Super-hydrophobic corrosion-resistant antifouling aluminum-based amorphous coating and preparation method thereof

An amorphous coating, super-hydrophobic technology, applied in the coating, metal material coating process, melt spraying and other directions, can solve the problem of no major breakthrough in the three-dimensional block preparation technology, achieve low cost, uniform composition, simple craftsmanship

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

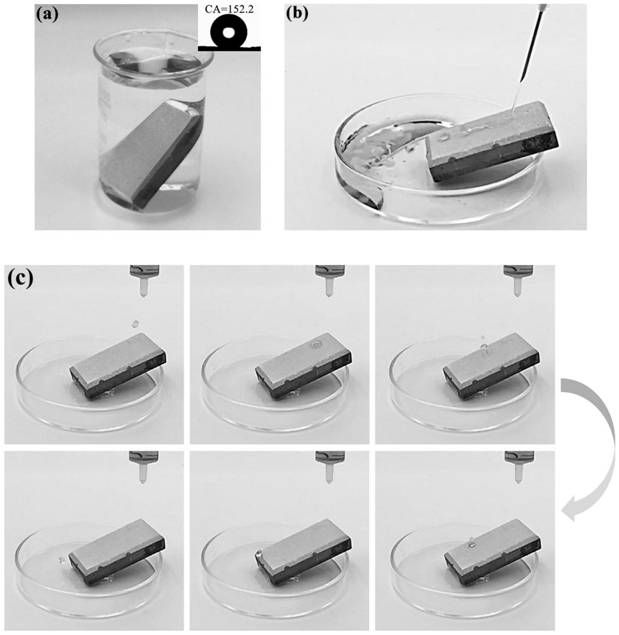

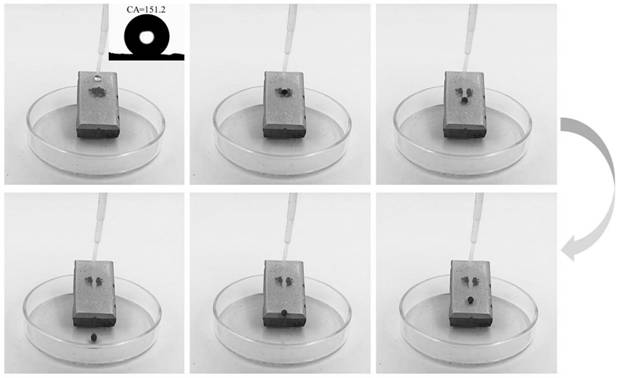

Examples

Embodiment 1

[0035] A method for preparing a superhydrophobic corrosion-resistant and anti-fouling aluminum-based amorphous coating, specifically comprising the following steps:

[0036] (1) Substrate surface pretreatment

[0037] The surface of the sample was polished with sandpaper to remove oxides, and the polished sample was ultrasonically cleaned with absolute ethanol and acetone for 10 minutes to remove surface particle impurities and oil stains. After natural air-drying, in order to ensure a good bonding force between the coating and the substrate, the surface of the sample is sandblasted by sandblasting to improve the surface roughness. The sandblasting process parameters are: compressed air pressure 0.7MPa, The relative distance is 100mm, the angle is 70-90°, and the particle size of white corundum sand for sandblasting is 20 mesh.

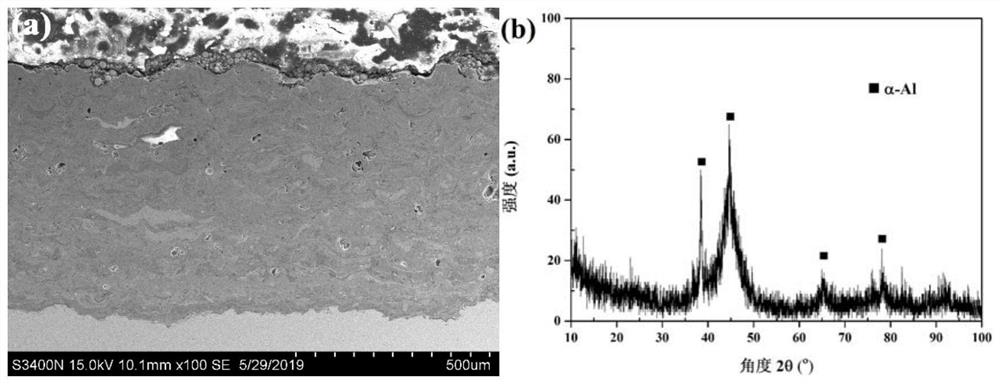

[0038] (2) Preparation of aluminum-based amorphous coating

[0039] The aluminum-based amorphous coating is prepared by high-speed arc spraying tec...

Embodiment 2

[0046] A method for preparing a superhydrophobic corrosion-resistant and anti-fouling aluminum-based amorphous coating, specifically comprising the following steps:

[0047] (1) Substrate surface pretreatment

[0048] The surface of the sample was polished with sandpaper to remove oxides, and the polished sample was ultrasonically cleaned with absolute ethanol and acetone for 10 minutes to remove surface particle impurities and oil stains. After natural air-drying, in order to ensure a good bonding force between the coating and the substrate, the surface of the sample is sandblasted by sandblasting to improve the surface roughness. The sandblasting process parameters are: compressed air pressure 0.7MPa, The relative distance is 100mm, the angle is 70-90°, and the particle size of white corundum sand for sandblasting is 20 mesh.

[0049] (2) Preparation of aluminum-based amorphous coating

[0050] The aluminum-based amorphous coating is prepared by high-speed arc spraying tec...

Embodiment 3

[0057] A method for preparing a superhydrophobic corrosion-resistant and anti-fouling aluminum-based amorphous coating, specifically comprising the following steps:

[0058] (1) Substrate surface pretreatment

[0059] The surface of the sample was polished with sandpaper to remove oxides, and the polished sample was ultrasonically cleaned with absolute ethanol and acetone for 10 minutes to remove surface particle impurities and oil stains. After natural air-drying, in order to ensure a good bonding force between the coating and the substrate, the surface of the sample is sandblasted by sandblasting to improve the surface roughness. The sandblasting process parameters are: compressed air pressure 0.7MPa, The relative distance is 100mm, the angle is 70-90°, and the particle size of white corundum sand for sandblasting is 20 mesh.

[0060] (2) Preparation of aluminum-based amorphous coating

[0061] The aluminum-based amorphous coating is prepared by high-speed arc spraying tec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Self-corrosion current density | aaaaa | aaaaa |

| Self-corrosion potential | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com