Low-content nanometer conducting silver paste and its prepn

A technology of conductive paste and nano-silver, applied in conductive coatings, conductive adhesives, conductive materials dispersed in non-conductive inorganic materials, etc., can solve the problem of reducing the performance of materials such as resistance to cold and heat cycles, heat and humidity resistance, and high viscosity , Weaken the problems of printing processability, line resolution and adhesion, etc., and achieve the effect of easy size distribution, low viscosity and convenient construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-3

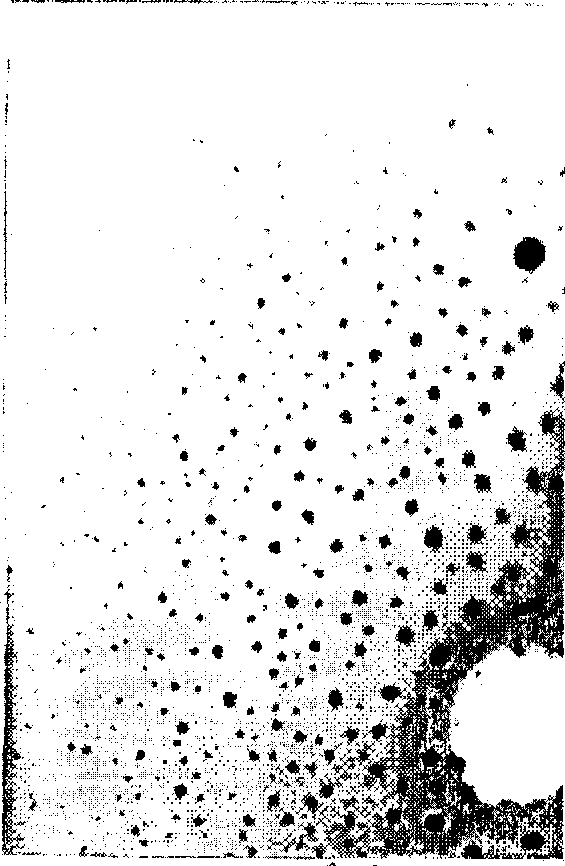

[0021] NaBH 4 Prepare colloidal nano-Ag particles for the reducing agent, the specific composition and product particle size are shown in Table 1, and the TEM photos of the product are as follows figure 1 shown. The TEM experiment method is as follows: the obtained Ag particles are dispersed with cyclohexane, and after ultrasonic vibration, samples are prepared on a Cu grid coated with a carbon film. Then observe the shape of the particles and take pictures under a HITACHI HU-12 transmission electron microscope, and then perform statistical analysis to obtain the average particle size and distribution of the nano-Ag particles. It can be seen from Table 1 that with the increase of the weight ratio of water / surfactant, the particle size of nano-silver basically increases proportionally, indicating that the microemulsion method can effectively control the particle size of the product. A few samples of Example 3 were taken for DSC scanning, and it was found that the nano-silver ...

Embodiment 4-7

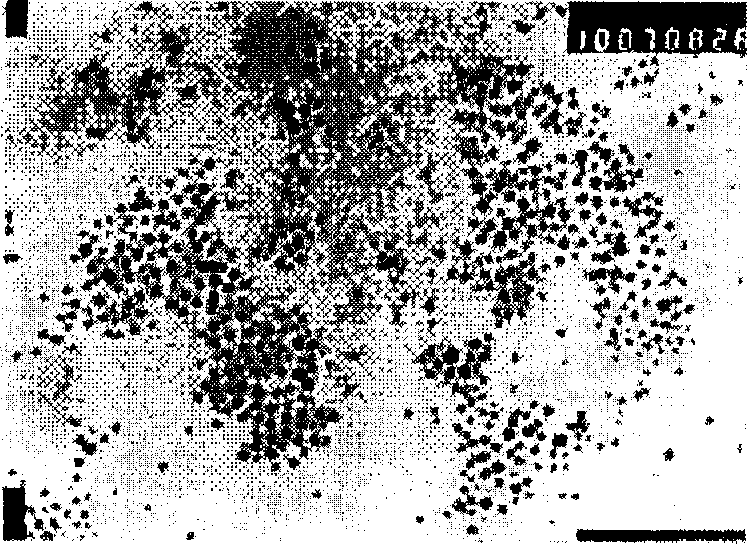

[0023] Using hydrazine hydrate as a reducing agent to prepare colloidal nano-Ag particles, the specific composition is shown in Table 2, the particle size of the product is shown in Table 3, and the TEM photo of the product is as follows figure 2 shown. Other properties are similar to Examples 1-3.

Embodiment 8

[0024] Embodiment 8: Get 10g of the nano-silver powder obtained in the above-mentioned embodiment 3, mix with 90g of epoxy resin at 80°C, mechanically stir at room temperature for 30min, ultrasonically treat for 15min, then add curing agent 2-ethyl 4-methylimidazole 2phr, After stirring evenly, it becomes a low-viscosity conductive paste. Its viscosity increases only slightly over pure epoxy resin. Paint the conductive paste on a glass plate, and after curing at 90°C for 1h+150°C for 4h, use the flat glass method to measure its resistivity to 5×10 -3 Ω.cm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Resistivity | aaaaa | aaaaa |

| Resistivity | aaaaa | aaaaa |

| Resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com