Lubricant composition and mechanical element

a technology of mechanical elements and lubricants, applied in the field of lubricant compositions, can solve the problems of not being able to disclose friction coefficients under standard evaluation systems, low viscosity ones operable as lubricants are not so readily available, etc., and achieve excellent friction resistance, low traction coefficient, and low viscosity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

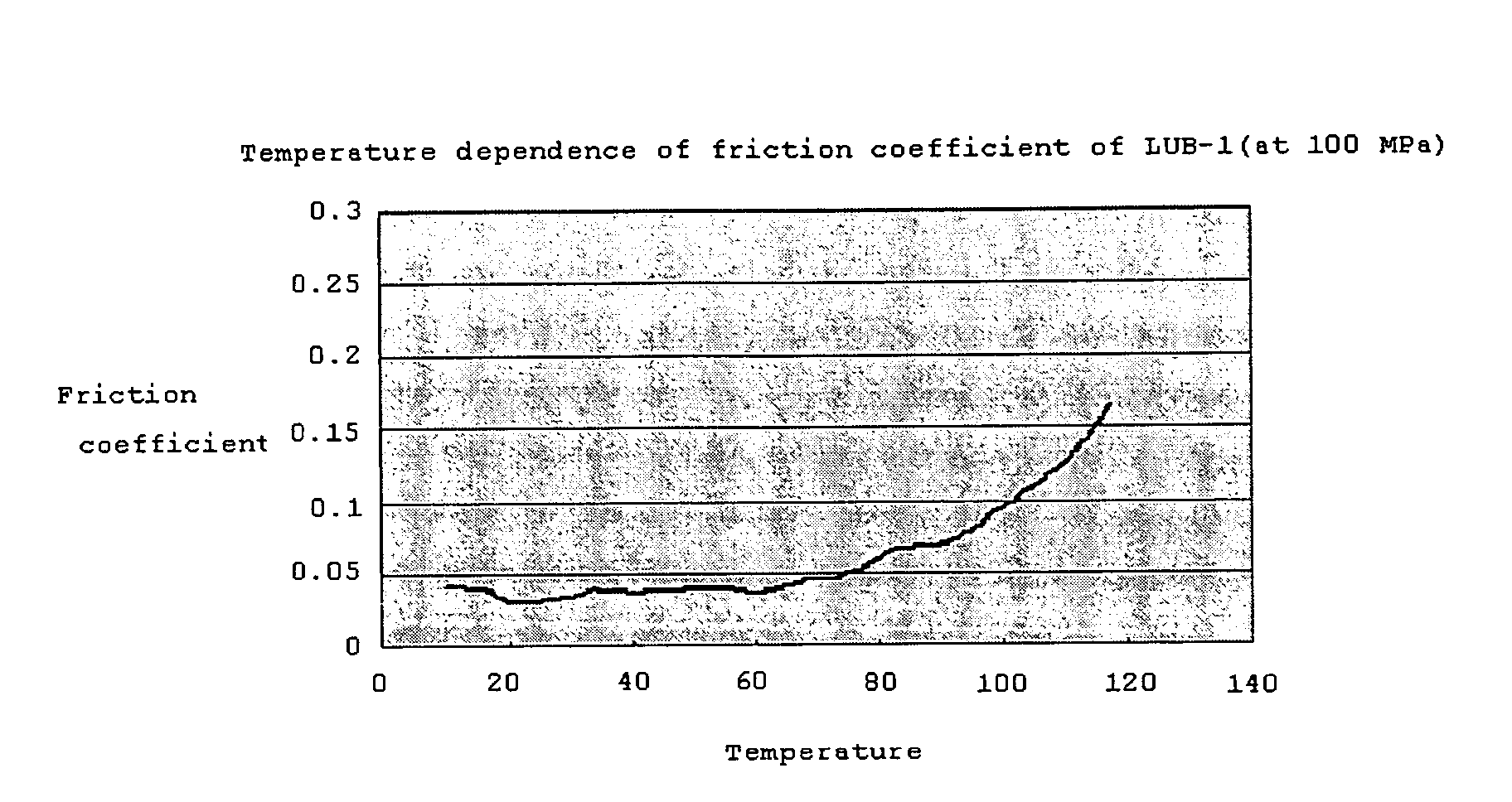

[0044] A lubricant LUB-1 having a composition below was evaluated by the reciprocating (SRV) friction wear test. Results are shown in FIG. 1. Composition of LUB-1 and phase transfer temperatures are shown below.

Composition of LUB-1

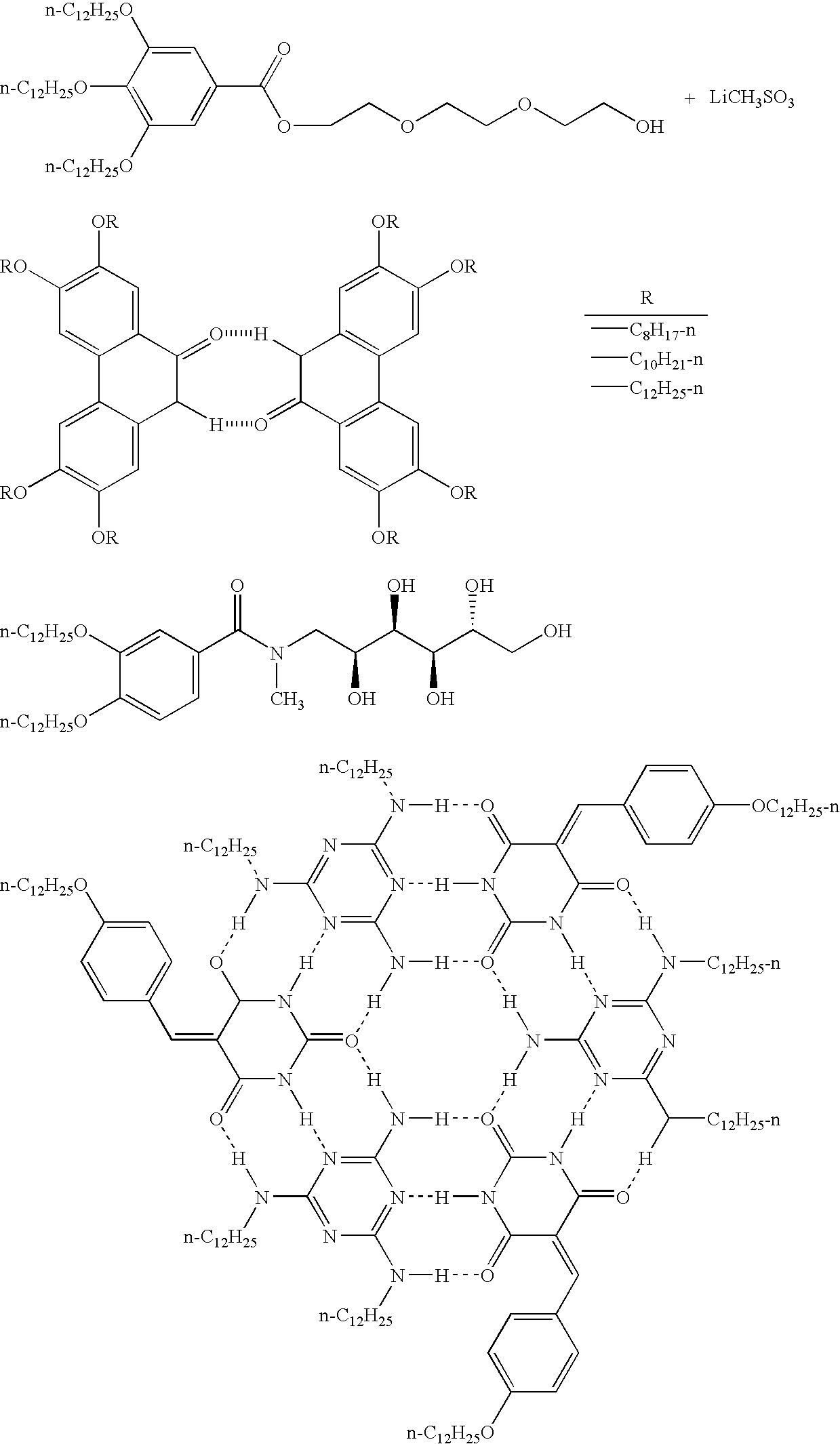

[0045] Isomolar mixture of a and b

Liquid Crystal Phase Transfer Temperatures of LUB-1

[0046] LUB-1 is a composition exhibiting liquid crystallinity under normal pressure and normal temperature, and showed a property of being readily aligned under shear. Molecules of discotic compounds are horizontally aligned with respect to a polar surface, unless the surface is specifically treated for allowing thereon vertical alignment. Under the conditions of this experiment, LUB-1 is therefore supposed to form a molecular assembly film in which molecules are aligned with their molecular plane, having a maximum diffusion sectional area, being parallel to the shear plane. Changes in the phase transfer temperature could otherwise be observed also under pressure, b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pressure | aaaaa | aaaaa |

| friction coefficient | aaaaa | aaaaa |

| speed | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com