Basalt fiber filled ultrahigh molecular weight polyethylene composite material and preparation method thereof

An ultra-high molecular weight, basalt fiber technology is applied in the field of basalt fiber-filled ultra-high molecular weight polyethylene composite materials and their preparation, which can solve the problems of poor fatigue wear resistance and adhesive wear resistance, low surface hardness, and poor creep resistance. , to achieve the effect of good anti-fatigue wear and anti-adhesive wear, improved creep resistance and improved wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

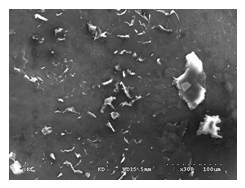

Image

Examples

Embodiment 1

[0024] Example 1: The composition of the composite material is 95 grams of ultra-high molecular weight polyethylene, 5 grams of basalt fiber, and 0 grams of coupling agent.

[0025] Based on the above, the viscosity-average molecular mass of the ultra-high molecular weight polyethylene matrix is 9 million.

[0026] A method for preparing a basalt fiber-filled ultra-high molecular weight polyethylene composite material, the method comprising the following steps: (1) Mixing: Put basalt fiber and ultra-high molecular weight polyethylene into a mixer for full mixing to form a uniform (2) Hot press molding: put the above-mentioned mixture into the mold of the desired finished shape, keep it warm at 180°C-220°C for 1-2 hours, and then press it under a pressure of 10-30MPa for 20-60 Minutes, and finally cooled to room temperature, the basalt fiber-filled UHMWPE composite without coupling agent can be prepared.

[0027] The single diameter of the basalt fiber is 5-50 microns; the l...

Embodiment 2

[0028] Embodiment 2: the difference between this embodiment and embodiment 1 is:

[0029] The composition of the composite material is 90 grams of ultra-high molecular weight polyethylene, 10 grams of basalt fiber, and 1.5 grams of silane coupling agent.

[0030] Based on the above, the viscosity-average molecular weight of the ultra-high molecular weight polyethylene matrix is 8 million.

[0031] Based on the above, in the preparation method, the basalt fiber, the ultra-high molecular weight polyethylene and the coupling agent are put into a mixer and fully mixed to form a uniform mixture.

Embodiment 3

[0032] Embodiment 3: the difference between this embodiment and embodiment 2 is:

[0033] The composition of the composite material is 85 grams of ultra-high molecular weight polyethylene, 15 grams of basalt fiber, 1 gram of silane coupling agent, and 1 gram of aluminate coupling agent.

[0034] Based on the above, the viscosity-average molecular weight of the ultra-high molecular weight polyethylene matrix is 6 million.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com