Double-curved-surface metal plate curtain wall three-dimensional adjustment installing structure and double-curved-surface metal plate curtain wall three-dimensional adjustment installing method

A three-dimensional adjustment and installation structure technology, applied in the field of building curtain wall engineering, can solve the problems of inability to disassemble and assemble multiple times, complicated connection and alignment, difficult maintenance, etc., and achieve the effect of meeting installation requirements, convenient and fast installation, and good overall effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

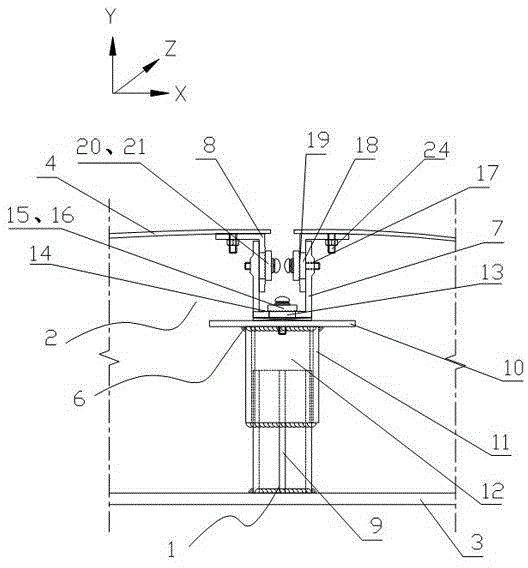

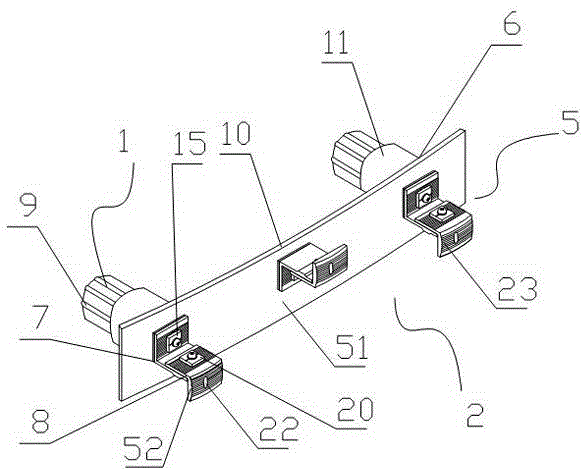

[0030] exist figure 1 , figure 2 In the shown embodiment, a hyperboloid metal plate curtain wall three-dimensional adjustment installation structure includes a fixed connection part 1 and a three-dimensional adjustment part 2, the fixed connection part 1 is fixedly connected to the main structure 3, and the three-dimensional adjustment part 2 is connected to the fixed connection part 1 The connection can be adjusted in the three-dimensional direction to realize the three-dimensional installation and adjustment of the hyperboloid metal plate 4 . The three-dimensional adjusting member 2 is provided with a hyperbolic arc surface structure 5 matching the curved surface of the hyperboloid metal plate 4 .

[0031] The three-dimensional adjusting part 2 includes a mounting base 6, an adapter 7 and a connecting piece 8, and the hyperbolic arc structure 5 includes a hyperbolic arc structure 51 of the mounting base and a hyperbolic arc structure 52 of the connecting piece, and the moun...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com