Cutting tool with micro textures and gradient coatings as well as preparation method of cutting tool

A gradient coating and micro-texture technology, applied in coating, metal material coating process, ion implantation plating, etc., can solve problems such as tool wear and life reduction, achieve small coating internal stress, and improve surface quality and machining accuracy, good self-lubricating performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

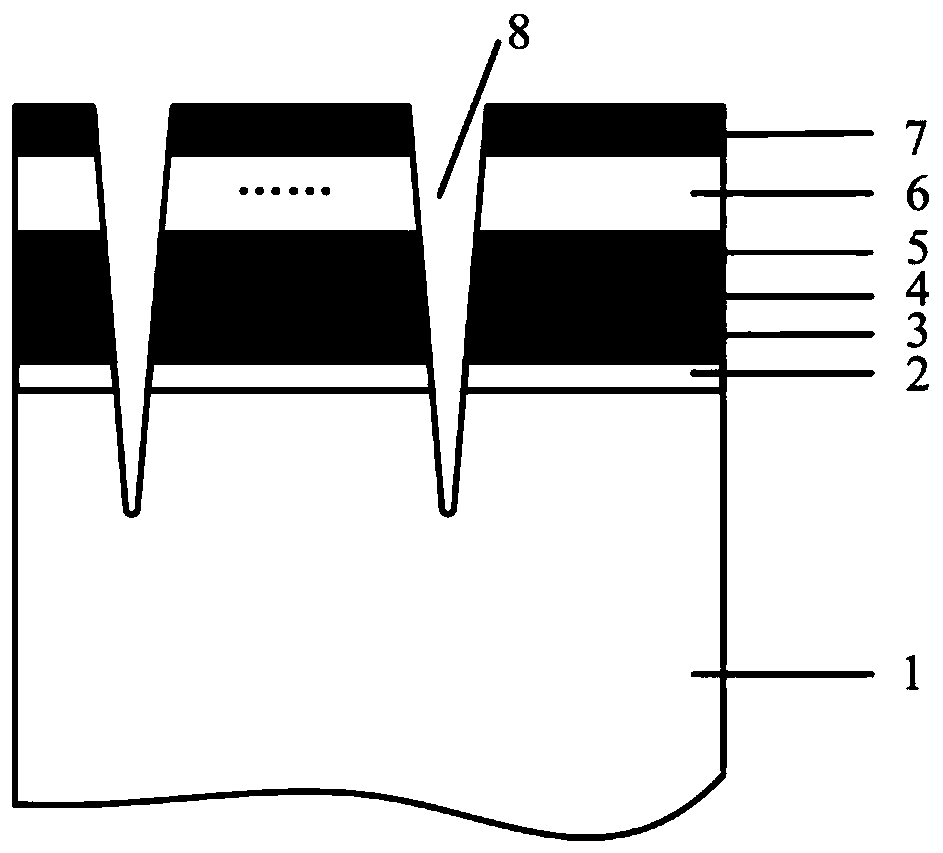

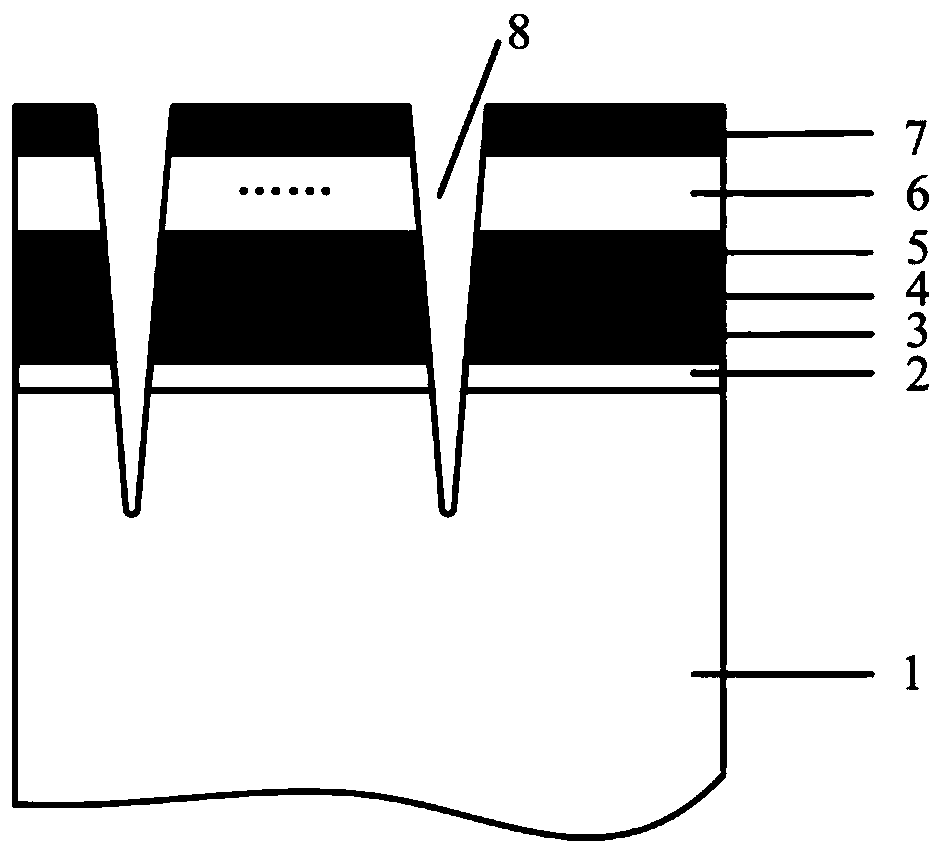

[0026] Example 1: A micro-textured gradient coating tool, the base material of the tool is high-speed steel, the rake face and the flank face of the tool have micro-texture, and the surface of the micro-texture is deposited with alternating layers of ZrVCN+TiSiNbC hard coating and WBSe soft coating. The coating, from the coating to the surface of the tool base material is a ZrN+Zr transition layer in sequence. The ZrVCN+TiSiNbC alternate laminated hard coating in the micro-texture gradient coating tool contains two layers of ZrVCN and two single layers of TiSiNbC, and the thickness of the single layer of ZrVCN and TiSiNbC is less than or equal to 100nm.

[0027] A method for preparing a micro-texture gradient coating tool, using laser-induced liquid plasma processing technology to process a circular hole-shaped micro-texture in the knife-chip contact area on the rake face of the tool and the knife-work contact area on the flank face of the tool; The Zr+ZrN transition layer, Zr...

example 2

[0042] Example 2: A micro-textured gradient coating tool, the tool base material is cemented carbide, the rake face and the flank face of the tool have micro-texture, and the micro-textured surface is deposited with alternating layers of ZrVCN+TiSiNbC hard coating and WBSe Soft coating, from the coating to the surface of the tool base material is a ZrN+Zr transition layer in turn. The ZrVCN+TiSiNbC alternately laminated hard coating in the micro-texture gradient coating tool contains 20 layers of ZrVCN and 20 layers of TiSiNbC single layers, and the thickness of the single layers of ZrVCN and TiSiNbC is less than or equal to 100nm.

[0043] A method for preparing a micro-texture gradient coating tool, using laser-induced liquid plasma processing technology to process a grid-like micro-texture in the tool-chip contact area on the rake face of the tool and the tool-work contact area on the flank face of the tool; The Zr+ZrN transition layer, ZrVCN+TiSiNbC alternate lamination ha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com