Method for preparing superhydrophobic coating by adopting supersonic electric arc spaying technique

A supersonic arc and super-hydrophobic coating technology, which is applied in the coating, metal material coating process, melt spraying, etc., can solve the problems of unfavorable industrial production and practical application, complicated operation process, and difficulty in large-scale preparation. Achieve good self-cleaning performance, simple process, and good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

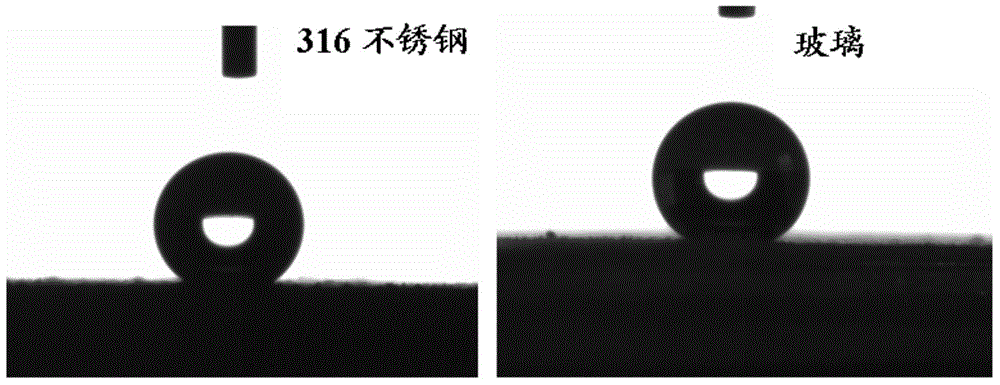

[0041] In this embodiment, the base material is 316 stainless steel or glass, and the coating is well combined with the base material. The concrete preparation method of this superhydrophobic coating is as follows:

[0042] 1. Use 60-mesh brown corundum sand to roughen the surface of 316 stainless steel and glass. The air pressure used for sandblasting is 0.5MPa and 0.3MPa respectively, so that the roughness can meet the spraying requirements;

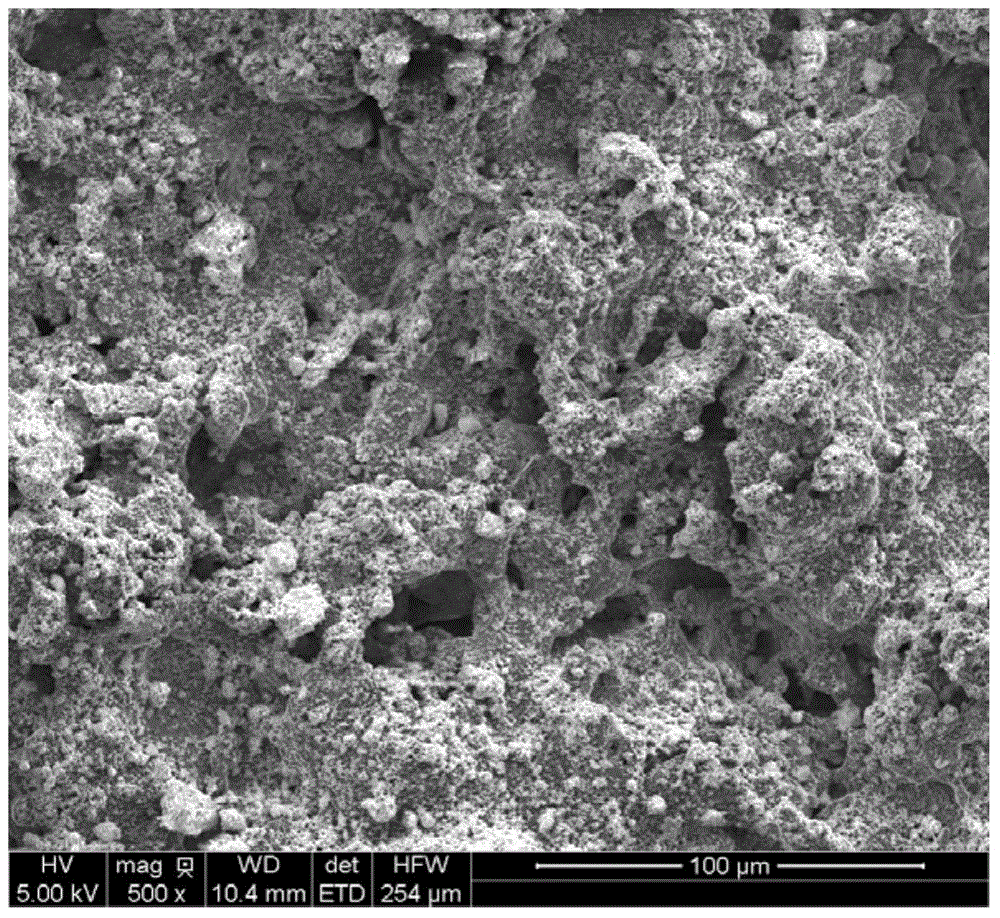

[0043] 2. Using the supersonic arc spraying method, aluminum wire is used as the spraying material to form an aluminum coating with a thickness of about 150 microns on the surface of the substrate. Among them, the spraying parameters for controlling supersonic arc spraying are: current 100A, voltage 25V, compressed air pressure 0.5MPa, spraying distance 150mm, supersonic arc gun moving speed 20mm / s.

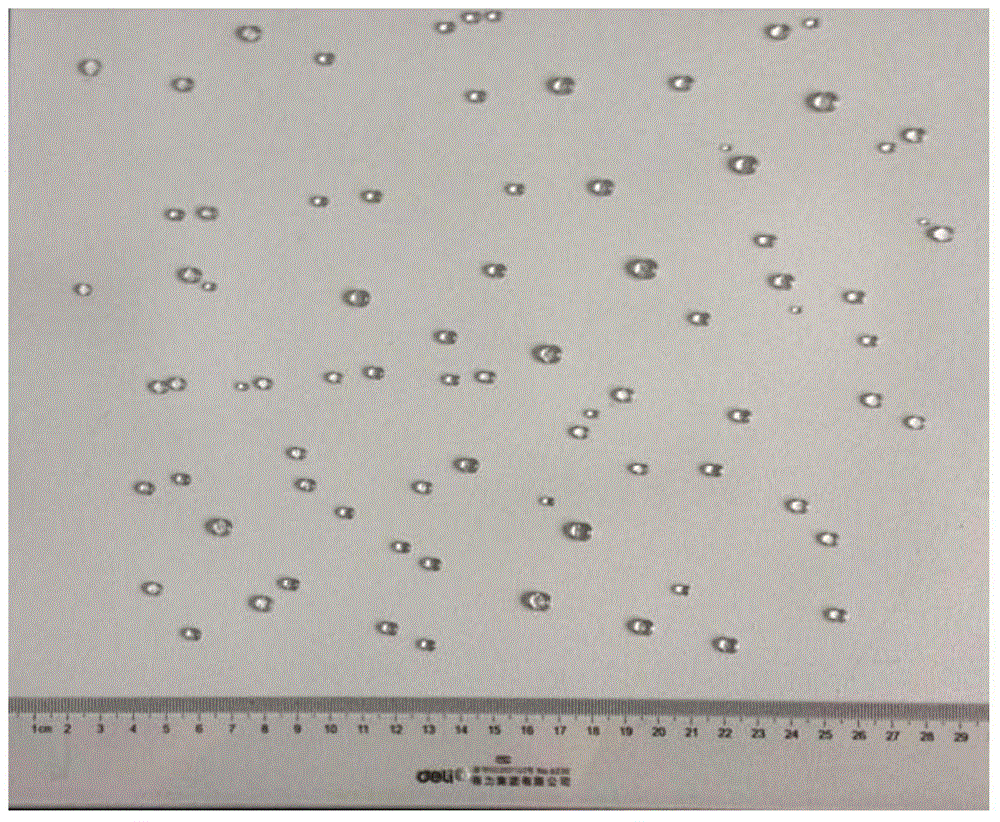

[0044] 3. Use polyurethane with a mass concentration of 1% to spray and modify the coating, and dry at 100°C for 2 hours to obtain a supe...

Embodiment 2

[0046] In this embodiment, the base material is AZ91D magnesium alloy, TC4 titanium alloy or aluminum alloy, and the coating is well bonded to the base material. The concrete preparation method of this superhydrophobic coating is as follows:

[0047] 1. For AZ91D magnesium alloy, TC4 titanium alloy and aluminum alloy, use 60-mesh brown corundum sand for surface roughening treatment. The air pressure used for sandblasting is 0.5MPa to make the roughness meet the spraying requirements;

[0048] 2. Using the supersonic arc spraying method, copper wire is used as the spraying material to form a copper coating with a thickness of about 200 microns on the surface of the substrate. Among them, the spraying parameters for controlling supersonic arc spraying are: current 120A, voltage 25V, compressed air pressure 0.5MPa, spraying distance 150mm, supersonic arc gun moving speed 20mm / s.

[0049] 3. Use polytetrafluoroethylene with a mass concentration of 5% to spray and modify the coati...

Embodiment 3

[0051] In this embodiment, the base material is copper sheet or ceramic tile, and the coating is well combined with the base material. The concrete preparation method of this superhydrophobic coating is as follows:

[0052] 1. Use 60-mesh brown corundum sand to roughen the surface of copper sheets and ceramic tiles. The air pressure used for sandblasting is 0.5MPa and 0.3MPa respectively, so that the roughness can meet the spraying requirements;

[0053] 2. Using the supersonic arc spraying method, zinc wire is used as the spraying material to form a zinc coating with a thickness of about 250 microns on the surface of the substrate. Among them, the spraying parameters for controlling supersonic arc spraying are: current 80A, voltage 20V, compressed air pressure 0.5MPa, spraying distance 150mm, supersonic arc gun moving speed 20mm / s.

[0054] 3. Use polytetrafluoroethylene with a mass concentration of 7% to spray and modify the coating, and dry at 250°C for 2 hours to obtain a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com