Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

146results about How to "Reduce gap size" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

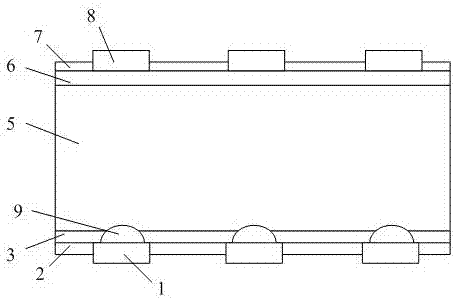

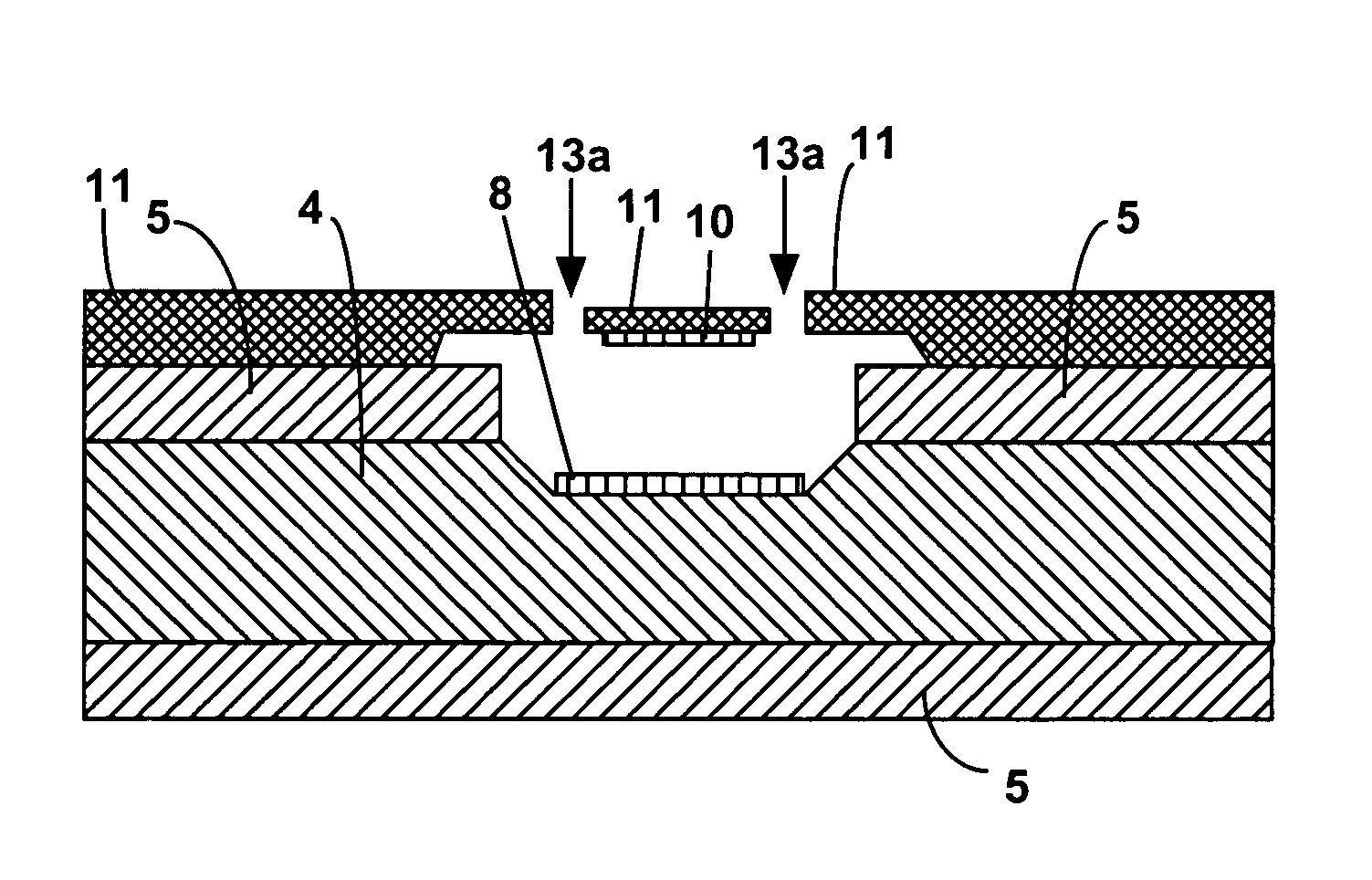

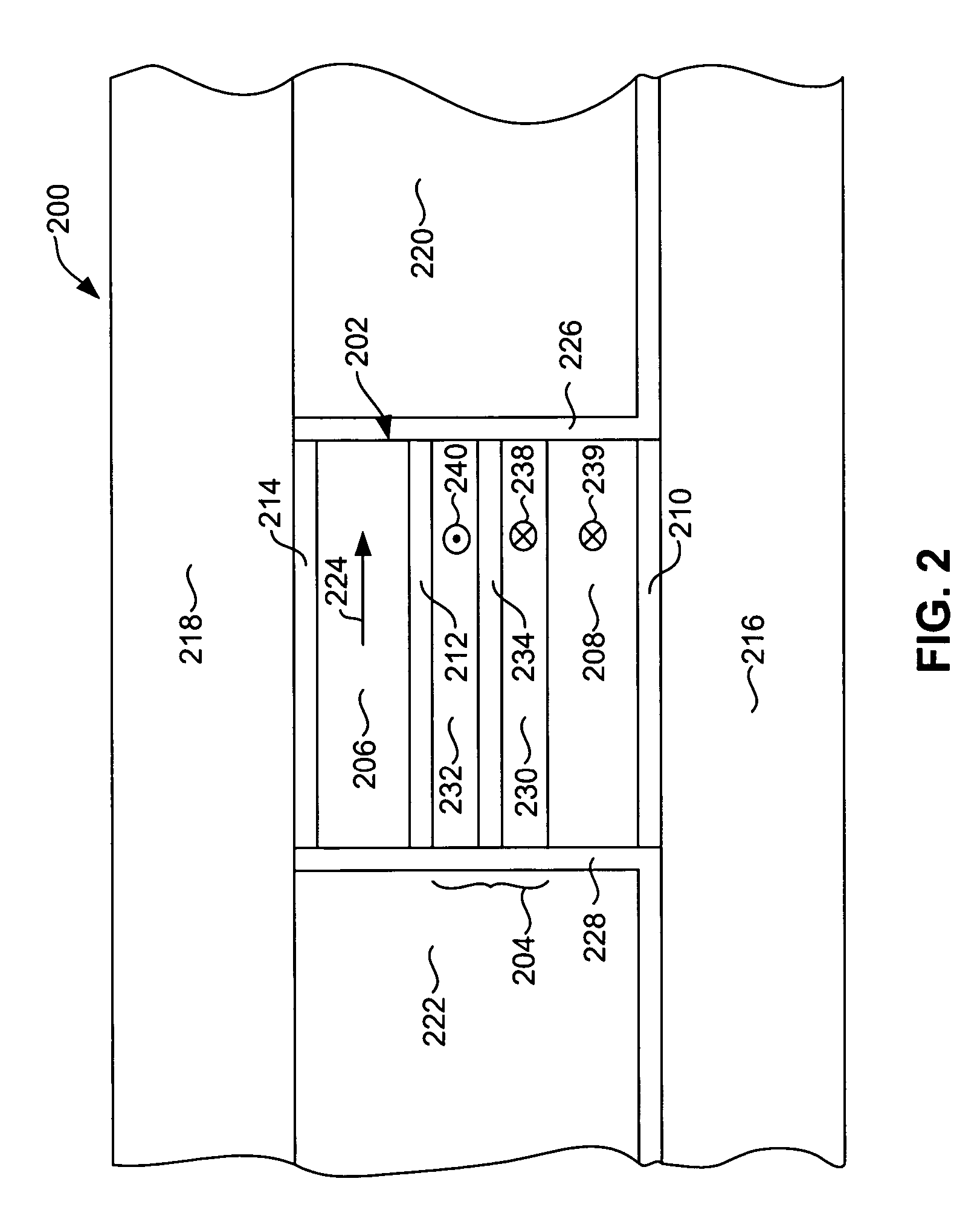

Impedance based devices and methods for use in assays

ActiveUS20050112544A1Increases magnitudeReduce gap sizeBioreactor/fermenter combinationsBiological substance pretreatmentsPhysicsElectrically conductive

A device for detecting cells and / or molecules on an electrode surface is disclosed. The device detects cells and / or molecules through measurement of impedence changes resulting from the cells and / or molecules. A disclosed embodiment of the device includes a substrate having two opposing ends along a longitudinal axis. A plurality of electrode arrays are positioned on the substrate. Each electrode array includes at least two electrodes, and each electrode is separated from at least one adjacent electrode in the electrode array by an expanse of non-conductive material. The electrode has a width at its widest point of more than about 1.5 and less than about 10 times the width of the expanse of non-conductive material. The device also includes electrically conductive traces extending substantially longitudinally to one of the two opposing ends of the substrate without intersecting another trace. Each trace is in electrical communication with at least one of the electrode arrays.

Owner:AGILENT TECH INC

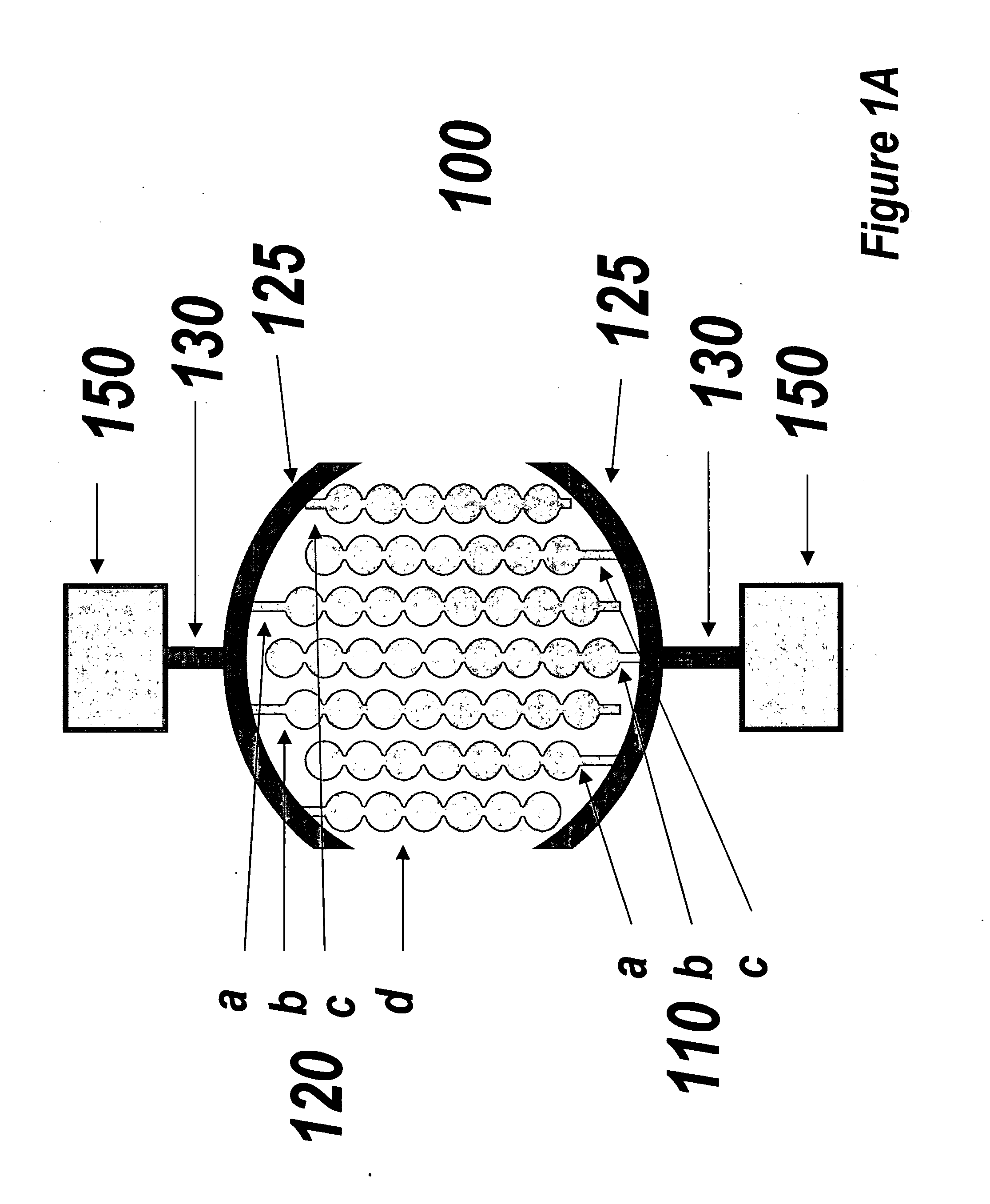

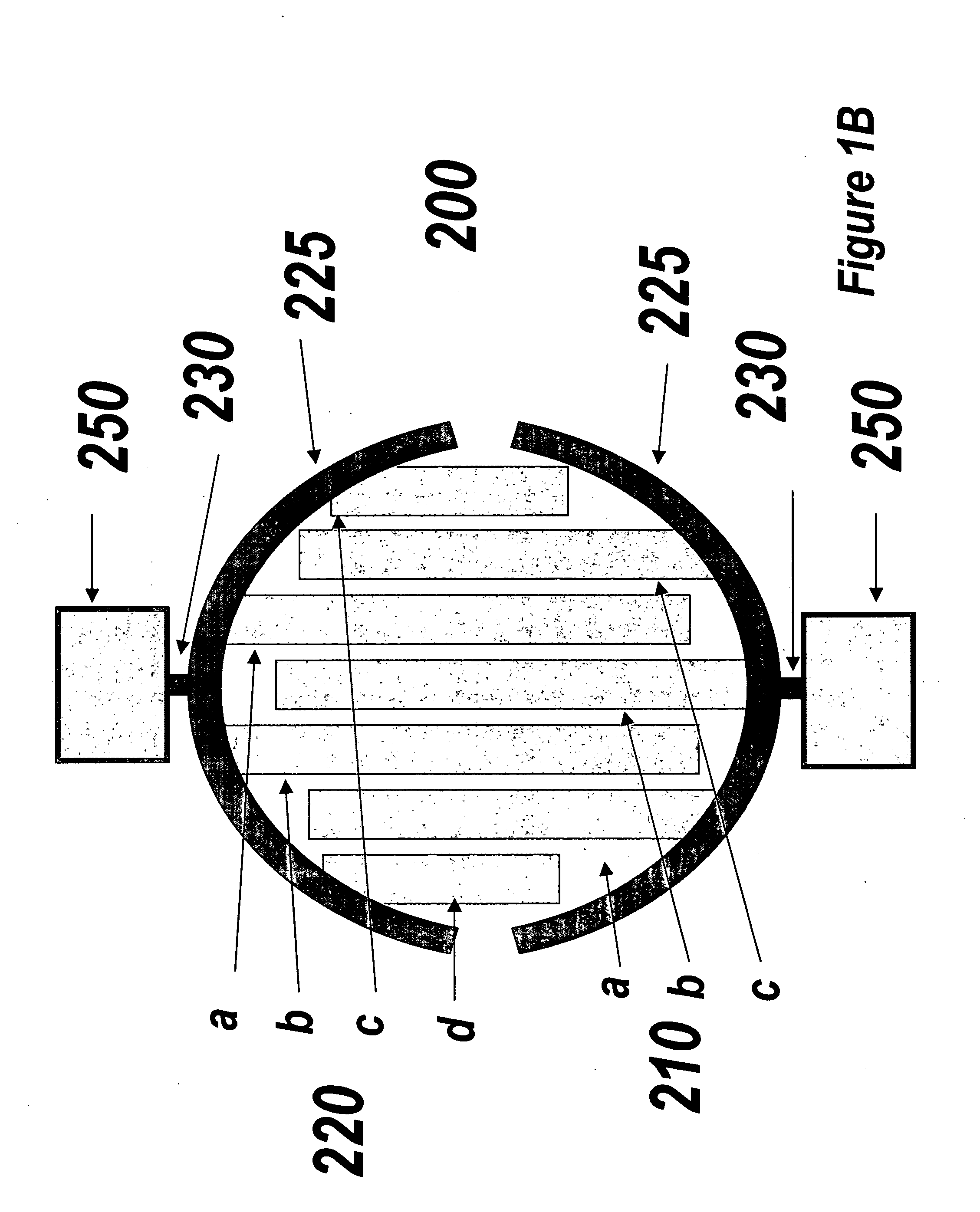

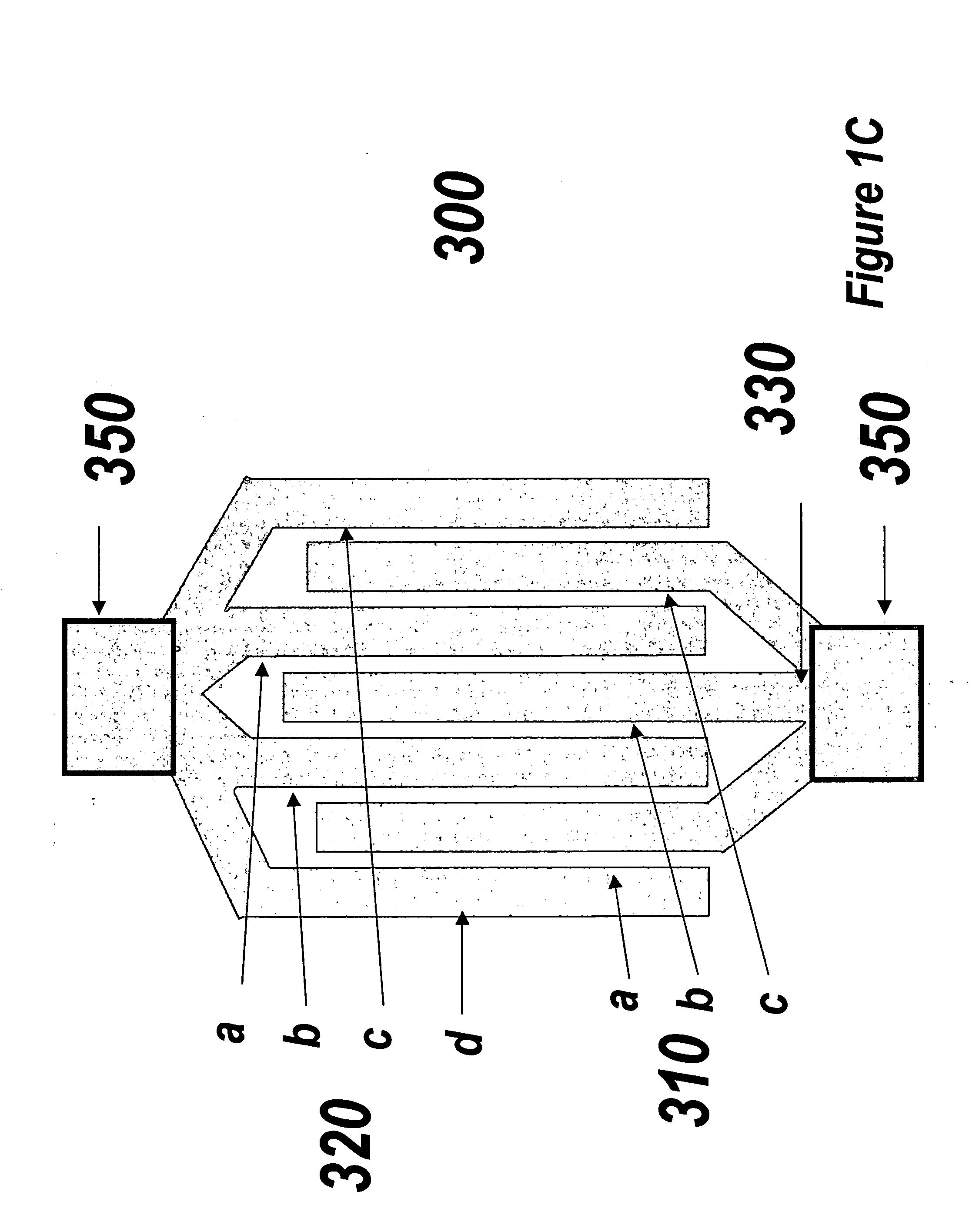

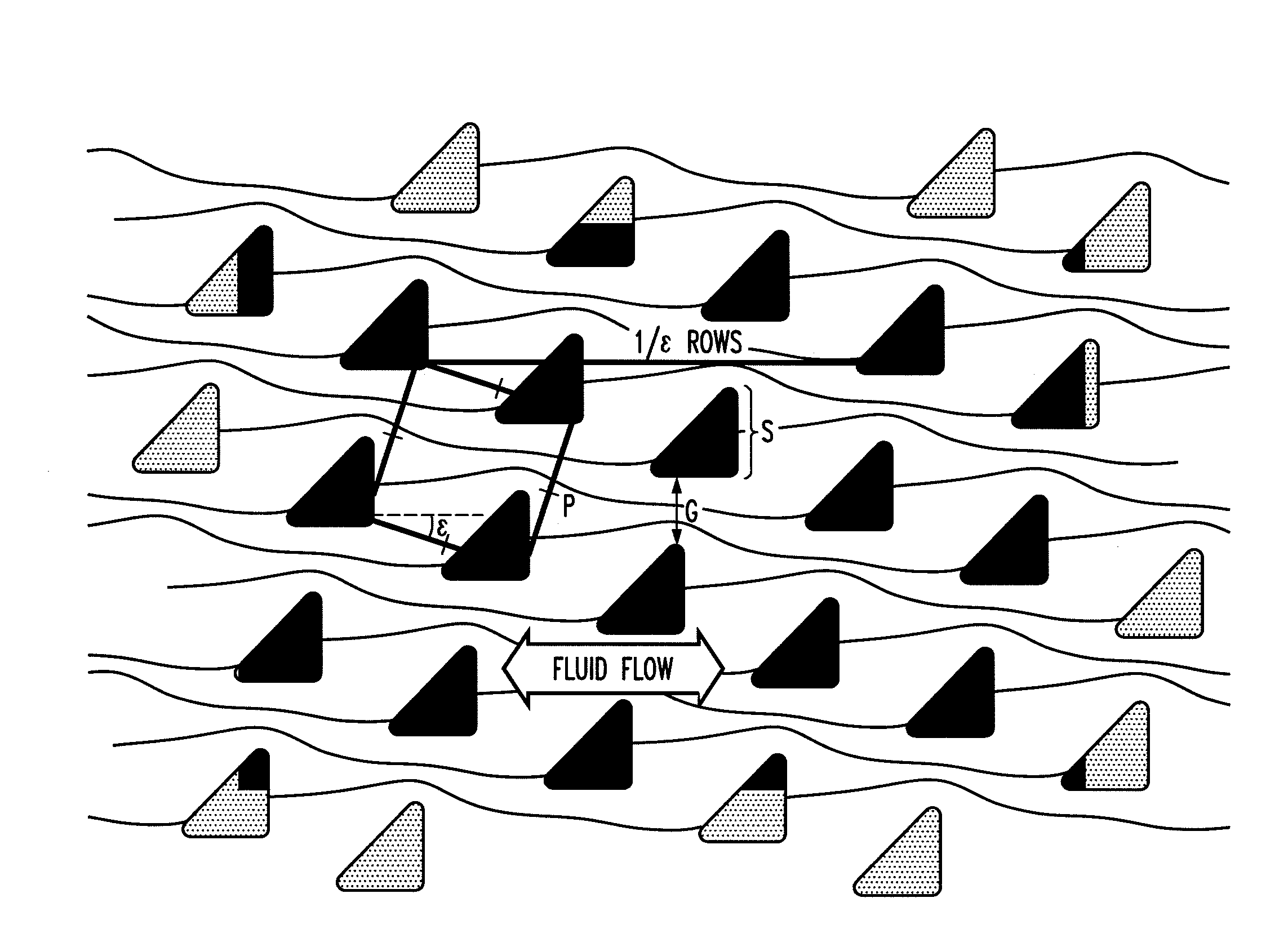

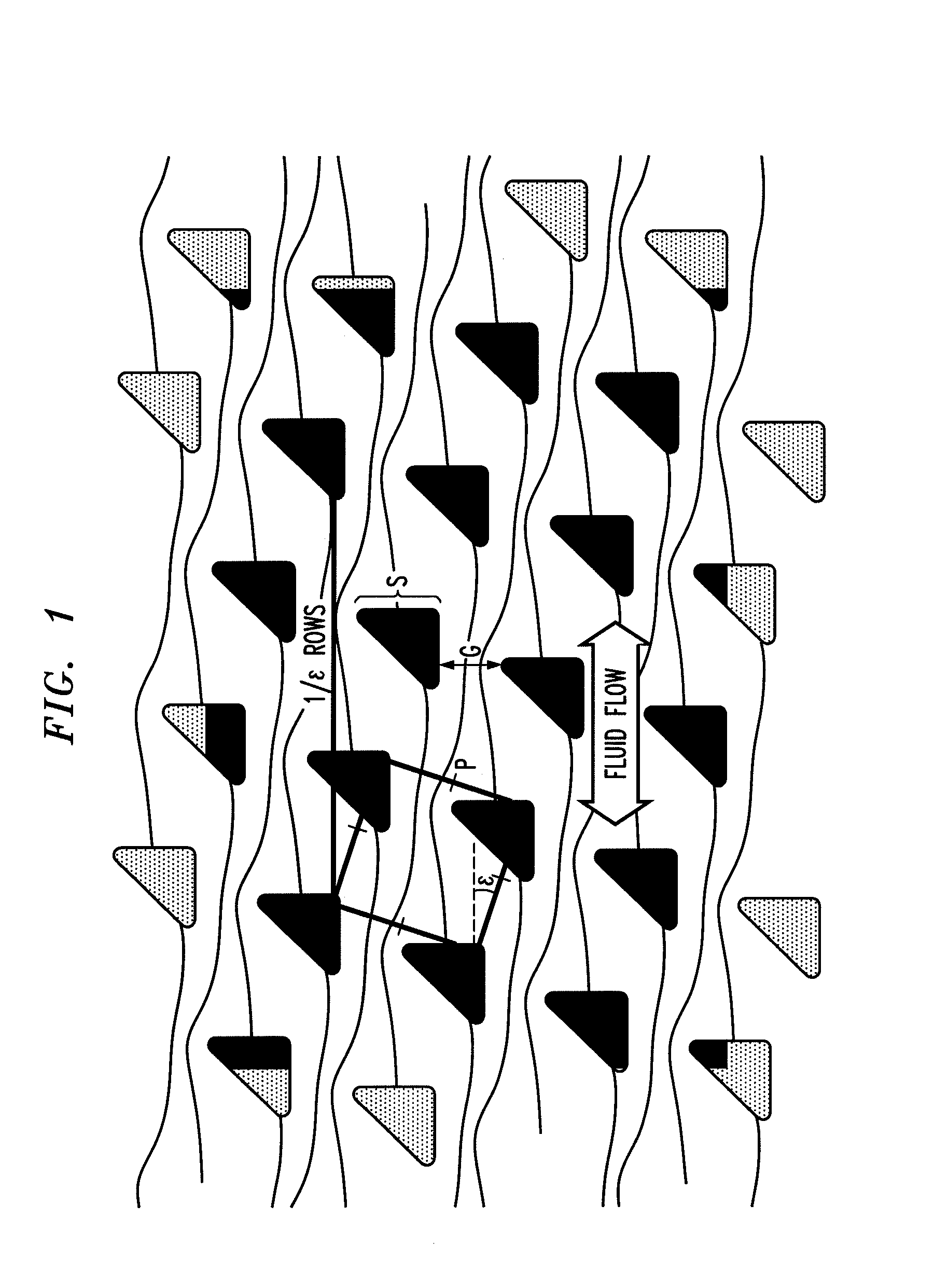

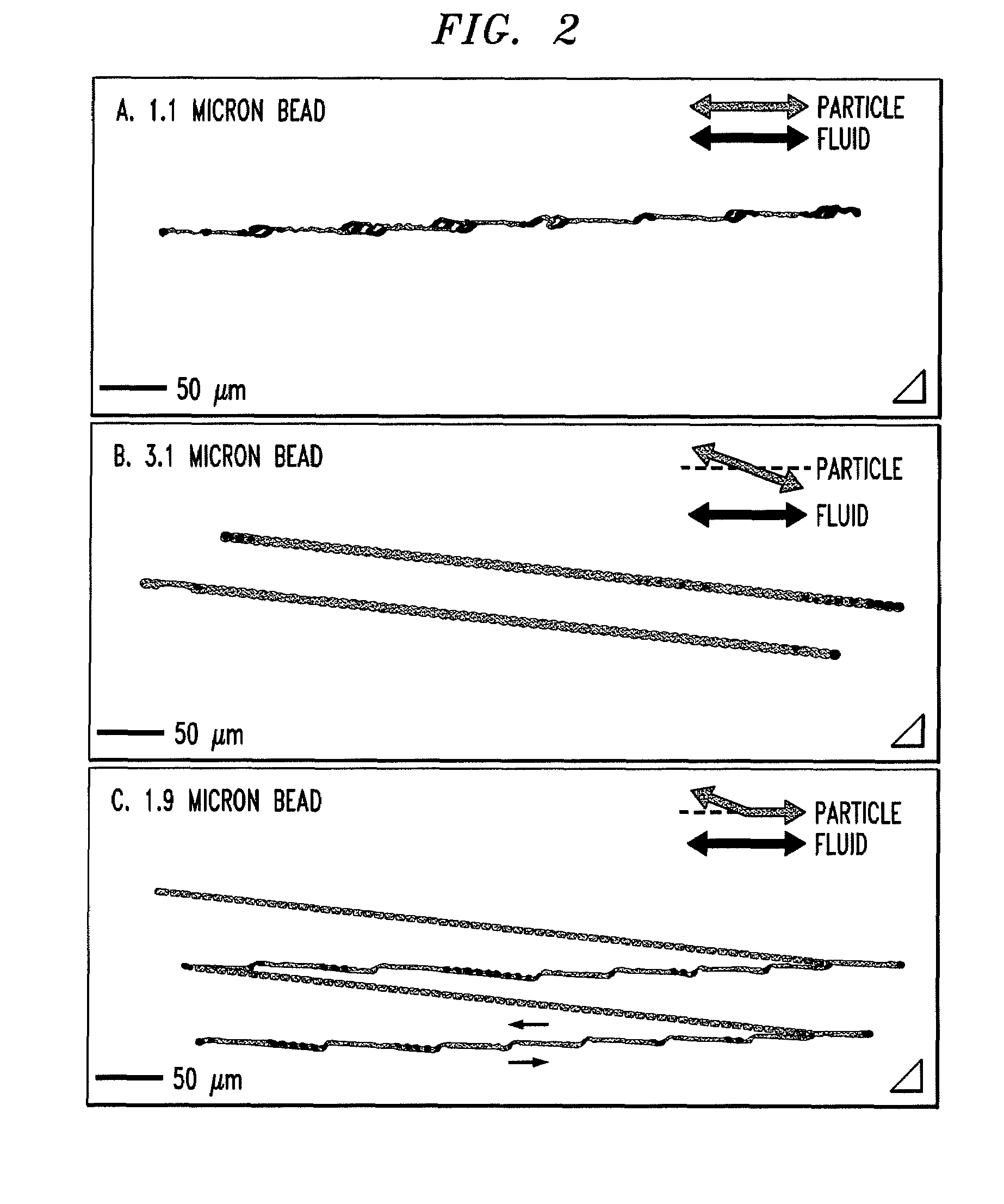

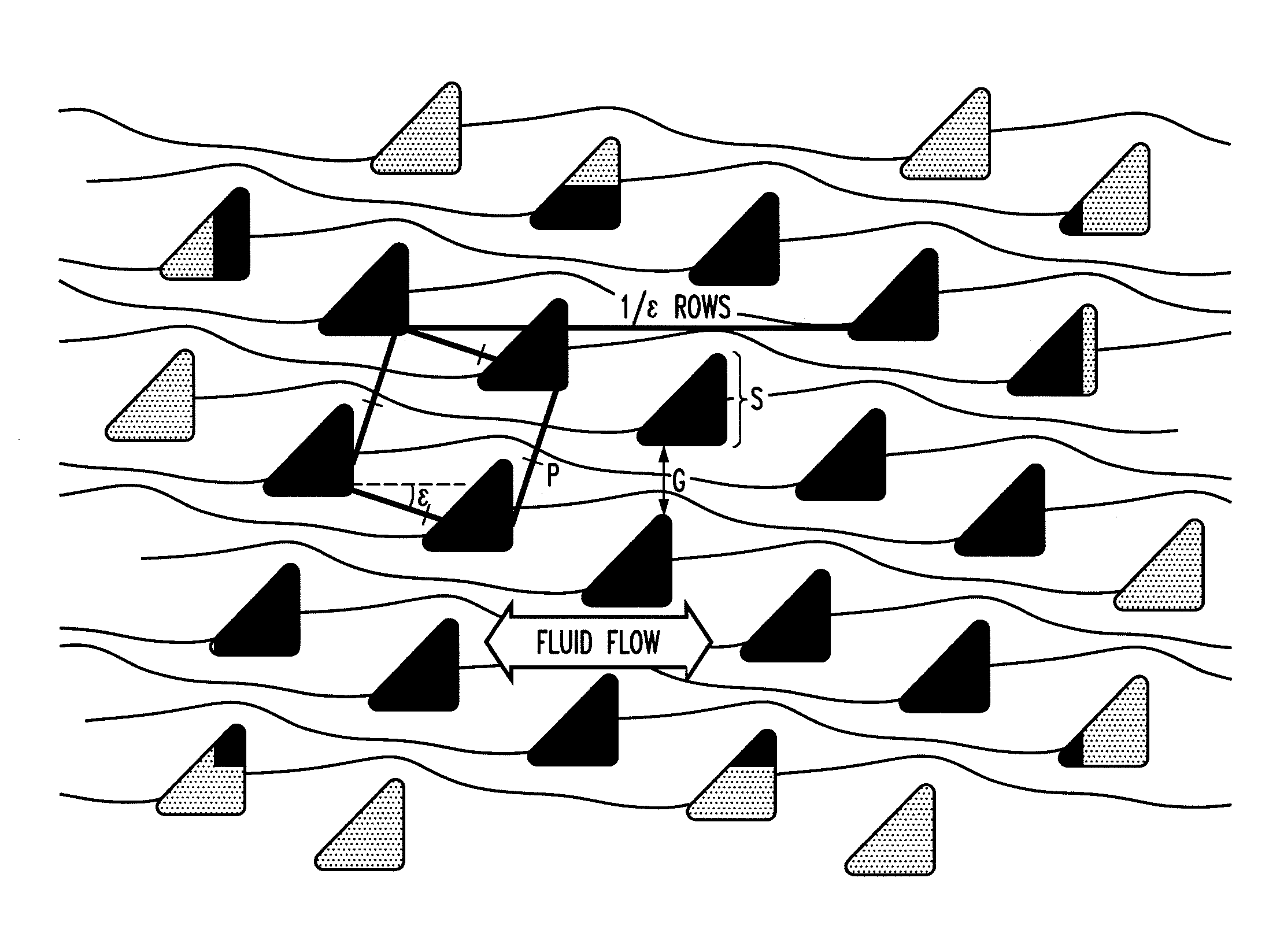

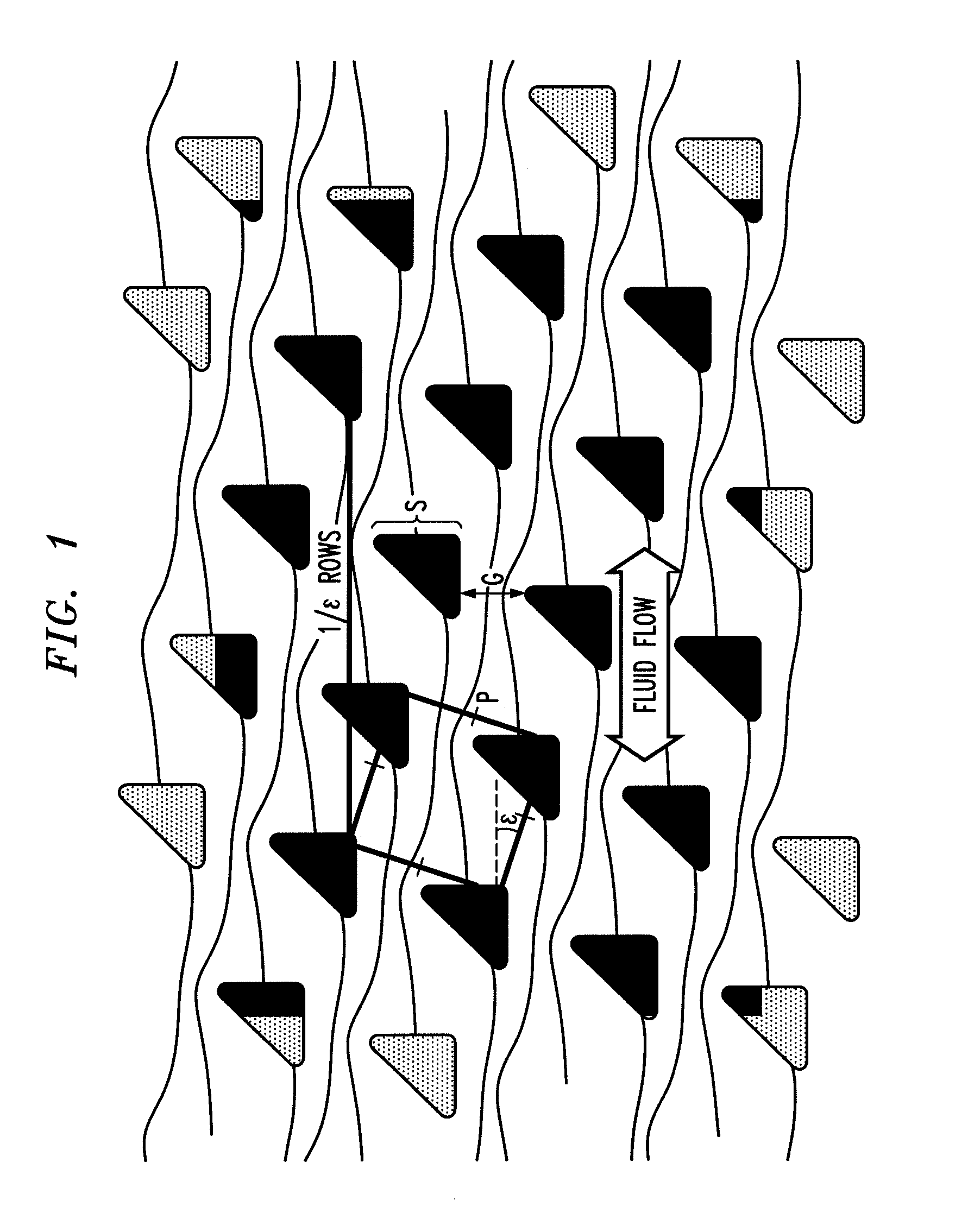

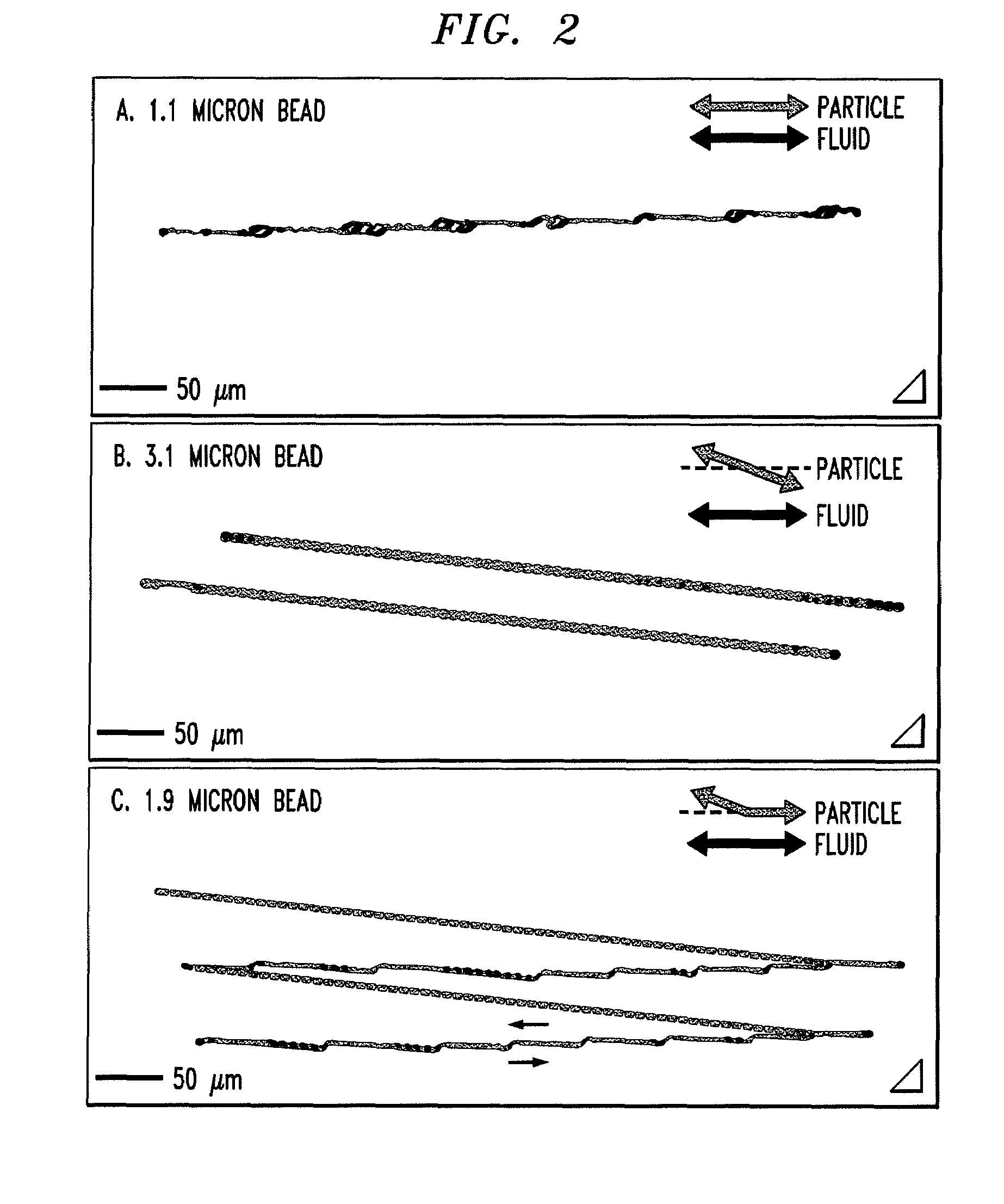

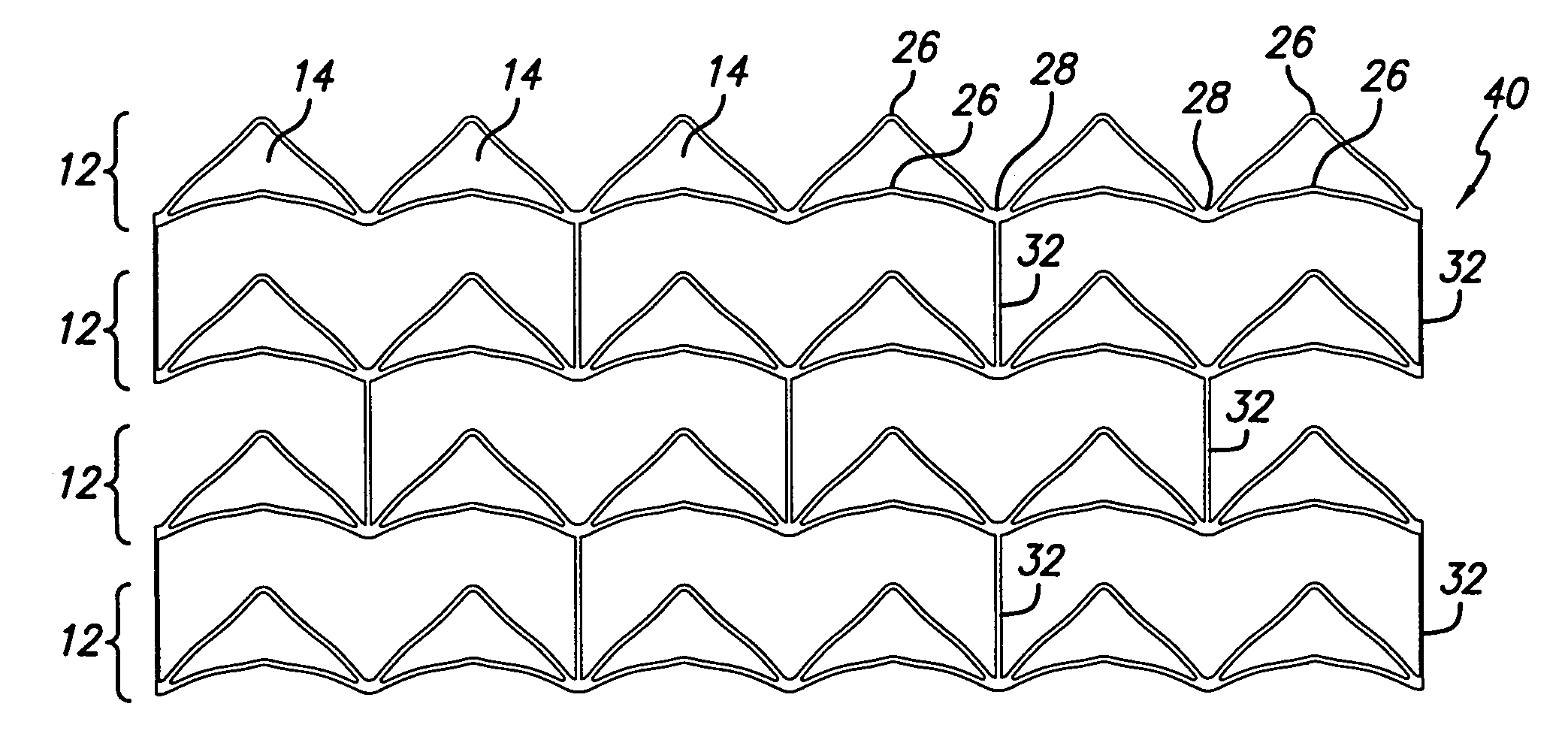

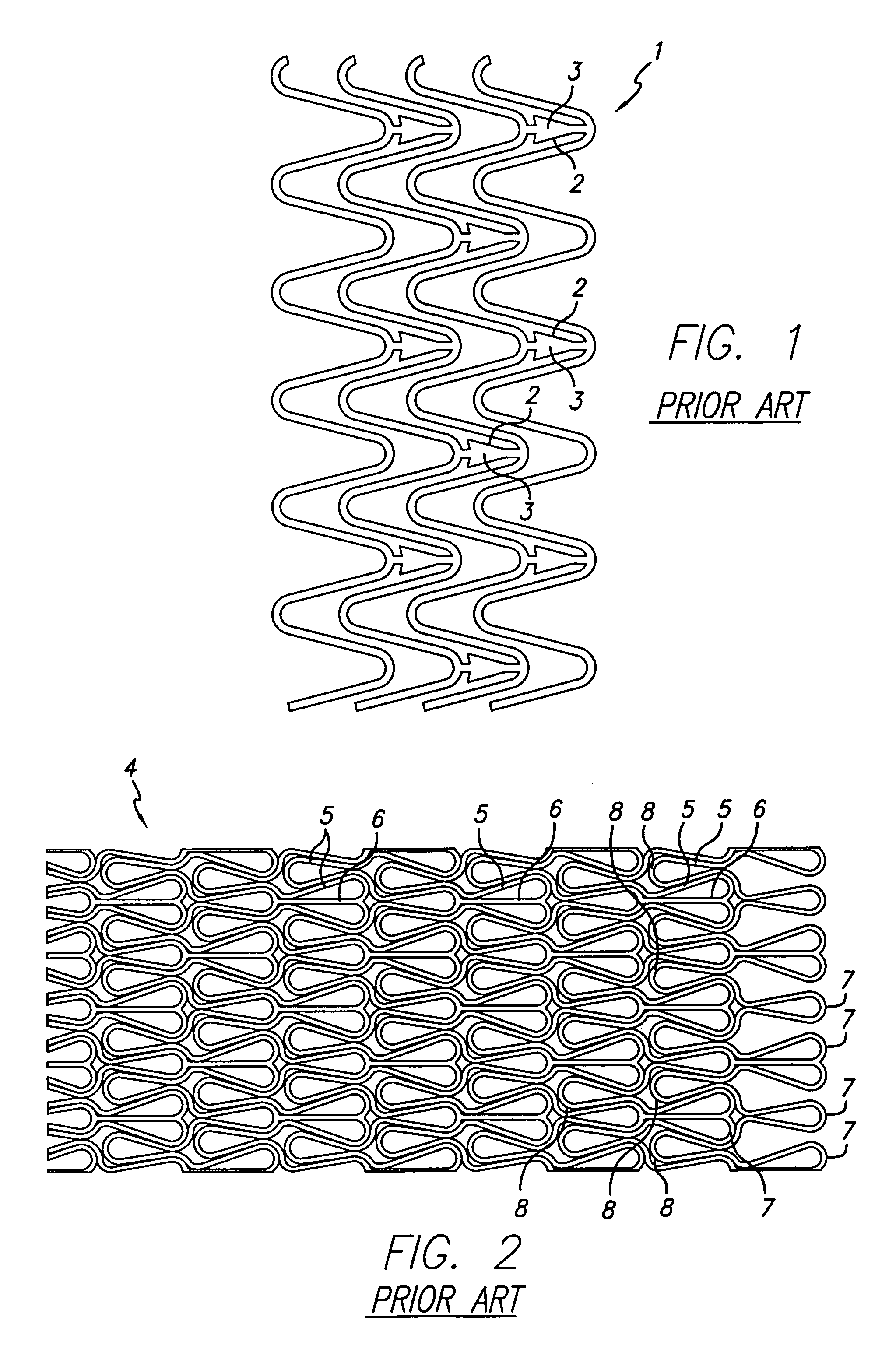

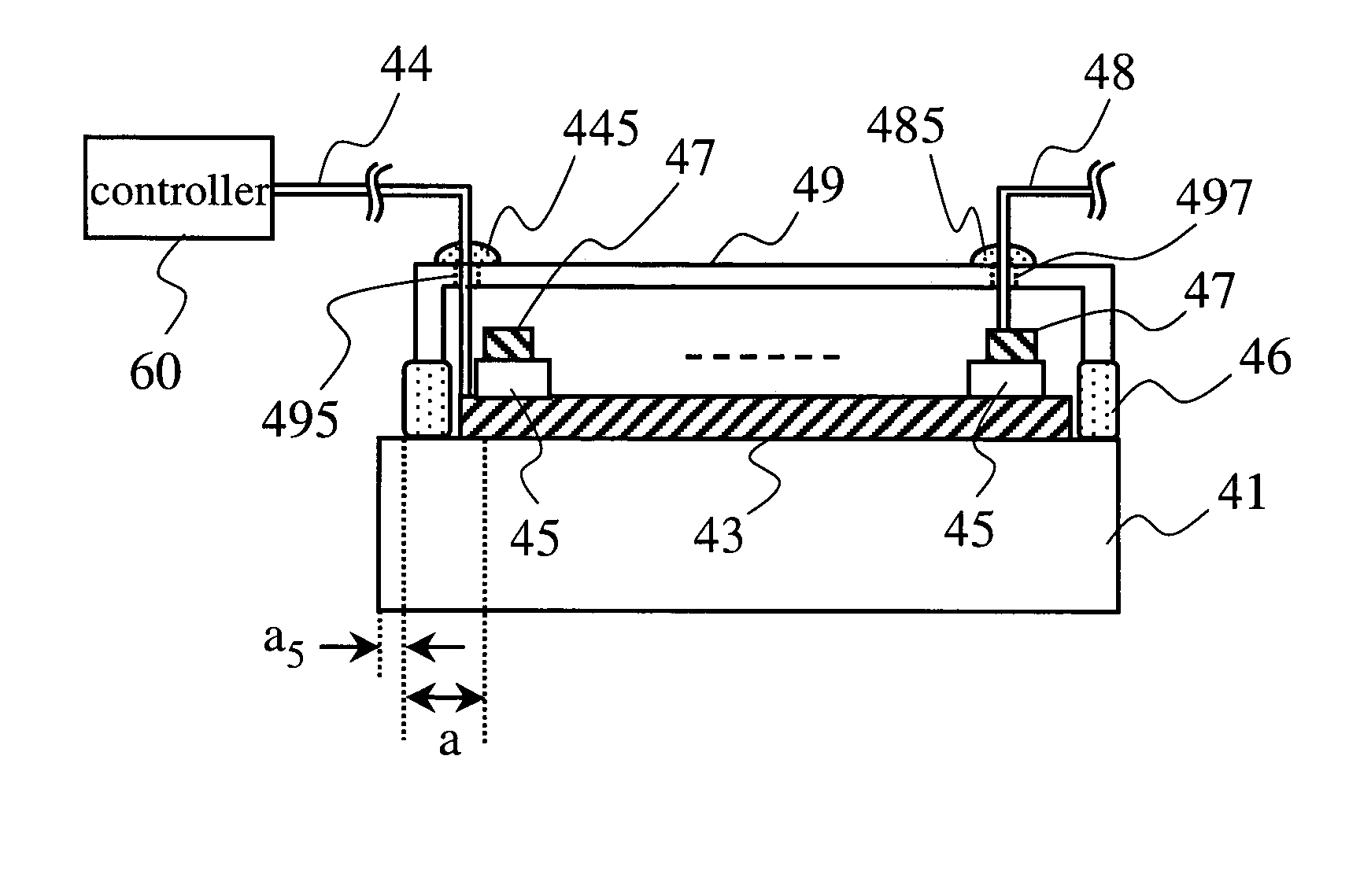

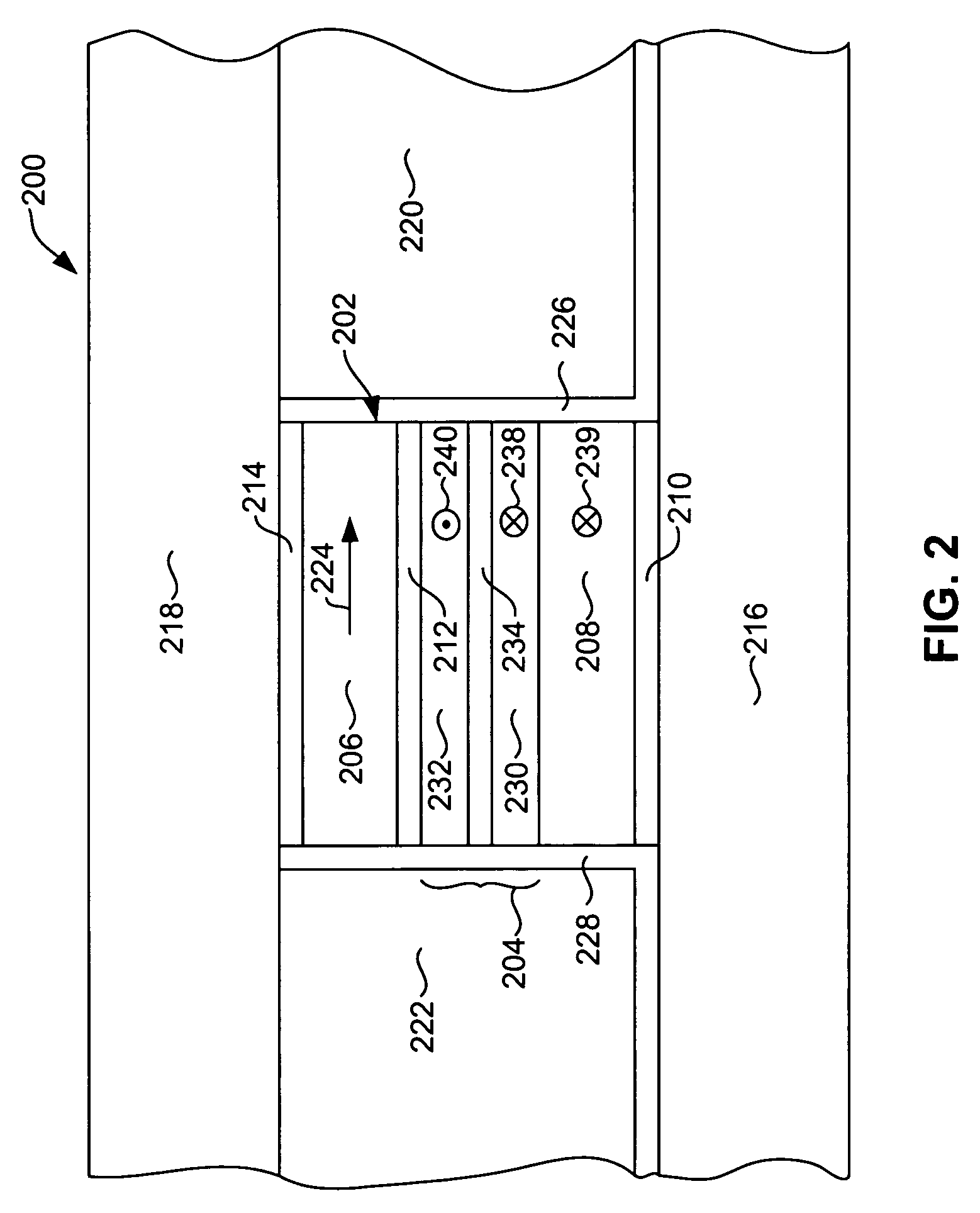

Bump array device having asymmetric gaps for segregation of particles

ActiveUS20100059414A1Easy to operateReduce gapGas current separationComponent separationEngineeringMechanical engineering

The disclosure relates to obstacle array devices (also known as bump array devices) for separating populations of particles by size. Improvements over previous obstacle array devices are realized by causing the fluid velocity profile across gaps between obstacles to be asymmetrical with respect to the plane that bisects the gap and is parallel to the direction of bulk fluid flow. Such asymmetry can be achieved by selecting the shape(s) of the obstacles bounding the gap such that the portions of the obstacles upstream from, downstream from, or bridging the narrowest portion of the gap are asymmetrical with respect to that plane. Improvements are also realized by using obstacles that have sharp edges bounding the gaps. Other improvements are realized by selecting obstacle shapes such that the critical particle dimensions defined by the gaps in two different fluid flow directions differ.

Owner:THE TRUSTEES FOR PRINCETON UNIV

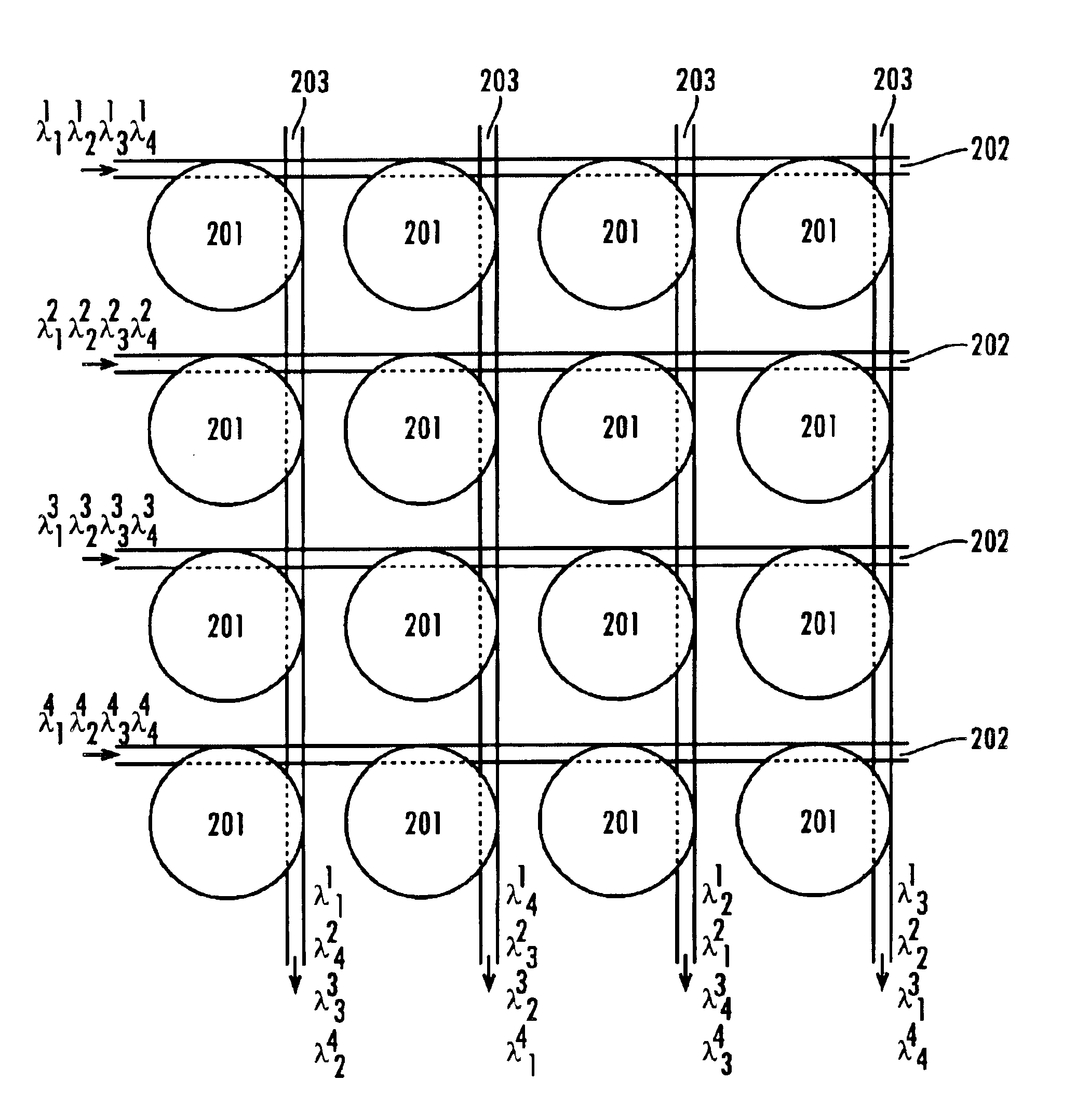

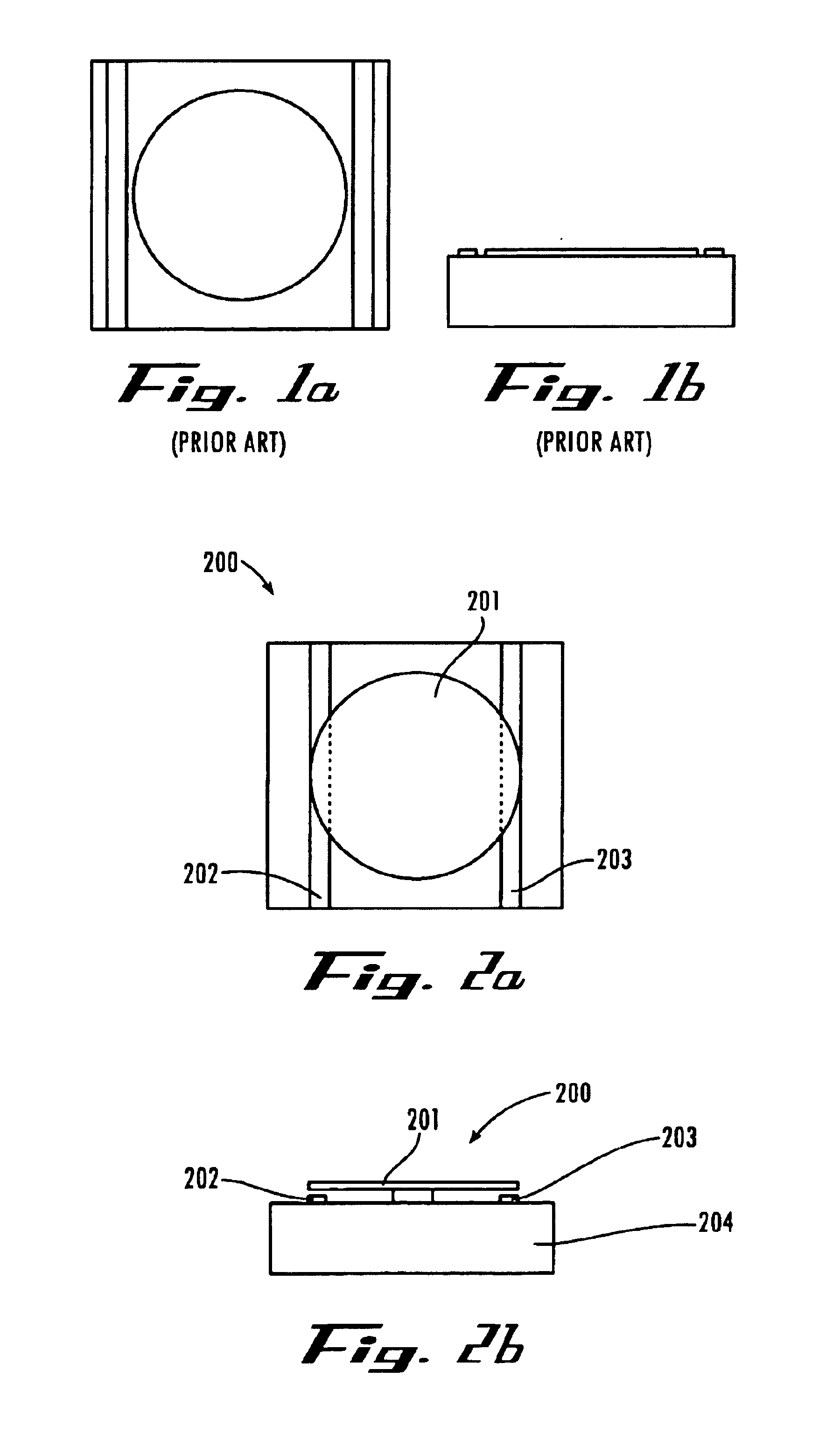

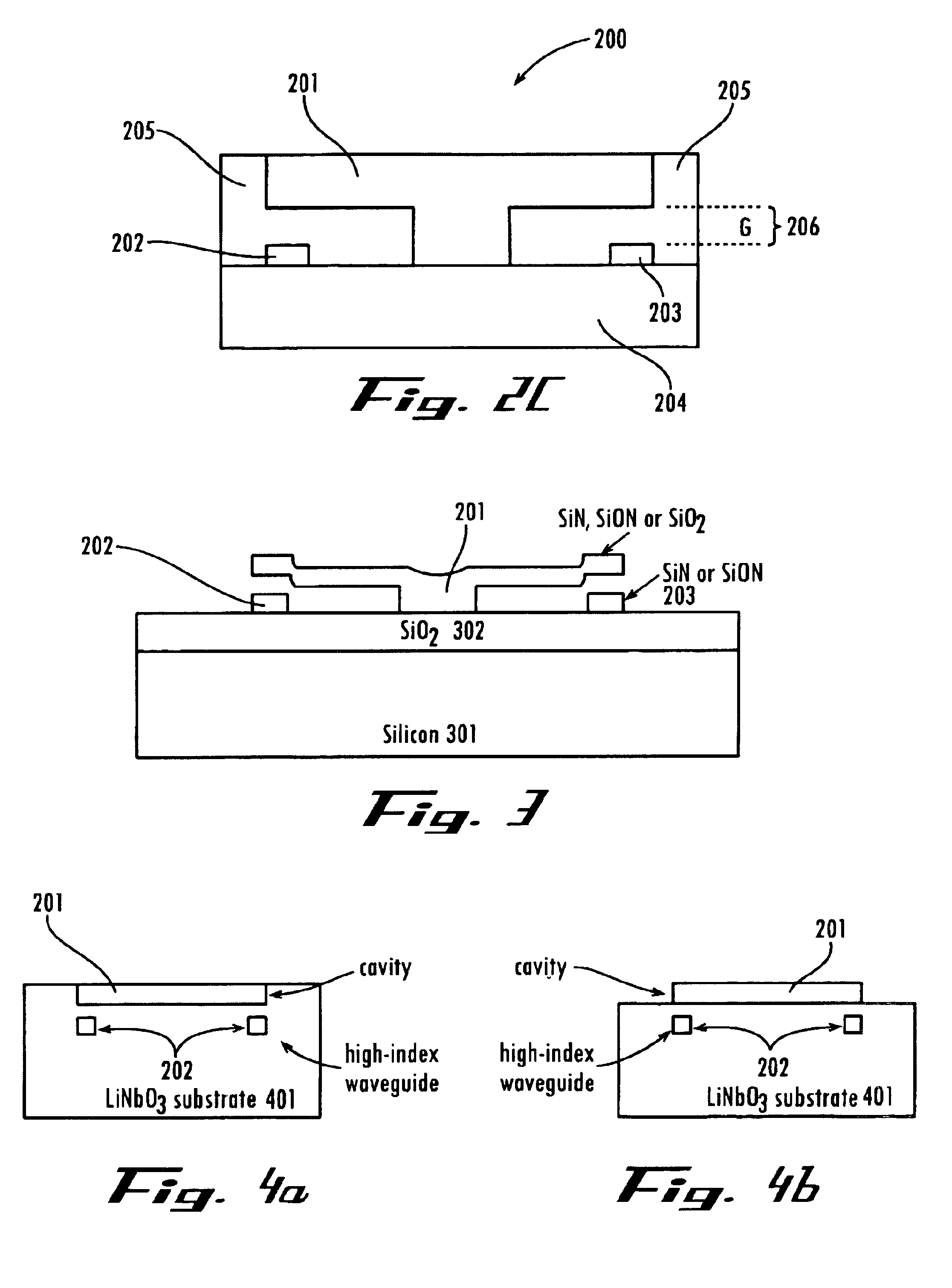

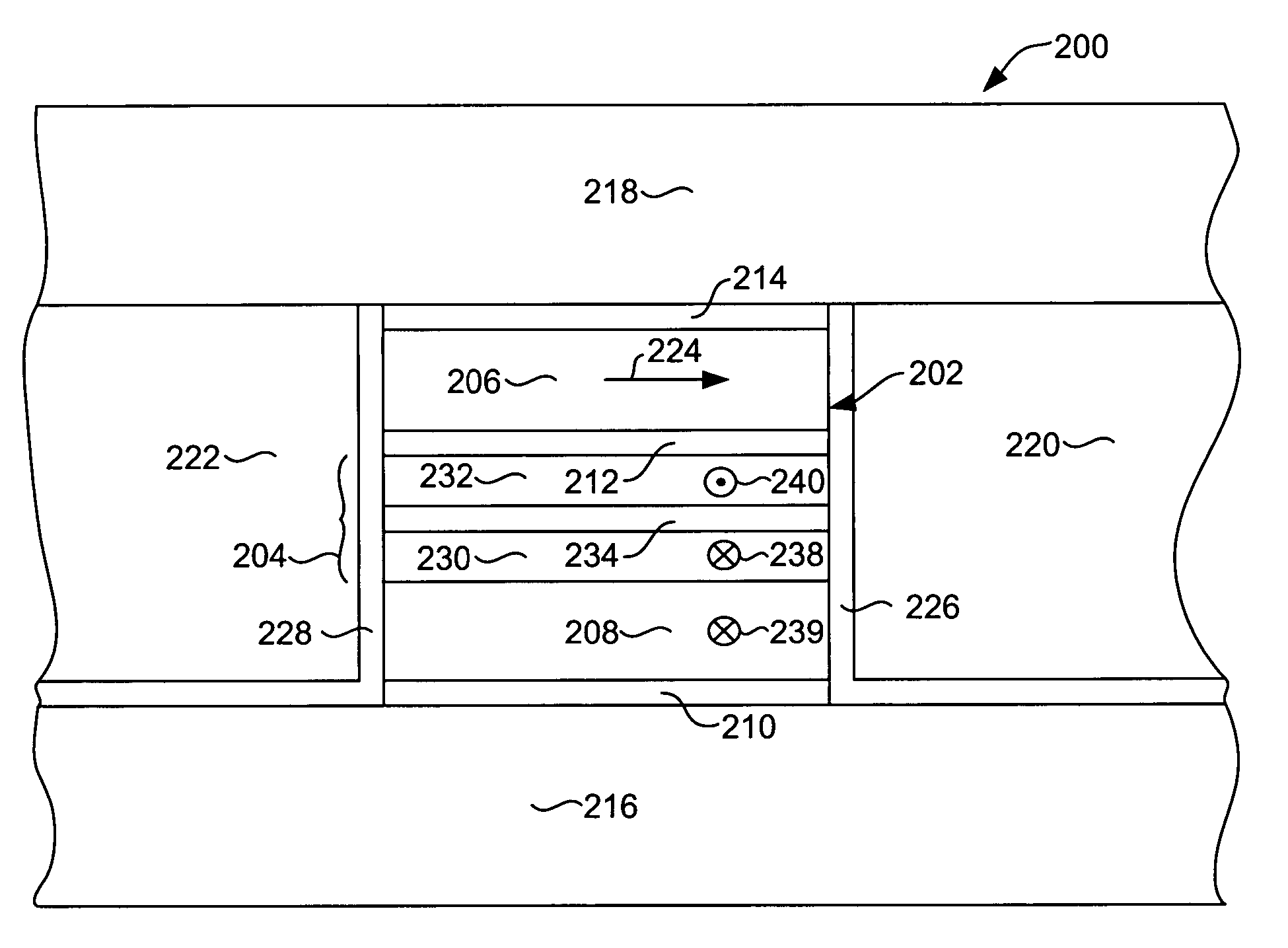

Tunable optical wavelength filters and multi-level optical integrated circuits

InactiveUS6865314B1Reduce gap sizeEasy to controlNanoopticsCoupling light guidesOptical cavityVertical alignment

The present invention comprises tunable optical wavelength filters and multi-level optical integrated circuits which use resonant optical cavities in a vertical arrangement with input and output waveguides. The resonant optical cavities are vertically separated from the input and output waveguides by a material or region of lower refeactive index. The vertical arrangement allows accurate control over the gap size between the waveguides and the cavities during manufacture. The present invention also enables the use of electrodes for enhancing tuning characteristics and for multiple tunable optical wavelength filters to be created in vertical alignment with one another by placing two resonant optical cavities and their respective input and output waveguides in vertical alignment with a low refractive index buffer between the multiple tunable optical wavelength filters. In addition, the present invention includes multiple manufacturing methods in which tunable optical wavelength filters are created on different substrates.

Owner:BLAIR STEVEN M +1

Bump array device having asymmetric gaps for segregation of particles

ActiveUS8579117B2Easy to operateReduce gapGas current separationComponent separationEngineeringAsymmetry

The disclosure relates to obstacle array devices (also known as bump array devices) for separating populations of particles by size. Improvements over previous obstacle array devices are realized by causing the fluid velocity profile across gaps between obstacles to be asymmetrical with respect to the plane that bisects the gap and is parallel to the direction of bulk fluid flow. Such asymmetry can be achieved by selecting the shape(s) of the obstacles bounding the gap such that the portions of the obstacles upstream from, downstream from, or bridging the narrowest portion of the gap are asymmetrical with respect to that plane. Improvements are also realized by using obstacles that have sharp edges bounding the gaps. Other improvements are realized by selecting obstacle shapes such that the critical particle dimensions defined by the gaps in two different fluid flow directions differ.

Owner:THE TRUSTEES OF PRINCETON UNIV

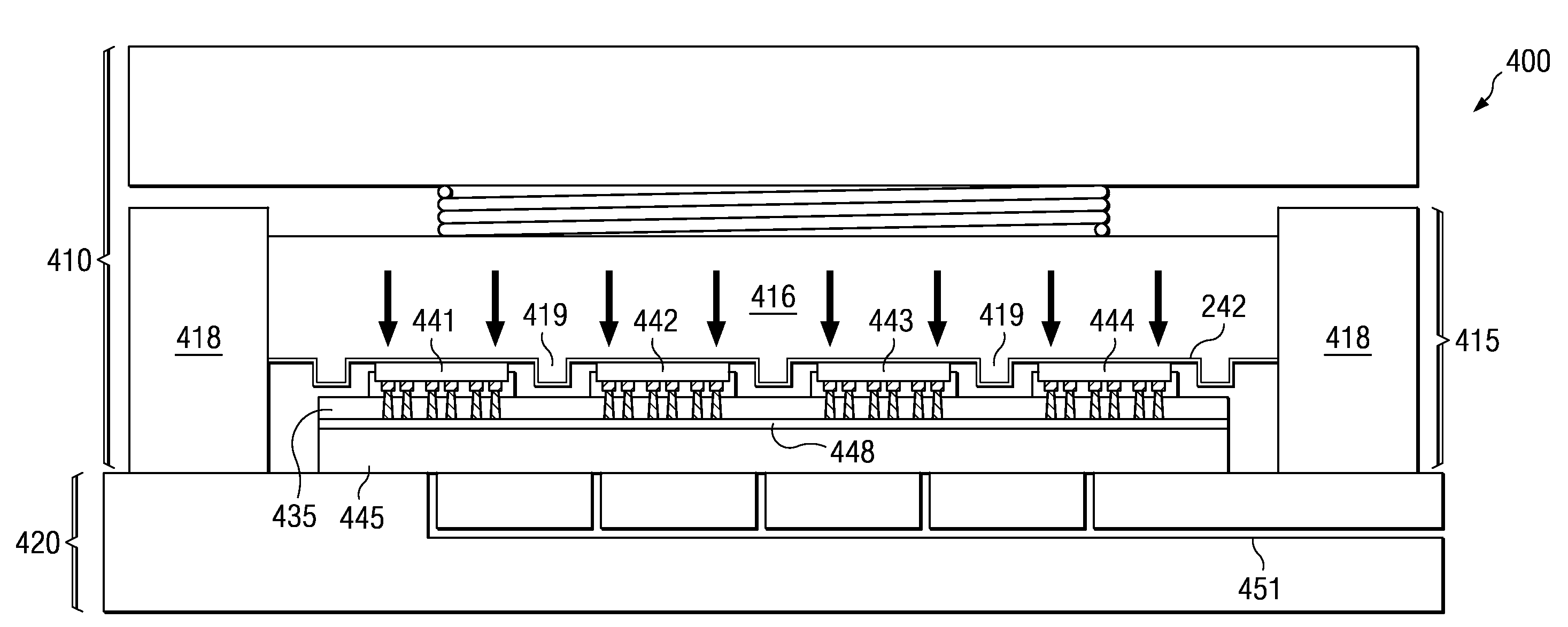

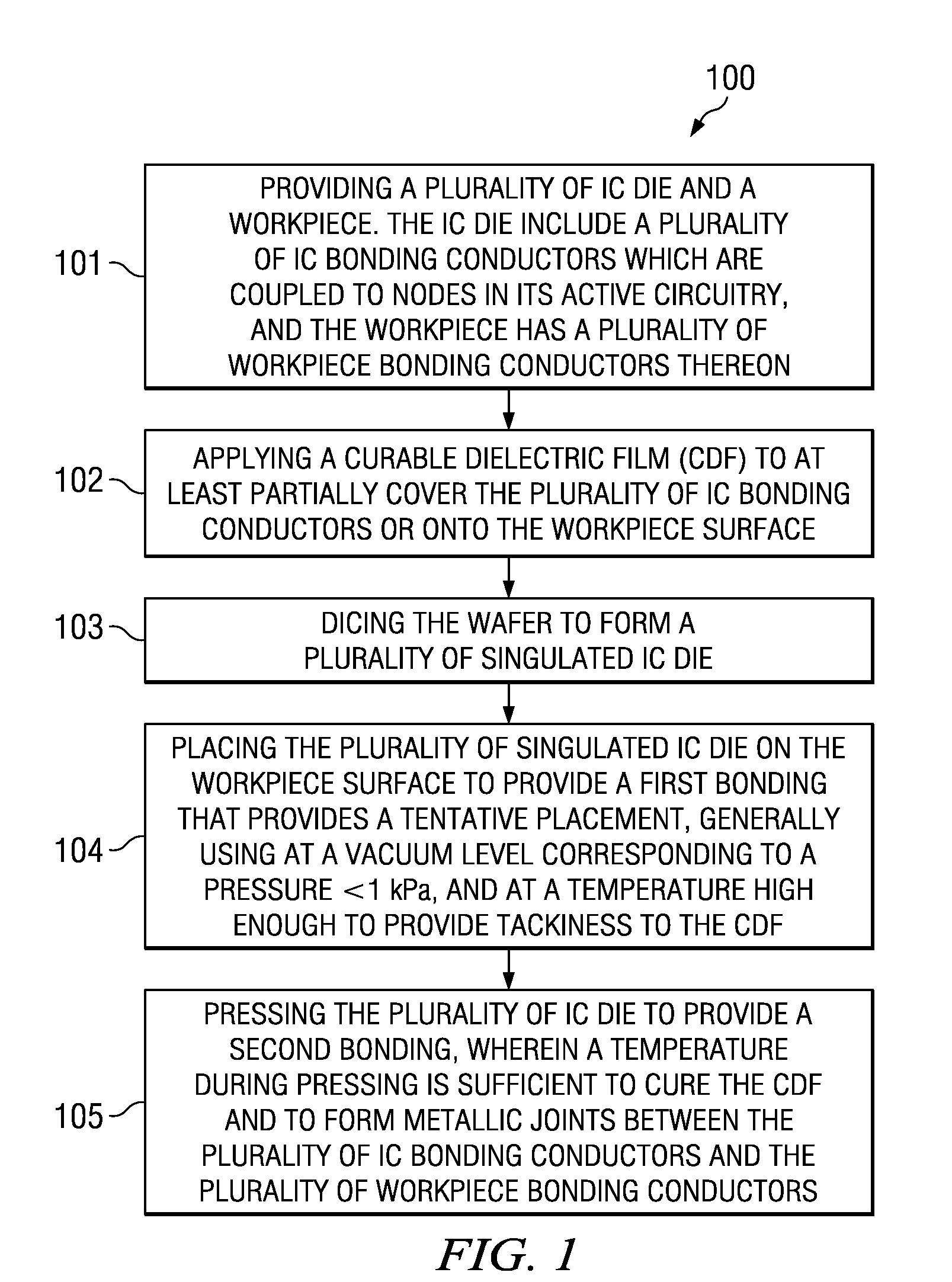

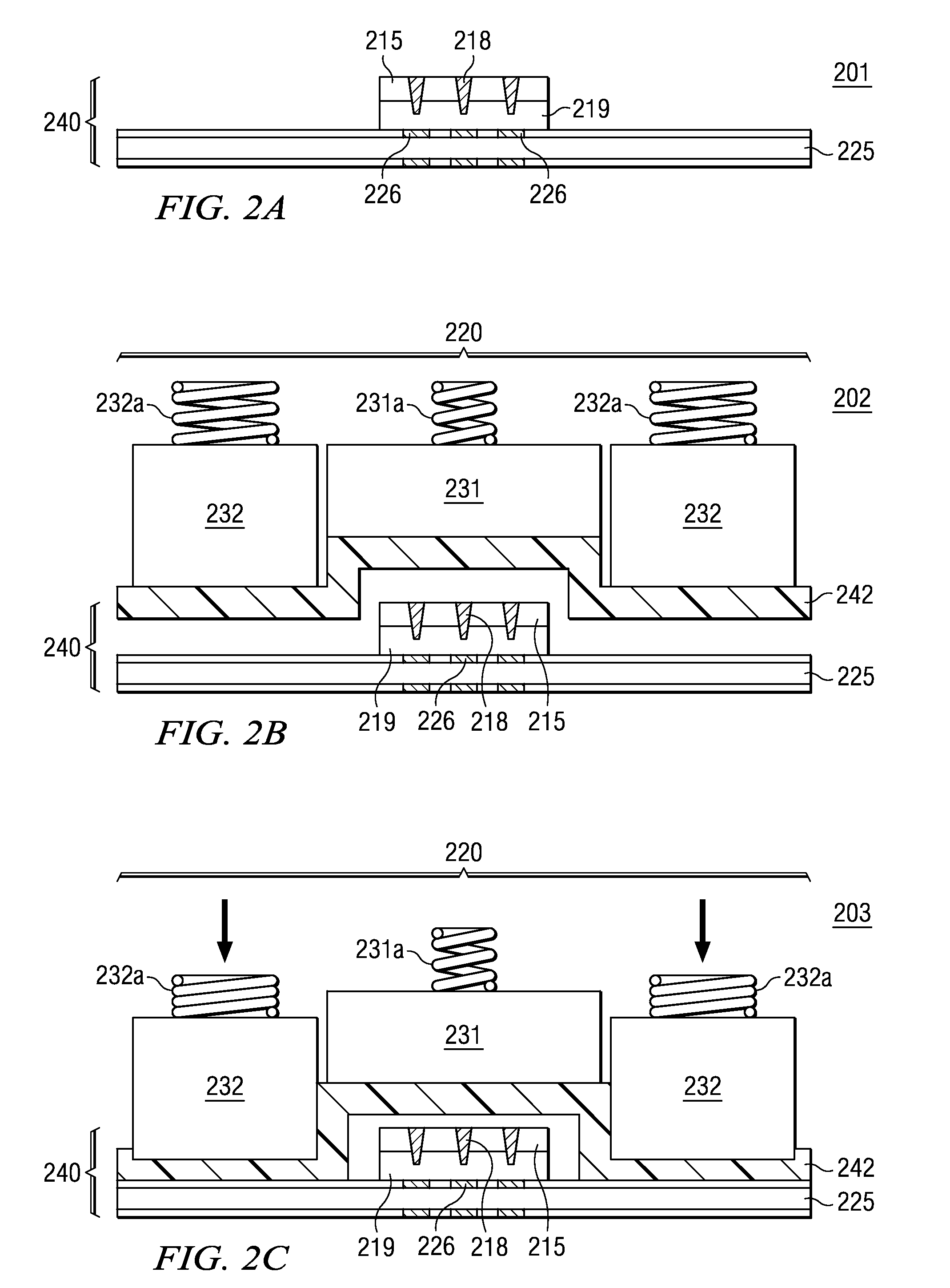

Combined metallic bonding and molding for electronic assemblies including void-reduced underfill

ActiveUS20090291524A1Small sizeReducing joint misalignmentCasting safety devicesSolid-state devicesElectrical conductorDielectric membrane

A method for forming electronic assemblies includes providing a plurality of IC die each having IC bonding conductors and a workpiece having workpiece bonding conductors. A curable dielectric film is applied to the IC bonding conductors or the workpiece surface. The plurality of IC die are placed on the workpiece surface so that the plurality of IC bonding conductors are aligned to and face the plurality of workpiece bonding conductors to provide a first bonding. The placing is performed at a vacuum level corresponding to a pressure <1 kPa, and at a temperature sufficient to provide tackiness to the curable dielectric film. The plurality of IC die are then pressed to provide a second bonding. A temperature during pressing cures the curable dielectric film to provide an underfill and forms metallic joints between the plurality of IC bonding conductors and the plurality of workpiece bonding conductors.

Owner:TEXAS INSTR INC

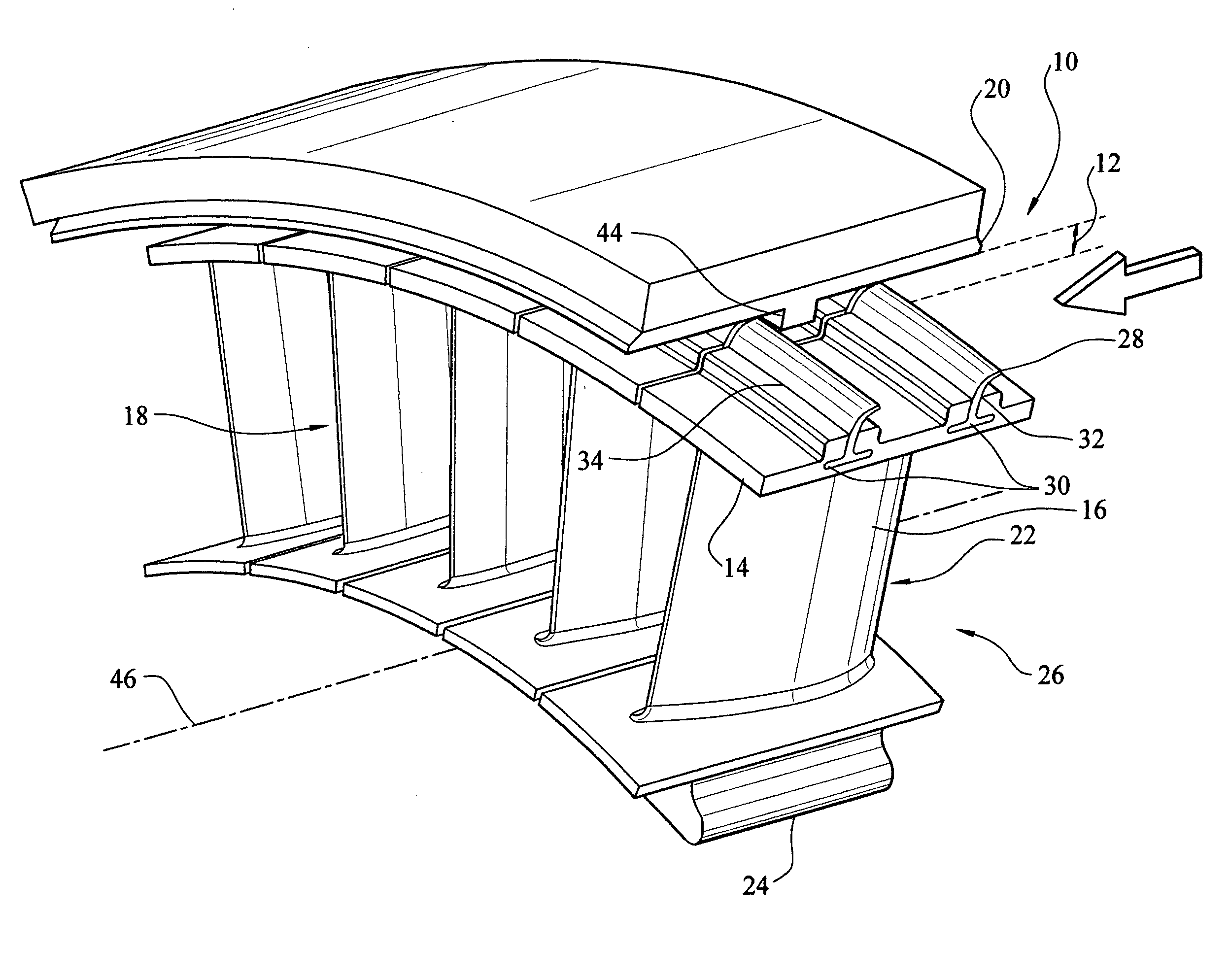

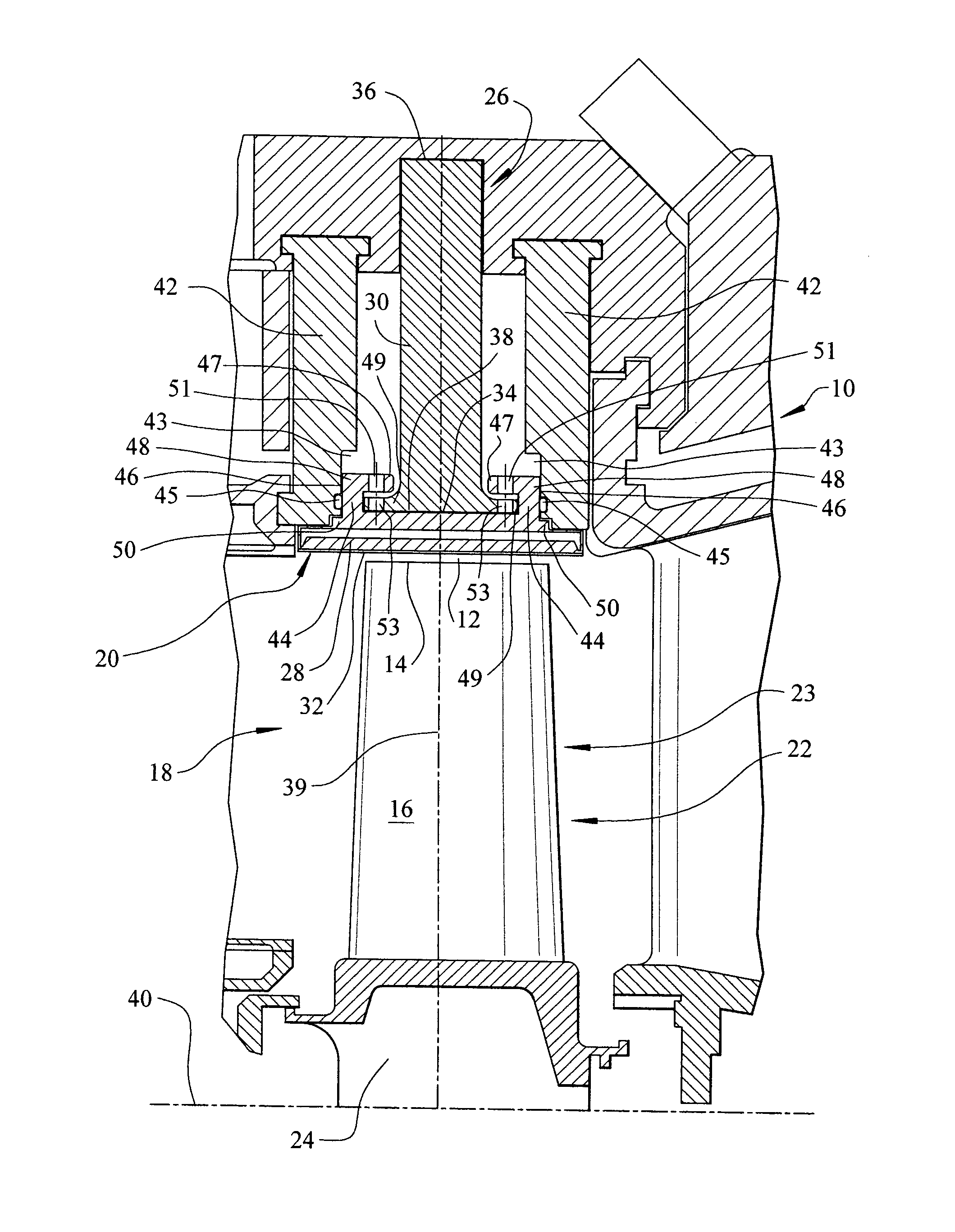

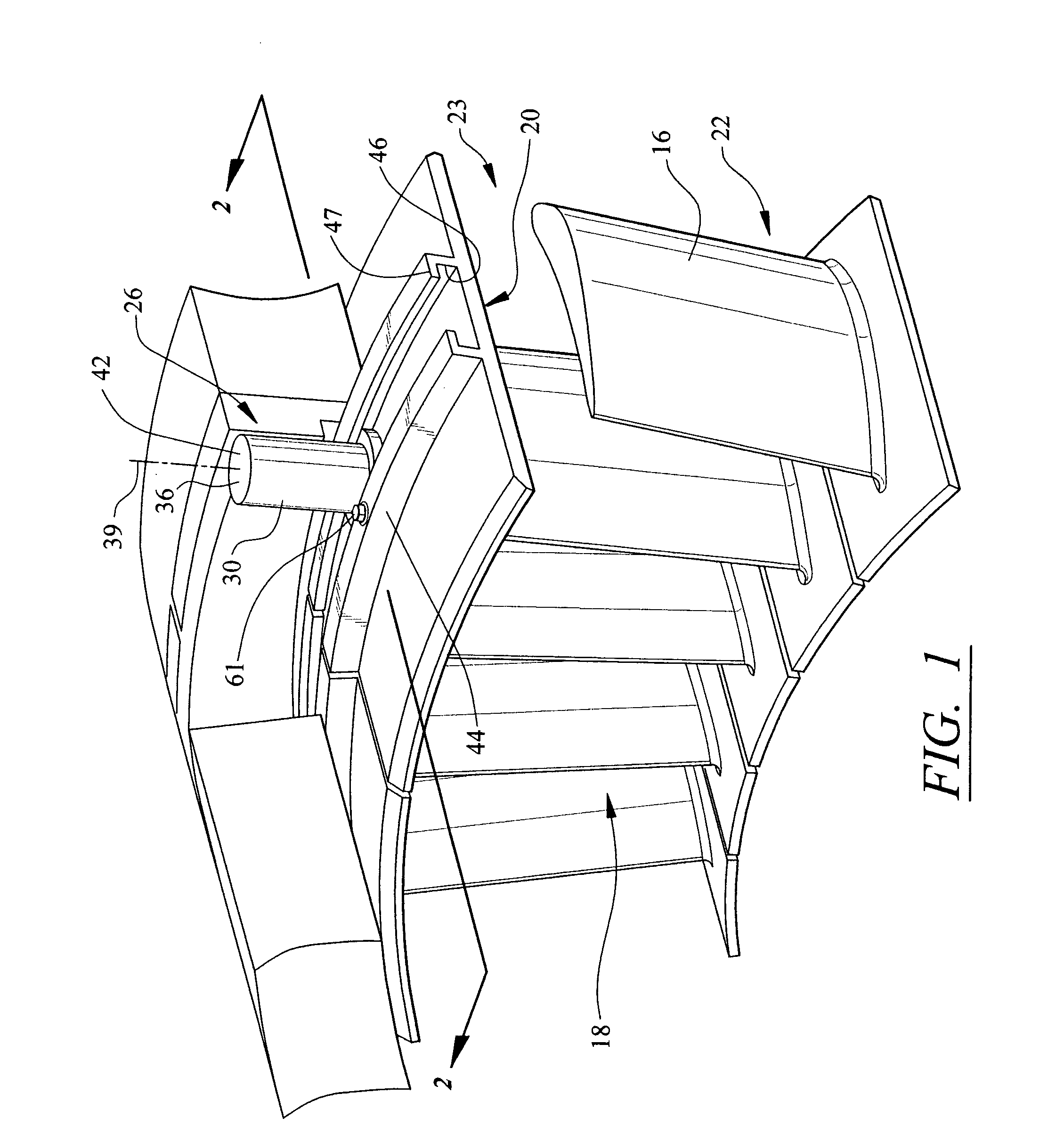

Turbine blade tip clearance control device

InactiveUS6926495B2Reduce air leakageImprove efficiencyWind motor controlPump componentsTurbine bladeTip clearance

A sealing system for reducing a gap between a tip of a shrouded turbine blade and a stationary shroud of a turbine engine. The sealing system includes one or more seal lands extending from a shrouded turbine blade toward a stationary shroud of a turbine engine. During operation of the turbine engine, the seal lands straighten and extend towards the stationary shroud of the turbine engine, thereby reducing the leakage of air past the shrouded turbine blades and increasing the efficiency of the turbine engine. The sealing system may also include one or more protrusions extending from the stationary shroud towards the tips of the shrouded turbine blades.

Owner:SIEMENS ENERGY INC

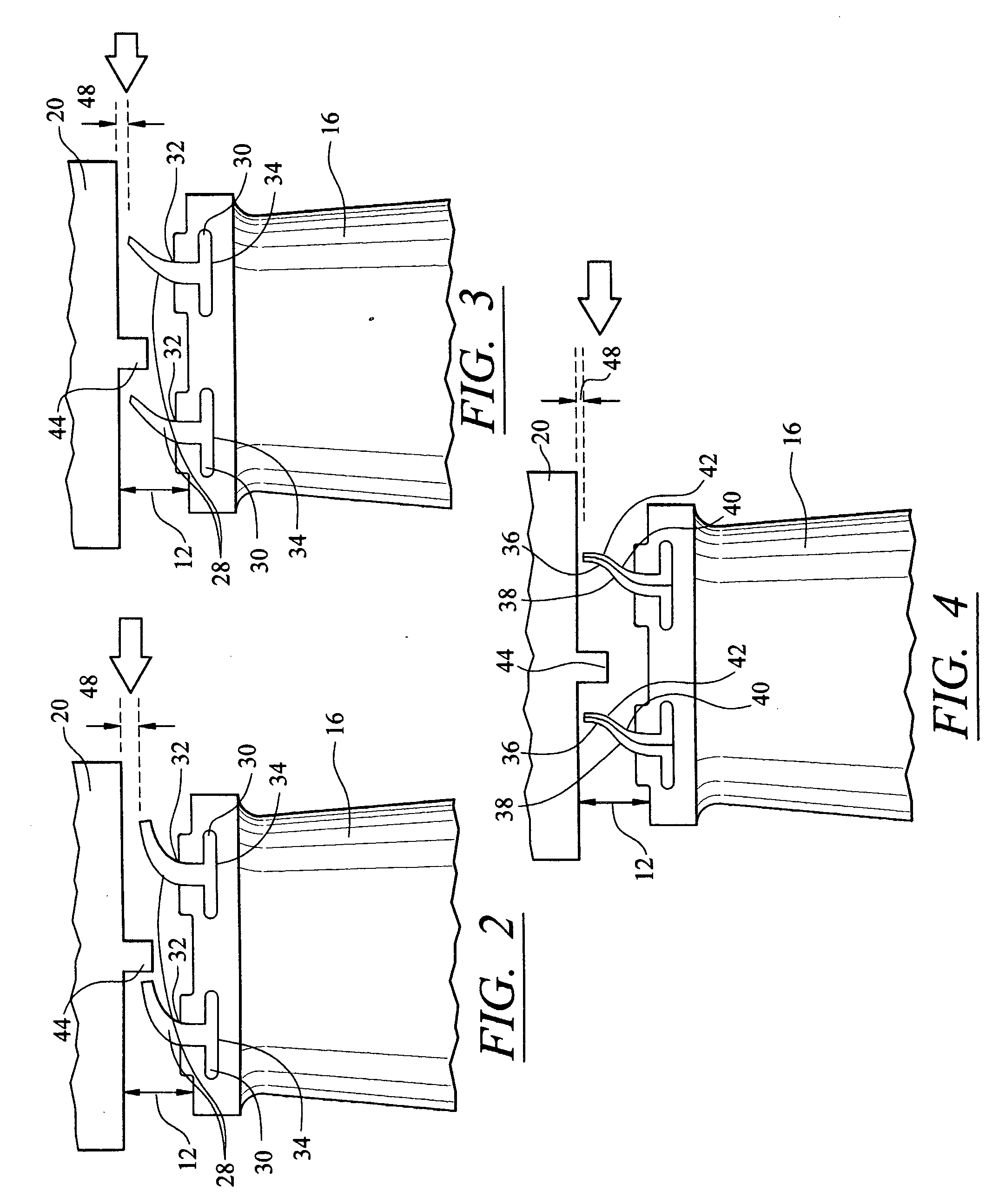

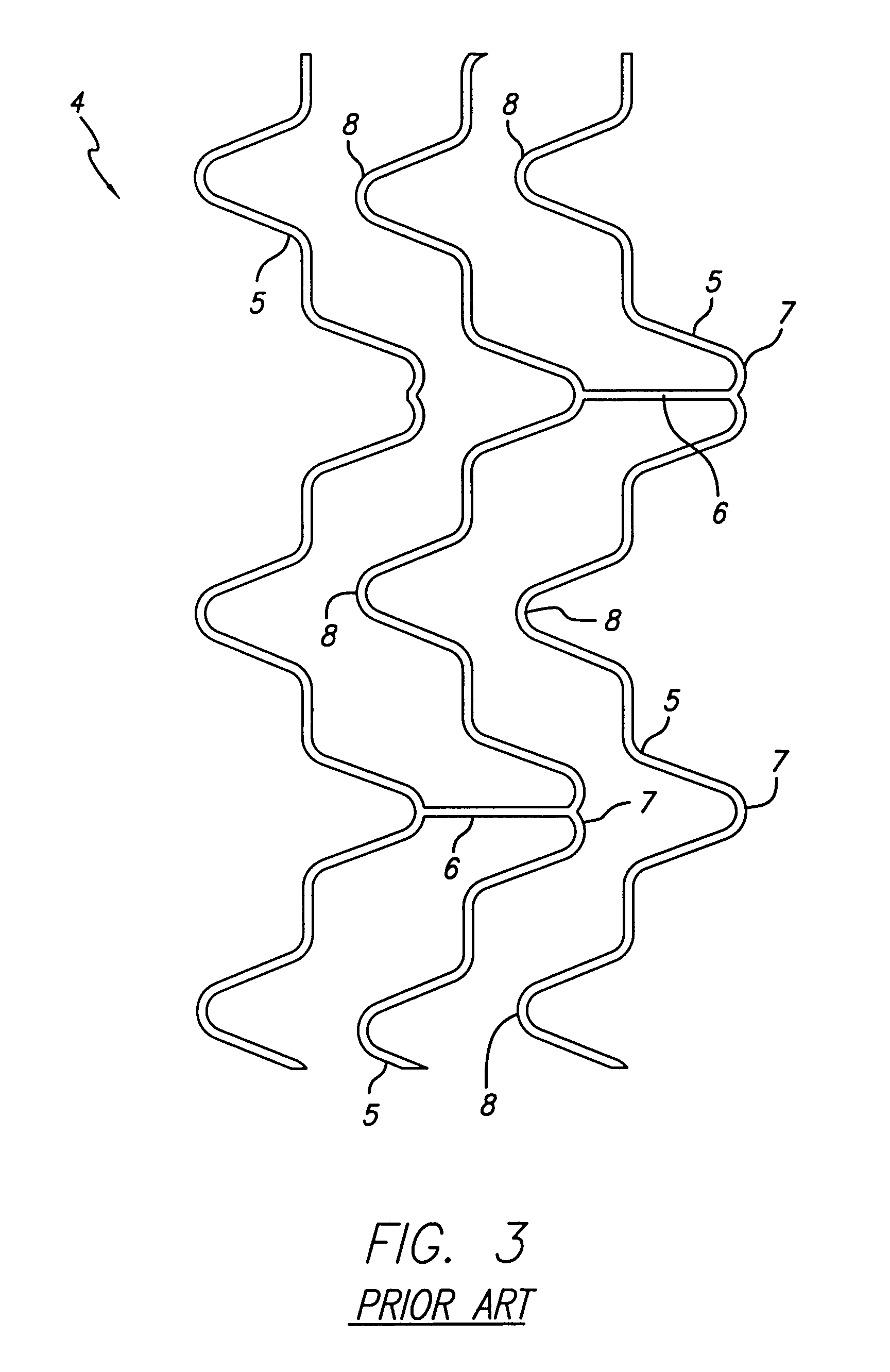

Apparatus and method for decreasing stent gap size

InactiveUS6997944B2Reduce deliveryIncreased vessel coverageStentsBlood vesselsTriangular cellVascular wall

Owner:ABBOTT CARDIOVASCULAR

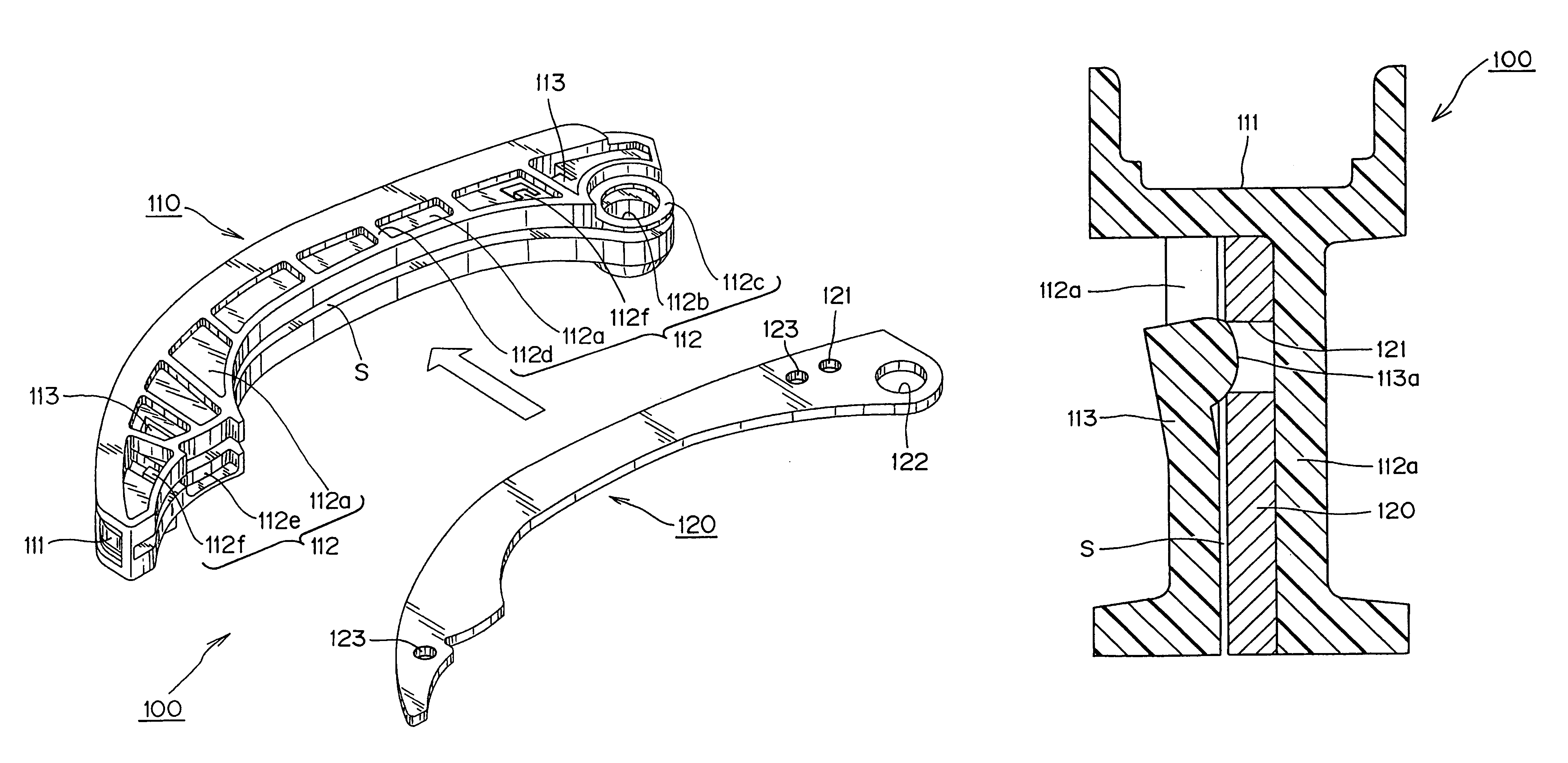

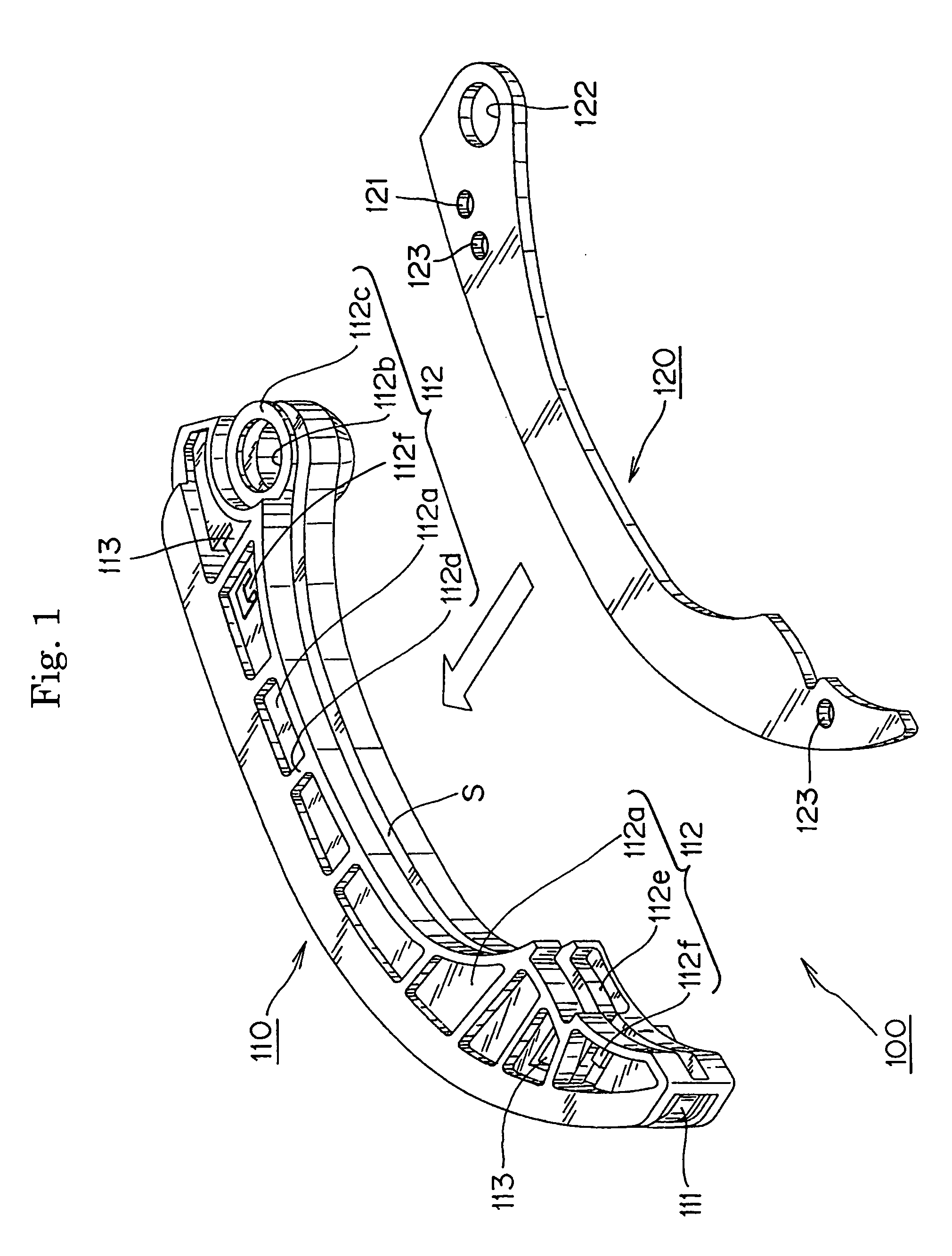

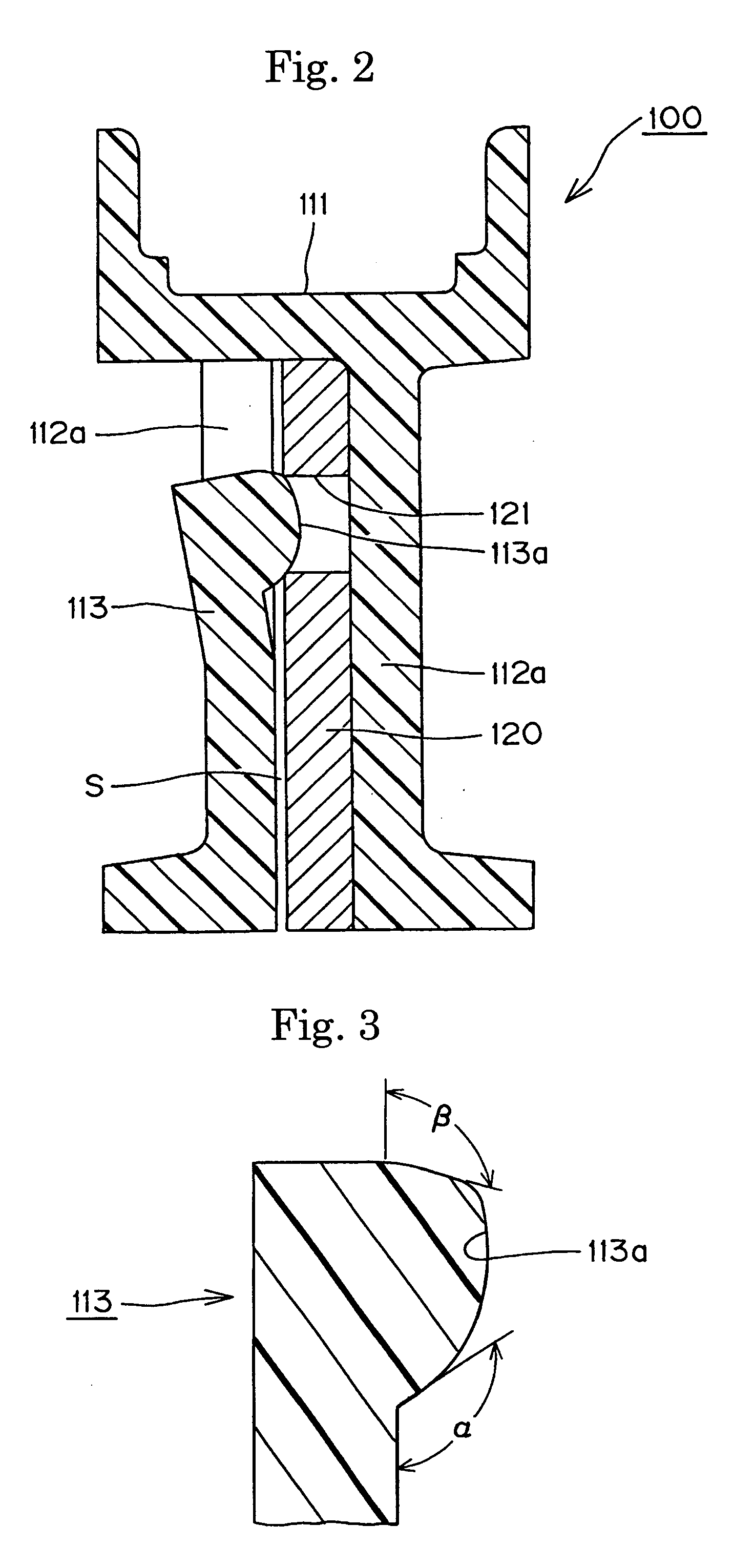

Synthetic resin guide

InactiveUS20050277506A1Lower requirementIncreased dimensional tolerancesGearingEngineeringSynthetic resin

A synthetic resin guide for a transmission device comprises an integrally molded, synthetic resin guide body having a shoe with a front surface for sliding contact with a chain, and a support on its back surface, the support having a longitudinal slot, formed between two opposed walls, for receiving a reinforcing plate. Both the guide body and the plate having mounting holes that are coaxial when the plate is incorporated into the guide body. A pressing member, integrally formed on one of the walls of the guide body, includes an eccentric head which uniformly presses against opposite parts of the edge of an opening of a positioning hole in the reinforcing plate.

Owner:TSUBAKIMOTO CHAIN CO

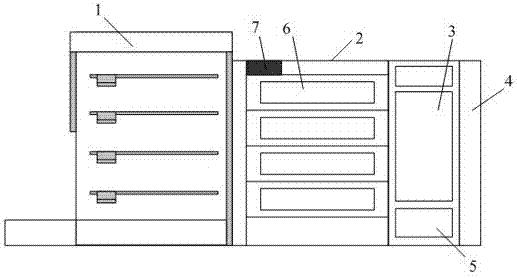

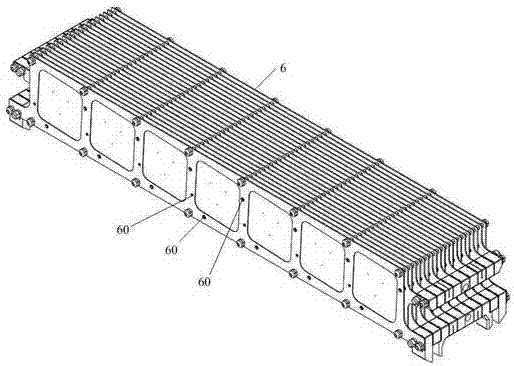

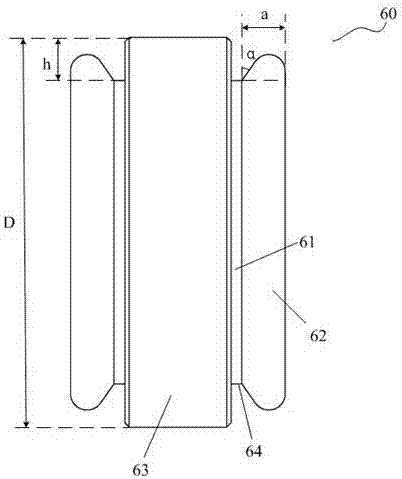

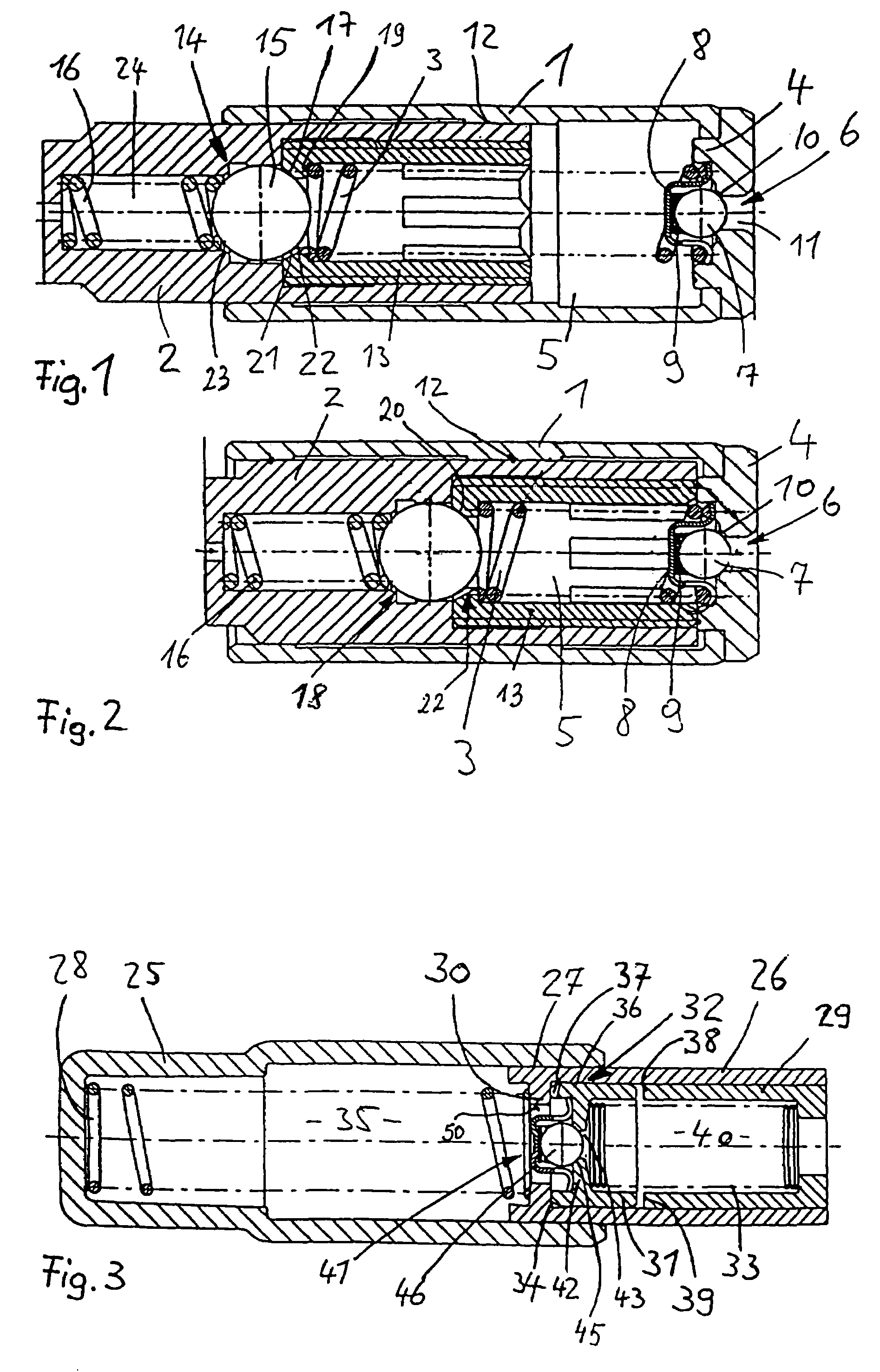

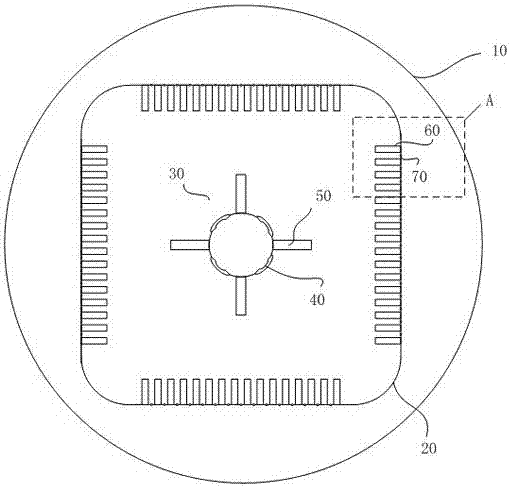

Coating equipment and method for tube-type PERC solar cells

ActiveCN107287579AReduce depthReduce gap sizeFinal product manufactureChemical vapor deposition coatingSilanesSolar cell

The invention discloses coating equipment for tube-type PERC solar cells. The coating equipment comprises a wafer loading region, a furnace body, a gas cabinet, a vacuum system, a heating system, a control system and a graphite boat; the gas cabinet is provided with a first gas pipeline for introducing silane, a second gas pipeline for introducing ammonia, a third gas pipeline for introducing trimethylaluminum, a fourth gas pipeline for introducing laughing gas and a fifth gas pipeline for introducing methane; the graphite boat is used for loading or unloading a silicon wafer; before being used or after being coated many times, the graphite boat needs to be subjected to pretreatment comprising the steps: drying the graphite boat; and coating at least one layer of silicon carbide film on the surface of the dried graphite boat. Correspondingly, the invention further discloses a coating method for tube-type PERC solar cells. By using the coating equipment and method, the pretreatment step of the graphite boat is simplified, the consumption of the silicon wafer is reduced, the silicon wafer is prevented from being scratched, and the EL yield of the cells is increased.

Owner:GUANGDONG AIKO SOLAR ENERGY TECH CO LTD +1

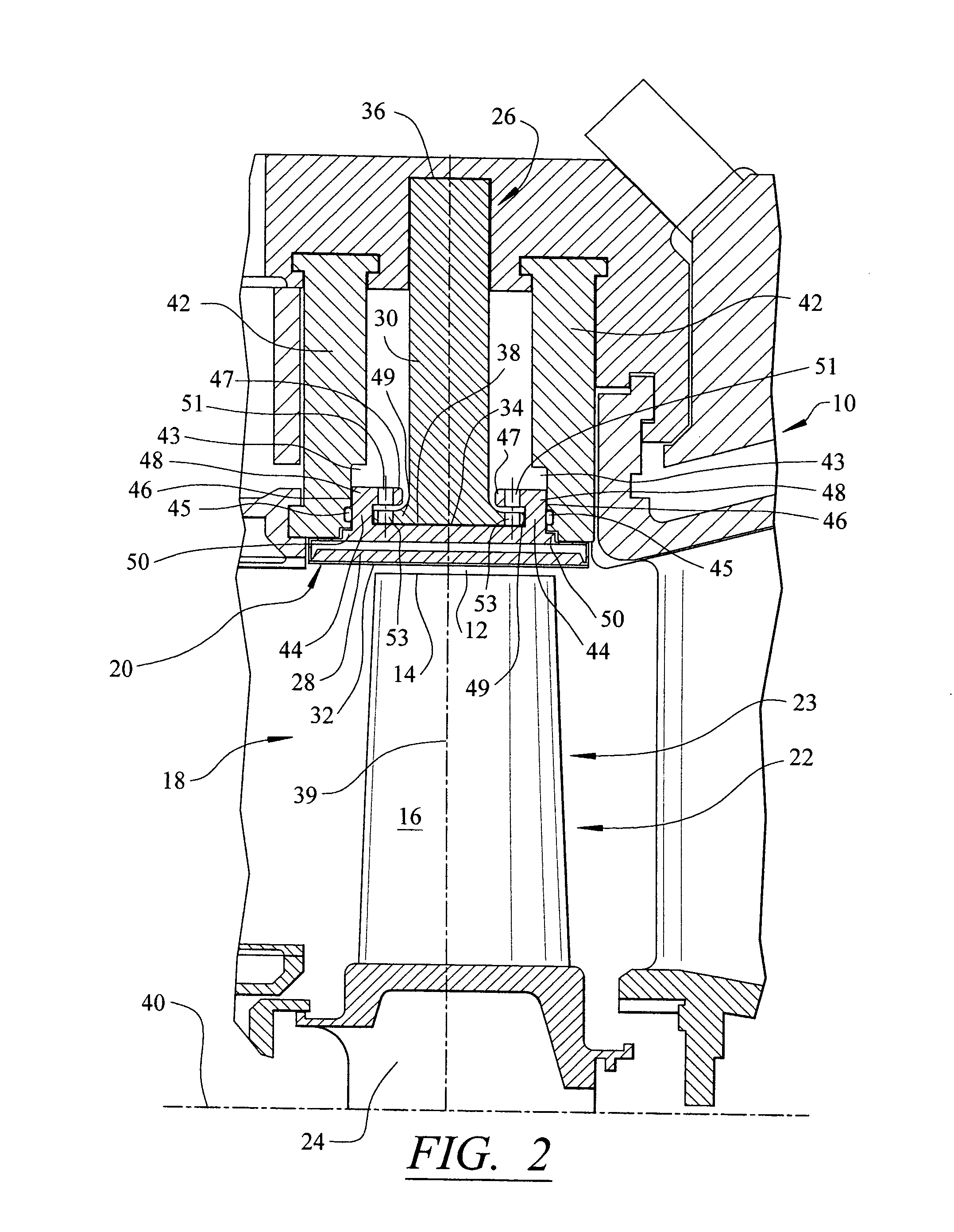

Turbine engine sealing device

InactiveUS6896484B2Reduce air leakageImprove efficiencyPropellersPump componentsTurbine bladeThermal expansion

A sealing system for reducing a gap between a tip of a turbine blade and a shroud of a turbine engine. As a turbine engine reaches steady state operating conditions, components of the sealing system reach their maximum expansion and reduce the size of the gap located between the blade tips and the engine shroud, thereby reducing the leakage of air past the turbine blades and increasing the efficiency of the turbine engine. The sealing system includes a ring segment having a sealing surface positioned proximate to a tip of a turbine blade. The ring segment may be coupled to a blade ring using a spindle having a coefficient of thermal expansion greater than the coefficient of thermal expansion for the blade ring.

Owner:SIEMENS ENERGY INC

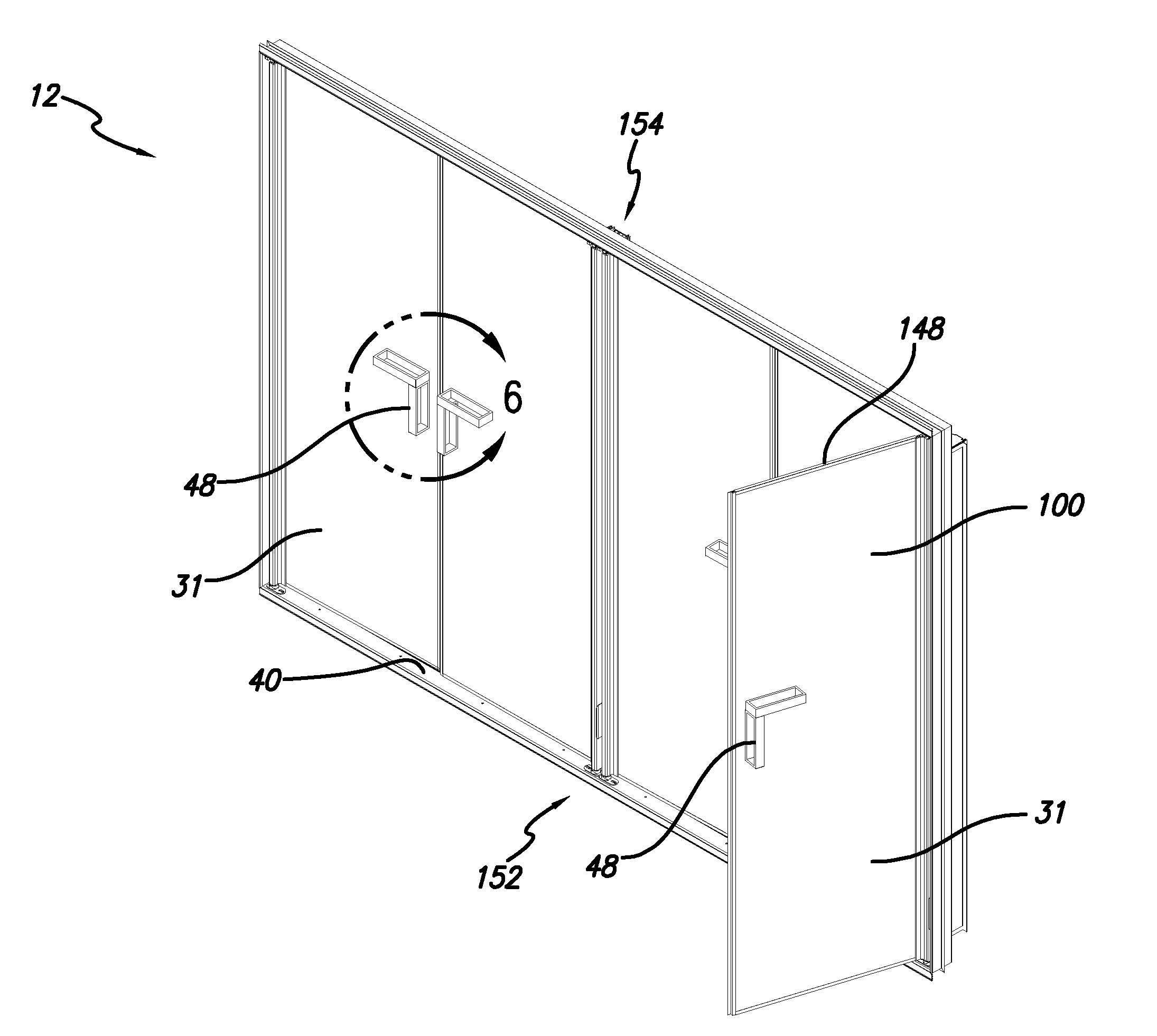

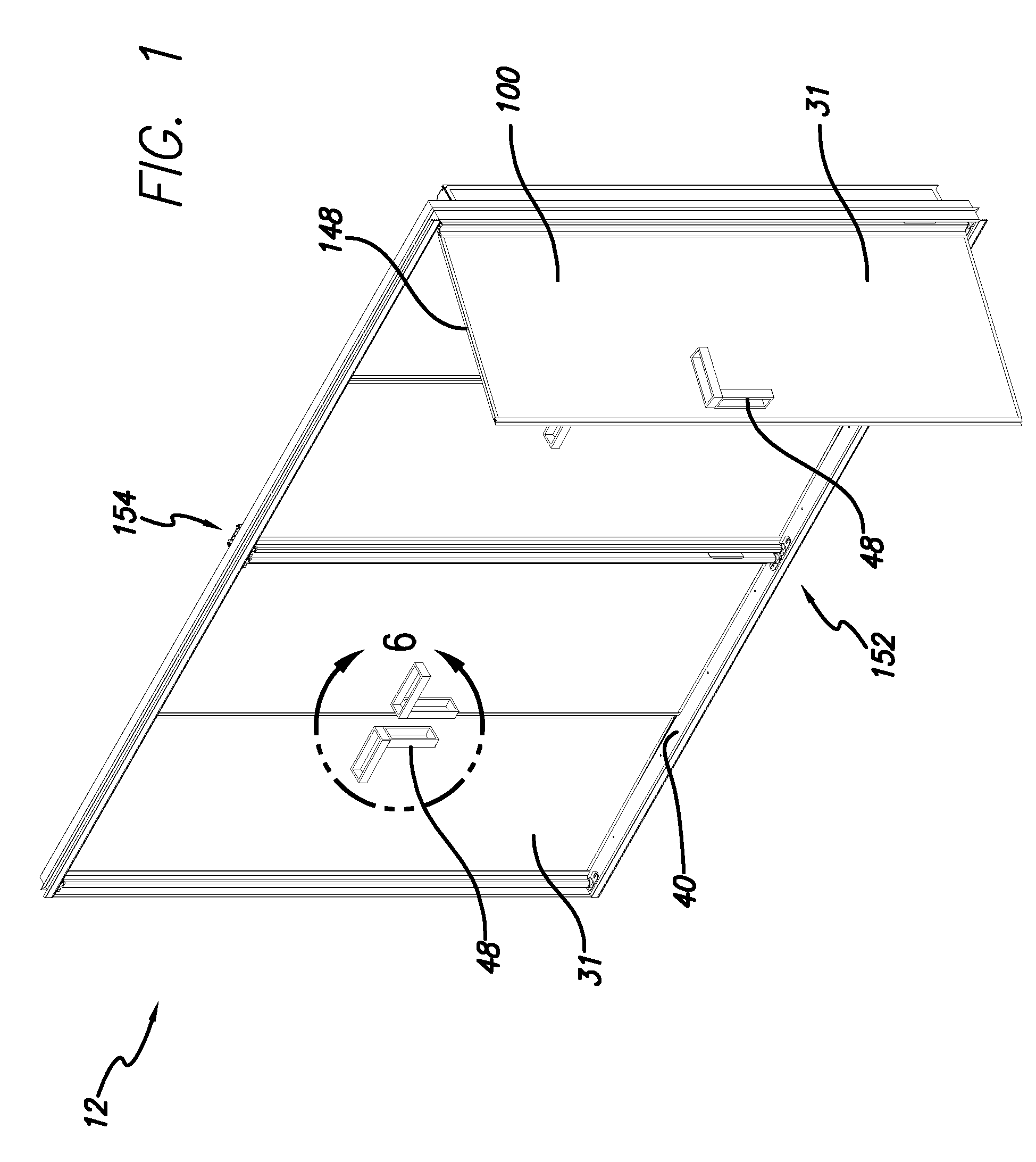

Refrigerator door construction including a laminated package

ActiveUS8613161B2Reduce gap sizeShow cabinetsLighting and heating apparatusConductive coatingEngineering

A door assembly that includes a a frame having an upper portion and a lower portion, an electrical hinge mounted to the upper portion of the frame, a gravity hinge mounted to the lower portion of the frame and a door pivotably mounted to the frame by the electrical hinge and the gravity hinge. The electrical hinge pin has a hinge pin part having a plurality of electrical conductors extending downwardly therefrom. The gravity hinge also includes a hinge pin part. The door includes a laminated package having first, second and third layers adhered to one another. At least one of the layers includes an electro-conductive coating thereon that is in electrical communication with the electrical hinge. The door also includes a rail secured adjacent a hinge side edge of the laminated package. The rail includes a tunnel defined therein that includes a top opening that receives the hinge pin part of the electrical hinge and a bottom opening that receives the hinge pin part of the gravity hinge.

Owner:ANTHONY INC

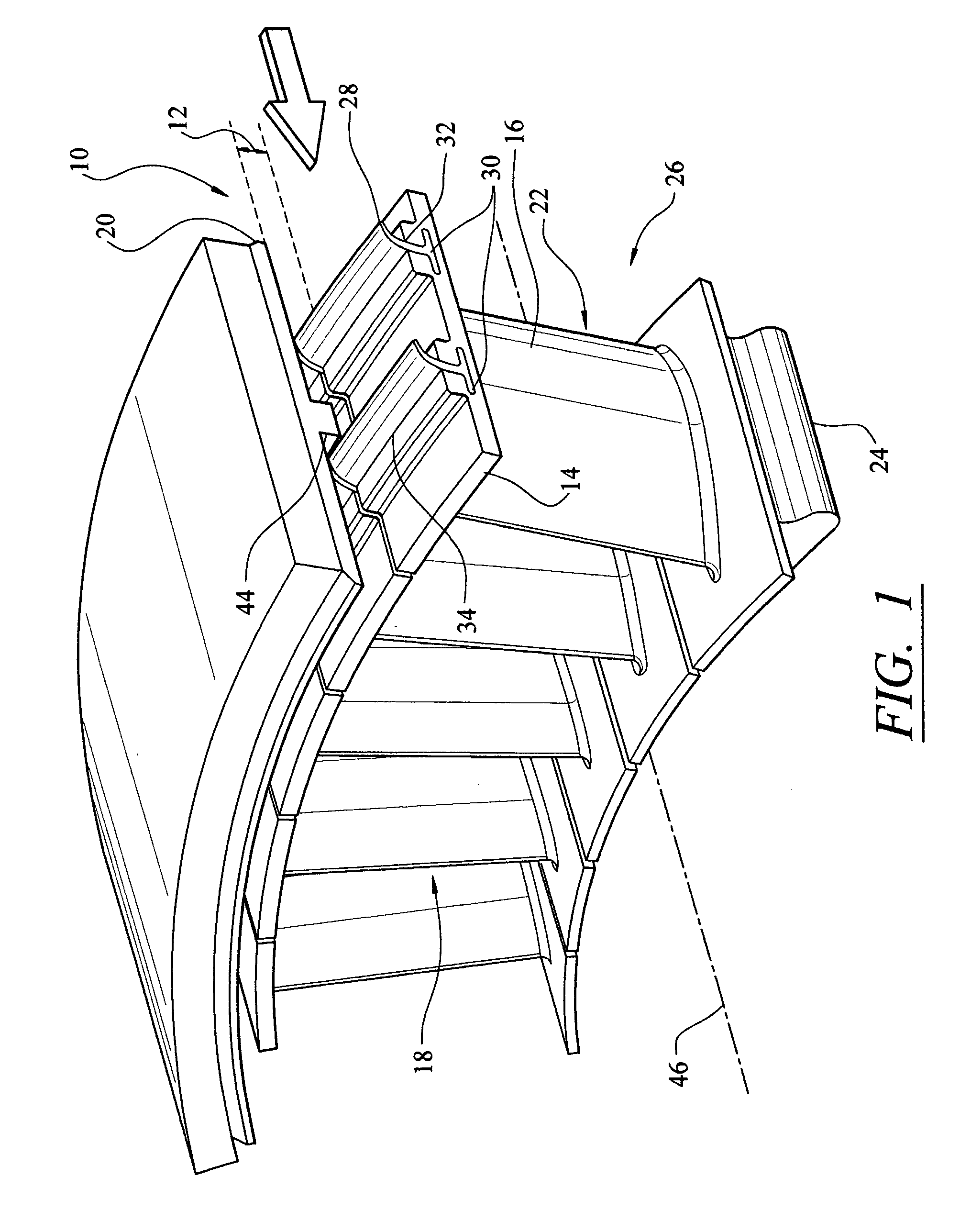

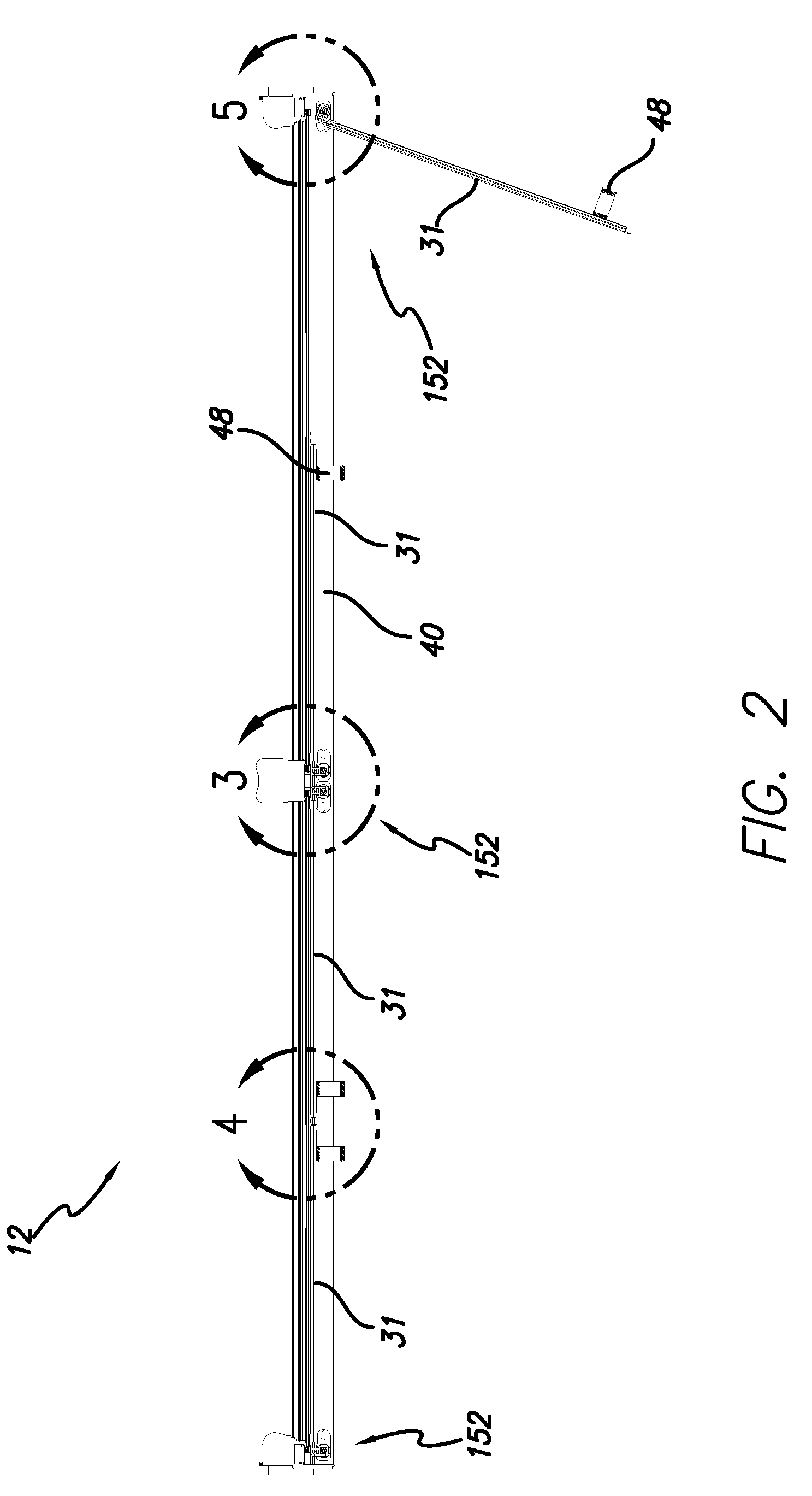

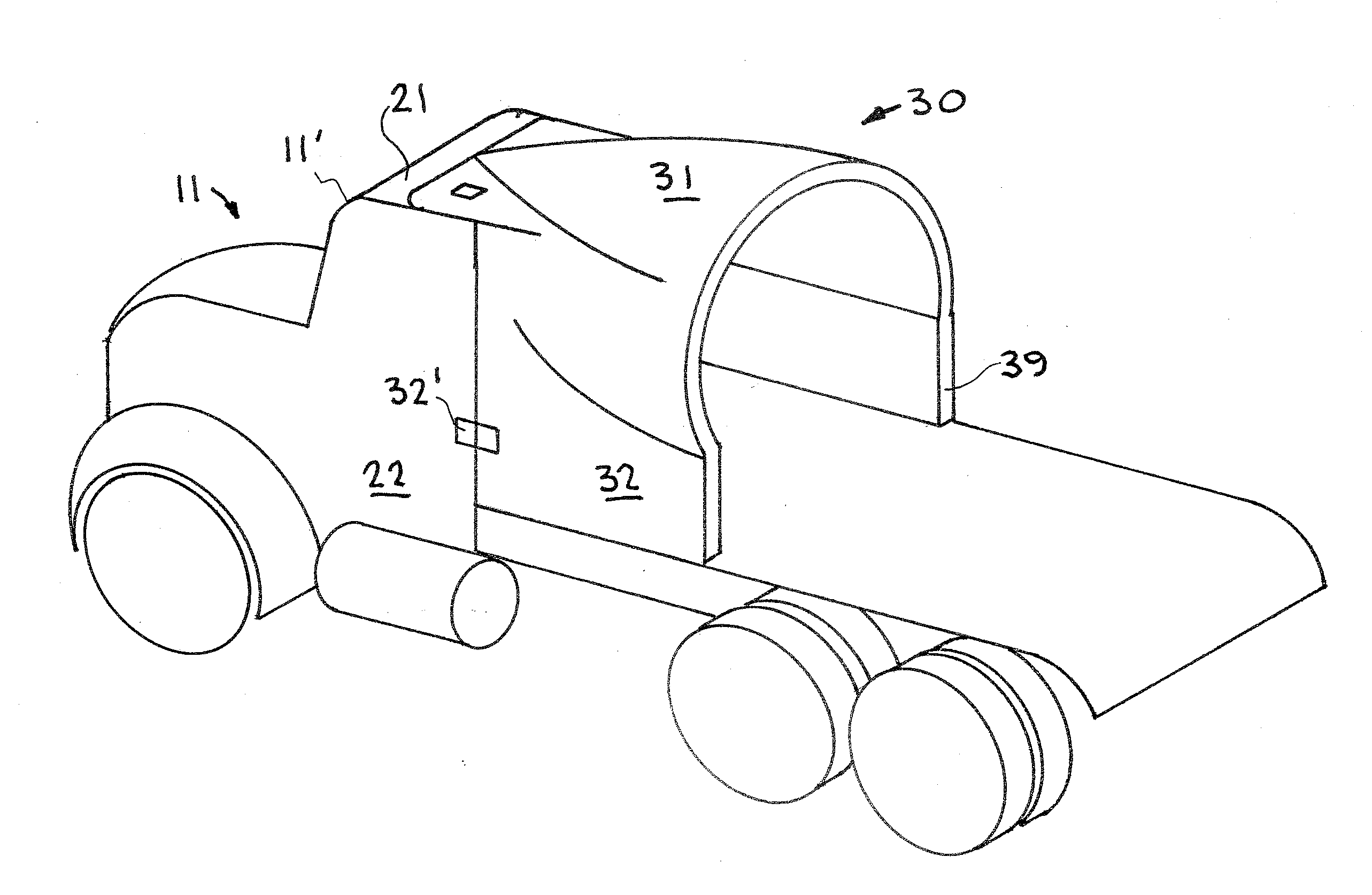

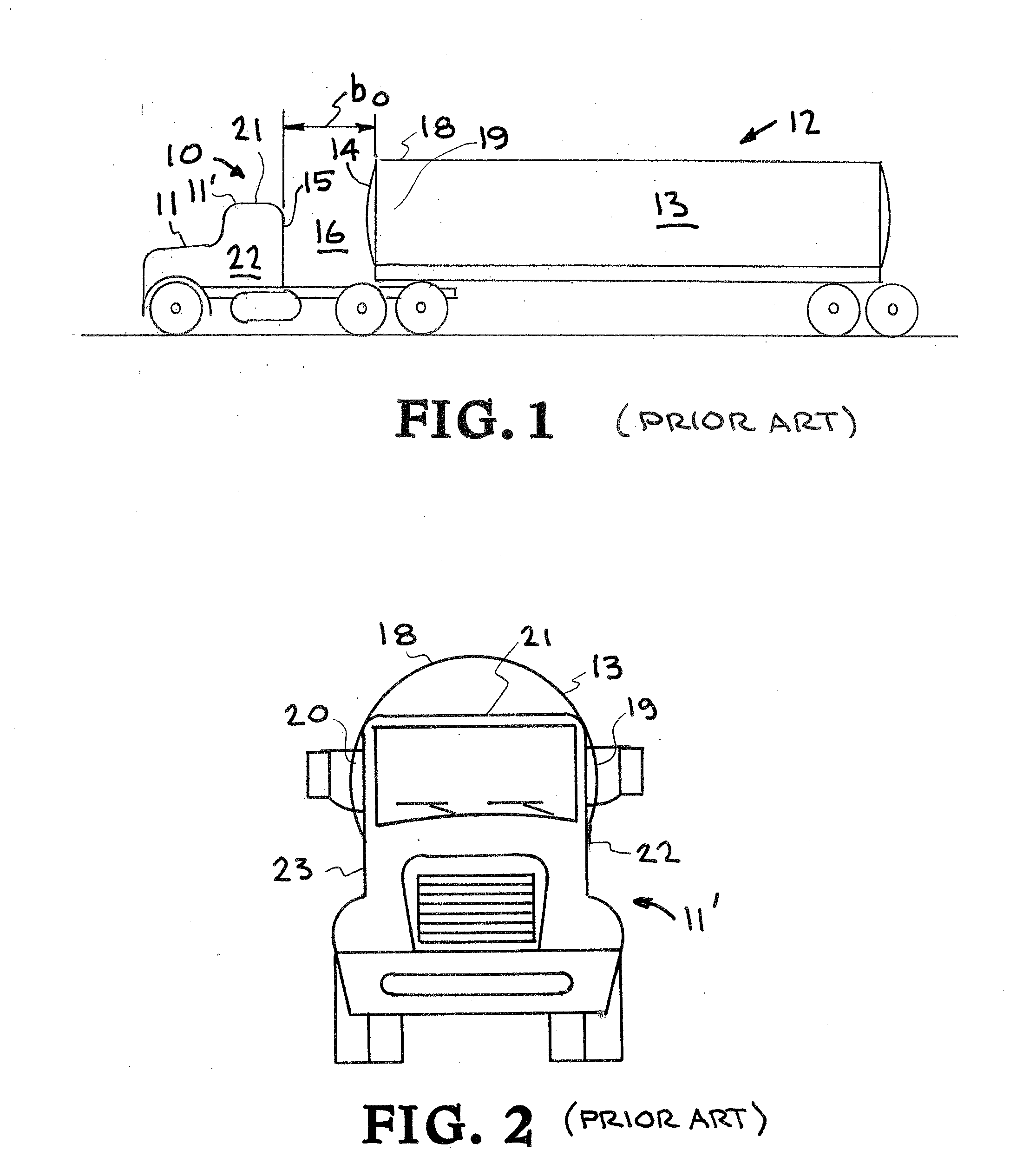

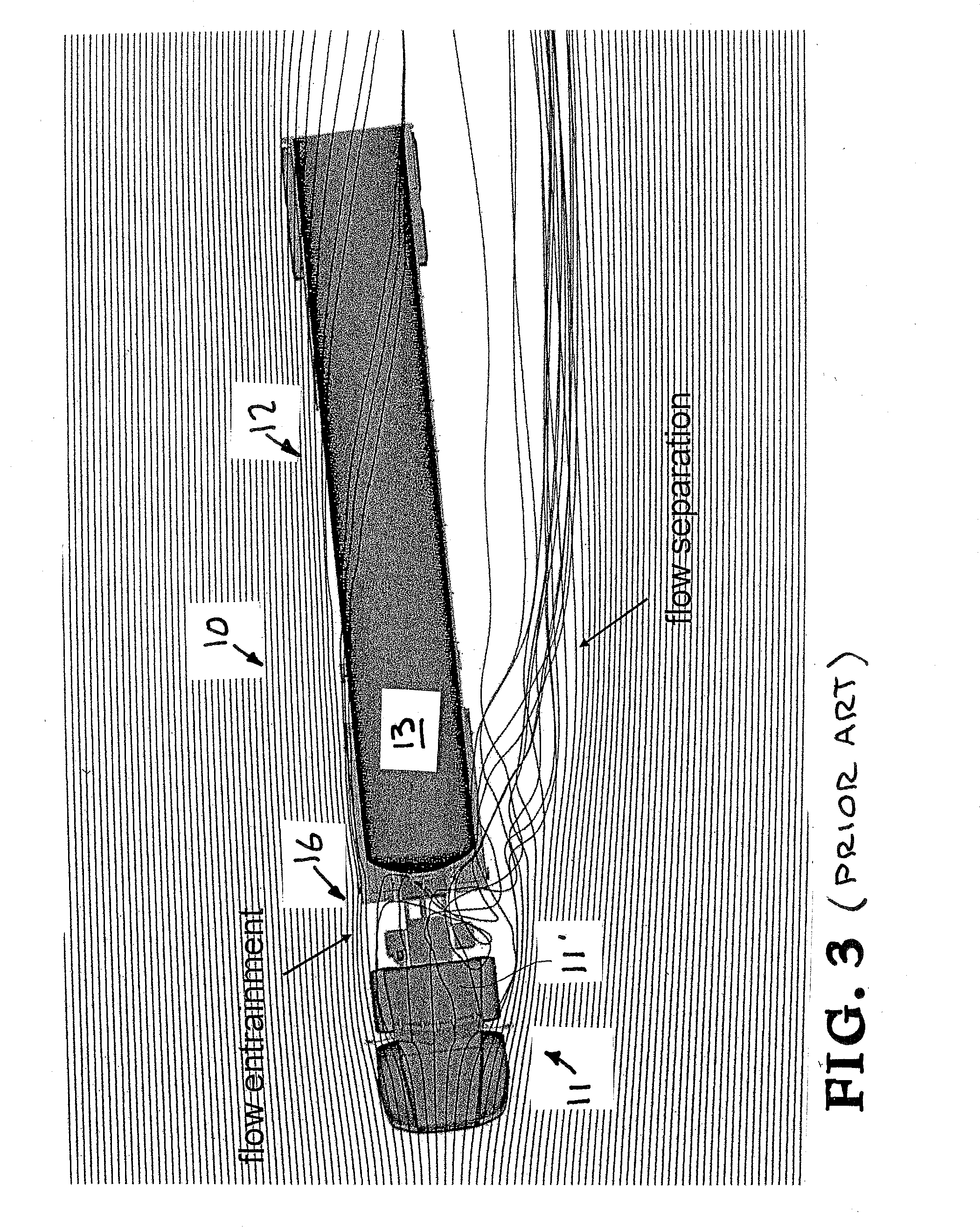

Roof and gap fairing for the aerodynamic drag reduction of tanker trucks

InactiveUS20110109121A1Reduce air resistanceDecreases the amount of cross-stream flowVehicle seatsWindowsAerodynamic dragFuel tank

A fairing apparatus for reducing aerodynamic drag of a tanker in a freestream, and including a fairing body with a roof section, and left and right side sections connected to and extending below the roof section. Fasteners, for example, mount the fairing body on a cab of the tanker so that the roof, left, and right side sections extend from the roof, left and right side surfaces, respectively, of the cab towards a cylindrical tank carried behind the cab to reduce the gap between the cab and the tank and impede cross-flow therethrough, and the fairing surfaces of the roof, left, and right side sections are angled and preferably curvilinearly contoured to redirect airflow from the top and side surfaces of the cab to the curvilinearly contoured top and side surfaces of the tank to compensate for a profile mismatch between the cab and the taller and / or wider tank.

Owner:LAWRENCE LIVERMORE NAT SECURITY LLC

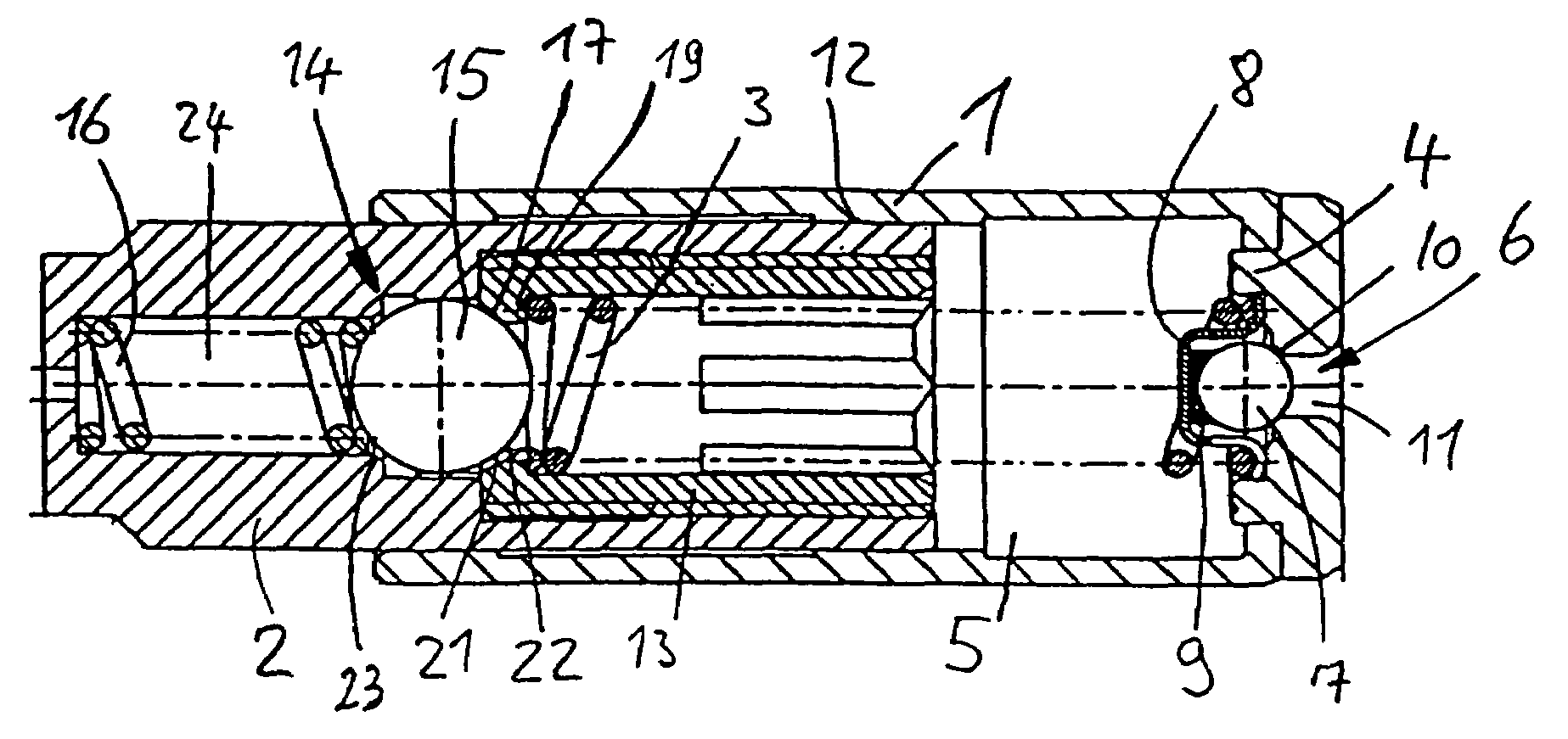

Chain tensioner

A tensioner for a chain, includes a tensioner piston bearing upon a chain and guided by a cylinder for movement in the direction of the chain. The cylinder and the piston define a pressure chamber for receiving hydraulic fluid, wherein hydraulic fluid is able to escape from the pressure chamber via a leakage gap. A control member is provided to at least reduce the leakage gap in size, when a pressure in the pressure chamber increases.

Owner:INA WALZLAGER SCHAEFFLER KG

Tube type PERC single-sided solar cell, preparation method thereof and special equipment thereof

ActiveCN107256894AReduce the ratio of scratchesReduce impact forceFinal product manufactureSemiconductor/solid-state device manufacturingScratchingSilica membrane

The invention discloses a tube type PERC single-sided solar cell, which comprises a main silver back gate, an all-aluminum back electric field, a back-side composite film, a P-type silicon, an N-type emitting electrode, a front-side passivation film and a positive silver electrode. The back-side composite film is composed of one or more selected from an aluminum oxide film, a silicon dioxide film, a silicon oxynitride film and a silicon nitride film and is deposited at the back of a silicon chip by adopting tube type PECVD equipment. The tube type PECVD equipment comprises four gas pipelines of silane, ammonia, trimethyl aluminum and laughing gas. The appliance of the tube type PECVD equipment, used for loading and unloading silicon chips, is a graphite boat. The depth of a sticking point groove of the graphite boat is 0. 5-1 mm. The invention also discloses a preparation method and special equipment of the tube type PERC single-sided solar cell. According to the invention, the photoelectric conversion efficiency is high. Meanwhile, the appearance yield and the EL yield are high. The problems of scratching, winding and plating can be solved.

Owner:GUANGDONG AIKO SOLAR ENERGY TECH +1

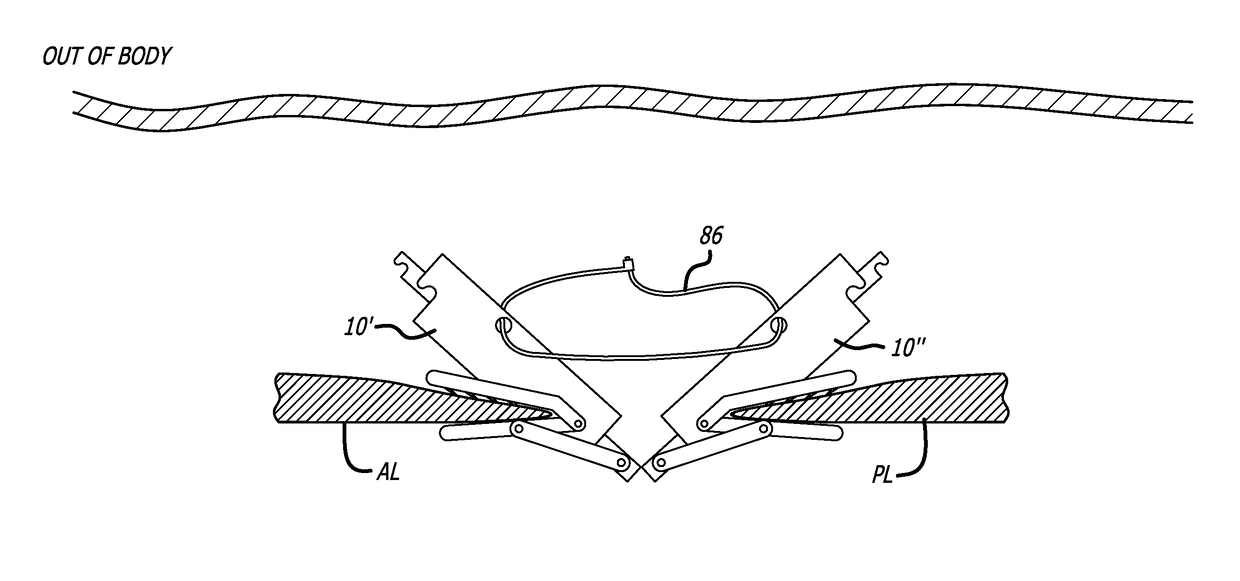

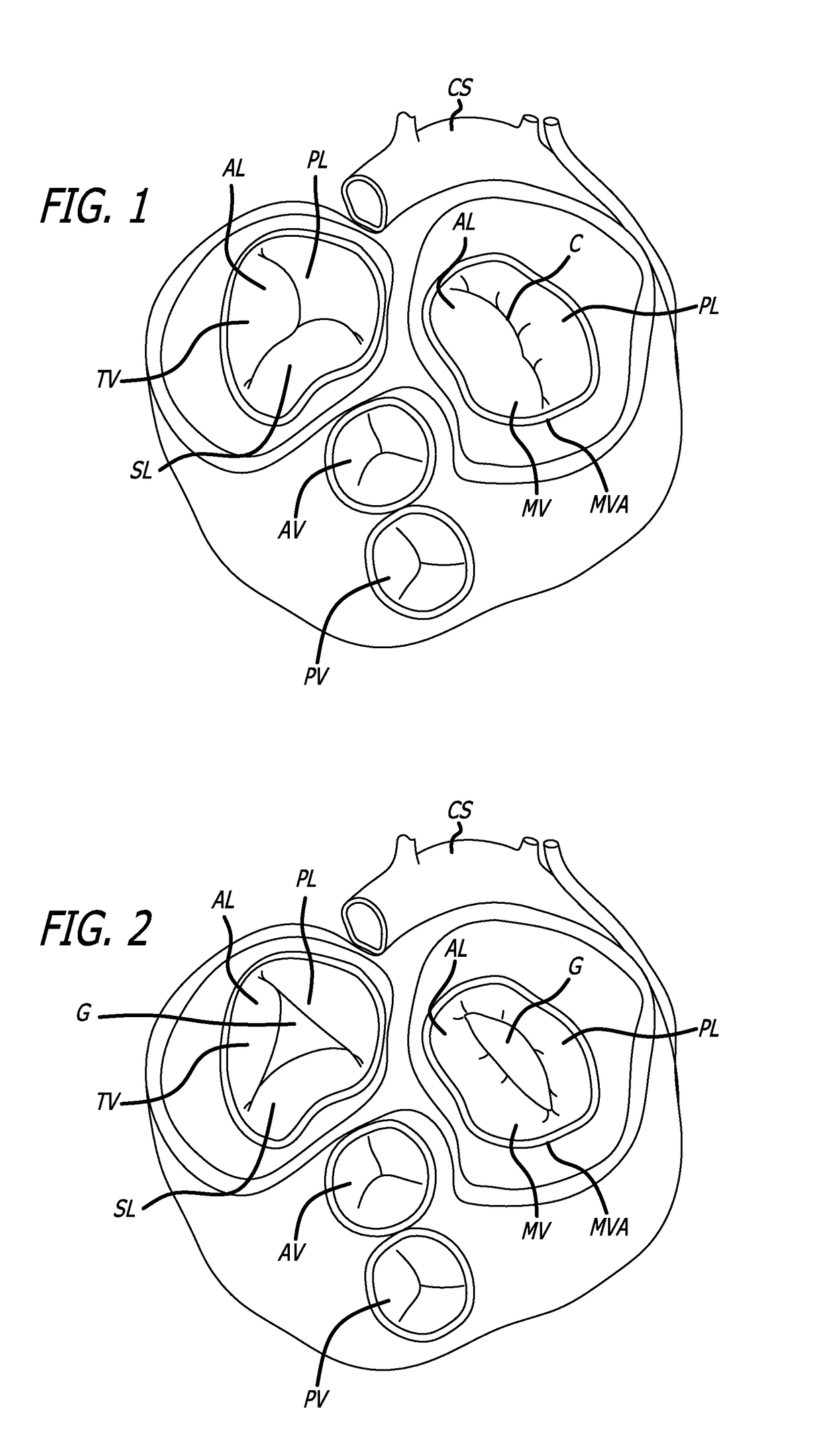

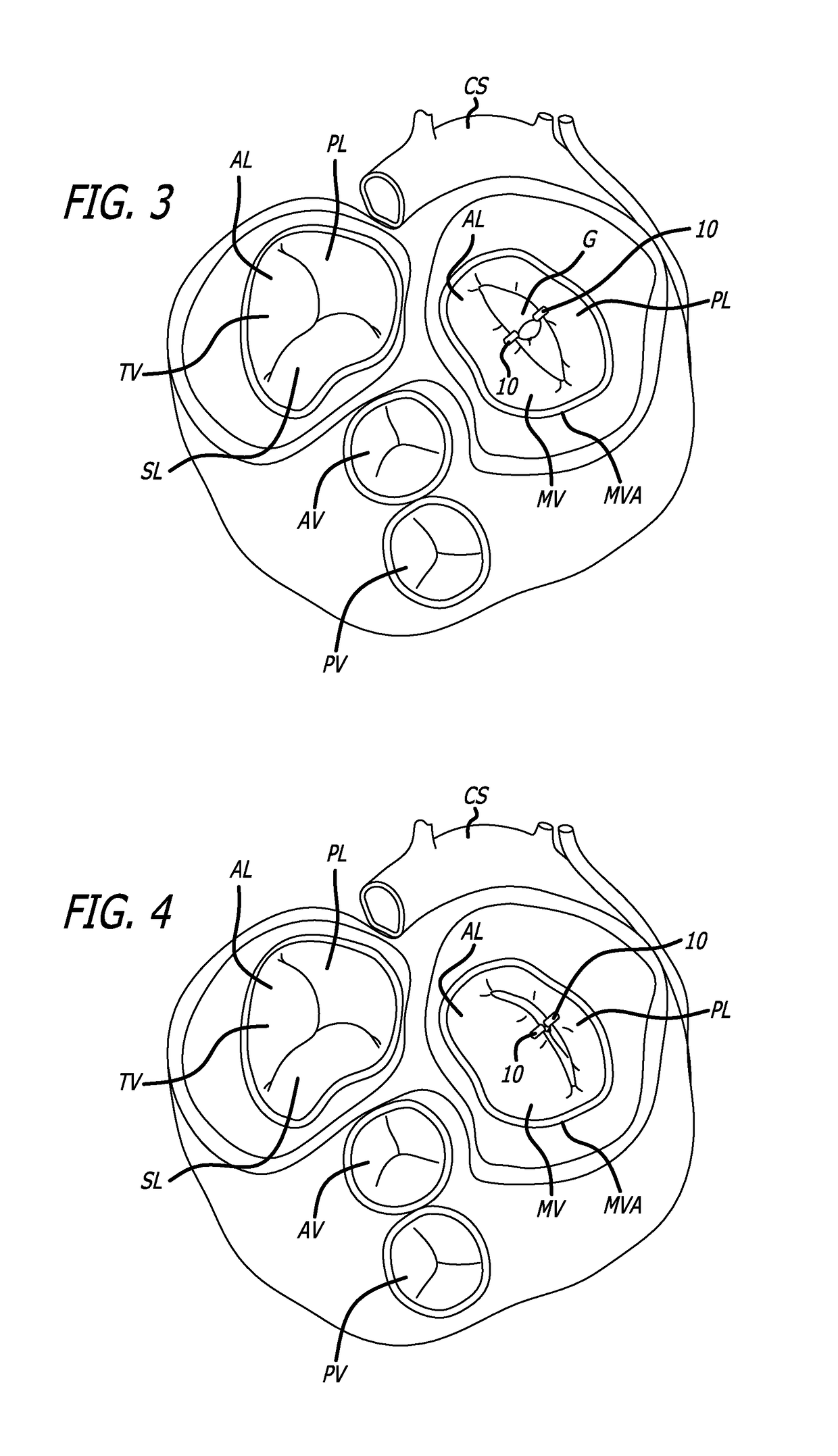

Fixation devices, systems and methods for heart valve leaf repair

ActiveUS20180133008A1Alter physiological positioningSmall sizeSuture equipmentsAnnuloplasty ringsHeart valve repairTarget tissue

Devices, systems and methods for repairing a valve in a patient's heart includes a two or more fixations devices, each fixation device being attachable to the free end of a target tissue, such as a valve leaflet, the fixation devices being coupled together by a coupling device capable of repositioning and coupling the fixation devices in order to re-position the free ends of the valve leaflets.

Owner:ABBOTT CARDIOVASCULAR

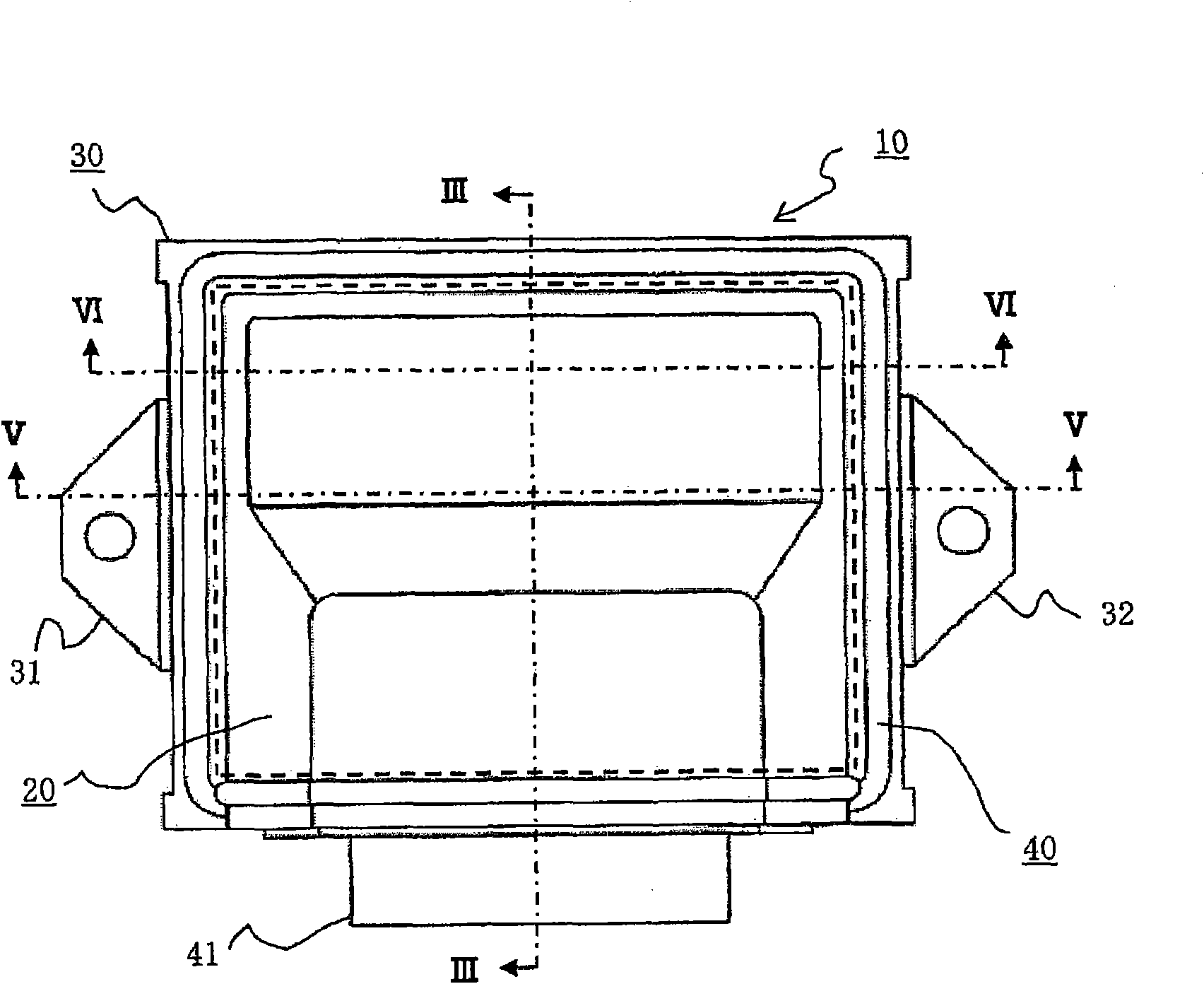

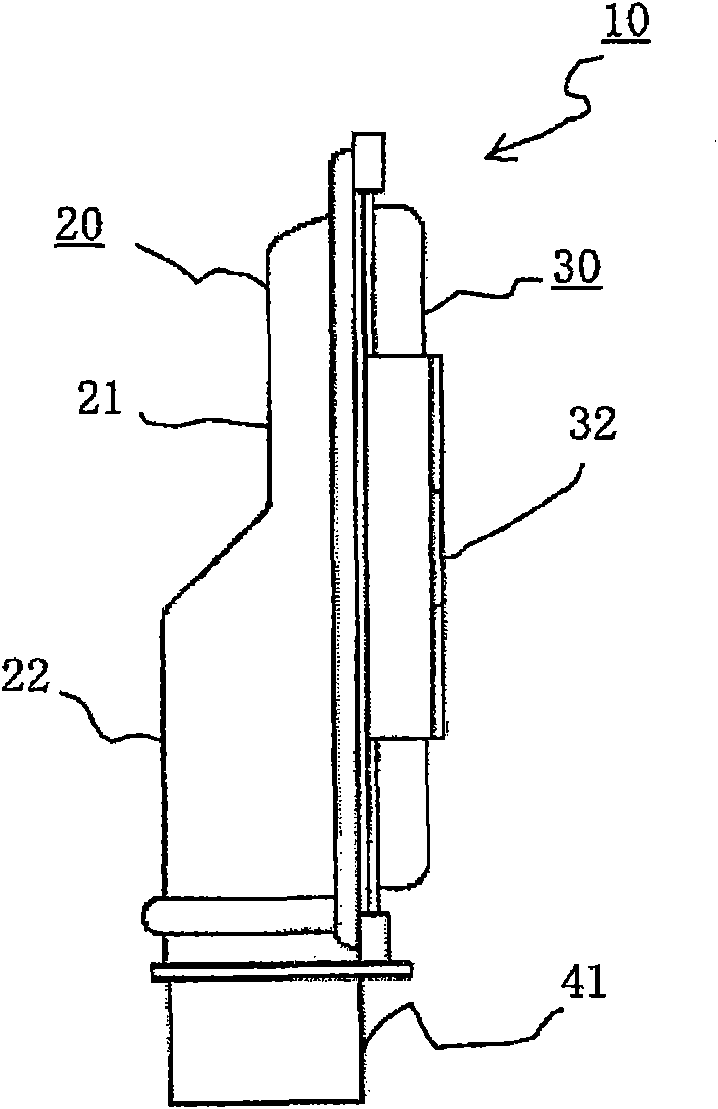

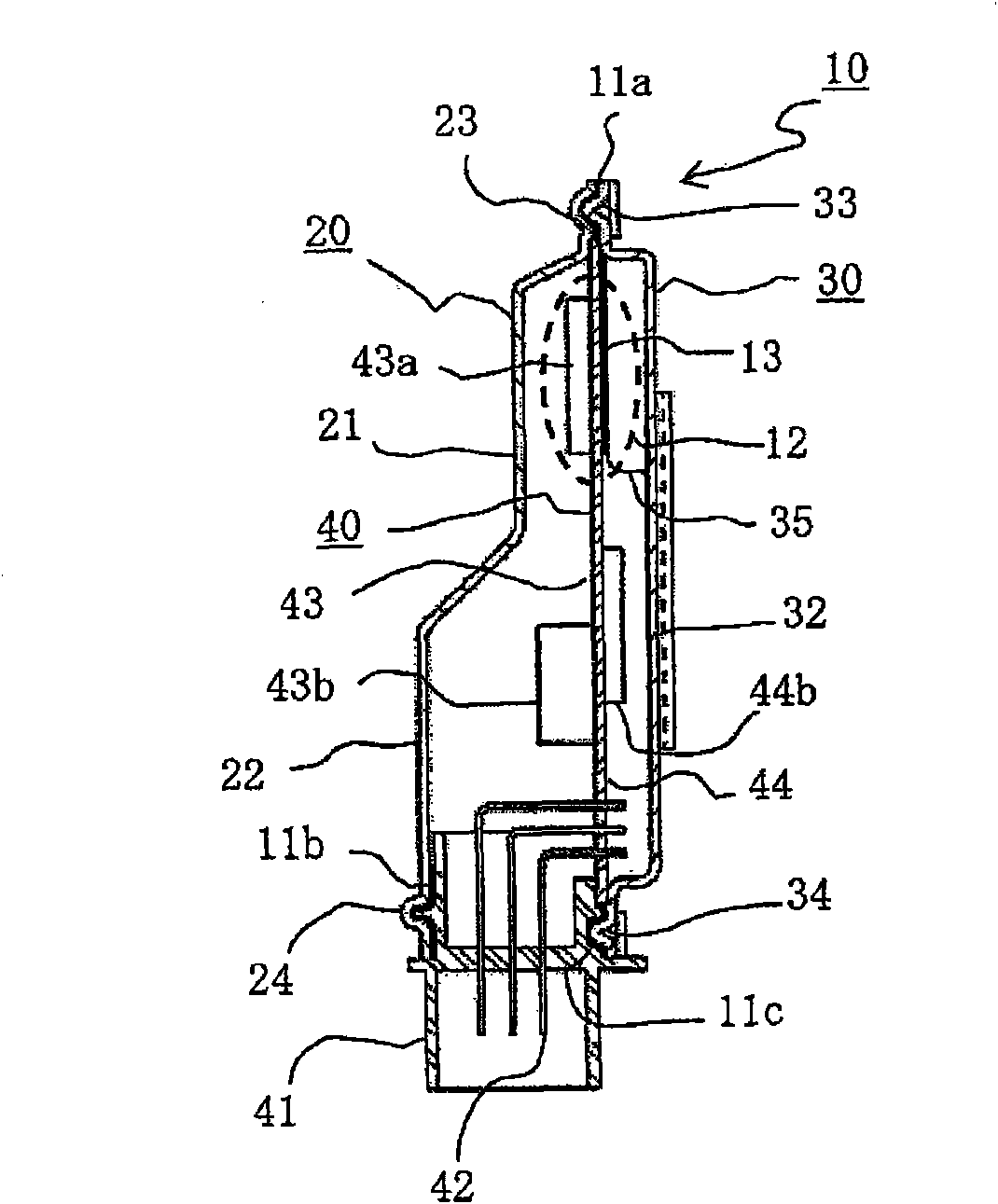

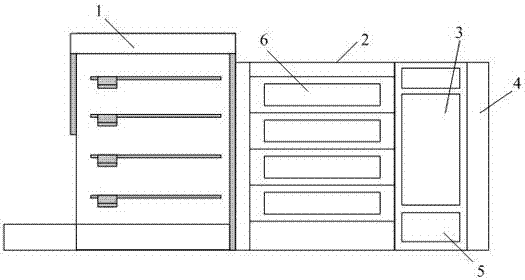

Board housing case for vehicle-mounted electronic device

InactiveCN102833983AReduce gap sizeAverage and stable heat dissipationHermetically-sealed casingsCooling/ventilation/heating modificationsSurface finishEngineering

A circuit board is hermetically-sealed and housed in a steel case that is composed of a metal base (30) and a metal cover (20), the cover disposed opposite to a first board surface (43) has a tall flat portion disposed opposite to a connector housing (41) and a short flat portion (22) disposed opposite to a heating component (43a), and the heat generated from the heating component is directly transferred to a heat transfer base portion (35) of the base via a heat transfer mechanism (12) and a heat transfer filling material (13). Surface finishing in which the coefficients of heat radiation are mutually 0.7 to 1.0 is applied to the surface of the heating component (43a) and the opposite inner surface of the cover (20), and radiation and heat transfer are efficiently performed to the short flat portion (21) of the cover.

Owner:MITSUBISHI ELECTRIC CORP

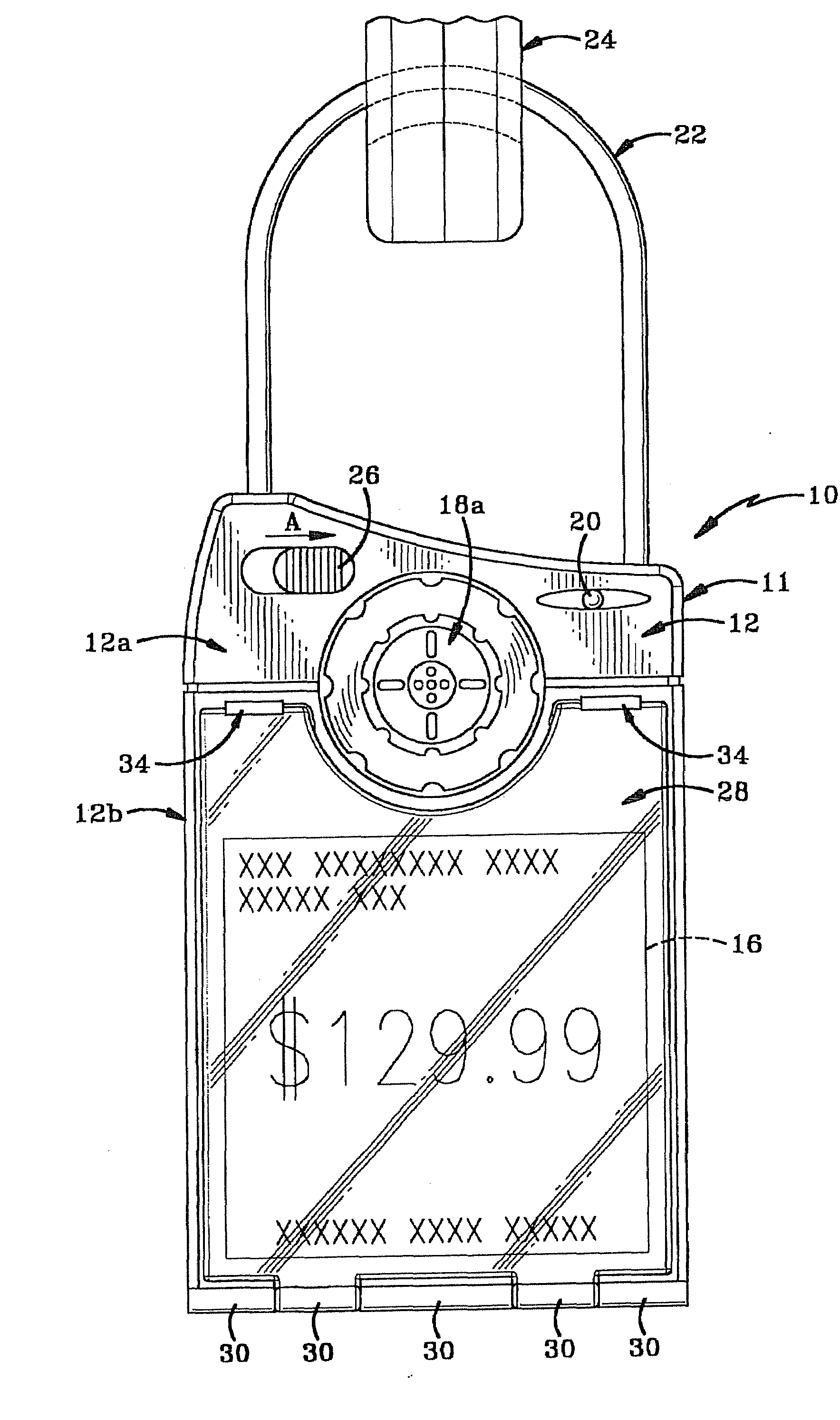

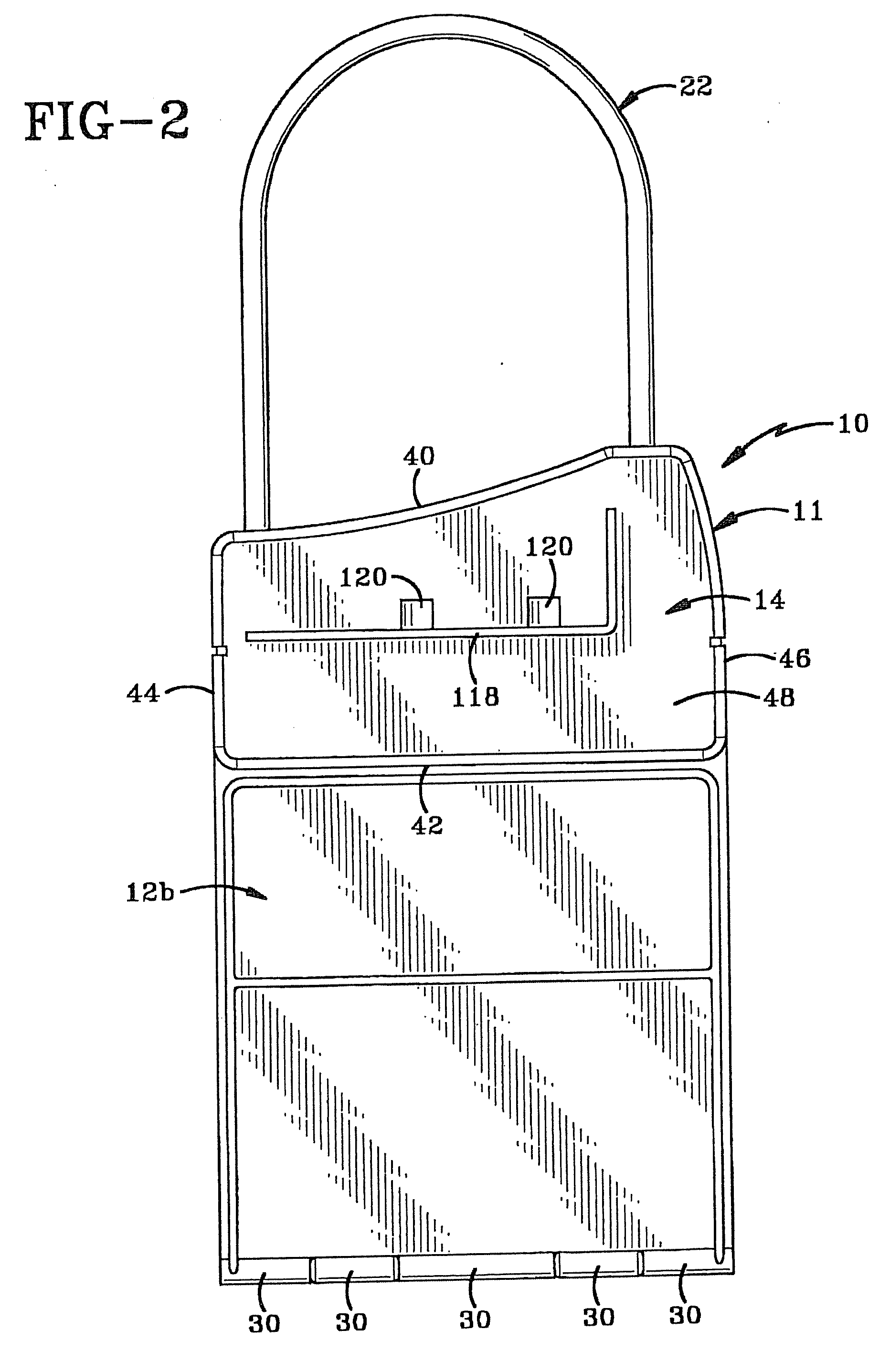

Merchandise tag with alarming features for securing tag to merchandise

InactiveUS20090102666A1Increase the gap sizeReduce gap sizeStampsLocks for portable objectsLocking mechanismEngineering

A security device for a product for sale. The device includes a housing having a cable for engaging the product. A free end of the cable has a locking pin receivable within a bore in the housing. A locking mechanism is provided to lock the locking pin within the bore. The mechanism includes a slider and a clamping member. When the slider moves away from the clamping member, the locking pin is clamped in the bore. When the slider moves toward the clamping member, the member disengages the locking pin which may then be withdrawn from the bore. The locking mechanism further includes a magnetic spring clip that prevents the slider from being moved toward the clamping member. The spring clip is only deactivateable by a complementary magnetic key.

Owner:CHECKPOINT SYST INC

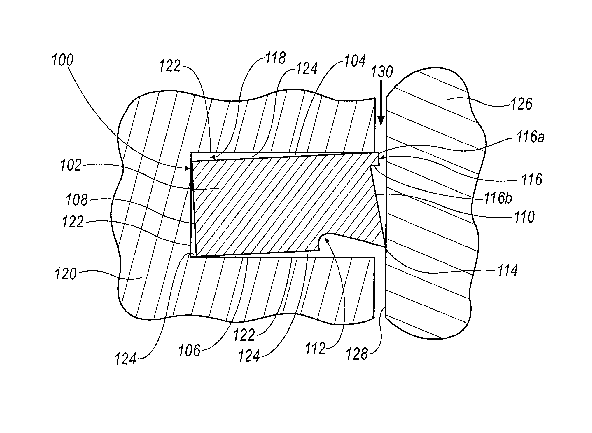

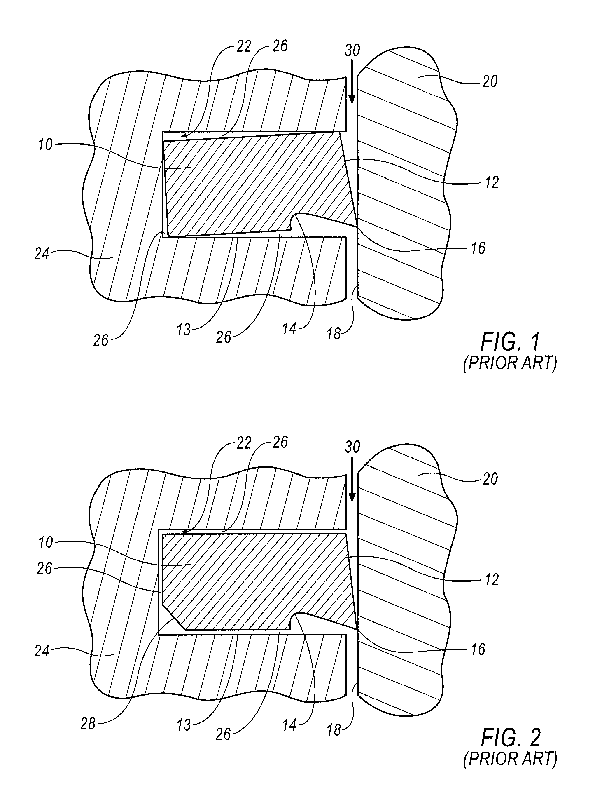

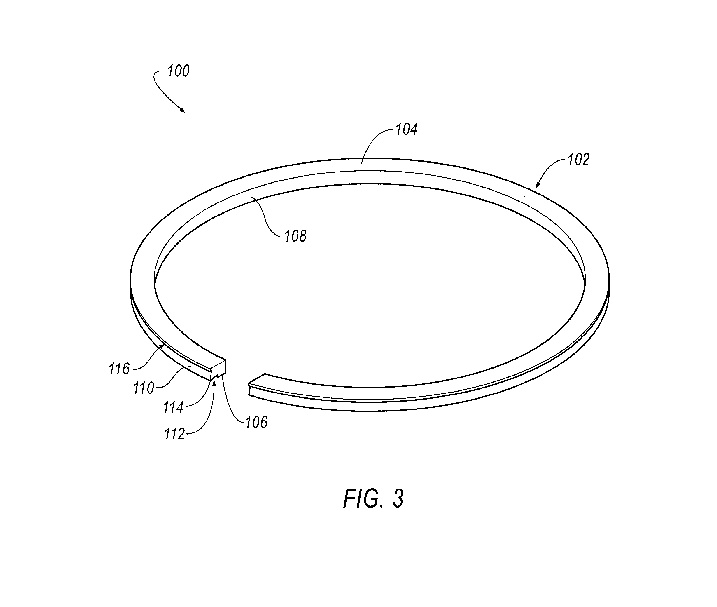

Piston ring with projection

ActiveUS7429048B1Reduce gap sizeEliminate ring collapsePiston ringsBraking action transmissionPiston ringEngineering

A piston ring is positioned in a groove of a piston and has an outer peripheral face. The outer peripheral face is generally tapered to an edge and includes a projection. The projection extends radially outwardly from the outer peripheral face along an upper surface of the piston ring. The projection reduces the gap between the outer peripheral face and a wall of the surrounding cylinder. The gap is typically exposed to combustion gases and the projection reduces the exposed area. Ring collapse is the separation of the outer peripheral face from the wall of the cylinder because of downward pressure forces of the combustion gases. Accordingly, the projection reduces the occurrence of ring collapse.

Owner:MAHLE ENGINE COMPONENTS USA

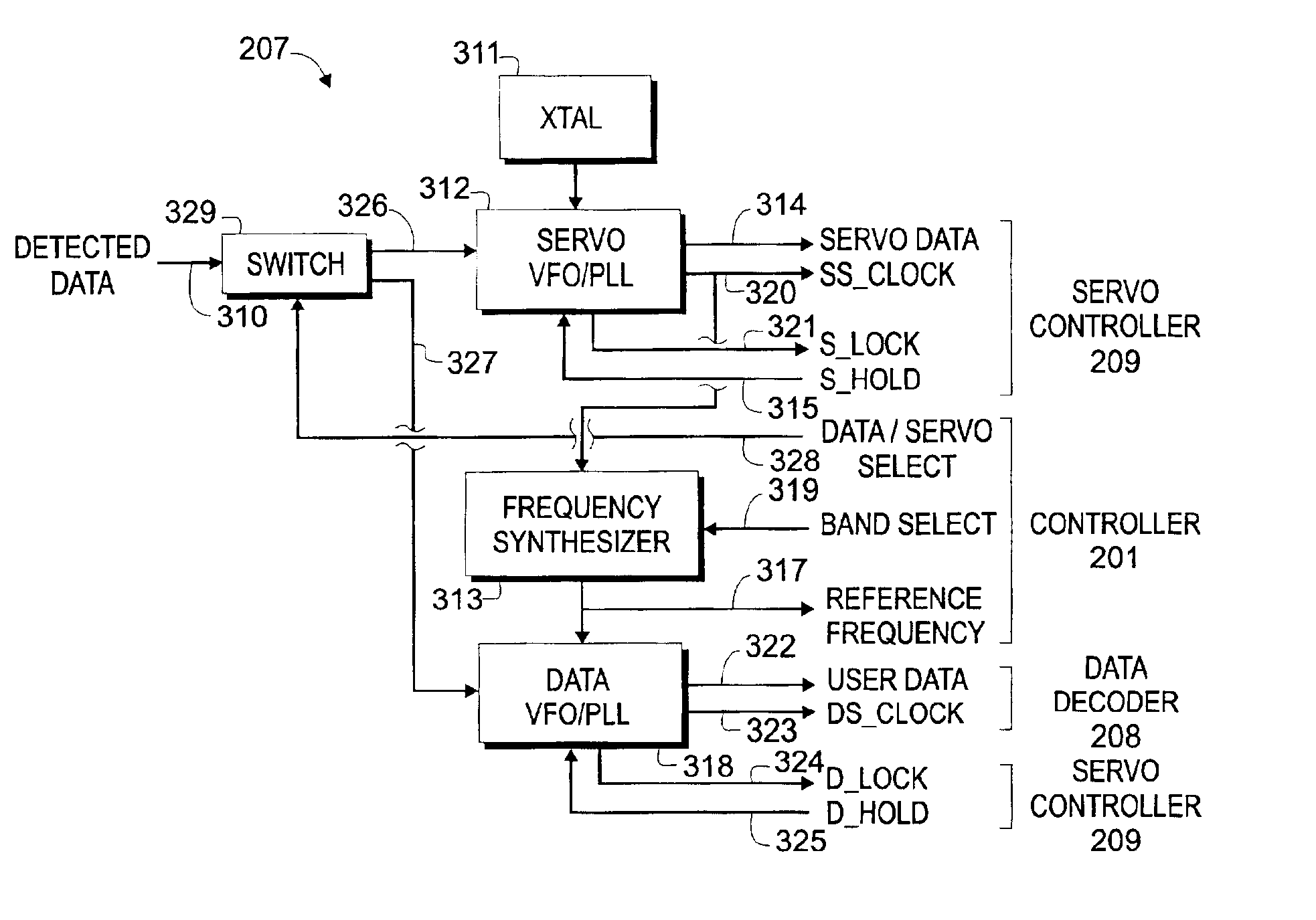

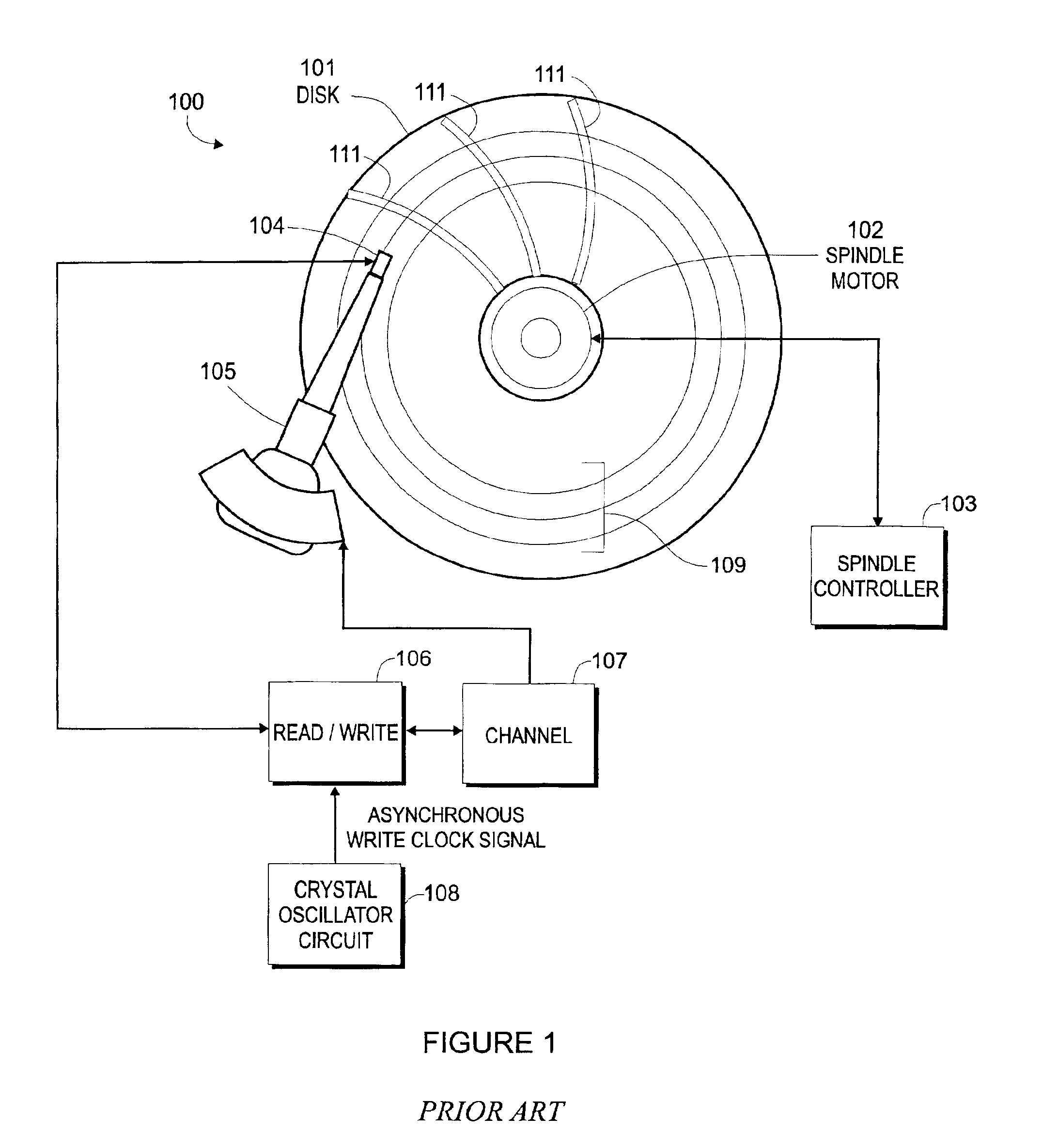

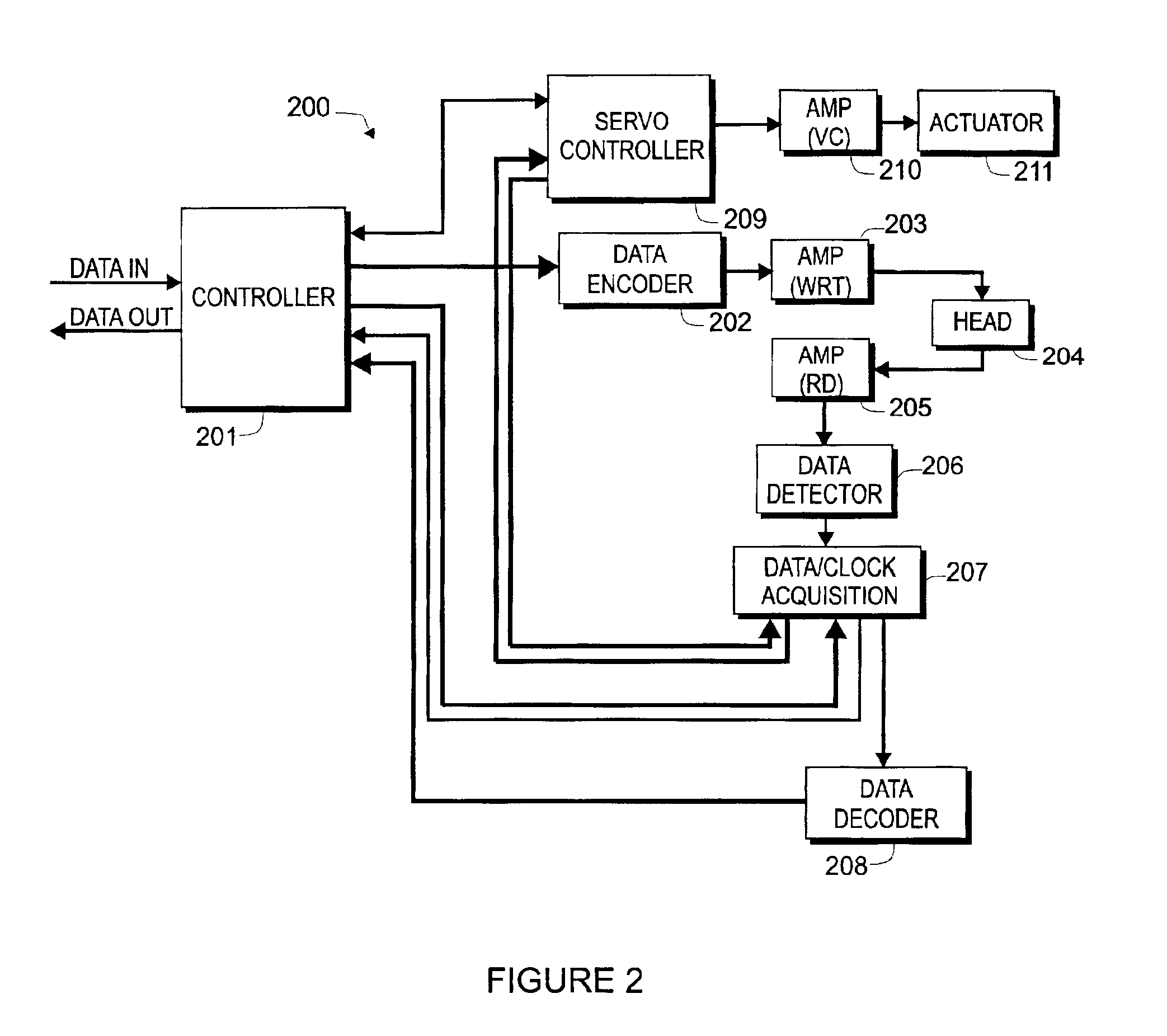

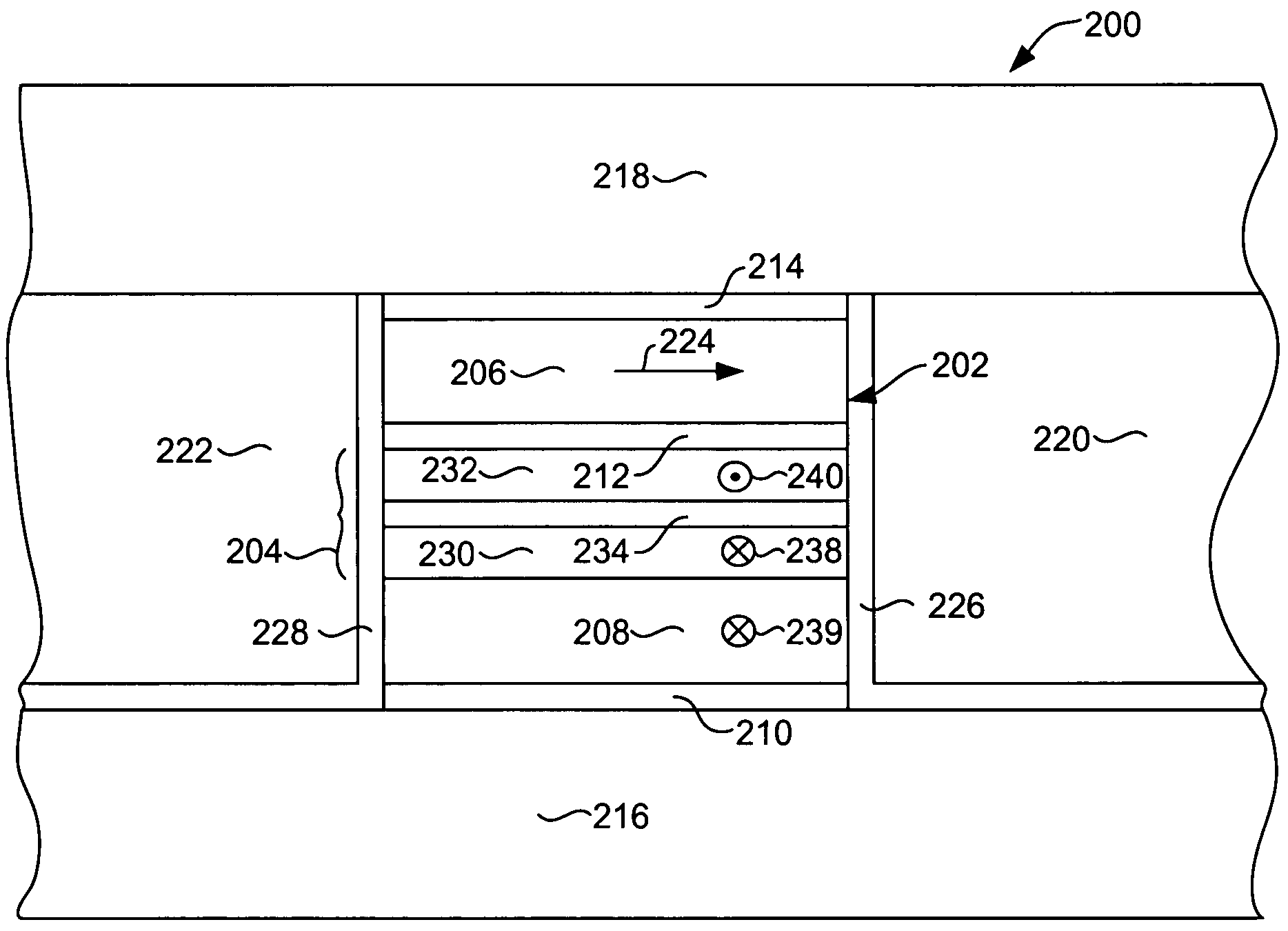

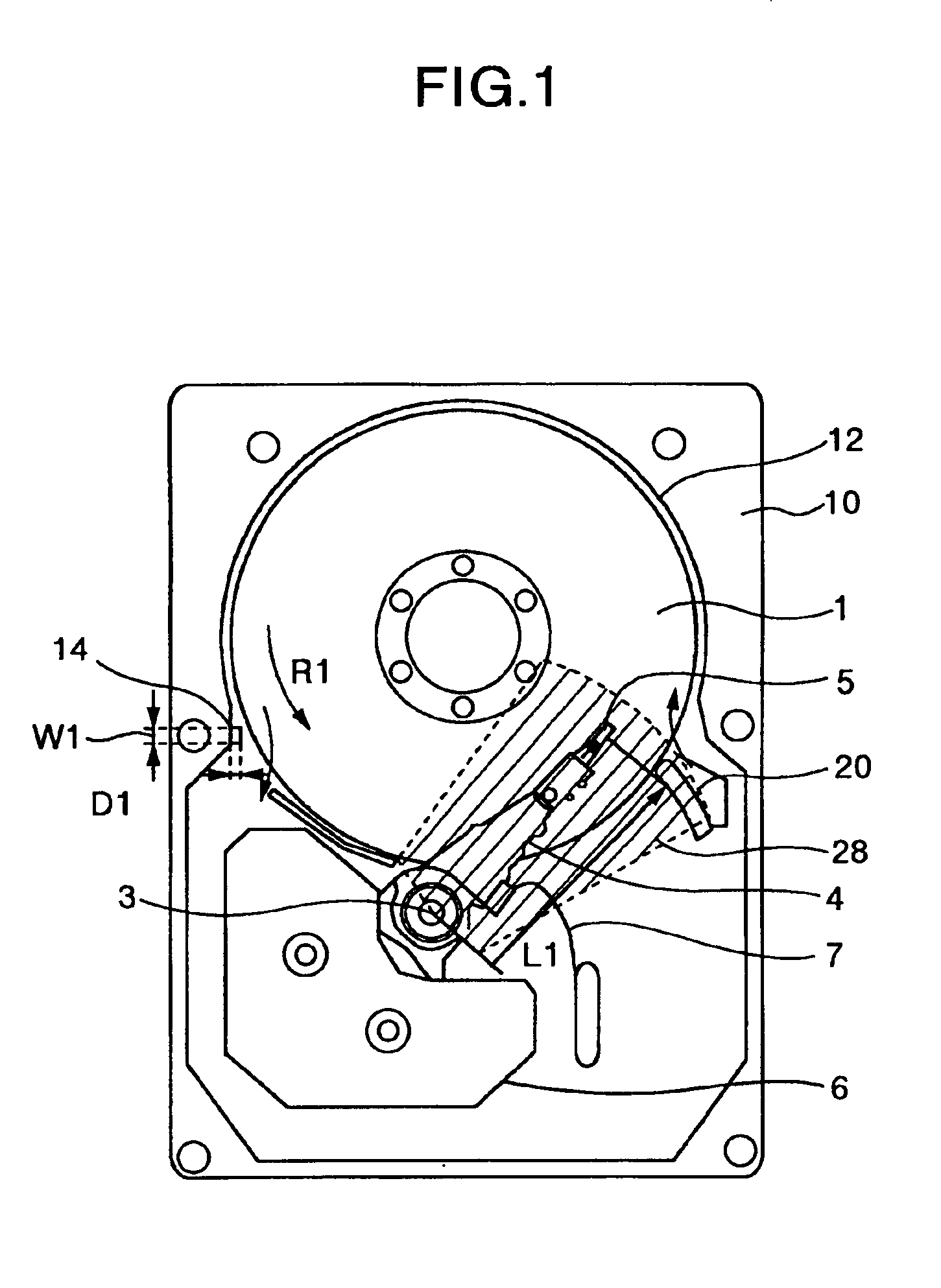

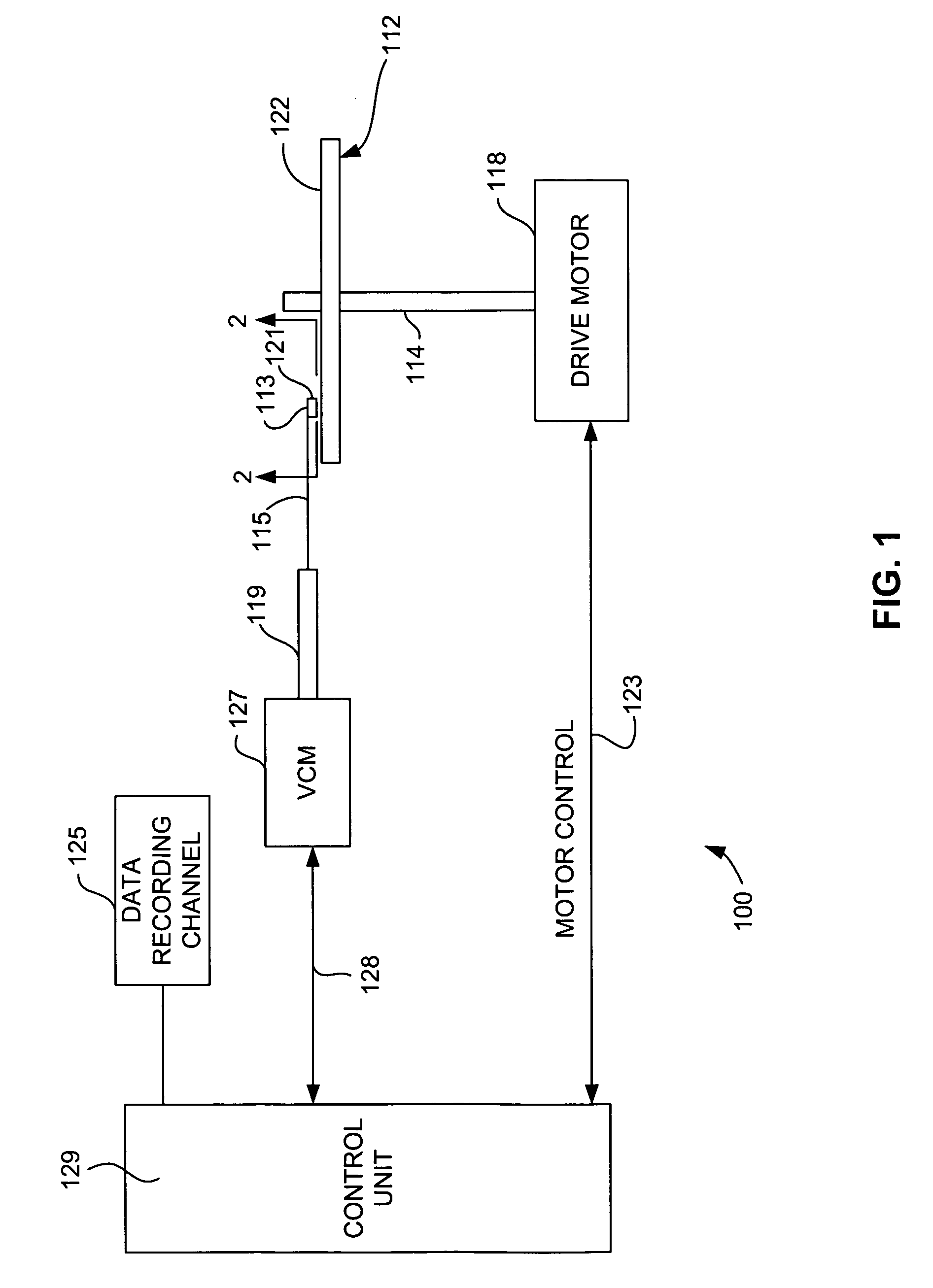

Disk drive with servo synchronous recording

InactiveUS6873483B2Avoiding data read errorAvoid dataDisc-shaped record carriersDriving/moving recording headsFrequency synthesizerEngineering

A read clock circuit for a disk drive includes a phase-locked loop / voltage controlled oscillator (VFO / PLL) and a frequency synthesizer. The VFO / PLL receives a servo sector transition signal that is related to detected transitions in a servo sector field of a magnetic recording disk, and outputs a servo frequency signal that is synchronous to the servo sector transition signal. The frequency synthesizer receives the servo frequency signal and generates the read clock signal that is synchronous with the servo frequency signal. In a banded recording disk drive the frequency synthesizer generates a unique read clock signal for each data band.

Owner:HITACHI GLOBAL STORAGE TECH NETHERLANDS BV

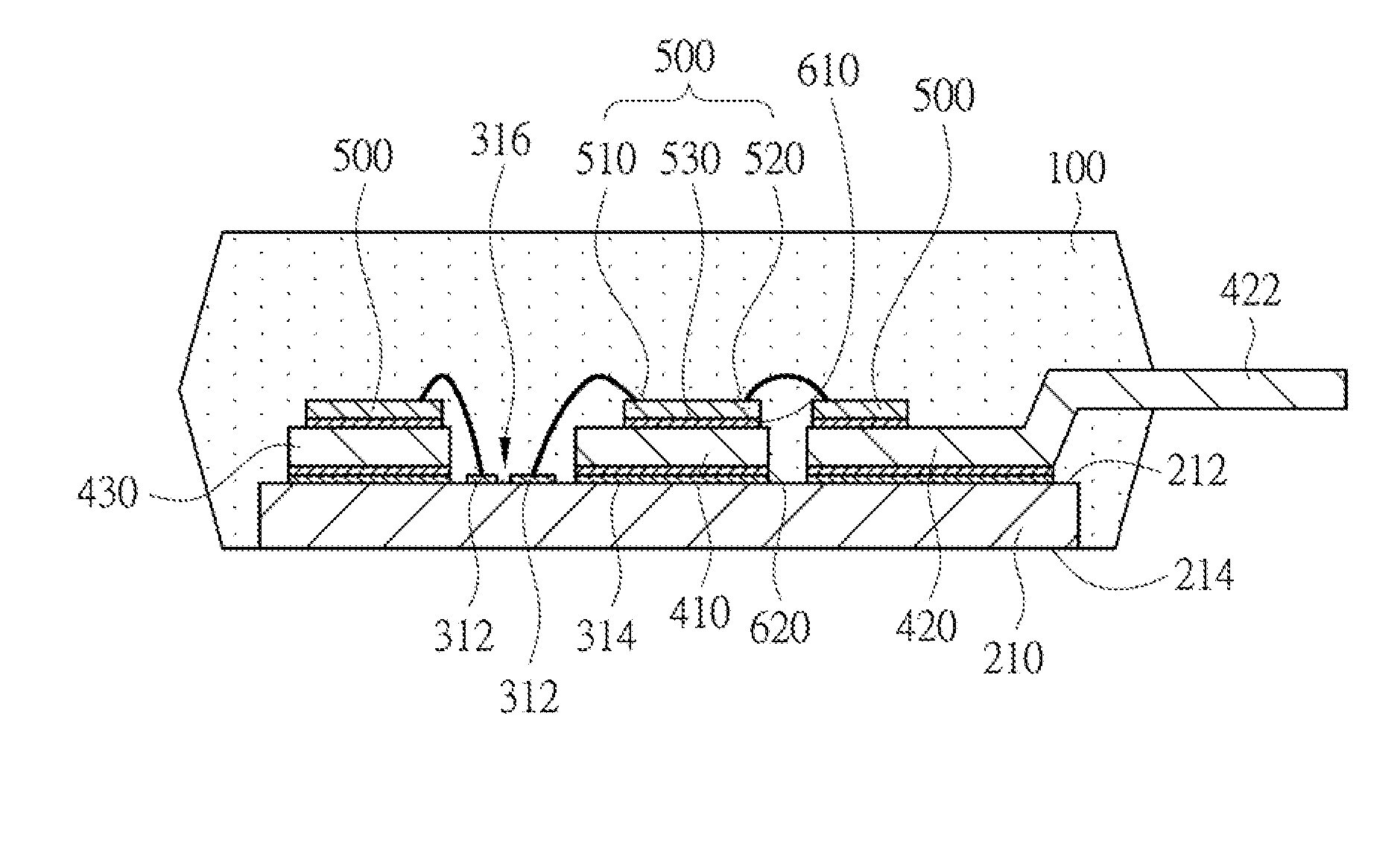

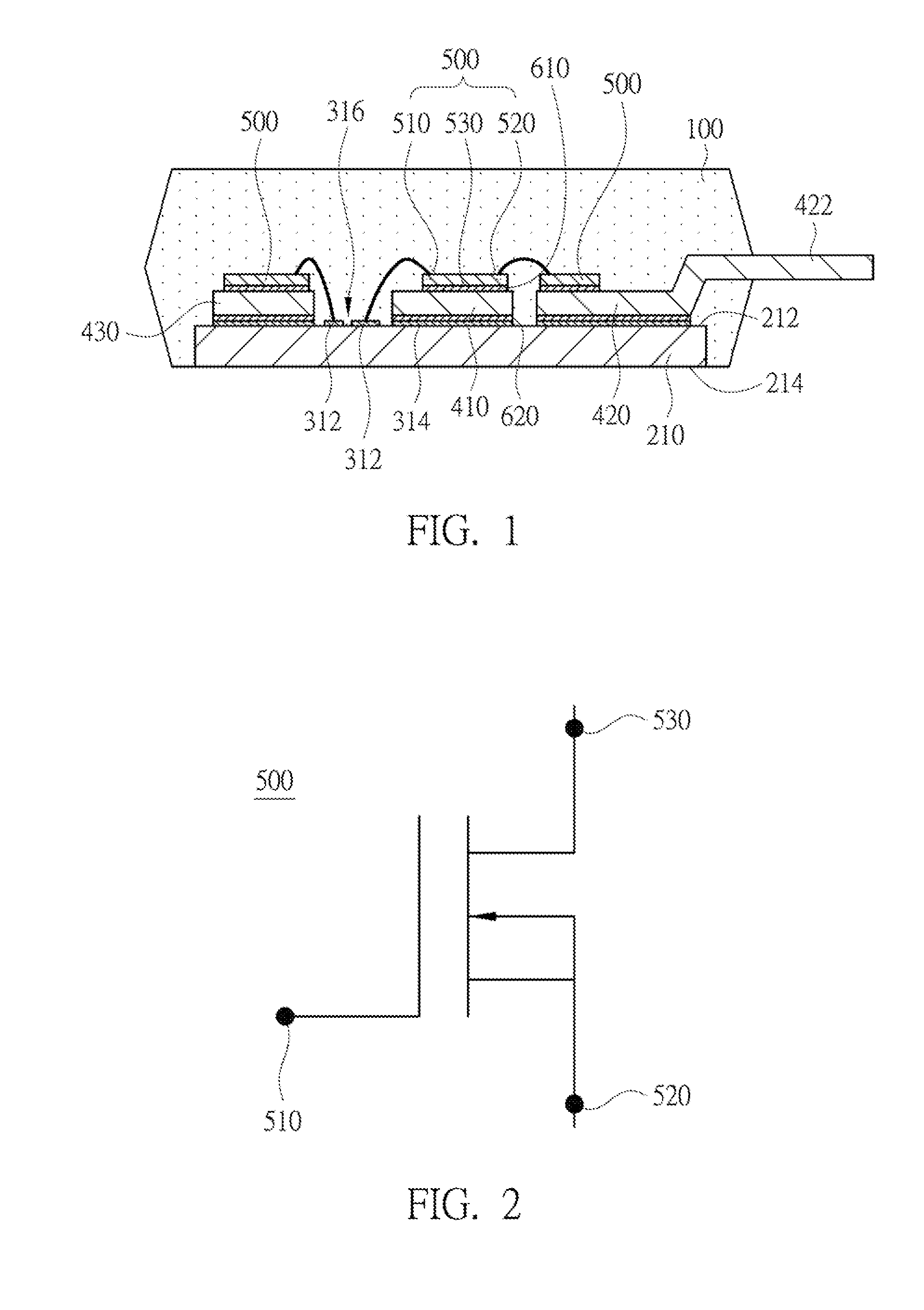

Organic electroluminescent device adapted for assembly function

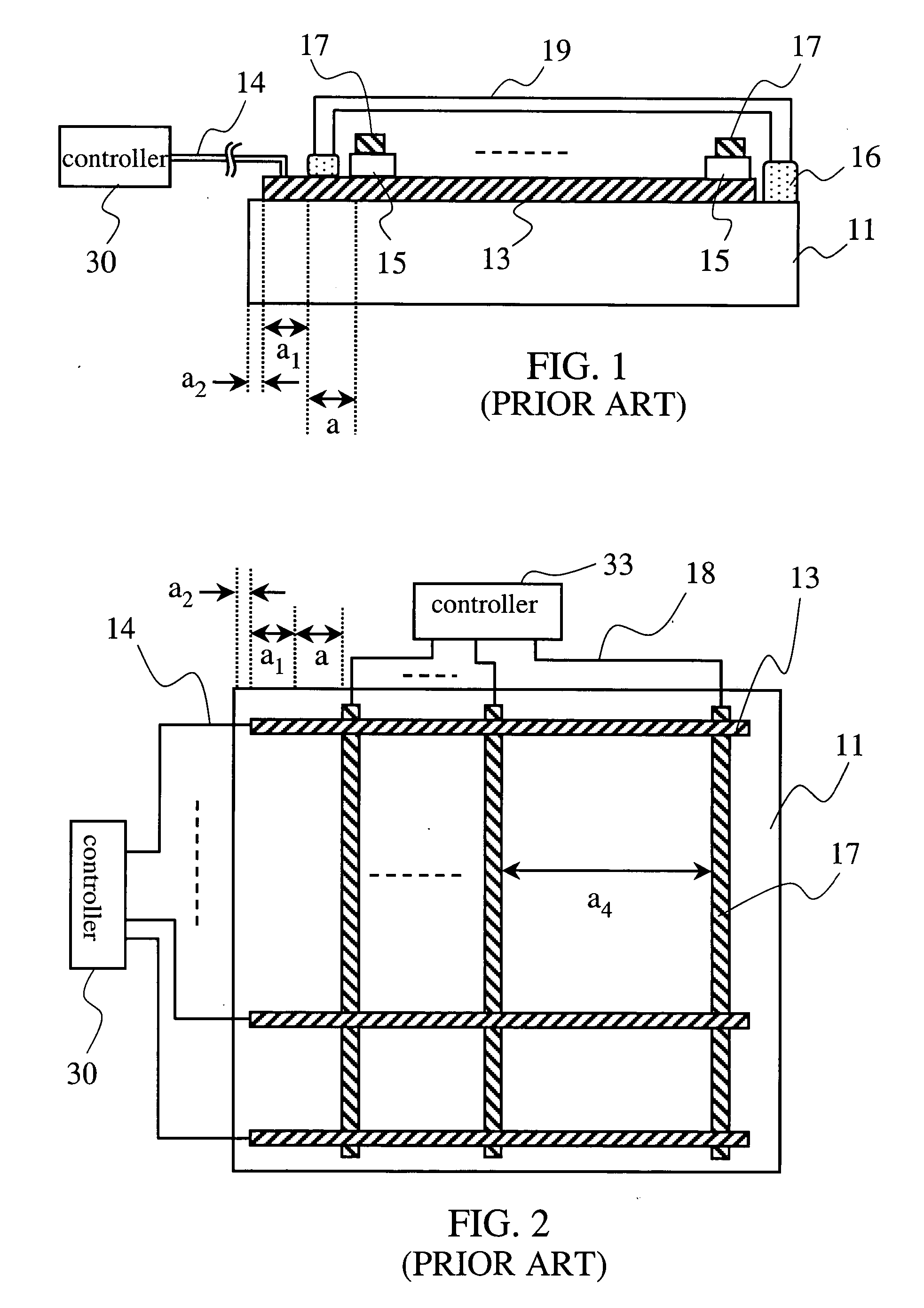

InactiveUS20050012103A1Reduce area of substrateImprove quality requirementsDischarge tube luminescnet screensSolid-state devicesImage resolutionOrganic electroluminescence

An organic electroluminescent device adapted for assembly function of a greater display size is provided. The device comprises forming first electrodes, a light-emitting layer, second electrodes, and isolating seal cap in turn. One side of the isolating cap is chiseled to form at least one channel, each channel being passed through by a corresponding connecting line. The end faces of the connecting lines may be contacted with a part of surface the first electrodes or second electrodes formed inside the isolating seal cap. The side ends of the first electrodes and second electrodes may be not necessarily exposed outside the isolating seal cap, due to the fact that the contacting point between the first electrodes or second electrodes and the connecting lines may be formed inside the isolating seal cap, whereby the area of the substrate, the first electrodes, and the second electrodes exposed outside the isolating seal cap may be reduced, further greatly decreasing the size of the gap during the assembly for two light-emitting devices correspondingly as well. Not only adapting for the assembly for a larger-sized display device, but also effectively increasing the quality requirement for higher resolution of the light-emitting device may be provided.

Owner:PENG KUAN CHANG

Method for manufacturing a magnetic read sensor employing oblique etched underlayers for inducing uniaxial magnetic anisotropy in a hard magnetic pinning layer

InactiveUS7360300B2Reduce parasitic resistanceReduce gap sizeManufacture head surfaceElectrical transducersMagnetic anisotropyFacet

A magnetoresistive sensor having a hard magnetic pinning layer with an engineered magnetic anisotropy in a direction substantially perpendicular to the medium facing surface. The hard magnetic pinning layer may be constructed of CoPt, CoPtCr, or some other magnetic material and is deposited over an underlayer that has been ion beam etched. The ion beam etch has been performed at an angle with respect to normal in order to induce anisotropic roughness for example in form of oriented ripples or facets oriented along a direction parallel to the medium facing surface. The anisotropic roughness induces a strong uniaxial magnetic anisotropy substantially perpendicular to the medium facing surface in the hard magnetic pinning layer deposited there over.

Owner:HITACHI GLOBAL STORAGE TECH NETHERLANDS BV

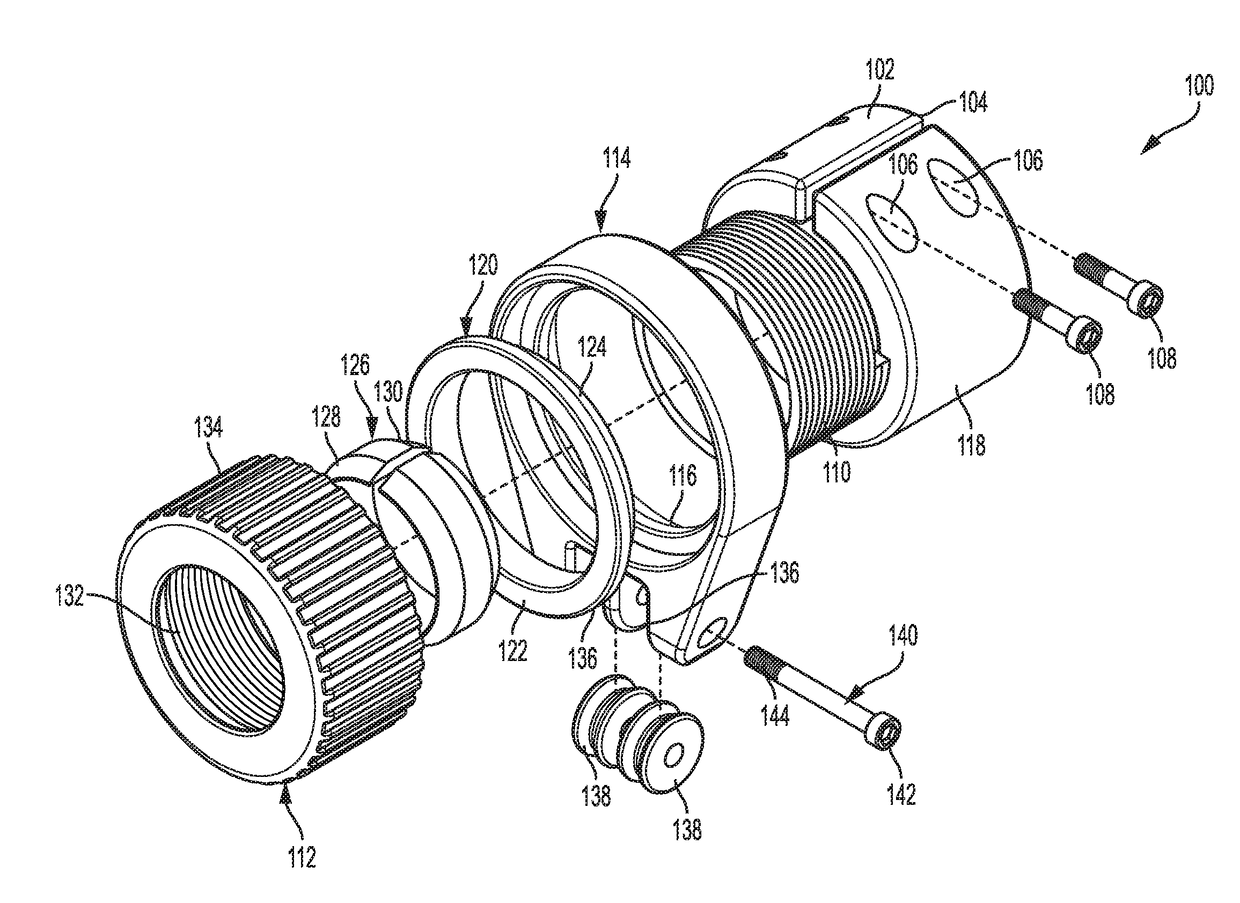

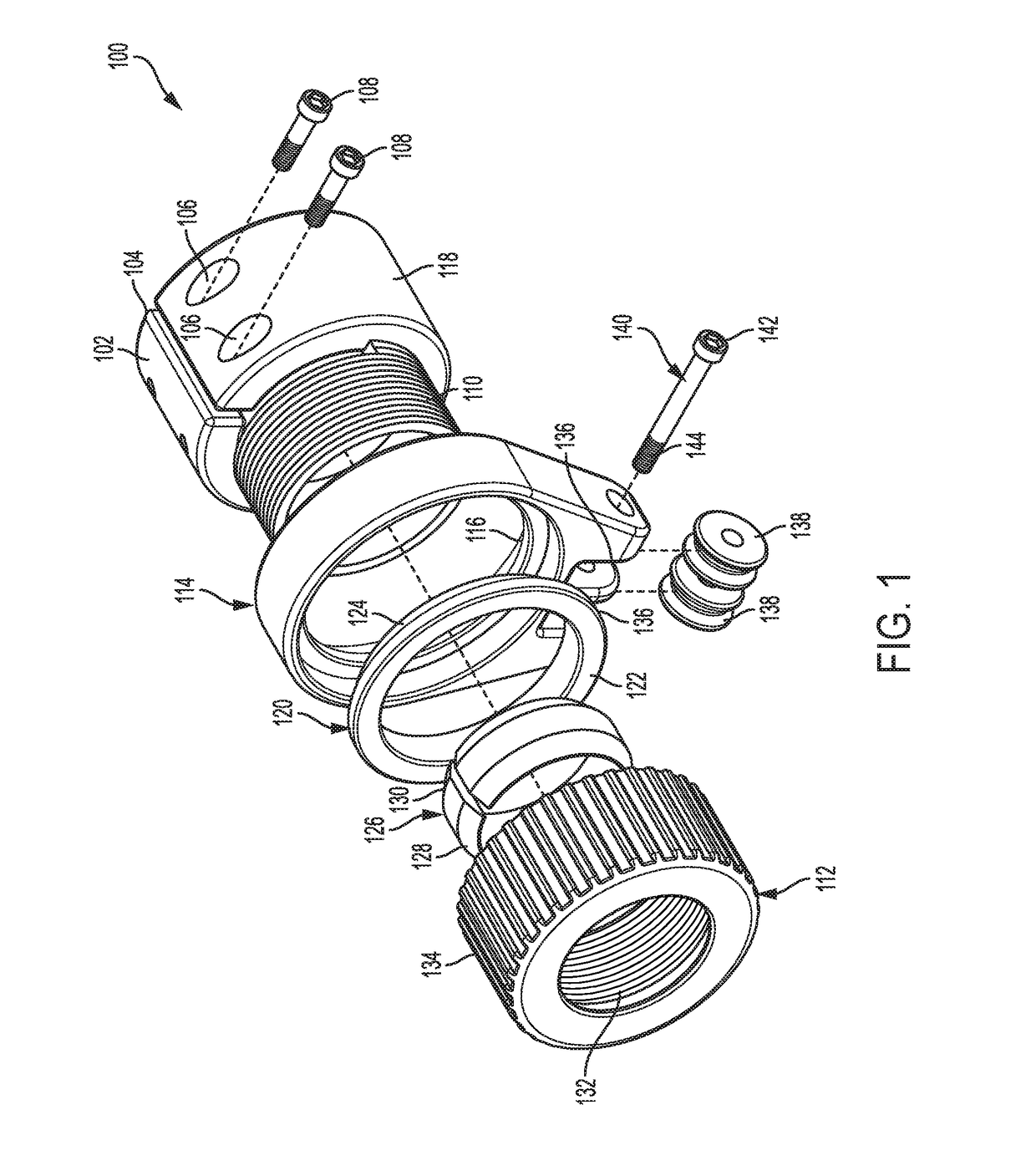

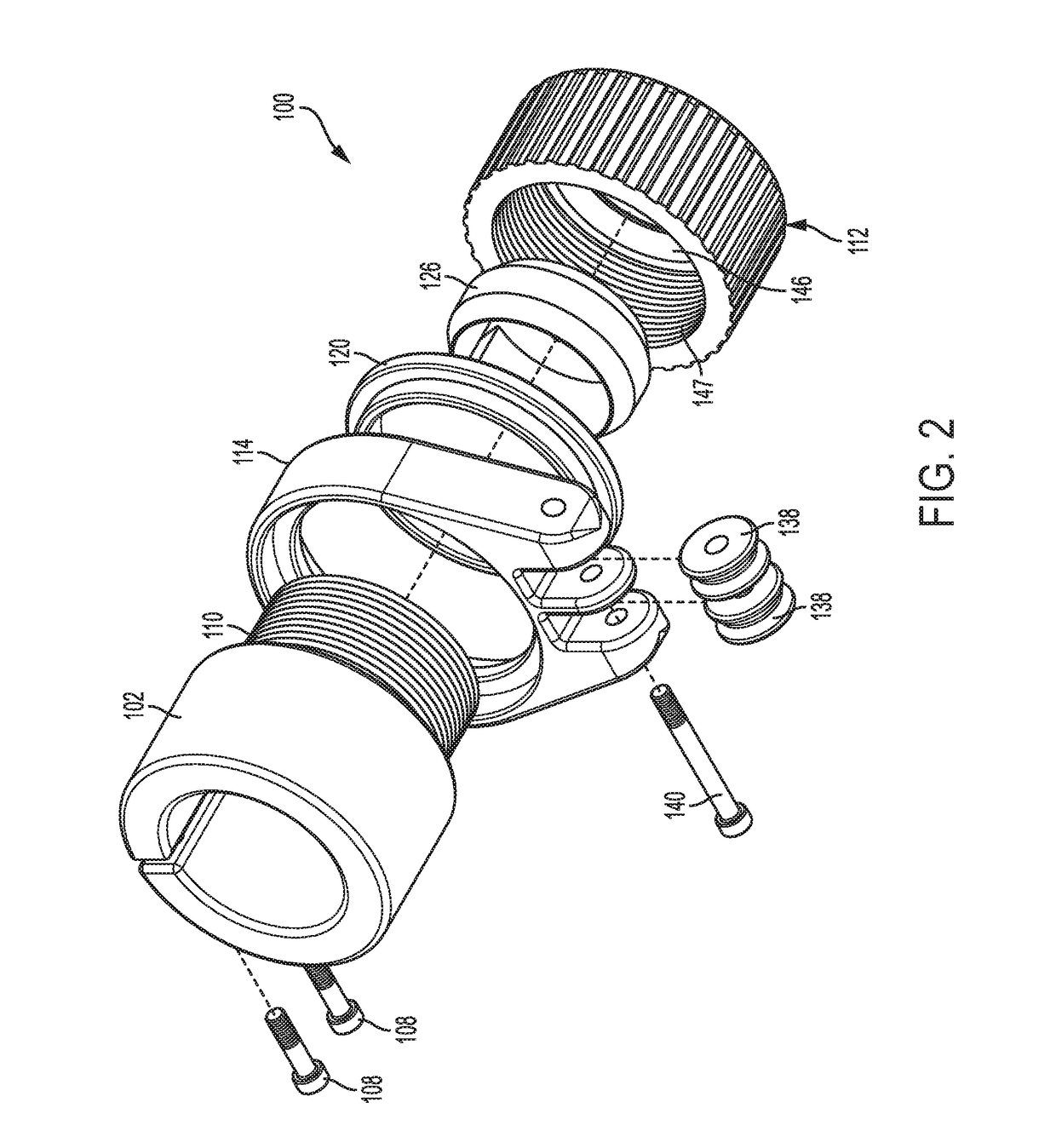

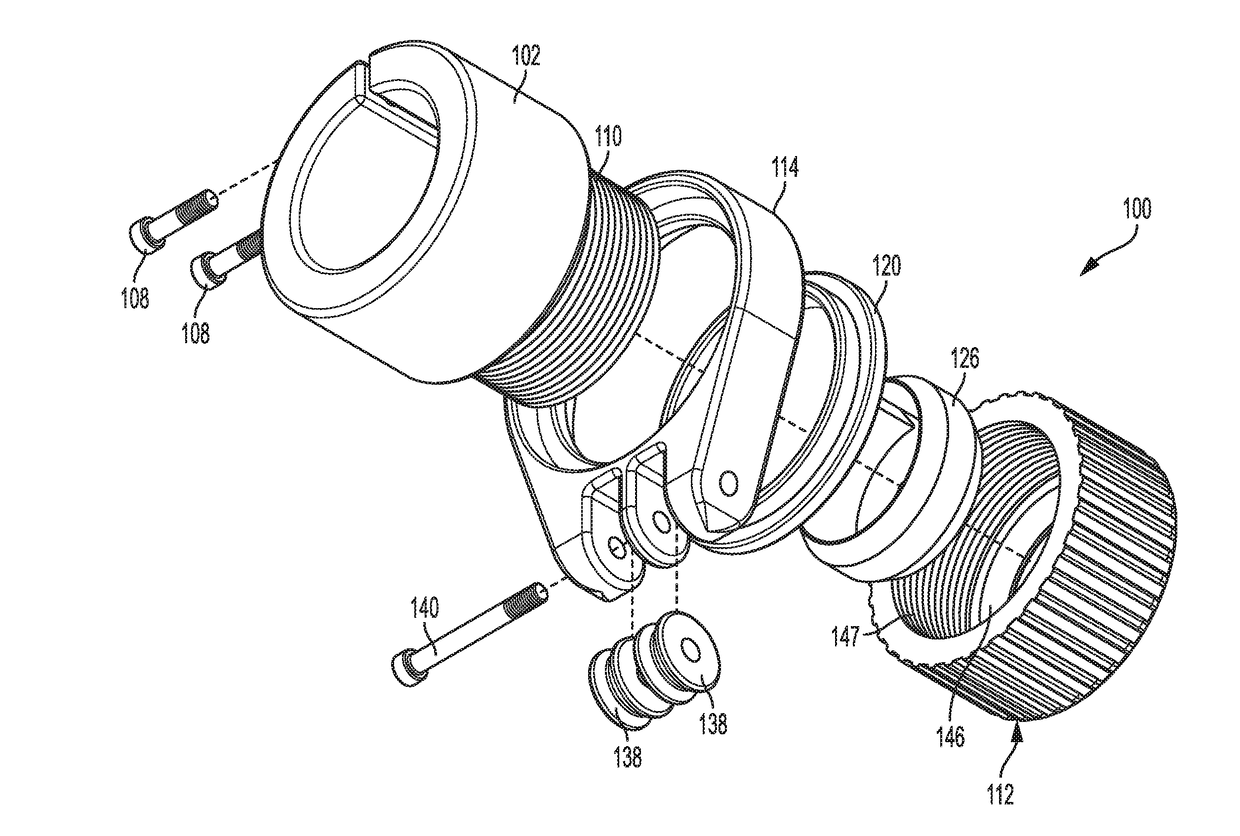

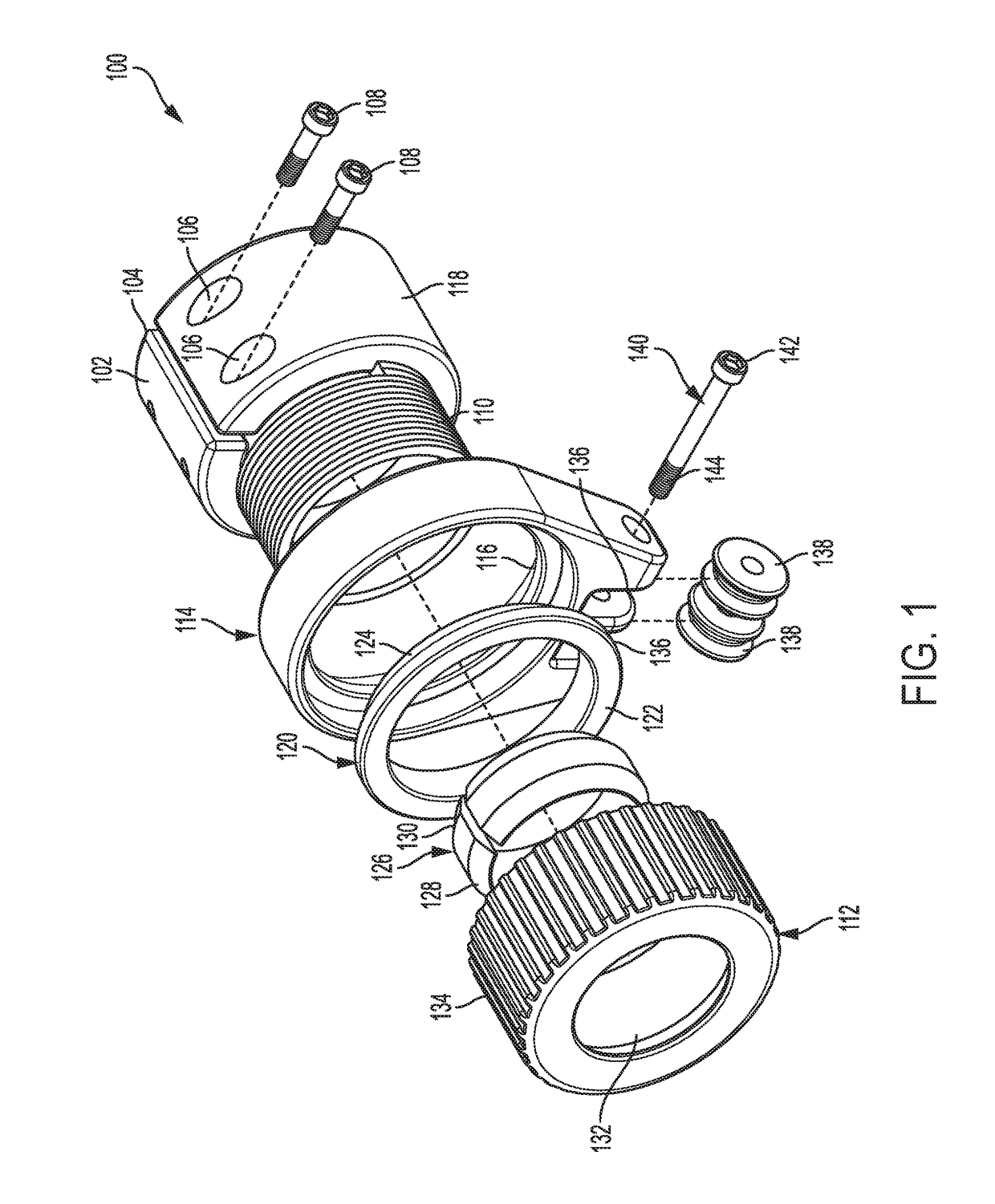

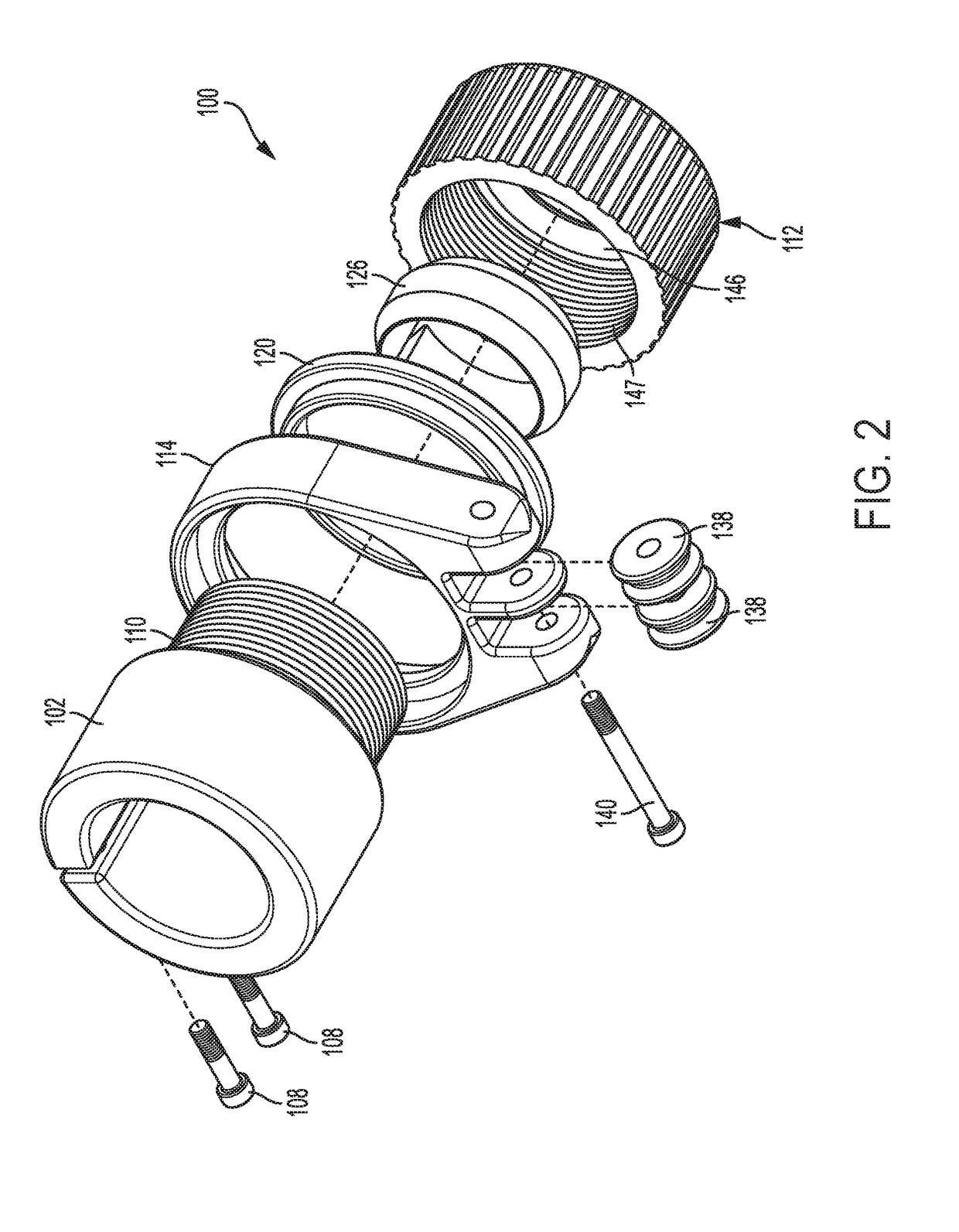

Outrigger Clamp with Attachment Point

ActiveUS20180014522A1Prevent crease and kinkPrevent the filament from becoming creased or kinkedRodsRod connectionsEngineeringMechanical engineering

An outrigger clamp to couple together two or more nestable tubes. The clamp includes a guide for retaining filament, and an attachment point for receiving accessories without interfering with the filament and guides. The guide and attachment point can rotate about an axis based on the forces applied to the outrigger to better align the filament and guides, and therefore align the forces applied to the outrigger and filament. The retainer can be, for example, one or more rollers that help prevent the filament from becoming creased or kinked during use.

Owner:GEM PROD LLC

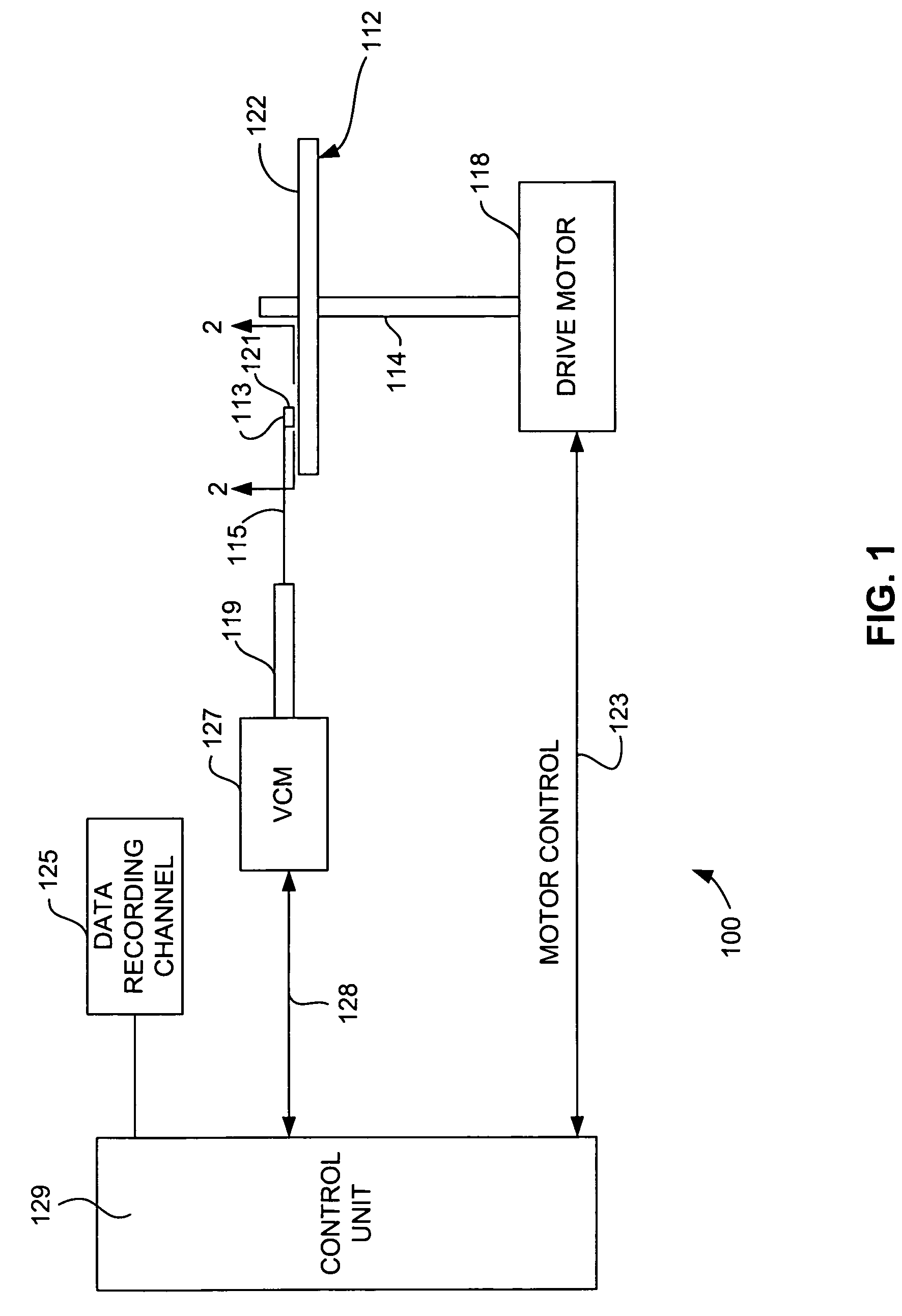

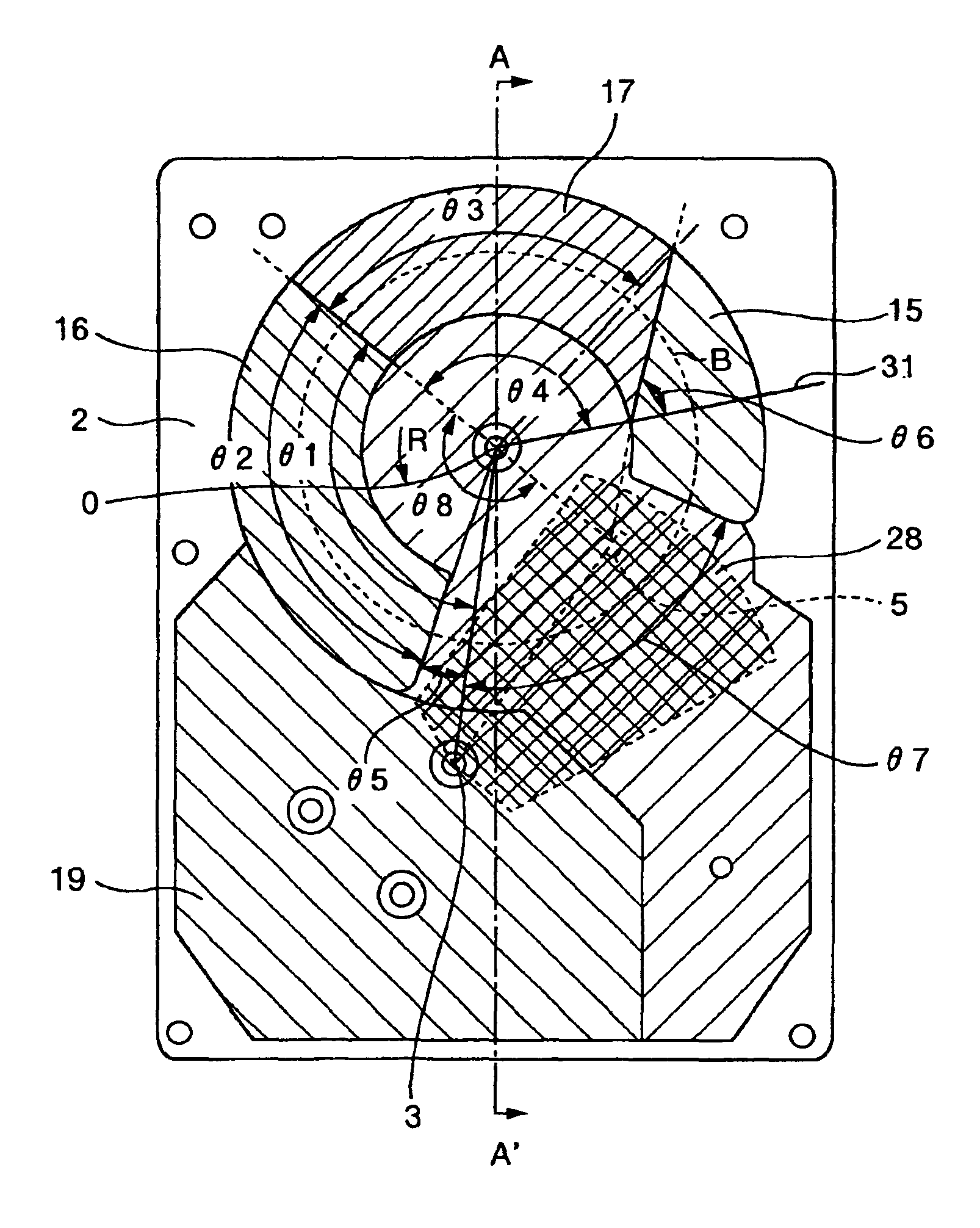

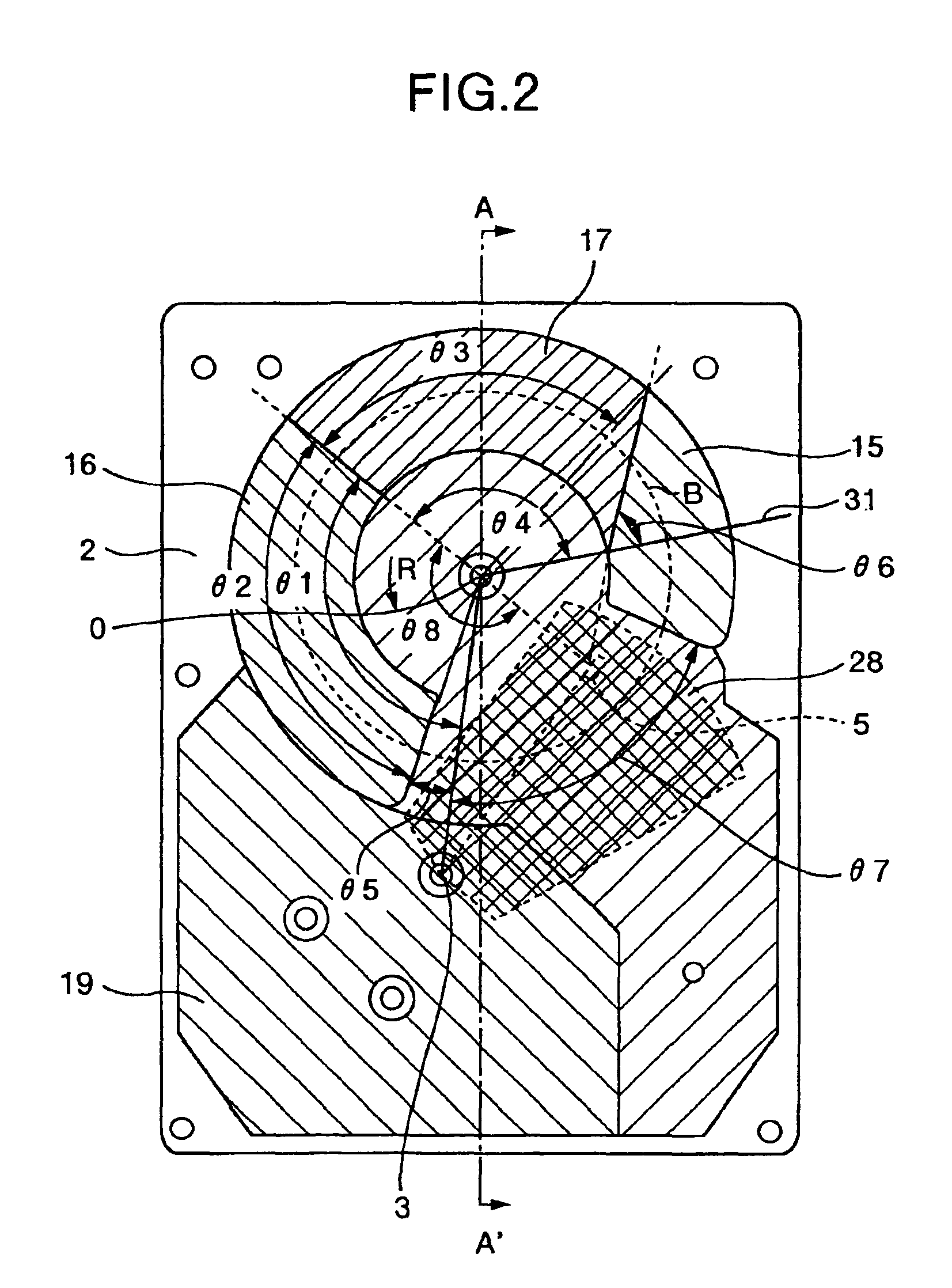

Recording apparatus having improved anti-vibration arrangements

InactiveUS6894866B2Reduce gap sizeReduce flutterReducing temperature influence on carrierApparatus for flat record carriersEngineeringCounter rotation

In a recording apparatus capable of reducing an airflow and disturbance of the air flow simultaneously, thereby reducing flutter vibration effectively, a cover includes first convex sections for reducing a size of a gap between a disk surface and a cover or between the disk surface arid a housing in an area outside of an area in which an arm traverses on a disk in comparison with the area in which the arm traverses, and a second convex section on a part of the first convex sections to further reduce the size of the gap, and the second convex section is provided in a range extending with a tan shape thereof in a reverse rotational direction of said disk from a position distant by 110-170° in the reverse rotational direction from a straight line connecting the rotational shaft of said disk and the rotational shaft of said arm.

Owner:HITACHI GLOBAL STORAGE TECH JAPAN LTD

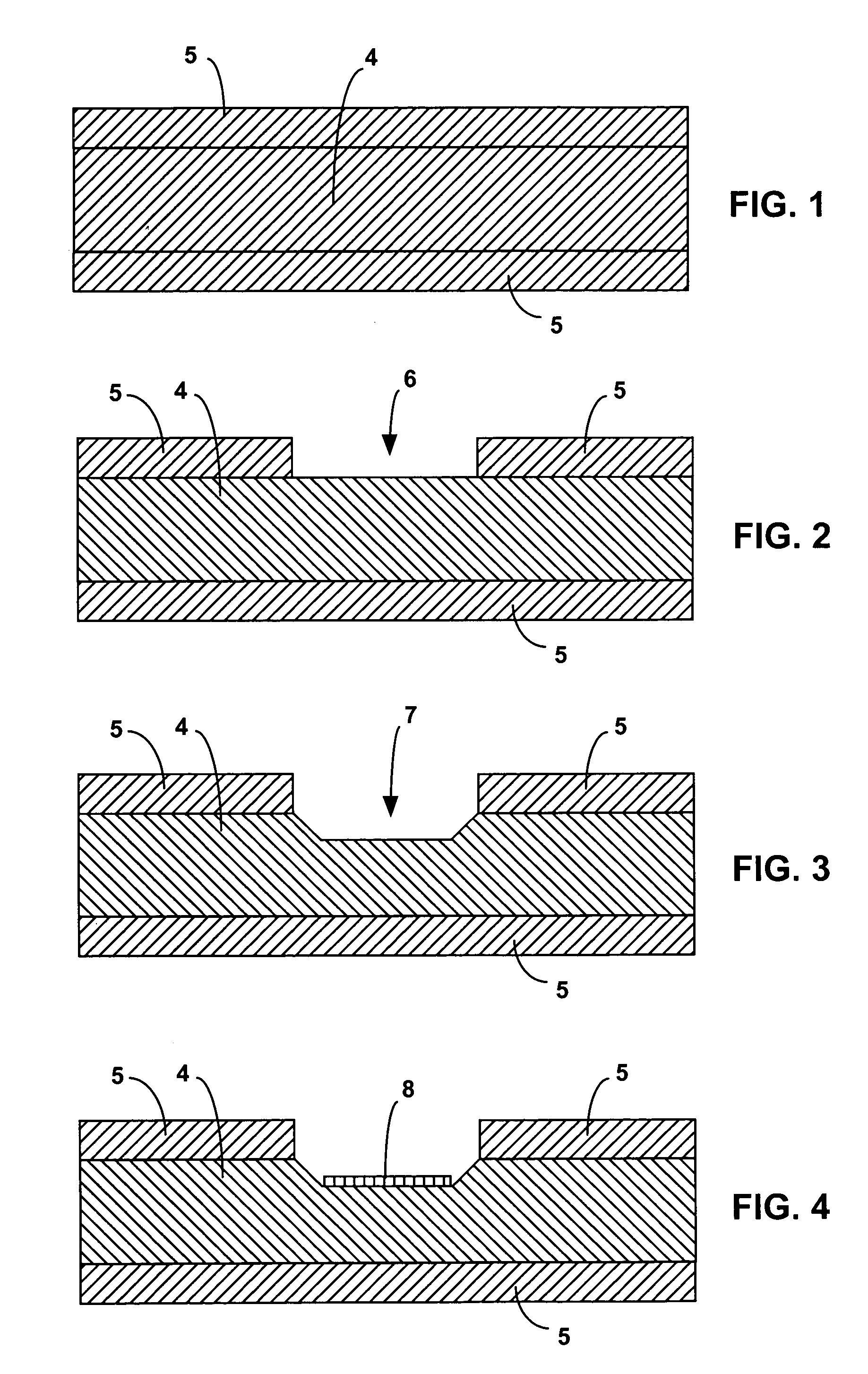

Process for fabricating monolithic membrane substrate structures with well-controlled air gaps

InactiveUS7128843B2Easy to makeReduce gap sizeDecorative surface effectsLayered productsWell controlMetal

A process for fabricating monolithic membrane structures having air gaps is disclosed, comprising the steps of: providing a wafer; depositing and patterning a protective layer on the wafer; providing a trench in the wafer; depositing and patterning a metal in the trench; depositing and patterning a sacrificial layer on the metal; depositing and patterning a membrane pad on the sacrificial layer; providing a polymeric film on the protective layer and sacrificial layer, wherein part of the polymeric film has a tensile stress; and releasing part of the polymeric film from the protective layer and sacrificial layer, wherein the tensile stress of a portion of the polymeric film releases the portion of the polymeric film from the wafer and generates the air gap.

Owner:HRL LAB

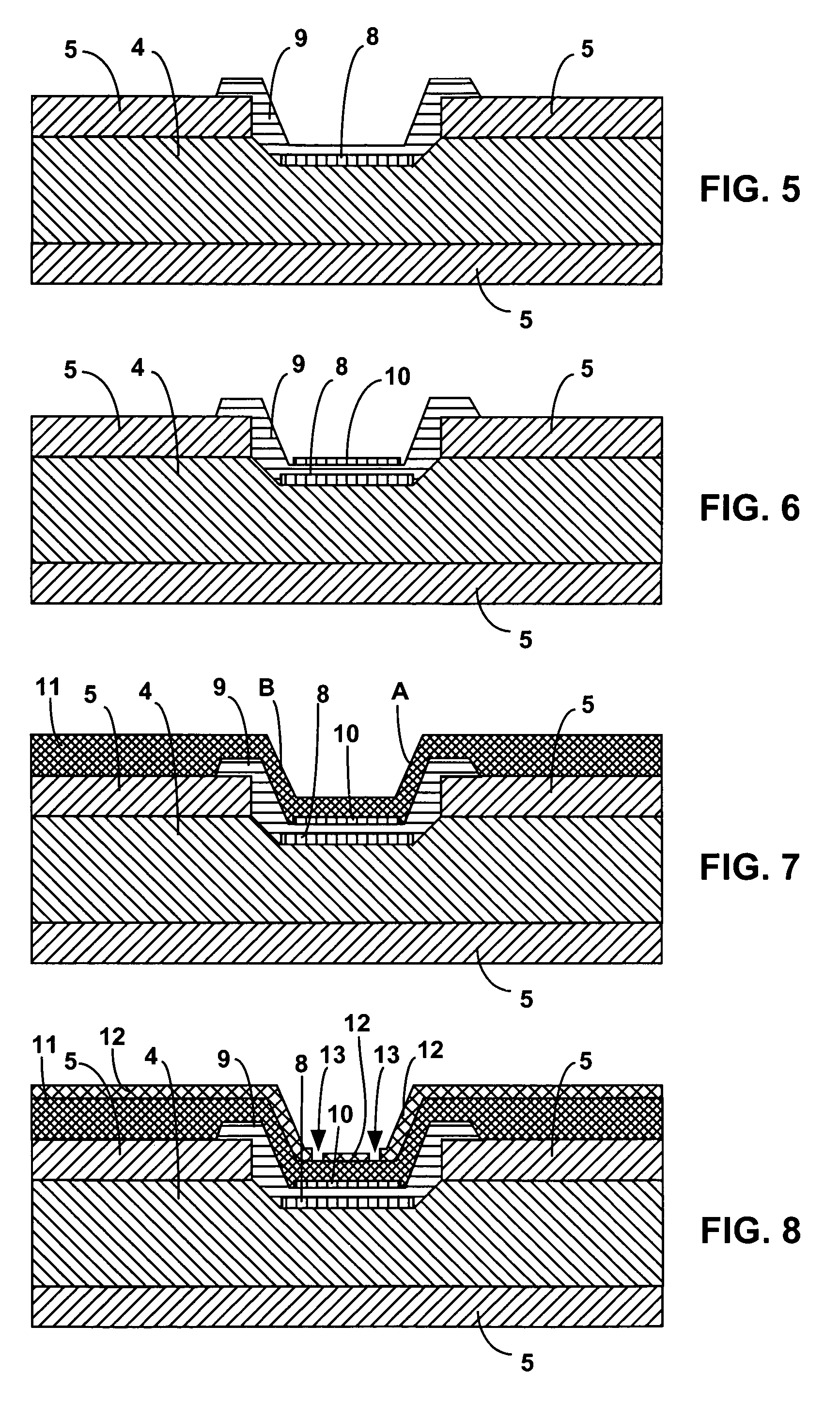

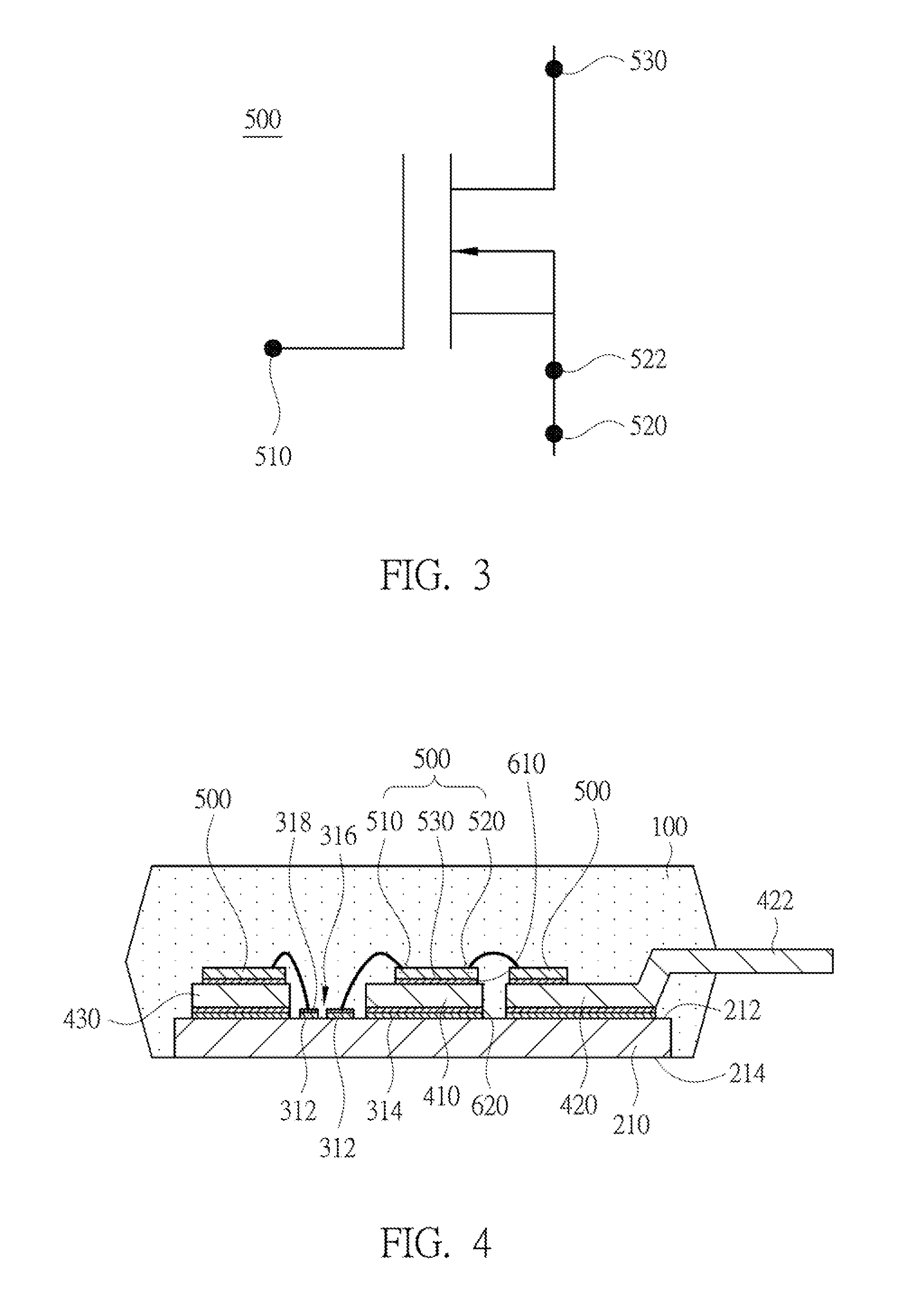

Power module

InactiveUS20150085454A1Reduce size of gapIncreased power densitySemiconductor/solid-state device detailsSolid-state devicesElectricityMetal

A power module is disclosed. The power module includes a first substrate, a first metal layer, at least one conductive structure and at least one power device. The first metal layer is disposed on the first substrate. The first metal layer has a first thickness d1. The first thickness d1 satisfies: 5 μm≦d1≦50 μm. The conductive structure is disposed at a position different to the first metal layer on the first substrate. The conductive structure has a second thickness d2. The second thickness d2 satisfies: d2≧100 μm. The power device is disposed on the first substrate, the first metal layer or the conductive structure. The driving electrode of the power device is electrically connected to the first metal layer. The power electrode of the power device is electrically coupled to the conductive structure.

Owner:DELTA ELECTRONICS SHANGHAI CO LTD

Repair technology and preparation technology of tubular PERC solar cell

ActiveCN107331730AEL yield improvementIncrease power generationFinal product manufactureSemiconductor/solid-state device manufacturingNitrogenRoom temperature

The invention discloses repair technology of a tubular PERC solar cell. The repair technology is set after annealing of a silicon wafer and before film coating of a back face of the silicon wafer. The repair technology comprises the following steps: (1) a semi-finished silicon wafer which stays over 4 hours after the annealing and before the film coating is placed into a repair furnace, nitrogen having a flow rate of 5-10slm is introduced into the repair furnace to achieve self-cleaning, and inlet time of the nitrogen is 1-5min; (2) nitrogen having a flow rate of 5-20slm is introduced to blow and sweep dust on the silicon wafer; (3) temperature of the repair furnace is raised from room temperature to 500-650 DEG C, and nitrogen having a flow rate of 1-5slm is introduced at the same time; and (4) the temperature of the repair furnace is kept at 500-650 DEG C for 5-30min, and nitrogen having a flow rate of 5-20slm is introduced at the same time. Correspondingly, the invention further discloses a preparation technology of the tubular PERC solar cell. Through adoption of the repair technology and the preparation technology, the problem of efficiency reduction brought by too long semi-finished product stay time is solved, and the EL yield rate is improved.

Owner:ZHEJIANG AIKO SOLAR ENERGY TECH CO LTD +1

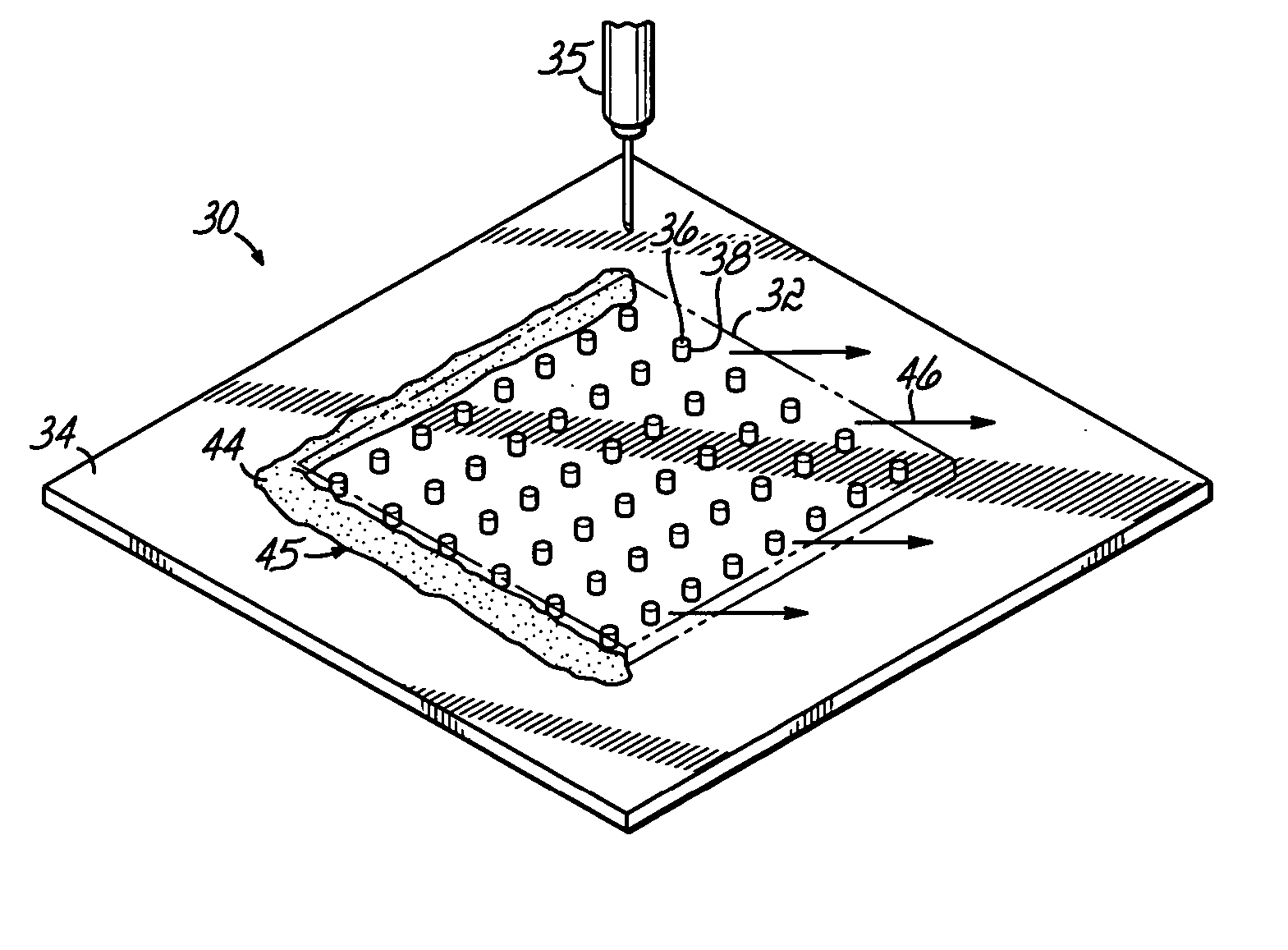

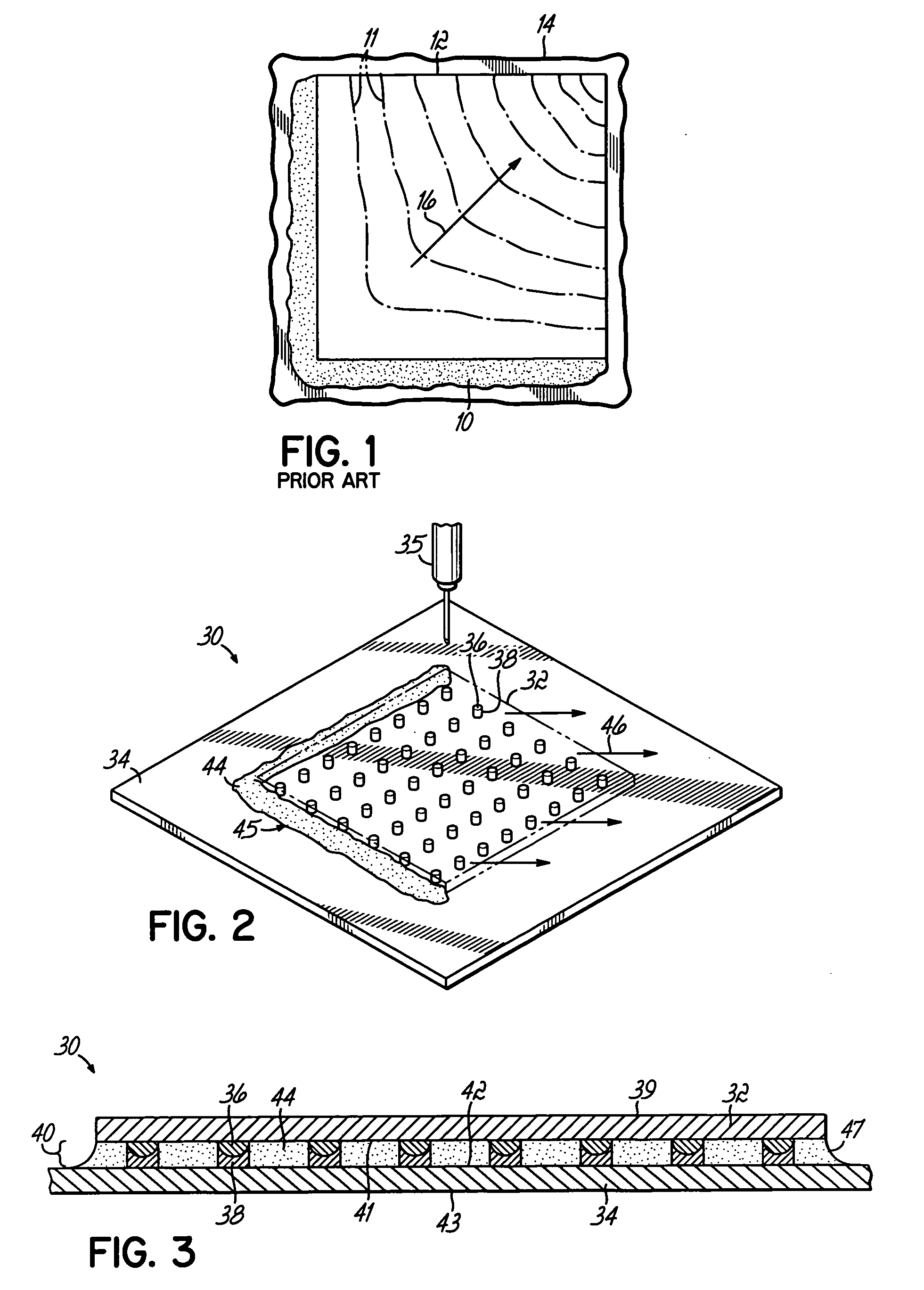

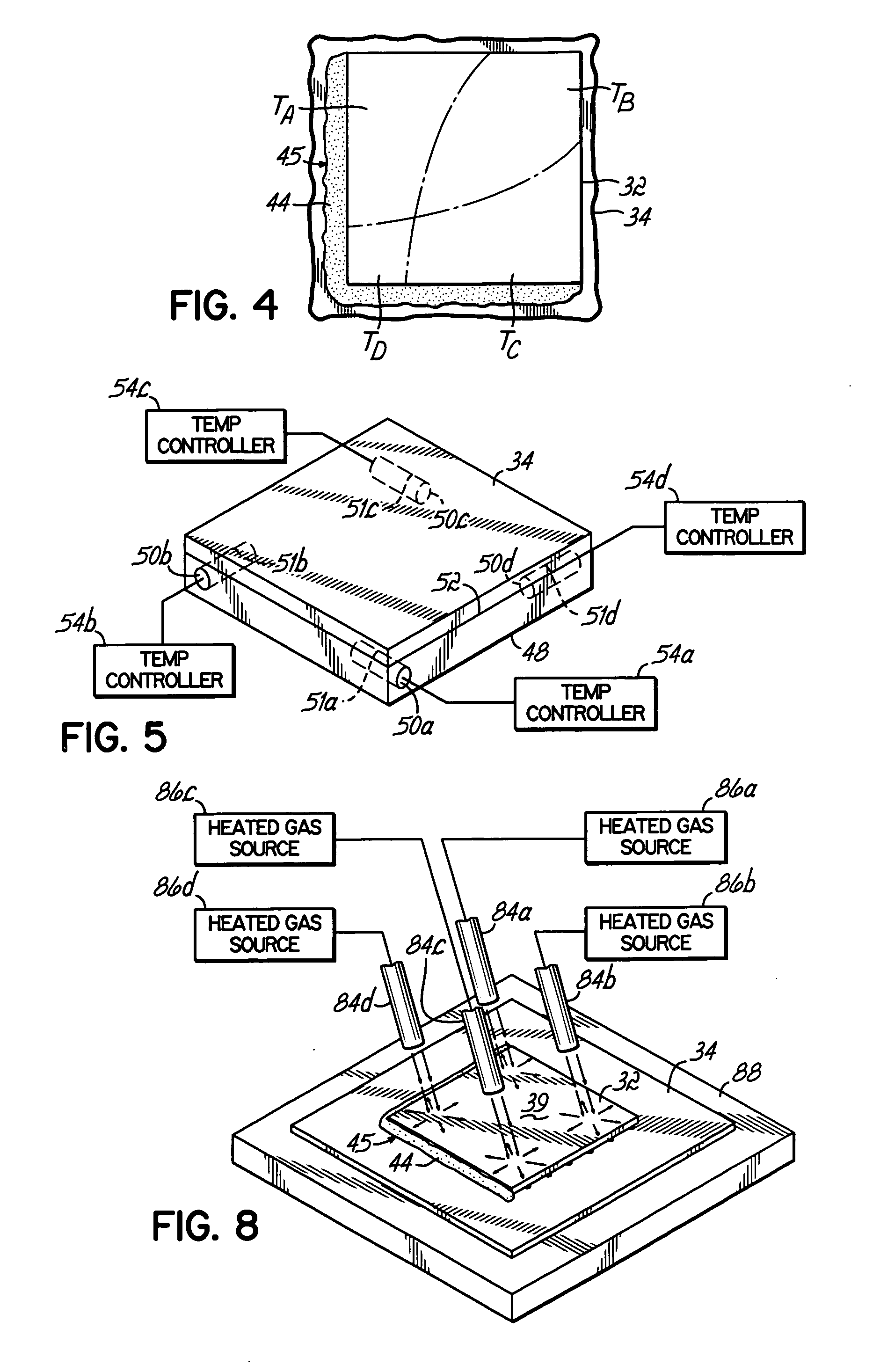

Method and apparatus for underfilling semiconductor devices

InactiveUS20050161846A1Reduce incidenceLarge space to underfillSolid-state devicesSemiconductor/solid-state device manufacturingDevice materialSealant

A method and apparatus for underfilling a gap between a multi-sided die and a substrate with an encapsulant material. The die and / or the substrate is heated non-uniformly by a heat source to generate a temperature gradient therein. The heated one of the die and the substrate transfers heat energy in proportion to the temperature gradient to the encapsulant material moving in the gap. The differential heat transfer steers, guides or otherwise directs the movement of the encapsulant material in the gap. The temperature gradient may be established with heat transferred from the heat source to the die and / or the substrate by conduction, convection, or radiation. The temperature gradient may be dynamically varied as the encapsulant material moves into the gap.

Owner:NORDSON CORP

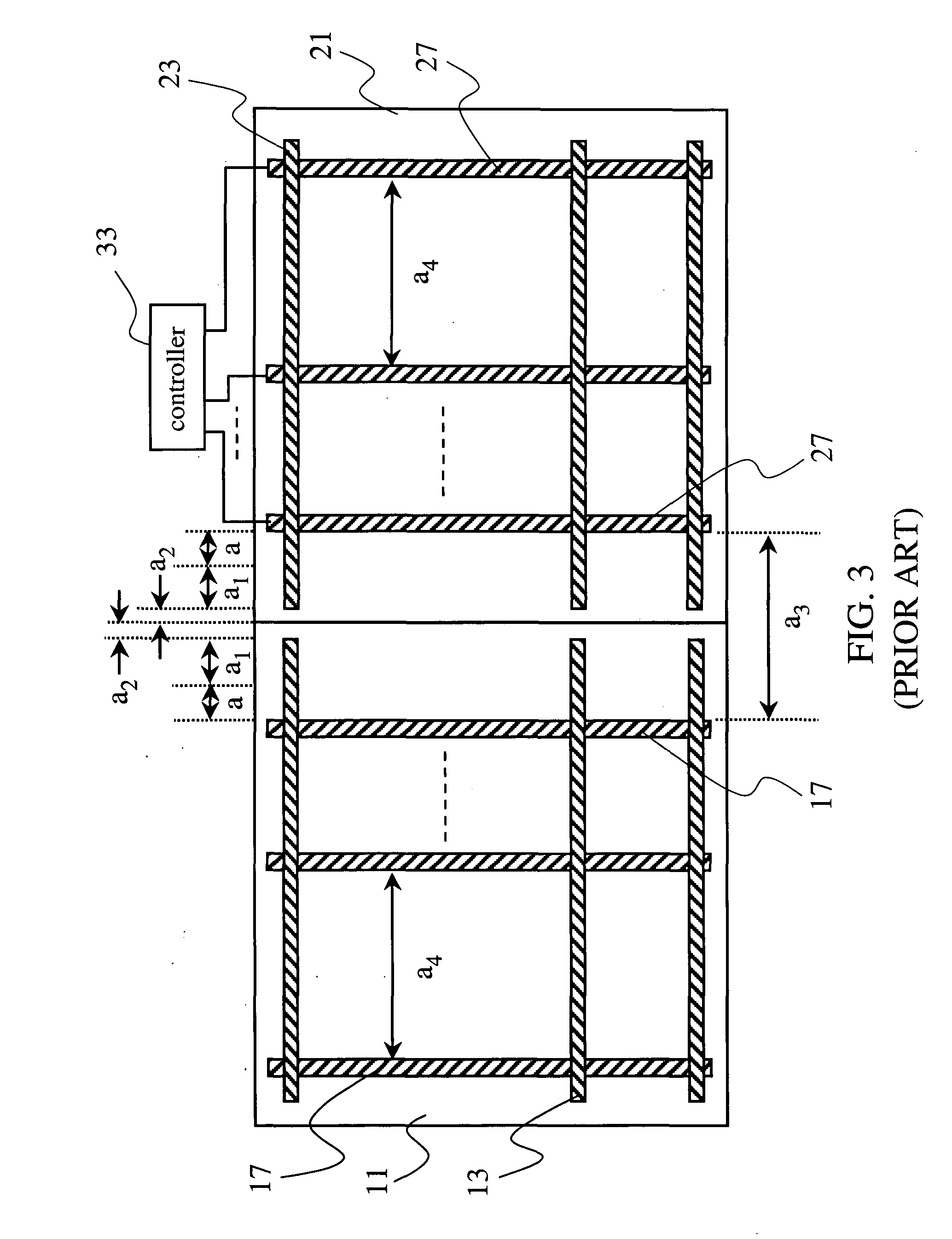

Magnetic read sensor employing oblique etched underlayers for inducing uniaxial magnetic anisotropy in a hard magnetic pinning layer

InactiveUS7672090B2Reduce parasitic resistanceReduce gap sizeNanomagnetismMagnetic-field-controlled resistorsMagnetic anisotropyFacet

A magnetoresistive sensor having a hard magnetic pinning layer with an engineered magnetic anisotropy in a direction substantially perpendicular to the medium facing surface. The hard magnetic pinning layer may be constructed of CoPt, CoPtCr, or some other magnetic material and is deposited over an underlayer that has been ion beam etched. The ion beam etch has been performed at an angle with respect to normal in order to induce anisotropic roughness for example in form of oriented ripples or facets oriented along a direction parallel to the medium facing surface. The anisotropic roughness induces a strong uniaxial magnetic anisotropy substantially perpendicular to the medium facing surface in the hard magnetic pinning layer deposited there over.

Owner:WESTERN DIGITAL TECH INC

Outrigger clamp

An outrigger clamp to couple together two or more nestable tubes. The clamp can include a guide for retaining filament. The guide can rotate about an axis based on the forces applied to the outrigger to better align the filament and guides, and therefore align the forces applied to the outrigger and filament. The retainer can be, for example, one or more rollers that help prevent the filament from becoming creased or kinked during use.

Owner:GEM PROD LLC

Seamless knitting anti-electromagnetic radiation clothing and manufacturing method thereof

The invention relates to seamless knitting anti-electromagnetic radiation clothing and a manufacturing method thereof. The seamless knitting anti-electromagnetic radiation clothing consists of two layers of fabrics which are outer knitting fabric and inner shielding fabric. The outer knitting fabric comprises the following fiber compositions by weight percentage: 80-90 percent of chinlon 6 stretch yarns, 5-10 percent of chinlon 66 stretch yarns and 5-10 percent of spandex elastic fiber yarns; and the inner knitting fabric comprises the following fiber compositions by weight percentage: 50-55 percent of chinlon 6 stretch yarns and 45-50 percent of silver metal conductive fiber yarns; and after assistants such as 3 percent of leveling agents, 4 percent of detergents, 4 percent of creasing agents, 2 percent of penetrants and 0.5 percent of ammonium sulfate are added, an appropriate amount of dyes is added again. The seamless knitting anti-electromagnetic radiation clothing has the advantages of anti-electromagnetic radiation and good shielding effect and is comfortable to wear.

Owner:GUANGDONG RUIYUAN TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com