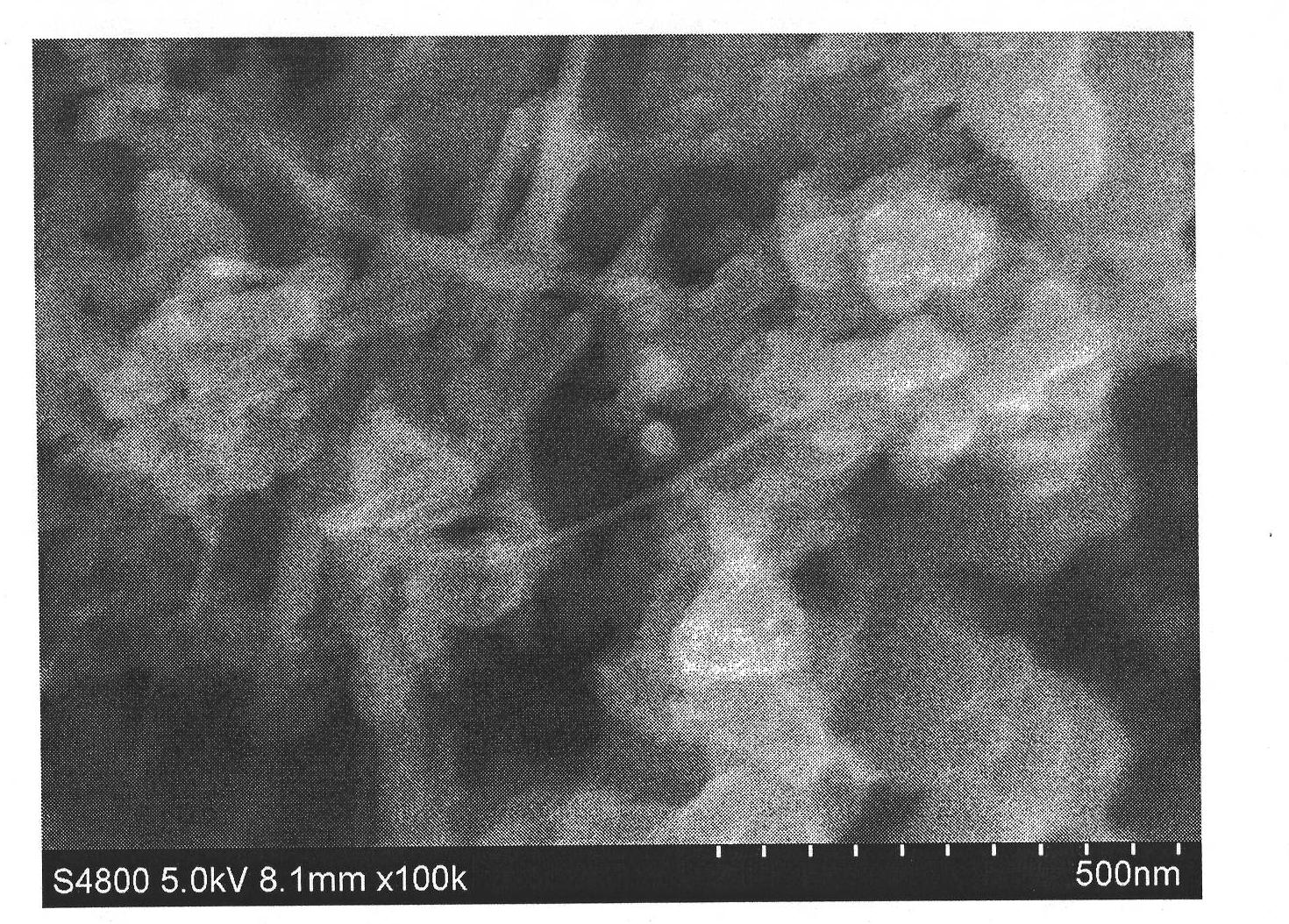

[0018] Embodiment 1: A method for producing conductive carbon black using methane as a raw material, using hydrogen as a carrier gas, adding methane into the carrier gas, discharging at a voltage of 360V, a current of 20A, and a discharge gap of 2 to 3 mm, using needle tip discharge Mode; the molar ratio of carbon source to hydrogen is 1:5, the residence time of the gas in the plasma generator is 0.01 second and then enters an insulated fluidized bed reactor; the primary plasma generator and fluidized bed reaction are adopted device. Its reaction scheme sees appendix figure 1 shown. In the test, it is measured by using a high-temperature radiometer. Under the above-mentioned working conditions, the temperature in the reactor is about 1200-1600 degrees, and the single-pass conversion rate of methane is about 30%. The SEM and TEM of the prepared product are as attached figure 2 And attached image 3 shown.

Embodiment 2

[0019] Embodiment 2: A method for producing conductive carbon black with propane as a raw material, using hydrogen as a carrier gas, adding propane to the carrier gas to carry out a cracking reaction, the voltage is 560-580V, the current is 25-30A, and the discharge gap is 3-5 mm, using pin-ring discharge mode; the molar ratio of carbon source to hydrogen is 1:5, the residence time of the gas in the plasma generator is 0.01 seconds and then enters an insulated fluidized bed reactor; the primary plasma is used generators and fluidized bed reactors. Its reaction scheme sees appendix figure 1 shown. It is found that there are many carbon nanotubes in the product conductive carbon black, and its HRTEM is as attached Figure 4 shown. The conversion of propane is about 50% per pass.

Embodiment 3

[0020] Embodiment three: a kind of method that is raw material production conductive carbon black and pure hydrogen with methane, use hydrogen as carrier gas, add methane in the carrier gas, the voltage of the first plasma generator is at 5kV, and electric current is at 10A, and discharge gap is 1.5 cm, using the needle ring discharge mode; the molar ratio of carbon source to hydrogen is 1:5, the residence time of the gas in the plasma generator is 0.02 seconds and then enters an insulated fluidized bed reactor; using three-stage plasma Combination of bulk generator and fluidized bed reactor, the voltage of the second plasma generator is 5kV, and the current is 8A; the voltage of the third plasma generator is 5kV, and the current is 5A. The purity of the final hydrogen is about 96%, with the remainder being unconverted methane.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com