Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

63results about How to "Suitable for on-site construction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for preparing superhydrophobic coating by adopting supersonic electric arc spaying technique

The invention discloses a method for preparing a superhydrophobic coating by adopting a supersonic electric arc spaying process. The method comprises the following steps of: firstly, roughening the surface of a substrate; then preparing a coating on the surface of the substrate by adopting a supersonic electric arc spaying technique; and finally, modifying the surface of the coating with a substance with low surface energy, and drying to form a superhydrophobic surface. The method disclosed by the invention has the advantages of easy operation, low cost and good repeatability and is suitable for industrial production. In addition, the method can be used for preparing superhydrophobic coatings on a variety of surfaces such as metal surfaces, glass surfaces and tile surfaces, thus the scope of application of the superhydrophobic coating can be broadened, and large-scale production with high market value can be archived.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

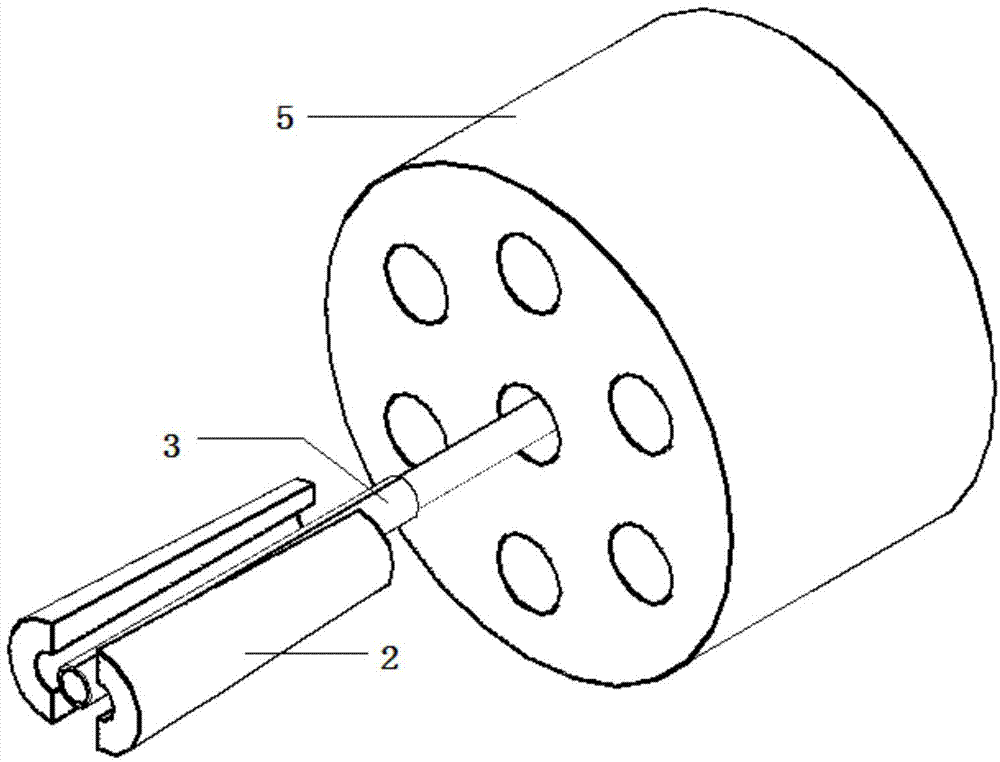

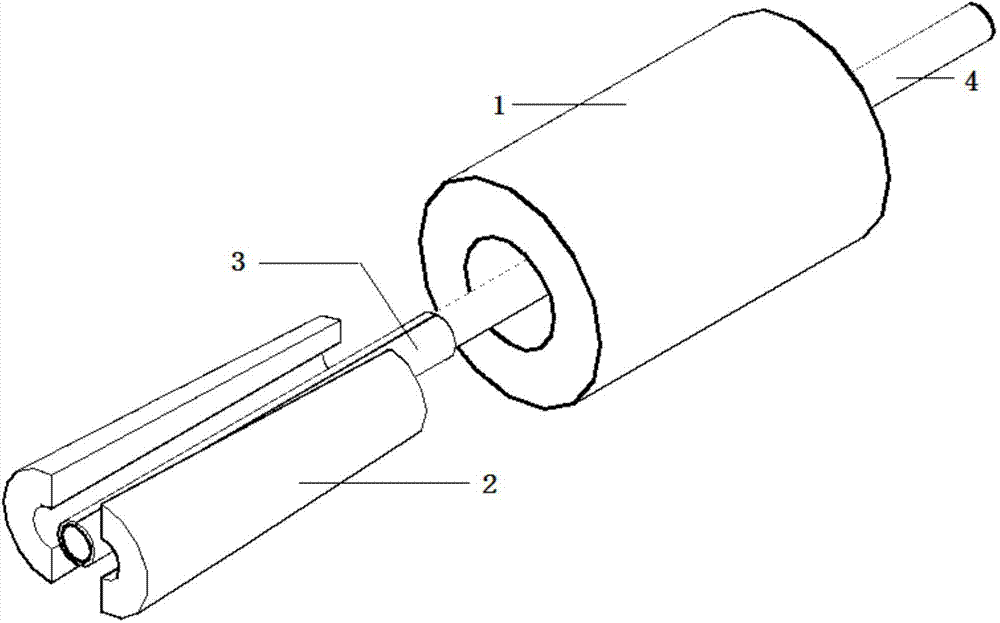

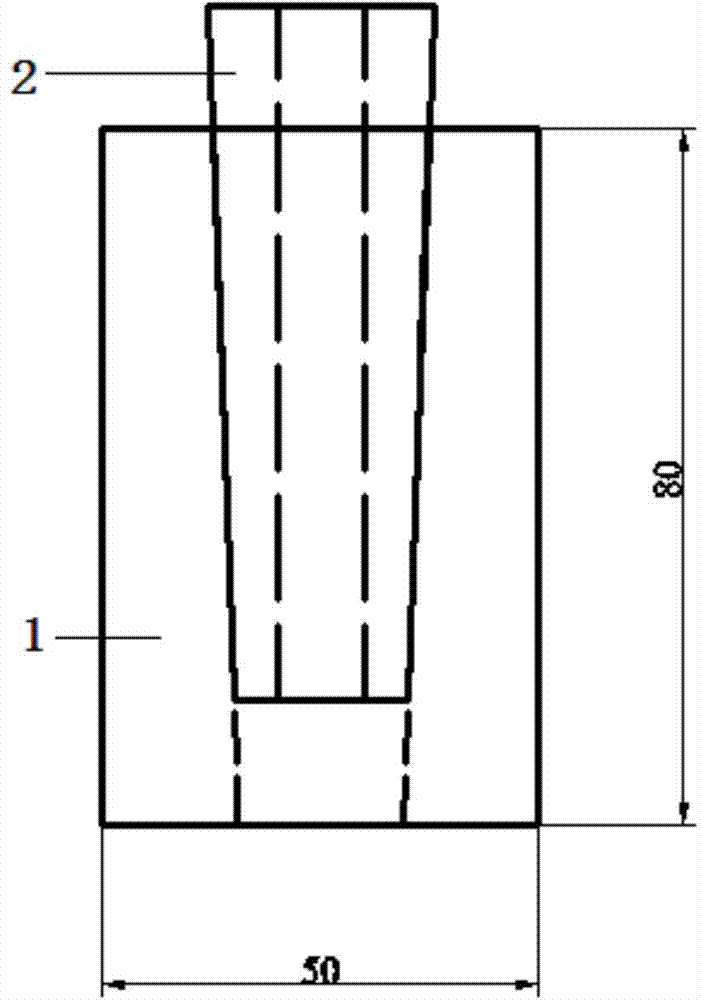

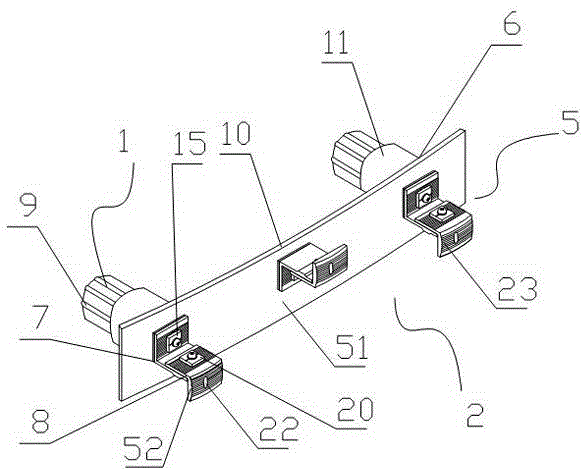

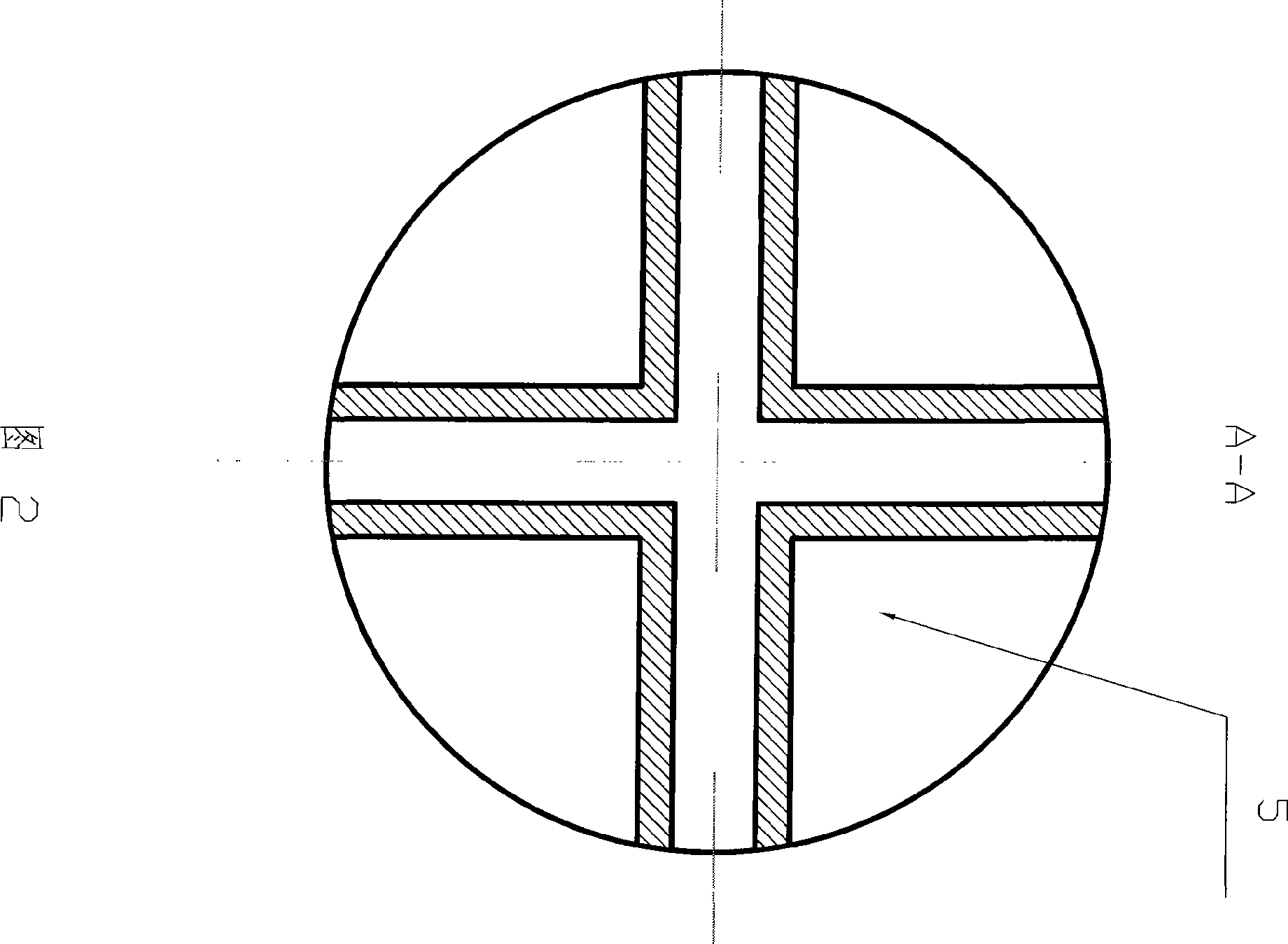

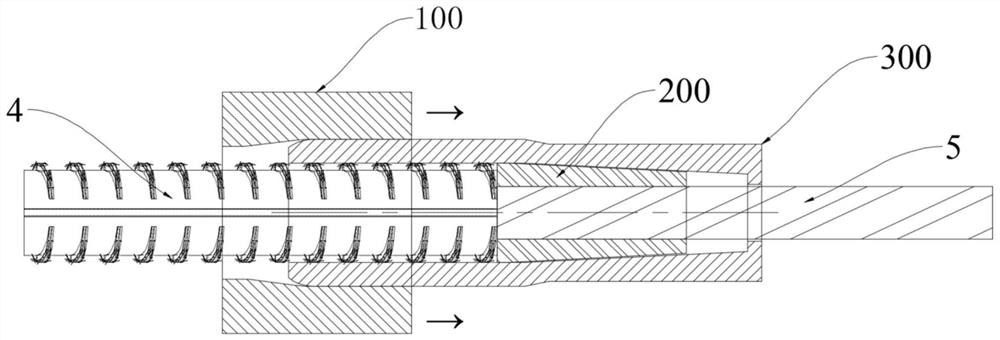

Composite CFRP (Carbon Fibre Reinforced Polymer) tendon anchoring system

InactiveCN104727487ASolve the problem of small anchoring forceSolve the disadvantages that it is not suitable for anchoring multiple CFRP tendonsBuilding reinforcementsTransverse forcePre stress

The invention discloses a composite CFRP (Carbon Fibre Reinforced Polymer) tendon anchoring system which comprises an anchor ring, a two-piece wedge-shaped clip, a soft metal sheath and an epoxy adhesive film, wherein the soft metal sheath is fixed at the anchoring end of a CFRP tendon by the epoxy adhesive film so as to form an integral apparatus; and the integral apparatus is inserted in the two-piece wedge-shaped clip, and the two-piece wedge-shaped clip extends in the anchor ring and then is fixed. The composite anchorage device has the characteristics of small size, large anchoring force, and easiness for installation and use, and is applicable to the on-site construction of prestressed structures. Under the condition of not increasing the size of the anchor ring, the anchoring force can be increased in a mode of increasing the bonding length of the soft metal sheath, and the transverse force of the CFRP tendon is protected. The composite CFRP tendon anchoring system can anchor a single tendon, and also can anchor multiple tendons, thus being extremely applicable to prestressed structures.

Owner:TIANJIN UNIV

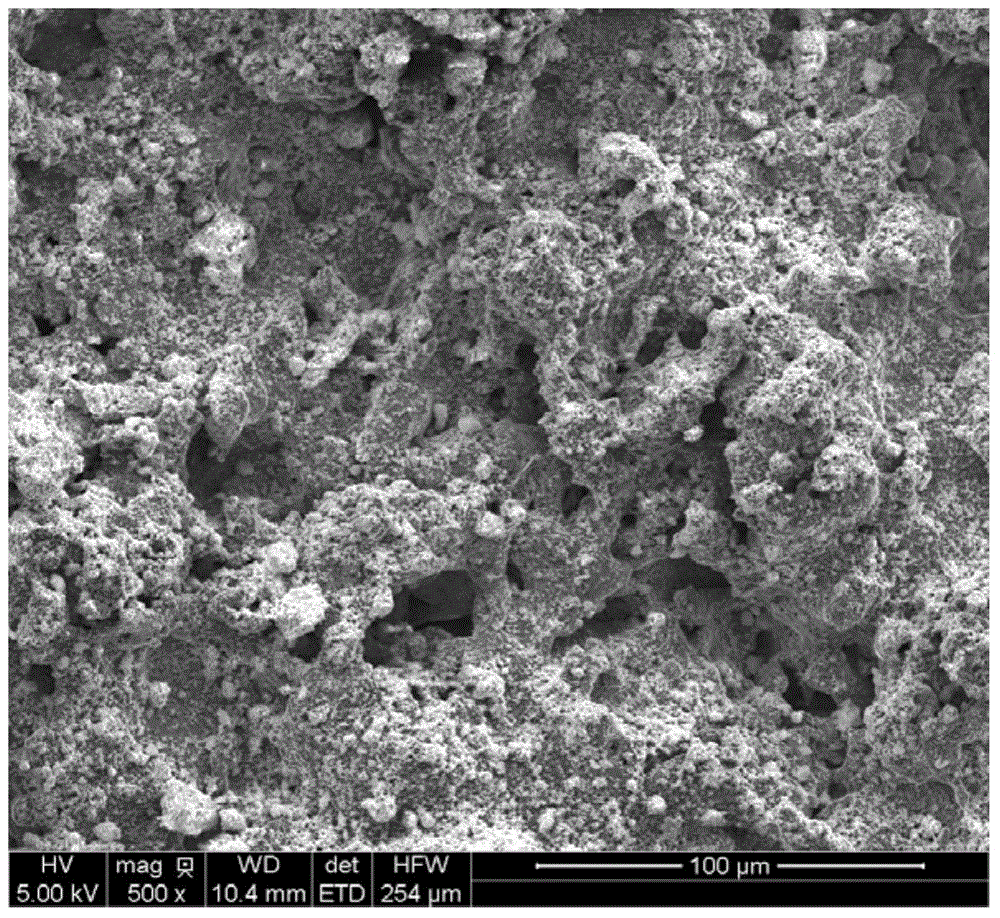

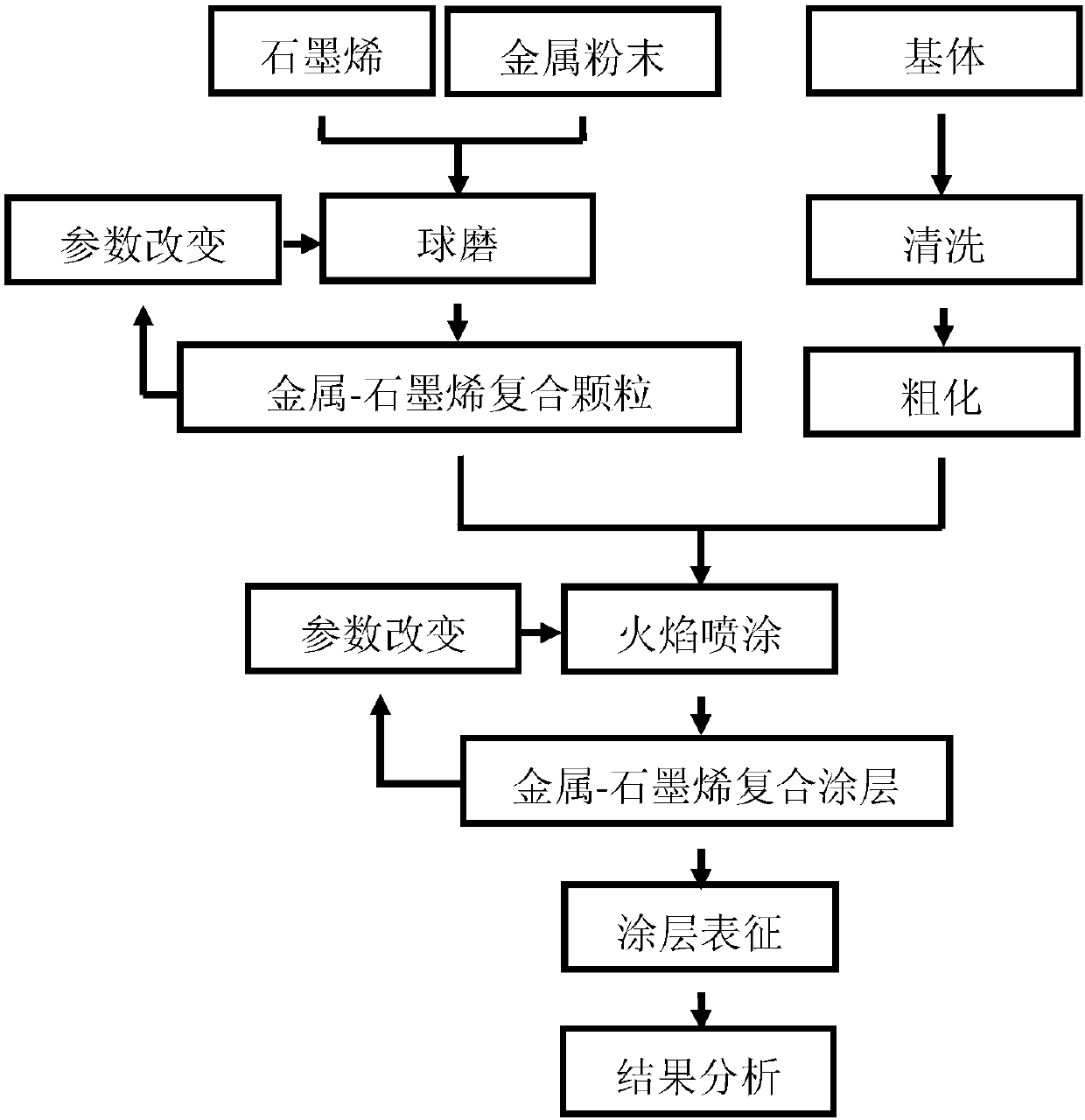

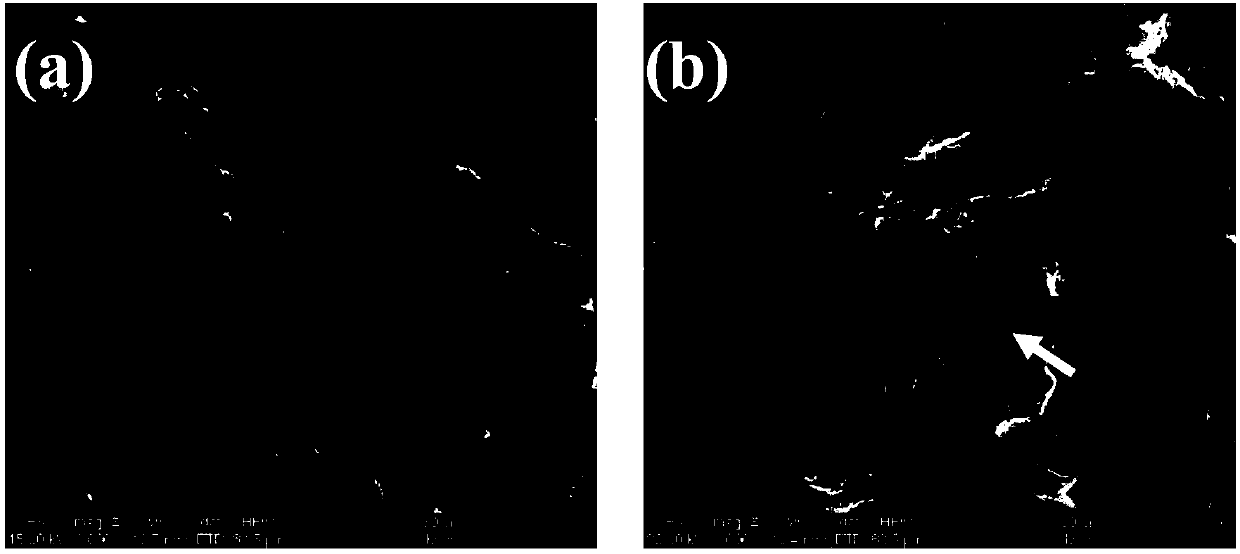

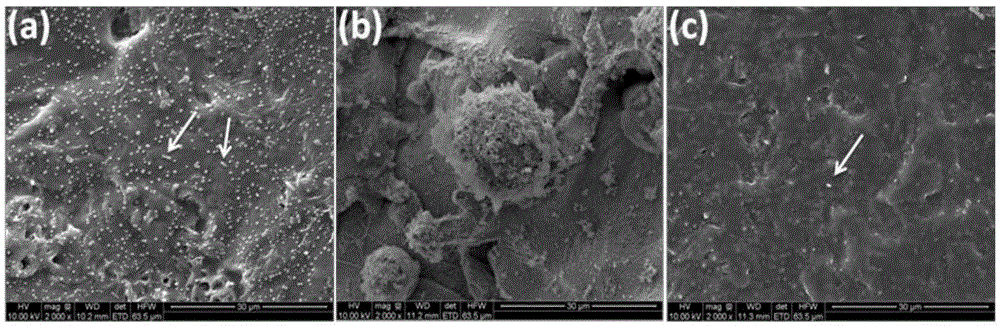

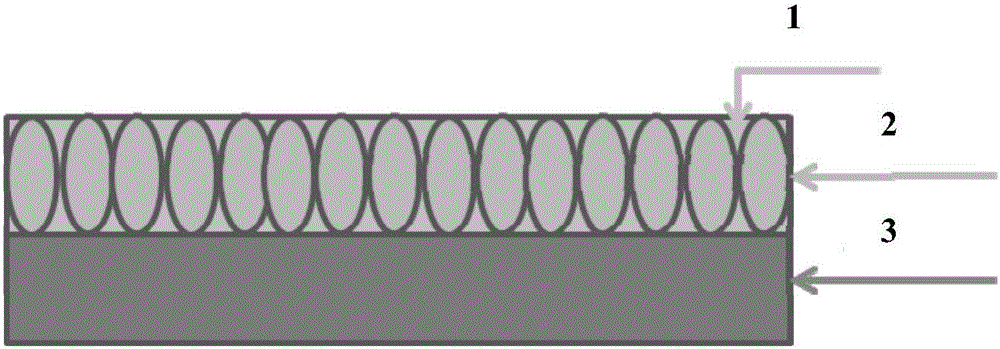

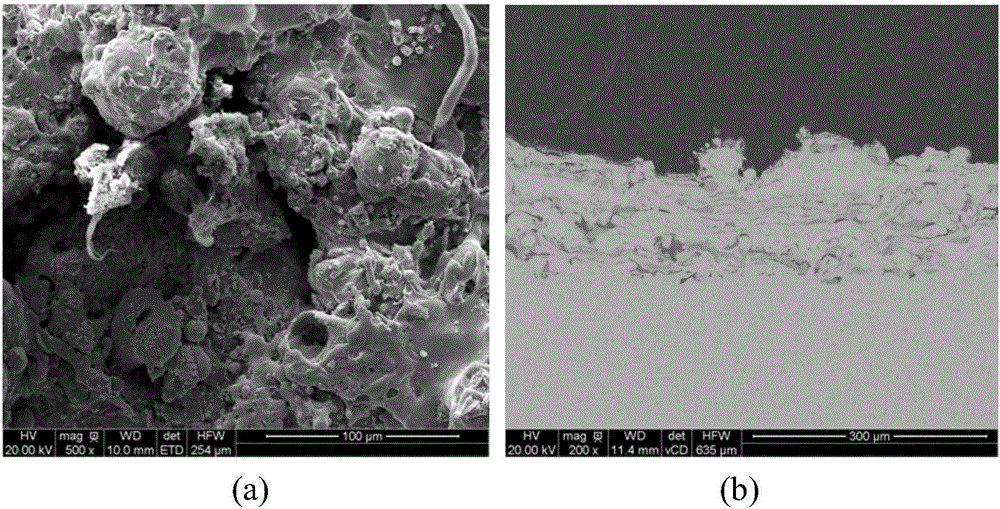

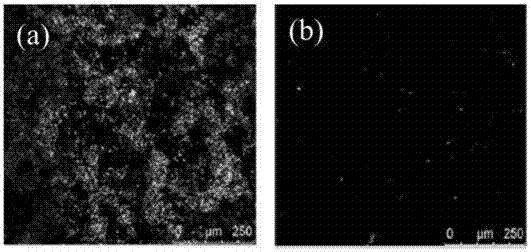

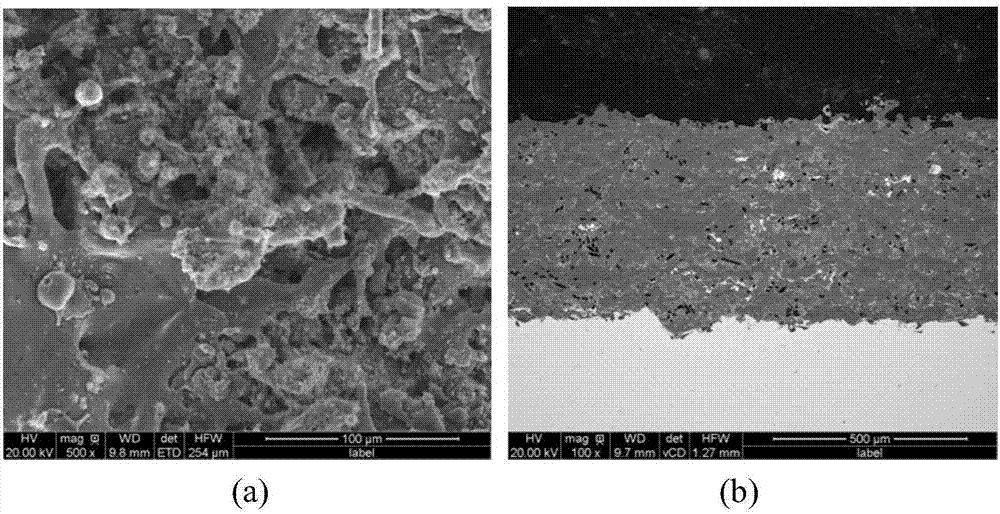

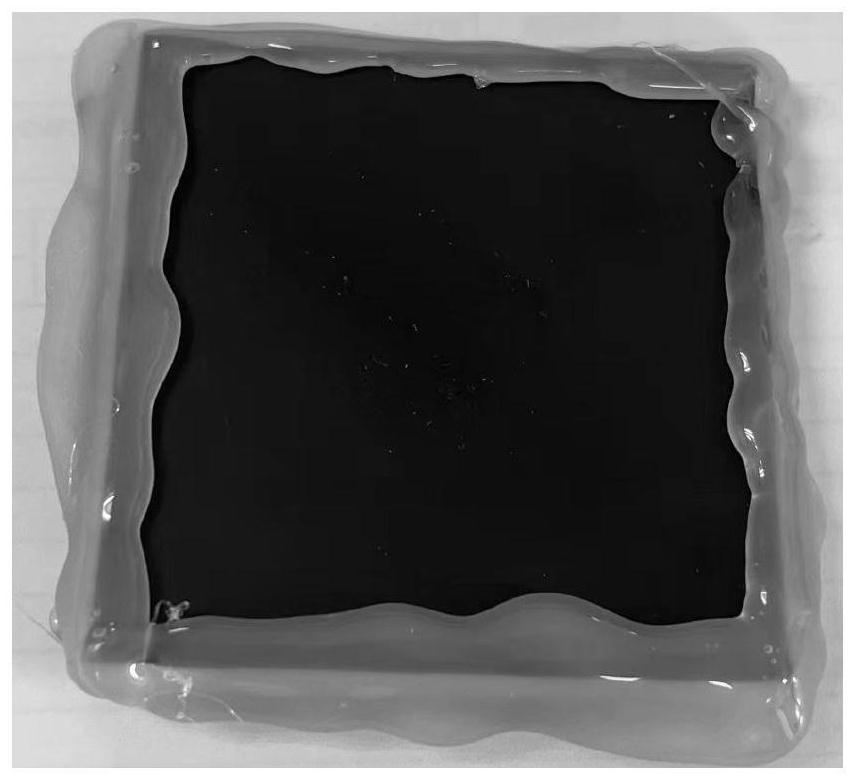

Preparation method of metal-graphene composite coating

The invention discloses a preparation method of a metal-graphene composite coating. The preparation method comprises steps as follows: firstly, metal-graphene composite particles are prepared; a matrix is subjected to surface treatment, and the composite coating is prepared on the surface of the matrix with a thermal spraying technology. The preparation method of the metal-graphene composite coating is simple to operate, low in cost, high in efficiency and suitable for industrial production. The prepared metal-graphene composite coating has a compact structure, has good bonding property with the matrix, has the thickness of 10 mu m-10 mm and has corrosion resistance, friction resistance, high mechanical strength, anti-bacterial property and biological stain and damage prevention property.The metal-graphene composite coating has good application prospects and economic benefits in the fields of friction resistance, corrosion resistance and biological stain and damage prevention.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

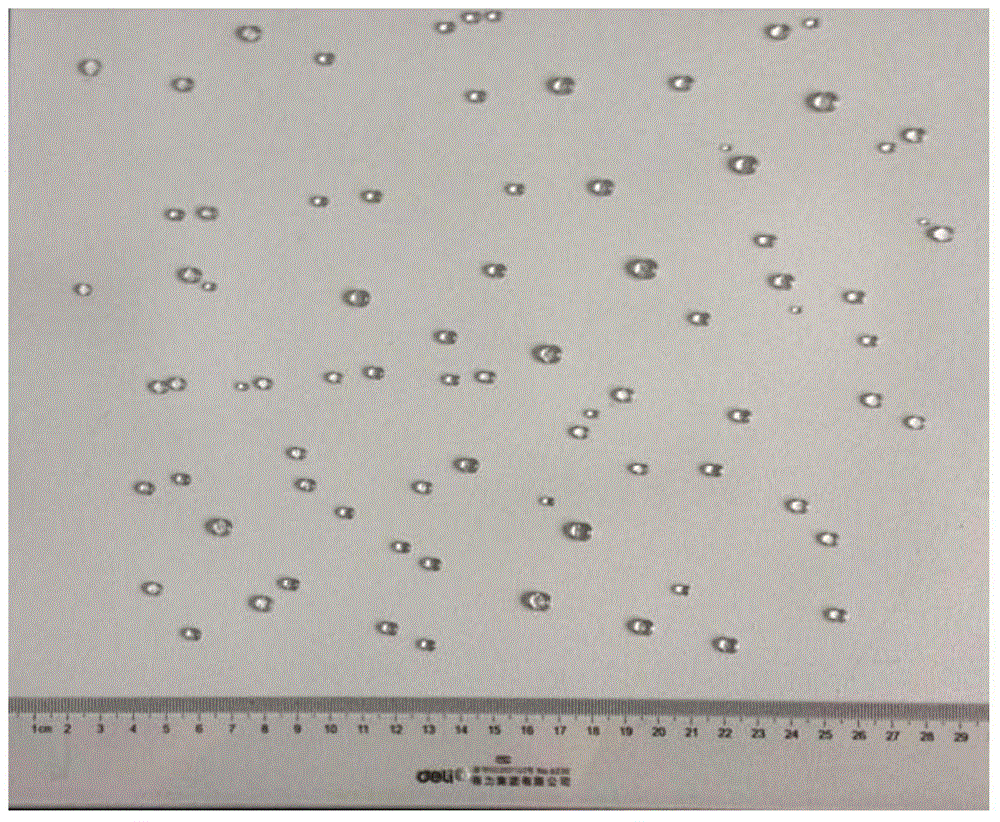

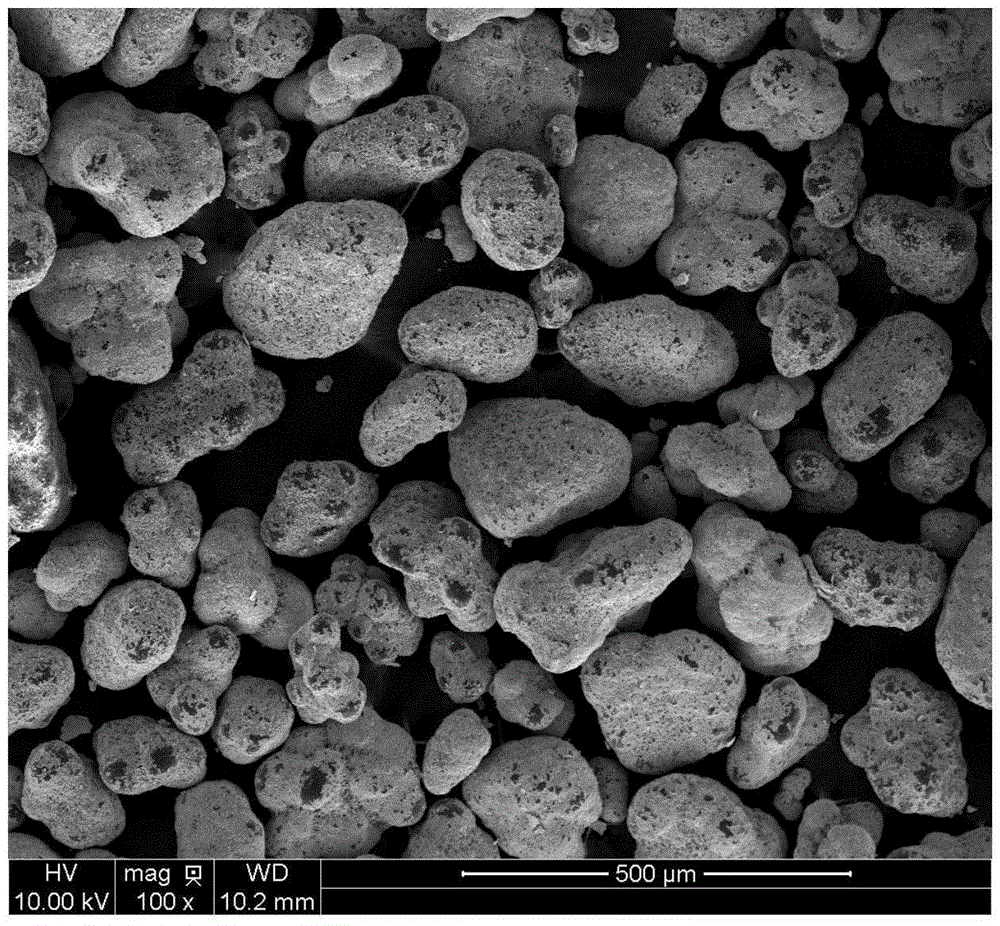

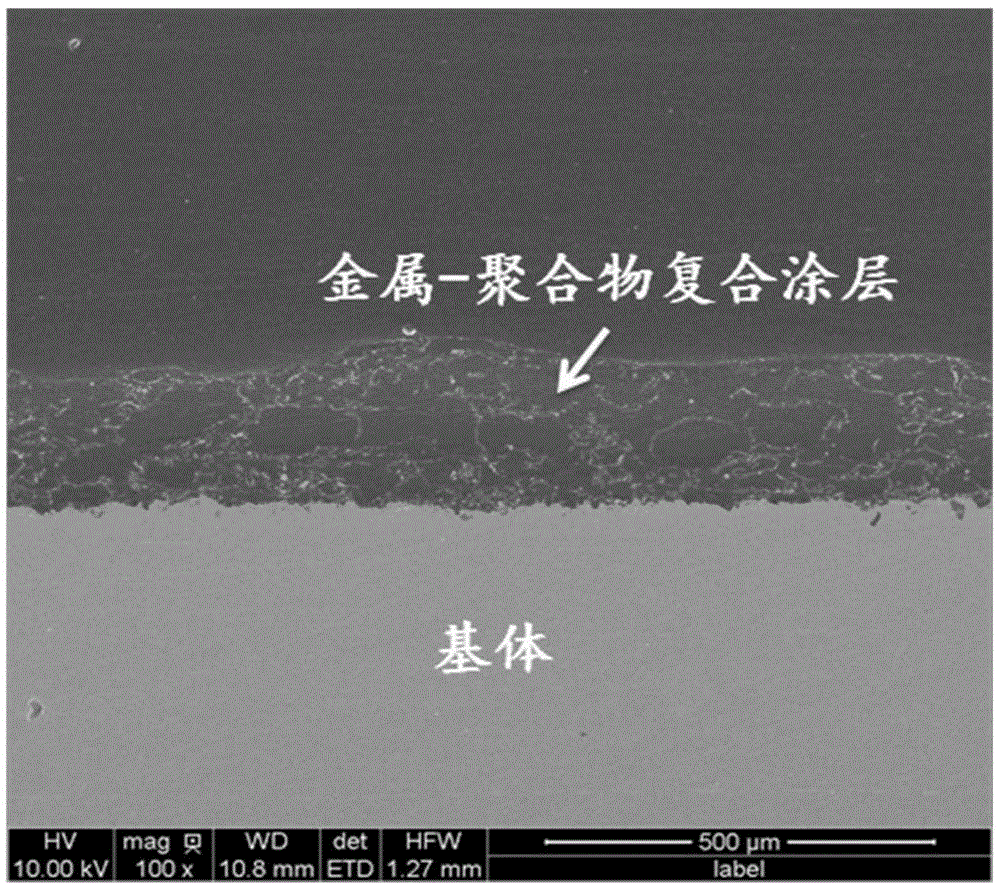

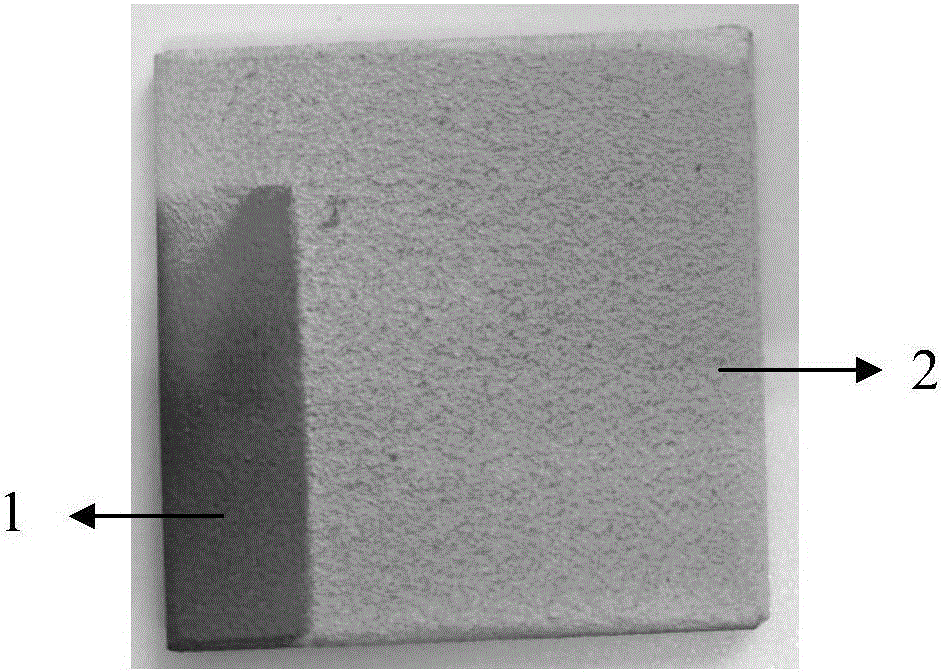

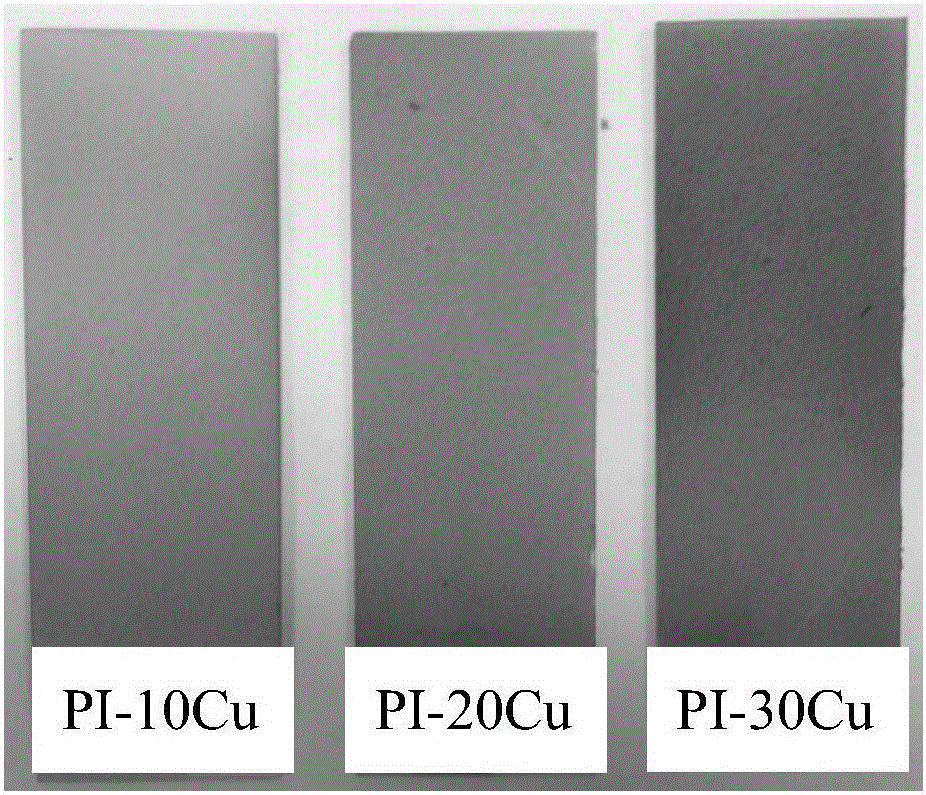

Metal/polymer composite coating and manufacturing method thereof

ActiveCN105420656AReduce equipment costsSimple processMolten spray coatingLiquid/solution decomposition chemical coatingPolypropylenePolymer composites

The invention discloses a metal / polymer composite coating which comprises a substrate and a composite layer on the surface of the substrate. The composite layer comprises, by volume, 5% to 50% of metal and 50% to 95% of a polymer, wherein the metal is copper or nickel, and the polymer is polyethylene or polypropylene or polytetrafluoroethylene or polyimide. The invention further discloses a manufacturing method of the metal / polymer composite coating. The method includes the following steps that metal / polymer composite microspheres are manufactured; the surface of the substrate is subjected to oil removal and roughing treatment; and the manufactured metal / polymer composite microspheres are thermally sprayed, so that a composite layer is manufactured on the treated surface of the substrate, and therefore the metal / polymer composite coating is obtained. The metal / polymer composite coating can be well combined with a base body, stain resistance and corrosion resistance can be effectively achieved, and the metal / polymer composite coating can be applied to outer surfaces of marine industrial parts and other occasions with the stain resistance and corrosion resistance requirements.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

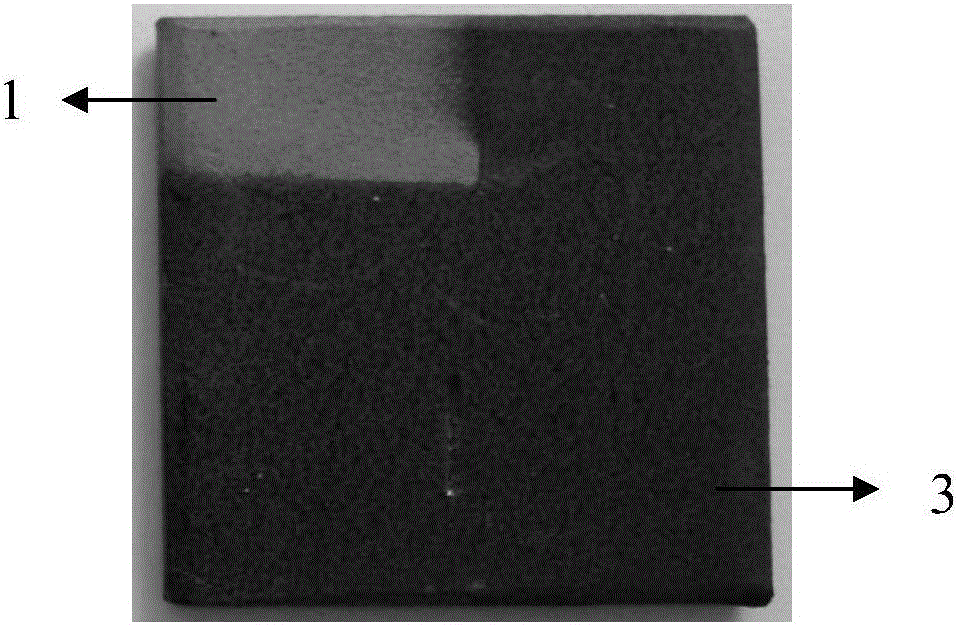

Polyimide composite coating and preparation method thereof and application thereof

ActiveCN105838239ASimple processImprove efficiencyLiquid surface applicatorsAntifouling/underwater paintsThermal sprayingThermoplastic polyimide

The invention discloses a preparation method of polyimide composite coating. The method includes the following steps: step 1: preparing the polyimide spraying raw material, wherein the polyimide spraying raw material is thermosetting polyimide composite precursor slurry, thermoplastic polyimide composite precursor slurry or thermoplastic polyimide composite powder; step 2: performing surface oil-removing of the matrix and coarsening processing; and step 3: sending the spraying raw material prepared by step 1 to a thermal spraying flame flow, and spraying on the treated matrix surface to form the polyimide composite coating. The invention discloses the preparation method of polyimide composite coating, and the method has simple technology, high efficiency and low cost, and is suitable for site operation. The spraying is not limited by the size and shape of the workpiece. The prepared polyimide composite coating is combined well with the matrix, has effective antifouling and anticorrosion performances, and can be used for a plurality of antifouling and anticorrosion occasions such as external surface of industrial component used for ocean.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

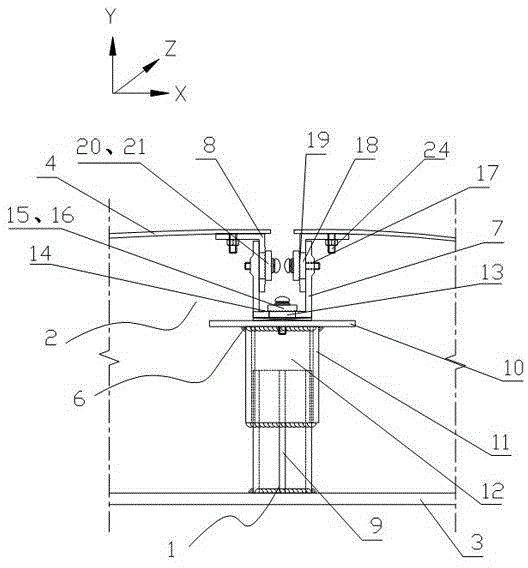

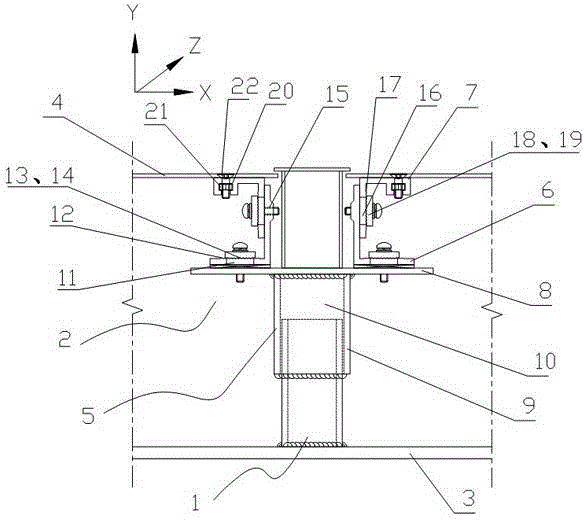

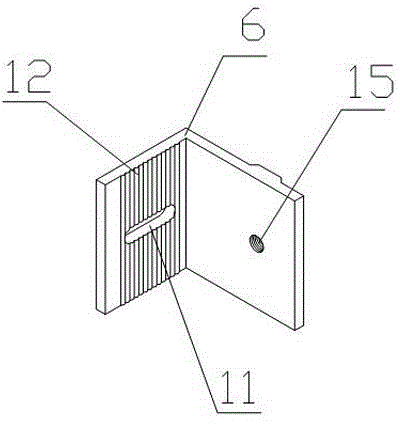

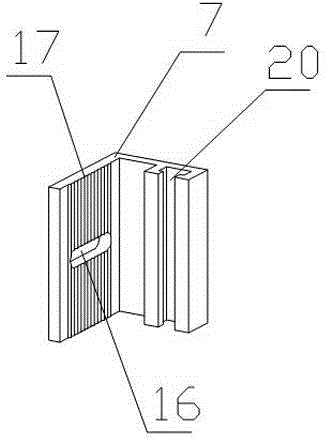

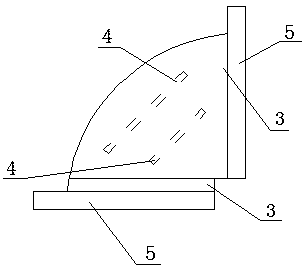

Double-curved-surface metal plate curtain wall three-dimensional adjustment installing structure and double-curved-surface metal plate curtain wall three-dimensional adjustment installing method

ActiveCN104975666AGood effectNice appearanceWallsBuilding material handlingEngineeringSurface structure

The invention discloses a double-curved-surface metal plate curtain wall three-dimensional adjustment installing structure, which comprises a fixed connecting element and a three-dimensional adjustment element, wherein the fixed connecting element is fixedly connected with a main body structure; the three-dimensional adjustment element is adjustably connected with the fixed connecting element in the three-dimensional direction; the three-dimensional installation adjustment of a double-curved-surface metal plate is realized; and a double-curved-arc-surface structure matched with the double-curved-surface metal plate through curved surfaces is arranged on the three-dimensional adjustment element. The double-curved-surface metal plate curtain wall three-dimensional adjustment installing structure has the advantages that the adjustment of the double-curved-surface metal plate in the three-dimensional direction position in the installing process is realized, so that the field installation is more convenient and faster; safety and firmness are realized; the integral effect of the double-curved-surface metal plate after the installation is enabled to be good; the appearance is attractive; and the installation requirements of double-curved-surface metal plates with different curvatures can be met. The invention also discloses a double-curved-surface metal plate curtain wall three-dimensional adjustment installing method, which has the advantages that the installation is fast; the operation is convenient; the installing method is suitable for field construction; and the installing speed of the double-curved-surface metal plate curtain wall is greatly accelerated.

Owner:ZHEJIANG YASHA CURTAIN WALL

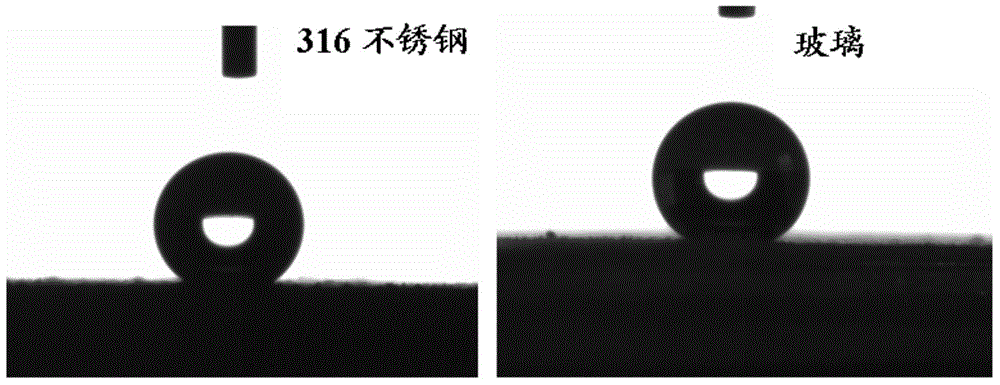

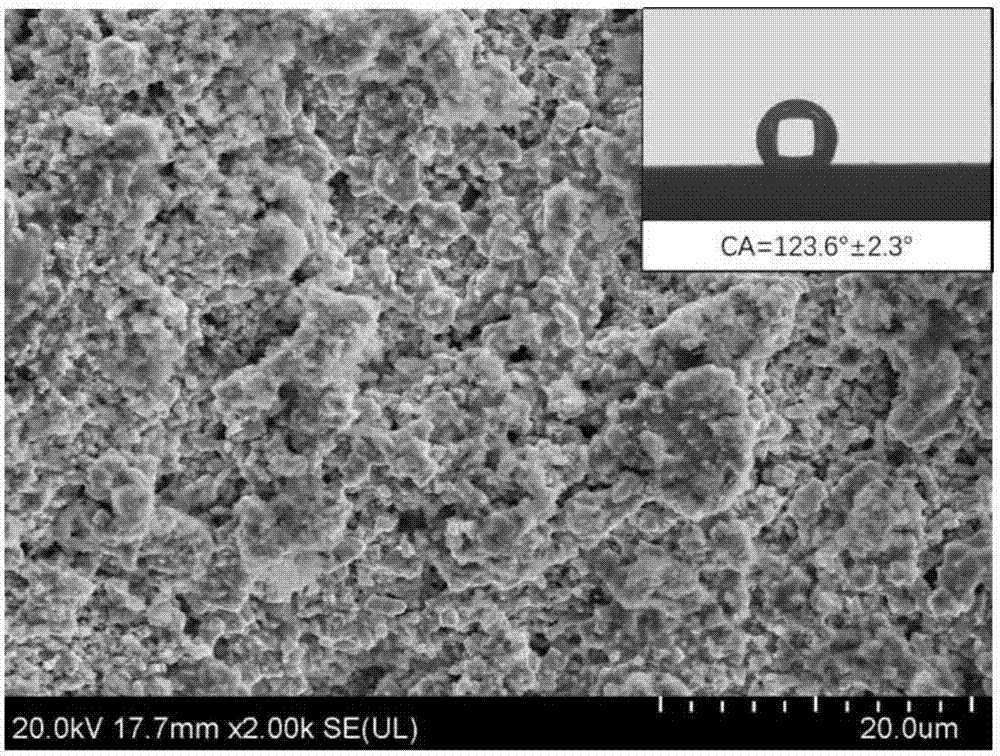

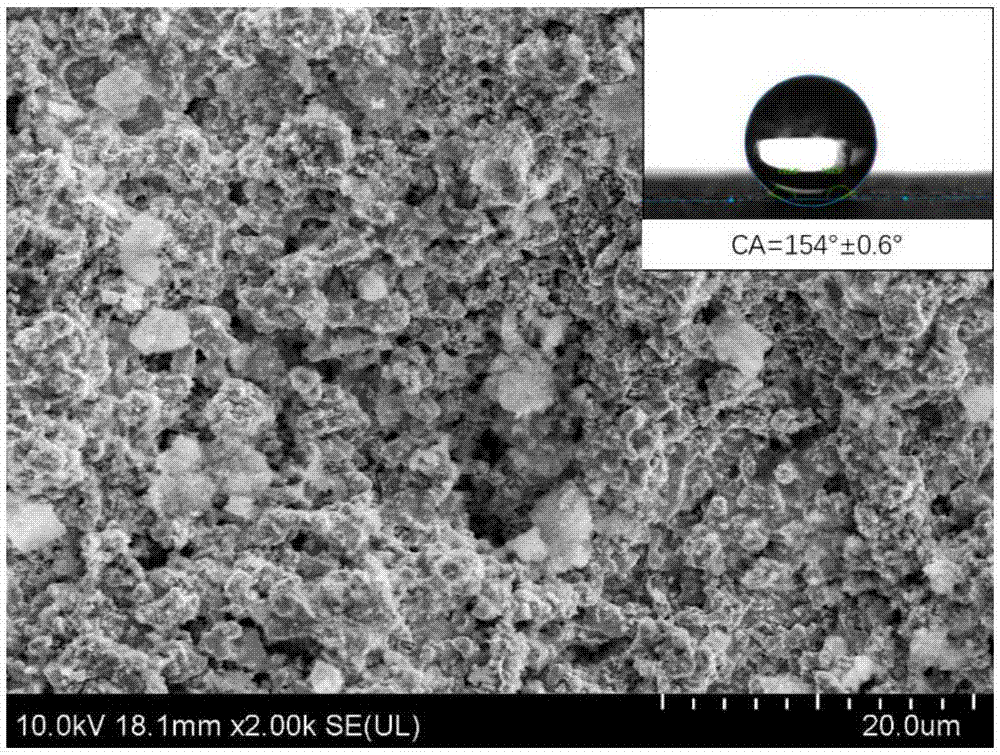

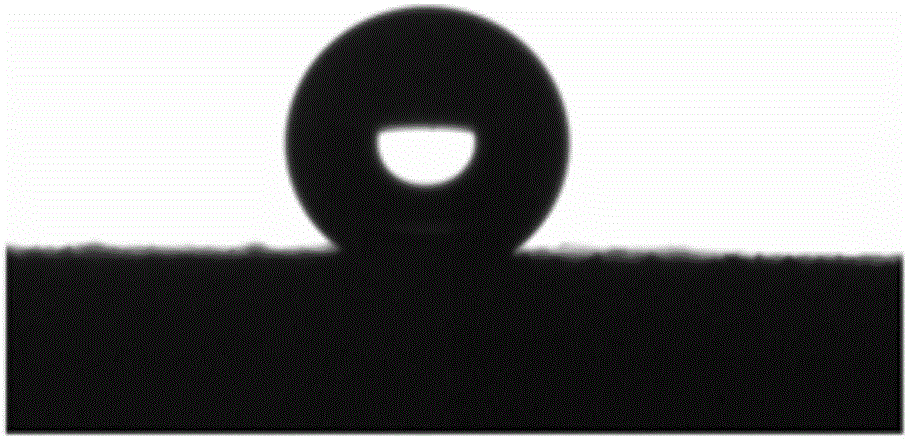

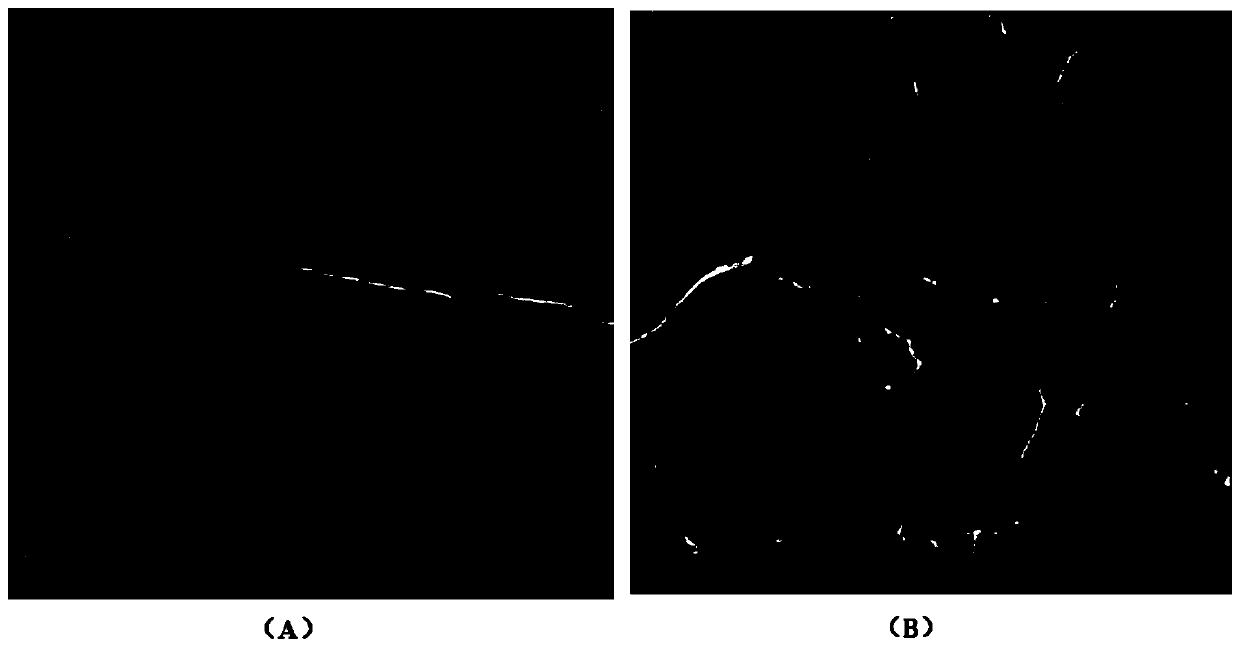

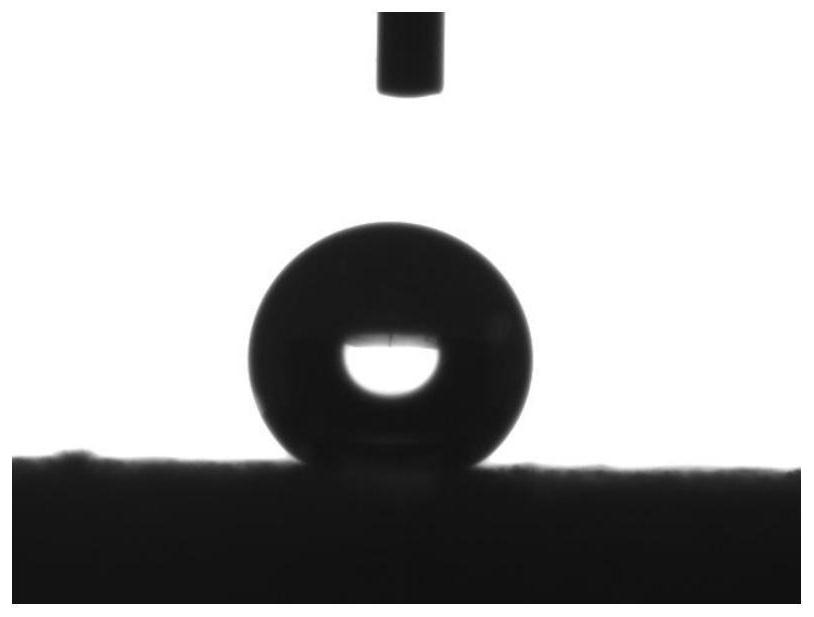

Method for preparing superhydrophobic surface by utilizing supersonic flame spraying

ActiveCN107299308AImprove bindingGuaranteed stabilityMolten spray coatingCeramic coatingSuperhydrophobic coating

The invention discloses a method for preparing a superhydrophobic surface by utilizing supersonic flame spraying. The method comprises the following steps: A, carrying out pretreatment on a matrix surface; B, preparing a tungsten carbide system coating on the pretreated matrix surface by adopting a supersonic flame spraying method, wherein spraying powder is tungsten carbide system powder; C, modifying a layer of low surface energy material on the surface of the tungsten carbide system coating prepared in the step B to obtain a superhydrophobic coating. The method has the advantages that the superhydrophobic surface with a large area can be prepared on various workpiece bases with complex structures, and the method is simple in manufacturing process, high in preparation efficiency, low in cost, suitable for field construction and the like. In addition, the hydrophobic surface prepared by the method has an excellent hydrophobic property and an self-cleaning effect, also has both the toughness of a metal coating and the wear resistance performance and the corrosion resistance performance of a ceramic coating, and has a certain anti-icing function.

Owner:SOUTHWEST JIAOTONG UNIV +1

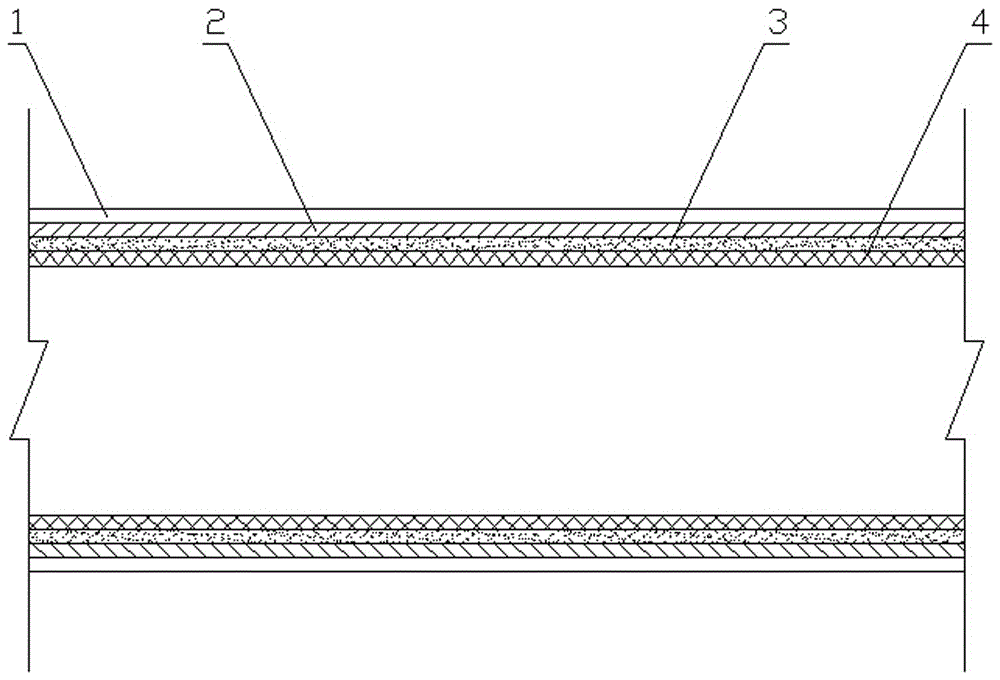

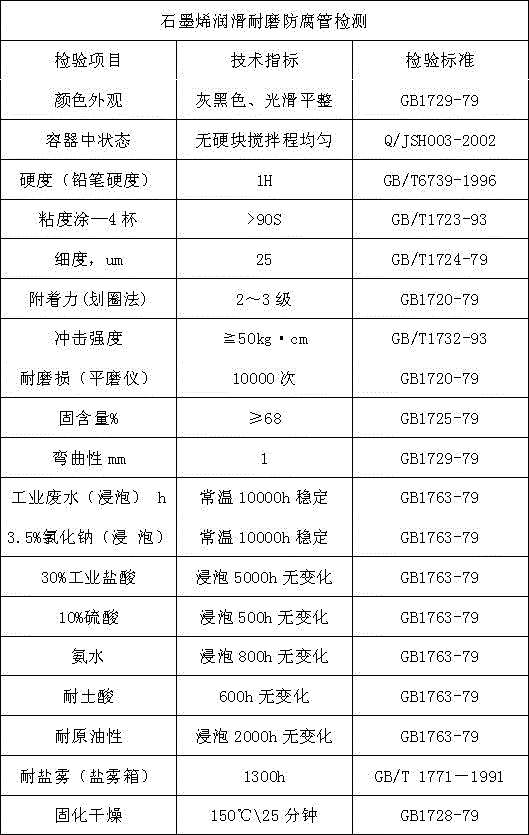

Lubricant, wear-resistant and anti-corrosion graphene pipe and preparation process thereof

InactiveCN106337977AExcellent chemical corrosion resistanceStrong adhesionPretreated surfacesSpecial surfacesAdhesive cementGraphene

The invention provides a lubricant, wear-resistant and anti-corrosion graphene pipe and a preparation process thereof and relates to the technical field of petroleum equipment. The pipe comprises an oil pipe, a lubricant, wear-resistant and anti-corrosion layer, an adhesive layer and a protecting layer, wherein the oil pipe is in a hollow cylindrical structure, the inner wall of the oil pipe is sprayed with the lubricant, wear-resistant and anti-corrosion layer, the adhesive layer and the protecting layer from outside to inside sequentially by a high-pressure gas-free spraying system in a hot-air curing manner. The lubricant, wear-resistant and anti-corrosion layer is made of lubricant, wear-resistant and anti-corrosion powder, and the thickness of the lubricant, wear-resistant and anti-corrosion layer is larger than 100um; the adhesive layer consists of an adhesive, and the thickness of adhesive layer is 120-260 mum; the protecting layer consists of graphene, and the thickness of the protecting layer is 0. 5-3.7 mum. The graphene lubricant, anti-wear and anti-corrosion pipe reduces conveying resistance to the oil pipe, and when the pipe is applied as a gas field well pipe is used to improve gas well productivity, reduce corrosion of inner wall of gas field pipeline, reduce the number of pigging and prolong service life of gas field pipeline.

Owner:大庆市盛日石油技术开发有限公司

Cored wire with super-hydrophobic function and application of cored wire with super-hydrophobic function to preparation of coating with super-hydrophobic function

ActiveCN106676451AImprove self-cleaning effectImprove corrosion resistanceMolten spray coatingThermal sprayingAlloy

The invention provides a cored wire with a super-hydrophobic function. The cored wire with the super-hydrophobic function comprises a cored material and a metal wire coat, wherein the metal wire coat is used for coating the cored material. The cored material is formed by a metal cored material and a high molecular cored material through mixing. The metal cored material is selected from metal aluminum, copper, nickel and chromium or is any one kind of alloy formed by two kinds of the metal. The high molecular cored material is at least one of teflon, fluorinated ethylene-propylene, polytrifluorochloroethylene, polyvinylidene fluoride, ethylene-tetrafluoroethylene copolymer, ethylene-chlorotrifluoroethylene copolymer, polyvinyl fluoride, fluorocarbon resin and polyurethane. The invention further provides a coating with a super-hydrophobic function. The coating with the super-hydrophobic function is made of cored wires with the super-hydrophobic function and prepared through a thermal spraying technology. The coating has excellent super-hydrophobic performance and corrosion resistance, and has the good application prospect in the fields of self-cleaning, marine pollutant prevention, contamination resistance and the like.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

Double-curved-surface metal plate curtain wall installing structure and double-curved-surface metal plate curtain wall installing method

ActiveCN104975667AGuaranteed effectAchieve regulationWallsBuilding material handlingEngineeringMetal

The invention discloses a double-curved-surface metal plate curtain wall installing structure, which comprises a fixed connecting element and a three-dimensional adjusting element, wherein the fixed connecting element is fixedly connected with a main body structure; and the three-dimensional adjusting element and the fixed connecting element are in adjustable connection in the three-dimensional direction, so that the three-dimensional adjustment of a double-curved-surface metal plate is realized. The double-curved-surface metal plate curtain wall installing structure effectively solves the problems of installation complexity, operation inconvenience and the like of the double-curved-surface metal plate in the conventional metal curtain wall installing structure; the adjustment on the three-dimensional direction position of the double-curved-surface metal plate in the installing process is realized, so that the field installation is more convenient and faster; safety and firmness are realized; and the integral effect of the installed double-curved-surface metal plate is ensured. The invention also discloses a double-curved-surface metal plate curtain wall installing method, which has the advantages that the installation is fast; the operation is convenient; the method is suitable for field construction; the installing speed of the double-curved-surface metal plate curtain wall is greatly accelerated; and the work efficiency is improved.

Owner:ZHEJIANG YASHA CURTAIN WALL

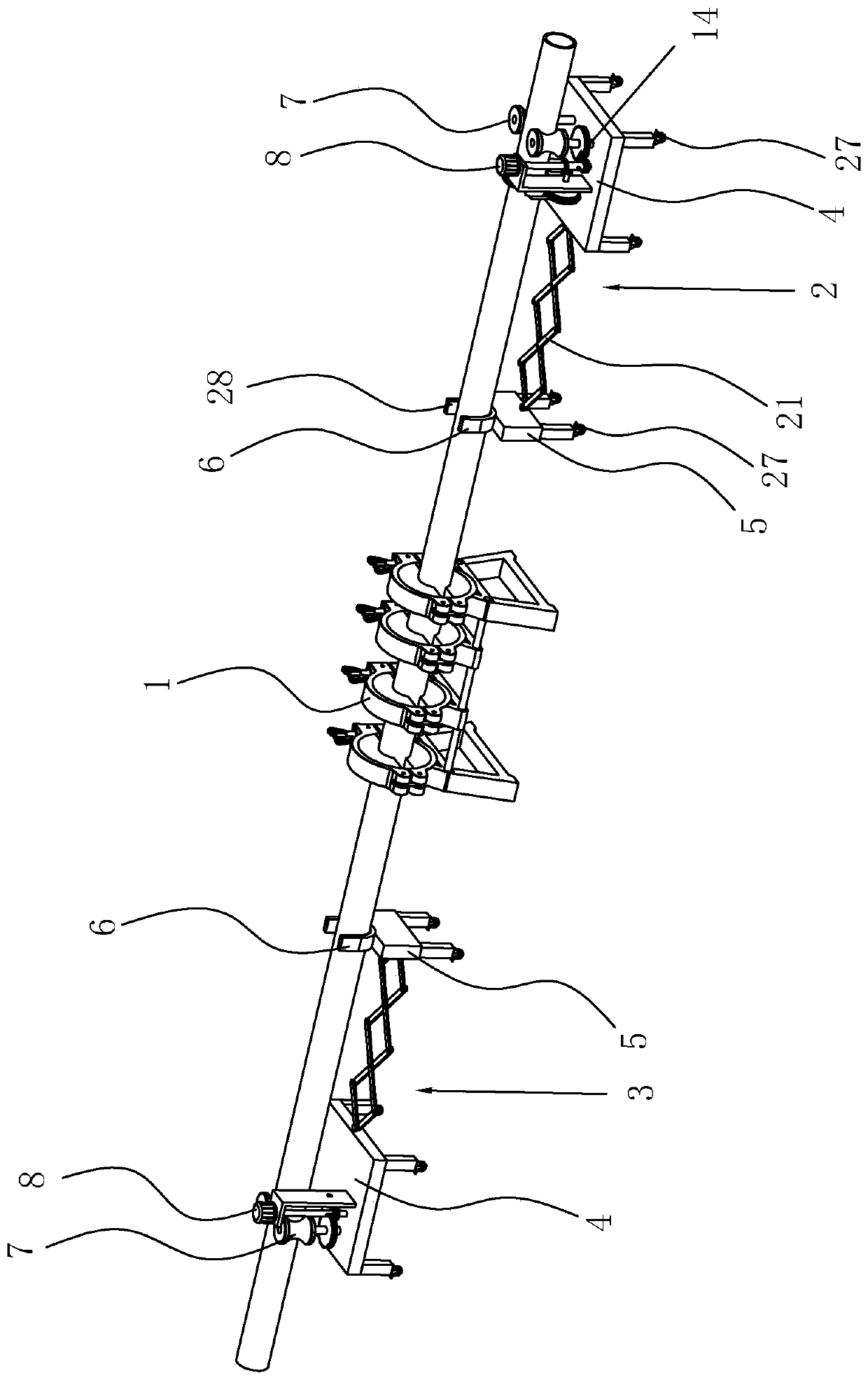

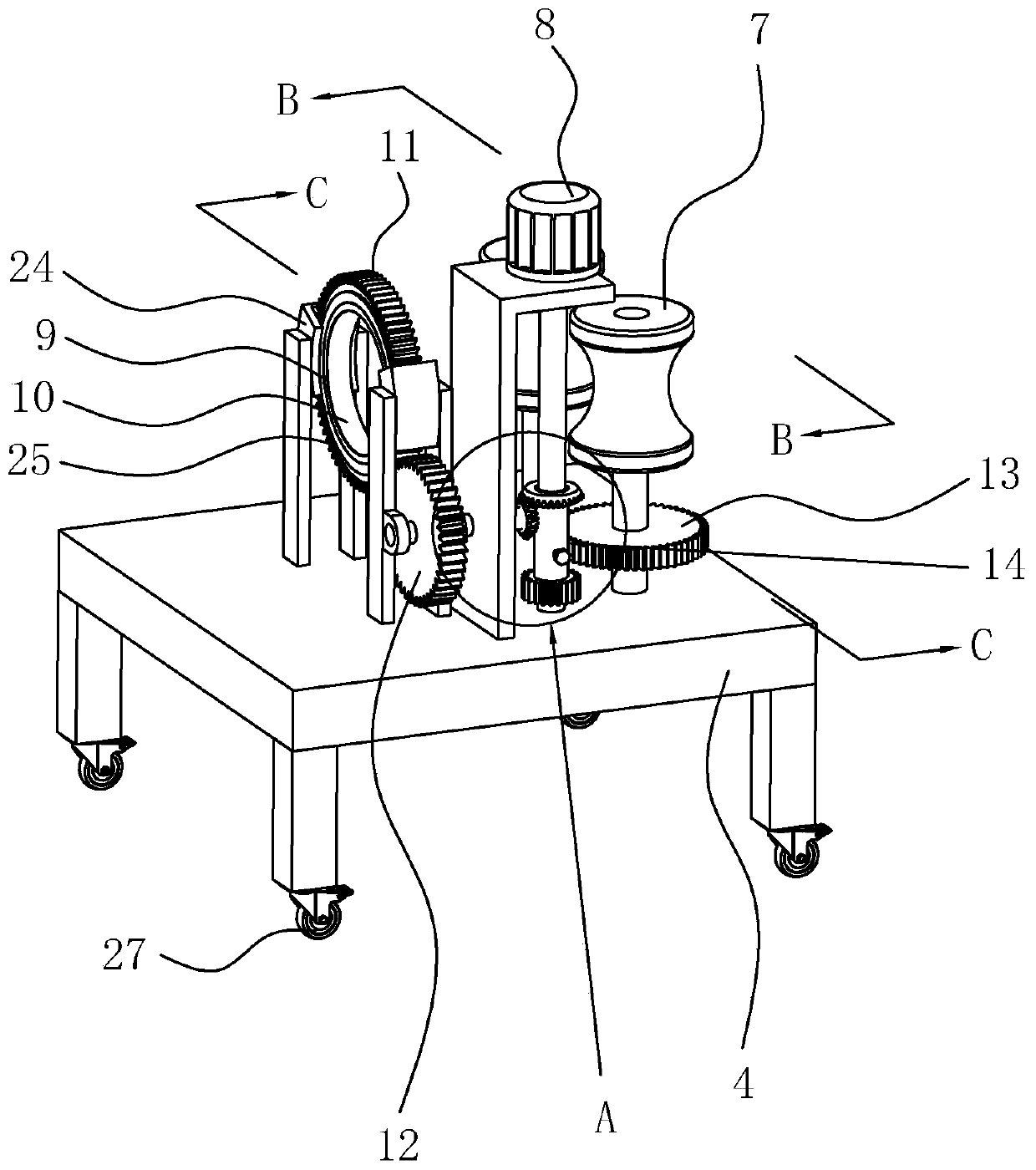

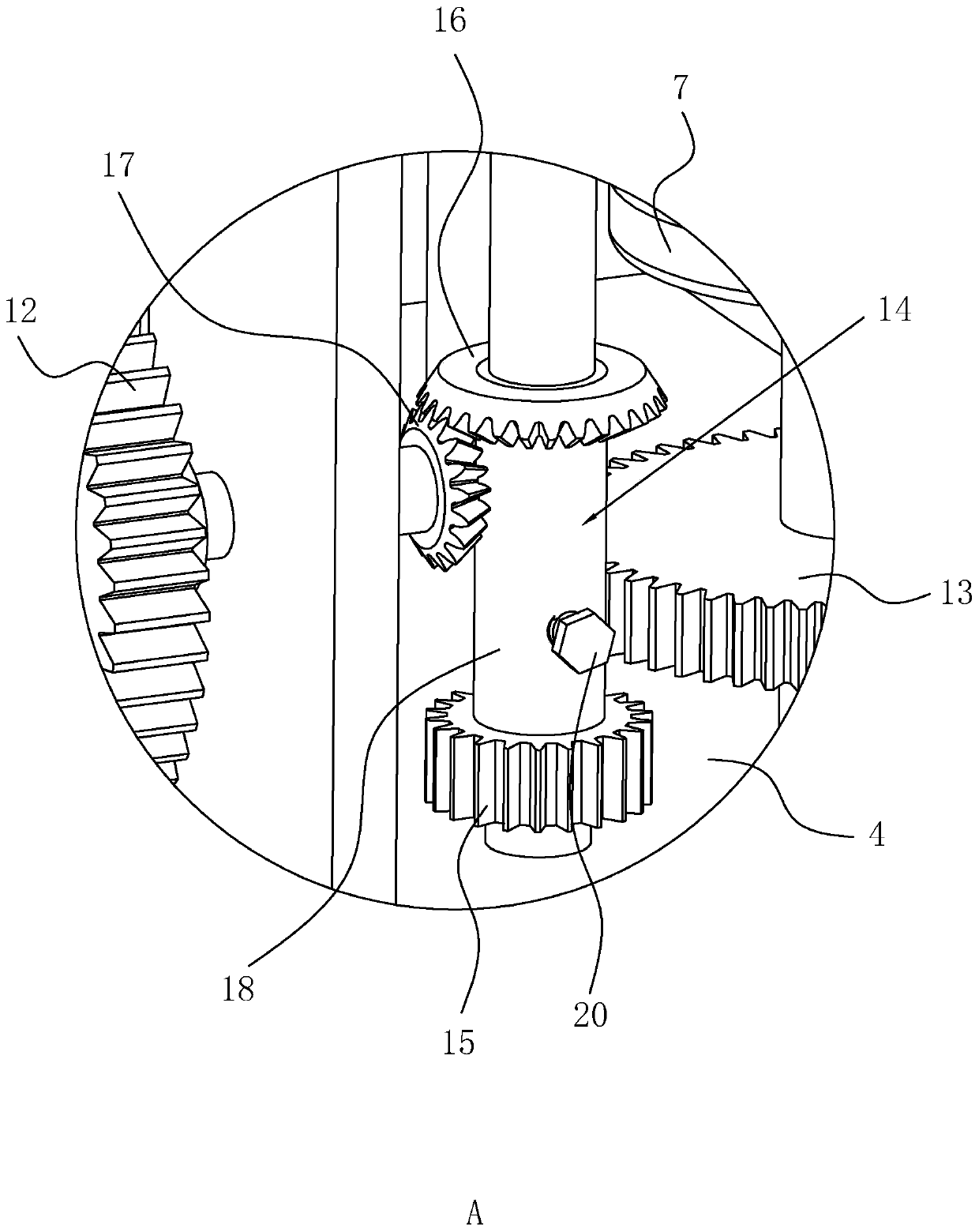

Electric power engineering pipeline connection construction method and fuse machine for construction

ActiveCN111516278AImprove fitting accuracyImprove connection qualityTubular articlesControl engineeringPower engineering

The invention relates to an electric power engineering pipeline connection construction method and a fuse machine for construction. The fuse machine for electric power engineering pipeline connectionconstruction comprises a fuse machine body, a main bearing device and an auxiliary bearing device, wherein the main bearing device and the auxiliary bearing device are arranged on the two sides of thefuse machine body correspondingly; and the main bearing device and the auxiliary bearing device comprise main bases and auxiliary bases, the auxiliary bases are arranged close to the fuse machine body, brackets are arranged on the auxiliary bases, feeding mechanisms used for driving electric power pipelines to advance in the arrangement direction of the main bases and the auxiliary bases are arranged on the main bases, and an overturning mechanism used for driving the electric power pipelines to rotate around the axial direction of the main base in the main bearing device is further arrangedon the main base in the main bearing device. According to the electric power engineering pipeline connection construction method and the fuse machine for construction, the overturning mechanism drivesthe short electric power pipeline to rotate on the main bases and the auxiliary bases to enable the end part of the electric power pipeline to be matched with the other electric power pipeline, so that the problem of inaccurate butt joint caused by local bending due to the dead weight of the electric power pipelines is effectively avoided, the matching accuracy of the two electric power pipelinesis improved, and the construction efficiency is improved.

Owner:河南博泰电力工程有限公司

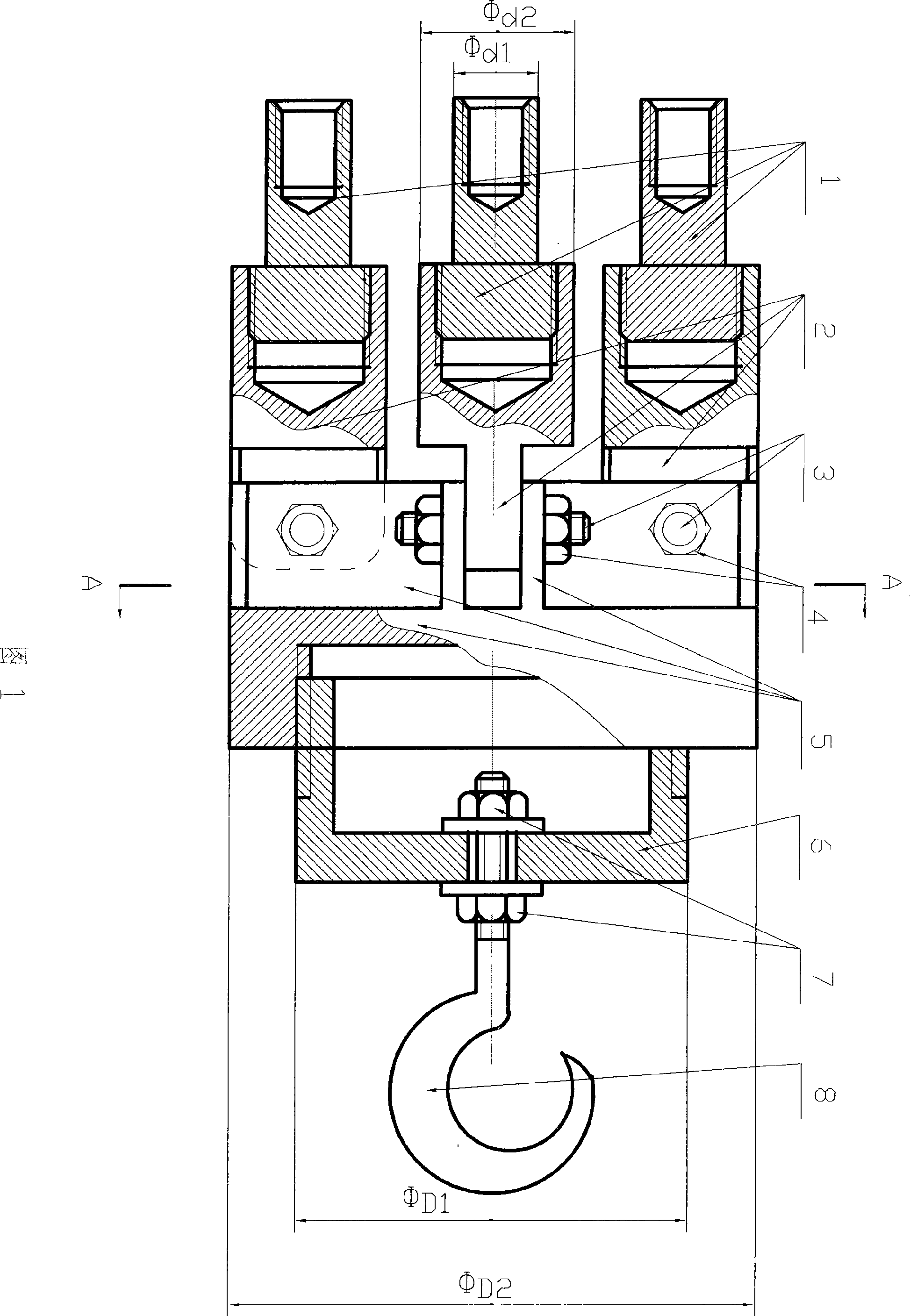

Device and method for towing multi-core cable

InactiveCN101447655APrevent water ingressEven by forceApparatus for laying cablesMulticore cableGeneral purpose

The invention provides a device and a method for towing a multi-core cable, and belongs to the technical field of electromechanical products. The device comprises a compression connection component, an intermediate connection component, a towing base, a sleeve and a towing hook. The device is characterized by convenient assembly and disassembly and towing force on the cable conductors. The method comprises the following steps: making a cable head, connecting the cable head with the device, and finally hanging a steel cable on the device. The method is characterized by finishing the connection and assembly by general-purpose tools and standard components, providing simple operation and being applicable to site operation. The device and the method for towing the multi-core cable can tow cables with huge towing force, the multi-core conductors are stressed evenly, and cables are not damaged. The assembly and disassembly are convenient, and the compression connection components can be flexibly used together with conductors with different specifications. PE self-adhesive tapes wrap the cables to prevent water entering the cables during towing the cables.

Owner:刘忠良

Anticorrosive coating material for a concrete base material, and construction method thereof

ActiveCN110540797AImprove anti-corrosion performancePrevent penetrationAnti-corrosive paintsPolyurea/polyurethane coatingsFluorocarbonGraphene

The invention discloses an anticorrosive coating material for a concrete base material, wherein the anticorrosive coating material comprise a component A and a component B, the component A comprises,by weight, 0.1-0.5 part of modified graphene micro-powder, 36-54 parts of a fluorocarbon resin, 4-6 parts of an organic silicon resin, 1-2 parts of a drier, 1-3 parts of a mildew-proof and algae-proofagent, 1-3 parts of a leveling agent, 1-3 parts of a wetting dispersant, 1.5-3 parts of a coloring agent, and 1-3 parts of a defoaming agent, the component B comprises: 40-60 parts of a polyisocyanate prepolymer, a mass ratio of the component A to the component B is 1:2-4, and the modified graphene micro-powder is obtained by modifying graphene micro-powder with a silane coupling agent. Accordingto the present invention, by matching the modified graphene micro-powder, the fluorocarbon resin, the organic silicon resin and the polyisocyanate prepolymer according to a certain ratio, the anticorrosive performance of the coating is effectively improved, and the anticorrosive coating material has excellent comprehensive performance. The invention further provides a construction method of the anticorrosive coating material.

Owner:武汉长弢新材料有限公司

Organosilicon coating rubber for rail transit, and preparation method thereof

The invention discloses an organosilicon coating rubber for rail transit, and a preparation method thereof, and belongs to the technical field of silicone rubber application, wherein the organosiliconcoating rubber comprises: 60-80 parts of hydroxyl-terminated polydimethylsiloxane, 10-20 parts of a reinforcing filler, 10-20 parts of an adhesive film reinforcing agent, 4-8 parts of a cross-linkingagent, 1-5 parts of a chain extender, 0.02-0.5 part of a catalyst, 1-4 parts of a tackifier, and 0.8-3 parts of an antifungal agent, and is prepared through heating drying, vacuum defoaming, vacuum mixing and other steps. According to the present invention, the organosilicon coating rubber is a ketoxime removing type one-component room temperature vulcanized organosilicon elastomer, is used for rail transit, can effectively achieve the effects of water resistance, dust resistance, mildew resistance, insulating protection and the like on the outer layer, can solve the mildew problem of the existing organosilicon coating rubber, can achieve the mildew-resistant grade of 0 grade, does not contain volatile solvents such as petroleum ether, solvent gasoline, toluene and the like, and is safe and environmentally friendly, and the cured rubber layer has good strength and good toughness.

Owner:CHINA BLUESTAR CHENGRAND CO LTD

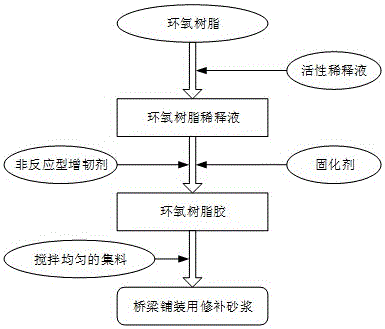

Repairing mortar for bridge pavement repairing paving, and preparation method and construction method thereof

ActiveCN105906232AMeet the technical requirements of local rapid repairMeet the strength indexAdditive ingredientRoad surface

The invention provides a repairing mortar for bridge pavement repairing paving, and a preparation method and a construction method thereof. The repairing mortar for bridge pavement repairing paving is prepared through adding ingredients to bisphenol A epoxy resin, a curing agent, an active diluent and aggregates and mixing above materials, the repairing method has a fast setting speed, the early compression strength, the early bending strength and the early bonding bending strength of the repairing mortar can met fitted traffic opening strength indexes, the later strength of the repairing mortar is high, and the repairing mortar also has good ductility, and can well meet local rapid repairing technology requirements of a cement concrete bridge pavement paving layer; the preparation method of the repairing mortar for bridge pavement repairing paving has the advantages of simple operation flow, easy onsite construction operation, and suitableness for local rapid repairing of the bridge paving layer pavement; and the pavement repairing laying construction method of the repairing mortar combines the advantages of high compression strength, high bending strength and high bonding bending strength, and realizes good repairing quality and long service life of the repaired paving position.

Owner:CHONGQING UNIV

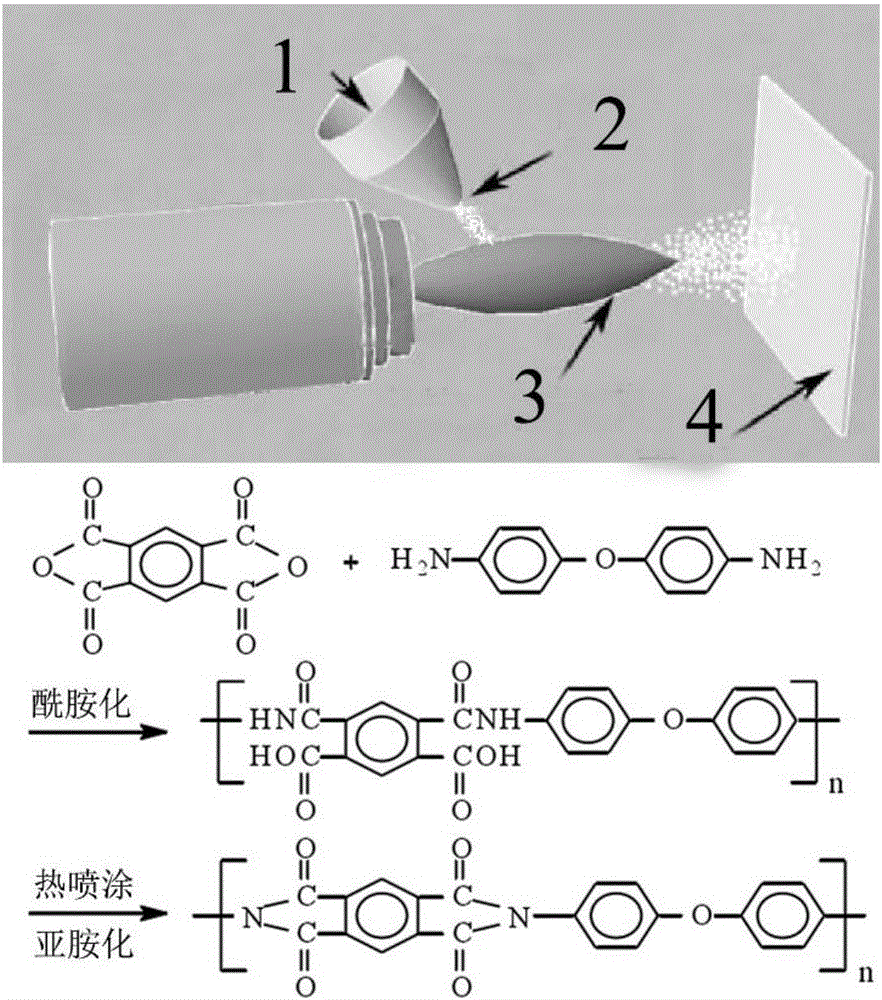

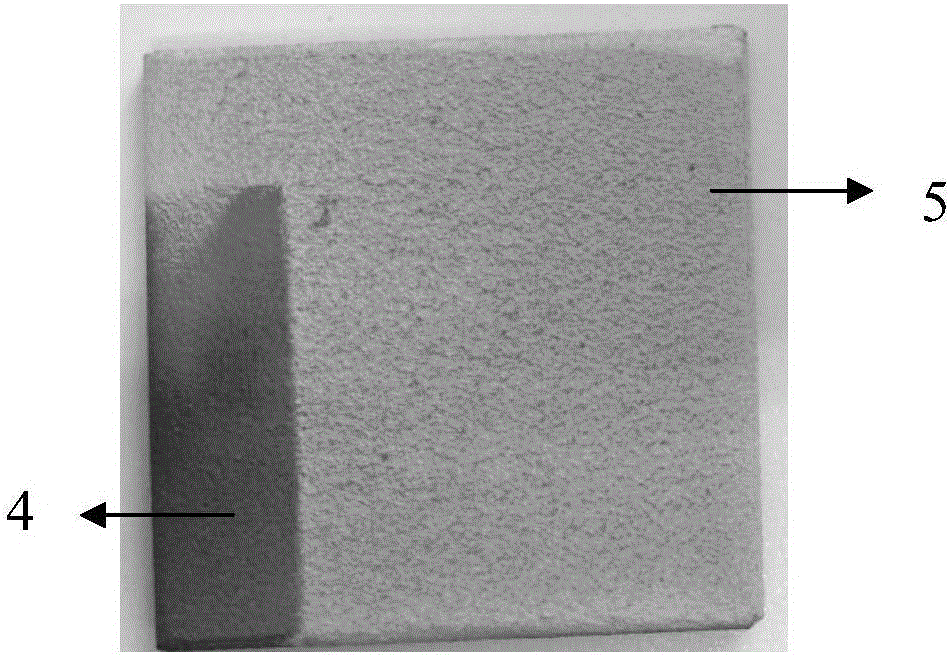

Method utilizing thermal spraying technique for preparing polyimide coating and product of method

ActiveCN105903650AImprove bindingSimple processLiquid surface applicatorsCoatingsThermal sprayingSizing

The invention discloses a method utilizing a thermal spraying technique for preparing polyimide coating and a product of the method. The method includes steps of 1, preparing polyimide spray material which is a thermosetting polyimide precursor sizing agent, a thermoplastic polyimide precursor sizing agent or a thermoplastic polyimide powder; 2, performing surface deoiling and roughening on a substrate; 3, sending the spray material prepared in step 1 into thermal spraying flame flow and forming the polyimide coating on the processed substrate surface through spraying. The method is simple in technique, high in efficiency and suitable for field construction. Spray limits of work piece sizes and shapes are removed and the cost is low. The prepared polyimide composite coating can be combined well with the substrate and the microstructures are adjustable. The method can be applied to fields of electrics, mechanics, thermotics, anti-radiation and medical science and the like.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

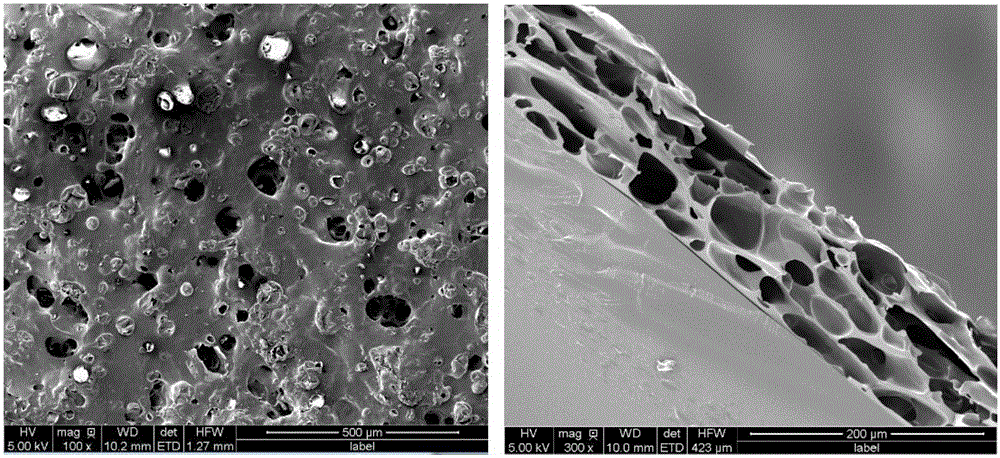

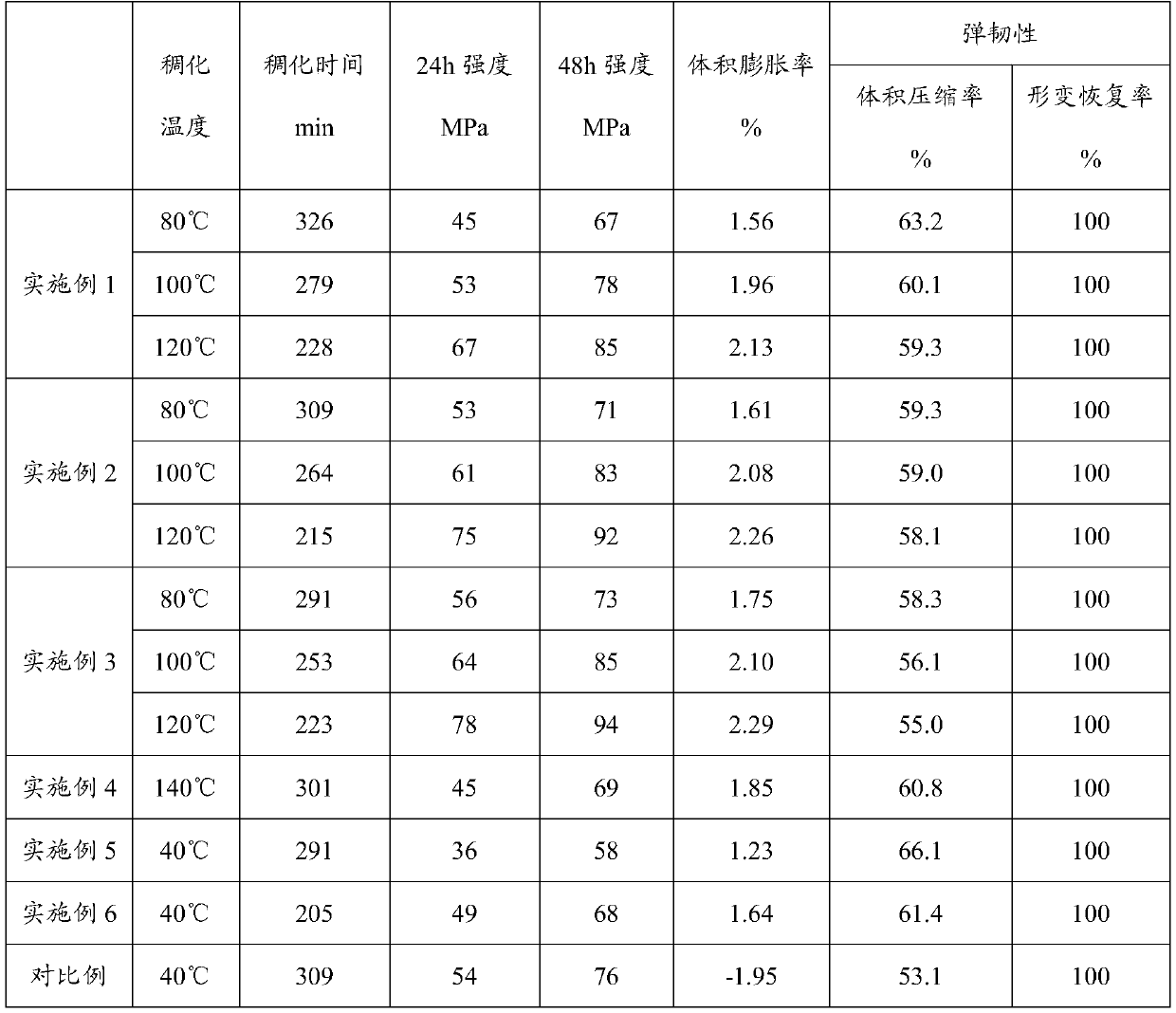

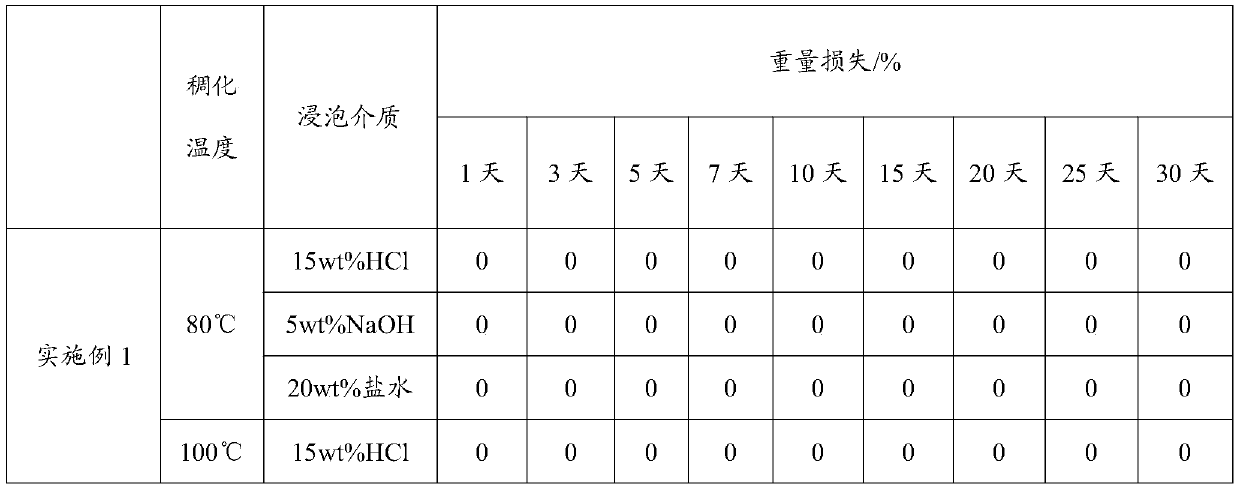

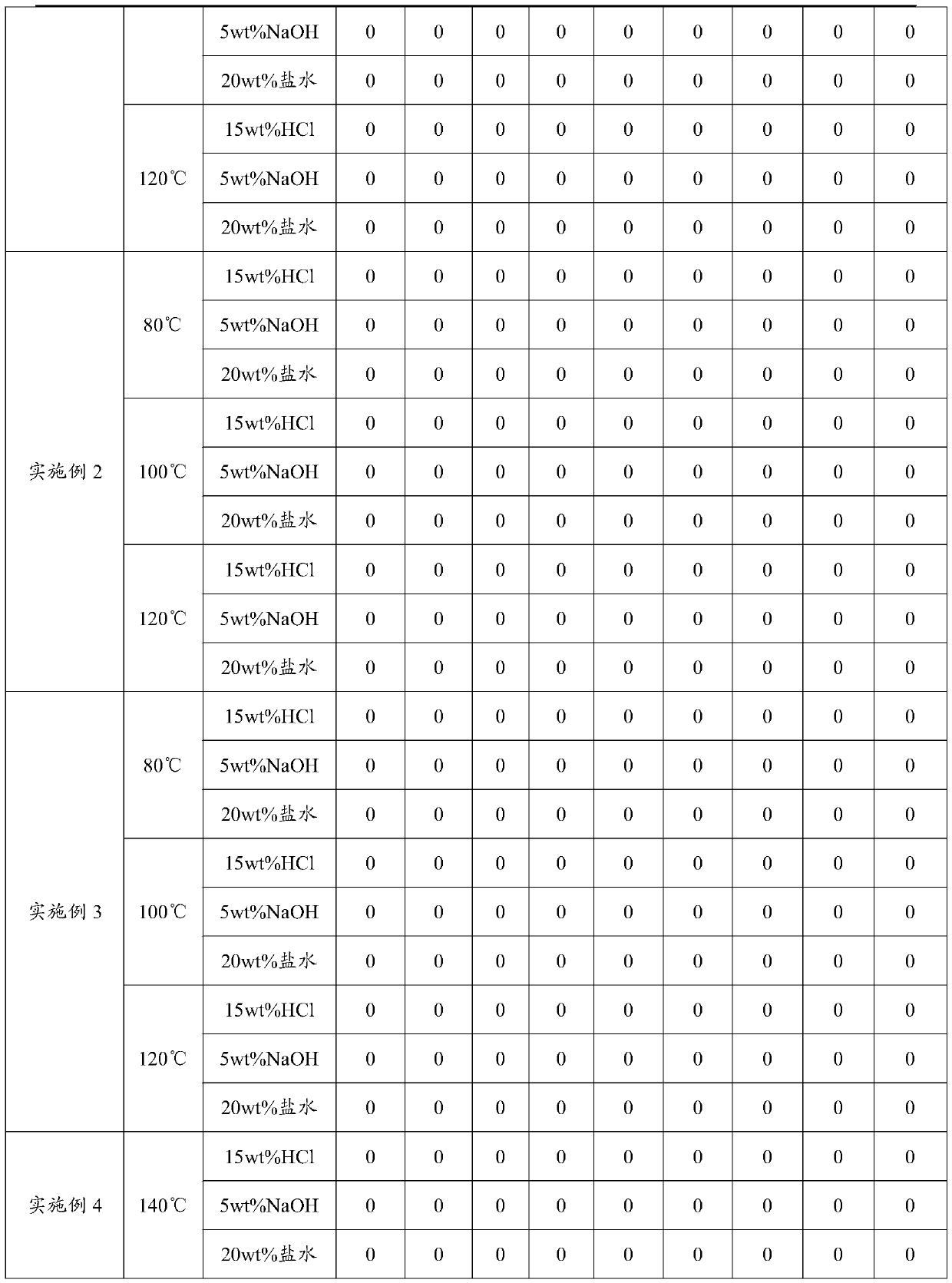

Chemical plugging rubber plug, preparation method and application thereof

ActiveCN109943302AImprove rheologyGood expansion performanceDrilling compositionSealing/packingFluid phaseSulfur hydride

This invention provides a chemical plugging rubber plug, a preparation method and application thereof, and belongs to technical field of oil and gas exploration and development. The chemical pluggingrubber plug comprises the following preparation raw materials by weight: 100 parts of a basic liquid including a resin base liquid and a flow pattern regulator; 1-5 parts of an expansion agent including a liquidoid expansion agent and a solidoid phase expansion agent; 1-25 parts of a gelatinizer. The chemical plugging rubber plug takes the base liquid composed of resin base liquid and flow pattern regulator as the main body, and cooperates with the expansion agent and the thickener, so the obtained chemical sealing rubber plug has the advantages of good rheological properties, excellent expansion property and elastic toughness, high bearing strength, strong corrosion resistance to acid, alkali, salt and hydrogen sulfide, irreversible sealing and long validity period.

Owner:JINGZHOU JIAHUA TECH

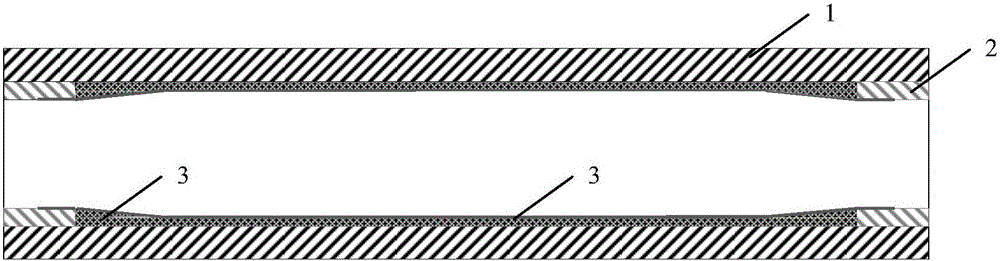

Corrosion-resistance composite pipe and manufacturing method thereof

InactiveCN105927822AExtended service lifeReduce gapPretreated surfacesCorrosion preventionHot TemperatureMetal

The invention relates to a corrosion-resistance composite pipe and a manufacturing method thereof and belongs to the technical field of pipeline connection. The corrosion-resistance composite pipe comprises a pipe material base body and a lining corrosion-resistance layer arranged on the inner wall of the pipe material base body. The lining corrosion-resistance layer comprises metal corrosion-resistance layers arranged on the inner walls of the two ends of the pipe material base body and a non-metal corrosion-resistance layer arranged between the metal corrosion-resistance layers. By means of the corrosion-resistance composite pipe, the lining corrosion-resistance layer composed of the metal corrosion-resistance layers and the non-metal corrosion-resistance layer is arranged on the inner wall of the steel pipe base body, high-temperature heating is not needed in the manufacturing process of the lining corrosion-resistance layer, the phenomena that the steel pipe base body expands due to heating, and a gap exists between the lining corrosion-resistance layer and the steel pipe base body due to or contraction are avoided, corrosion at the combined position of the lining corrosion-resistance layer and the steel pipe base body is relieved, and the service life of the composite pipe is prolonged.

Owner:中石化河南油建工程有限公司

Method for improving rapid cold repair strength of abrasion damage of flow passage component of water turbine

ActiveCN111843373AShort construction periodNo deformationHydro energy generationMetal fiberWater turbine

The invention provides a method for improving the rapid cold repair strength of abrasion damage of a flow passage component of a water turbine. According to the method, a metal fiber or metal wire texture framework is adopted firstly, then a viscous filling body is adopted for filling, a high-strength repair layer is formed after curing, and the method comprises the following specific steps that (1) polishing is carried out on cavitation and abrasion areas, and pits in smooth transition are formed; (2) metal fibers or metal wires are adopted and planted in the pits to be repaired in an energystorage welding mode to serve as a framework of the viscous filling body; (3) an epoxy resin, ceramic particles and fibers are mixed and a curing agent is added to form the viscous filling body; (4) the viscous filling body is poured into the pits, and the pits are filled with the viscous filling body by taking the metal wires as the framework; and (5) after the viscous filling body is cured, a polishing machine is adopted for polishing and flattening. The method for improving the rapid cold repair strength of abrasion damage of the flow passage component of the water turbine has the characteristics of simple process, high bonding strength of the repairing layer, difficulty in deformation of a workpiece, short construction period and low safety risk.

Owner:云南联合电力开发有限公司

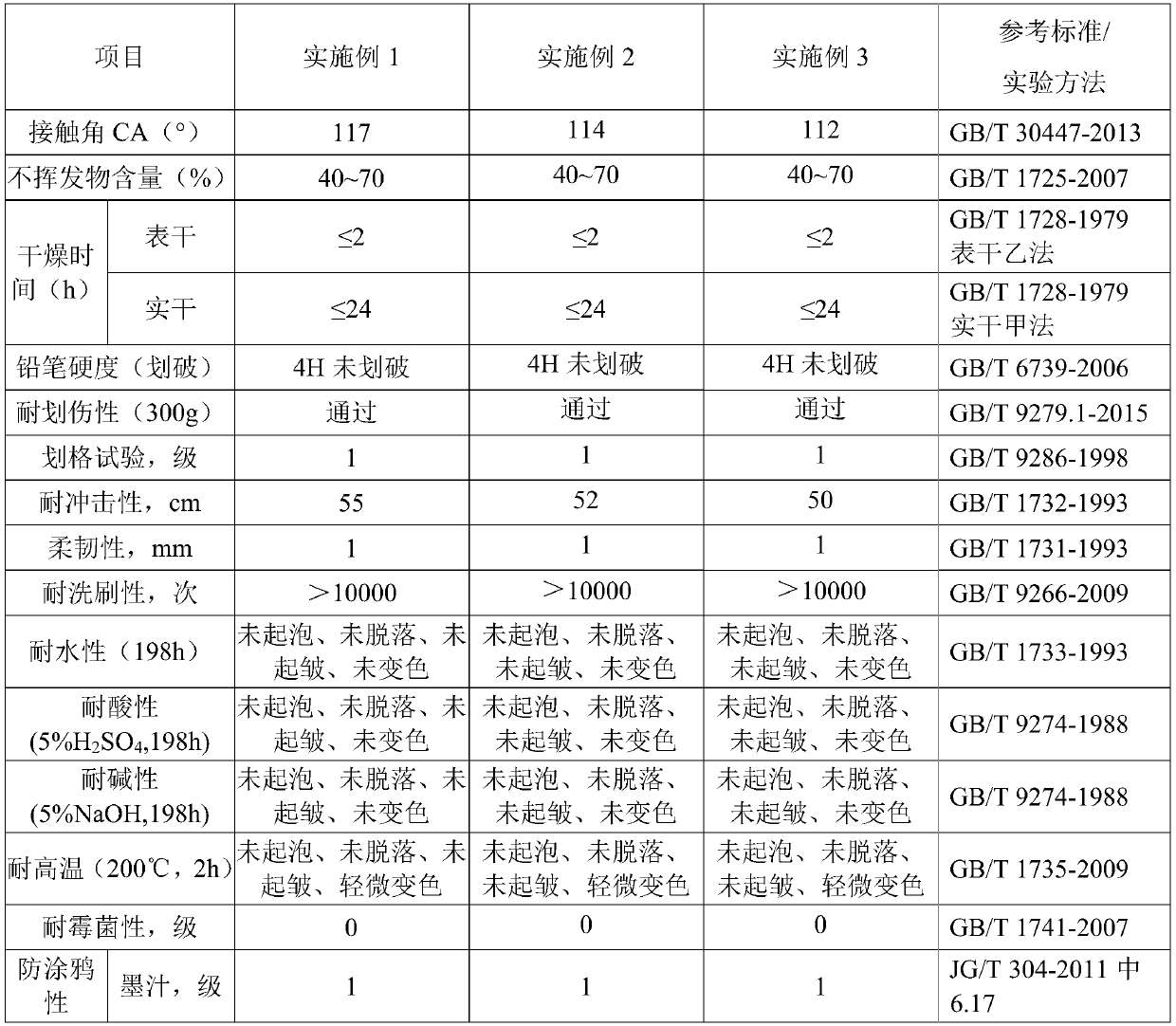

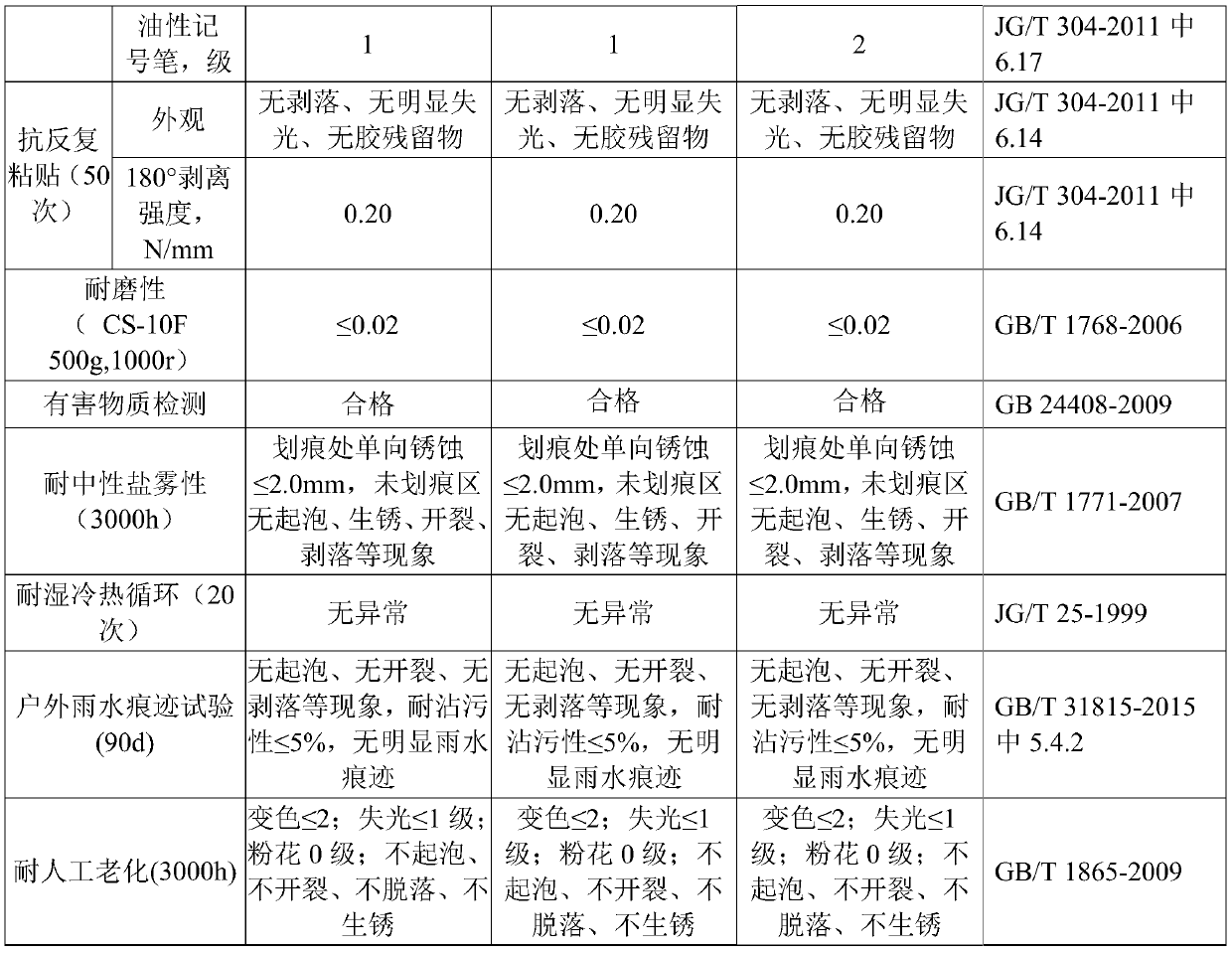

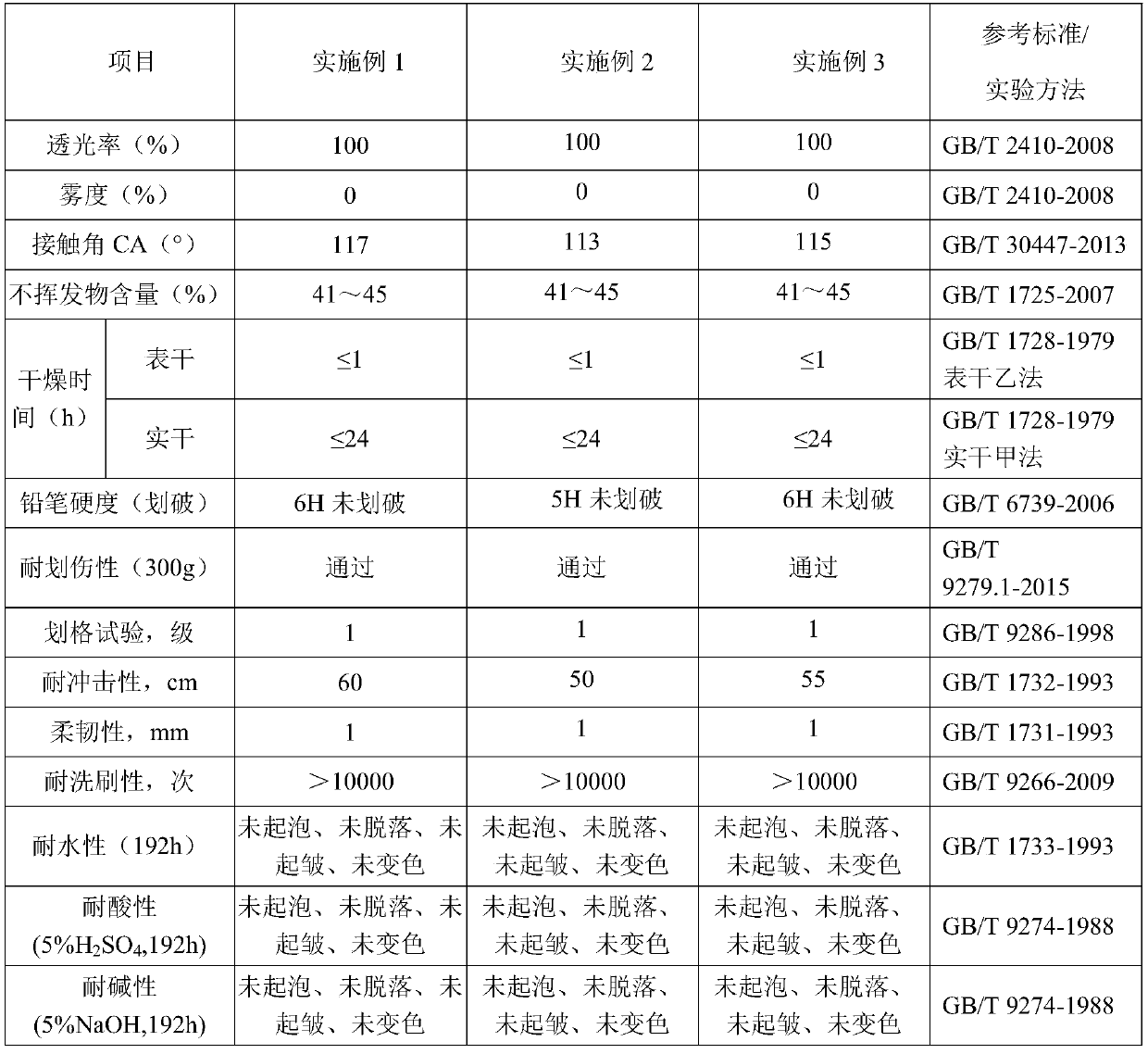

Multi-effect anti-fouling coating and construction method thereof

ActiveCN110437723ALower surface energyStrong water and oil repellencyFireproof paintsCovering/liningsPolyester resinAlgae

The invention discloses multi-effect anti-fouling coating. The multi-effect anti-fouling coating is prepared from a component A and a component B; the component A is prepared from the following components in parts by weight: 40-45 parts of fluorine-silicon modified polyester resin, 0.5-2 parts of an anti-static agent, 0.5-2 parts of a hydrophobic restorer, 0.5-2 parts of an anti-mold and anti-algae agent, 0.5-2 parts of a leveling agent, 0.5-2 parts of a wetting dispersant and 2-5 parts of a defoaming agent; the component B is prepared from 30-50 parts of a polyisocyanate pre-polymer; the massratio of the component A to the component B is (4 to 10):1; and the fluorine-silicon modified polyester resin contains hydroxyls. Through the synergistic effect of the fluorine-silicon modified polyester resin, the polyisocyanate pre-polymer and the multiple functional additives, the multi-effect anti-fouling coating has the functions of corrosion prevention, fouling prevention, self-cleaning, scrawling prevention and pasting prevention, and has excellent overall performance. The invention further discloses a construction method of the multi-effect anti-fouling coating.

Owner:武汉长弢新材料有限公司

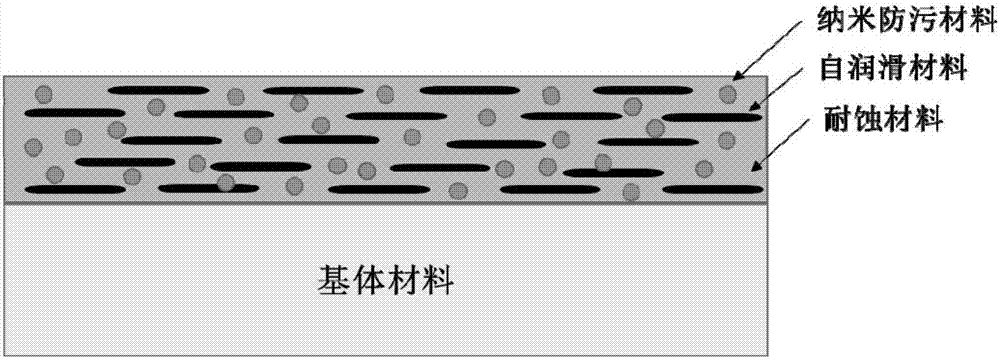

Cored wire used for preparing anti-corrosion antifouling self-lubricating functional coating and coating preparing method

ActiveCN107881454AGood antifouling performanceGood corrosion resistance and self-lubricating anti-friction propertiesMolten spray coatingPre treatmentMetal

The invention discloses a cored wire used for preparing an anti-corrosion antifouling self-lubricating functional coating. The novel anti-corrosion antifouling self-lubricating cored wire is preparedthrough a mixed material composed of a metal wire coated anti-corrosion metal material, a nanometer antifouling material and a self-lubricating anti-attrition material. The invention further disclosesa method for preparing the anti-corrosion antifouling self-lubricating functional coating with the anti-corrosion antifouling self-lubricating functional cored wire as the raw material. The method comprises the steps that firstly, a base material is subject to pre-treatment; secondly, a hot spraying technology is adopted to spray the cored wire to the pretreated base material surface, and the anti-corrosion antifouling self-lubricating functional coating is obtained. The coating has the excellent corrosion resistance, self-lubricating wear resistance and antifouling properties, and the coating has the good application prospect in the surface protection fields of corrosion resistance, wear resistance, antifouling, and pollution resistance properties of ocean equipment.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

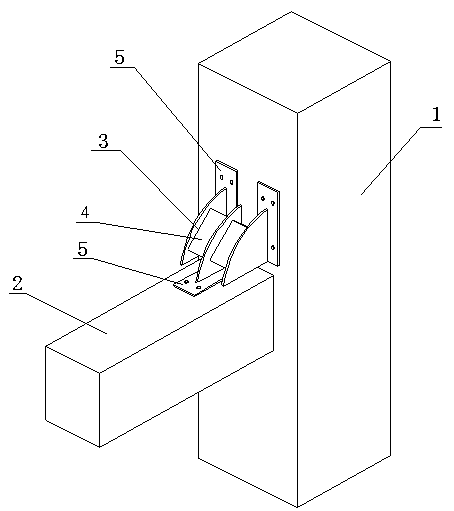

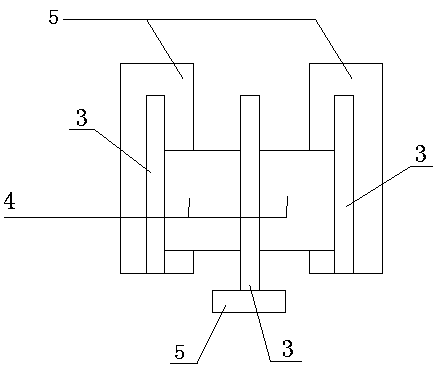

Damper with staging energy consumption function

ActiveCN110499833AThe connection is stable and effectiveImprove energy consumptionProtective buildings/sheltersShock proofingCentre of rotationEngineering

The invention relates to a damper with a staging energy consumption function, and belongs to the technical field of building structural engineering. The damper comprises two energy consumption platesand connecting plates. The two energy consumption plates are arranged in the corner between a frame beam and a frame column and conduct staging energy consumption. The connecting plates are used for connecting the energy consumption plates with the frame beam and the frame column. The distances between the two energy consumption plates and the center of rotation are different. The connecting plates and the energy consumption plates are connected through welded joints. The distance between the energy consumption plate on the inner side and the center of rotation and the distance between the energy consumption plate on the outer side and the center of rotation are different. Along with the increase of the rotational angle, the energy consumption plate on the outer side consumes energy, thenthe energy consumption plate on the inner side consumes energy, and then staging energy consumption is achieved. Compared with an existing damper, the damper with the staging energy consumption function has the advantage of achieving the better energy consumption effect. The damper with the staging energy consumption function is simple in structure, the most of connection is bolted connection, andthe assembling operation can be achieved. After an earthquake happens, seismic reduction and energy dissipation can be conducted, replacement is convenient, and the damper with the staging energy consumption function can be widely applied to the technical field of seismic reduction and energy dissipation of building structures.

Owner:YANSHAN UNIV

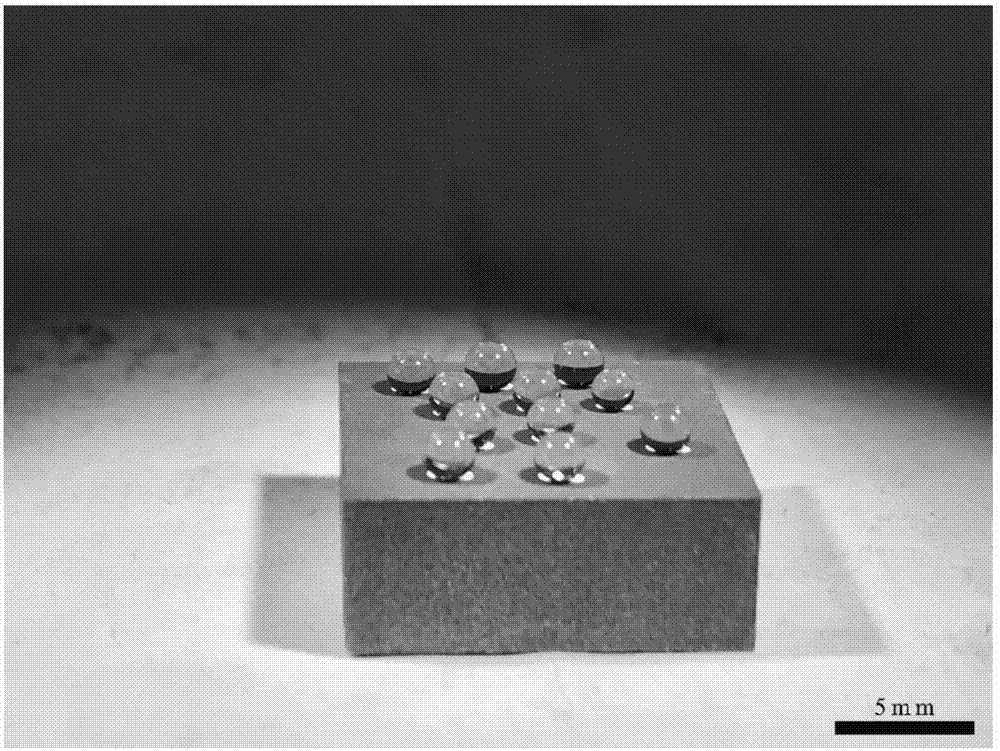

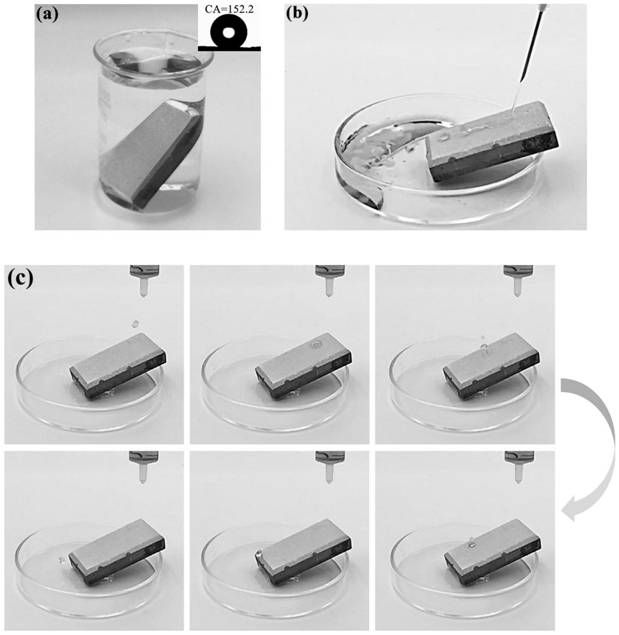

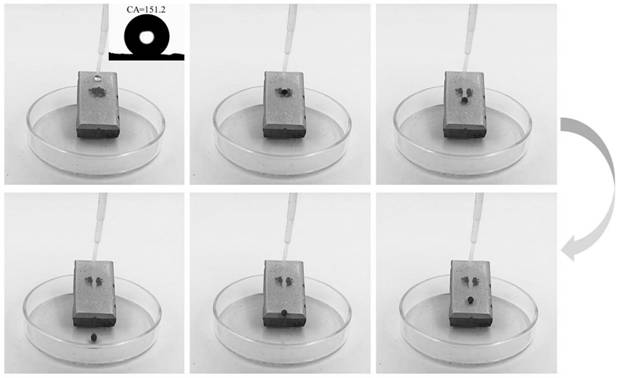

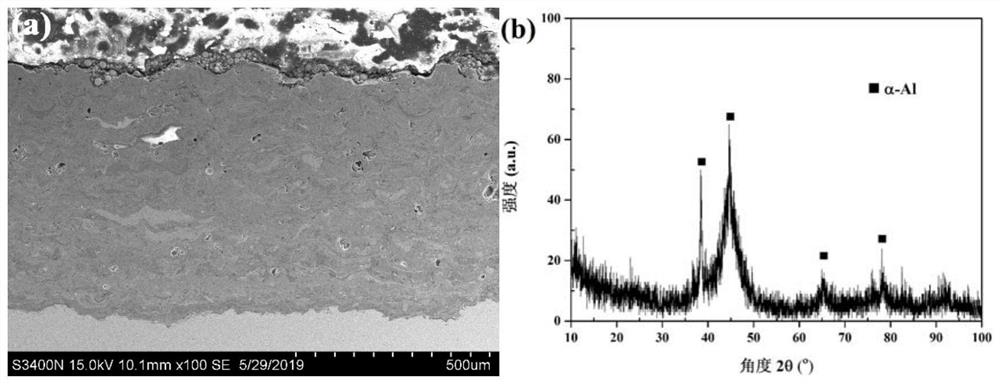

Super-hydrophobic corrosion-resistant antifouling aluminum-based amorphous coating and preparation method thereof

The invention discloses a super-hydrophobic corrosion-resistant antifouling aluminum-based amorphous coating and a preparation method thereof. The method comprises the following steps of S1, base material surface pretreatment, S2, aluminum-based amorphous coating preparation, S3, coating surface chemical etching and S4, low-surface-energy substance modification. The method has the following advantages that (1) the process is simple, the efficiency is high, the method is suitable for site construction, the cost is low, and large-area preparation on a non-planar complex structure substrate can be realized; (2) the coating is low in oxide content, uniform in component and compact in structure, the porosity is less than 2%, the coating is well combined with a substrate, the amorphous content of the coating is greater than 80vol.%, and the coating has excellent wear resistance and corrosion resistance; (3) a contact angle is larger than 150 degrees, a rolling angle is smaller than 10 degrees, and the coating has good hydrophobicity, shows excellent waterproof, self-cleaning and corrosion-resistant properties, and also has high wear resistance of an amorphous coating; and (4) the coating can be applied to various occasions needing self-cleaning, corrosion resistance, icing resistance, energy-saving fluid conveying and the like, such as the outer surfaces of various industrial parts and the inner walls of pipelines.

Owner:HOHAI UNIV +1

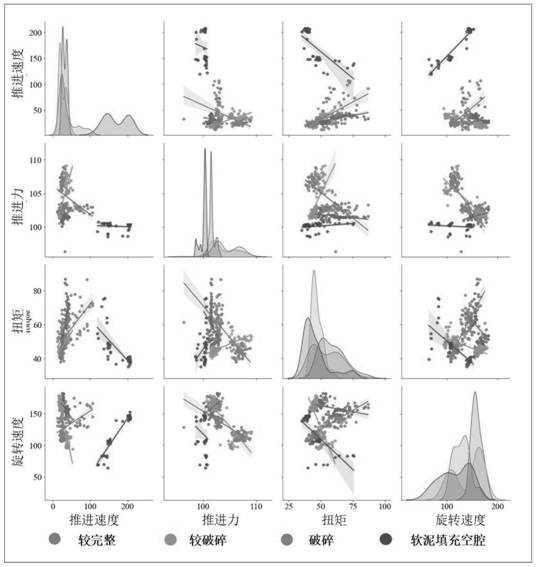

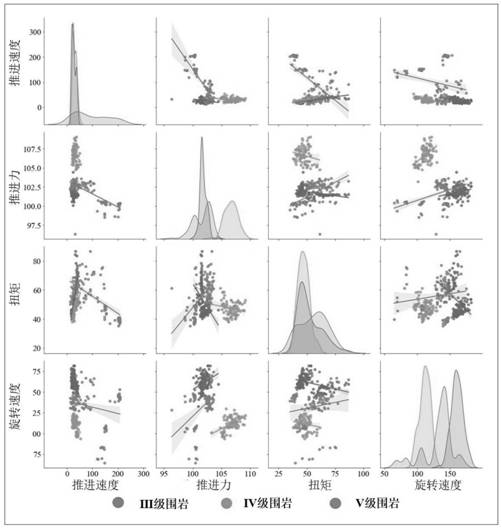

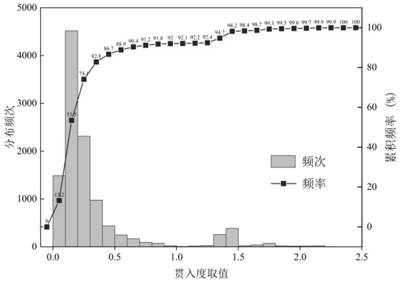

Tunnel surrounding rock two-dimensional quality evaluation method based on advanced drilling data

PendingCN113779880AReduce difficultyAvoid adverse effectsCharacter and pattern recognitionDesign optimisation/simulationTunnel engineeringMulti-label classification

The invention relates to the technical field of tunnel engineering, and especially relates to a tunnel surrounding rock two-dimensional quality evaluation method based on advanced drilling data. The method comprises the following steps: 1, randomly sampling a tunnel to be excavated through an advanced drilling technology, acquiring drilling data of the tunnel to be excavated, and preprocessing the drilling data, wherein the drilling data comprises four indexes including propelling speed, propelling force, torque and rotating speed; and 2, inputting the preprocessed drilling data into a pre-established CC-GA-XGBoost model for two-dimensional quality evaluation, and outputting two-dimensional quality evaluation results, wherein the evaluation results comprise two dimensions of the surrounding rock integrity degree and the surrounding rock grade, the evaluation results of the surrounding rock integrity degree comprise relatively complete, relatively broken, broken and muddy filling cavities, and the evaluation results of the surrounding rock integrity degree comprise relatively complete, relatively broken, broken and muddy filling cavities, and the surrounding rock grade evaluation results comprise grade III, grade IV and grade V; and the CC-GA-XGBoost model is a model which adopts a GA algorithm to train an XGBoost model and then calls a CC algorithm to carry out multi-label classification. Model hyper-parameter automatic optimization and multi-label output are realized, the modeling difficulty is reduced, and the prediction accuracy is improved.

Owner:GUANGXI ROAD & BRIDGE ENG GRP CO LTD

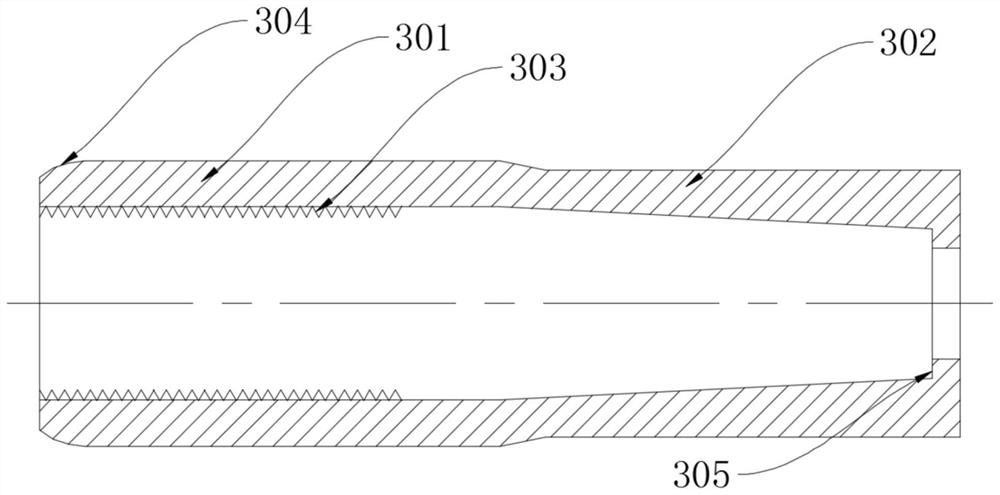

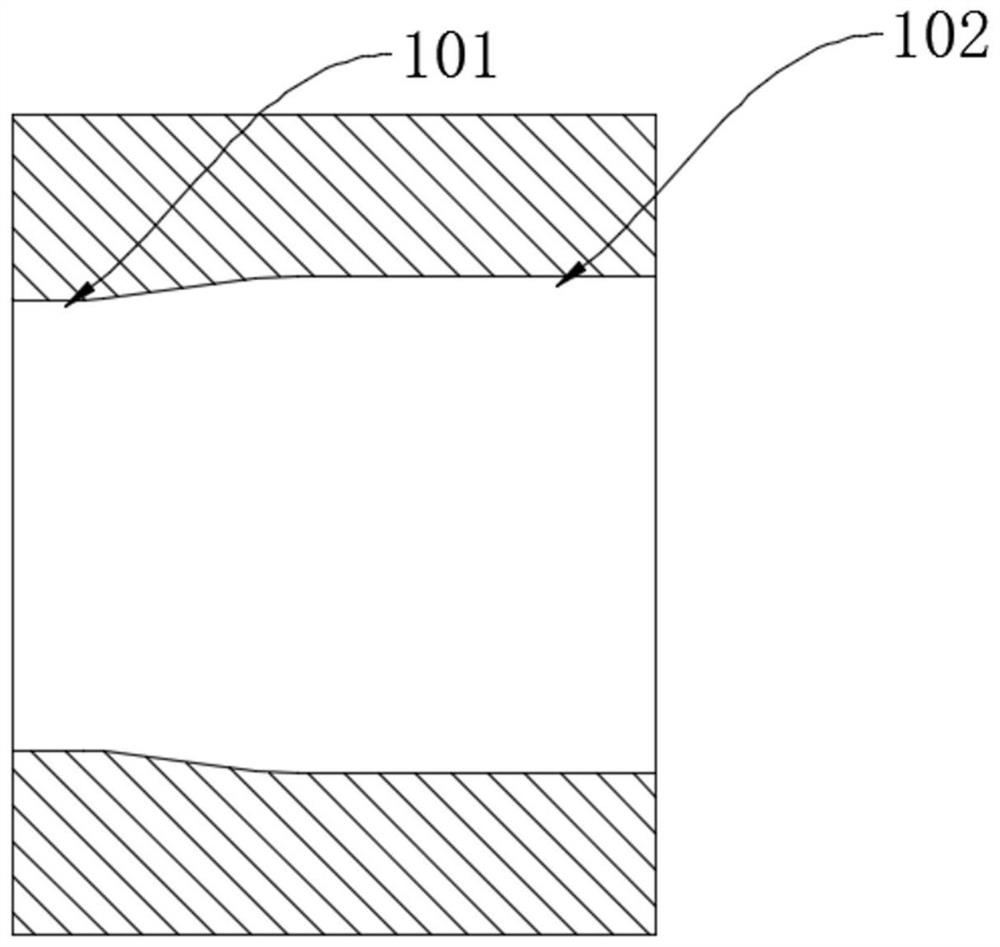

Connecting method and connecting device for materials with different diameters

PendingCN113818633ASolve the problem of not being able to connectSolve the problem of insufficient connection strengthBuilding reinforcementsMechanical engineeringInner/Lumen Diameter

The invention discloses a connecting method and a connecting device for materials with different diameters. The connecting device comprises a connecting sleeve, a locking sheet and a reducing sleeve, wherein two ends of the connecting sleeve are respectively an equal-diameter end and a reducing end which are respectively used for connecting materials with large and small diameters, and an inner hole of the reducing end is gradually reduced from the middle to the end part; the locking sheet is arranged between the small-diameter material and the hole wall of the conical inner hole; the outer diameter of the connecting sleeve is larger than the inner diameter of the small-inner-diameter end of the reducing sleeve and smaller than the inner diameter of the large-inner-diameter end of the locking sleeve; and the reducing sleeve is used for being arranged on the connecting sleeve in a sleeving mode under the action of an external force and penetrating through the connecting sleeve in the axial direction, so that the connecting sleeve and / or the locking sheet generate radial plastic deformation, and the large-diameter material and the small-diameter material are connected together through the connecting sleeve. The problem that in the prior art, materials with different diameters cannot be connected in a high-strength mode is solved, and the device is simple in structure, convenient to use, good in stability, high in practicability and suitable for large-area application and popularization.

Owner:湖北垚尚科技有限公司

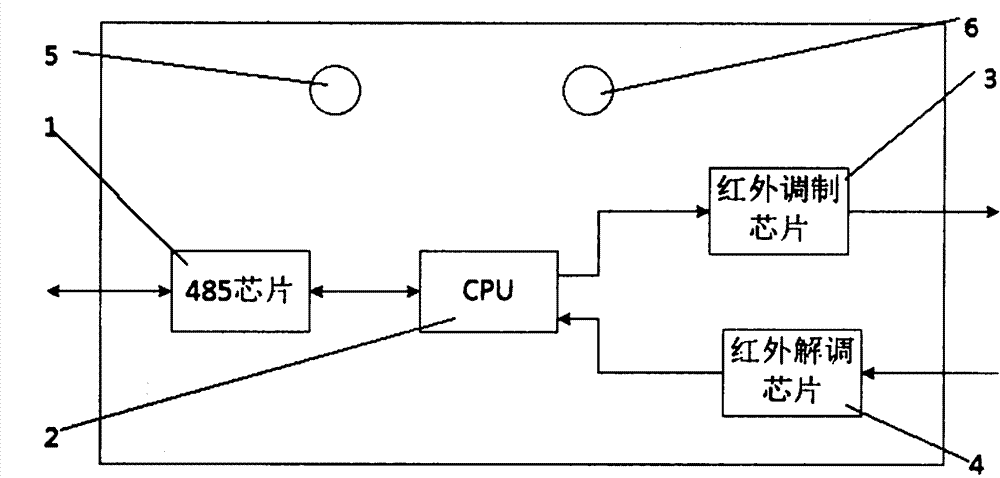

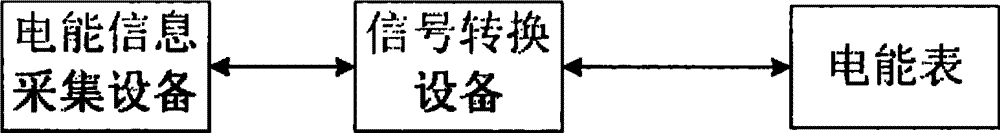

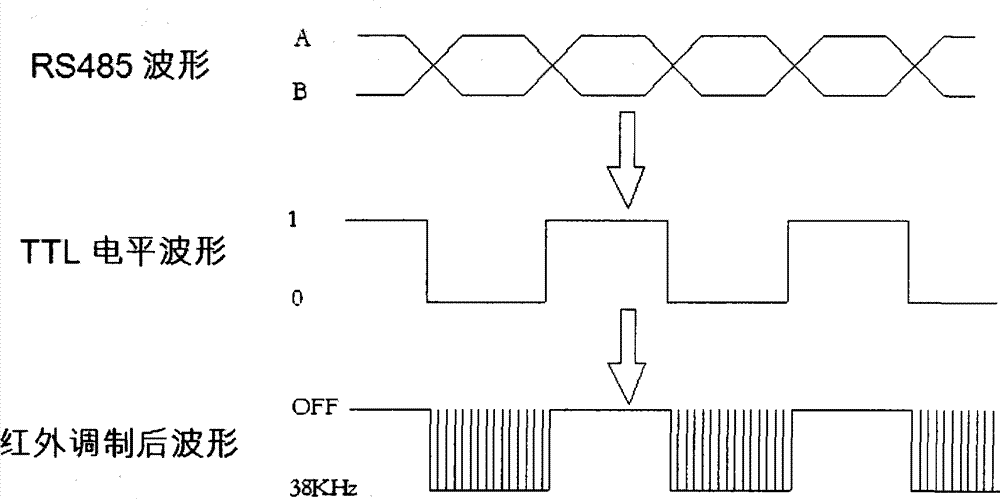

Signal conversion equipment of remote power meter reading system

InactiveCN104123831ASimple installation and constructionEasy maintenanceElectric signal transmission systemsNon-electrical signal transmission systemsDemodulationElectric power

The invention relates to signal conversion equipment of a remote power meter reading system. The signal conversion equipment comprises an RS485 receiving and transmitting chip, an STM8CPU, an infrared modulation chip, an infrared demodulation chip, an infrared indicating lamp and an RS485 communication indicating lamp, wherein a group of receiving and transmitting ports are formed in the RS485 receiving and transmitting chip to the outside and are locally called by electric energy information acquisition equipment; a group of ports are respectively formed in each of the infrared modulation chip and the infrared demodulation chip to the outside and are used for interacting infrared signals with an electric energy meter; the STM8CPU is used for processing RS485 signals received by the RS485 receiving and transmitting chip and the infrared signals received by the infrared demodulation chip and performing signal transmission so as to realize data conversion under different signals; the infrared indicating lamp is used for indicating that whether the infrared demodulation chip is in a working state or not; the RS485 communication indicating lamp is used for indicating that whether the RS485 receiving and transmitting chip is in a working state or not. The signal conversion equipment can be mounted on the electric energy meter so as to convert signals, therefore, demands for acquiring the data are met, and various expenses are greatly lowered.

Owner:党彬 +5

Soda residue soil regeneration backfill material and preparation method thereof

The invention discloses a soda residue soil regeneration backfill material and a preparation method thereof, and relates to the technical field of civil engineering materials. The soda residue soil regeneration backfill material comprises the following formula components in parts by weight: 15-20 parts of soda residue; 5-10 parts of calcium-richened fly ash; 5-10 parts of fly ash; 5-10 parts of muck; 5-10 parts of fine gravel; and 3-7 parts of cement. The soda residue in the soda residue soil regeneration backfill material can be used as a soil skeleton constituent part, and can be used as engineering soil; calcium-richened fly ash and the fly ash can be used for filling gaps among particles such as soda residue and fine gravels and absorbing moisture, so that the dry volume weight and thestrength of the soda residue soil regeneration backfill material can be improved, and the appearance of the soda residue soil regeneration backfill material can also be improved; therefore, the sodaresidue soil regeneration backfill material can be used for engineering filling of low-lying areas and mudflat areas, resource utilization of soda residue is achieved, land utilization resources are effectively increased, environmental pollution is reduced, and economic, social and environmental benefits are obvious.

Owner:POWERCHINA WATER ENVIRONMENT GOVERANCE

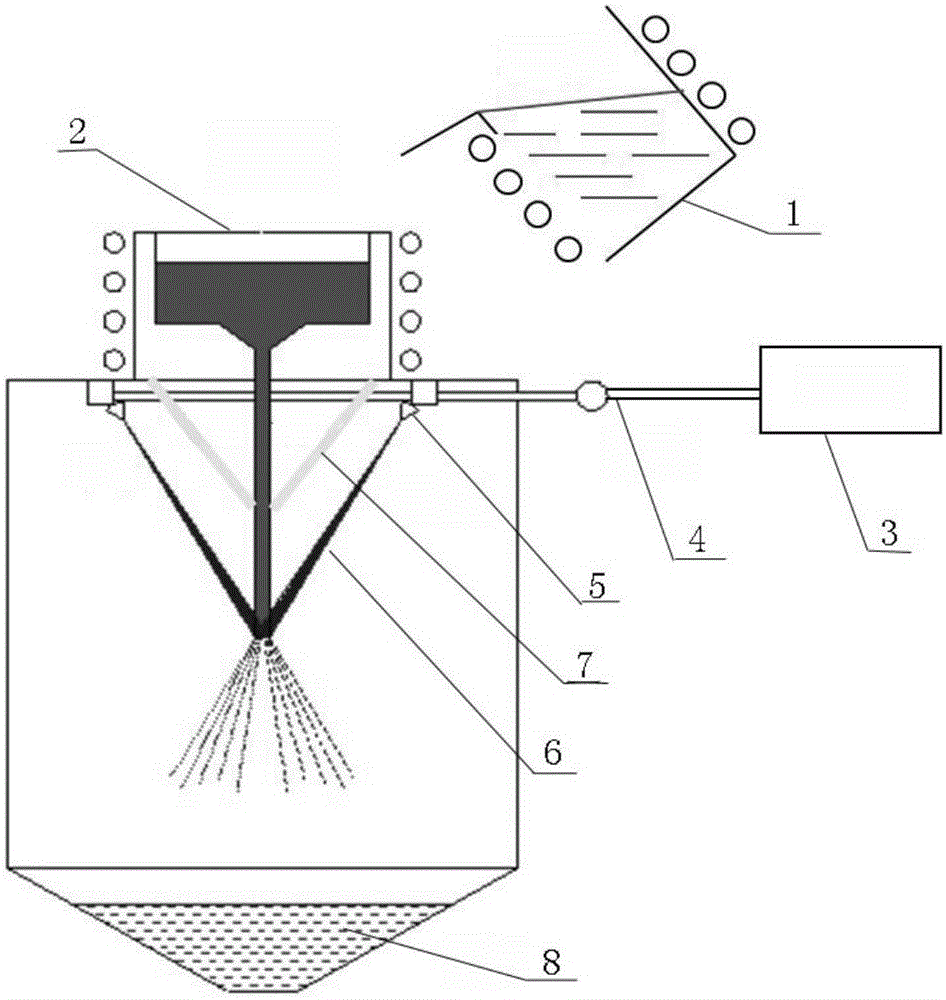

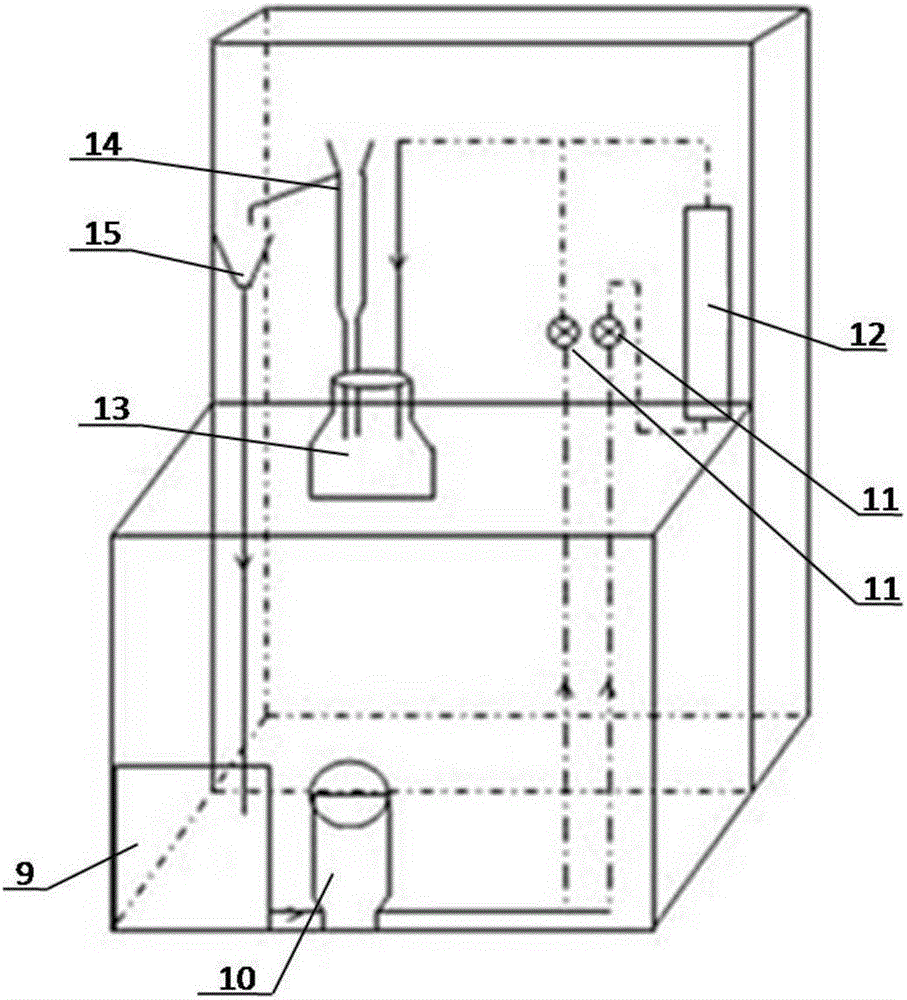

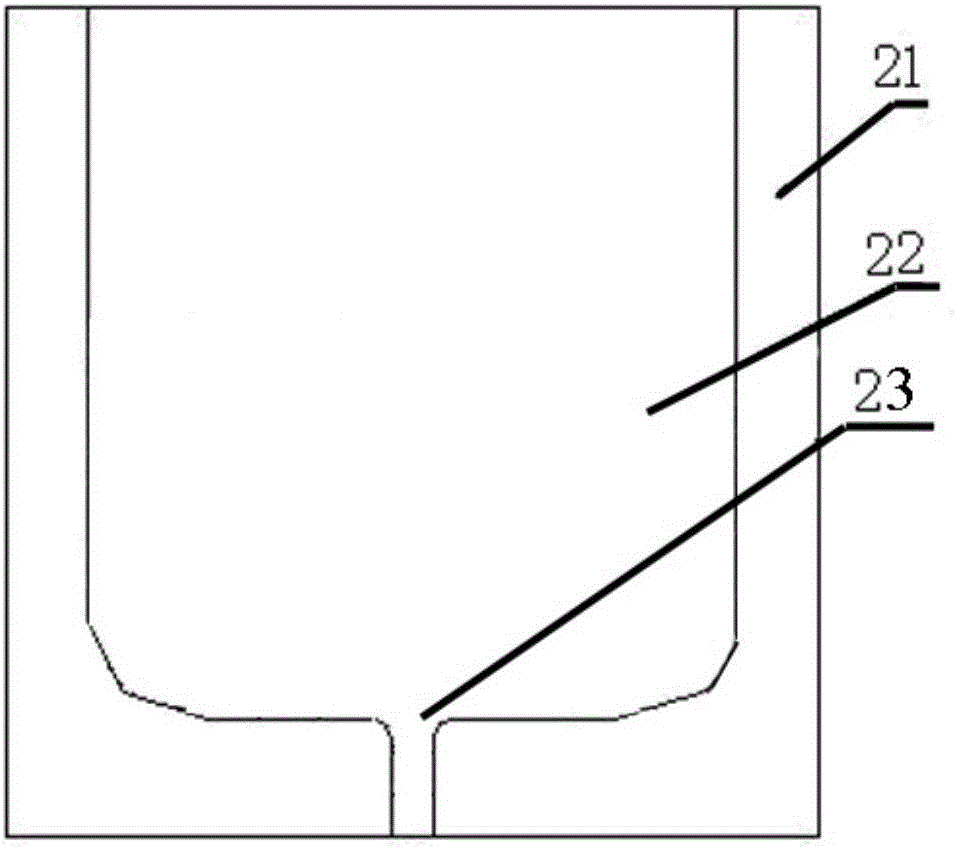

Tundish for preparing iron-based water-atomized soft magnetic alloy powders and manufacturing method of tundish

The invention relates to a tundish for preparing iron-based water-atomized soft magnetic alloy powders and a manufacturing method of the tundish and belongs to the field of powder metallurgy. The tundish for preparing the iron-based water-atomized soft magnetic alloy powders comprises a tundish body; an alloy liquid containing part used for containing molten alloy liquid is formed in the tundish body; a liquid weeping hole is formed in the bottom surface of the tundish body for making the alloy liquid in the tundish body fall naturally; a protective coating is arranged on the inner wall of the tundish body for preventing the molten alloy liquid from corroding the tundish body. According to the tundish and the method, a high-performance and anti-drop coating tundish can be obtained by processing the inner wall of a clay tundish with aluminium dihydrogen phosphate adding aluminium oxide or aluminium dihydrogen phosphate adding zirconium oxide, so that the strength of the clay tundish is increased by the coating, and the clay tundish can be reused for 2-3 times, so that the production cost can be lowered; moreover, the falling of a tundish body refractory can be reduced, the quantity of inclusions in the iron-based soft magnetic alloy powders prepared by an atomization method can be reduced effectively, the property of the alloy powders can be improved and the condition can be reduced that the tundish body refractory falls off and blocks the tundish to make the atomization be interrupted.

Owner:ADVANCED TECH BAZHOU SPECIAL POWDER CO LTD +1

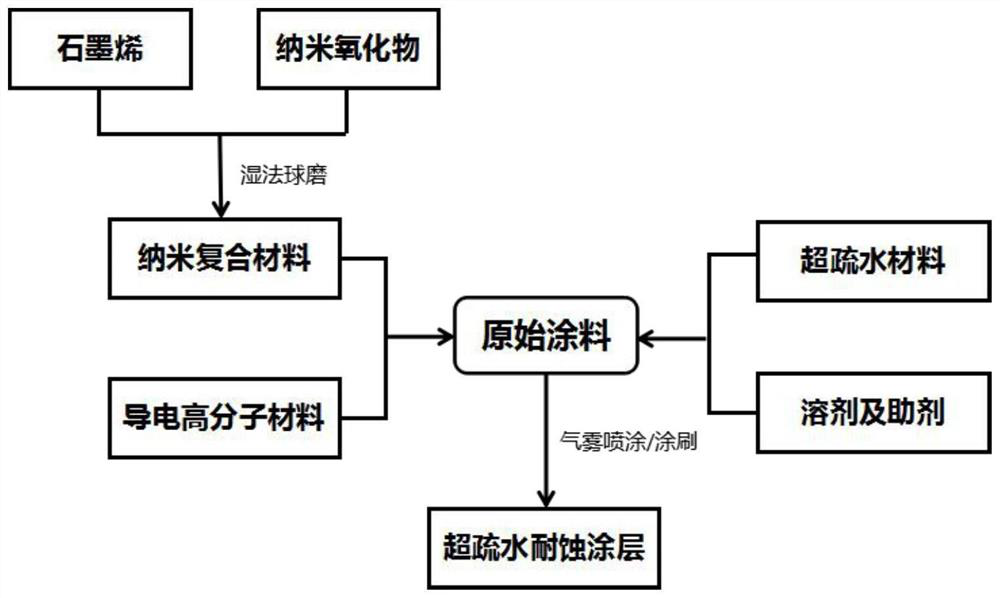

Super-hydrophobic corrosion-resistant paint for grounding electrode and preparation method of coating of super-hydrophobic corrosion-resistant paint

PendingCN114836069AImprove antioxidant capacityImprove corrosion resistanceAnti-corrosive paintsSpecial surfacesElectrically conductivePower grid

The invention relates to a super-hydrophobic corrosion-resistant coating for a grounding electrode and a preparation method of a coating of the super-hydrophobic corrosion-resistant coating. The invention relates to the super-hydrophobic corrosion-resistant coating for the grounding electrode and the preparation method of the coating of the super-hydrophobic corrosion-resistant coating. In order to solve the problems that a power grid grounding electrode is easy to corrode and low in conductivity after being placed in a humid soil environment for a long time and the conventional conductive anticorrosive paint is easy to age and degrade at present, the paint comprises a conductive polymer material, a nano composite material, a super-hydrophobic material, a solvent and an auxiliary agent, the preparation method of the coating comprises the step of preparing the super-hydrophobic corrosion-resistant coating on the surface of the pretreated grounding electrode component in a coating or aerial fog spraying mode. The coating has a good super-hydrophobic function and a corrosion-resistant function, also has excellent conductivity, and can be applied to a long-acting corrosion-resistant scene of a grounding electrode in a humid soil environment. The method is applied to the technical field of grounding electrode surface treatment.

Owner:国网黑龙江省电力有限公司大兴安岭供电公司

Preparation method of waterborne polyurethane coating with good corrosion resistance

InactiveCN110804384AImprove corrosion resistanceGood acid and alkali resistanceAnti-corrosive paintsPolyurea/polyurethane coatingsPolyurethane coatingCorrosion resistant

The invention discloses a preparation method of a waterborne polyurethane coating with good corrosion resistance, and particularly relates to the technical field of anticorrosive coatings, and the prepared waterborne polyurethane coating has excellent corrosion resistance, good acid and alkali resistance, scratch resistance, strong adhesive force and high hardness; he method comprises the following steps: carrying out ball milling treatment on graphene oxide and 3, 5-diamino-1, 2, 4-triazole at high temperature, so that on one hand, amino in the 3, 5-diamino-1, 2, 4-triazole can react with anepoxy group on a graphene oxide sheet layer, and a large conjugated system is formed by cyclic conjugation of the 3, 5-diamino-1, 2, 4-triazole and the graphene oxide; the flow of electrons is facilitated, and the electrical conductivity is enhanced; on the other hand, the 3,5-diamino-1,2, 4-triazole provides amino and triazole with stronger activity, nitrogen atoms in the triazole can be complexed with cobalt ions added subsequently and oxygen atoms in calcium titanate, so that more metal ions are introduced to the surface of the graphene oxide to form a conductive network in a high polymer matrix, and the corrosion resistance of the obtained coating is improved.

Owner:ANHUI XINDALU SPECIAL PAINT CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com