Repairing mortar for bridge pavement repairing paving, and preparation method and construction method thereof

A repairing mortar and pavement repairing technology, which is applied in the field of bridge pavement repairing materials, can solve the problems of seriousness, strength shrinkage, and long time of closed traffic, etc., achieve high bending resistance and bonding bending strength, and be easy to site The effect of simple construction operation and operation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

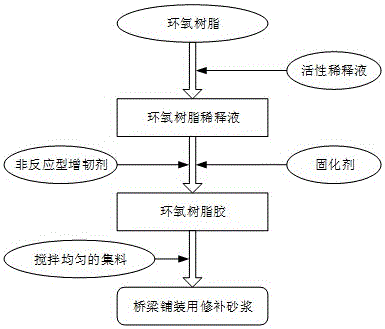

[0042] The preparation method of the repair mortar used for repairing pavement of bridge pavement of the present invention is comparatively simple, is easy to on-site construction operation, and its preparation process is as follows figure 1 shown, including the following steps:

[0043] 1) Prepare sufficient epoxy resin, composite curing agent, diluent and aggregate according to the batching components of the repair mortar of the present invention;

[0044] 2) Stir the aggregate in the plastic sand mixing pot evenly and set aside;

[0045] 3) Add the diluent into the rubber compounding barrel containing the epoxy resin according to the ingredients, and continue to stir with a stirrer until the mixture is uniform to obtain the epoxy resin dilution;

[0046] 4) According to the ingredients, add the composite curing agent into the rubber compounding barrel containing the epoxy resin diluent obtained in the above steps, and continue to stir with a stirrer until the mixture is un...

Embodiment 1

[0051] In this embodiment, aiming at the different ratios of the repair mortar used for bridge pavement repair and paving according to the present invention, compressive test pieces and bending resistance test pieces were made respectively to test the repair mortar for bridge pavement repair pavement of the present invention Compressive and flexural strengths to reflect the mechanical strength performance of the repair mortar of the present invention. In the present embodiment, adopted 7 kinds of different respectively, prepare the repairing mortar of the present invention respectively, the batching component situation of each proportioning is as shown in table 1:

[0052] Table 1

[0053]

epoxy resin

Hardener

Thinner

Aggregate

Matching ratio 1

12 parts by weight

7.5 parts by weight

0.75 parts by weight

100 parts by weight

Matching 2

15 parts by weight

7.5 parts by weight

0.75 parts by weight

100 parts by w...

Embodiment 2

[0059] In this example, in order to verify the influence of the compounding scheme and dosage of the composite curing agent in the repair mortar of the present invention on the performance of the mortar, when preparing the repair mortar, the weight ratio of epoxy resin, diluent and aggregate is first fixed, The amount of diluent is 5% of the epoxy resin, and the weight ratio of epoxy resin and aggregate is 15:100; then, adjust the compounding ratio of T31 type curing agent and 651 type curing agent in the composite curing agent respectively 3:1 or 4:1, and use different amounts of composite curing agent in the repair mortar. The weight ratio of epoxy resin and composite curing agent is 3:1, 2:1, 1.5:1. According to the preparation method of the present invention, the repair mortar of the present invention is made according to the preparation method of the present invention, and manually inserted and pounded until compact, and then smoothed with a trowel, under the conditions of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| epoxy value | aaaaa | aaaaa |

| amine value | aaaaa | aaaaa |

| amine value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com