Cu-Sn-Ti solder and method for brazing Ti2AlC ceramics and Cu with same

A cu-sn-ti, solder technology, applied in welding media, welding equipment, welding/cutting media/materials, etc., can solve the problems of short life and high cost of current-carrying friction devices, and achieve good conductivity and high temperature. Excellent thermal stability, high conductivity connection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0016] Specific embodiment 1: The Cu-Sn-Ti solder of this embodiment is made of 70% to 80% of Cu powder, 10% to 20% of Sn powder and 10% of TiH by mole percentage. 2 The powder is prepared by mechanical alloying.

[0017] The specific operation method of mechanical alloying described in this embodiment is: weighing 70% to 80% of Cu powder, 10% to 20% of Sn powder and 10% of TiH by mole percentage 2 Powder, then Cu powder, Sn powder and TiH 2 Put the mixed powder of the powder into the Al attached to the QM-3SP04 planetary ball mill 2 O 3 In the ceramic tank, the ball-to-material ratio is controlled to be 5:1, the speed is 260r / min, and the mixed powder can be ball milled.

[0018] The Cu-Sn-Ti solder in this embodiment is a powder solder, which can ensure the electrical conductivity of the joint. The Cu-Sn-Ti solder is a Cu-based solder, and since one side of the base material is pure copper, a certain amount of Sn is added to the solder to reduce the melting point. However, consid...

specific Embodiment approach 2

[0020] Specific embodiment two: this embodiment is different from specific embodiment one in that the Cu-Sn-Ti solder is made of 75% Cu powder, 15% Sn powder and 10% TiH by mole percentage. 2 The powder is prepared by mechanical alloying. Other parameters are the same as in the first embodiment.

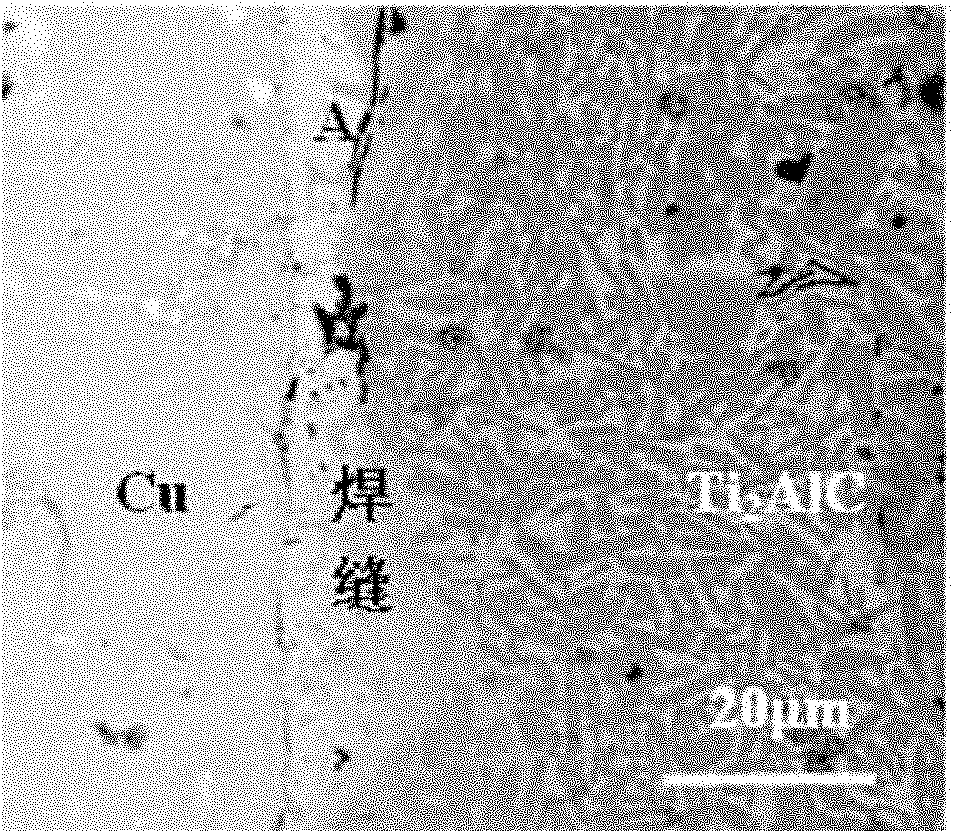

[0021] The Cu-Sn-Ti solder brazing Ti of this embodiment 2 The compressive shear strength of the joint obtained from AlC ceramic and copper reaches 40.53~187MPa, and the electrical conductivity reaches 5.130×10 6 ~5.997×10 6 S / m.

specific Embodiment approach 3

[0022] Specific embodiment three: Brazing Ti using Cu-Sn-Ti solder in this embodiment 2 The method of AlC ceramics and copper is achieved through the following steps: 1. The Ti 2 AlC ceramics are polished with 320#, 600#, 800#, 1000#, 1200# and 1600# metallographic sandpaper to a bright surface, and then the Ti is polished with a 0.5μm diamond polishing agent. 2 The surface to be connected to the AlC ceramic is polished; then the copper is polished with 1000# and 1600# metallographic sandpaper until the surface is bright, and then the surface of the copper to be connected is polished with a diamond polishing agent of type 0.5μm; Ti after treatment 2 AlC ceramics and copper are immersed in absolute ethanol, ultrasonically cleaned for 10-20 minutes, taken out, and air-dried; 3. Mixing Cu-Sn-Ti solder and hydroxyethyl cellulose binder to obtain paste-like Cu-Sn-Ti solder Material, then paste Cu-Sn-Ti solder, Ti 2 AlC ceramic and copper are assembled into Ti 2 AlC ceramic / Cu-Sn-Ti br...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive shear strength | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

| Compressive shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com